Preparation method for multifunctional TiO2 nano-paint

A nano-coating, multi-functional technology, applied in the direction of anti-fouling/underwater coatings, coatings, titanium oxide/hydroxide, etc., can solve the problem of no superhydrophilicity and decomposition of organic matter, poor cleaning effect, and no increase in light Transmittance and the effect of decomposing organic matter and other issues to achieve the effect of improving photoelectric conversion efficiency, avoiding interaction, and increasing effective luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

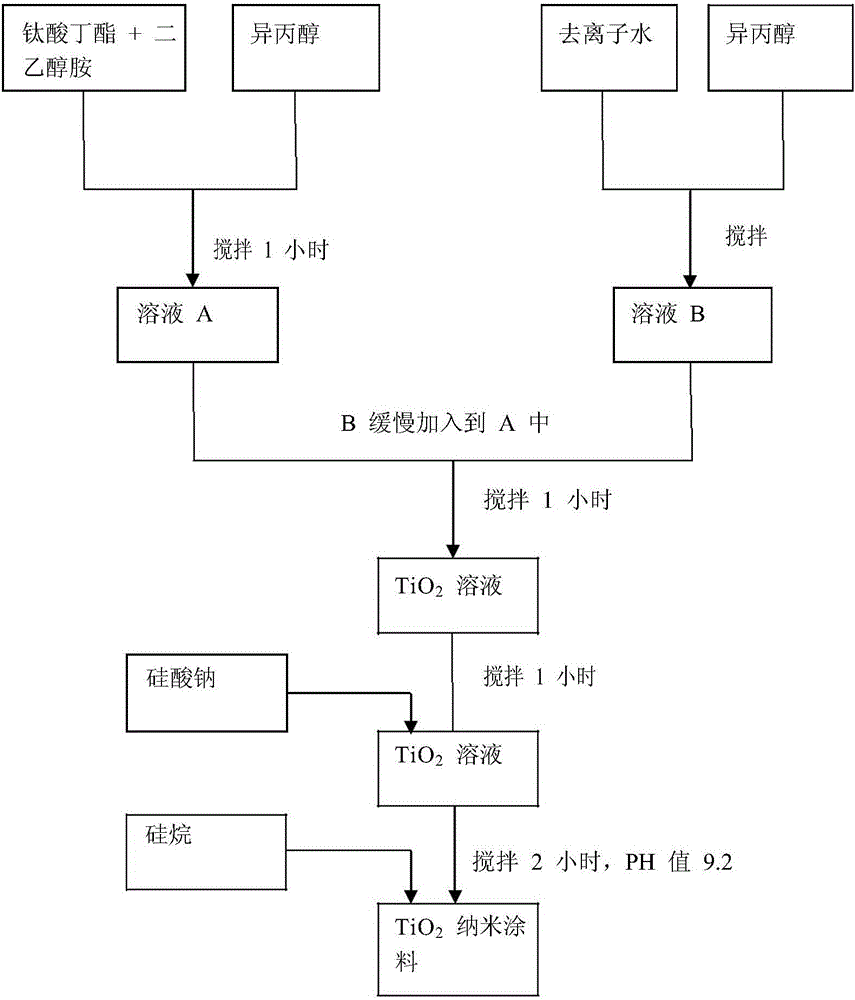

[0089] Embodiment 1 Multifunctional TiO of the present invention 2 The preparation method of nano coating

[0090] 1.1 Test steps:

[0091] Table 1 Multifunctional TiO of the present invention 2 The consumption of each component in the preparation method of nano coating

[0092]

[0093] Table 1 shows the multifunctional TiO of groups 1 to 3 in this example 2 The consumption of each component of nano coating. Taking group 3 as an example, prepare the multifunctional TiO of group 3 in this embodiment according to the following steps 2 Nano coatings.

[0094] (1) Primary TiO 2 Solution preparation:

[0095] The preparation environment is 25°C.

[0096] Mix 40ml of butyl titanate, 10ml of diethanolamine, and 300ml of isopropanol, mix and stir evenly to make solution A, and stir solution A with a stirrer for 1 hour;

[0097] Mix 200ml of isopropanol and 300ml of deionized water, stir evenly to make solution B, slowly add it to the stirring solution A, and keep the cont...

Embodiment 2

[0105] Example 2 The multifunctional TiO prepared by the present invention 2 Effect test of nano-coating on conversion efficiency of photovoltaic modules

[0106] 2.1 Light transmittance detection test

[0107] 2.1.1 Test material: multifunctional TiO prepared according to Example 1 2 Nano coatings, ultra-clear patterned glass for components, commercial TiO 2 self-cleaning products

[0108] 2.1.2 Test steps:

[0109] 1) Roughness test

[0110] 2) Light transmittance comparison test instrument GST3 air flotation spectrophotometer

[0111] 2.1.4 Results

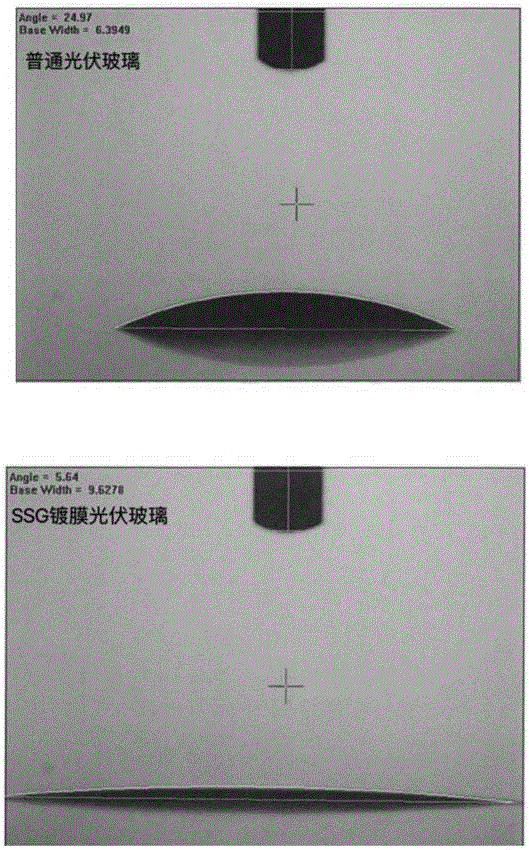

[0112] 1) The surface roughness of the glass is reduced

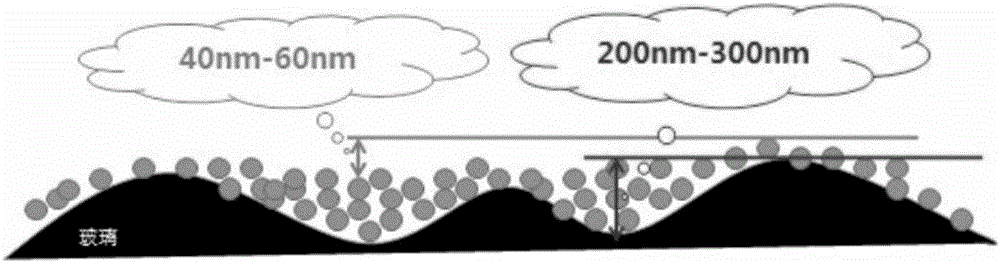

[0113] Surface improvement after spraying see figure 2 . Such as figure 2 As shown, the roughness of the substrate (glass) surface before spraying is 200~300nm, using the multifunctional TiO prepared by the present invention 2 After the nano-coating is sprayed, the roughness is reduced to 40-60nm, thereby reducing the influence of diffuse reflection and incr...

Embodiment 3

[0136] Embodiment 3 Multifunctional TiO of the present invention 2 Photolysis Index Test of Nano Coatings

[0137] 3.1 Test method

[0138] South Germany TUV certification center for testing

[0139] Number: No.70.406.15.189.02-01

[0140] 3.2 Test material:

[0141] Multifunctional TiO prepared according to Example 1 2 Nano-coating, 3 sample components ultra-clear embossed glass

[0142] 3.3 Test procedure: according to JC / T2168-2013 "self-cleaning coated glass" standard, spray the multifunctional TiO prepared according to Example 1 2 The nano-coated photovoltaic module glass is subjected to methylene blue test to test the photolysis index. Six times of irradiation under 3.0±0.10mW / ㎡ of ultraviolet light, each lasting 20 minutes

[0143] 3.4 Results

[0144] According to the standard definition of JC / T2168-2013 "self-cleaning coated glass", the photolysis index represents the photocatalytic multifunctional TiO 2 Numerical values of the photocatalytic properties of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com