Patents

Literature

189 results about "Dicyclohexylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dicyclohexylamine is a secondary amine with the chemical formula HN(C₆H₁₁)₂. It is a colorless liquid, although commercial samples can appear yellow. It has a fishy odor, typical for amines. It is sparingly soluble in water. As an amine, it is an organic base and useful precursor to other chemicals.

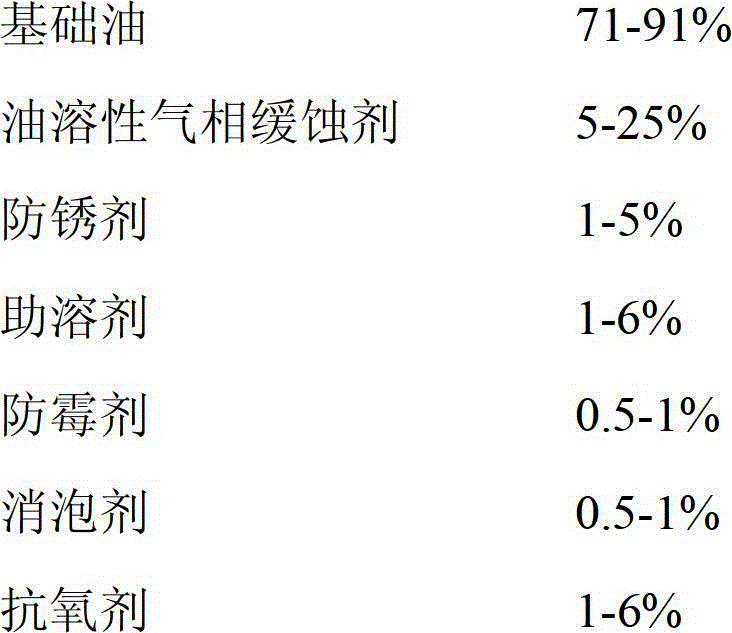

Volatile rust preventive oil

InactiveCN102719302AInhibit corrosion and rustClean working environmentAdditivesGas phaseAntioxidant

The invention discloses volatile rust preventive oil which comprises, by weight, 71-91% of base oil, 5-25% of an oil soluble volatile corrosion inhibitor, 1-5% of an antirusting agent, 1-6% of a cosolvent, 0.5-1% of a mildew-proof agent, 0.5-1% of an antifoaming agent and 1-6% of antioxidant, wherein the base oil is one of 500SN 46# machine oil, 32# machine oil, 600SN 150# machine oil and 100# machine oil; and the oil soluble volatile corrosion inhibitor is a mixture of four kinds of 2-heptadecenyl-imidalidine, octadecylamine, triazole tributylamine, dicyclohexylamine carbonate, dicyclohexylaminenitrite, benzotriazole, tert-butyl chromate, nephthenic soap, petroleum sodium sulfonate, sorbitan monooleate and stearic acid; and the antioxidant is sulfurphosphorousbutyloctyl zinc salt. The volatile rust preventive oil has good volatile rust preventive and corrosion resistant performances, metal which cannot be coated with rust preventive oil can achieve rust preventive protection, the operation is simple, and the cost is low.

Owner:上海福岛新材料科技有限公司

Metallic bearing water-based detergent and rinsing agent used together with the same, and method for producing the same

InactiveCN101195790AAvoid corrosionImprove rust resistanceOrganic detergent compounding agentsNon-ionic surface-active compoundsWater basedPhosphoric Acid Esters

The invention relates to metal bearing water-based cleaning agent, rinsing agent matched with the water-based cleaning agent, and the preparation method thereof. Petroleum sodium sulfonate, triethanol amine oleate, fatty alcohol-polyoxyethylene ether, emulgator, and cocoanut oil diethanolamine phosphoric acid ester are mixed with tiethanolamine and ethanolamine according to the weight percentage, are stirred uniformly at room temperature, then are mixed with other raw materials and water, then antibubbling agent AF9020 is added, and therefore the brown yellow and transparent concentrated cleaning agent is formed; nitrous acid dicyclohexylamine, oleic acid triethanolamine and petroleum sodium sulfonate are respectively dissolved into the mixed solvent of tiethanolamine and mono ethanolamine, then benzotriazole is dissolved into water to mix the two solvent, to form the brown yellow and transparent concentrated rinsing agent; the cleaning agent and the rinsing agent are mixed into 5 percent treatment fluid and 1 percent of treatment fluid, then the treatment fluid is cleaned for 30 seconds to 1 minute under ultrasonic wave, rinsed for 30 seconds, and then hot air seasoning, drying and 48 h rust preventing are performed. The invention can replace gasoline cleaning agent, kerosene cleaning agent, and universal water-based cleaning agent, the used raw material is easy to be acquired, the production cost is low, and the invention without parkerizing process can effectively prevent the environmental pollution.

Owner:白马轴承技术(洛阳)有限公司

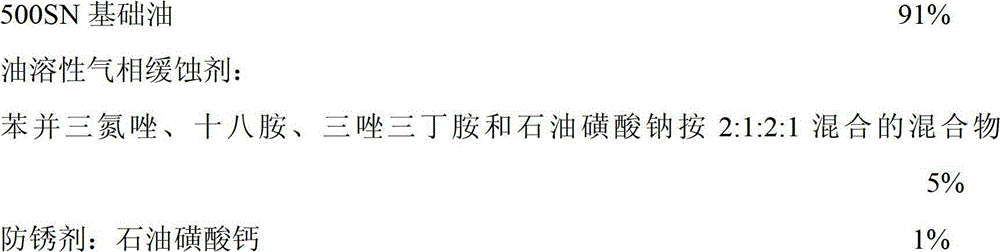

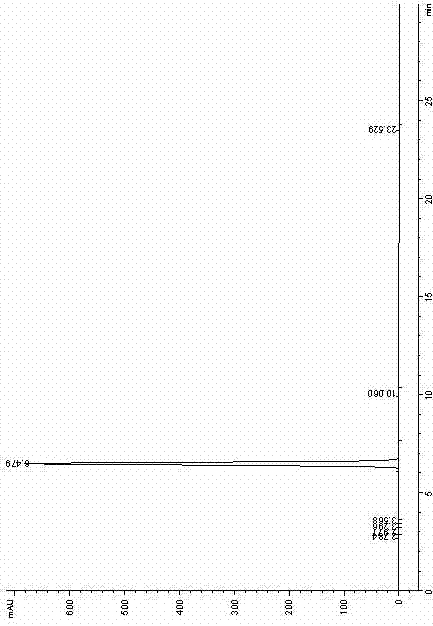

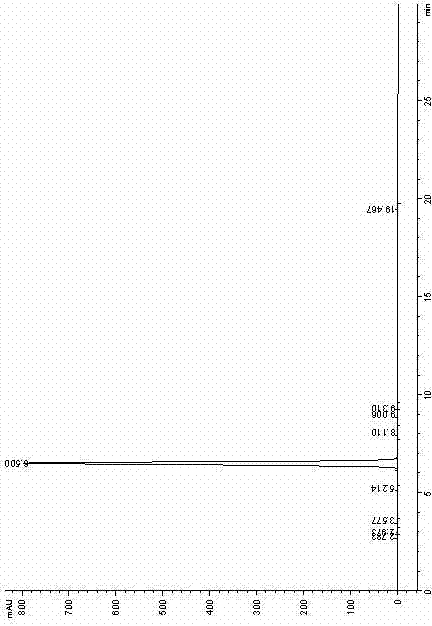

Resource utilization preparation method for high-purity dicyclohexyl amine

ActiveCN102516087AHigh degree of hydrorefiningIncrease contentAmino compound purification/separationOrganic compound preparationHydrogenResource utilization

The invention discloses a resource utilization preparation method for high-purity dicyclohexyl amine. The method has the characteristics of low temperature, low pressure, large variable scale of raw material component content and long service life of a catalyst, and can be widely applied and popularized in industrial production. The preparation method for high-purity dicyclohexyl amine disclosed by the invention comprises the following steps of: preparing crude dicyclohexyl amine by performing catalytic hydrogenation on aniline with the conventional method; and refining the crude dicyclohexyl amine into high-purity dicyclohexyl amine, wherein a method for refining the crude dicyclohexyl amine into high-purity dicyclohexyl amine comprises the following steps of: introducing crude dicyclohexyl amine and hydrogen into a fixed bed tubular reactor in the presence of a granular nickel-based high-activity catalyst under the condition that the reaction pressure is 0.1-3 MPa, the reaction temperature is 140-210 DEG C, the liquid air speed is 0.2-2.5 h<-1>, and the hydrogen-oil volume ratio is 100-1,000.

Owner:JIANGSU NUOMENG CHEM

Water-based metal rust inhibitor and preparation method thereof

The invention provides a water-based metal rust inhibitor and a preparation method thereof. The rust inhibitor comprises sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate, acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine, octadecylamine oleyl sarcosinate, oxidized barium petrotate, sodium ethylenediamine teramethylene phosphonate, 1-hydroxyethylidene, dimethylaminoethyl acrylate, sulfomethylated polyacrylamide, a film forming agent and deionized water. The preparation method comprises the steps of firstly, mixing sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate and water, and adding octadecylamine oleyl sarcosinate; then, adding acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine and oxidized barium petrotate into the deionized water, and adding 1-hydroxyethylidene; and mixing a mixture I and a mixture II, and adding the left components to obtain the water-based metal rust inhibitor. The rust inhibitor can be attached to the surface of metal, so that the metal has better wear resistance and corrosion resistance.

Owner:NINGBO SHEN XIN ELECTRONICS CO LTD

Method for preparing Montelukast sodium

InactiveCN104119270AReduce dosageSimple process conditionsOrganic chemistryAcetic acidPurification methods

The invention provides a method for preparing and purifying Montelukast sodium. The method comprises the following steps: A. preparing a disodium salt of 2-[1-(mercapto methyl) cyclopropyl] acetic acid; B. preparing an Montelukast free acid; C. preparing an Montelukast di-n-propylamine salt; D. preparing an Montelukast dicyclohexylamine salt; E. converting the Montelukast dicyclohexylamine salt into an Montelukast sodium salt. The synthesis method is simple in process conditions, good in impurity removal effect and small in risk factor, the sulfoxide impurity is less than 0.1%, other impurities are less than 0.05%, and even a certain impurity cannot be detected, and the purity of the Montelukast sodium is larger than 99.8%. All impurities of the Montelukast sodium can be effectively controlled to be less than 0.05%.

Owner:MUDANJIANG HENGYUAN PHARMA CO LTD

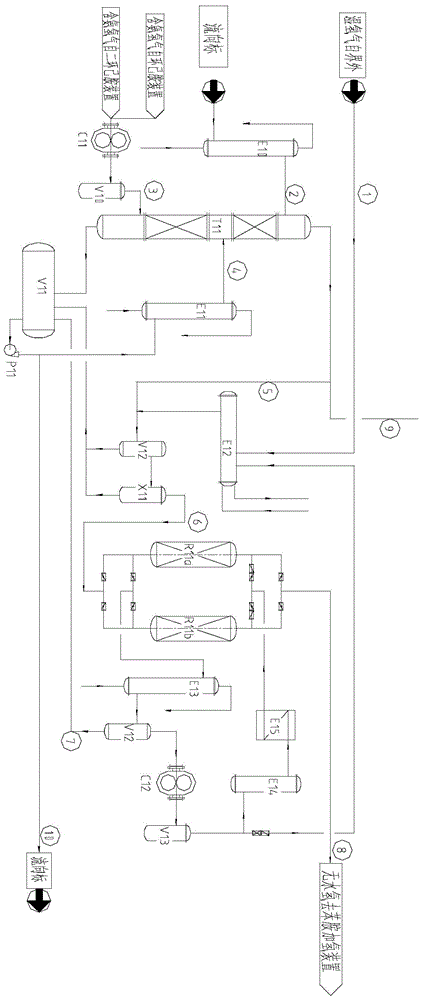

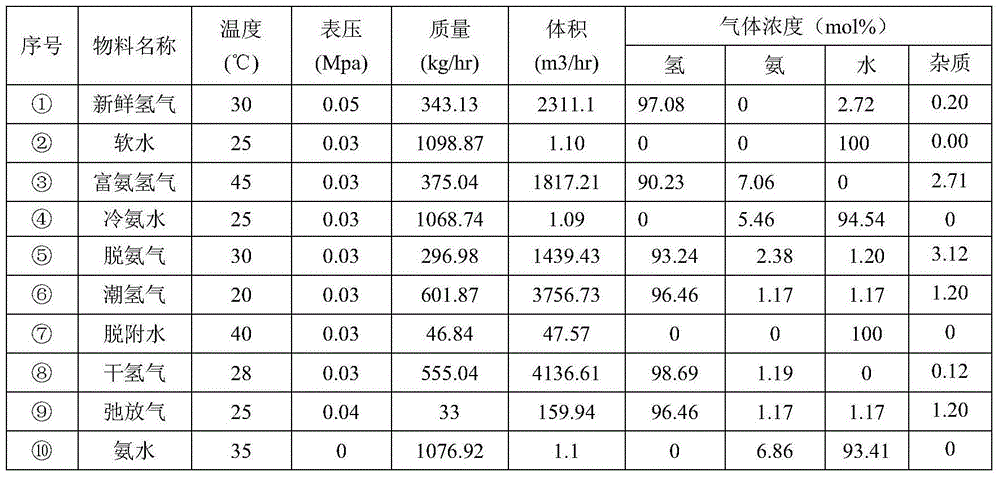

Method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation

InactiveCN104445067AHigh purityAchieving zero emissionsHydrogen separationAmmonia preparation/separationWater vaporGas phase

The invention relates to a tail gas refining method, and in particular relates to a method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation, belonging to the technical field of chemical engineering. The method comprises the following steps: allowing tail gas discharged by a cyclohexylamine device and a dicyclohexylamine device to enter an ammonia absorption tower by virtue of a Roche hydrogen compressor and a degreaser, wherein most of ammonia is absorbed by water to be converted into ammonia water to be output from the tower bottom in the tower, and the gas output from the tower top is water-containing hydrogen; allowing the water-containing hydrogen to pass through a water segregator, a fiber filter and a water adsorption tower so as to further remove water vapor, thereby obtaining the refined hydrogen. The concentration of the refined hydrogen can be 98.0-99.8 percent, the material and energy consumption is reduced, and the aims of energy conservation and emission reduction are achieved. The refined hydrogen can serve as recycling gas to be used for an aniline hydrogenation reaction, and gas phase zero emission is realized.

Owner:NANJING UNIV OF TECH

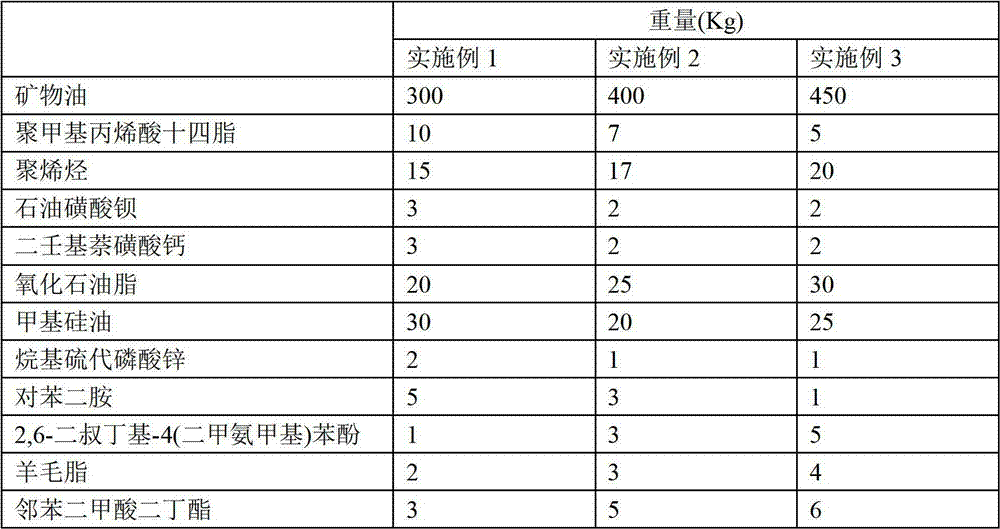

Corrosion-resistant anti-rust oil

The invention provides anti-rust oil capable of resisting corrosion and salt mist and belongs to the technical field of lubricating oil. The anti-rust oil comprises the following components in part by weight: 300 to 450 parts of mineral oil, 5 to 10 parts of polymethylacrylic acid tetradecyl ester, 15 to 20 parts of polyolefin, 2 to 3 parts of barium petroleum sulfonate, 2 to 3 parts of calcium dinonylnaphthalenesulfonate, 20 to 30 parts of oxidation petrolatum, 20 to 30 parts of methyl silicone oil, 1 to 2 parts of zinc alkyl thiophosphate, 1 to 5 parts of p-phenylenediamine, 1 to 5 parts of 2,6-di-tert-butyl-4(dimethylamine methyl)phenol, 2 to 4 parts of wool grease, 3 to 6 parts of dibutyl phthalate, 3 to 6 parts of octanoic acid dicyclohexylamine, 1 to 3 parts of epoxy polyaniline, 1 to 2 parts of calcium dodecyl benzene sulfonate, 2 to 4 parts of dibutyl succinate, 30 to 50 parts of hydrogenated castor oil, 15 to 20 parts of hydrogenated styrene-diene copolymer and 3 to 5 parts of magnesium borate. The anti-rust oil has high lubricating performance, wherein the durability in a salt mist test can reach 108 days and the durability in a warm test can reach 30 days.

Owner:SUZHOU XIELU NETWORK TECH

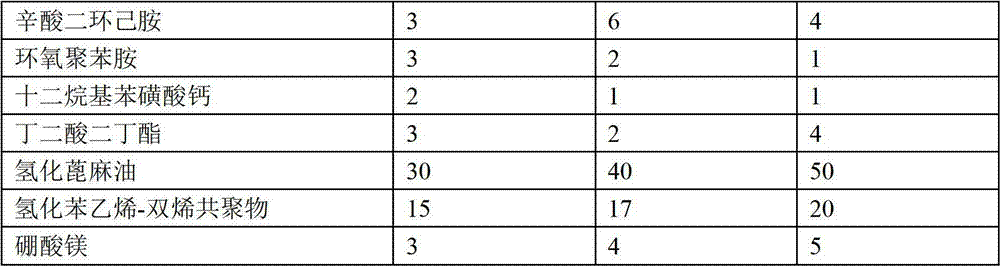

Preparation method of rubber vulcanization accelerator DCBS

InactiveCN102838564AEliminate the refining processReduce the generation of "three wastes"Organic chemistrySaline waterVulcanization

The invention relates to a preparation method of a rubber vulcanization accelerator DCBS. The preparation method comprises the following steps of: directly adding crude MBT obtained in a high-pressure reaction into a container filled with water under violent stirring, dropping a sodium hydroxide aqueous solution into the container to ensure that the MBT is completely dissolved into an M-Na saline solution, standing still, and then transferring supernatant liquor into a measuring tank; simultaneously dropping a sodium hypochlorite solution, the M-Na saline solution and a sulfuric acid solution into a container filled with isopropanol and dicyclohexylamine, and after the M-Na saline solution is finished being dropped, stopping dropping the other two solutions; standing still a reaction mixture obtained at a reaction endpoint, separating out saline water and the isopropanol, wherein the isopropanol is directly recycled; carrying out suction filtration on a material layer, washing a filter cake with water to neutrality, and distilling material washing water to recover the isopropanol; and drying the material to obtain a DCBS finished product. According to the preparation method, because the MBT crude product is used as a raw material to directly synthesize the accelerator, the preparation method has the advantages of simple operation, low cost, small environmental pollution and high yield.

Owner:KEMAI CHEM

Preparation method of polylactic acid-chitose graft copolymer

The invention discloses a method for making polylactic acid-chitosan graft copolymer. The method comprises the following steps that: (1) the chitosan with a deacetylation between 50 and 90 percent and a molecular weight between 500 and 30000 is dissolved into a lactic acid solution; (2) a nonpolar solvent capable of forming a low-boiling point azeotrope is added into the mixture to dehydrate at the temperature of between 40 and 90 DEG C; (3) after the dehydration is finished, an organic base and a catalyst are added to react at the temperature of between 10 and 100 DEG C, the catalyst is an acid catalyst, a Lewis acid catalyst, a strong acid type positive ion-exchange resin or an N, N'- dicyclohexylamine carbimide; (4) the drying and concentrating processes are performed and the product is obtained. The synthetic method is simple, the reaction condition is moderate, and the energy consumption is low, therefore, the method is suitable for the industrial production.

Owner:NORTHWEST UNIV

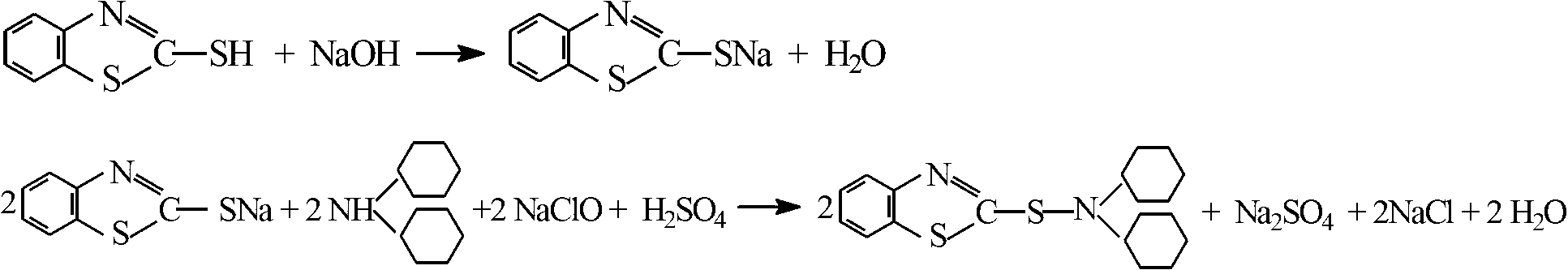

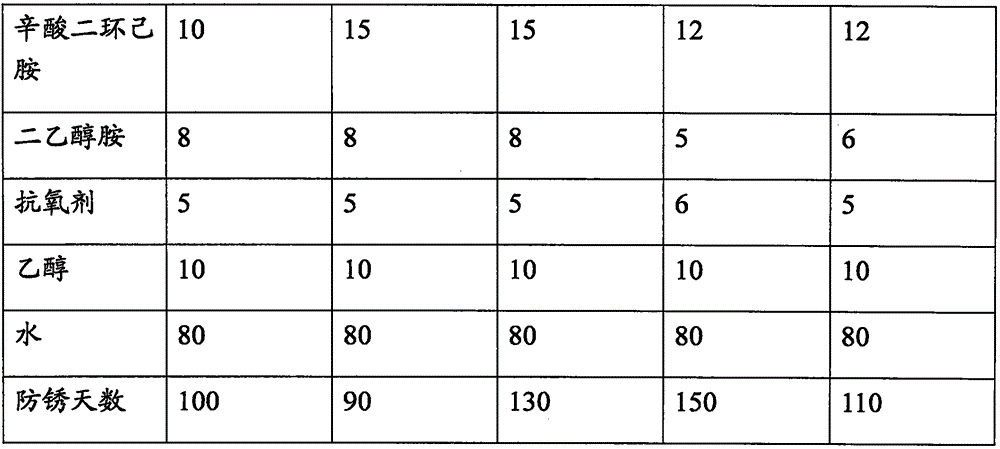

Water-soluble antirust agent

The invention provides a water-soluble antirust agent. The water-soluble antirust agent is prepared from fatty acid, specific amine, an additive, ethyl alcohol and water. The mass ratio of the fatty acid to the alcohol amine to the additive to the ethyl alcohol to the water is (2-3):(1-15):(5-10):(10-15):(80-100). The fatty acid is selected from one or more of oxalic acid, valeric acid, naphthenic acid, citric acid, benzoic acid, lauric acid, adipic acid, oleic acid and sebacic acid, the apecific amine is selected from one or more of octanoic acid dicyclohexylamine, triethanolamine, diethanol amine and ethanol amine, and the additive is an antioxidant. The antirust valid period of the water-soluble antirust agent is long and can reach 3-6 months; an antirust film is thin and is only tens of microns thick, a follow-up process cannot be influenced even though the antirust film is not removed, and the film can be removed with warm water due to the good film removability of the water-soluble antirust agent; and the water-soluble antirust agent is low in production cost, free of foreign smells and beneficial to environmental protection.

Owner:彭国泉

Method for preparing cyclohexylamine and dicyclohexylamine from nitrobenzene through one-step catalytic hydrogenation

ActiveCN103450028AHigh purityReduce pollutionOrganic compound preparationAmino compound preparationHydrogenNitrobenzene

The invention relates to a method for preparing cyclohexylamine and dicyclohexylamine from nitrobenzene through one-step catalytic hydrogenation, belonging to the technical field of organic catalysis. The method comprises the steps: with the nitrobenzene and hydrogen as raw materials, adding a solvent, the nitrobenzene and a catalyst into a reaction kettle, and controlling the reaction pressure at 0.5-4Mpa, the reaction temperature at 60-160 DEG C and the reaction time within 2-8h to obtain the cyclohexylamine and the dicyclohexylamine, wherein the adopted catalyst is a Pd / CNTs catalyst or Pd-Ni / CNTs catalyst. According to the invention, the cyclohexylamine and the dicyclohexylamine are synthesized by using the nitrobenzene at one step, so that the reaction loss is reduced, the utilization ratios of the raw materials are increased, the emission of various waste reaction liquids can be reduced, and the cost for treating waste liquid can be reduced. The method has the advantages of greenness, economy, safety, simplicity and convenience in operation, few equipment requirements and the like so as to be suitable for industrial production.

Owner:XIANGTAN UNIV

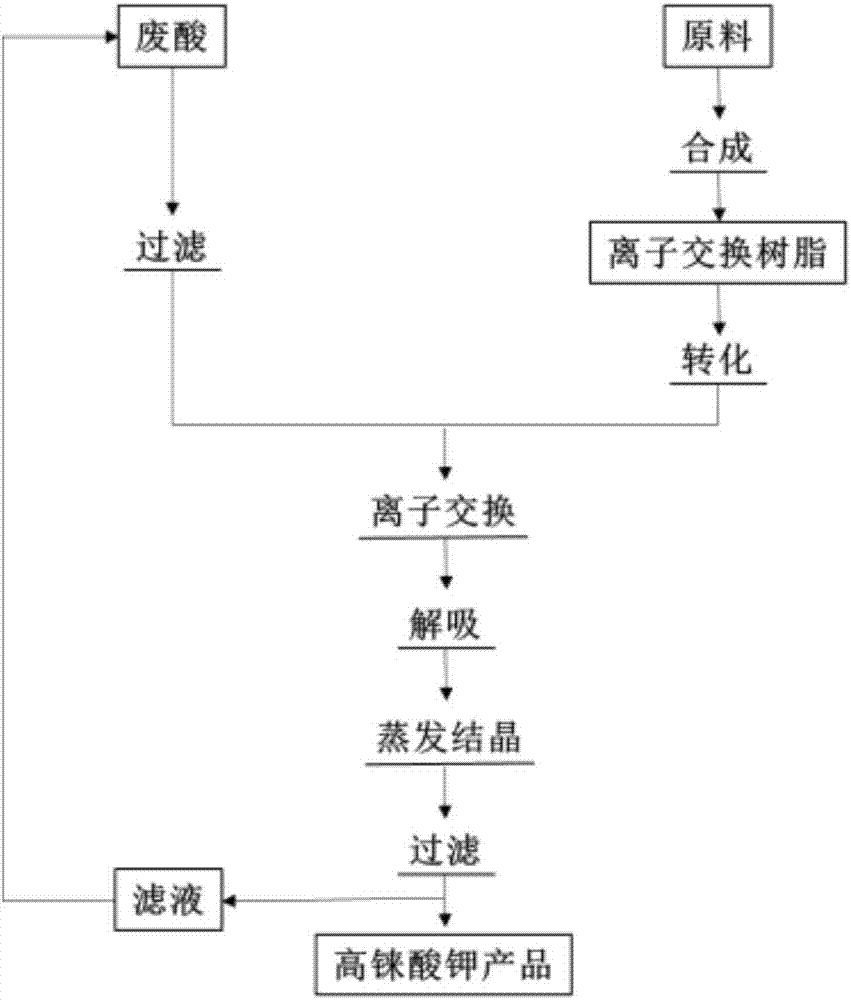

Composite vinylamine-series weakly-basic anion exchange resin and method for recovering rhenium from waste acid produced in copper smelting

The invention relates to a composite vinylamine-series weakly-basic anion exchange resin and a method for recovering rhenium from waste acid produced in copper smelting, belonging to the technical field of recycling of metallic rhenium. The composite vinylamine-series weakly-basic anion exchange resin is prepared by swelling chloromethylated polystyrene microspheres in an organic solvent for 4 to 10 h; then slowly adding a mixture of dicyclohexylamine, pyridine and N-methylcyclohexylamine and carrying out a reaction at room temperature for 1 to 6 h; then carrying out heating to 40 to 90 DEG C and continuing the reaction for 6 to 18 h; and then carrying out vacuum pumping filtration. The composite vinylamine-series weakly-basic anion exchange resin provided by the invention has good adsorptive selectivity on low-concentration rhenium (2 to 10 mg / L) under the conditions of high acidity and existence of high-concentration impurity ions, and almost does not adsorb impurity ions, especially toxic arsenate ions; waste acid directly enters an arsenate after filtering; so process flow is simplified and the recovery rate of rhenium is increased.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

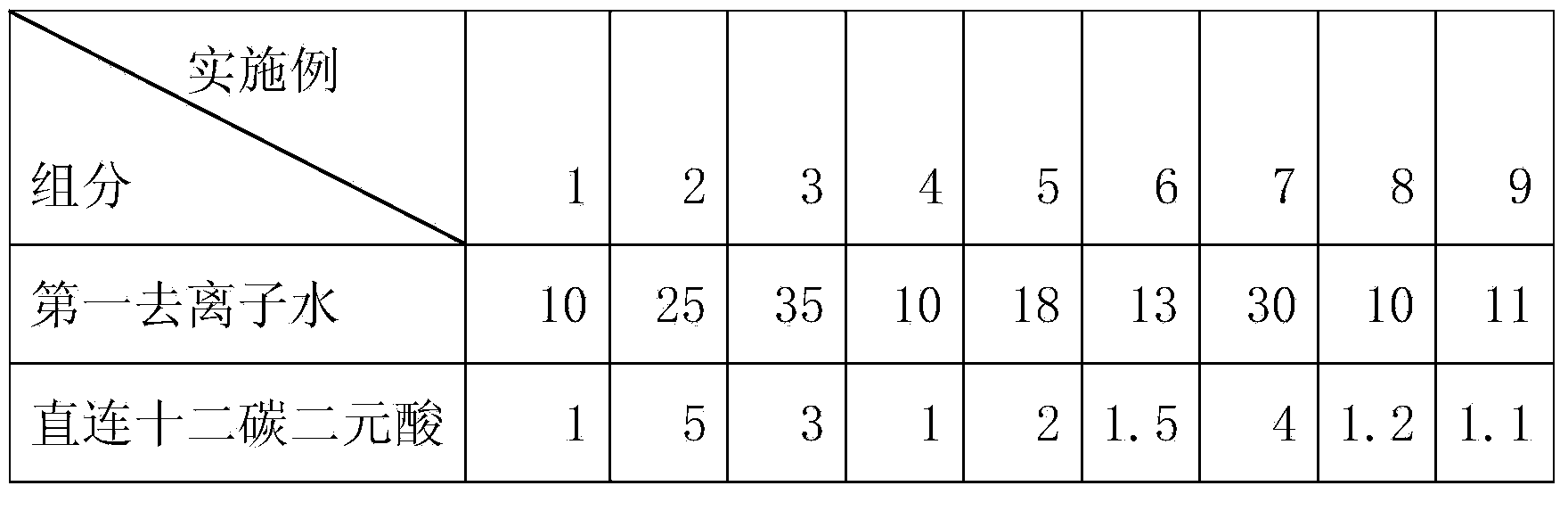

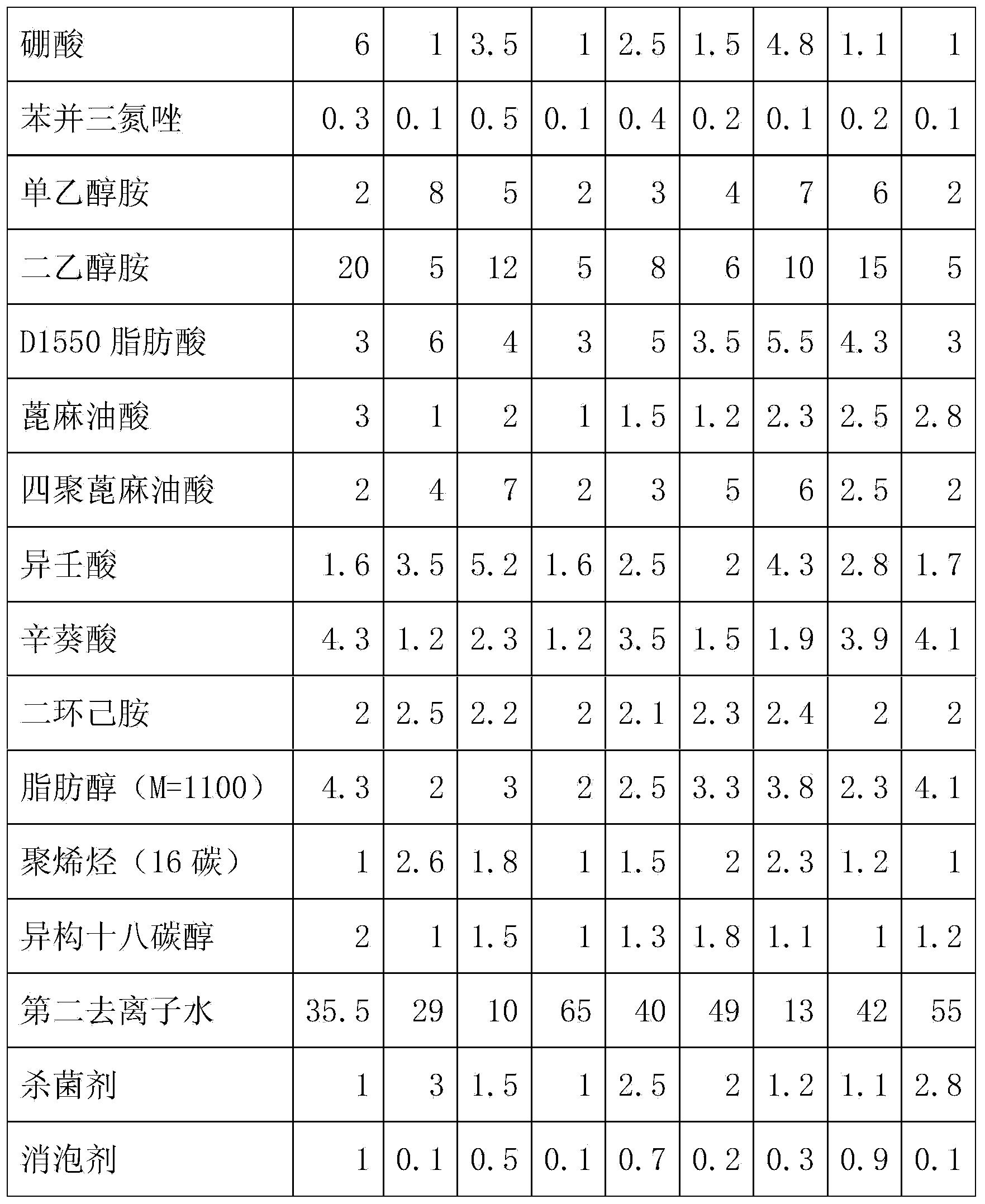

Fully synthetic cutting fluid for metal processing and preparation method thereof

InactiveCN104232283AGood adsorption and anti-rust effectImprove the lubrication effectLubricant compositionPolyolefinFatty acid

The invention discloses fully synthetic cutting fluid for metal processing. The cutting fluid is prepared from deionized water, linear chain dodecanedioic acid, boric acid, benzotriazole, monoethanolamine, diethanol amine, D1550 fatty acid, ricinoleic acid, tetraricinoleic acid, isononanoic acid, octanoic / decanoic acid, dicyclohexylamine, fatty alcohol, polyolefin, isooctadecanol, a sterilizing agent and an antifoaming agent according to a certain ratio. The fully synthetic cutting fluid for metal processing overcomes the defects that the using cost of the product is high, a diluent easily goes bad to generate foreign odor, lubrication is insufficient and the service time and cycle are short and the like existing in products in the market and also has excellent cooling and cleaning anti-rust performances, so that the metal processing and lubricating products are improved in the machining and lubricating aspects to a certain degree. The fully synthetic cutting fluid product for metal processing has the greatest characteristic that the lubricating property requirements of heavy processing modes of some materials which are difficult to machine in the machining process can be met, the fully synthetic cutting fluid does not contain base oil, and the service time can be greatly prolonged.

Owner:上海加美实业有限公司

Gas-phase anti-rust composite packaging film for industry and preparation method thereof

ActiveCN101319067AHigh mechanical strengthIncrease elasticityFlat articlesLow-density polyethyleneBenzoic acid

The invention relates to a rust proofing packaging film, in particular to a gas phase rust proofing industrial composite packaging film and a preparation method thereof. The gas phase rust proofing industrial composite packaging film comprises the compositions by weight proportion: 0 to 0.53 of drewamine, 0.12 to 0.42 of cyclohexane, 0.13 to 0.4 of dicyclohexylamine, 0.09 to 0.28 of phenylformic acid, 0.22 to 0.55 of tert-Butyl benzoic acid, 0 to 0.12 of cinnamylate, 29.5 to 45.1 of low density polyethylente, 29.5 to 45.1 of linear low density polyethylene, 0 to 0.02 of oleamide or erucyl amide and 0 to 0.12 of a diffusing impurity EB-FF. The gas phase rust proofing film has good barrier property and high intensity, saves cost, is nonpoisonous and harmless, prevents the pollution, and can be reused. The preparation method is simple and convenient, the process is easy to control and the production cost is low.

Owner:金荣范

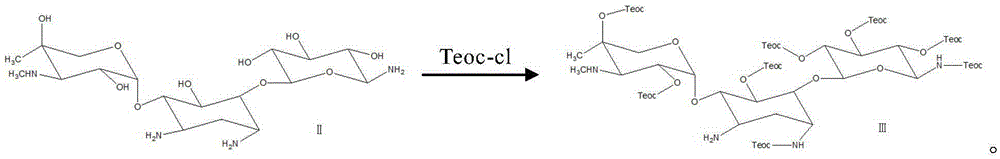

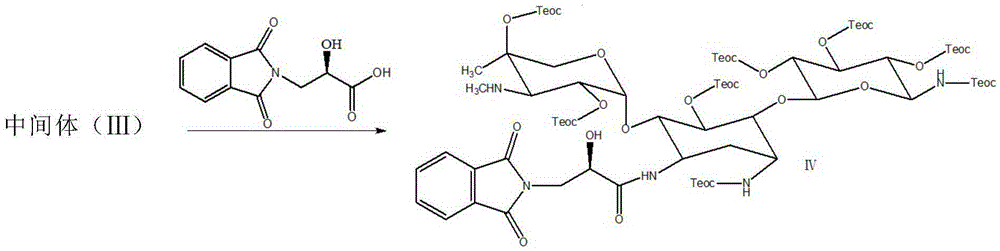

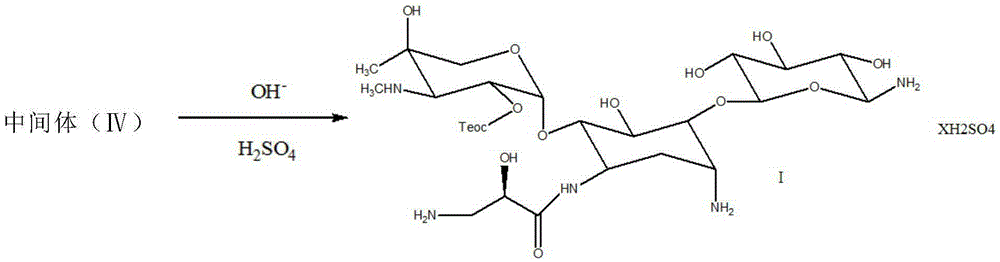

Preparation method of isepamicin sulfate (I)

InactiveCN105254688ALower synthesis costHigh puritySugar derivativesSugar derivatives preparationIsepamicin sulfateEthanol

The invention discloses a preparation method of isepamicin sulfate (I). The method comprises the following steps that (1) gentamicin gentamycin B (II) serves as a starting raw material, and after a reaction reagent and trimethyl silicone ethoxy carbonyl chloride protect, an intermediate (III) is obtained; (2) the intermediate (III) reacts with N,N-dicyclohexylamine and is coupled with N-phthalic anhydride-(S)-isoserine, and the product is subjected to column chromatography isolation to obtain an intermediate (IV); (3) the intermediate (IV) is de-protected and acidified by vitriol to obtain a crude product, and the crude product is re-crystallized with anhydrous alcohol to obtain isepamicin sulfate (I). The preparation method of the isepamicin sulfate (I) disclosed by the invention has the advantages of low synthesizing cost, short synthesizing period, and high product purity and yield, and is suitable for industrial production.

Owner:WUXI FORTUNE PHARMA

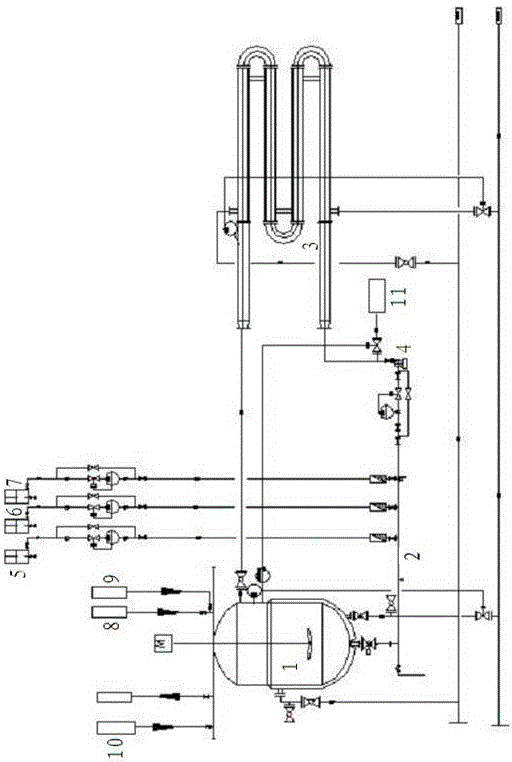

Preparation method and device of rubber vulcanization accelerator DZ

InactiveCN106749096AIncreased chance of collisionEmission reductionOrganic chemistryVulcanizationPolymer science

The invention relates to the technical field of production of rubber vulcanization accelerators and in particular discloses a preparation method and device of a rubber vulcanization accelerator DZ. The preparation method of the rubber vulcanization accelerator DZ is characterized by comprising the following steps: adding isopropyl alcohol and dicyclohexylamine into a reaction kettle; starting a circulating pipeline reactor; carrying out three-dropwise adding operation of sodium hypochlorite, M sodium salt and diluted sulfuric acid respectively; carrying out the whole oxidization process in a pipeline reactor; carrying out cyclic reaction through a circulating pump; after reacting, washing with water and drying to obtain an accelerator DZ product. According to the preparation method and device, the pipeline cyclic reaction is carried out and technological conditions are stable; a mother solution obtained by oxidization is cyclically utilized; the pipeline cyclic reaction and the mother solution recycle have dual effect and the yield of the obtained product is greatly improved; the product has stable quality and relatively low consumption; the energy consumption is relatively low, and wastewater is relatively easily treated.

Owner:SHANDONG SUNSINE CHEM

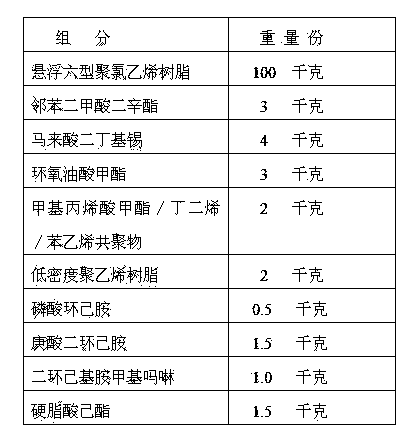

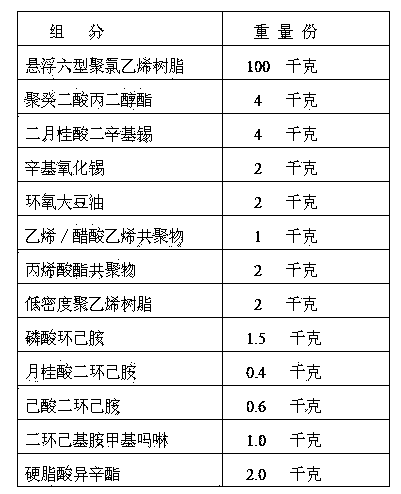

Composition for making polyvinyl chloride thermal contraction vapor phase antirust film

The invention discloses a composition for making a polyvinyl chloride thermal contraction vapor phase antirust film. The composition comprises a polyvinyl chloride resin, a plasticizer, a stabilizer, a secondary plasticizer, an impact modifier, a polyethylene resin, cyclohexylamine phosphate, fatty acid dicyclohexylamine, a morpholine derivative and a lubricant. The polyvinyl chloride thermal contraction antirust film is produced by utilizing the composition used for making the polyvinyl chloride thermal contraction antirust film and containing a vapor phase rust inhibitor through a routine production method of the polyvinyl chloride thermal contraction antirust film in order to realize convenient production and vapor phase antirust requirements; and the vapor phase rust inhibitor adopted in the invention does not like traditional nitrous acid vapor phase rust inhibitors, and is in favor of realizing environmental protection and the health of human bodies.

Owner:山东蓝盟防腐科技股份有限公司

Multifunctional composite gas phase anti rust agent and preparation method thereof

The invention discloses a multifunctional composite gas phase anti rust agent, which is characterized by comprising the following raw materials by weight: 1-2 parts of nitrite dicyclohexylamine, 1-2 parts of hydroxyethyl ethylenediamine, 0.5-1 part of ethyl maltol, 1-2 parts of propylene glycol alginate, 4-6 parts of decamethylcyclopentasiloxane, 2-4 parts of palm oil, 1-2 parts of glyceryl triisocaprylate, 1-2 parts of trimethylolpropane trioleate, 0.5-1 part of barium petroleum sulfonate, 6-8 parts of chitosan, 1-2 parts of mannitol, 6-8 parts of sodium tripolyphosphate, 2-4 parts of sodium alginate, 4-6 parts of a performance additive and 40-50 parts of water. The multifunctional composite gas phase anti rust agent has both contact antirust and gas phase antirust effects. The multifunctional composite gas phase anti rust agent has good antirust effect on iron and steel, copper, aluminum, zinc and other various metal materials, the time of duration is long, and the multifunctional composite gas phase anti rust agent has sustained release and controlled release effect, and is suitable for occasions requiring both waterborne antirusting and sealed space gas phase antirusting effects.

Owner:SUZHOU QINAN IND & TRADE

Method of producing rubber vulcanization accelerator DZ

The invention discloses a production method of rubber vulcanization accelerator DZ. 100 to 500 grams of M-Na salt is added into an oxygenation kettle containing catalyst KM-01; under the conditions of temperature between 20 DEG C and 70 DEG C and rotational speed between 100 rotations per minute and 1400 rotations per minute, at a flow speed between 30 ml per minute and 70 ml per minute, dicyclohexylamine with eighty to ninety percent of mass content is added into the oxygenation kettle; at a flow speed between 30 ml per minute and 50 ml per minute, sulphuric acid solution with thirty to sixty percent of mass content is dripped into the solution; at a flow speed between 30 ml per minute and 110 ml per minute, oxygen is pumped into the solution; after forty to one hundred and fifty minutes, the color of the sampled material is observed, when the color of the material is gray or white, the addition of oxygen, sulphuric acid and dicyclohexylamine is stopped, a rubber vulcanization accelerator DZ product is produced by pumping filtration, water washing, filtration and drying, and the purity of the accelerator DZ reaches over ninety nine percent. The invention has the advantages of simple process of the method, easy industrialization, little usage of dicyclohexylamine and usage of environment-friendly oxidant oxygen, and the yield rate of the accelerator DZ reaches over ninety nine percent.

Owner:KEMAI CHEM

Novel method for preparing vulcanized rubber accelerant DZ with cooling-down circulating water system

The invention discloses a method for producing a rubber vulcanization accelerator DZ by a novel circulating water cooling system. The method comprises the following steps of: adding 100 to 1,000ml of isopropanol and 100 to 1,000g of dicyclohexylamine into an oxidation kettle provided with the novel circulating water cooling system; sufficiently dissolving the dicyclohexylamine in the isopropanol at a temperature of between 20 and 70 DEG C and at a rotational speed of between 100 and 1,400 revolutions / minute; adding sulphuric acid with a mass content of between 10 and 35 percent into the mixed solution at a flow speed of between 20 and 50ml / minute with a pH value controlled between 9.0 and 12.0; then, adding M-Na salt into the mixed solution at a flow speed of between 30 and 100ml / minute, and simultaneously adding sodium hypochlorite with a mass content of between 8.0 and 18.0 percent as an oxidizing agent into the mixed solution at a flow speed of between 30 and 100ml / minute for 1.0 to 3.0 hours, with the pH value controlled between 9.0 and 12.0 during the process; and obtaining a product of the rubber vulcanization accelerator DZ through pumping and extracting, water scrubbing, filtering and drying after the reaction is completed. The purity of the vulcanization accelerator DZ reaches over 99 percent. The method has the advantages of simple process, easy industrialization, good cooling effect, less dicyclohexylamine, high yield, and over 99 percent purity of the vulcanization accelerator DZ.

Owner:KEMAI CHEM

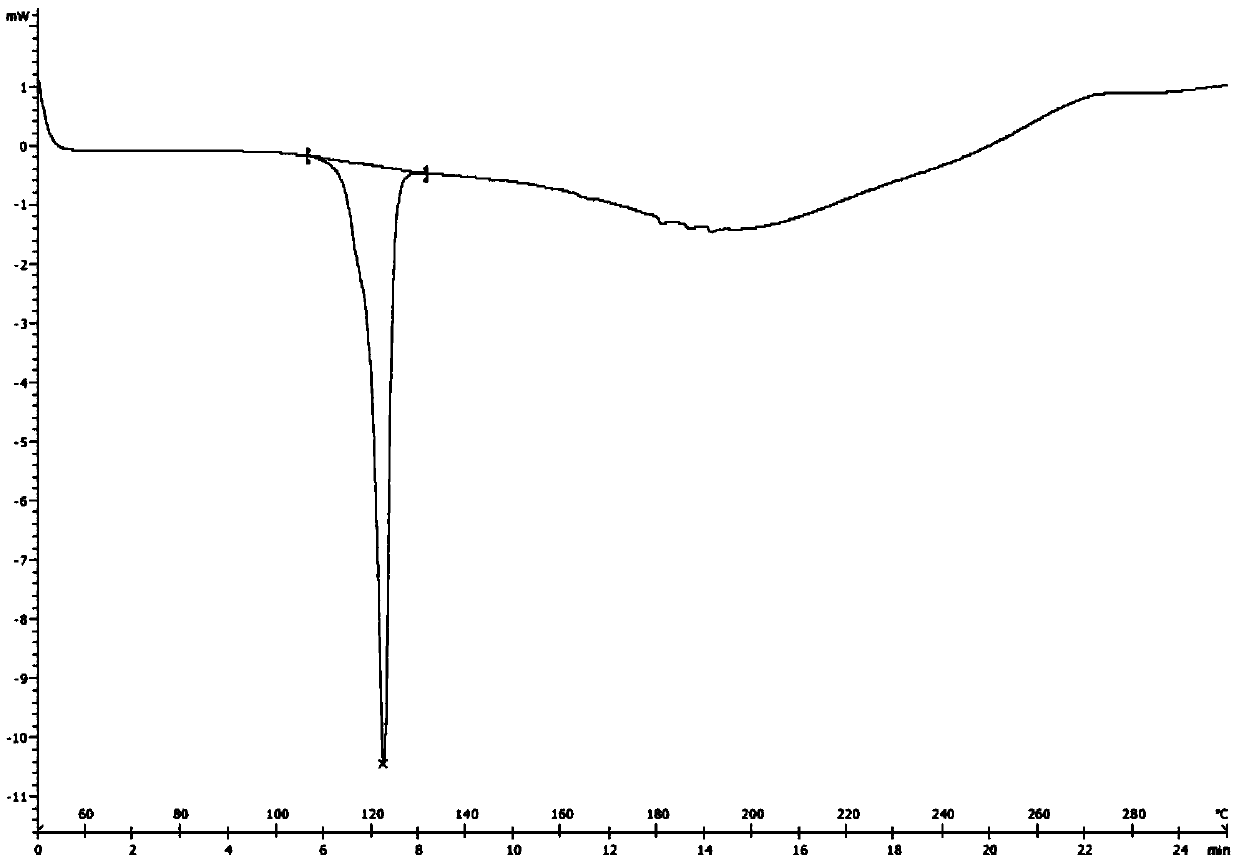

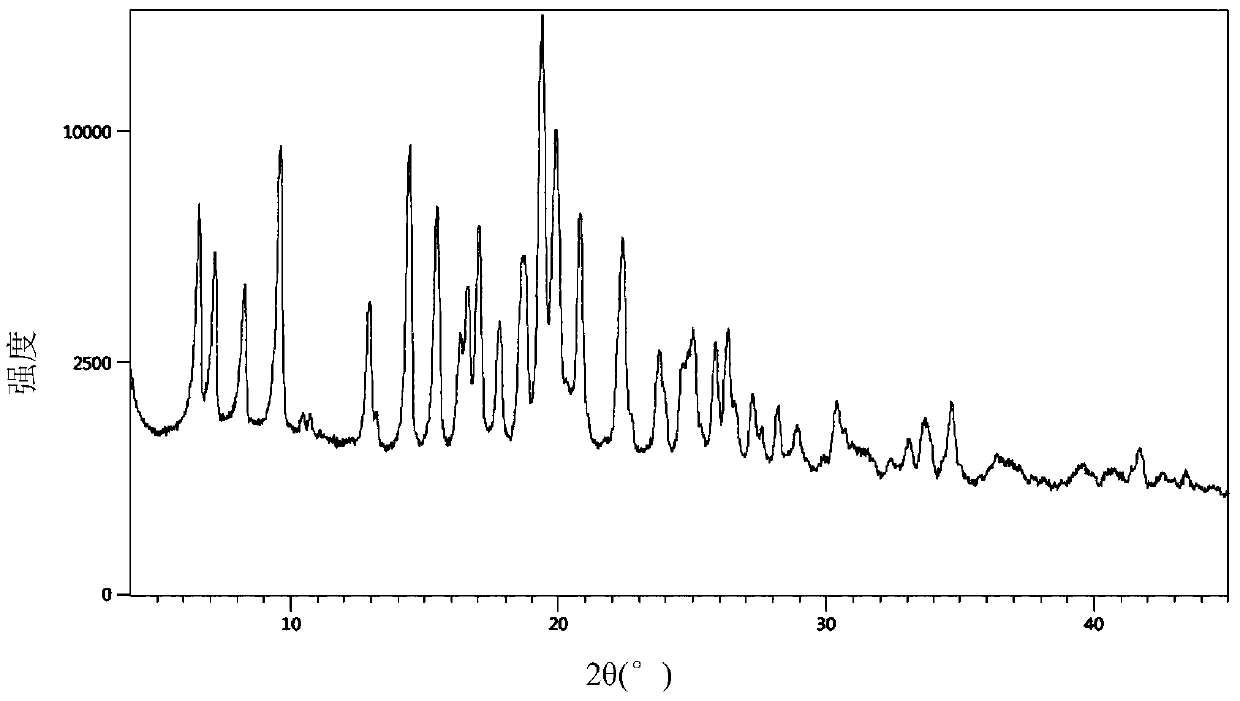

Sacubitril dicyclohexylamine salt, crystal form and preparation method of crystal form

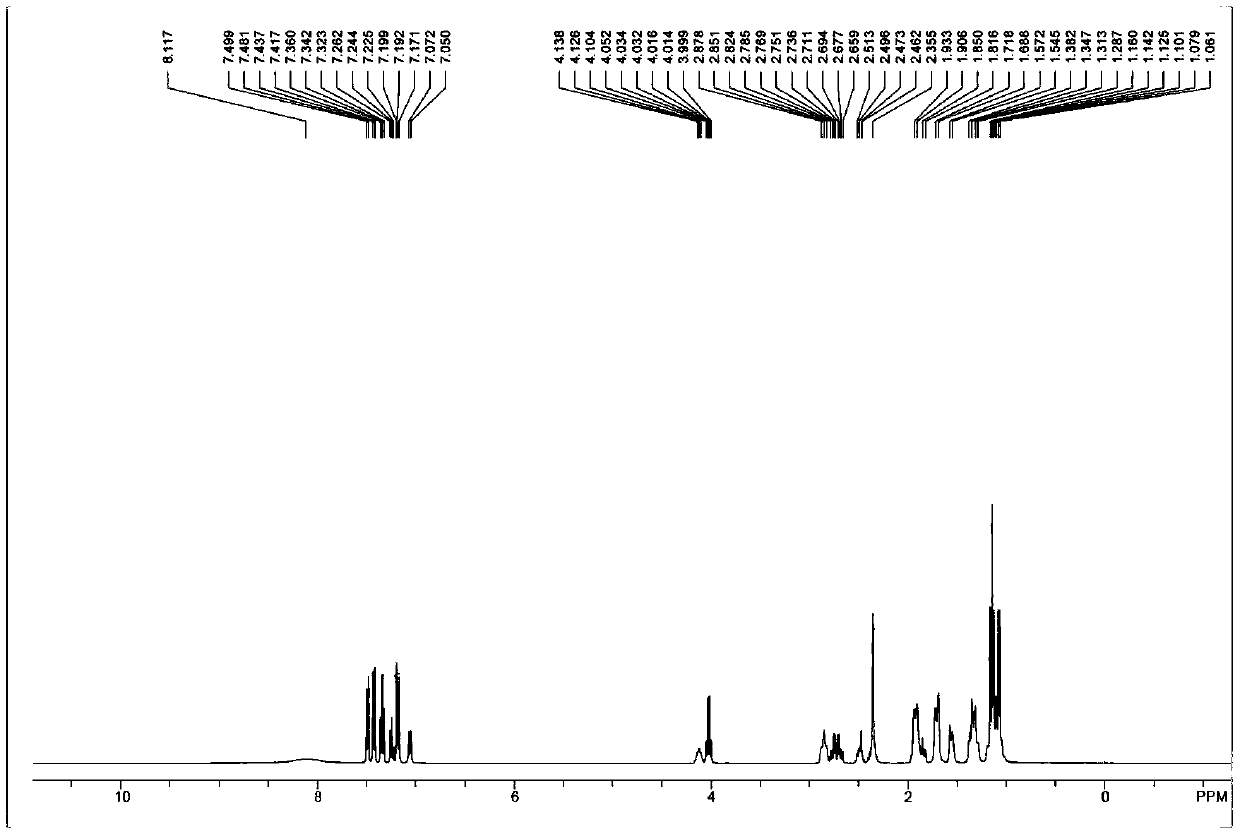

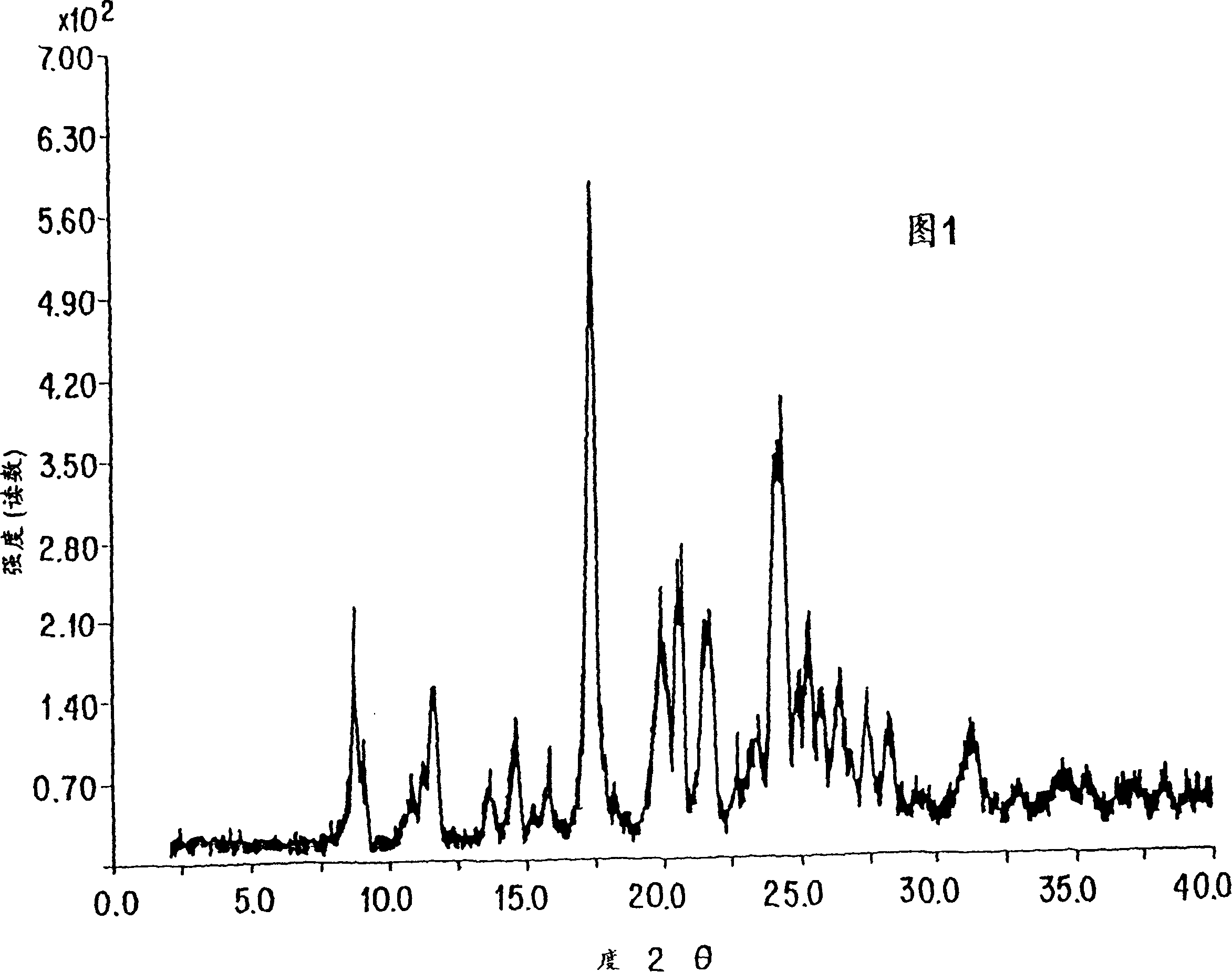

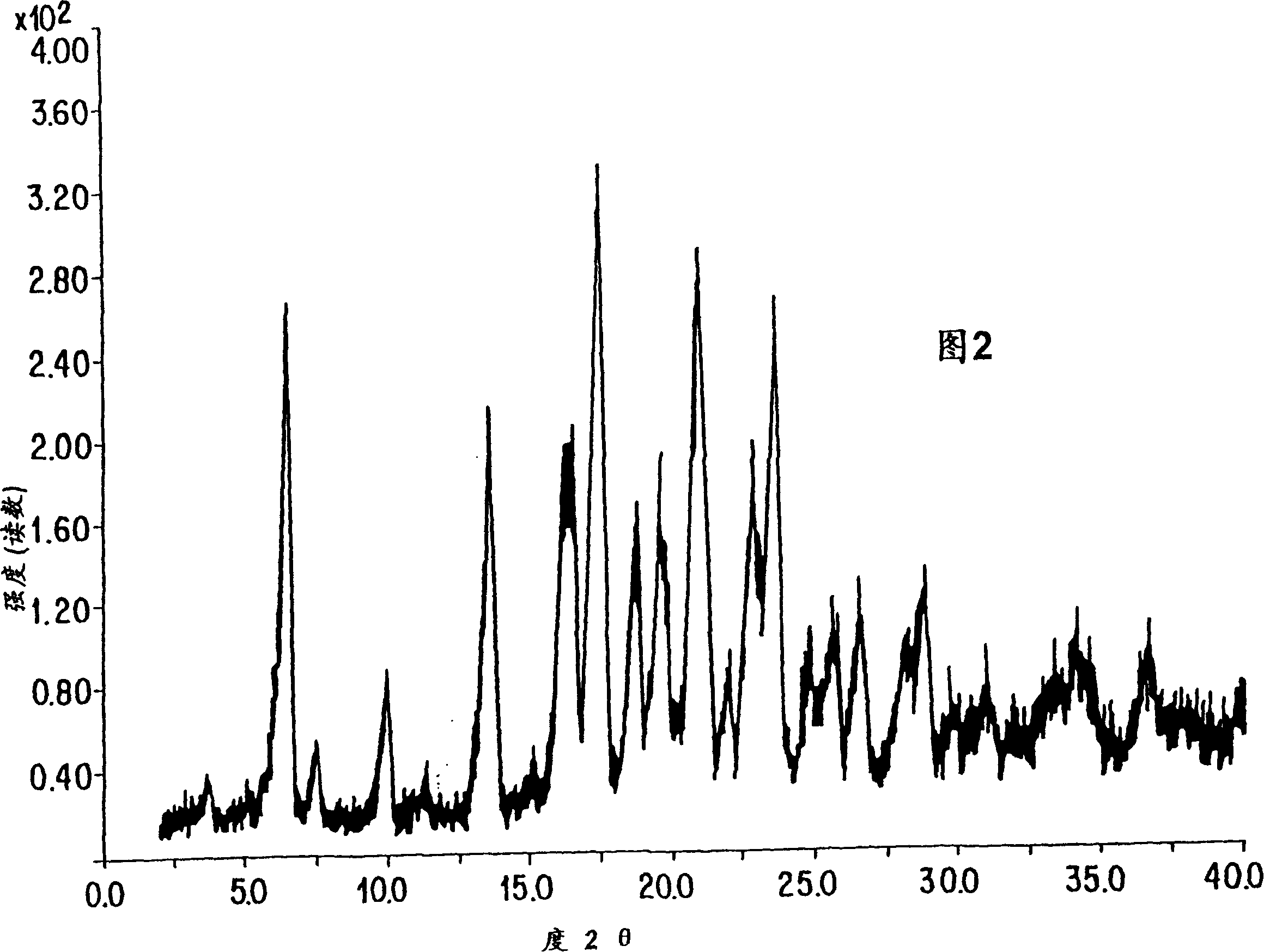

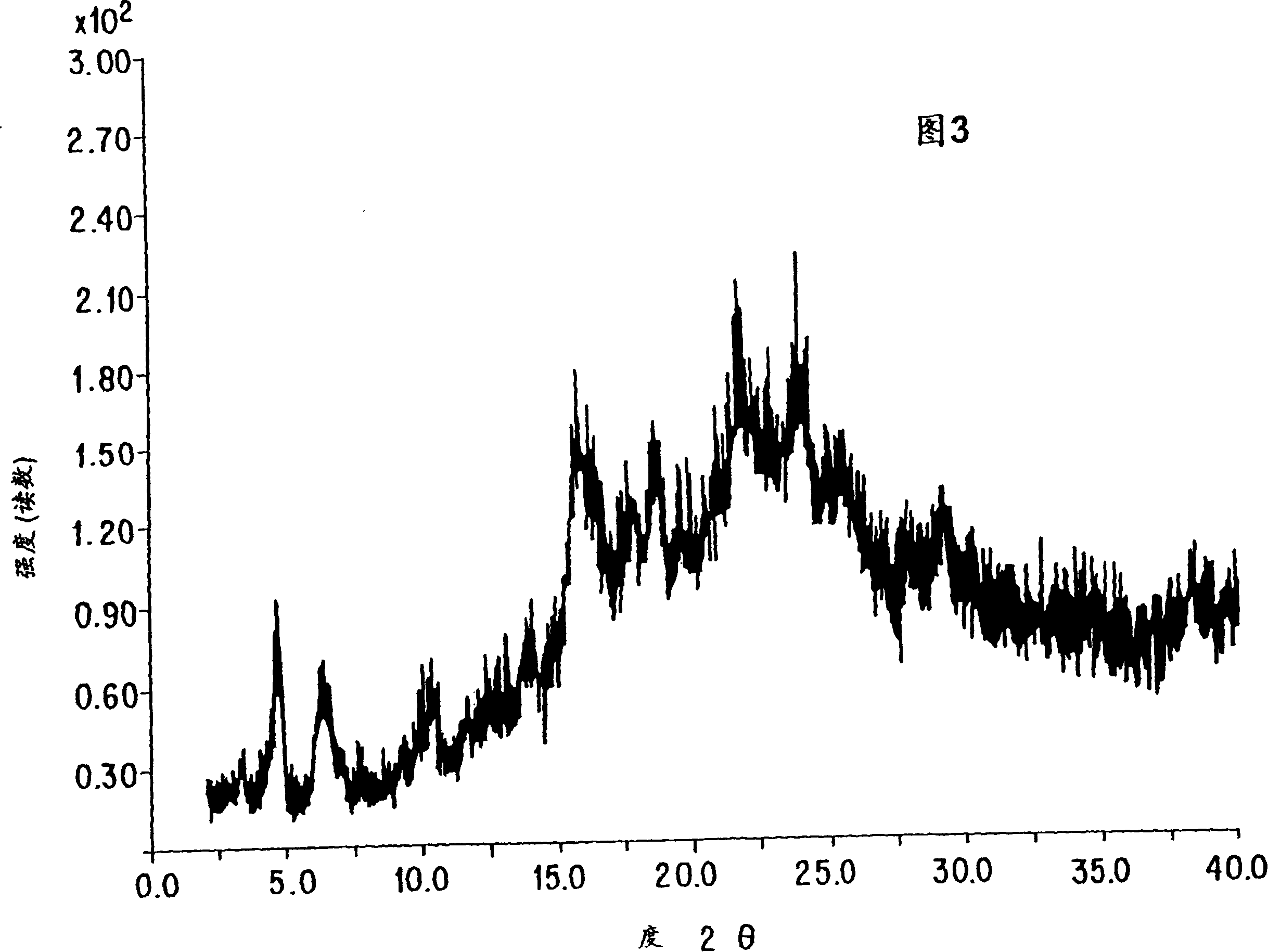

InactiveCN105503638ASalt forming process is simple and easyEasy to controlAmino compound purification/separationOrganic compound preparationImpurityCrystallization

The invention discloses Sacubitril dicyclohexylamine salt, a crystal form and a preparation method of the crystal form. The structure of the sacubitril dicyclohexylamine salt is shown in the formula III in the description. The invention also discloses the crystal from of the sacubitril dicyclohexylamine salt and the preparation method thereof. The sacubitril dicyclohexylamine salt provided by the invention is ideal on the aspects of refinement of the sacubitril and impurity control of a refined product, is conducive to controlling the quality of subsequent LCZ696, and is high in crystallization yield, can effectively reduce the production cost, and is beneficial to industrial production.

Owner:ZHEJIANG TIANYU PHARMA

Process for the preparation of leukotriene antagonists

InactiveCN101081834AOrganic chemistryOrganic compound preparationLeukotriene AntagonistsMethyl group

The present invention relates to a process for the preparation of a compound of formula (I) or a sodium salt thereof, wherein HET is 7-chloroquinolin-2-yl or 6,7-difluoroquinolin-2-yl, which comprises: reacting the dilithium dianion of 1-(mercapto-methyl)cyclopropaneacetic acid with a compound of formula (II), wherein HET is as defined above and L is arylsulfonyl or alkylsulfonyl. The invention further provides the dicyclohexylamine salt of a compound of formula (I), an intermediate falling within (II) and a 1-(Mercaptomethyl)cyclopropaneacetic acid intermediate.

Owner:SCHERING AG

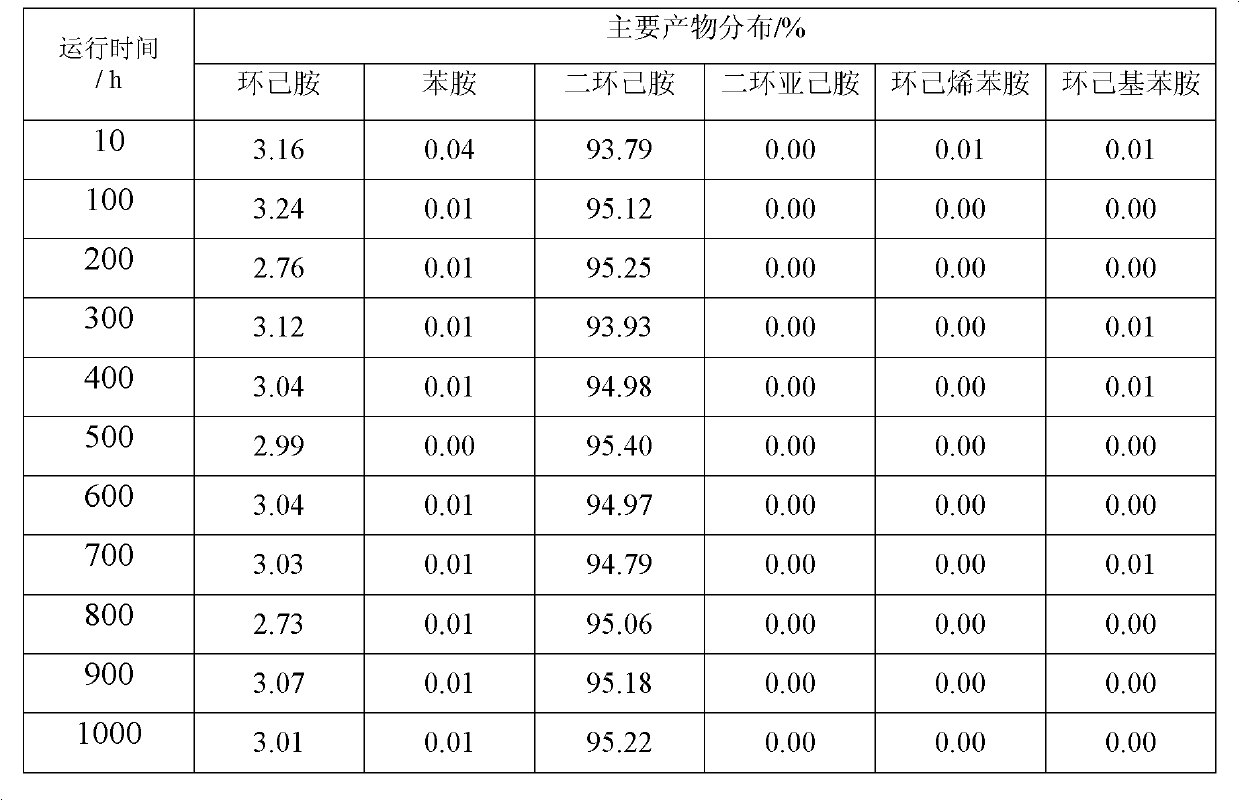

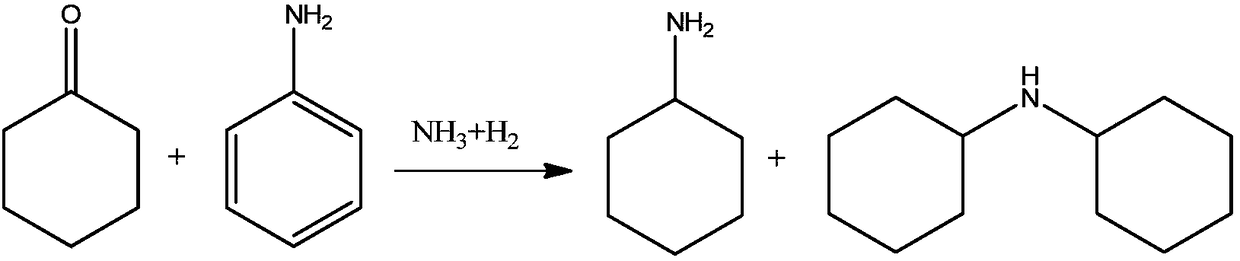

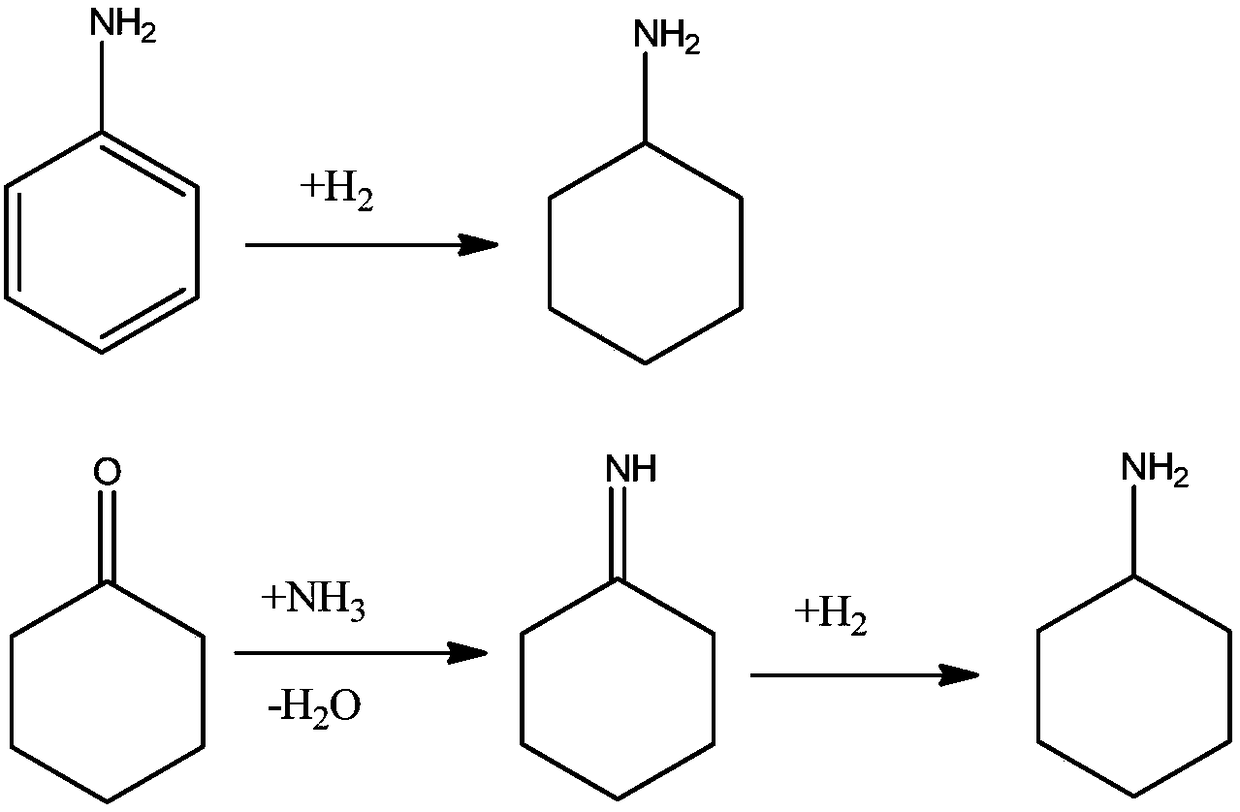

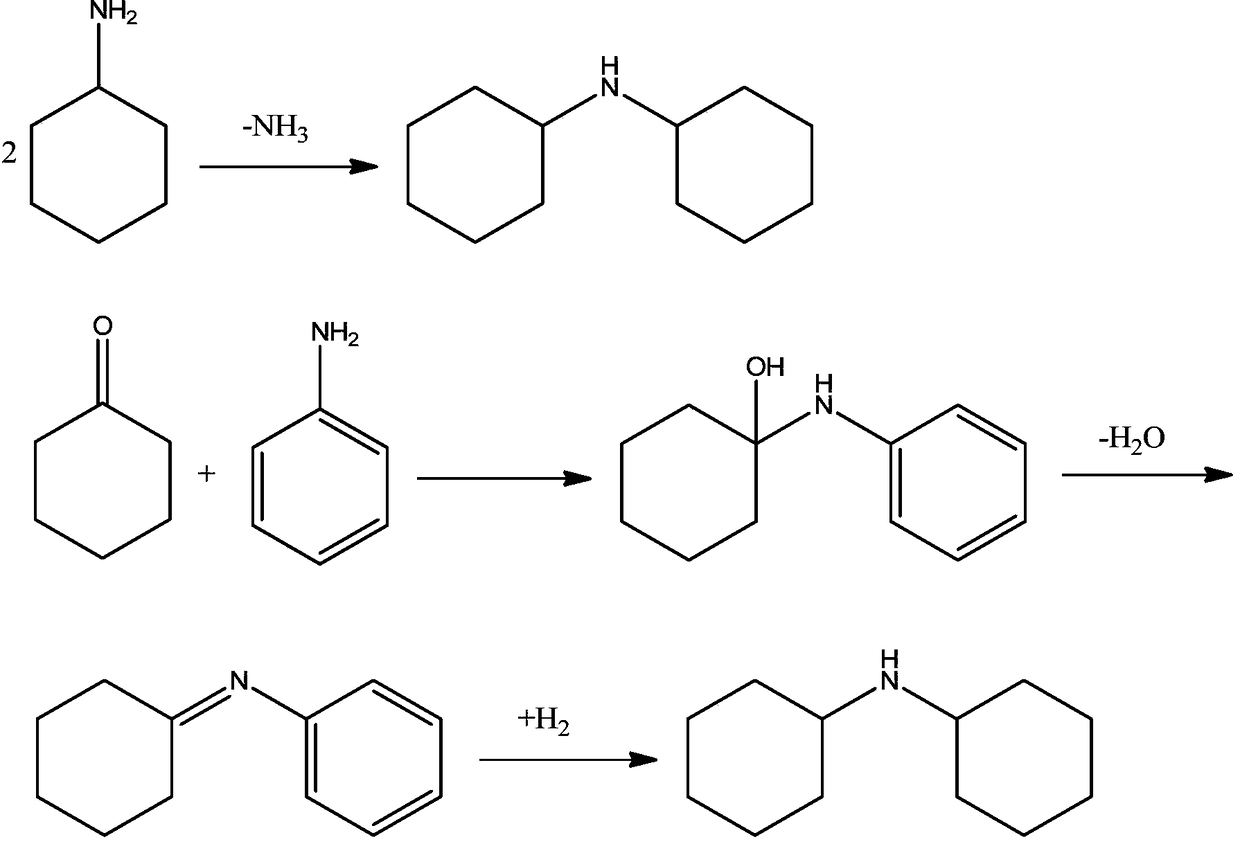

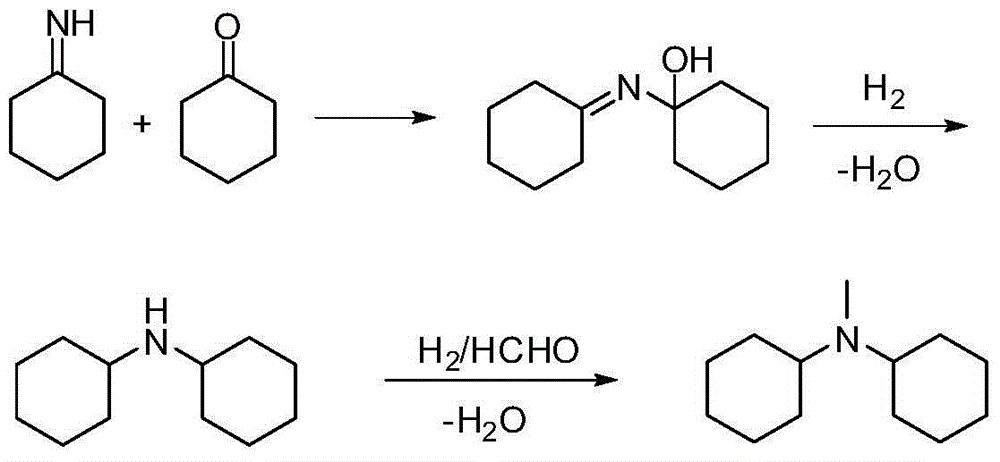

Joint production method for cyclohexylamine and dicyclohexylamine and catalyst system applied to method

ActiveCN109503388AAvoid churnReduce dosageOrganic compound preparationHeterogenous catalyst chemical elementsCyclohexanoneHydrogen

The invention discloses a joint production method for cyclohexylamine and dicyclohexylamine and a catalyst system applied to the method. The method comprises the following steps: (1) enabling the rawmaterials of phenylamine, cyclohexanone, ammonia and hydrogen to pass through a first section of a reactor which an Rh-Ni catalyst is filled into and loaded on to obtain first reaction liquid; (2) enabling the first reaction liquid pass through a second section of the reactor which an Rh-Co catalyst is filled into and loaded on to obtain reaction liquid containing the cyclohexylamine and the dicyclohexylamine. The combined production method disclosed by the invention has the advantages that the raw materials are cheap and easy to obtain, the conversion rate is high, product selectivity is good, service life of catalysts is long, technological processes are simple, a continuous technology is utilized, an automation degree is high, labor intensity is low, production cost is low, and the dicyclohexylamine with a high added value can be jointly produced; furthermore, product composition can be adjusted by changing reaction conditions according to the market need situation of the products;thus, the joint production method is suitable for industrial mass production.

Owner:WANHUA CHEM GRP CO LTD

Continuous production method for vulcanization accelerator DCBS

InactiveCN108586383AShort reaction residence timeHigh yieldOrganic chemistryVulcanizationDistillation

The invention provides a continuous production method for vulcanization accelerator DCBS. The continuous production method includes the steps that an MBT alkali solution, a dicyclohexylamine acid solution, solvent and oxidizing agent are subjected to an oxidizing reaction in a continuous flow reactor, then reacted materials are after-treated, and the vulcanization accelerator DCBS is obtained. According to the method, the MBT conversion percent is high, and the purity of the product is high; the continuous production method has the advantages of being high in reaction speed, high in product yield, low in wastewater COD (reacted wastewater is subjected to atmospheric distillation, residual solvent is recycled, and then the COD in residual water can be reduced to be 8,000 ppm or below), capable of facilitating treatment and the like, and is a new technology having the higher industry value.

Owner:KEMAI CHEM

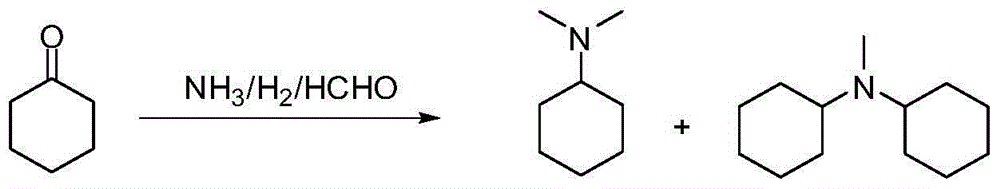

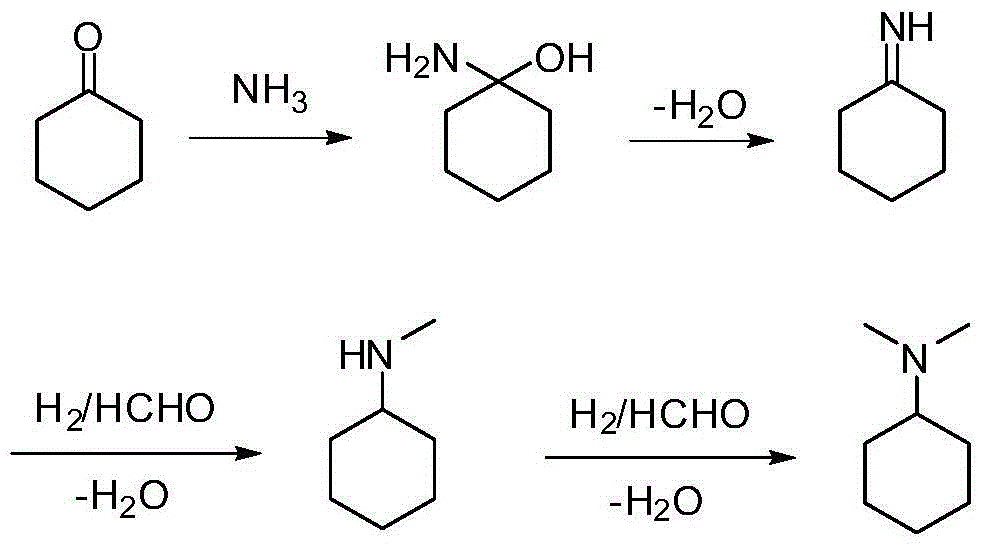

Method for preparing N,N-dimethylcyclohexylamine and N-methyl-dicyclohexylamine

ActiveCN104892429AIncrease added valueImprove conversion ratePreparation by reductive alkylationCyclohexanoneHydrogen

The invention discloses a method for preparing N,N-dimethylcyclohexylamine and N-methyl-dicyclohexylamine, which comprise the following steps: under certain reaction temperature and pressure condition, cyclohexanone, ammonia, hydrogen and formaldehyde pass through a two-stage reactor to obtain the N,N-dimethylcyclohexylamine and N-methyl-dicyclohexylamine. The method has the advantages of easily available raw material with low cost, high conversion rate, good product selectivity, little by-product, simple flow, and low production cost, N-methyl-dicyclohexylamine with high added value can be obtained through combined production, product composition can be adjusted by changing the reaction condition according to the market demand condition of the product, and the method is suitable for industrial large scale production.

Owner:WANHUA CHEM GRP CO LTD

Metal water-based rust inhibitor

The invention discloses a metal water-based rust inhibitor. The metal water-based rust inhibitor is prepared from the following raw materials in parts by weight: citric acid, sorbitan monooleate, phytate, zinc dihydrogen phosphate, acrylamide, glutamic acid, dinonyl naphthalene sulfonate, dicyclohexylamine, oxidized stone grease barium soap, ethylenediamine tetramethylene sodium phosphate, dimethylamino ethyl acrylate, sulfomethylated polyacrylamide, a film forming agent, deionized water, a water-soluble resin, a silane coupling agent, a passivating agent, silica sol, a pH regulator, a surfactant, a plant corrosion inhibitor and zinc sulfate heptahydrate. The metal water-based rust inhibitor can be attached to a surface of the metal to ensure the metal has better antiwear property and antirust property; and the metal water-based rust inhibitor is simple in preparation process, no harm to a human body, energy-saving and environment-friendly.

Owner:WUHAN JINPO CHEM TECH

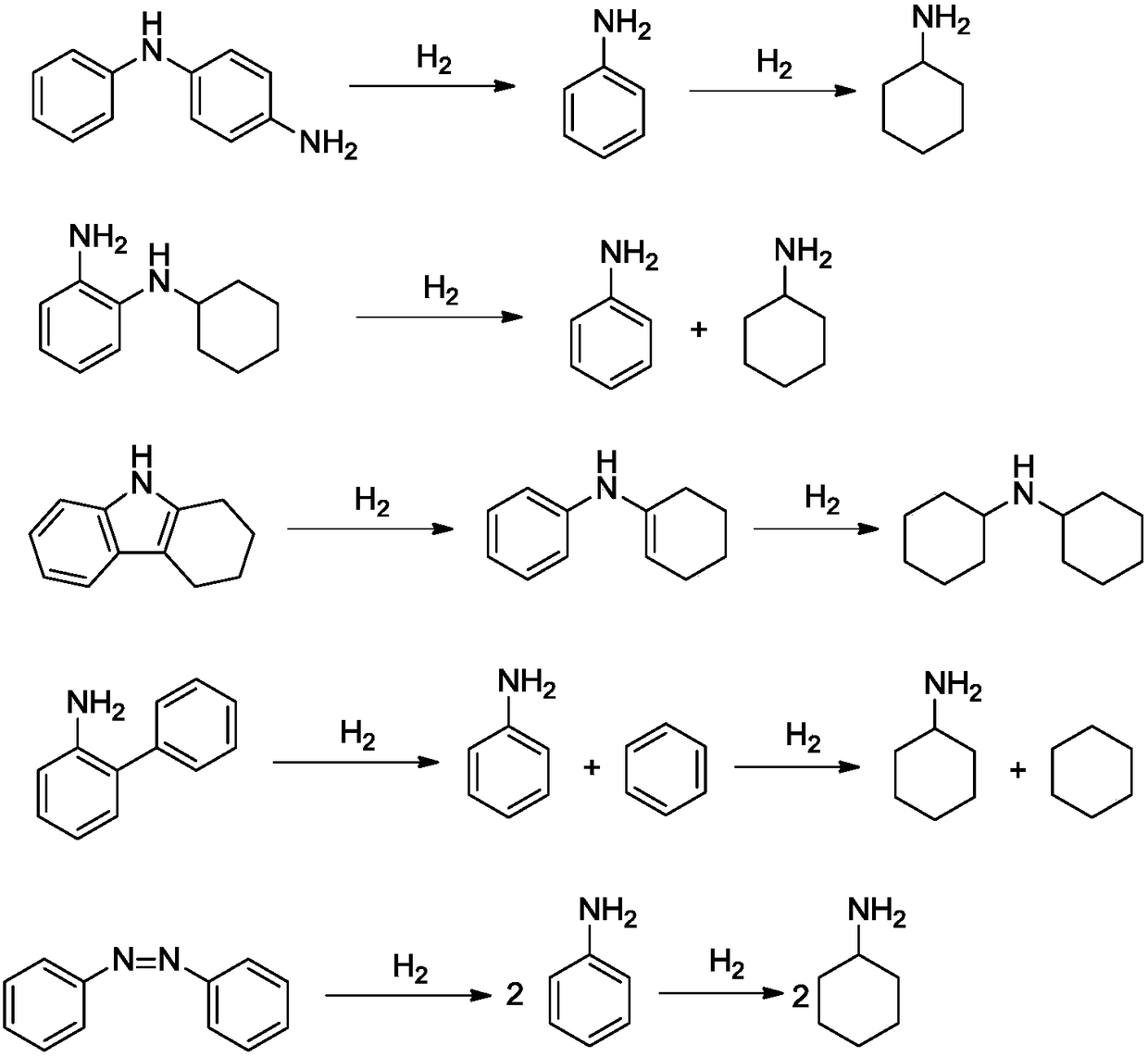

Catalyst for recycling phenylamine rectification residue and preparation method of catalyst

ActiveCN108067213AHigh activityHigh selectivityOrganic compound preparationCatalyst activation/preparationActive componentFixed bed

The invention relates to a catalyst for recycling fixed bed phenylamine rectification residue and a preparation method of the catalyst. The catalyst is prepared from a carrier and an active componentas well as an optional first auxiliary component and second auxiliary component; and the active component is prepared from Ni and Ru, and based on the total weight of the catalyst, the content of Ni is 10 to 40 percent, and the content of Ru is 0.5 to 5 percent. The catalyst has high activity and stability in the process for recycling the fixed bed phenylamine rectification residue, and the yieldof cyclohexane and dicyclohexylamine is high.

Owner:WANHUA CHEM GRP CO LTD

Anti-rust agent for special-shaped steel tubes and preparation method of anti-rust agent

The invention relates to the technical field of special-shaped steel tubes and in particular relates to an anti-rust agent for the special-shaped steel tubes and a preparation method of the anti-rust agent. The anti-rust agent comprises the following components in parts by weight: 10-20 parts of coal oil, 5-10 parts of petroleum sodium sulfonate, 4-8 parts of bentonite, 3-7 parts of Vaseline, 4-9 parts of zinc oxide, 10-20 parts of polyethylene glycol, 4-10 parts of trisodium phosphate, 3-9 parts of dicyclohexylamine, 8-15 parts of acrylamide, 10-20 parts of inositol hexaphosphate, 5-10 parts of a corrosion inhibitor, 1-6 parts of a pH regulator, 4-8 parts of a nonionic surfactant and 30-40 parts of de-ionized water. The anti-rust agent for rust prevention is good in anti-rust effect and long in anti-rust time, and has a good inhibition effect on rust due to dew formation in long-term storage; the surfaces of metal parts can be kept clean, so that when metal processing after storage is carried out, a washing process can be removed, the time is shortened, and the reagent expense is reduced.

Owner:张家港市华尊宝特种材料科技有限公司

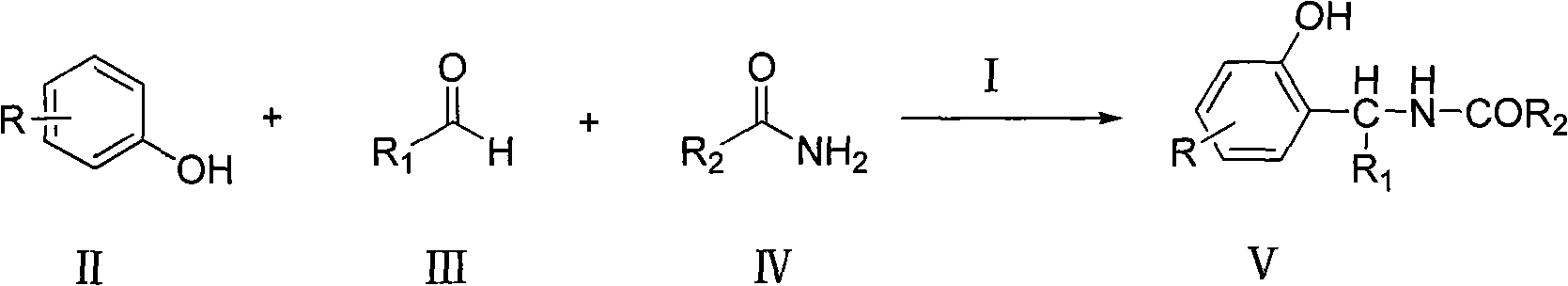

Dicyclohexyl trifluoromethanesulfonate ammonium salt and application thereof

ActiveCN101648893ARecyclableLow priceAmino preparation from aminesOrganic compound preparationTriflic acidPhenol

The invention relates to a dicyclohexyl trifluoromethanesulfonate ammonium salt and application thereof. The dicyclohexyl trifluoromethanesulfonate ammonium salt is prepared from trifluoromethanesulfonate and dicyclohexylamine. The dicyclohexyl trifluoromethanesulfonate ammonium salt can be applied to catalyzing the condensation reaction of three components such as aldehydes, amide and phenol, the condensation reaction of the three components such as the aldehydes, the amide and the phenol takes the phenol, the aldehydes and the amine as raw materials and is completely finished in an organic solvent under the action of the dicyclohexyl trifluoromethanesulfonate ammonium salt, and the reaction solution is separated and purified to obtain the corresponding multi-component condensation product. The invention develops a novel trifluoromethanesulfonate ammonium salt, promotes the application of a new generation of acid organic catalyst in the multi-component reaction, and promotes the further development of the multi-component reaction.

Owner:台州小试生物科技有限公司

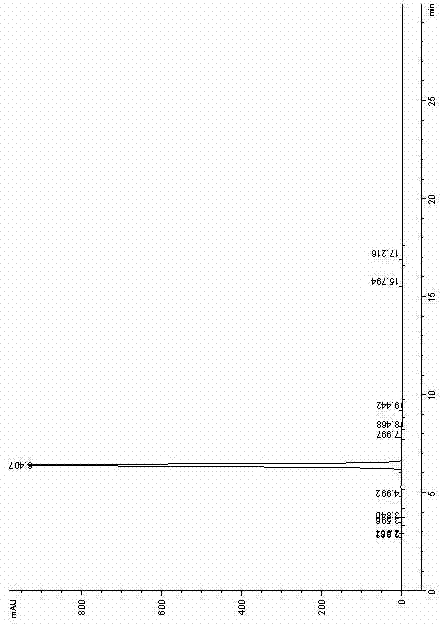

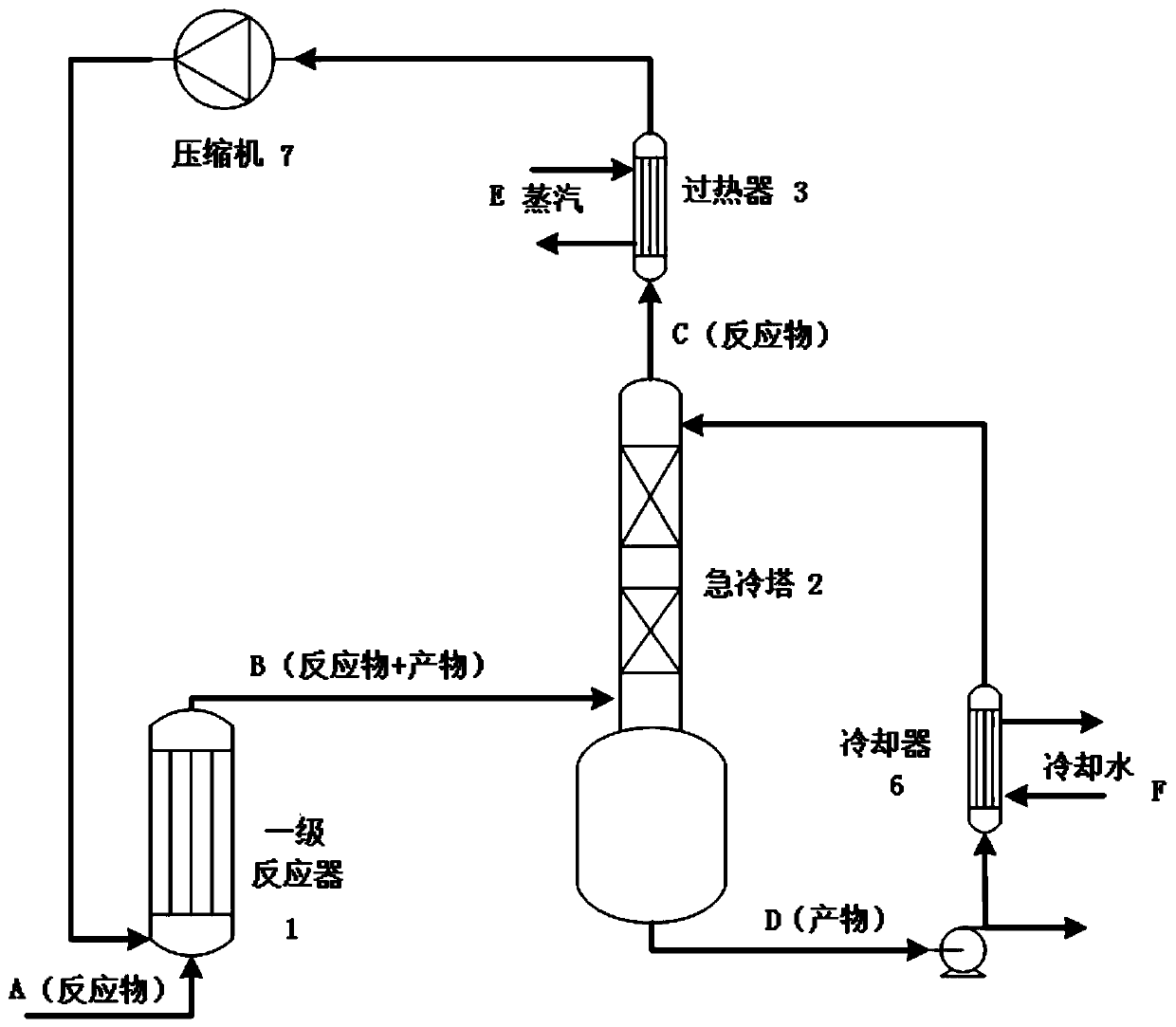

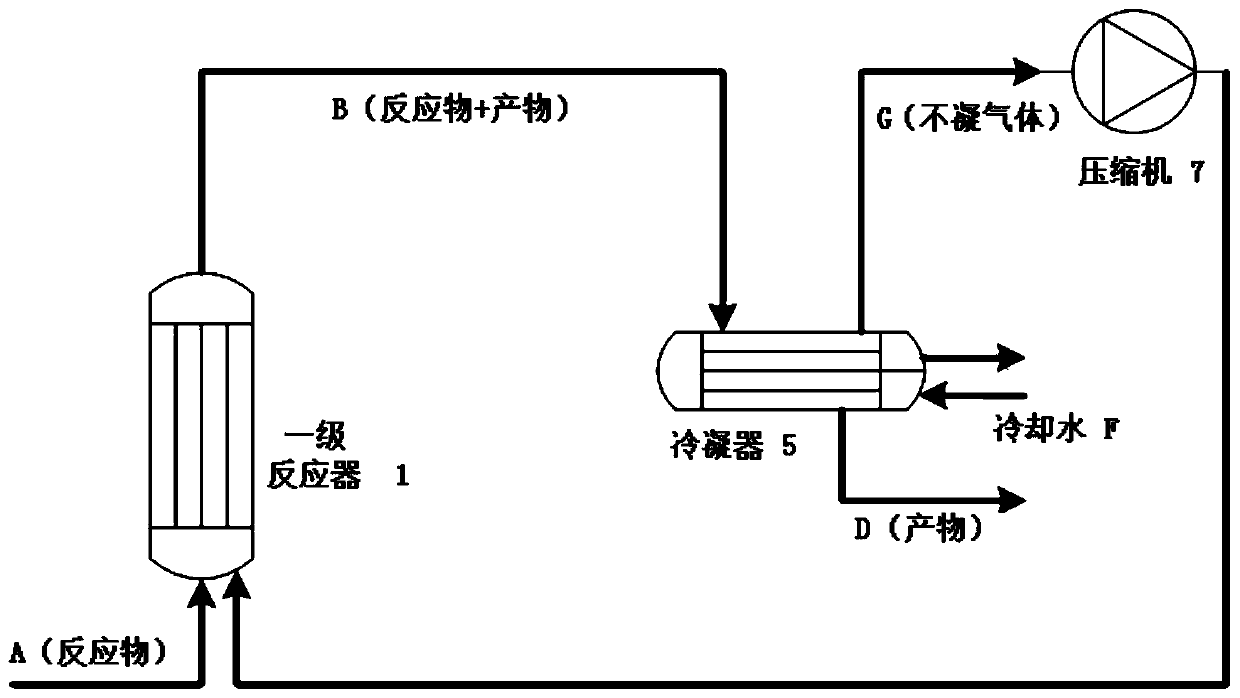

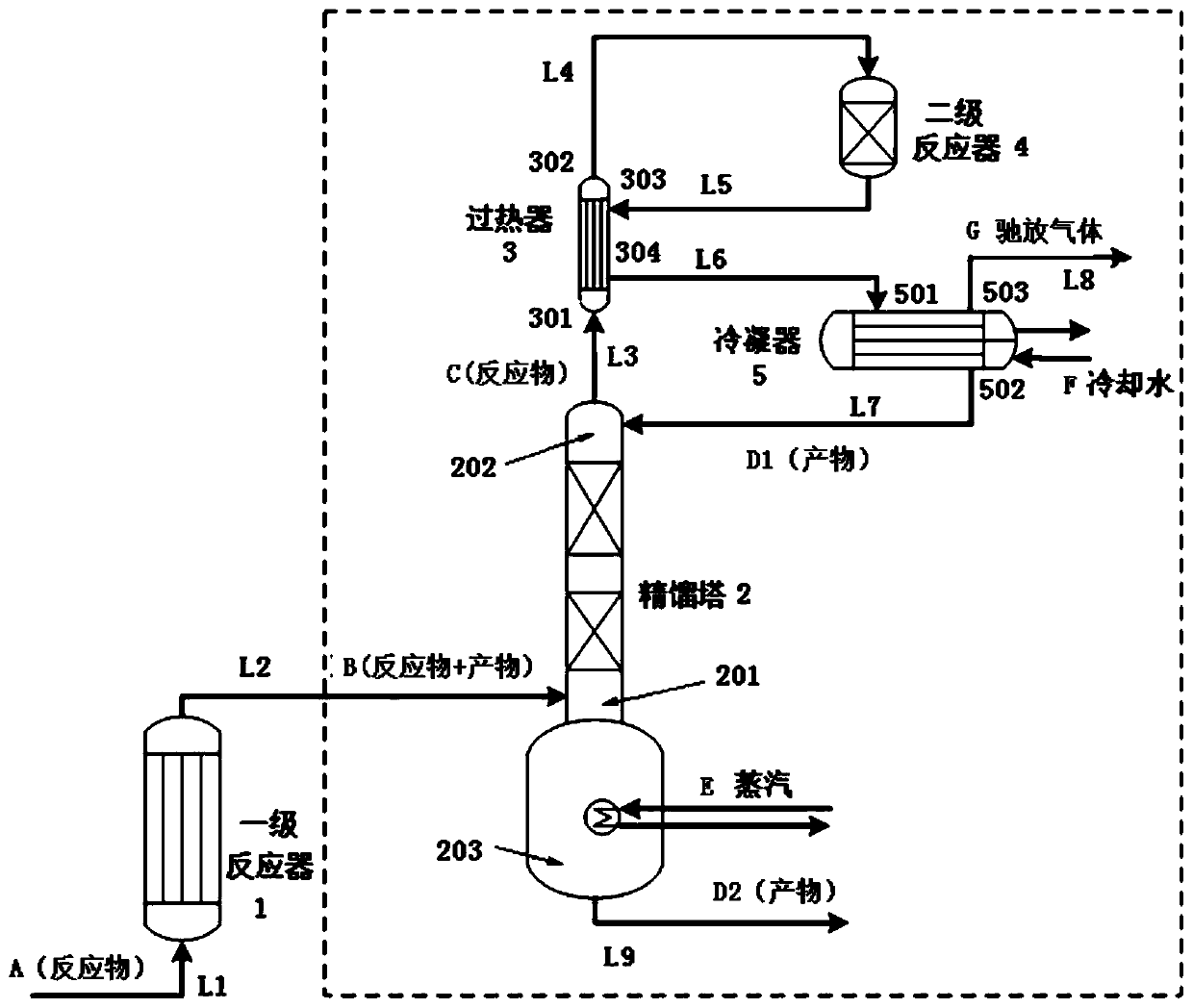

Gas-phase reaction device and preparation method of dicyclohexylamine

ActiveCN110665244ATake advantage ofSimple processOrganic compound preparationChemical industryFluid phaseGas phase

The invention discloses a gas-phase reaction device for breaking gas-phase reaction equilibrium limitation through reactive distillation outside a tower and a preparation method of dicyclohexylamine.The preparation method, aiming at gas-phase reaction with balance limitation; reactants or intermediate products being light components; and products being heavy components, comprises following steps:enabling gas reaching reaction equilibrium at an outlet of a primary reactor to enter a rectifying tower (or a stripping tower); cooling heavy component products into a liquid phase; wherein most ofthe reaction raw materials exist in a gas phase; enabling tower top gas phase to enter a secondary reactor after cross heat exchange through a superheater, after reaction, carrying out cooled mixturecondensation and refluxing, enabling heavy component products to enter a tower bottom through the rectification effect, enabling light component reactants or intermediate products to continuously enter the secondary reactor for reaction, so that the whole reaction yield is greatly improved.

Owner:WANHUA CHEM GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com