Method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation

A technology of dicyclohexylamine and cyclohexylamine, applied in the chemical industry, can solve the problems of increasing production costs, polluting the environment, wasting materials, etc., and achieve the effect of reducing material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

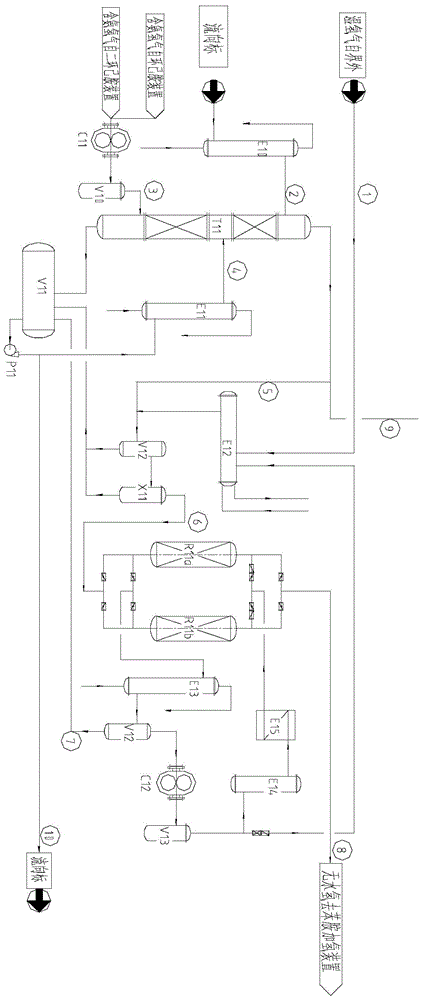

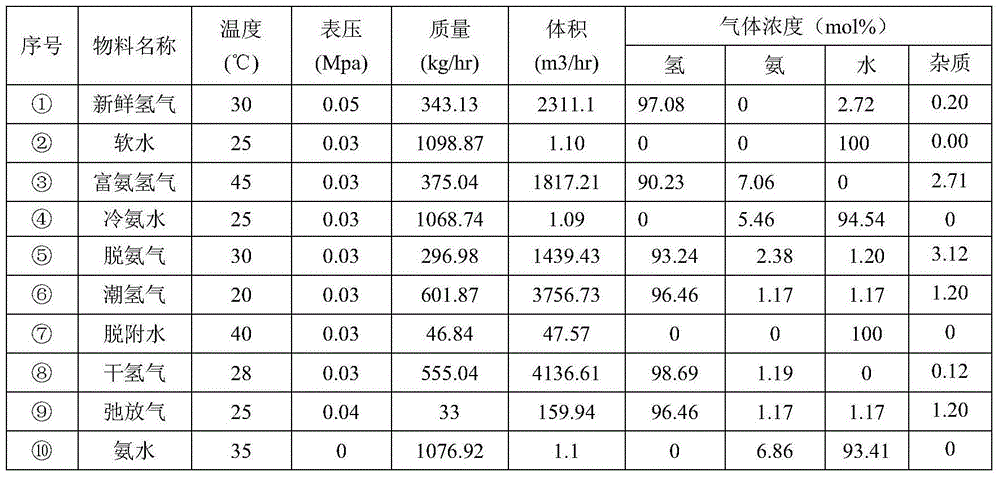

[0018] As attached to the manual figure 1 As shown, the ammonia-containing hydrogen tail stream of the aniline hydrogenation to cyclohexylamine and aniline hydrogenation to dicyclohexylamine units ③375.04kg / h, enters the absorption tower from the bottom of the ammonia absorption tower, and the operating pressure of the ammonia absorption tower is 0.05Mpa , the operating temperature is 15°C, the mass flow rate of water is 977.65kg / hr, and the mass ratio of water to gas is 2.61. The stream after deamination ⑤ enters the water adsorption tower a through the water separator and fiber filter. The adsorbent of the water adsorption tower is 5A molecular sieve, the operating pressure is 0.04Mpa, and the operating temperature is 12°C. Under this operating condition, aniline is hydrogenated Table 1 shows the parameters of each stream in the process of producing cyclohexylamine and dicyclohexylamine tail gas by removing ammonia and refining hydrogen. The refined hydrogen molar content i...

Embodiment 2

[0022] As attached to the manual figure 1 As shown, the ammonia-containing hydrogen tail stream of the aniline hydrogenation to cyclohexylamine and aniline hydrogenation to dicyclohexylamine units ③375.04kg / h, enters the absorption tower from the bottom of the ammonia absorption tower, and the operating pressure of the ammonia absorption tower is 0.03Mpa , the operating temperature is 25°C, the mass flow rate of water is 1098.87kg / hr, and the mass ratio of water to gas is 2.93. The stream after deamination ⑤ enters the water adsorption tower a through the water separator and fiber filter. The adsorbent of the water adsorption tower is silica gel, the operating pressure is 0.03Mpa, and the operating temperature is 25°C. Under this operating condition, aniline is hydrogenated to prepare Table 2 shows the parameters of each stream in the hydrogen purification process by deamination of cyclohexylamine and dicyclohexylamine tail gas. The refined hydrogen molar content is 98.69%, a...

Embodiment 3

[0026] As attached to the manual figure 1 As shown, the ammonia-containing hydrogen tail stream of the aniline hydrogenation to cyclohexylamine and aniline hydrogenation to dicyclohexylamine units ③375.04kg / h, enters the absorption tower from the bottom of the ammonia absorption tower, and the operating pressure of the ammonia absorption tower is 0.05Mpa , the operating temperature is 20°C, the mass flow rate of water is 977.65kg / hr, and the mass ratio of water to gas is 2.61. The stream after deamination ⑤ enters the water adsorption tower a through the water separator and fiber filter. The adsorbent of the water adsorption tower is 5A molecular sieve, the operating pressure is 0.04Mpa, and the operating temperature is 20°C. Under this operating condition, aniline is hydrogenated The parameters of each stream in the process of deamination and refining hydrogen from the tail gas of cyclohexylamine and dicyclohexylamine are shown in Table 3. Due to the high solubility of ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com