Patents

Literature

145results about How to "Keep surfaces clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

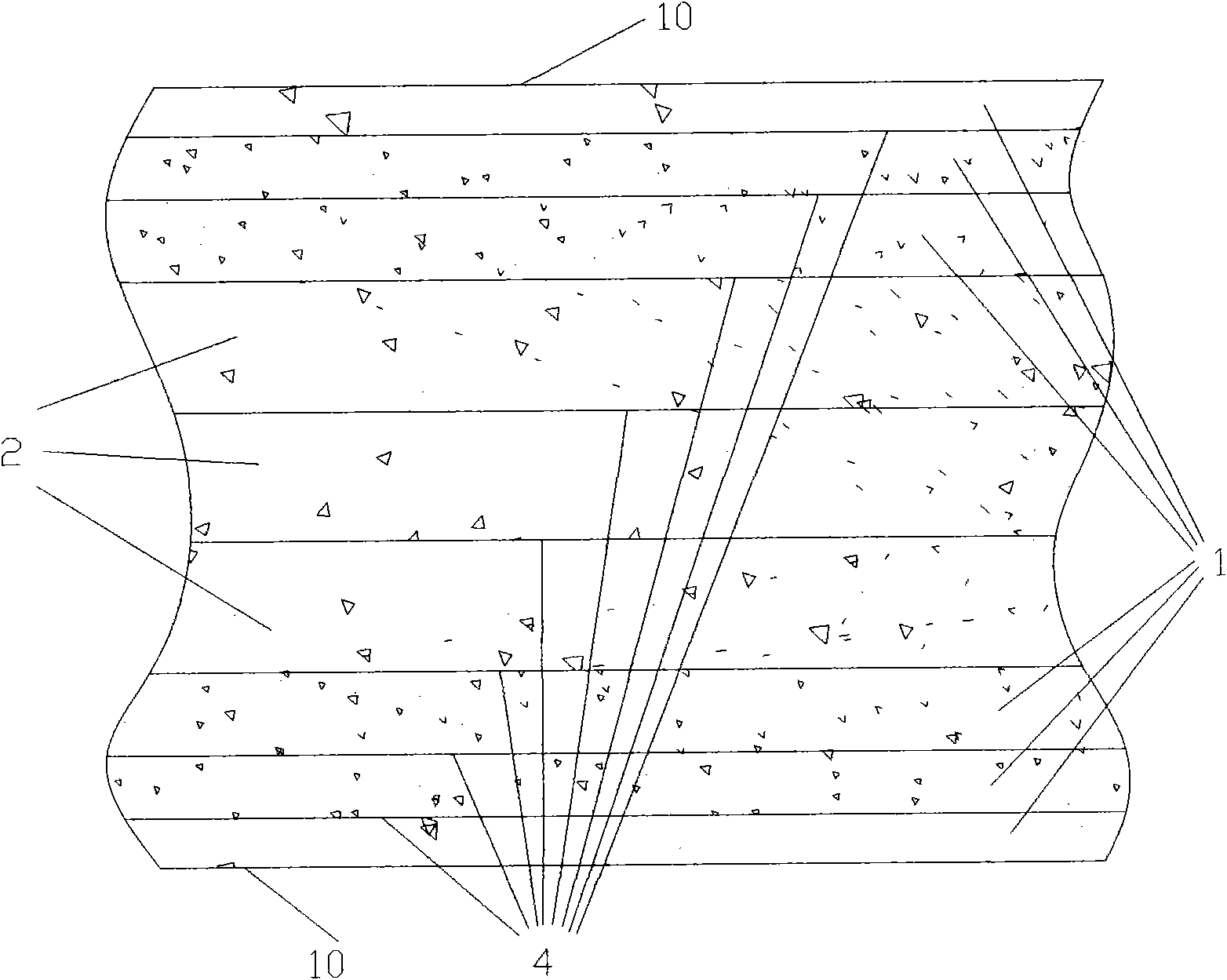

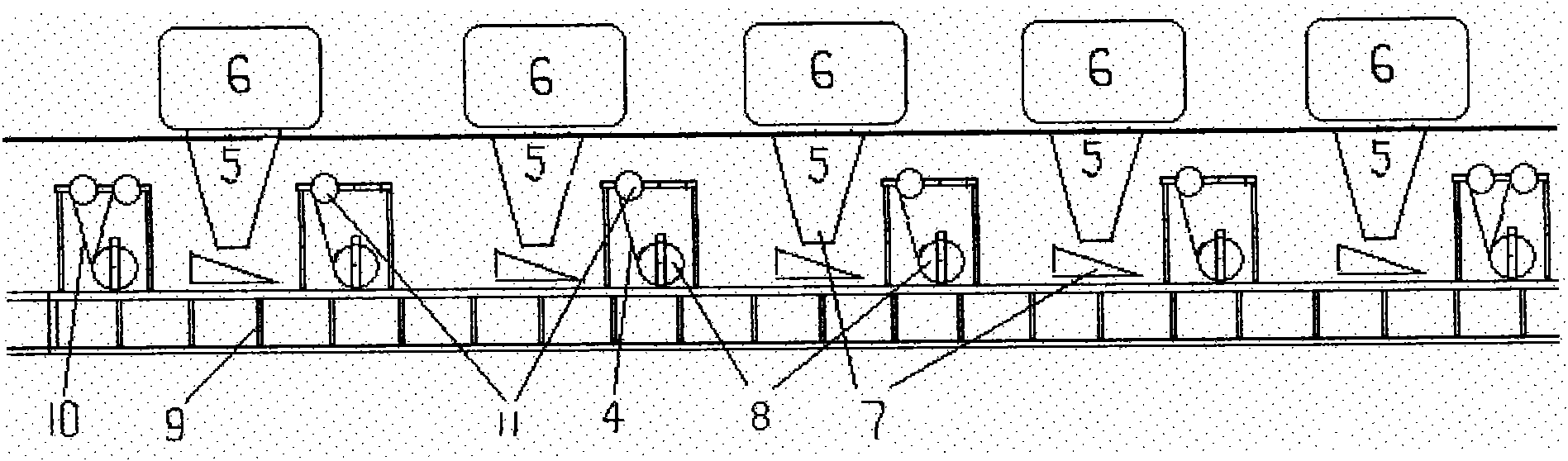

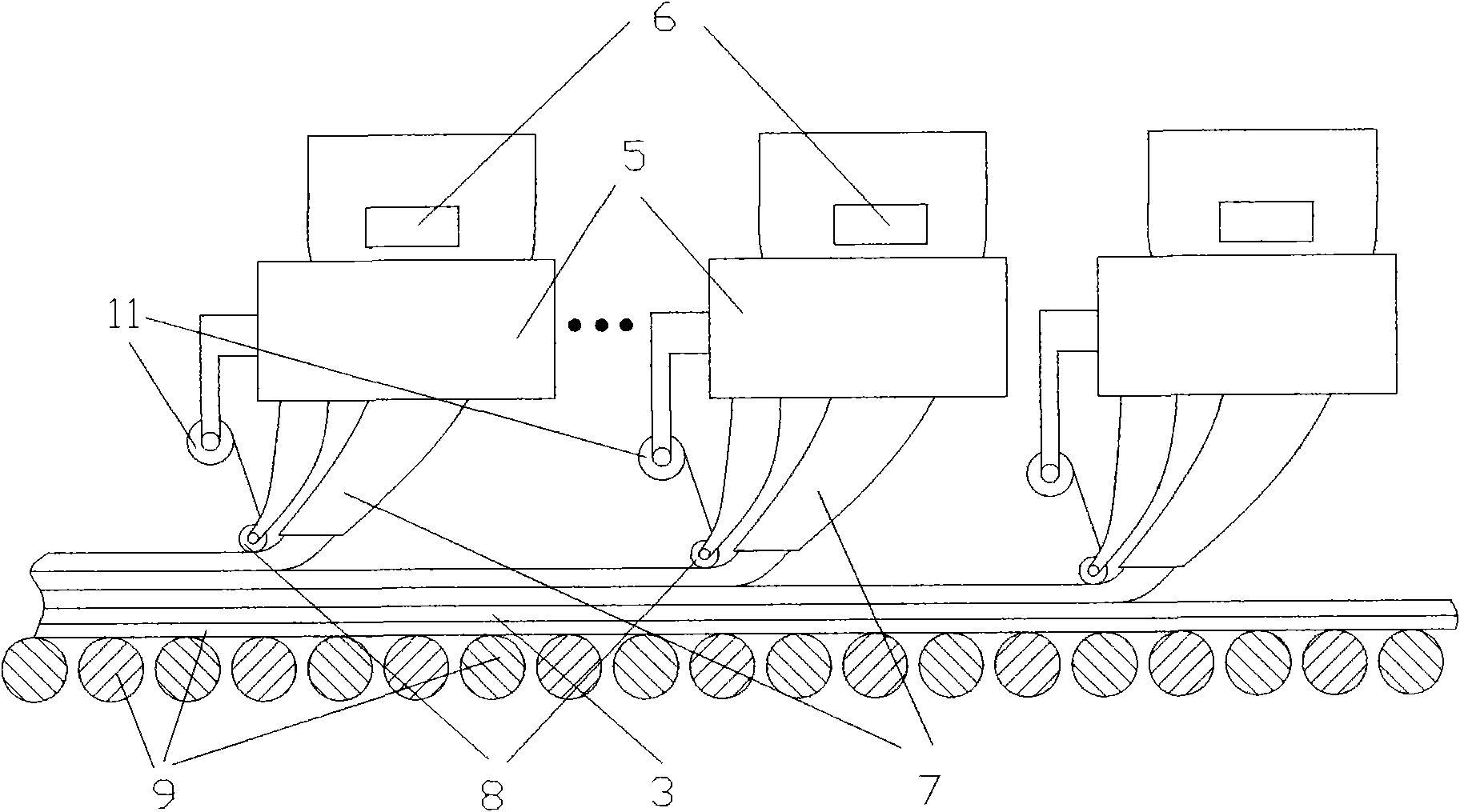

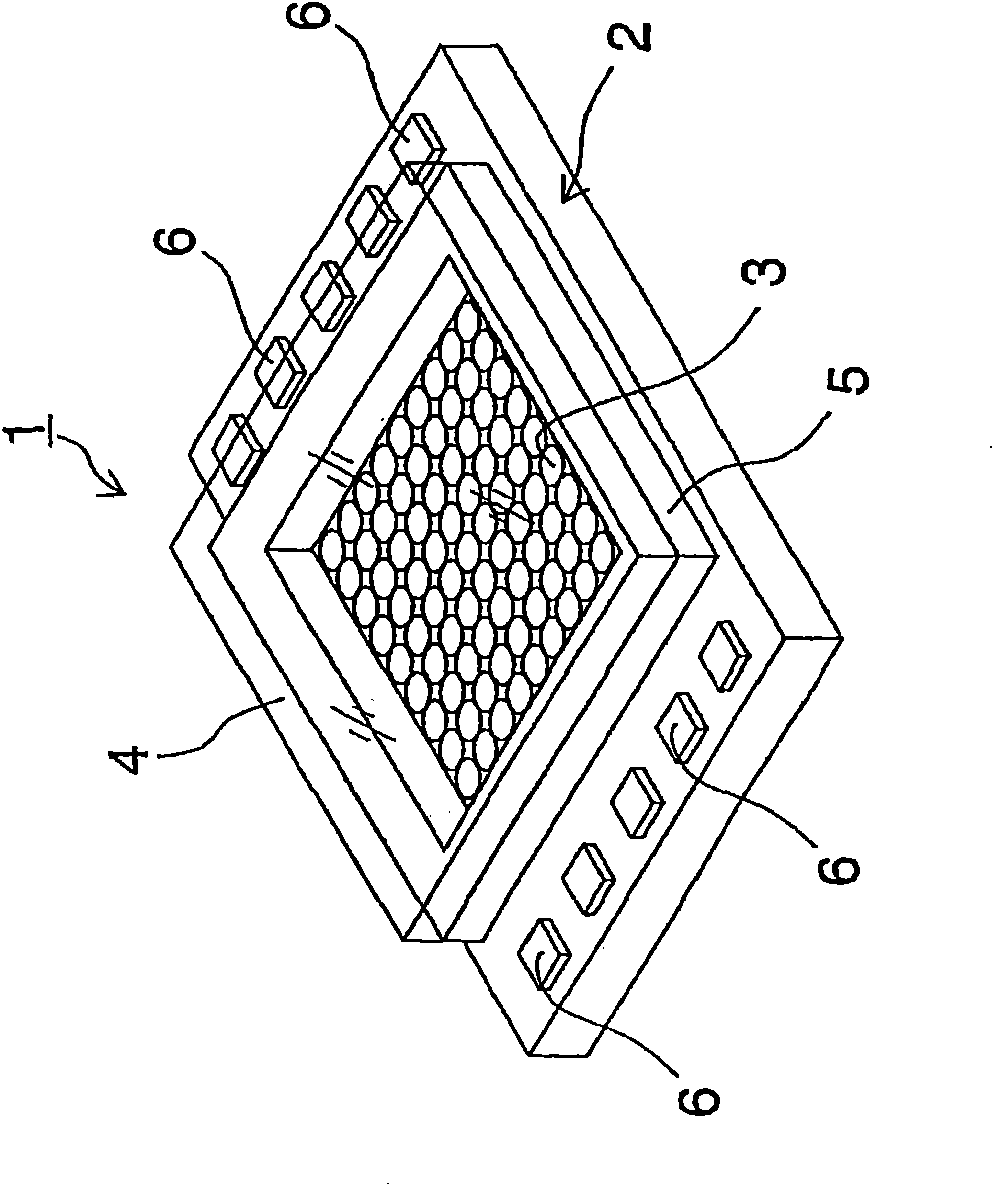

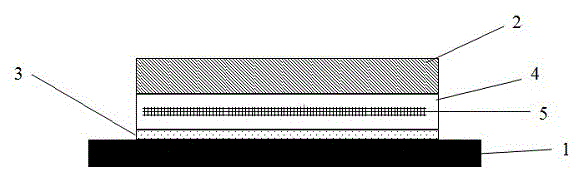

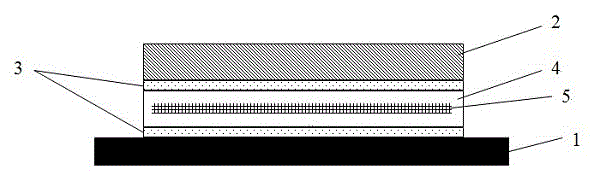

Multilayer composite plate for building templates and brick pallets and preparation process thereof

InactiveCN101633254AWith glazed effectEasy to demouldMouldsMixing operation control apparatusBrickSurface layer

The invention discloses a multilayer composite plate for building templates and brick pallets, which is prepared from magnesium cement gel added with a reinforcing material and a filler, and comprises surface layers (1) and sandwich layers (2); the surface layers (1) or / and the sandwich layers (2) comprise the filler or / and the reinforcing material with even content or gradient change; the number of the sandwich layers (2) is totally between 1 and 5; and the reinforcing material is arranged between adjacent sandwich layers (2). The invention also comprises a preparation process for the multilayer composite plate, which comprises that: production equipment with the capacity of stirring and preparing materials at multiple positions and rolling at multiple positions orderly rolls the surface layers (1) or / and the sandwich layers (2) on a subplate (3); and the reinforcing material is used as a reinforced structure between adjacent surface layers (1) or / and sandwich layers (2). The products corresponding to the invention have the characteristics of strong applicability, good technical effect and suitability for mechanical continuous production, and have predictable great economic and social values.

Owner:LIAONING FENGCHENG INDAL TECH

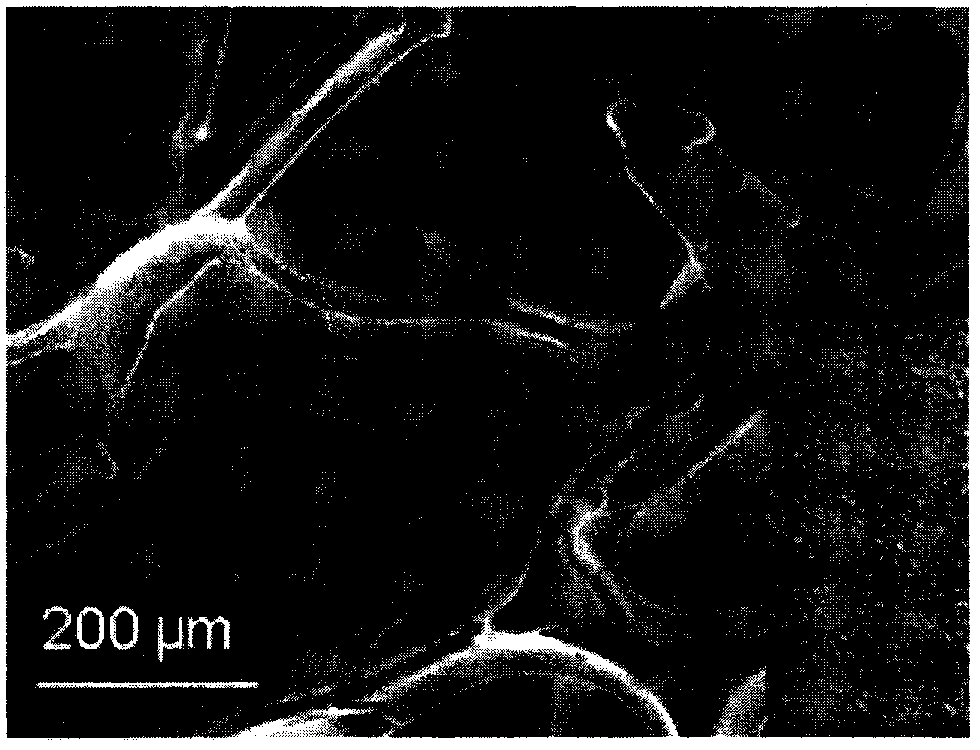

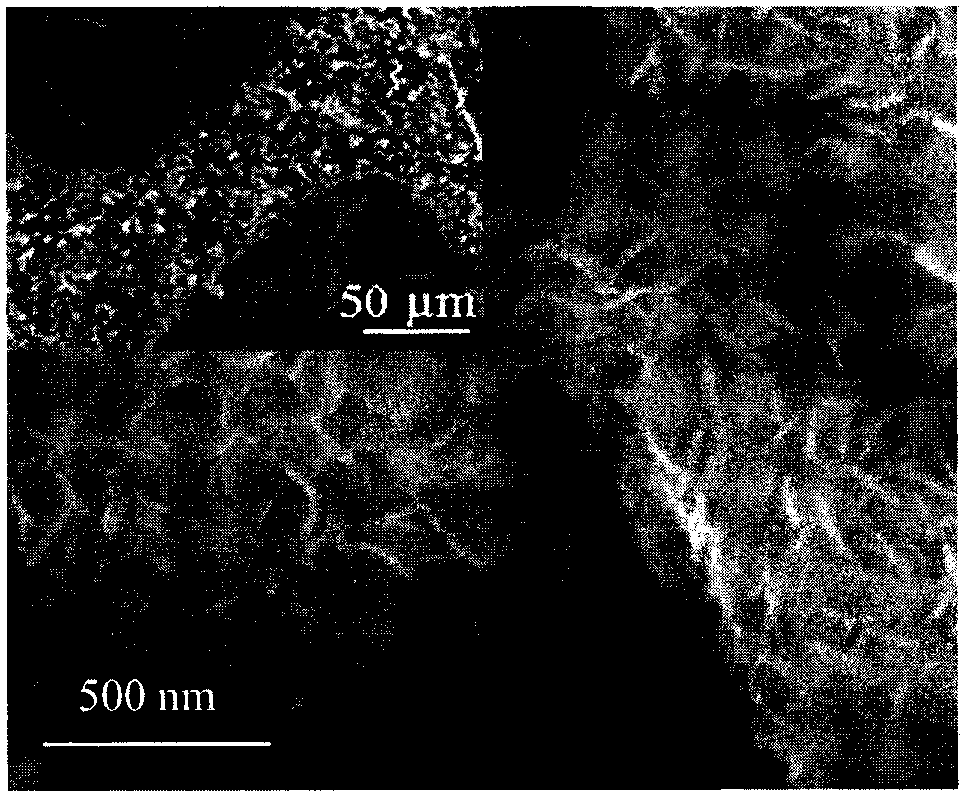

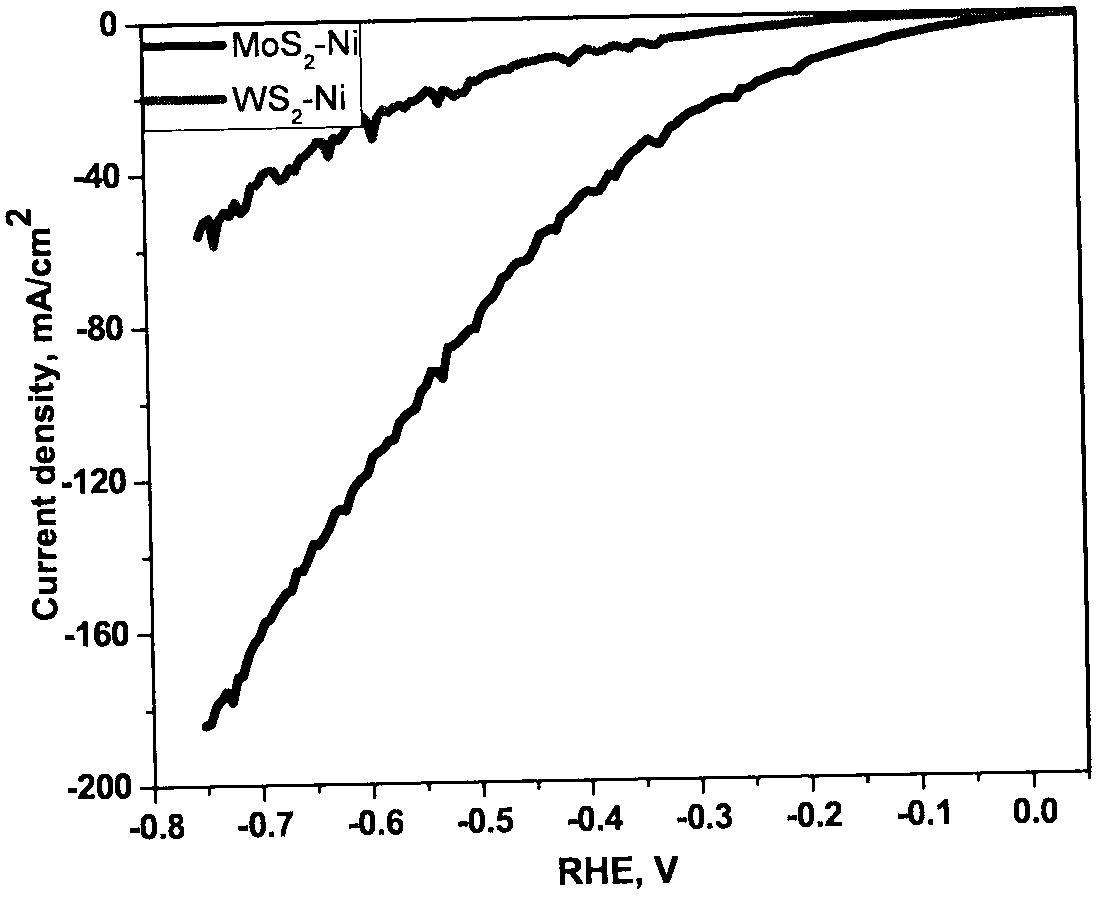

Method for preparing efficient hydrolysis metal sulfide electrode material through one-step method

InactiveCN108060411AIncrease surface areaShort delivery pathLiquid/solution decomposition chemical coatingElectrode shape/formsPower flowOxygen

The invention discloses a method for preparing an efficient hydrolysis metal sulfide electrode material through a one-step method. The method includes the following steps that nickel foam obtained after ultrasonic treatment serves as a carrier and is soaked into a high pressure reactor containing metal sulfide and a precursor, a hydrothermal reaction is made at 140 DEG C-200 DEG C so that the metal sulfide can be loaded on the nickel foam, and reacting is carried out for 6 h. the method has the following beneficial effects that (1) the three-dimensional porous metal sulfide is directly synthesized without the help of a template, the hydrolysis hydrogen evolution and oxygen evolution catalytic activity site density is high, the electronic transferring path is short, and the catalytic performance is good; (2) the metal sulfide of a nano-structure is directly connected with the electrical conductive nickel foam carrier, the contact and the electrical conductivity are good, the specific conductance and the electron transferring efficiency are better improved, and overpotential needed by energy barriers is reduced to a large extent; and (3) electrolyte can enter the interior of the porous electrode material easily, the electric current density is high, the crystal structure is stable, and the circulated stability and durability of the material are greatly improved.

Owner:SUN YAT SEN UNIV

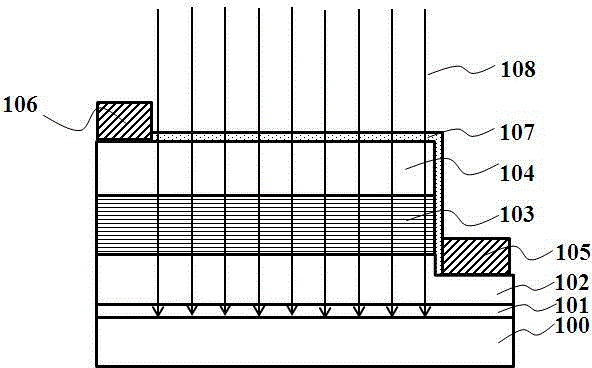

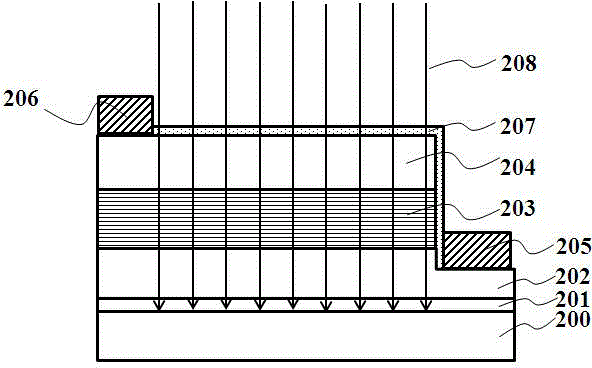

Preparation method for photoelectric device

ActiveCN104638070AReduce pollutionAvoid surface defectsFinal product manufactureSemiconductor devicesUltraviolet lightsEngineering

The invention discloses a preparation method for a photoelectric device. The preparation method comprises the following steps: performing UVLED (ultraviolet light-emitting diode) processing on a substrate after loading the substrate into a reaction chamber and before growing an epitaxial layer, thereby effectively reducing surface organic or / and inorganic substance pollution caused by processes of putting the substrate into a slide glass plate and loading the substrate into the reaction chamber, enabling the surface to be clean before growing the epitaxial layer and avoiding surface defects after growing the epitaxial layer; growing N-type, active and P-type epitaxial layers on the substrate subjected to the UVLED processing and performing UVLED processing in each epitaxial layer growing process, thereby effectively reducing point defects in each of doped or non-doped AlInGaN, AlGaInP, AlGaInAs multi-element epitaxial layers, improving the crystal quality and breaking Mg-H passivated bonds of the P-type layer. Therefore, free carrier concentration and migration rate of the N-type and P-type layers can be effectively increased, the active region efficiency is improved, and the performances of the photoelectric device is improved. The preparation method is suitable for a semiconductor photoelectric device.

Owner:TIANJIN SANAN OPTOELECTRONICS

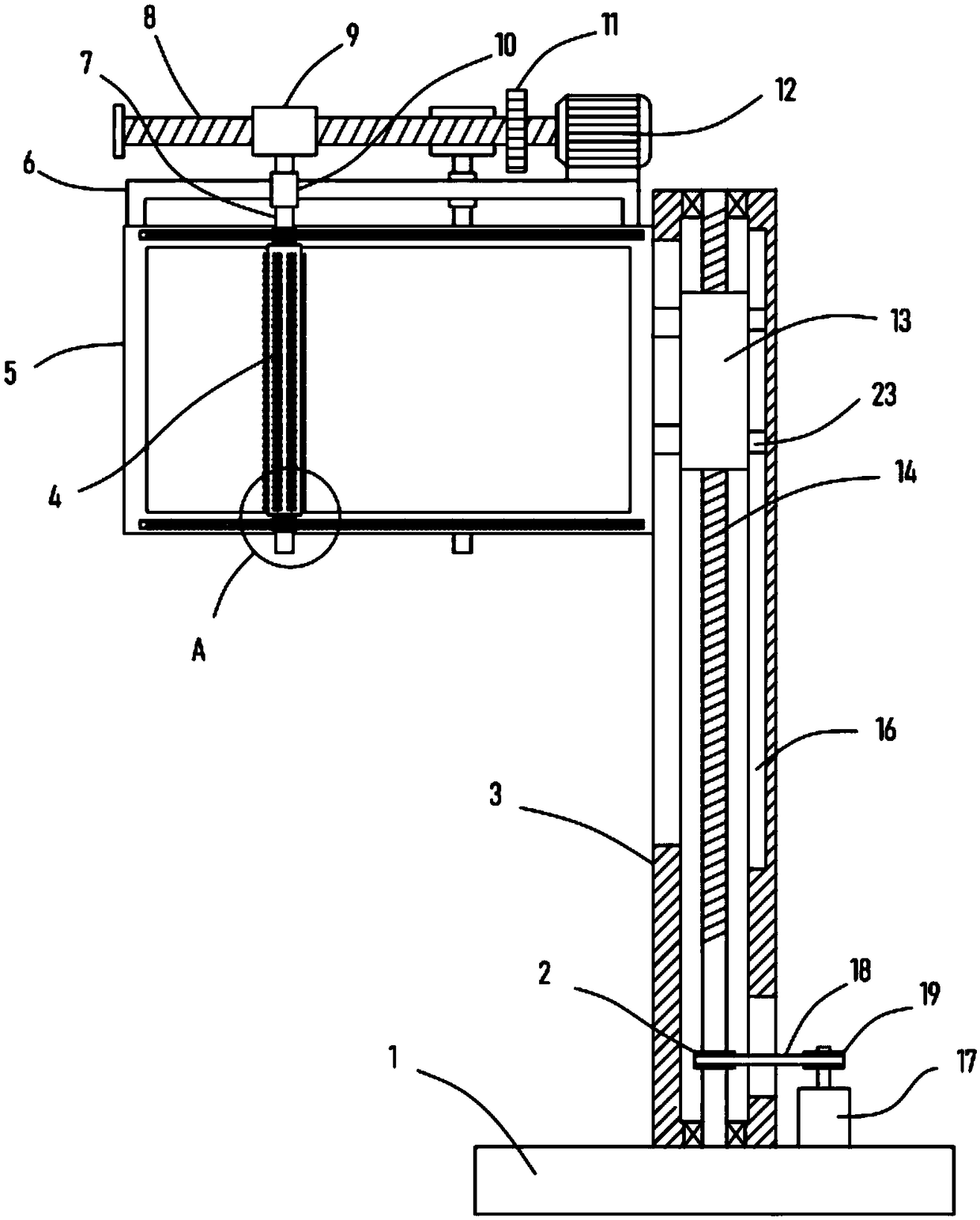

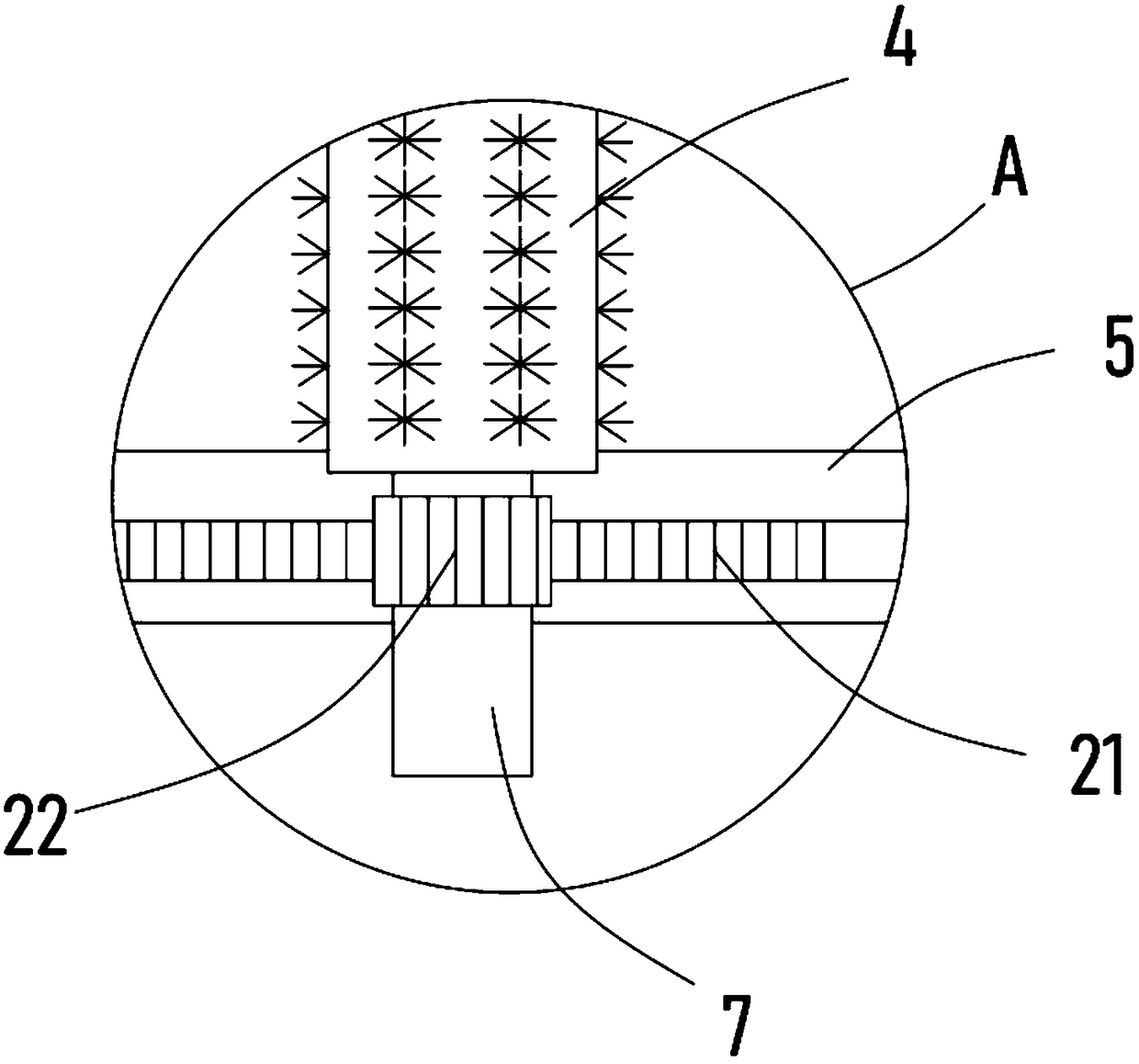

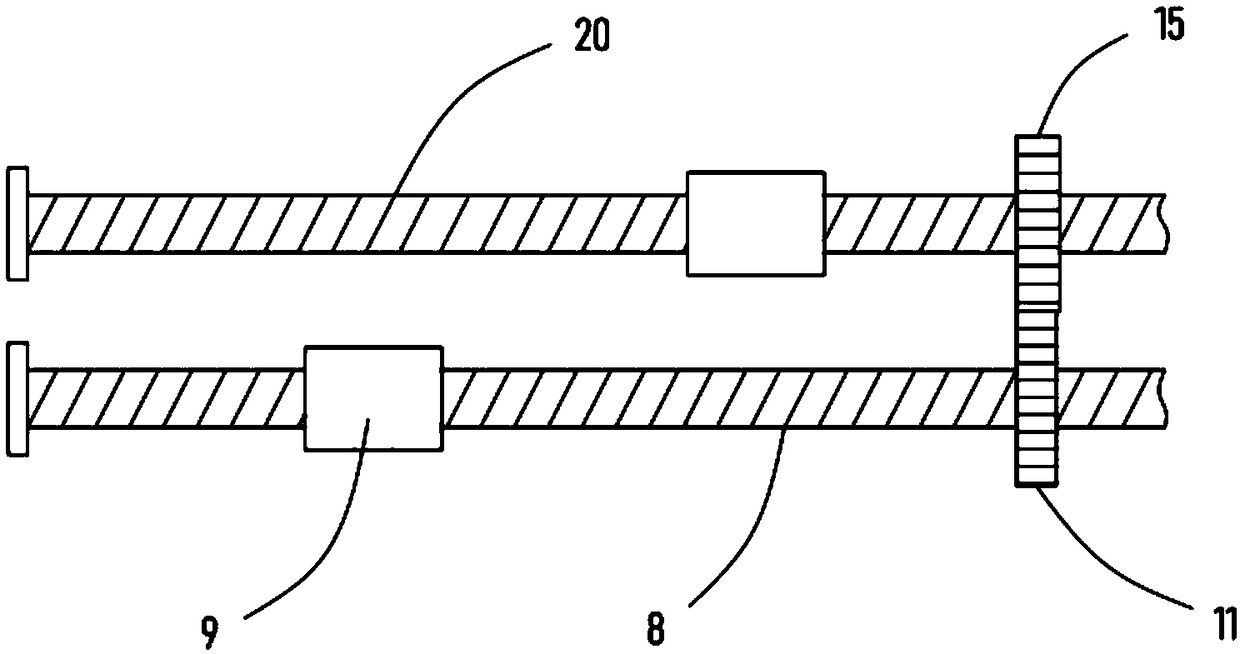

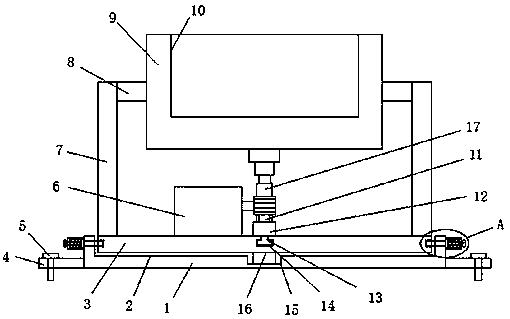

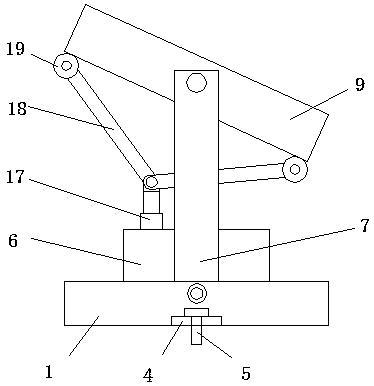

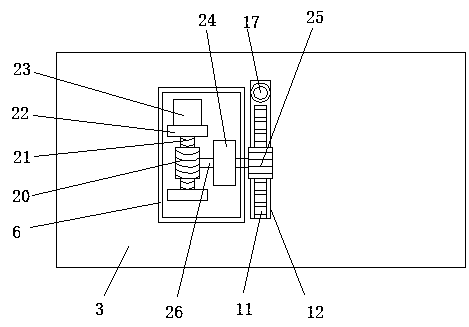

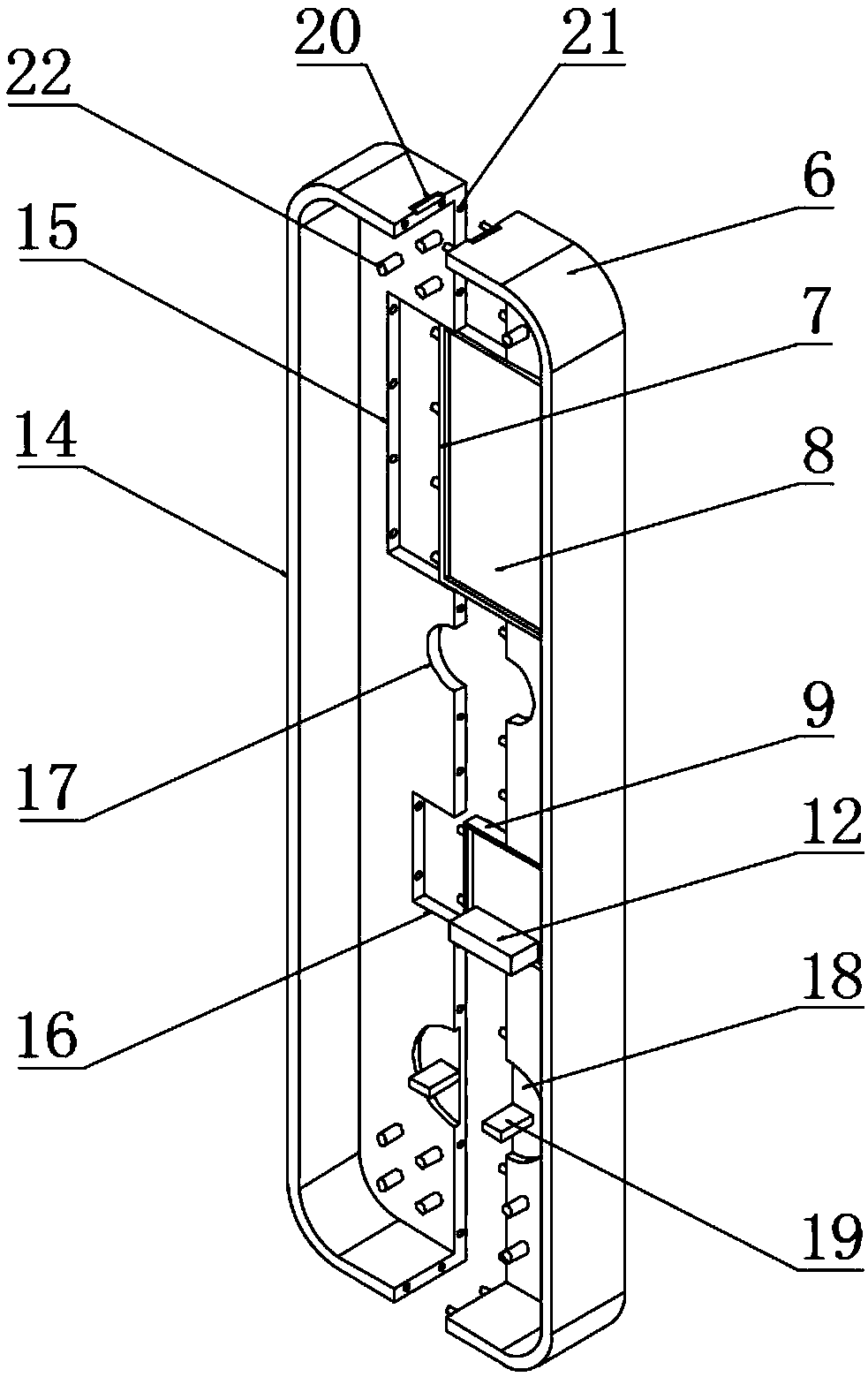

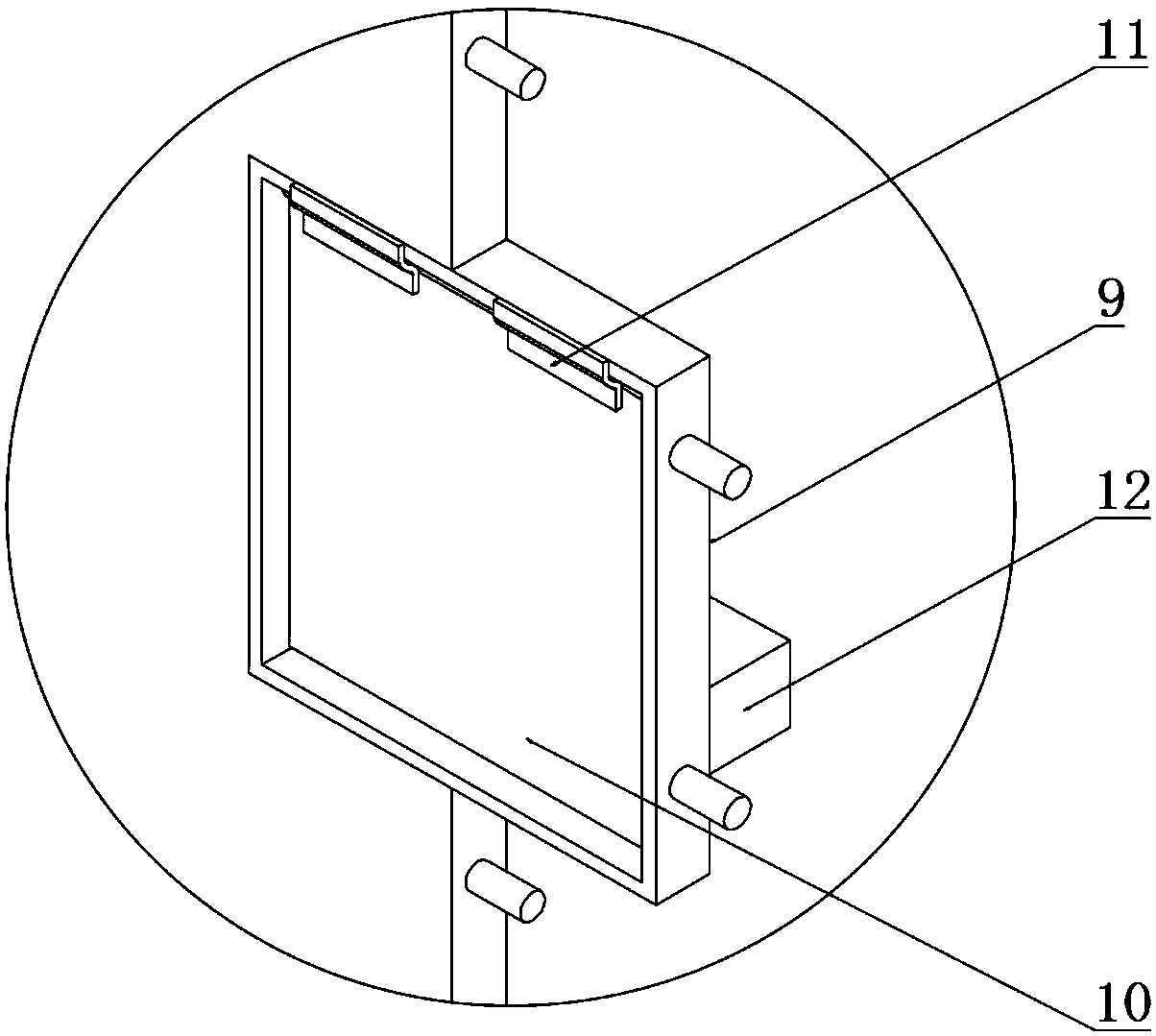

Electronic display screen mounting frame with cleaning function

InactiveCN109488859AFull cleaning effectKeep surfaces cleanStands/trestlesIdentification meansReciprocating motionEngineering

The invention discloses an electronic display screen mounting frame with a cleaning function, and relates to the technical field of electronic display screens. The electronic display screen mounting frame comprises a mounting bottom plate. A supporting tube is vertically fixed to the mounting bottom plate and is slidably provided with a display screen. A threaded rod I and a threaded rod II are rotatably arranged above the display screen in parallel. Transverse threaded sleeve blocks are connected to the threaded rod I and the threaded rod II in a threaded mode. A transmission gear meshed witha straight rack fixedly sleeves a rotating shaft. According to the electronic display screen mounting frame, transverse reciprocating motion of a brush roller can be realized through forward and reverse rotation of a motor I. In the transmission matching process of the transmission gear and the straight rack, the rotating shaft drives the brush roller to rotate, and the brush roller rotates whilereciprocating, so that the display screen can be sufficiently cleaned, the cleanness of the surface of the display screen is ensured, and the display effect is improved. Meanwhile, a screw rod is driven by a motor II to rotate, the display screen can be adjusted vertically, people can better watch content displayed on the display screen, and the display screen is simple and convenient to adjust.

Owner:HENAN HUANQIU AVIATION EQUIP TECH CO LTD

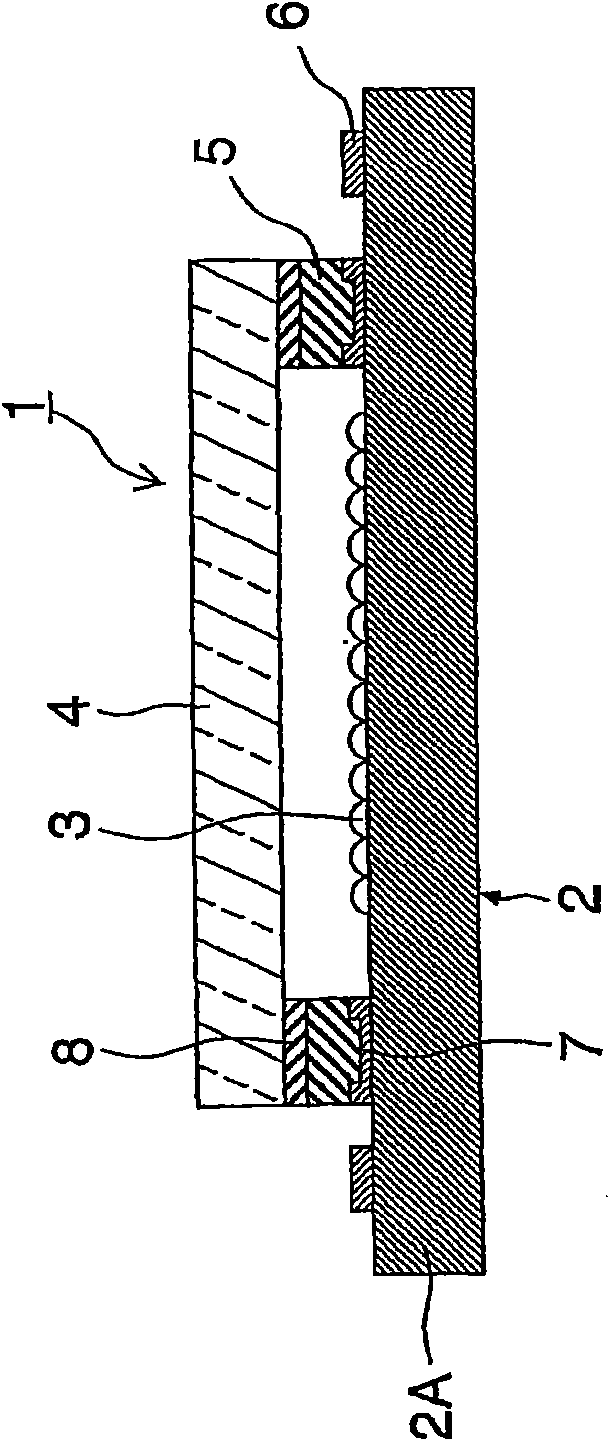

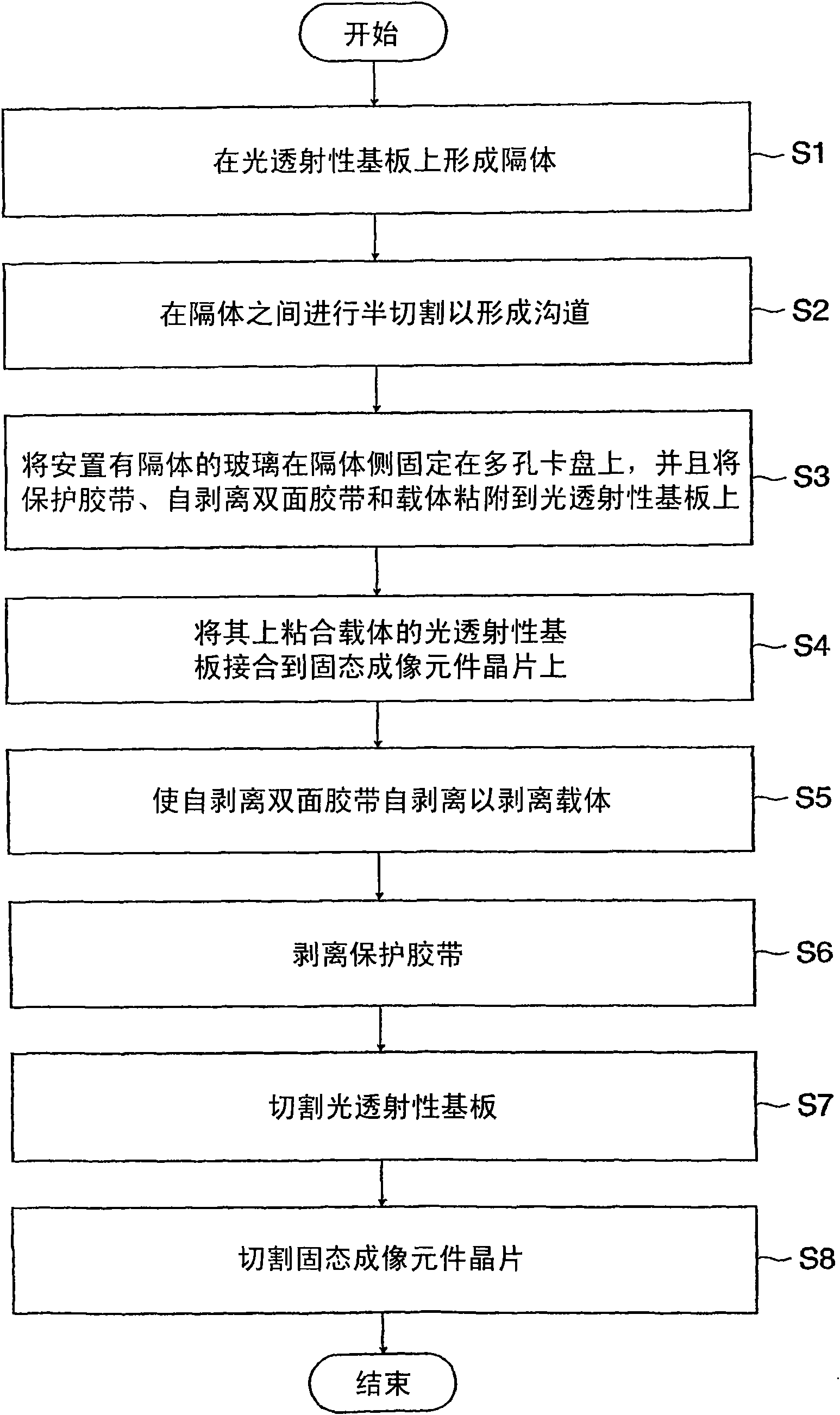

A method of producing solid-state imaging device

InactiveCN101569012AImprove stiffnessAvoid bendingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSolid-state

Owner:FUJIFILM CORP

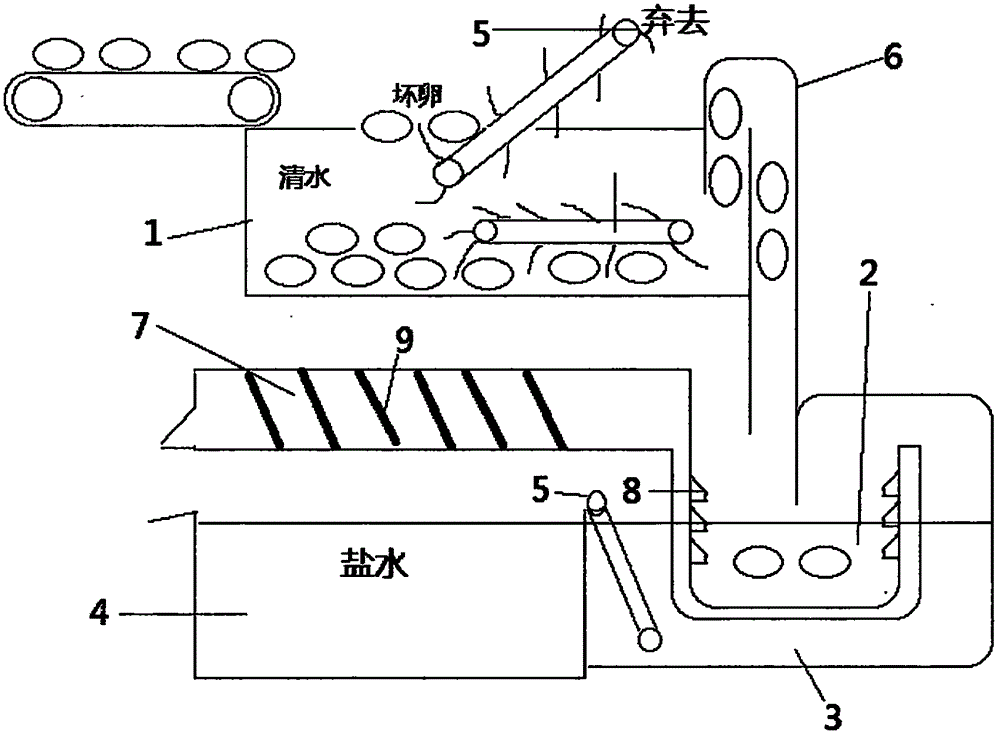

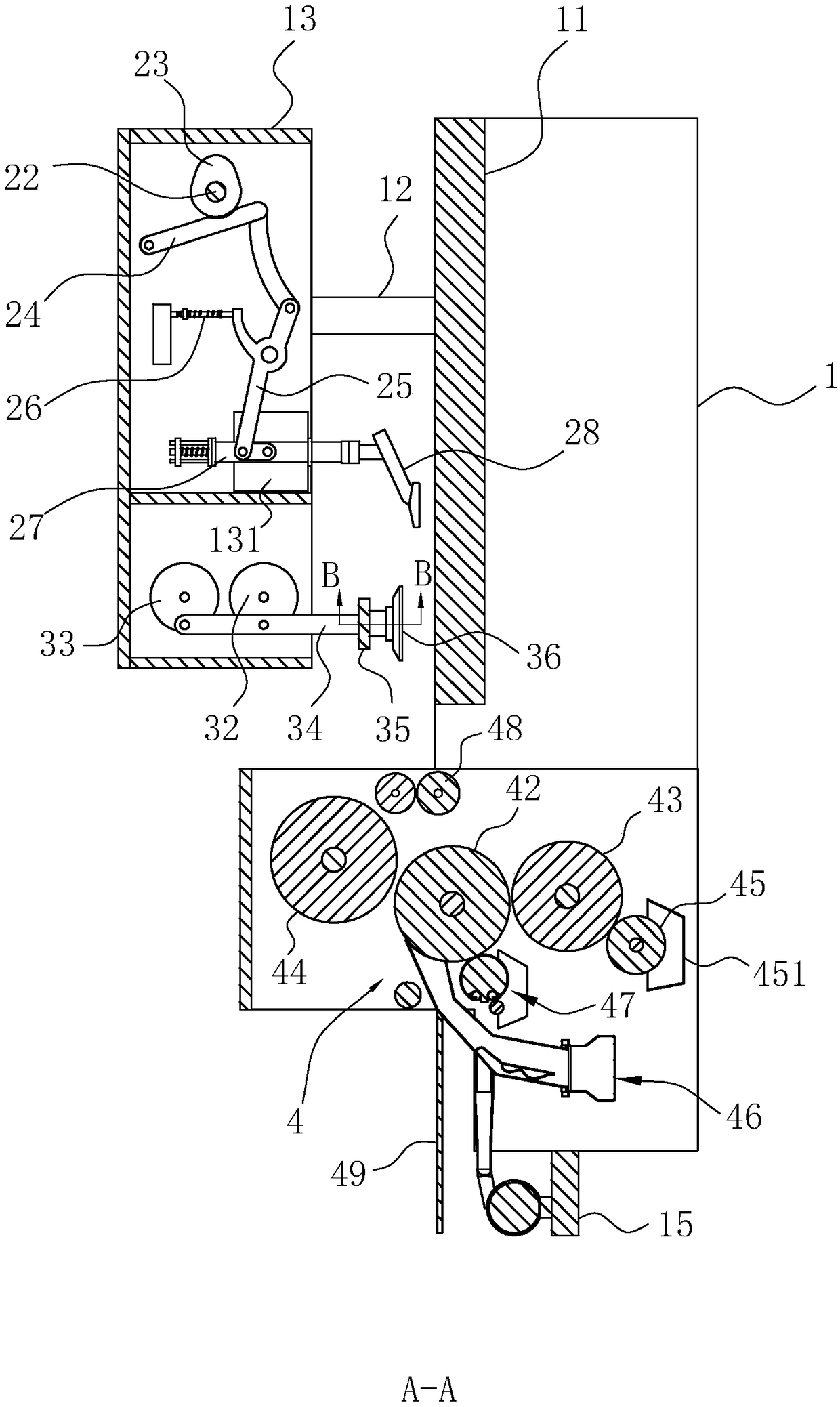

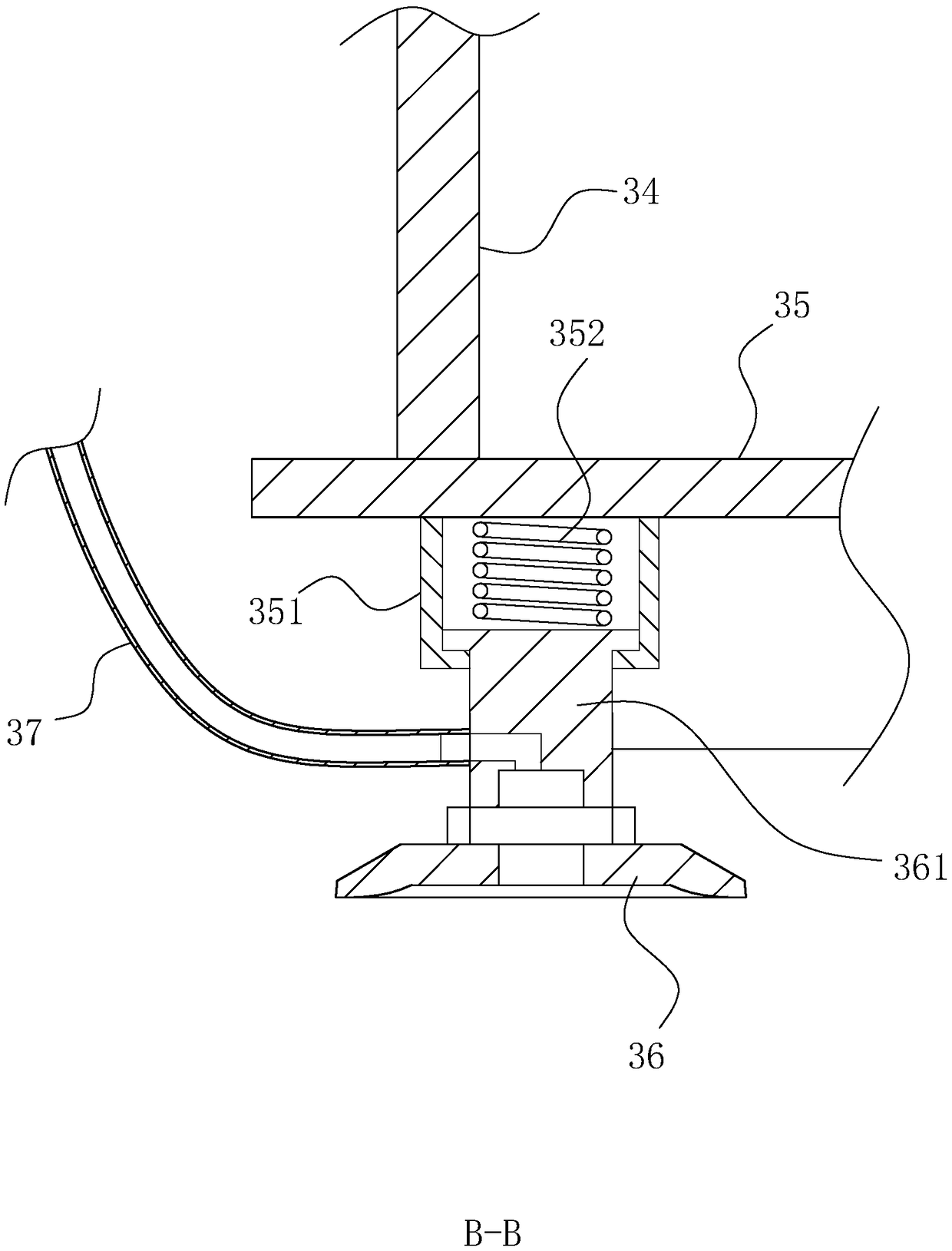

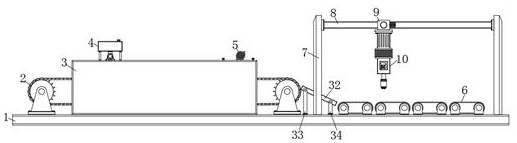

Egg product sorting production line

PendingCN105706957AKeep surfaces cleanExtended shelf lifeAvicultureProduction lineProcess engineering

The invention provides an egg product sorting production line. Aiming at the problems that a sub-packaging process of current egg products including raw eggs and the like is relatively rough and surfaces of the eggs are rarely disinfected, the invention designs sorting production line equipment capable of disinfecting the surfaces and washing to remove dirt. Meanwhile, according to the characteristics that the fresh degrees and densities of the raw eggs are different, rotten eggs are sorted and removed by buoyant force of water. The egg product sorting production line can be applied to sorting, cleaning and package of other egg products except the raw eggs. The egg product sorting production line has the advantages that a series of production line type operation process of sorting, washing and packaging the fresh eggs products is realized, the egg products are clean and the manual cost is reduced.

Owner:杨溢

Offsetpress

ActiveCN109080253AKeep surfaces cleanReduce splashRotary lithographic machinesPrinting press partsAcute angleCLARITY

The invention discloses an offsetpress, and relates to the field of pressing equipment. According to the technical scheme, the offset press comprises a machine frame and a rubber roller. An ink scraping mechanism fixed to the machine frame abuts against the rubber roller. The ink scraping mechanism comprises a scraping tool assembly arranged in the generatrix direction of the rubber roller and abutting against the rubber roller, and an ink collecting groove connected to the bottom end of the scraping tool assembly. The scraping tool assembly comprises a fixedly connected scraping tool and an arc covering plate arranged close to the upper portion of one end of the rubber roller. The rotary tangential direction of the contact line between the scraping tool and the rubber roller and the bladeface of the scraping tool form an acute angle and are arranged inclined downwards. An ink inlet is formed between the covering plate and the scraping tool. The scraping tool assembly is provided witha flat channel used for communicating the ink inlet and the ink collecting groove. An air pump is connected with the position, corresponding to the exit of the flat channel, of the scraping tool assembly above the opening of the ink collecting groove. The offsetpress solves the problem of an existing offset press of subsequent printing stack caused by residual ink on the rubber cylinder surface,and printing clarity improvement is facilitated.

Owner:浙江省邮电印刷股份有限公司

Preparation method of anti-migration thermoplastic polyurethane elastomer

The invention discloses a preparation method of an anti-migration thermoplastic polyurethane elastomer. The preparation method comprises the following steps: (1) adding heated and molten polyester polyol into a reaction kettle, and adding an antioxidant and a catalyst, and dewatering under heating and reduced pressure conditions to form a component A; (2) heating and melting diisocyanate to form a component B; (3) heating and melting a dihydric alcohol chain extending agent, and dewatering under the reduced pressure condition to form a component C; (4) reacting the components A, B and C in a double-screw extruder, and fully and uniformly mixing a reaction product with a macromolecular hindered amine light stabilizer to obtain the anti-migration thermoplastic polyurethane elastomer; (5) curing the anti-migration thermoplastic polyurethane elastomer obtained in the step (4). According to the anti-migration thermoplastic polyurethane elastomer, the smooth surface can be better kept and the physical property retention period can be better prolonged in processed products such as late-period wires and cables and films.

Owner:苏州奥斯汀新材料科技有限公司

Manufacturing method for two-layer silicon epitaxial wafer used for bipolar transistor

ActiveCN103367252AKeep surfaces cleanGuaranteed uniformitySemiconductor/solid-state device manufacturingHydrogenRepeatability

The invention discloses a manufacturing method for a two-layer silicon epitaxial wafer used for a bipolar transistor. Compared with a manufacturing method for a conventional two-layer silicon epitaxial wafer, the manufacturing method for the two-layer silicon epitaxial wafer used for the bipolar transistor is characterized by comprising the following steps of removing micro damages of the surface of a silicon wafer by using a hydrogen chloride (HCl) polishing process before a first layer silicon epitaxial wafer is grown; taking out the silicon wafer after the first layer silicon epitaxial wafer is grown to perform etching treatment on a system; and cleaning the silicon wafer before a second layer is grown to ensure the surface to be clean, removing the micro damages of the surface by using the HCl polishing process, and removing impurities by using hydrogen (H2) after polishing. According to the manufacturing method, a reaction chamber etching step is inserted, and therefore, the uniformity and the repeatability of the electrical resistivity of an epitaxial layer are ensured, and the performance and the finished product rate of a device are ensured.

Owner:HEBEI POSHING ELECTRONICS TECH

Method for preparing glazed drinking utensils

InactiveCN102249521AIncrease the variety of productionKeep surfaces cleanPolishing machinesGlass shaping apparatusGrindingProcess engineering

The invention discloses a method for preparing glazed drinking utensils. The method comprises the steps of product drawing designing, clay mould manufacturing, silicon rubber mould duplicating, wax mould casting and removing, wax mould modifying, plaster mould manufacturing, dewaxing for manufacturing a fire-proof plaster internal-hollow female mould, raw material configuration, high-temperature burning, mould removal, cutting and grinding, product finishing and polishing; between the step of wax mould modifying and the step of mould casting and firing, the method also comprises a step of manufacturing a product inner-core mould; and between the step of dewaxing and the step of raw material configuration, the method also comprises a step of mould splitting and assembling. The preparation method disclosed by the invention has the advantages that: the method is suitable for the demoulding and firing of large internal-hollow products, metal components are not easy to be separated out, and fingerprints cannot be left on the surface of a prepared product easily; meanwhile, an operation of precision annealing can be performed, the heat and cold tolerances of materials are high, and the prepared product is not easy to crack.

Owner:欧琳集团有限公司 +1

Multi-module combined type solar module

ActiveCN108418527AFlexible angle adjustmentKeep surfaces cleanPhotovoltaic supportsPhotovoltaic energy generationSurface cleaningLocking mechanism

The invention discloses a multi-module combined type solar module. The multi-module combined type solar module comprises a base, wherein a first mounting groove is formed in the upper end of the base;a second mounting groove is formed in the middle of the bottom wall of the first mounting groove; the bottom wall of the second mounting groove is rotatably connected with a first rotating shaft; a mounting seat is arranged in the first mounting groove; the upper end of the first rotating shaft is fixedly connected with the mounting seat; locking mechanisms are separately arranged on side walls of two sides of the base; two mounting columns are arranged at the upper end of the mounting seat, and are separately positioned on two sides of the mounting seat; and a photovoltaic battery mounting plate is arranged between the two mounting columns; photovoltaic battery panels are arranged on side walls of the photovoltaic battery mounting plate; and a rotating rod penetrates in the photovoltaicbattery mounting plate. The angle of the solar module can be adjusted flexibly according to the height of the sun in different periods in a year. The multi-module combined type solar module has a cleaning function, cleanness of the surface of the battery panel is maintained, and the illumination receiving effect is good.

Owner:徐州亿通光电有限公司

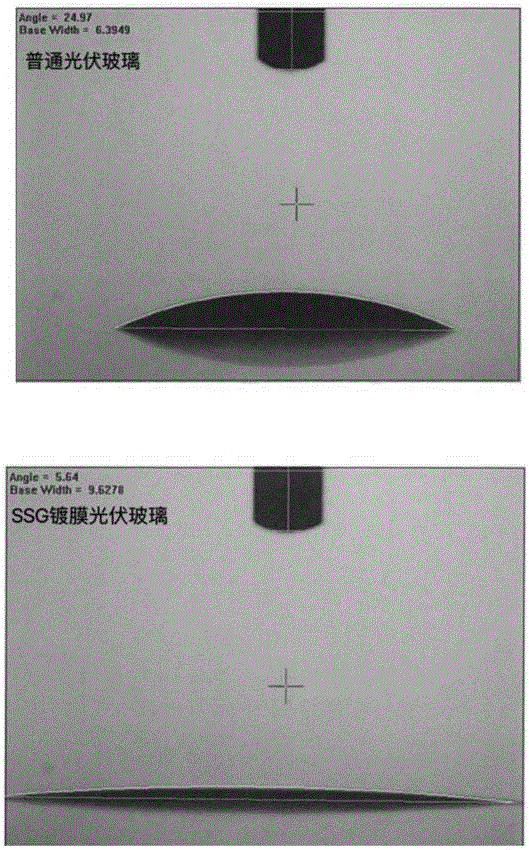

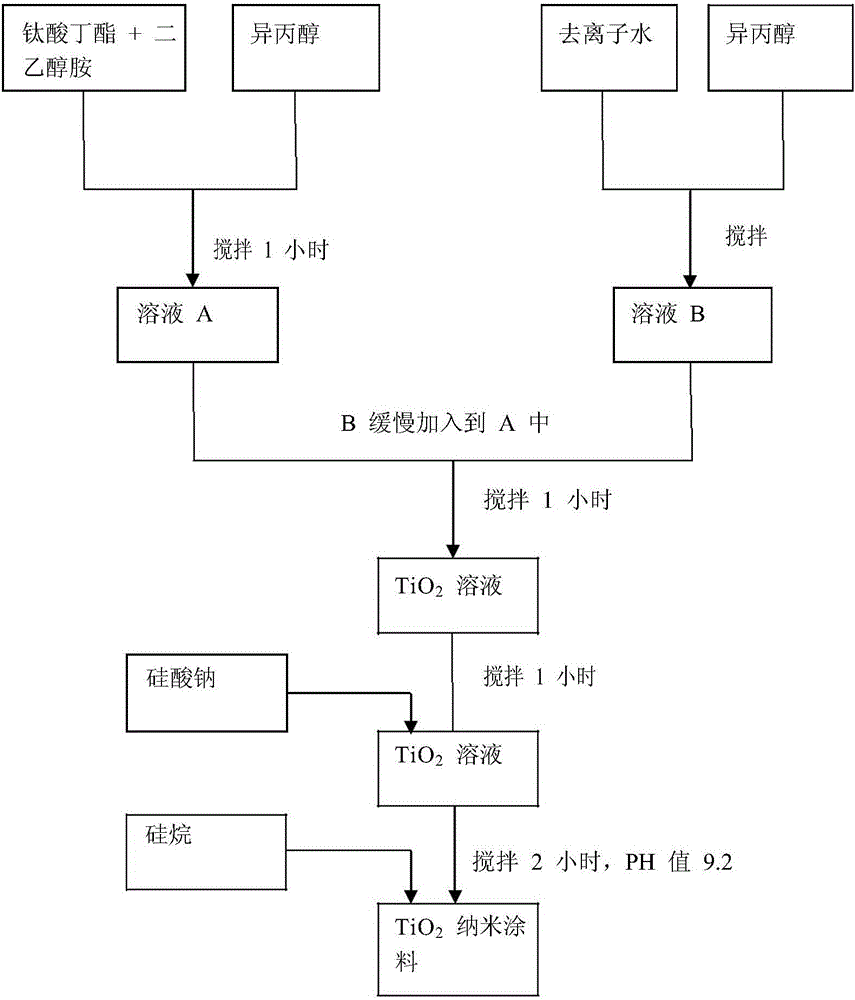

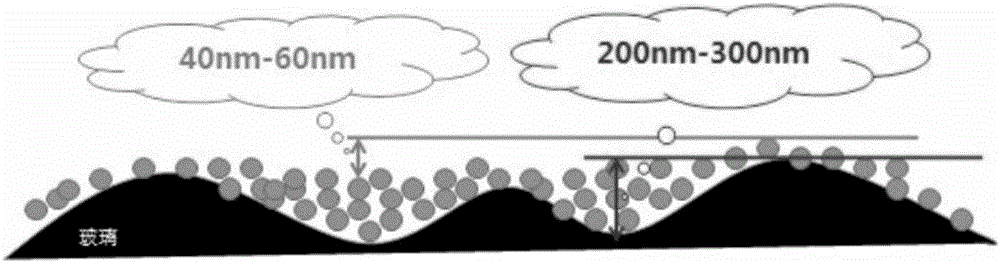

Preparation method for multifunctional TiO2 nano-paint

InactiveCN106046863AAvoid interactionImprove photoelectric conversion efficiencyAntifouling/underwater paintsPaints with biocidesSilanesSurface cleaning

The invention provides a preparation method for a multifunctional TiO2 nano-paint. The preparation method comprises the following steps: preparation of a TiO2 solution with butyl titanate as a titanium source, isopropanol as a solvent and diethanolamine as a hydrolysis inhibitor; and dispersion and surface modification of the TiO2 nano-solution: carrying out TiO2 surface modification on the obtained TiO2 solution with sodium silicate as a dispersing agent and silane as a coupling agent so as to obtain the multifunctional TiO2 nano-paint. The multifunctional TiO2 nano-paint prepared in the invention can be directly sprayed on the surface of a substrate at normal temperature and has good bonding action on the substrate; surface cleanness of a photovoltaic assembly is maintained mainly in virtue of super hydrophilicity and self-cleaning performance of a formed coating; and the photoelectric conversion rate of the photovoltaic assembly is improved.

Owner:BEIJING LION TRUNK NEW MATERIAL TECH CO LTD

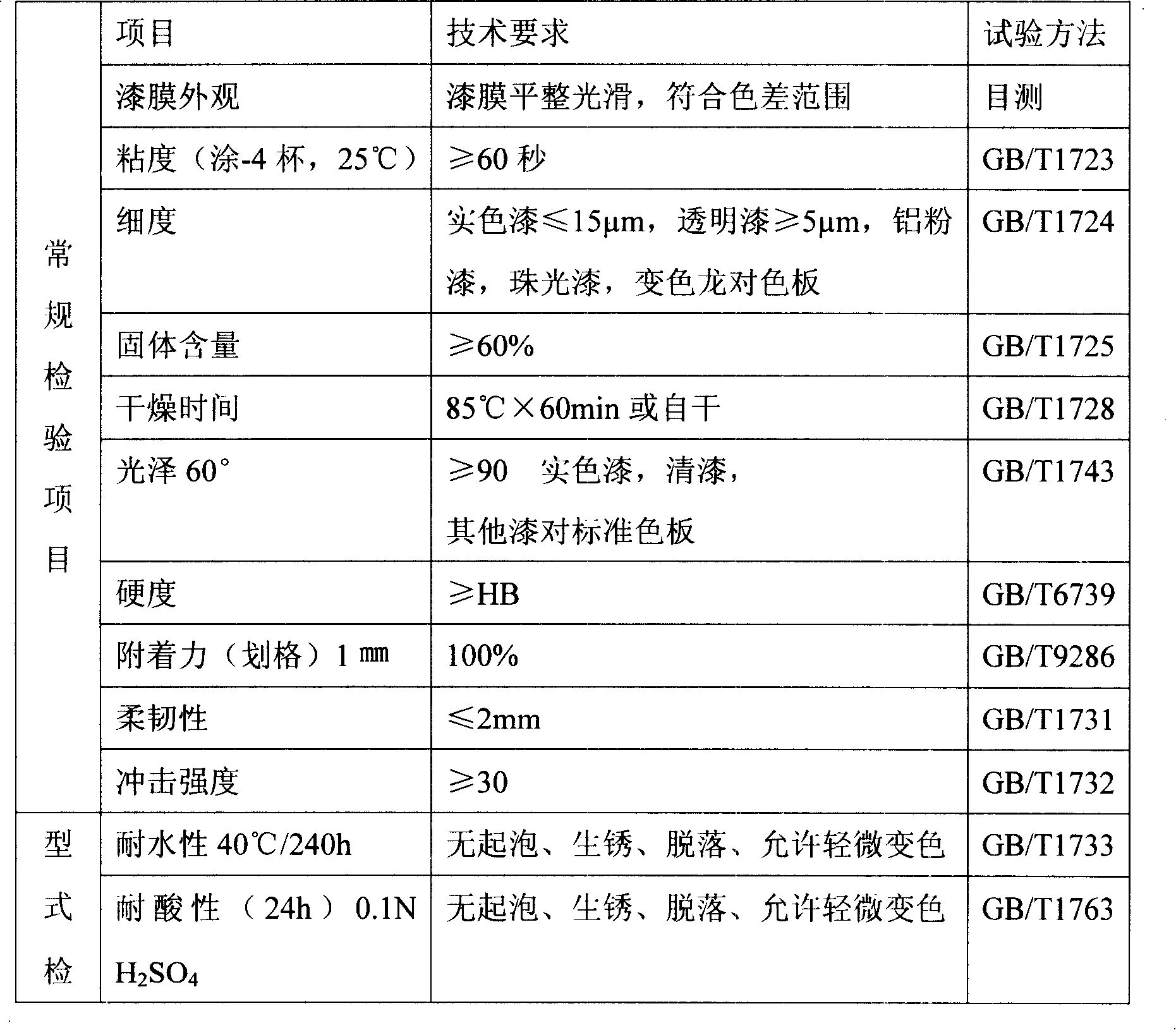

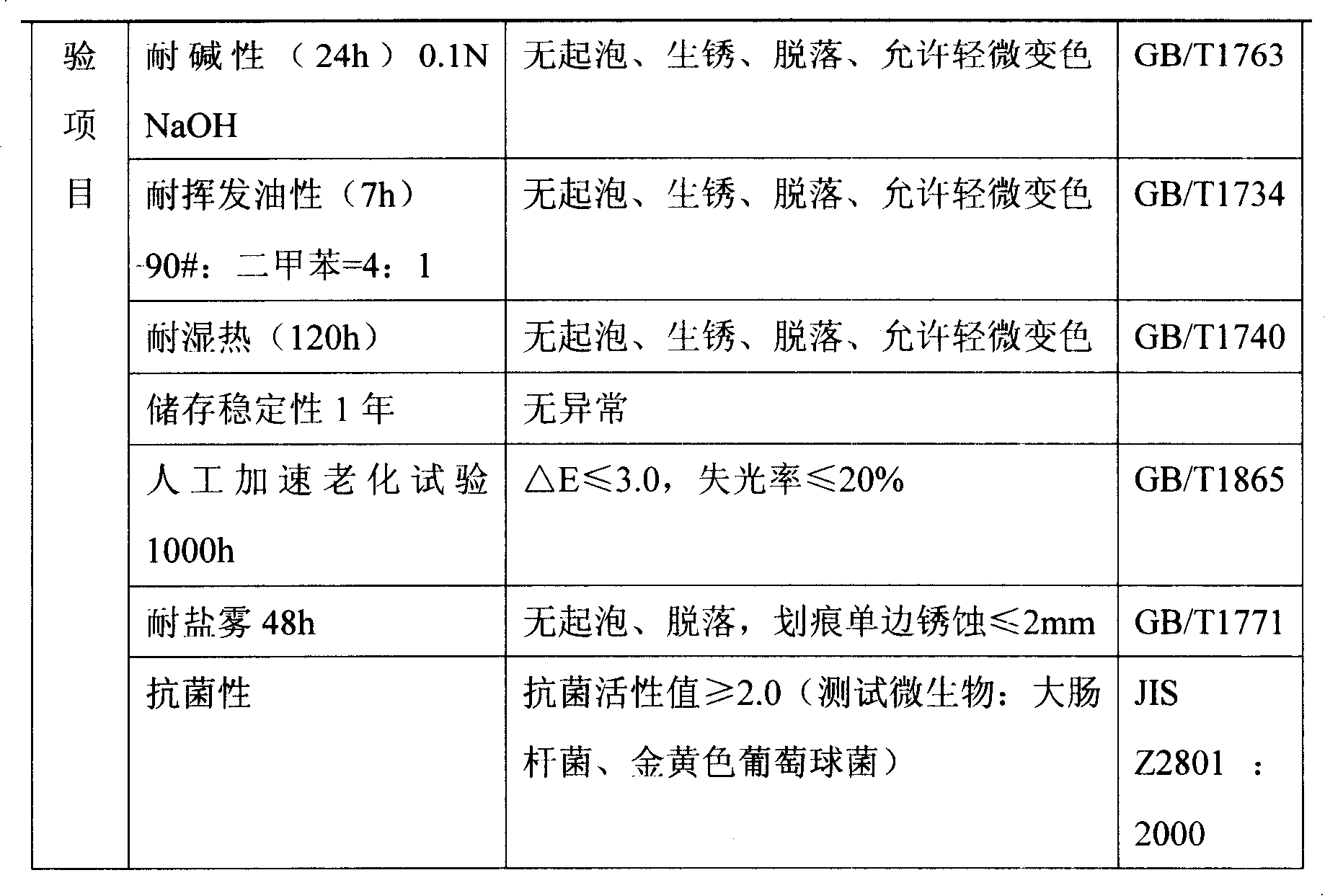

High glaze ornamental double-component acrylic acid polyurethane antimicrobial paint

InactiveCN101220242AGood mechanical propertiesHigh glossAntifouling/underwater paintsPaints with biocidesLacquerAntimicrobial

The invention provides a high glaze ornamental and double-component acrylic polyurethane anti-bacterium coating which contains the following components: 60 percent-80 percent of hydroxylated acrylic resin, 1 percent-10 percent of pigment, 3 percent to 5 percent of butyl acetate, 1 percent to 3 percent of dimethylbenzene, 0.5 percent to 1 percent of accessory ingredient and 1 percent to 5 percent of inorganic antiseptics. The anti-bacterium coating also contains curing agent, and the proportion of the anti-bacterium to the curing agent is 3 to 6: 1. The pigment can also adopt metallic flakes or pearls powder; the accessory ingredient is a flatting agent or a dispersant; the curing agent is urethane resin of fatty group. The novel anti-bacterium coating combines the functions of environmental protection, high decorativeness and protection and antibacterial property, and can be taken as the protective coating of electronic products, household appliances, sanitary wares and public facilities.

Owner:GUANGZHOU PAINT SOUTH FACTORY

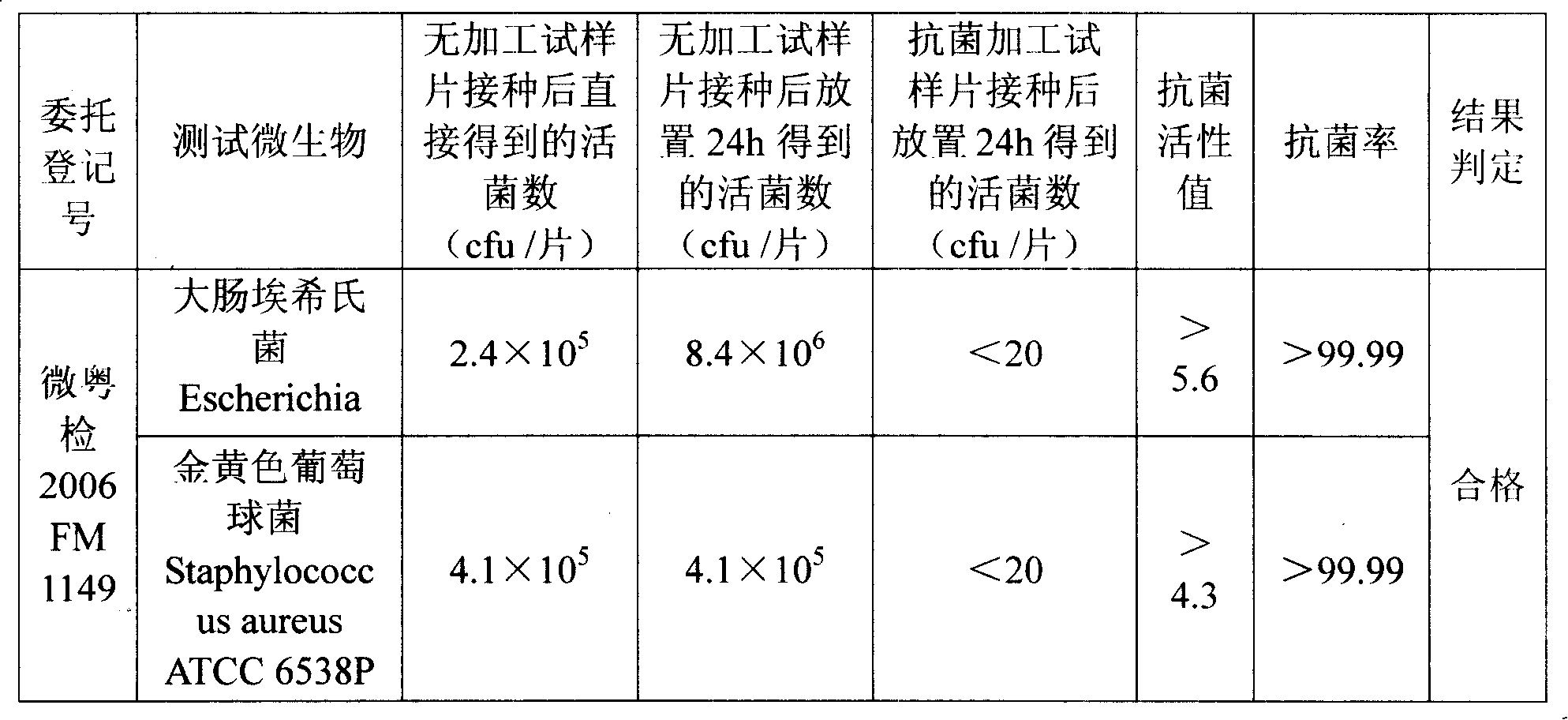

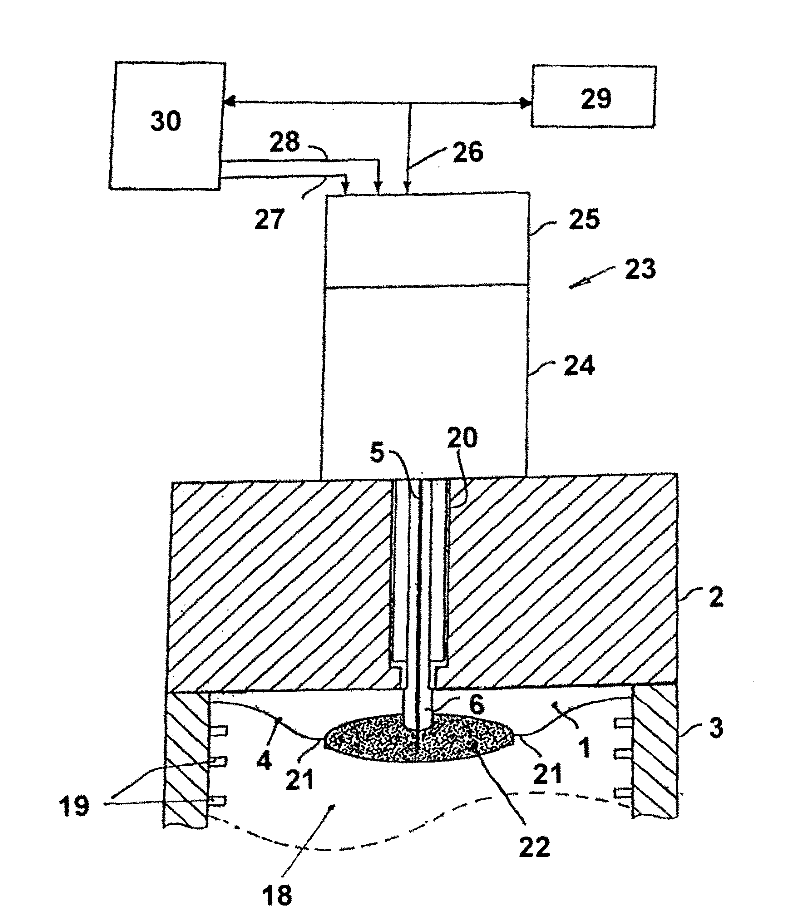

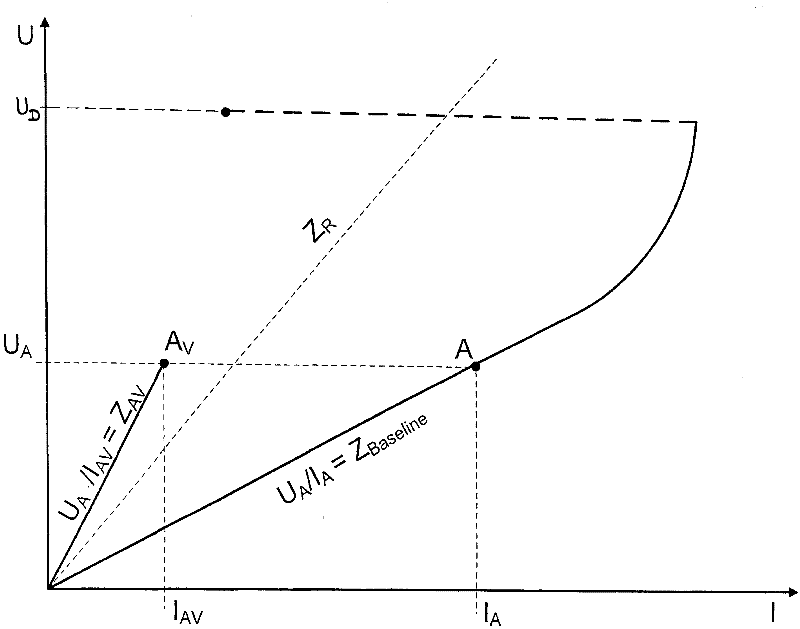

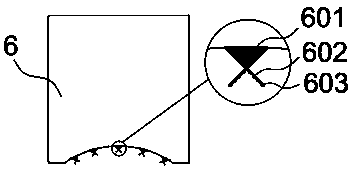

Method for igniting a fuel-air mixture in a combustion chamber of an internal combustion engine by corona discharge

ActiveCN102269094ADelayed replacementExtended service lifeSparking plugsMachines/enginesCapacitanceElectricity

A method of igniting a fuel-air mixture in a cyclically operating internal combustion engine comprising one or more combustion chambers (1) delimited by walls (2, 3, 4) at ground potential, using ignition means comprising The ignition electrode (5) in the chamber (1), in this method an electric oscillating circuit connected to the secondary side (17) of the DC / AC converter (12) is excited by the electric DC / AC converter (12) ( 7), wherein the ignition electrode (5) cooperates with the walls (2, 3, 4) of the combustion chamber (1) to form a capacitor, and the ignition electrode (5) is electrically insulated from the walls (2, 3, 4) through the insulator (6) is guided through one of the walls (2, 3, 4) of the combustion chamber (1) to extend into the combustion chamber (1), and the excitation of the oscillating circuit (7) is controlled to the ignition in each combustion chamber (1) The electrode (5) generates a corona discharge (22) that ignites the fuel-air mixture. According to the invention, combustion residues that have deposited on the surface of the insulator (6) in the combustion chamber (1) are removed from time to time using a combustion process and / or an electroerosion process.

Owner:BORGWARNER BERU SYST

Paint

The invention discloses paint. The paint is prepared from the following raw material components in parts by weight: 40-50 parts of water solution, 3-5 parts of zinc oxide, 3-5 parts of zinc sulfide, 1-2 parts of thickener, 30-40 parts of silica powder, 1-2 parts of preservative, 1-2 parts of bonder, 20-30 parts of titanium dioxide and 10-20 parts of solvent gasoline (paint solvent oil). A paint granule smaller than 1 micron can be formed on the surface of the paint, so that the smoothness is greatly improved and the surface cleanness can be kept for a long time.

Owner:王文浩

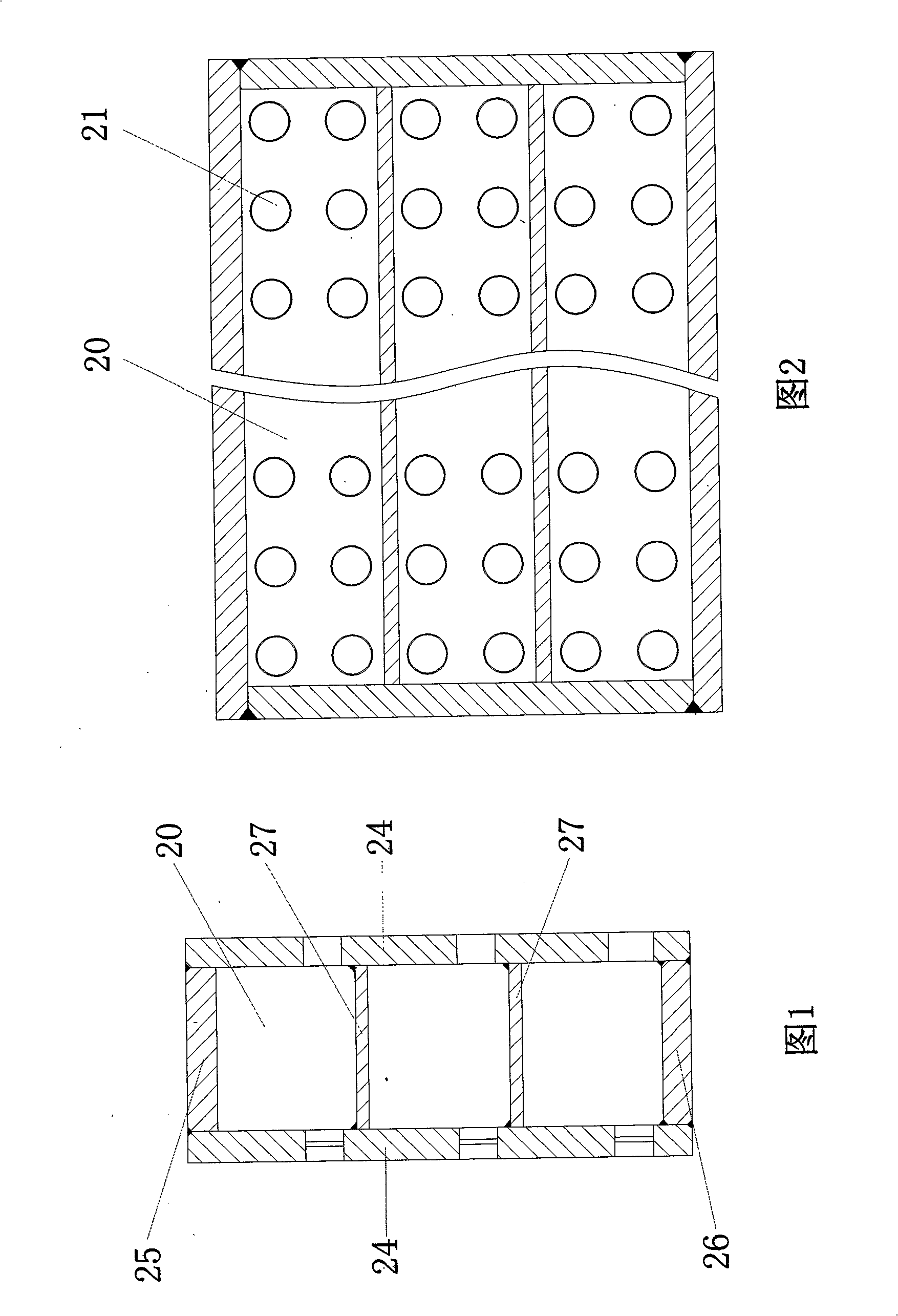

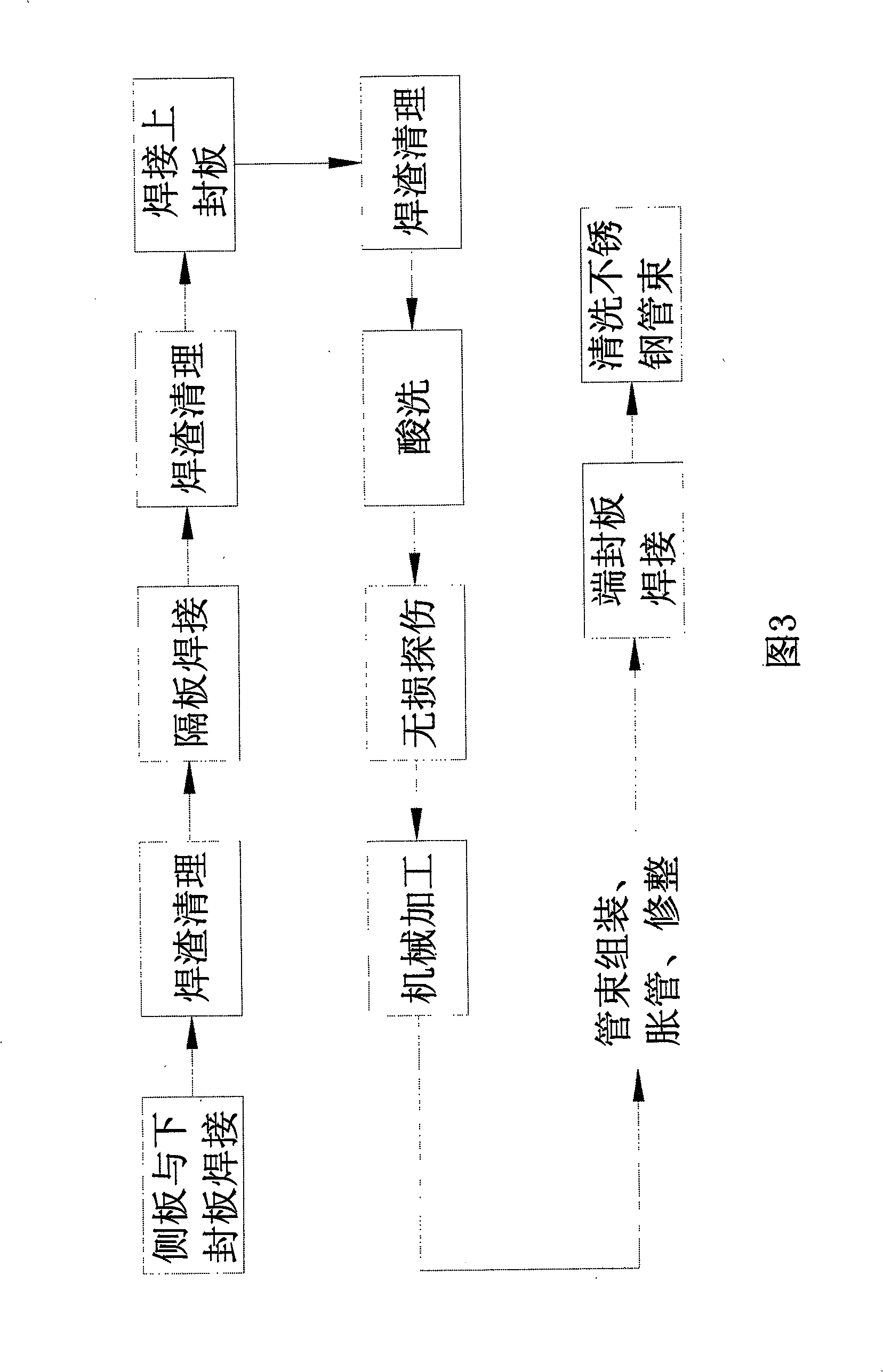

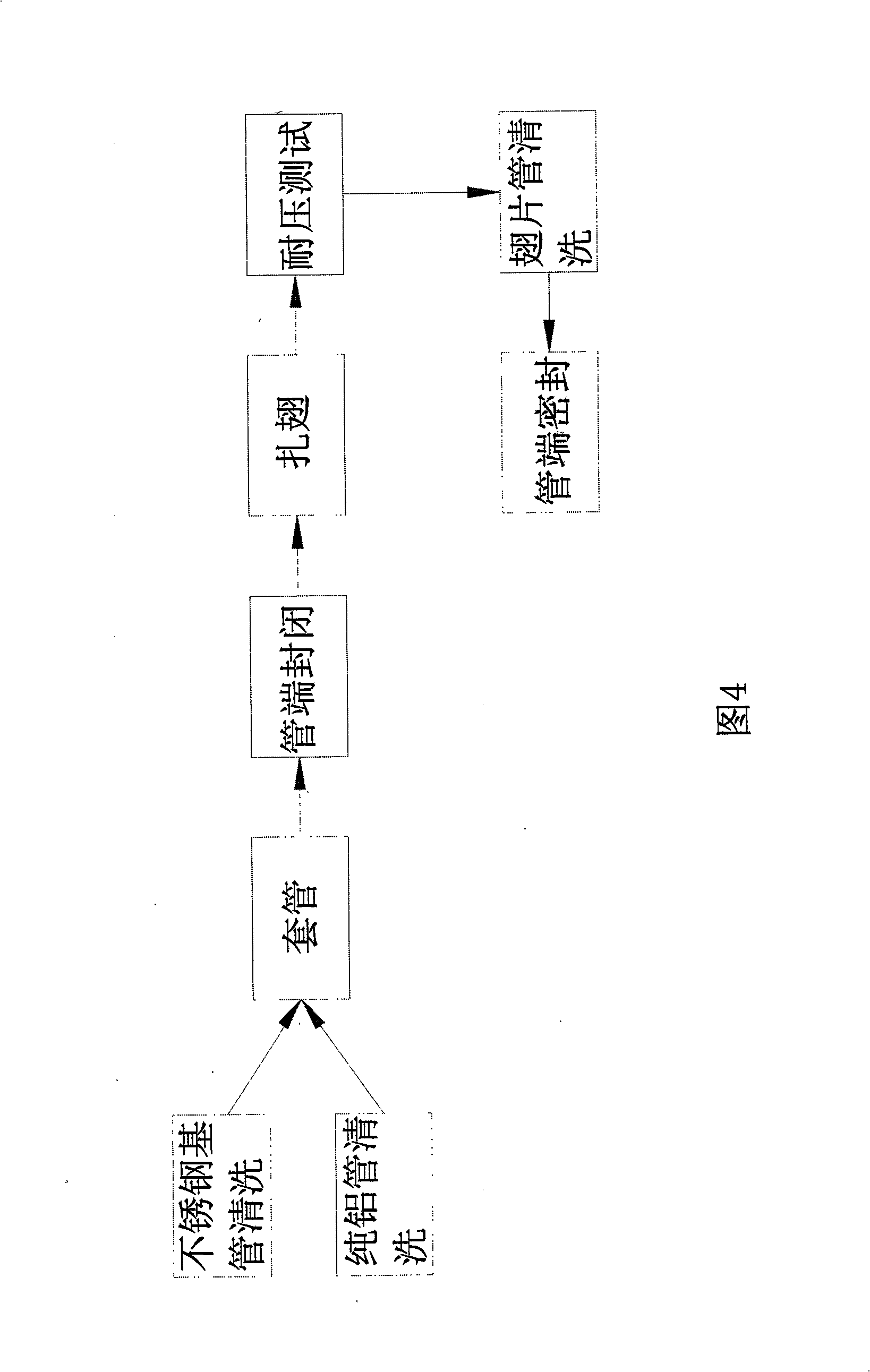

Air cooler for cooling DC converter valve and fabrication technology thereof

ActiveCN101493300AGuaranteed purityReduced ion extractionSemiconductor/solid-state device detailsSolid-state devicesEngineeringImpurity

The invention discloses an air cooler used for cooling a high voltage direct current transmission converter valve and a manufacturing process thereof. The air cooler comprises a channel box; clapboards are arranged in the channel box to divide the inside of the channel box to a plurality of relatively independent interlayers; a stainless steel tube bank comprising a plurality of stainless steel finned tubes is arranged in the interlayers; the stainless steel finned tube comprises an O6Cr18Ni9 or O6Cr17Ni12Mo2 material parent tube and aluminum rolled fins covering the outside of the parent tube; precipitation amount of ion is decreased to the minimum to ensure the purity of cooling water; specific pre-process treatment of rolled fins effectively decreases thermal resistance between a stainless steel tube and an aluminum tube to improve radiating efficiency; working procedures are arranged reasonably and impurity or roll scale is removed in time, so that the surface of the liquid contacting material of the air cooler is clean to ensure the high purity of fluid.

Owner:岳阳高澜节能装备制造有限公司

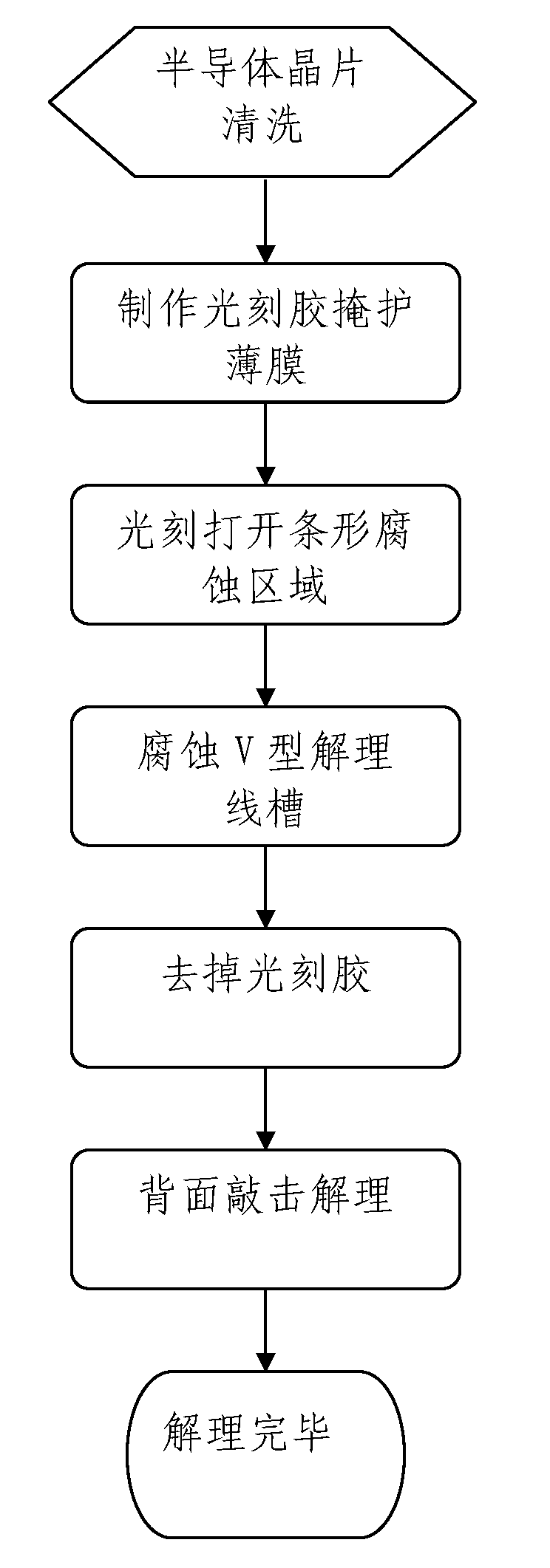

High-precision and pollution-free semiconductor wafer cleavage method

InactiveCN103060920AWon't happenKeep surfaces cleanAfter-treatment detailsWaferingChemical corrosion

The invention discloses a high-precision and pollution-free semiconductor wafer cleavage method. The method comprises the following steps: spinning photoresist on the surface of a semiconductor wafer to prepare a covering film; photoetching a strip-shaped run-through corrosion area on the covering film by using a photoetching machine; performing chemical corrosion in the corrosion area by using corrosive liquid to form a V-shaped cleavage slot; taking out the semiconductor wafer from the corrosive liquid and removing the covering film from the surface of the semiconductor wafer; and segmenting the semiconductor wafer along the V-shaped cleavage slot and finishing semiconductor wafer cleavage. The V-shaped cleavage slot is manufactured by a photoetching and corrosion mode, so the position precision of the V-shaped cleavage slot can be guaranteed to be within 1 micron, and the precision of the cleaved semiconductor wafer is guaranteed to be within 1 micron. The V-shaped cleavage slot is manufactured by the chemical corrosion method, so no substrate material scrap is generated, the surface of the cleaved semiconductor wafer is guaranteed to be clean, and the quality and the finished product rate of chips are improved.

Owner:WUHAN TELECOMM DEVICES

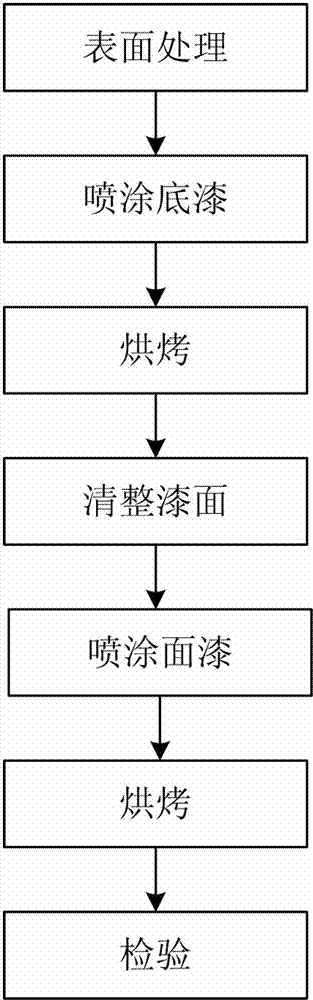

Paint spraying process of intermediate toothed plate

InactiveCN104324869AKeep surfaces cleanGuarantee the quality of sprayingPretreated surfacesCoatingsMaterials scienceRust

The invention discloses a paint spraying process of an intermediate toothed plate. The paint spraying process comprises the following steps of (1) surface treatment: removing oil, rust and dust; (2) primer spraying: spraying primer onto the intermediate toothed plate within 4-12 hours after the surface treatment; (3) baking: baking the intermediate toothed plate after the primer spraying, with the baking temperature of 90-100 DEG C and the baking time of 30-40 minutes; (4) finishing of paint surface: finishing the paint surface of the intermediate toothed plate after the baking; (5) topcoat spraying: spraying topcoat onto the intermediate toothed plate within 12 hours after the finishing of paint surface; (6) baking: baking the intermediate toothed plate after the topcoat spraying, with the baking temperature of 90-100 DEG C and the baking time of 30-40 minutes, and airing for 12-24 hours after the baking; (7) inspection: inspecting the appearance, coating thickness and adhesion. The paint spraying process has the advantage that the paint spraying quality of the intermediate toothed plate can be guaranteed by the process flow.

Owner:LIUZHOU JINMAO MACHINERY

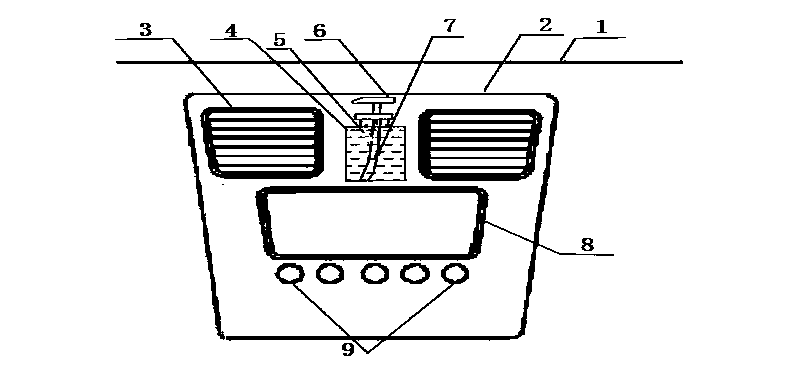

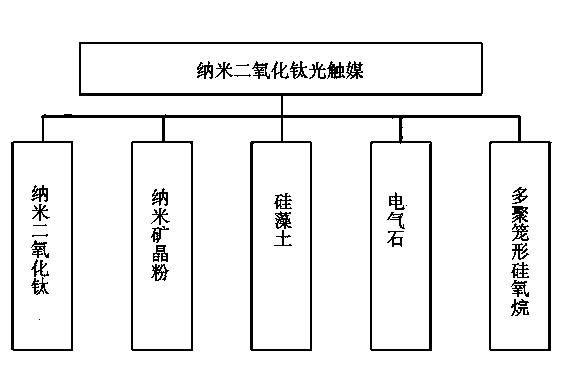

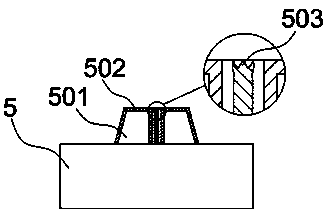

Novel automotive air conditioner with photocatalyst function

ActiveCN103465752AExtension of timeHas a persistent effectAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningFree state

The invention discloses a novel automotive air conditioner with a photocatalyst function. The novel automotive air conditioner comprises a device shell, a functional circuit and air conditioner grids, wherein the air conditioner grids are arranged on the surface of the device shell. The novel automotive air conditioner is characterized in that a containing box for storing a photocatalyst air purifying liquid is further arranged on the device shell, wherein the photocatalyst air purifying liquid is a liquid spray agent and is prepared from nanometer titania photocatalysts; an atomizing nozzle is further arranged on the containing box and extends to the bottom of the containing box through a guide pipe; the nanometer titania photocatalysts include nanometer titania, nanometer mineral crystal powder, diatomite, tourmaline and polysiloxane clathrate. As the spray agent used in the novel automotive air conditioner is in a moving free state, can be rapidly spread and has the characteristics of large purifying space and user-adjustable scope, the noxious and harmful gases in the air of an automobile can be rapidly and effectively degraded, and the novel automotive air conditioner has the functions of deodorization, mould proofing and air purification and has no toxicity and secondary pollution.

Owner:WM MOTOR TECH GRP CO LTD

Sputtering target and binding method thereof

InactiveCN106032568AReduced contentAvoid bendingVacuum evaporation coatingSputtering coatingSputteringIndium

The invention relates to a sputtering target and a binding method thereof. A layer of indium is infiltrated on a solder side of a backboard component of the sputtering target material, and a binder containing conductive particles is used for binding a target material and the backboard component together. The low melting point characteristic of indium is used, so that during unbinding, mutual separation of the target material, the conductive binder and the backboard component is easy. A metal mesh is arranged in the conductive binder, and during unbinding, the conductive binder is attached to the metal mesh, so that after recovery, the surface of the backboard component does not have conductive binder residues.

Owner:HANERGY CO INNO MOBILE ENERGY INVESTMENT CO LTD

Quick and convenient peanut shell-breaking device

InactiveCN108371331AImprove integrityHigh degree of automationCleaning using liquidsHuskingEngineeringMechanical engineering

Owner:浦江县元寿农业科技有限公司

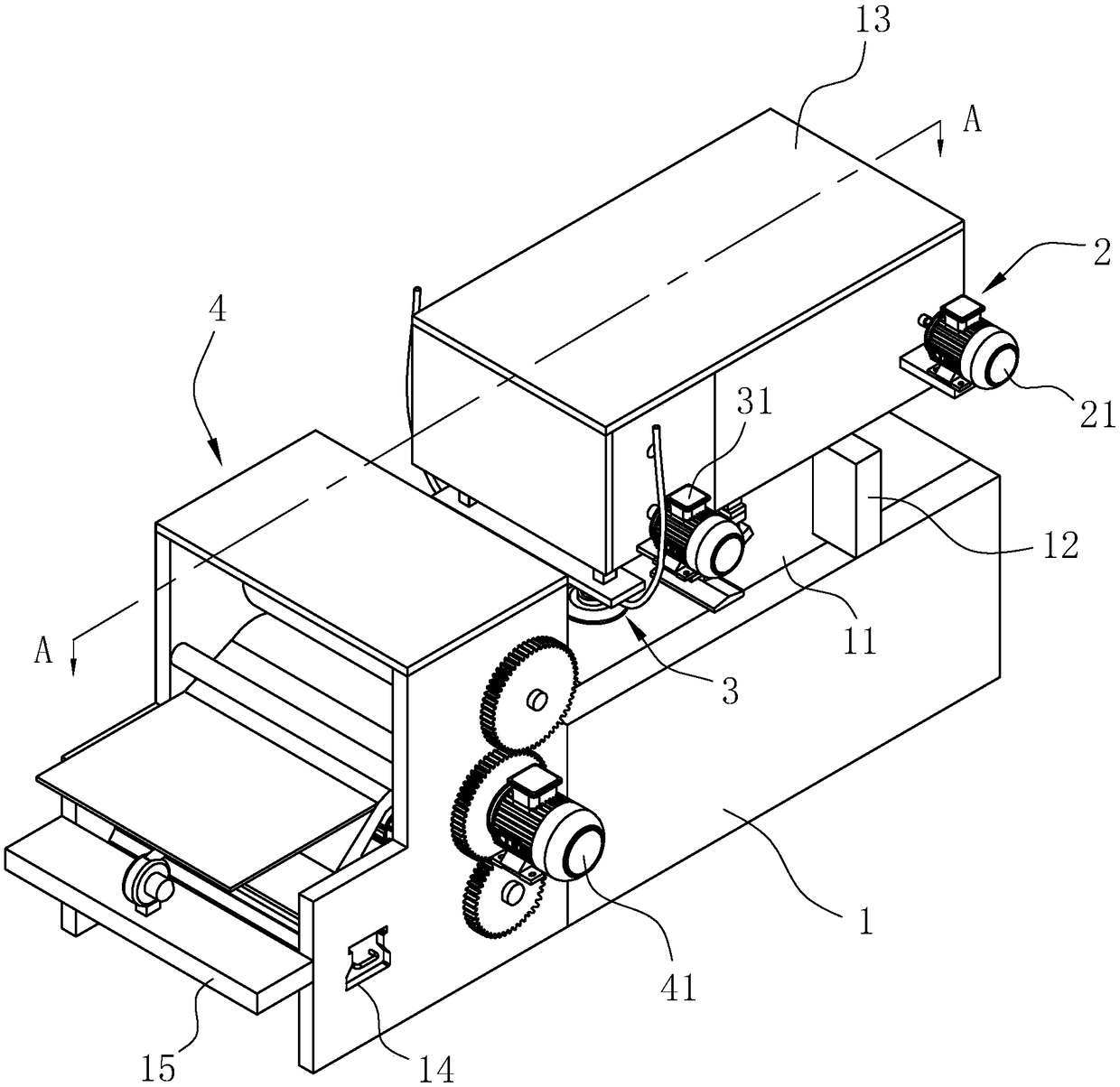

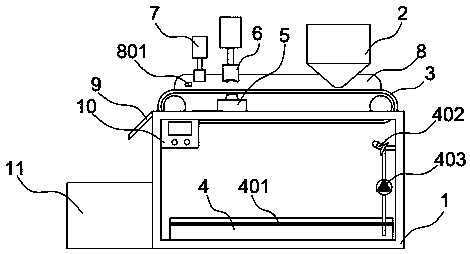

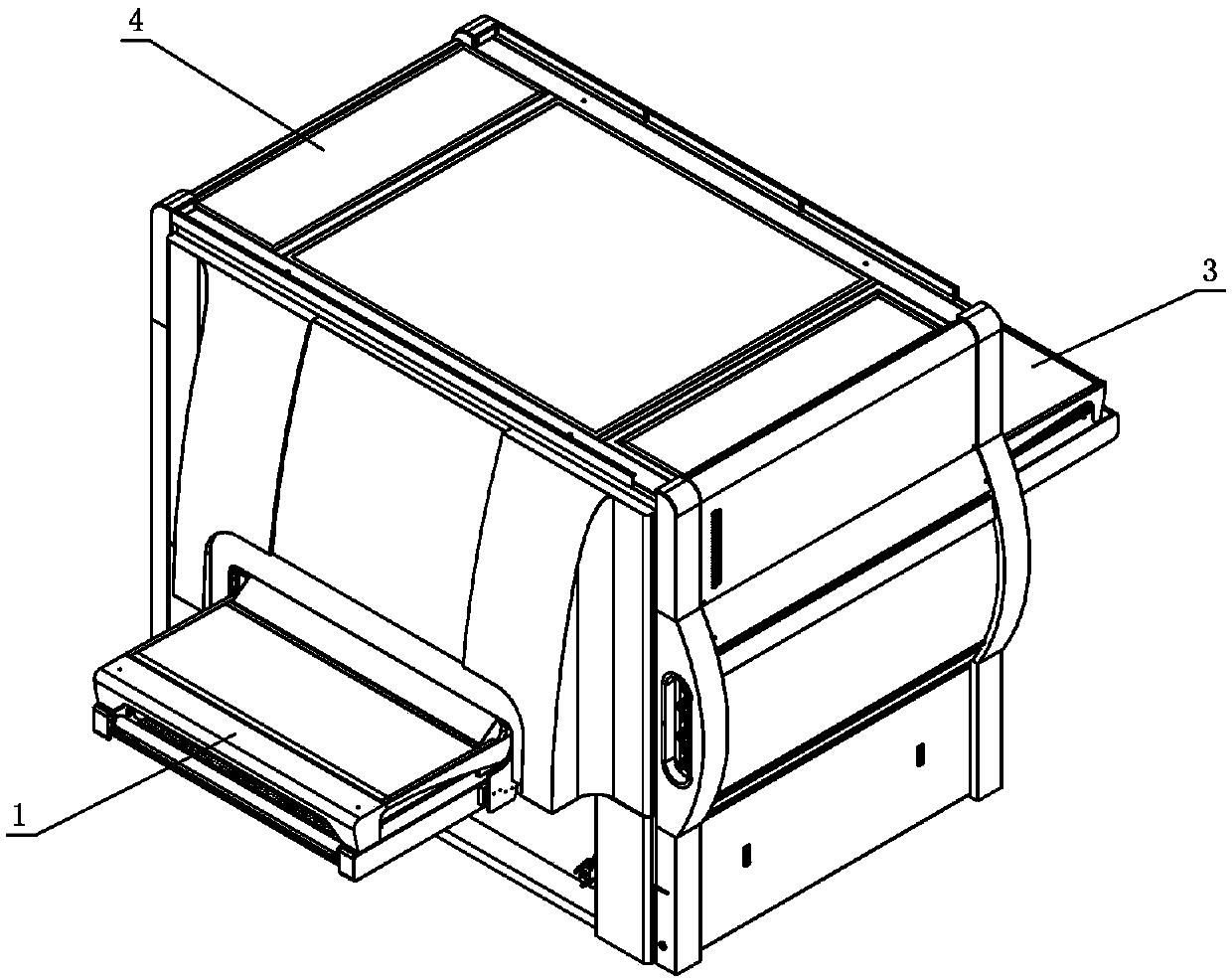

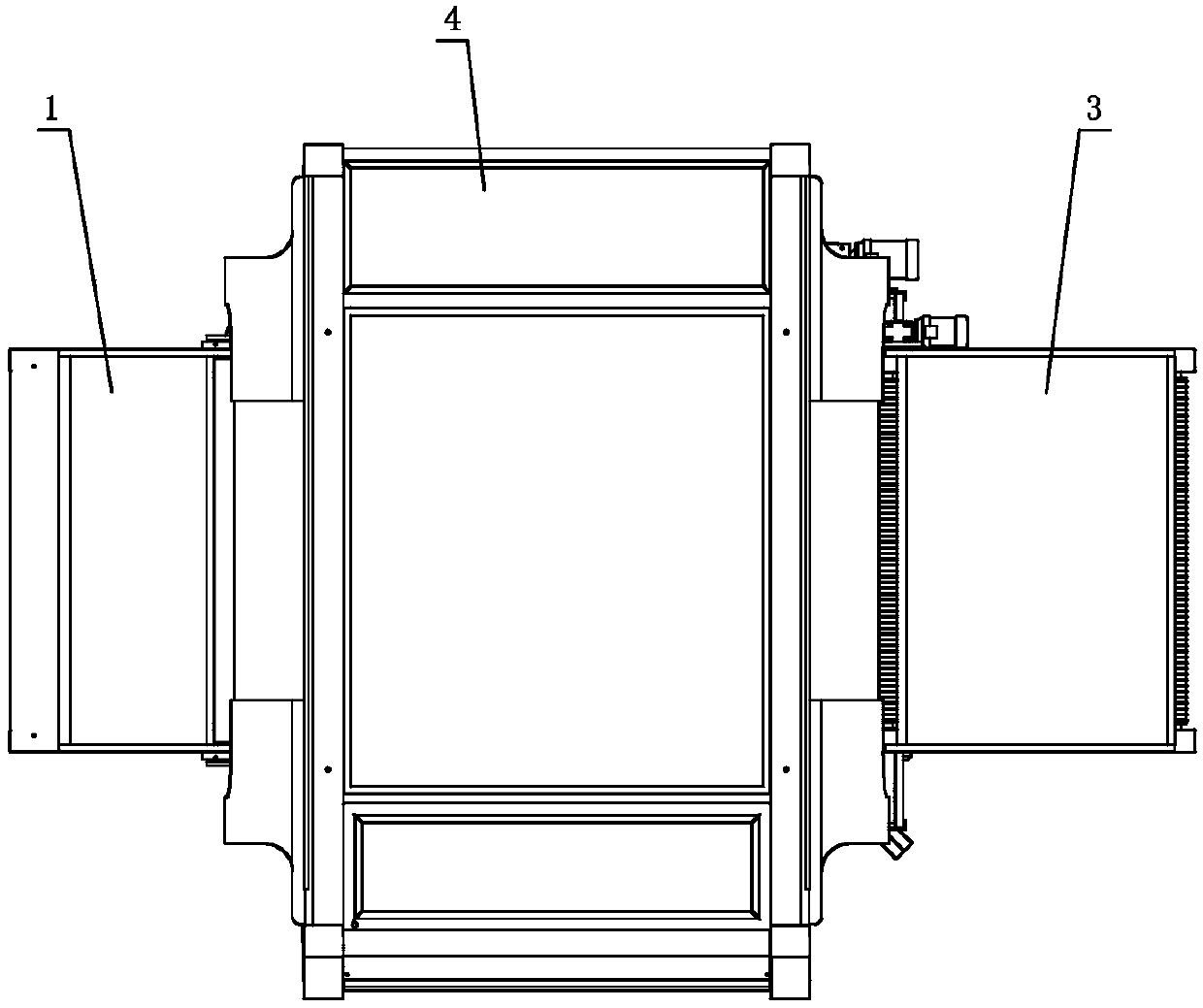

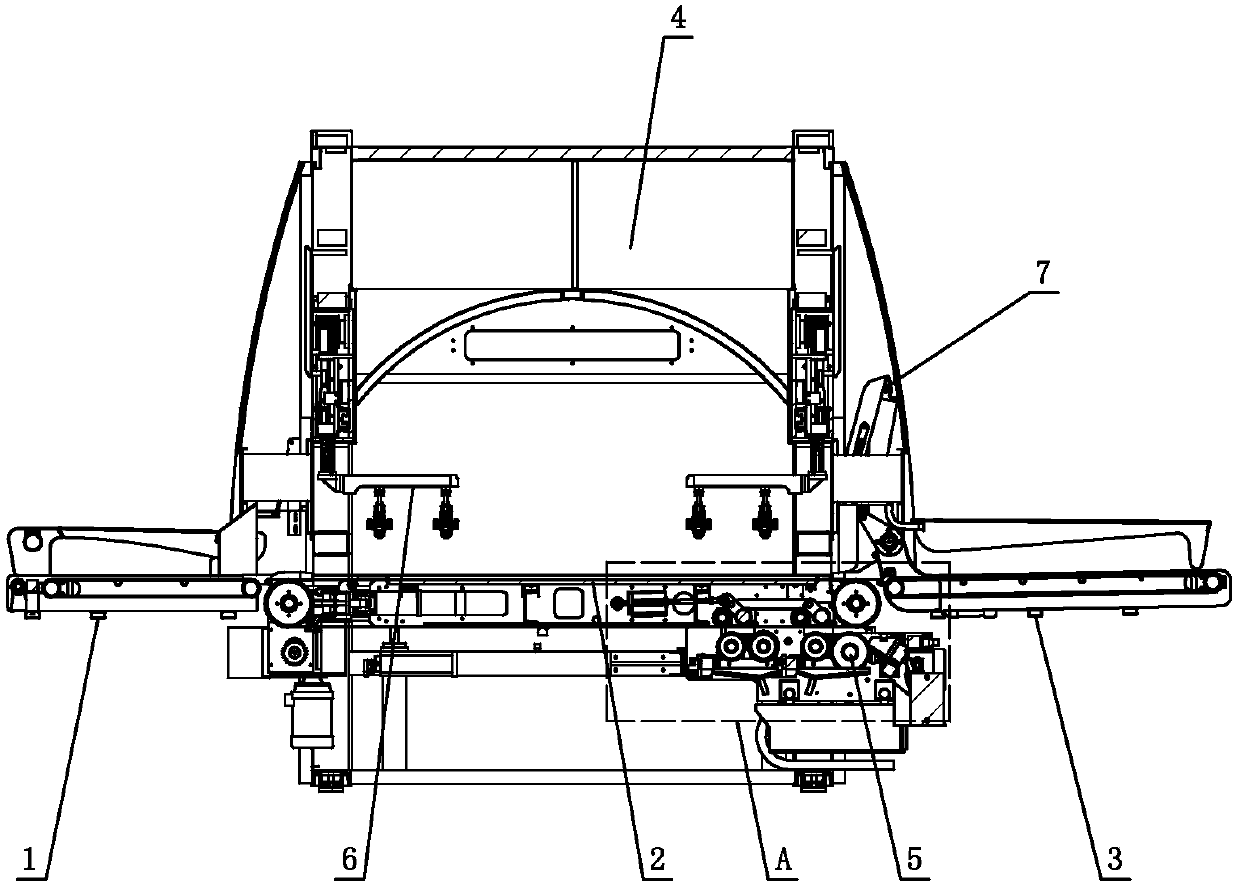

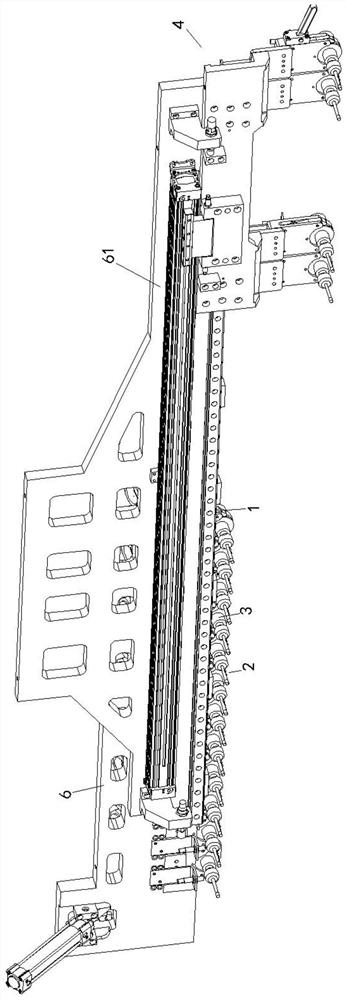

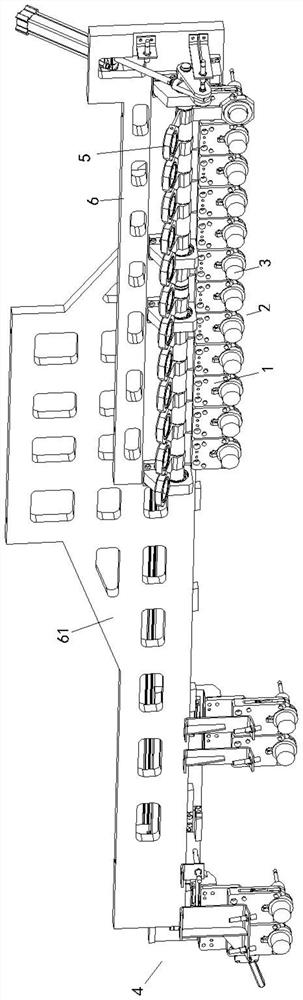

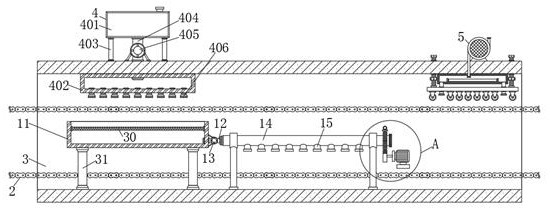

Zero-pollution conveying system of spray coater

PendingCN107857088AClean in timeKeep surfaces cleanConveyorsCleaningSpray coatingEnvironmental engineering

The invention relates to a zero-pollution conveying system of a spray coater. The zero-pollution conveying system of the spray coater comprises a spray coating chamber and a conveying group. The conveying group sequentially penetrates through a feed end, an inner cavity and a discharge end of the spray coating chamber, and comprises a front conveying mechanism, a middle conveying mechanism and a rear conveying mechanism; the front conveying mechanism is exposed on the feed end of the spray coating chamber; the middle conveying mechanism is arranged in an inner cavity of the spray coating chamber; the rear conveying chamber is exposed on the discharge end of the spray coating chamber; conveying surfaces of the front conveying mechanism, the middle conveying mechanism and the rear conveyingmechanism are on the same plane at least during work; the front conveying mechanism and / or the rear conveying mechanism are hinged with the spray coating chamber; a conveyor belt cleaning mechanism for cleaning the middle conveying mechanism is arranged under the middle conveying mechanism, and is integrally and slidably arranged on the spray coating chamber; and the conveyor belt cleaning mechanism is exposed on the feed end or the discharge end of the spray coating chamber when sliding to a certain position. The zero-pollution conveying system of the spray coater provided by the invention can be used for cleaning a conveyor belt and recovering a coating in time, and is convenient to maintain daily, reliable in performance and cost-saving.

Owner:GUANGDONG SHUNDE DIFENG MACHINE CO LTD

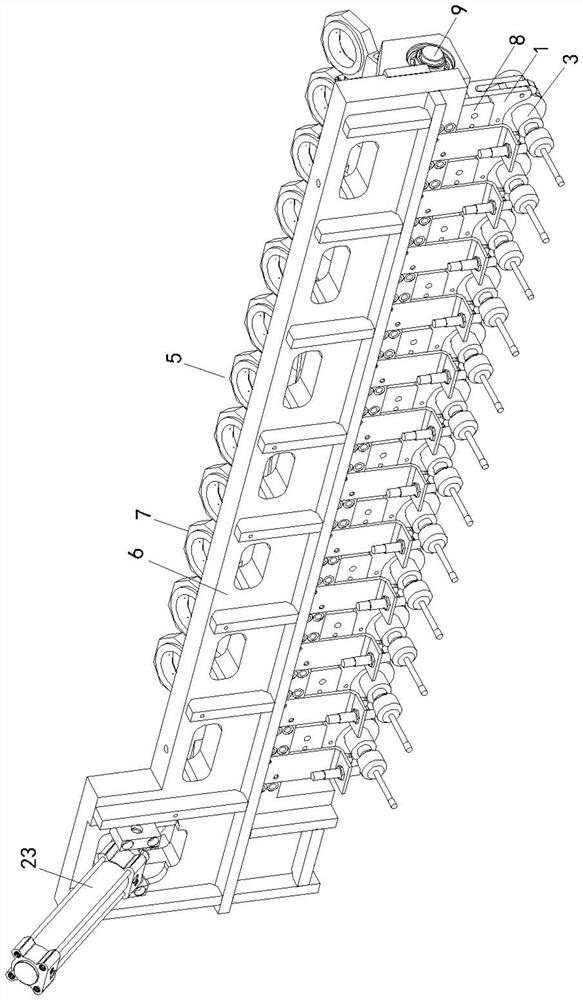

Horizontal machining center tool magazine

PendingCN112247606ATool Surface CleaningDoes not affect the tool change actionPositioning apparatusMaintainance and safety accessoriesManufacturing engineeringIndustrial engineering

The invention discloses a horizontal machining center tool magazine. The horizontal machining center tool magazine comprises a tool magazine assembly with a plurality of tool clamping jaws; the tool clamping jaws clamp tools; the horizontal machining center tool magazine further comprises a tool pushing mechanism used for pushing external tools to the position of the tool magazine assembly or pushing the tools in the tool magazine assembly to the outside and a cleaning mechanism used for cleaning the tools in the tool magazine assembly; When the tools clamped by the clamping jaws in the tool magazine are cleaned, a driving mechanism drives an overturning shaft to rotate, so that the cleaning mechanism is overturned to the positions of the tools to clean the tools; after cleaning is completed, the cleaning mechanism is driven by the driving mechanism to reset; the tool changing action of the tool magazine is not affected, and the cleaning action is executed before each time of tool changing; when the tools in the tool magazine are taken and conveyed, the tools are pushed into the machining center through the tool pushing mechanism; automatic tool changing is achieved; and the changed tools are taken out of the machining center through the pushing mechanism, and therefore risks caused by manual tool changing at the position of the tool magazine are avoided.

Owner:江苏威马悦达智能装备有限公司

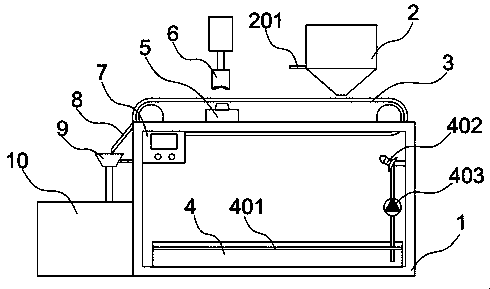

Walnut shell separating equipment

InactiveCN108477630AImprove integrityKeep surfaces cleanCleaning using liquidsHuskingWalnut NutTransmission belt

The invention discloses walnut shell separating equipment. The walnut shell separating equipment comprises a machine frame, wherein a transmission belt is mounted on the machine frame; a feeding hopper and a telescopic block are separately arranged at the upper parts of two ends of the transmission belt; an oblique guiding plate is arranged on the machine frame at the discharging end of the transmission belt; a collecting box is mounted under the guiding plate; a control panel is arranged at the upper part of the front of the machine frame; the telescopic block is connected with a telescopic motor; a supporting block which corresponds to the telescopic block is arranged on the inner side of the transmission belt just below the telescopic block; a liquid collecting tank is arranged at the bottom under the transmission belt, of the machine frame; a filter plate is arranged in the liquid collecting tank; the liquid collecting tank is connected with a water pump which is arranged on the inner wall of the machine frame at the upper part through a water pipe; the water pump is connected with a spray nozzle on the side wall of the machine frame; and the spraying direction of the spray nozzle faces the transmission belt. According to the walnut shell separating equipment disclosed by the invention, in the separating process of walnut shells, the walnuts can be crushed, so that processed products are high in edible safety, crushed walnut kernels are high in integrity, the efficiency of separating the walnut kernels and walnut shells is improved, and the bitter sense can be reduced.

Owner:浦江县元寿农业科技有限公司

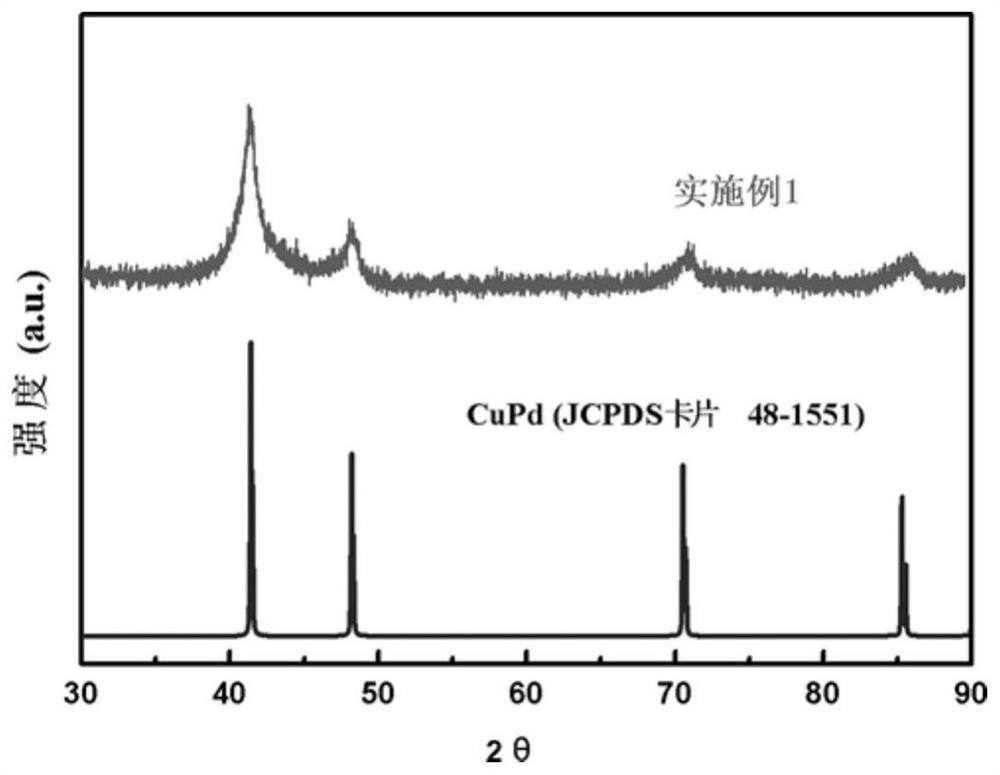

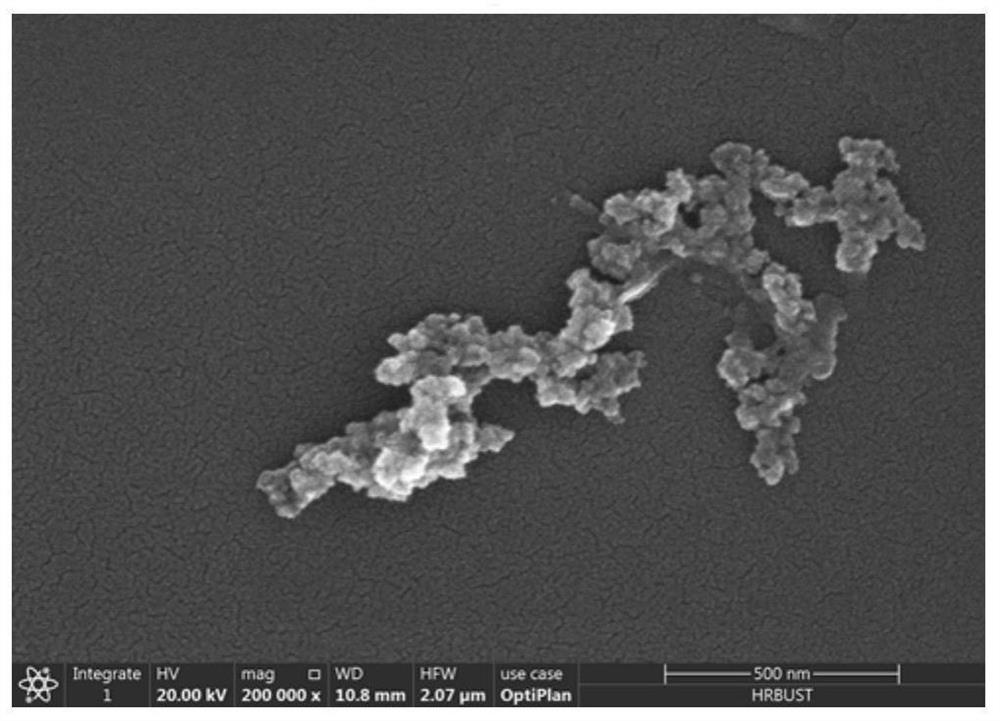

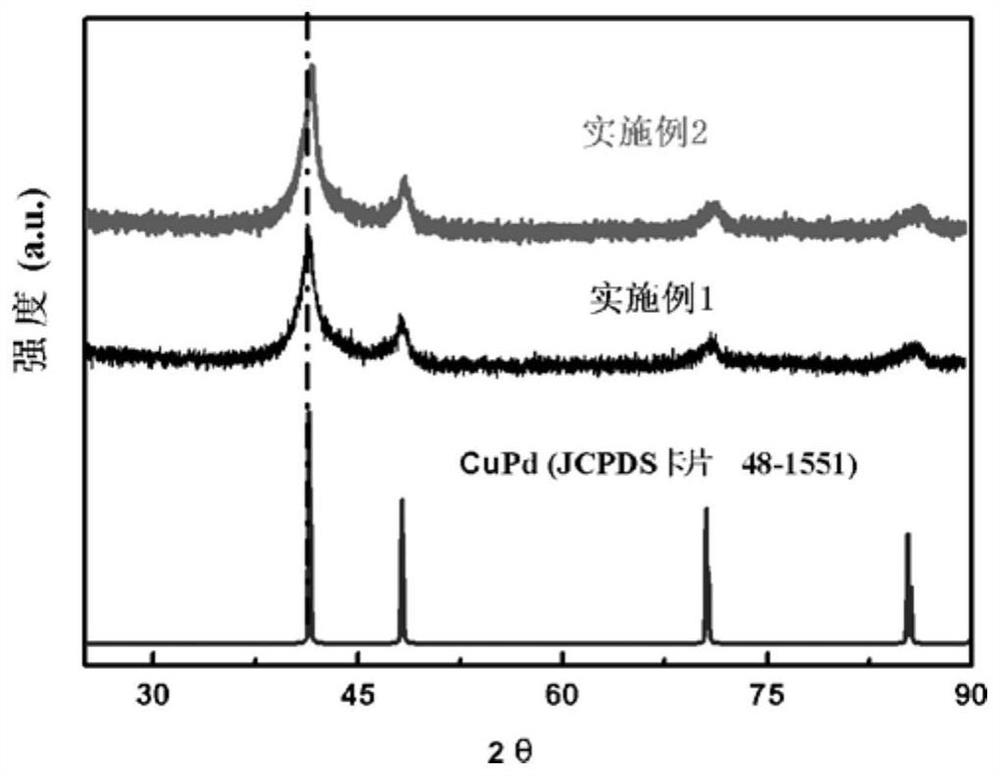

CuPd alloy nanocrystal preparation and component regulation and control method

The invention discloses a CuPd alloy nanocrystal preparation and component regulation and control method, and a synthesis method mainly comprises the following steps: preparing soluble copper salt, adding potassium chloride powder, and uniformly stirring in a high-temperature environment to obtain a mixture 1; dissolving palladium chloride powder in a hydrochloric acid solution at a high temperature, and adding the solution into the mixture 1; and adding an ascorbic acid solution, and carrying out high-temperature stirring reaction for 5-6 hours. The component regulation and control method comprises the step of regulating the dosage of hydrochloric acid and palladium chloride powder in a reaction solution to control the atomic percent of Cu and Pd in the alloy. The method takes water as a solvent, is carried out without gas protection, is simple in operation scheme, and does not add an organic surfactant in synthesis. The component regulation and control method provides a wider space for the application of the CuPd alloy nanocrystals.

Owner:HARBIN UNIV OF SCI & TECH

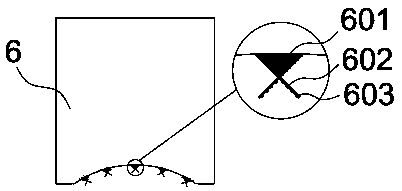

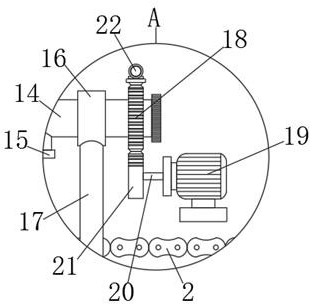

CNC machining equipment for mobile phone battery cover plate and working method of CNC machining equipment

InactiveCN112588676AEasy to processKeep surfaces cleanDrying solid materials without heatCleaningChain linkMobile phone

The invention belongs to the field of mobile phone battery cover plate machining, and relates to the technology of CNC machining equipment, in particular to CNC machining equipment for a mobile phonebattery cover plate and a working method of the CNC machining equipment. The equipment comprises a working platform, wherein a chain conveying mechanism is arranged on the top of the working platform,a cleaning mechanism and a drying mechanism are arranged on the top of an installation frame body, and a belt conveying mechanism is arranged on the top of the working platform; and two symmetrical straight plates are fixedly installed on the top of the working platform, a sliding rail is fixedly installed between the side faces, close to each other, of the two straight plates, a fixing base is movably connected to the outer surface of the sliding rail, and an electric welding mechanism is arranged at the bottom of the fixing base. According to the CNC machining equipment for the mobile phonebattery cover plate and the working method of the CNC machining equipment, the mobile phone battery cover plate can be cleaned by the cleaning mechanism before being machined, impurities on the mobile phone battery cover plate are washed away through spraying liquid sprayed out of a second spraying pipe, the surface of the mobile phone battery cover plate is kept clean during machining, and therefore the machining effect of the mobile phone battery cover plate is improved.

Owner:宜辰光电科技(安徽)有限公司

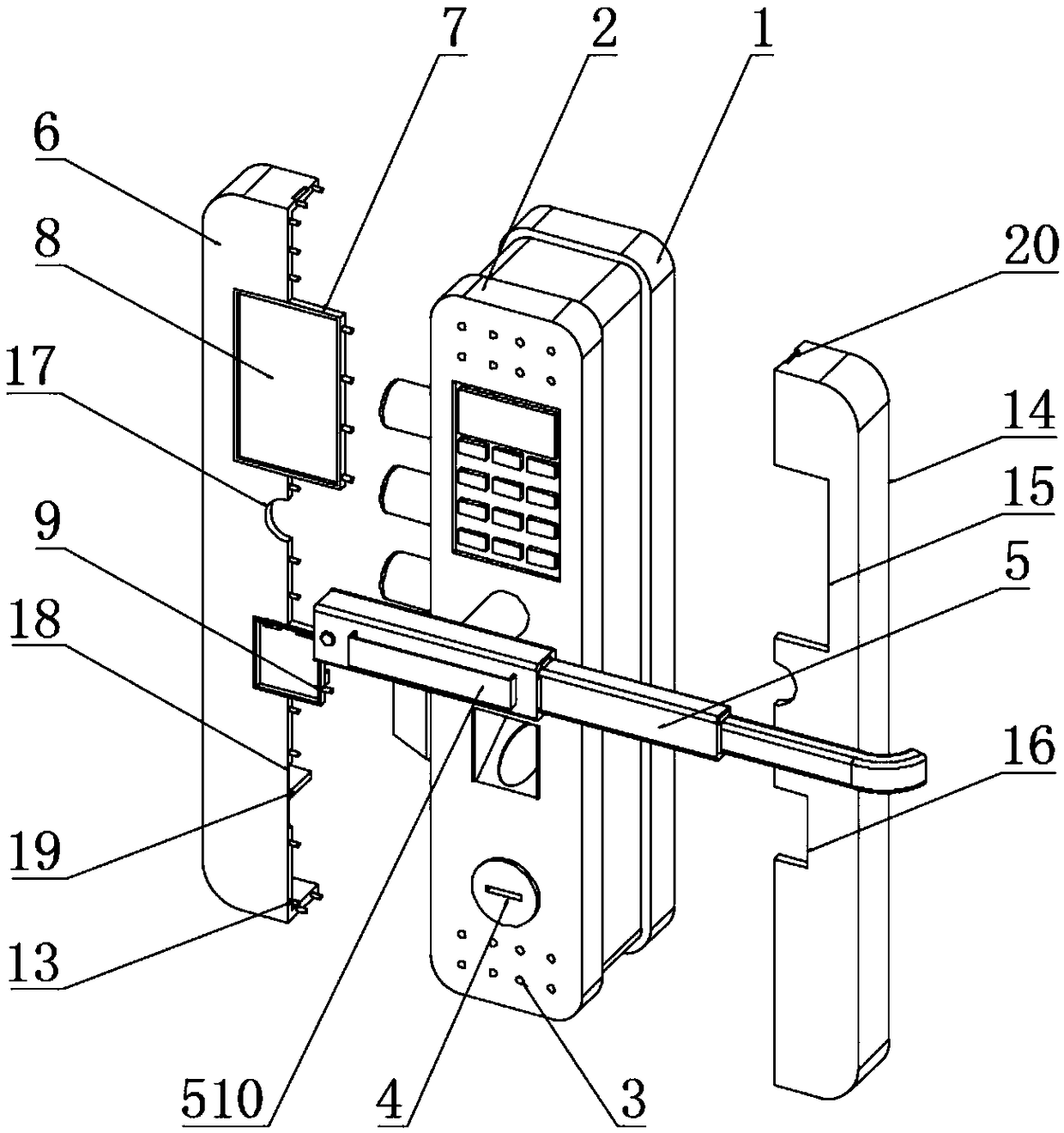

Novel fingerprint lock

InactiveCN108979321AScientific and reasonable structureEasy to useElectric permutation locksIndividual entry/exit registersFingerprint bodiesSurface cleaning

The invention discloses a novel fingerprint lock, which comprises a fingerprint lock body,a front cover plate is arranged on the front side of the fingerprint body, a first protective shell is arranged on one side of the front cover plate, a second protective shell is arranged on the other side of the front cover plate, corresponding to the first protection shell, a push-pull mechanism is arrangedat the middle part of the front cover plate, according to the invention, the structure is scientific and reasonable, the use is convenient, the first protective shell and the second protection shellcan effectively protect the fingerprint lock body and reduce the damage of the front cover plate,an emergency lock head is hidden, so that a lawbreaker is prevented from unlocking by using the emergency lock head; the surface of a fingerprint input device is cleaned by the cleaning block at the bottom of the protective plate, residual fingerprint marks on the surface of the fingerprint input device are avoided, the situation that the fingerprint is stolen and utilized by the lawbreaker is avoided, the surface cleaning of the fingerprint input device is ensured, and the fingerprint is input conveniently and more accurately; the surfaces of a second sleeve and push rod can be cleaned by a doctor blade so as to avoid bacterial carryover and infection caused by different users when the lock isused.

Owner:郴州多特科技发展有限公司

Economical environment-friendly degradable plastic sheet and preparation method thereof

The invention relates to an economical environment-friendly degradable plastic sheet and a preparation method thereof. The economical environment-friendly degradable plastic master batch is composed of polyolefin, calcium carbonate, a photosensitizer, an oxidative degradation agent, a biodegradation control agent, a processing assistant, a coupling agent, a heat stabilizer, a photostabilizer and an antioxidant. The sheet is prepared from the following raw materials in parts by weight: 30 parts of economical environment-friendly degradable plastic master batch, 60-100 parts of activated calcium carbonate, 10-20 parts of short fiber and 0.5-2.5 parts of coupling agent. The invention provides a production method of the economical environment-friendly degradable master batch. The master batch can be mixed with other plastics to process degradable plastic products. Compared with the prior art, the technique for processing the economical environment-friendly degradable sheet adopts abundant calcium carbonate and chopped fibers as the processing raw materials, and thus, ensures the operating requirements of the product on the premise of lowering the production cost. The sheet has high chemical stability (high temperature resistance, water resistance, oil resistance and the like), can be used for packaging in the fields of food, toys, hardware, electronic products and the like, has the advantages of high biological decomposition speed, low cost and the like, and can easily implement industrialization.

Owner:杨建

Environment-friendly paint for purifying air

InactiveCN106010252ANot easy to fall offSimple preparation processAntifouling/underwater paintsRosin coatingsMicrometerPlasticizer

The invention discloses environment-friendly paint for purifying air. The environment-friendly paint is prepared from, by weight, 60-70 parts of rosin resin, 15-18 parts of aloe powder, 12-15 parts of shell powder, 10-12 parts of talcum powder, 0.5-1 part of sumatriptan, 0.12-0.15 part of color black, 2-4 parts of brightener, 5-8 parts of titanium dioxide, 4-6 parts of non-polymer plasticizer, 8-10 parts of stearic acid, 2-4 parts of hydroxyethyl cellulose, 5-7 parts of glycerinum, 3-5 parts of a flatting agent and 0.5-1 part of aluminum powder. Coating particles with the particle size smaller than 1 micrometer can be formed on the surface of coating, smoothness is improved greatly, and surface cleanness can be kept for a long time.

Owner:程巧娜

Aluminum profile for controlling coarse-grained ring and manufacturing method thereof

The invention discloses an aluminum profile for controlling a coarse-grained ring and a manufacturing method thereof. The aluminum profile is prepared from the following elements in percentage by mass: 0.50-0.55% of Si, 0.15% of Fe, 0.01% of Cu, 0.15-0.25% of Mn, 0.54-0.62% of Mg, 0.14-0.2% of Cr, 0.01% of Zn, 0.02% of Ti, less than or equal to 0.15 part of the total content of other impurity elements, and the balance of Al, wherein the mass percentage of Mn+ Cr is 0.3-0.42%. According to the technical scheme, during casting of ingredients, it is better to control the content of Mn+ Cr in 0.32% to 0.34%, and the formation of the coarse-grained ring can be effectively prevented by controlling an ingot structure as a fine isometric crystal; in the extrusion type, a rapid coarse-grained extrusion process is adopted, rapid water-cooling is conducted, the extrusion ratio is controlled between 10 and 20, and the formation of the coarse-grained ring can be reduced; and in the quenching process, the bar diameter is controlled to 520 DEG C / 30-120 min, the coarse-grained ring cannot be deepened, and grains cannot grow coarse.

Owner:郑州明泰交通新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com