High-precision transparent hydro-viscous transmission experimental test device

A test device and transparent liquid technology, applied in the direction of machine gear/transmission mechanism test, material inspection products, etc., can solve the problems of inconvenient operation and detection, unreasonable structure of the experimental device, and inability to observe the oil film between the sheets, etc., to achieve comprehensive measurement parameters , Fast and convenient adjustment, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

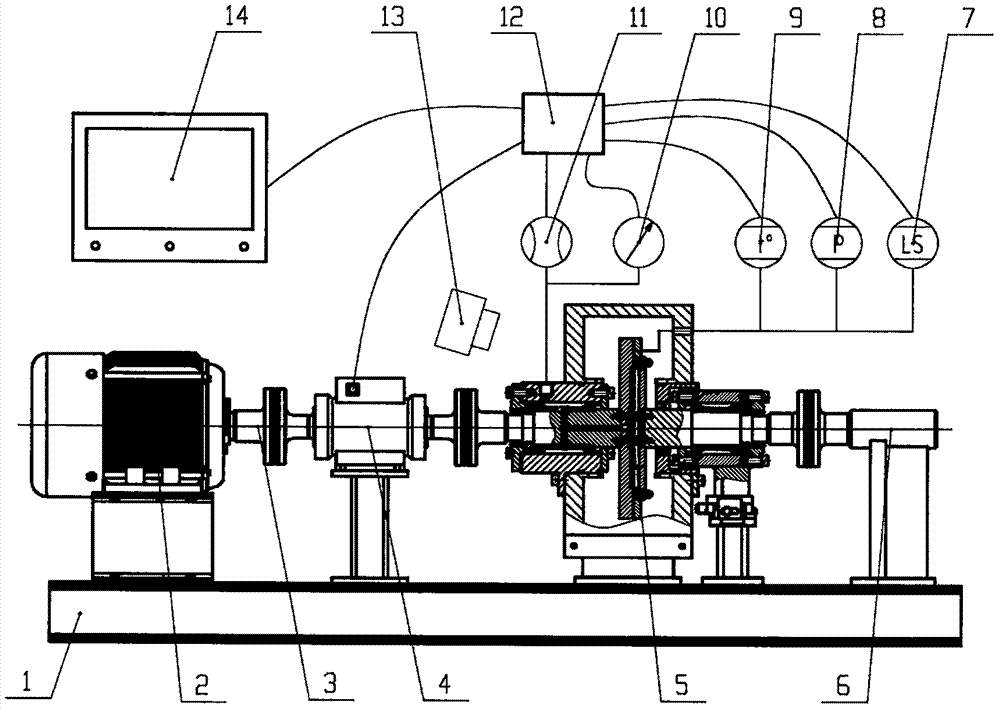

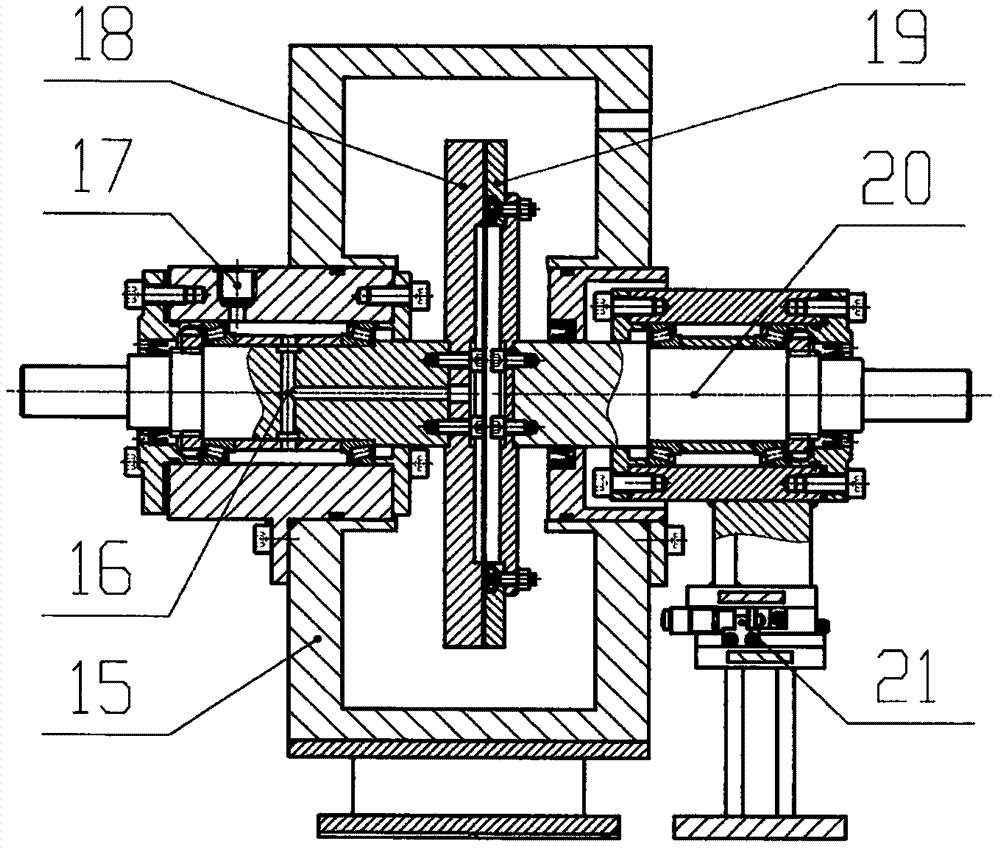

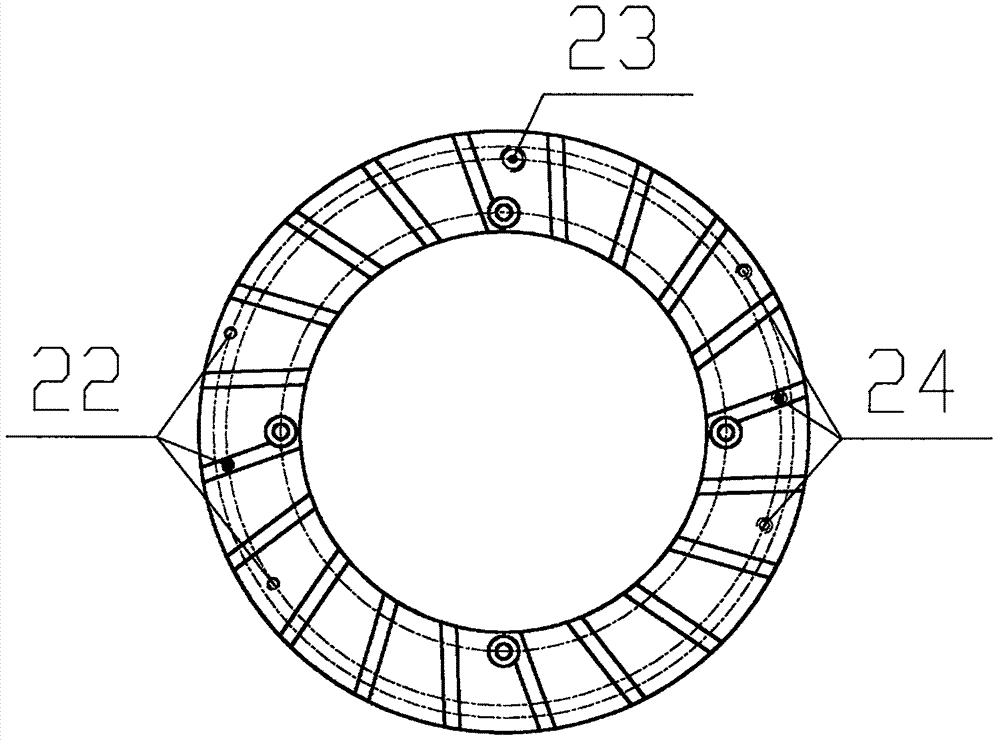

[0015] Such as figure 1 As shown, a high-precision transparent liquid-viscous transmission experimental testing device of the present invention mainly includes a base 1, a motor 2, a shaft coupling 3, a torque tachometer 4, a host 5, a locking device 6, a displacement sensor 7, a pressure Sensor 8, temperature sensor 9, pressure gauge 10, flow meter 11, data acquisition card 12, high-speed camera 13 and computer 14, etc. Such as figure 2 As shown, the main engine 5 mainly includes a transparent box body 15, a driving shaft assembly 16, an oil inlet 17, a transparent active sheet 18, a passive sheet 19, a driven shaft assembly 20, and a distance adjustment assembly 21, etc. Such as image 3 As shown, the passive plate 19 is provided with a temperature sensor mounting hole 22, a displacement sensor mounting hole 23 and a pressure sensor mounting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com