Hydrofining process integration method

A technology of hydrofining and combined process, which is applied in the direction of refined hydrocarbon oil and petroleum industry, etc. It can solve problems such as difficulty in use, achieve the effect of reducing operation, good application prospects, saving one-time investment equipment and equipment and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

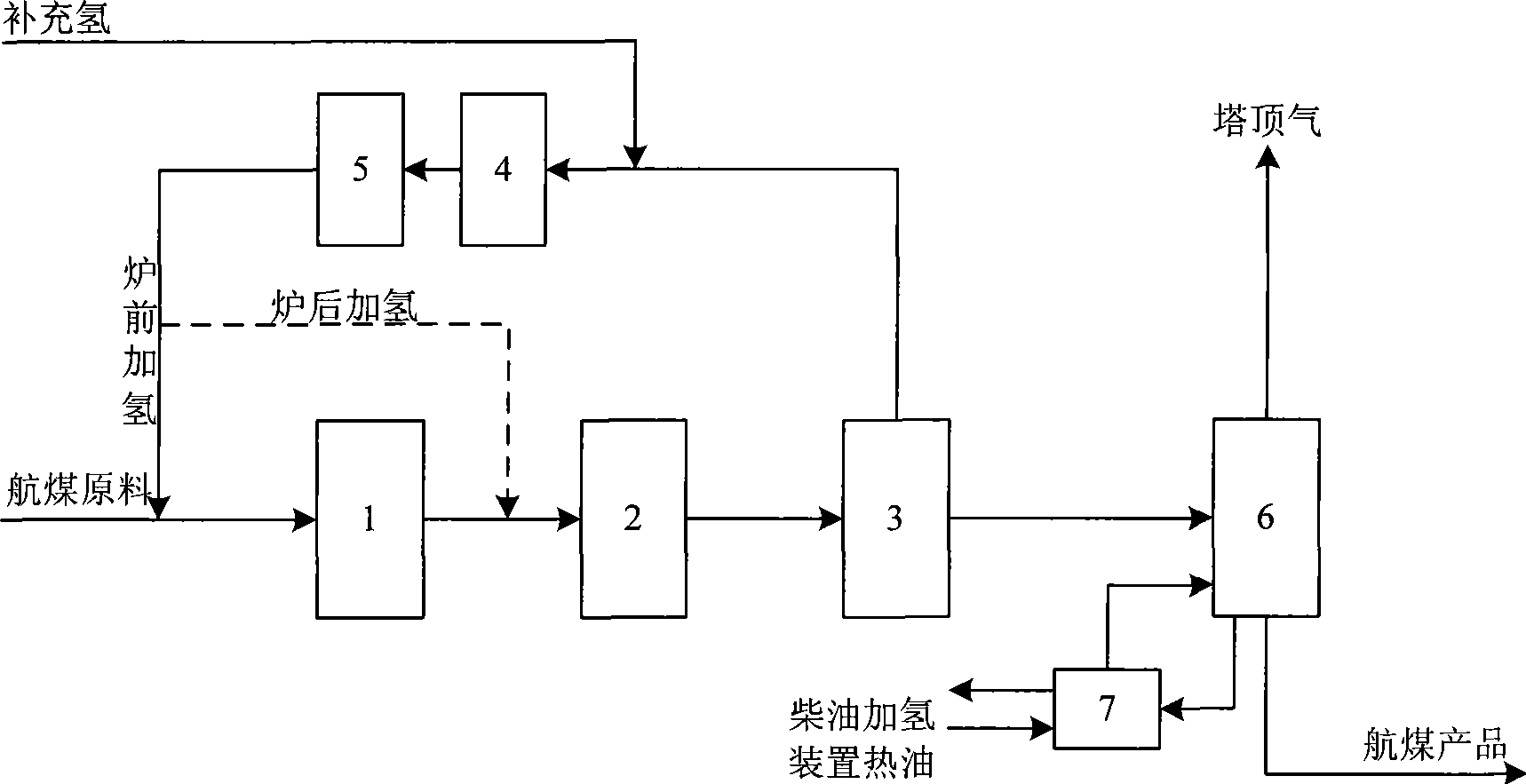

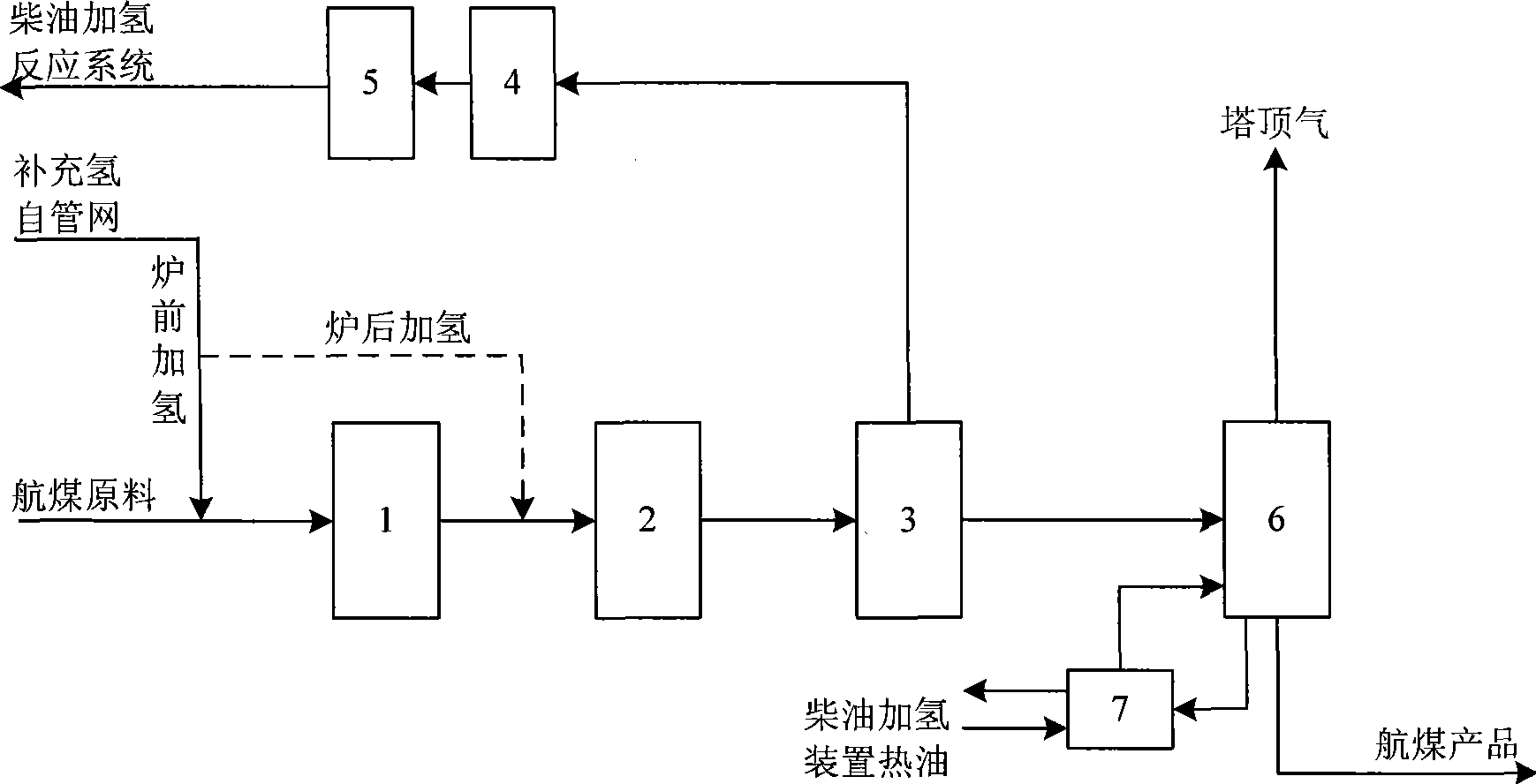

[0033] The 600,000 tons / year aviation kerosene hydrofining unit of an oil refinery and the 4.1 million tons / year diesel hydrofining unit form a combined unit.

[0034] After the feedstock oil of the aviation kerosene hydrorefining unit is filtered, heat-exchanged step by step, heated up, and boosted, it enters the heating furnace for heating, with a temperature of 245℃ and a pressure of 3.3MPa; the hot flue gas produced by the heating furnace enters the diesel through the flue The waste heat recovery system of the hydrorefining unit performs heat recovery; the raw oil is mixed with hydrogen and enters the hydrorefining reactor to carry out chemical reactions such as mercaptan removal. The reaction temperature is 245℃, the reactor inlet pressure is 2.7MPa, and the reactor inlet hydrogen oil Ratio ≥50, the hydrogen used comes from the first stage outlet of the supplementary hydrogen compressor of the diesel hydrofining unit in the combined unit, and the hydrogen is mixed with the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com