Patents

Literature

164results about How to "No deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel slit type spray head and spray coating machine head

InactiveCN102527578AConstant material pressureQuick responseLiquid surface applicatorsCoatingsSpray nozzleEngineering

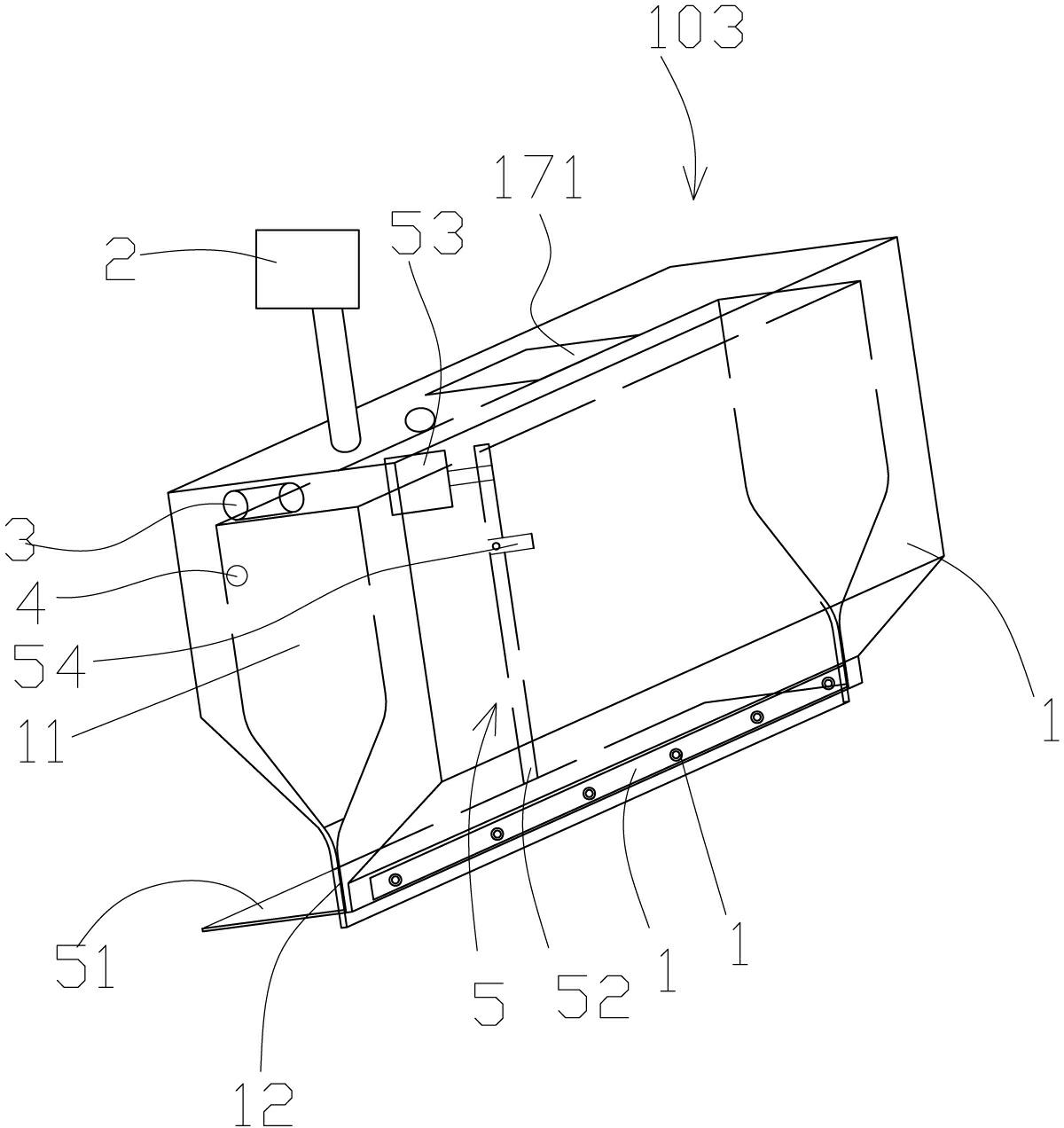

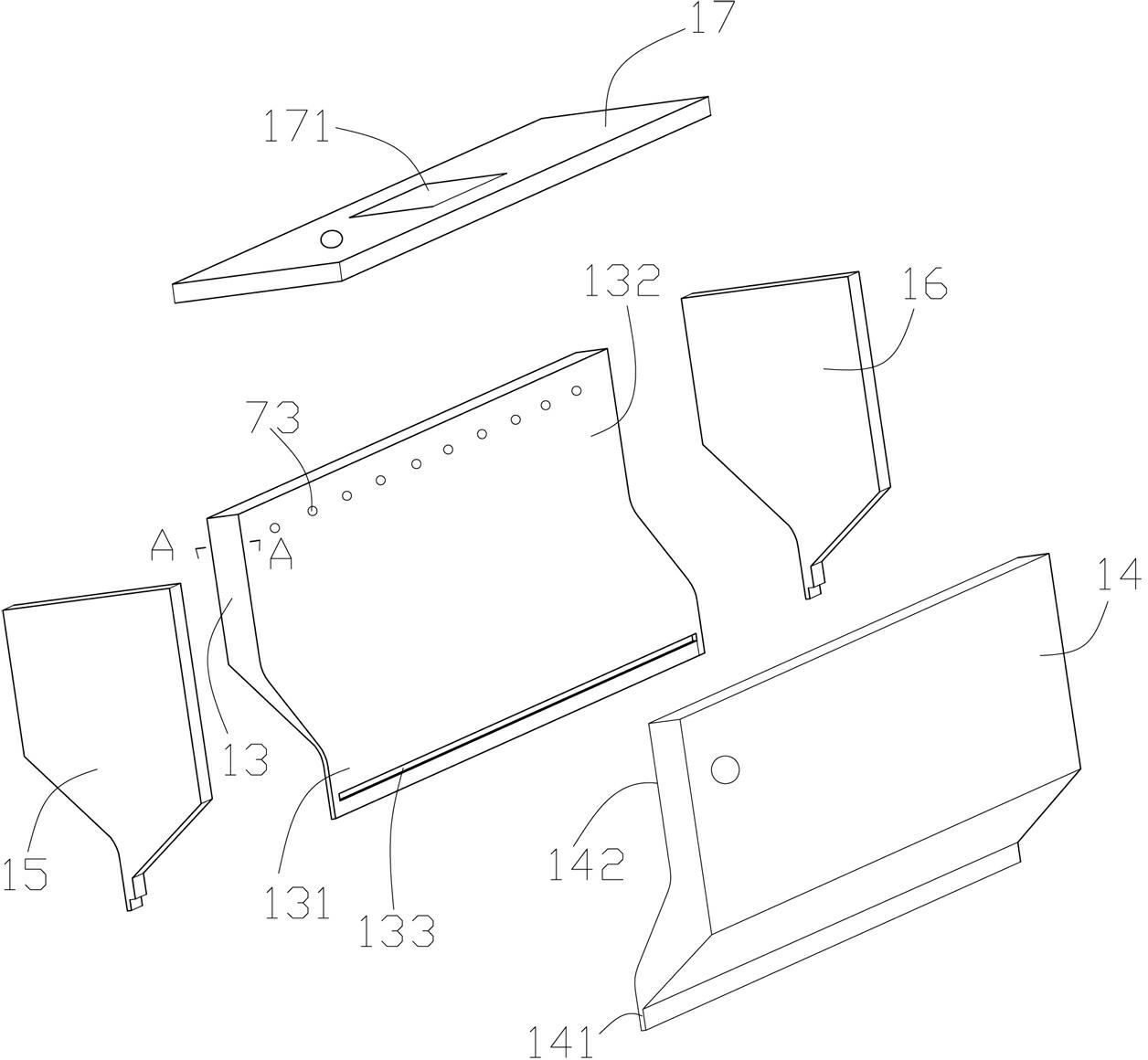

The invention discloses a novel slit type spray head, which comprises a spray head main body, a constant-pressure gas supply system, a slurry supply control system and a slit type spray nozzle switch control device, wherein an accommodation cavity and a slit type spray nozzle are formed in the spray head main body; the accommodation cavity is communicated with the slit type spray nozzle; the constant-pressure gas supply system is used for providing constant-pressure gas for the accommodating cavity; the slurry supply control system comprises a slurry supply device and a liquid level control system; the liquid level control system is used for controlling the operating condition of the slurry supply device according to the liquid level of slurry in the accommodation cavity to keep the liquid level of the slurry in the accommodation cavity constant; and the slit type spray nozzle switch control device is used for opening or closing the slit type spray nozzle according to signals of a main control device. By the novel slit type spray head, the problems of thick starting heads and stripe existence of the original spray coating machine are solved, and the stability and the consistency of gaps among coated electrodes can be ensured. In addition, the invention has the advantages that the novel slit type spray head is easy to manufacture and has low cost.

Owner:SHENZHEN XINYUREN TECH

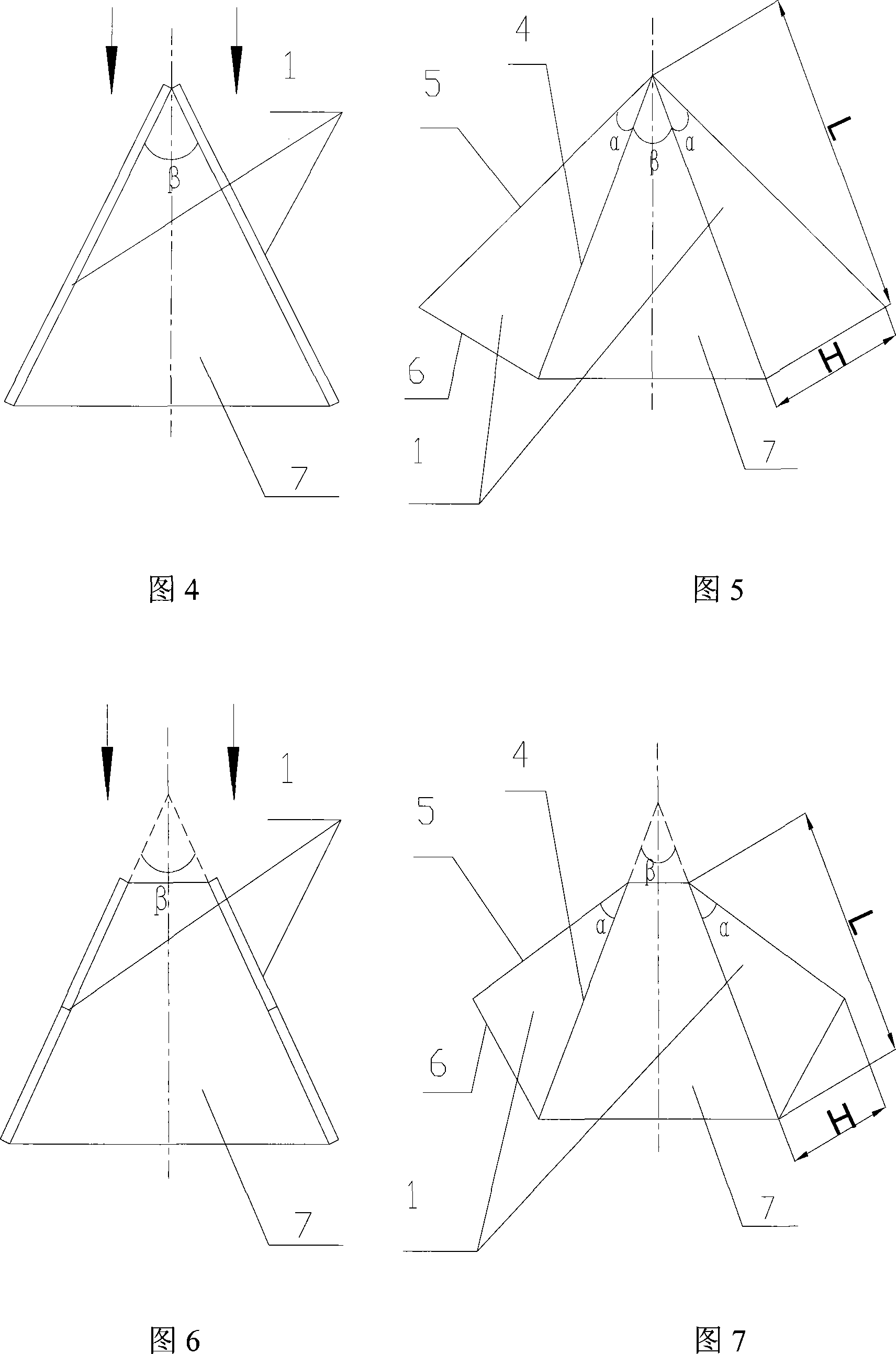

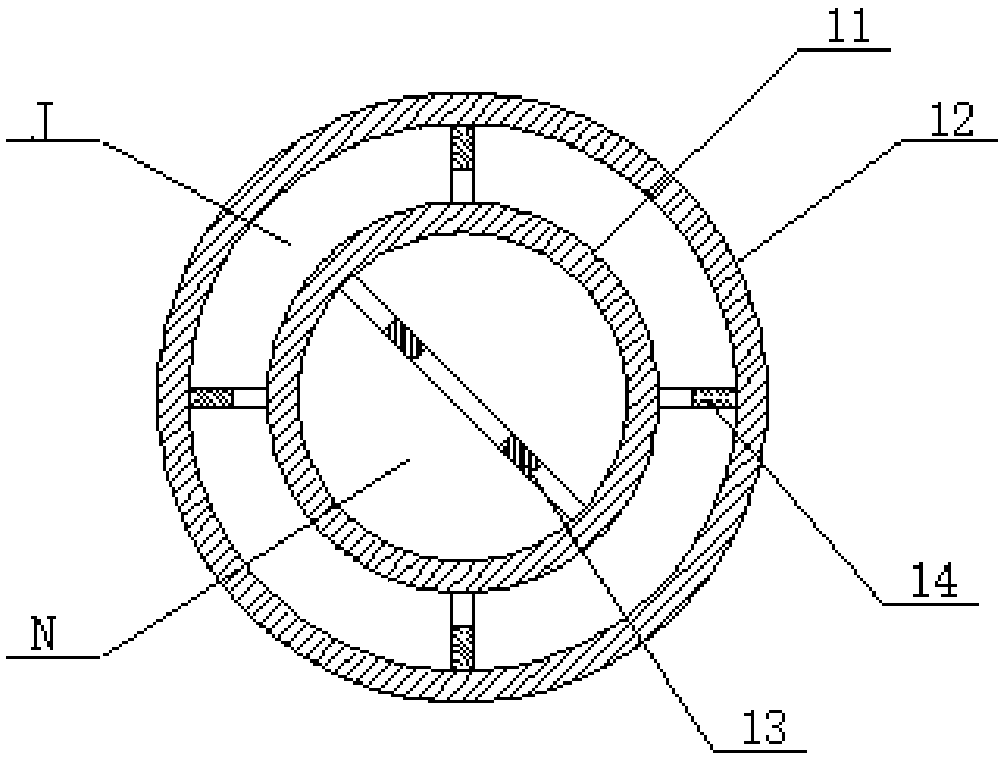

Novel draft-tube and preparation method thereof

InactiveCN101158328AAvoid generatingReduce thicknessFinal product manufactureHydro energy generationEngineeringHigh pressure

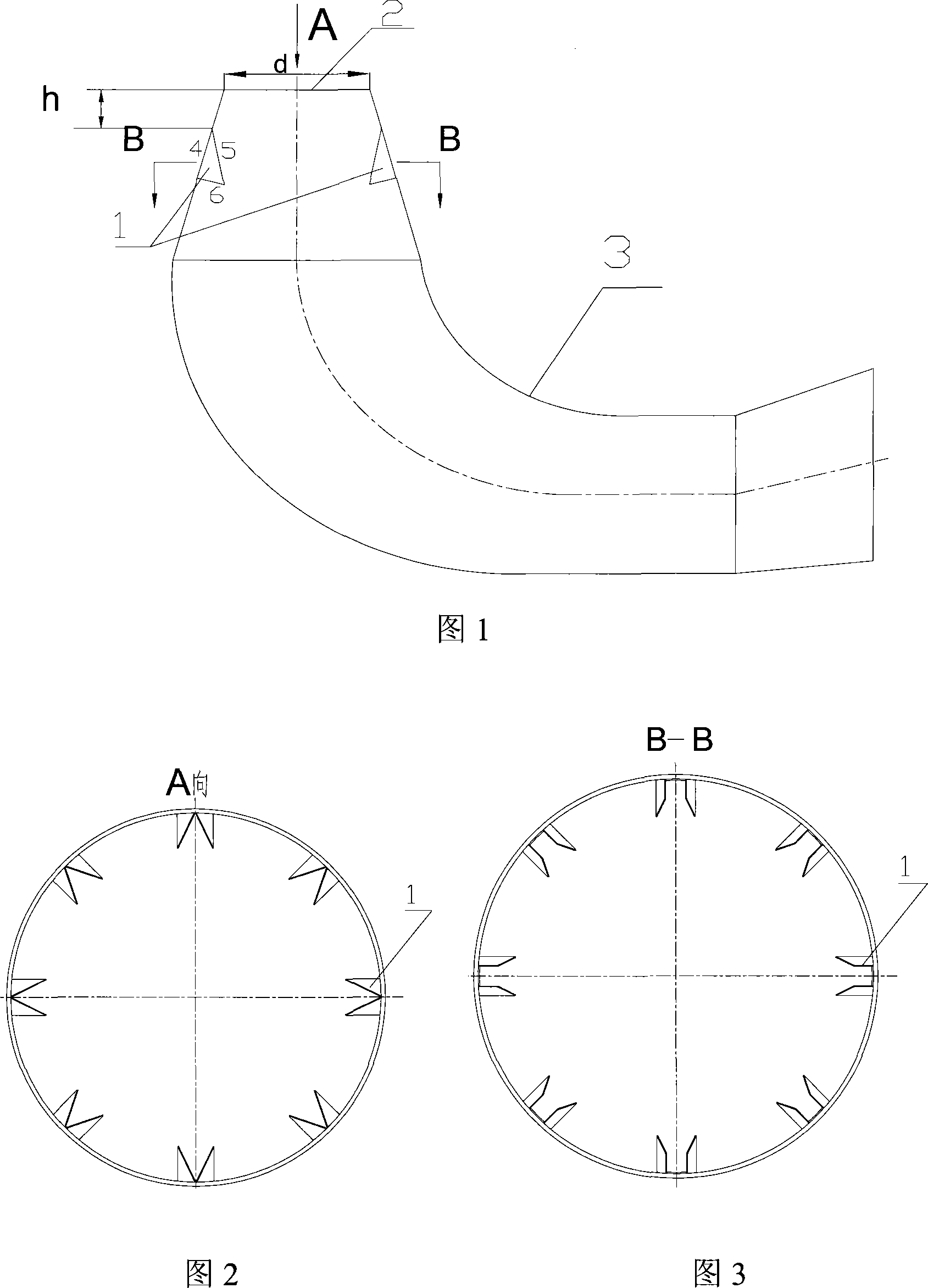

The invention relates to a draft tube used for a hydraulic turbine outlet and a manufacture method of the draft tube. The high pressure recovery coefficient of the draft tube of an existing hydraulic turbine is not enough, and the hydraulic turbine can not stably work with high efficiency. The internal wall of the water inlet of the draft tube body of the invention is fixedly provided with 8-30 triangle leaf pairs in the circumference direction. Each triangle leaf pair comprises two triangle leaves which are symmetrically arranged; each triangle leaf comprises a long edge, a short edge, and an installation edge which is connected with the whole edge of the internal wall of the water inlet; wherein, the long edge is arranged at one side close to the end surface of the water inlet; the short edge is arranged at one side far away from the end surface of the water inlet. The invention has the advantages of simple structure, smart arrangement, cheap cost, and wide applicable range, and can ensure the high-efficient and stable operation of hydraulic generator units with different capabilities on all flux working conditions.

Owner:HANGZHOU DIANZI UNIV

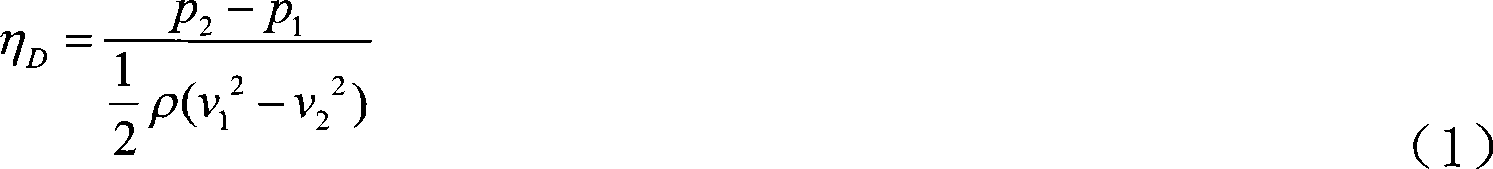

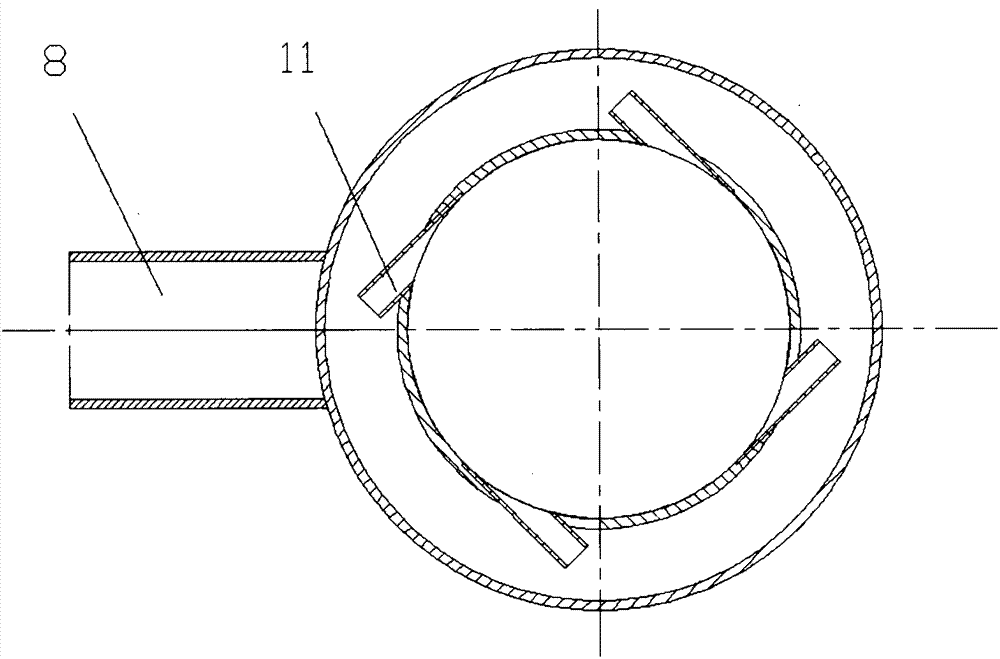

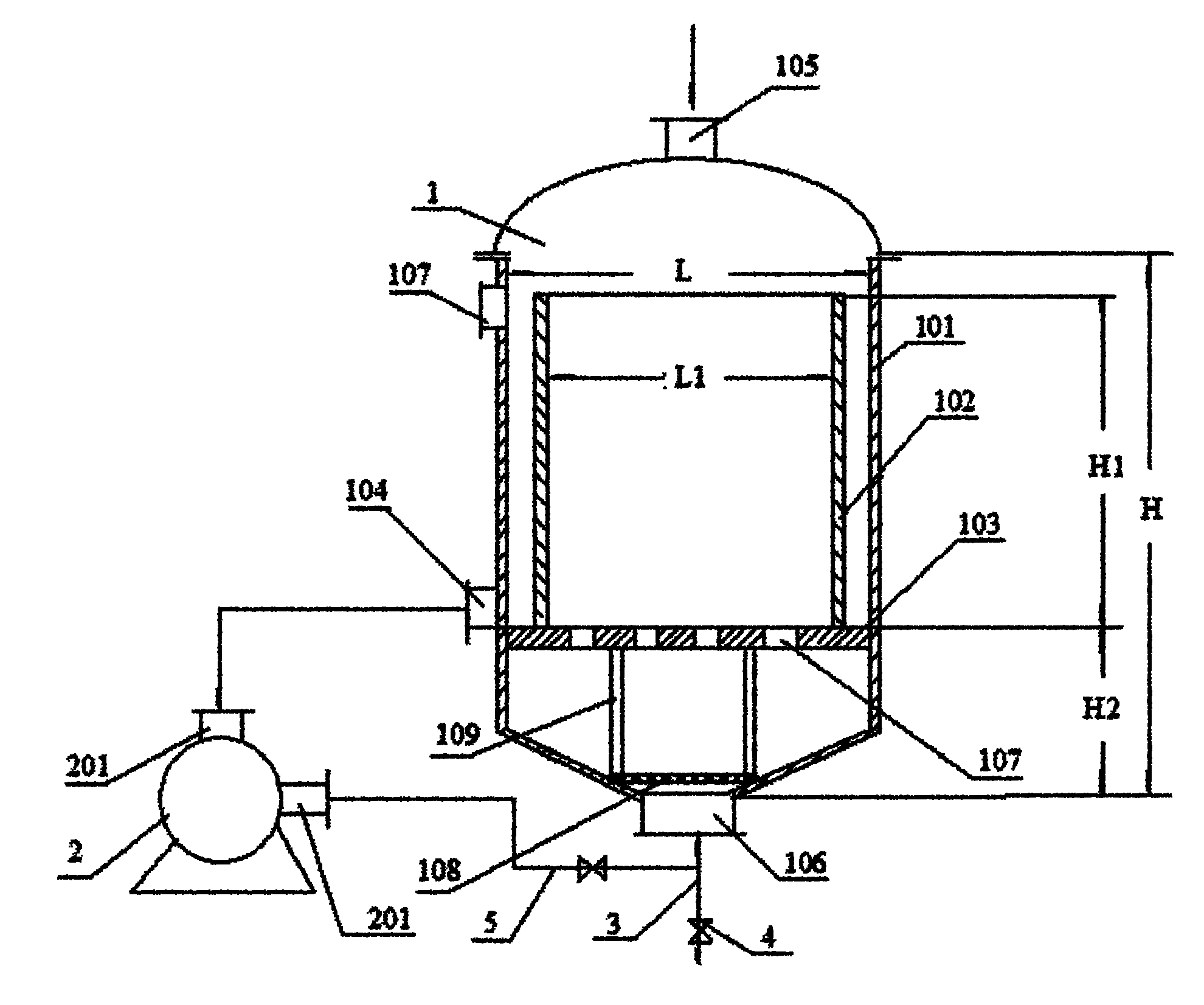

Semi-dry circulating cyclone bed desulfurizing tower

InactiveCN103480268AIncrease shear forceIncrease profitDispersed particle separationCycloneFluidized bed

The invention discloses a semi-dry circulating cyclone bed desulfurizing tower. By providing a tangential exhaust gas inlet structure of the desulfurizing tower, a rotating flow field is established inside the desulfurizing tower so as to sufficient mixing and contact of exhaust gas, so that the desulfurizing reaction process inside the desulfurizing tower is intensified, a desulfurizing agent is sufficiently utilized, the desulfurizing efficiency is improved; and secondary air is arranged to intensify the intensity of a rotating flow, so that separation of gas from solid is achieved inside the desulfurizing tower. By adopting the structure, an external cyclone separator in a conventional circulating fluidized bed desulfurizing process is omitted, so that the semi-dry circulating cyclone bed desulfurizing tower is compact in structure and easy to install and maintain.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Complex vacuum deposition device

InactiveCN101768727AOptimize working rangeReduce Coating DefectsVacuum evaporation coatingSputtering coatingDirect current magnetron sputteringGas pipeline

The invention relates to a complex vacuum deposition device which consists of a vacuum chamber 4, a cathodic arc evaporation source 2, a middle frequency magnetron sputtering source 7, a direct current magnetron sputtering source 8, a gas ion source 10, a workpiece rest 3 and the like; a gas extraction port 1 is formed at the back of the vacuum chamber 4, the cathodic arc evaporation source 2 is mounted on the vacuum chamber wall which is near to the gas extraction port 1, the middle frequency magnetron sputtering source 7 is mounted on the vacuum chamber wall in the middle position of the two sides of the vacuum chamber 4, and the direct current magnetron sputtering source 8 is mounted on a front door 9 of the vacuum chamber; the gas ion source 10 is mounted in the central position of the vacuum chamber 4, reaction gas is introduced into the gas ion source 10, an ion beam is sprayed to the direction of the gas extraction port 1, and baffle plates 5 of the gas ion source are arranged at the back part and on the side surface of the ion source 10; and working gas is introduced into the vacuum chamber 4 through a working gas inlet pipeline 6 which is in the vicinity of the middle frequency magnetron sputtering source 7 and the direct current magnetron sputtering source 8. The arrangement can form the ideal reaction gas concentration distribution in the vacuum chamber, thereby fully playing the advantages of various film-forming sources and significantly inhibiting the defects of thin films.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Low-conductivity nanofluid and preparation method thereof

The invention relates to a low-conductivity nanofluid and a preparation method thereof, belonging to the field of electrical and electronic equipment cooling. The conductivity of the nanofluid is less than 1 microsecond / cm; and the nanofluid comprises the following components in mass percentage: 40.0-99.0% of ultrapure water, 0.0-60.0% of dihydric alcohol, 0.1-10.0% of nanopowder and 0.01-3.0% of dispersing agent. The preparation method comprises the following steps of: dispersing the calcined nanopowder into ultrapure water, removing charged foreign ions, coating the dispersing agent on the surfaces of nanoparticles, and removing foreign ions again to obtain the low-conductivity nanofluid. Compared with the conventional cooling liquid, the nanofluid is high in heat exchanging capability and significant in technical advantages.

Owner:QINGDAO UNIV OF SCI & TECH

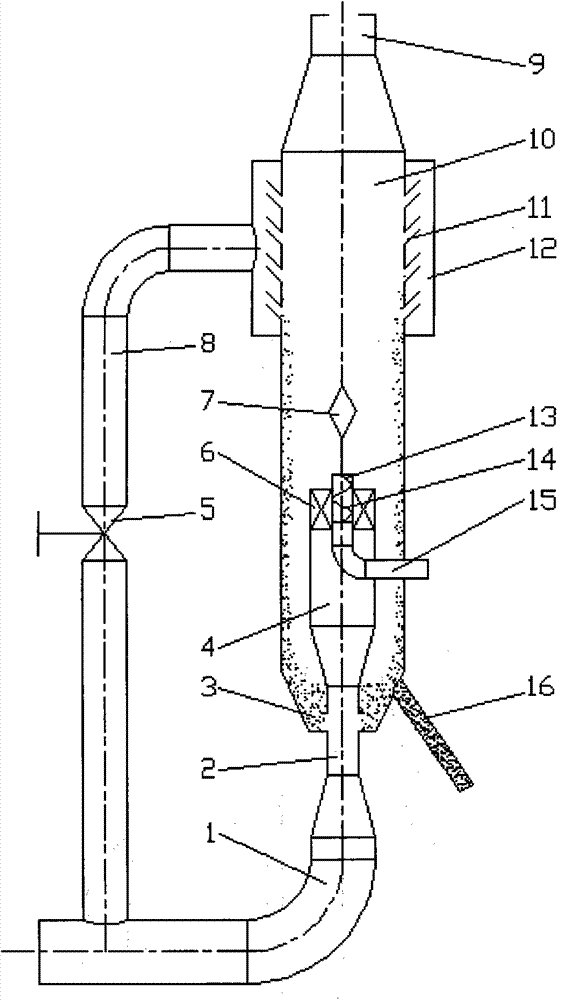

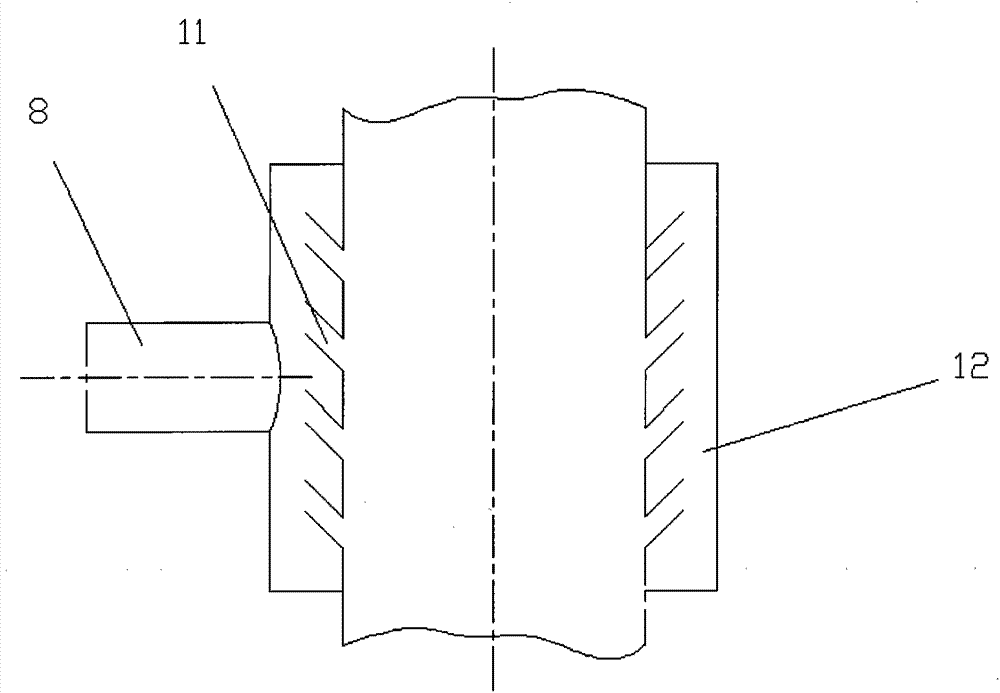

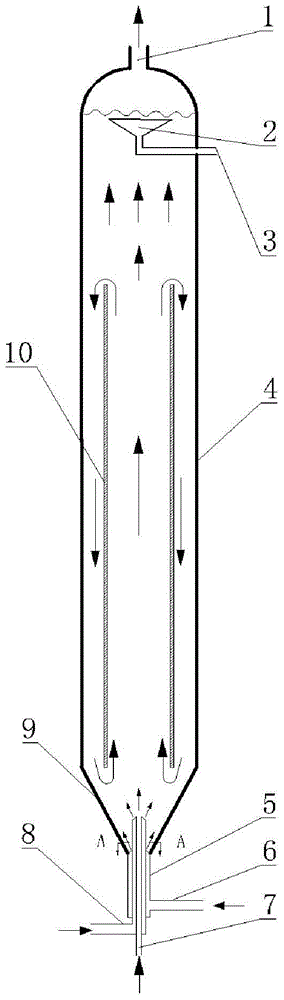

Double-solid-phase suspended bed reactor used for heavy oil hydrocracking and application thereof

ActiveCN105727845AImprove efficiencyHigh activityHydrocarbon oil crackingChemical/physical processesSolid phasesLow activity

The invention discloses a double-solid-phase suspended bed reactor used for heavy oil hydrocracking.The reactor comprises a shell, a conical bottom, a flow guide cylinder and a nozzle.A material outlet is formed in the top of the shell, the conical bottom is arranged at the bottom of the shell, the flow guide cylinder is coaxially arranged in the shell, the two ends of the flow guide cylinder are provided with openings, and the nozzle is disposed at the bottom of the conical bottom.The nozzle is provided with a loosening gas outlet hole, a driving gas outlet and a liquid outlet.The loosening gas outlet hole is close to the bottom of the conical bottom, and the driving gas outlet and the liquid outlet are higher than the loosening gas outlet hole.The invention further discloses application of the double-solid-phase suspended bed reactor to the heavy oil hydrocracking technology.According to the reactor, two catalysts with different particle sizes are used at the same time, the low-activity micron-size fine particle catalyst has the coke and metal adsorbing function and is discharged along with liquid-phase materials during operation, the high-activity micromicron-size coarse particle catalyst maintains high activity in reaction all the time and stays in the reactor for a long time to participate in reaction, and use efficiency of the catalysts is improved.

Owner:ZHEJIANG UNIV

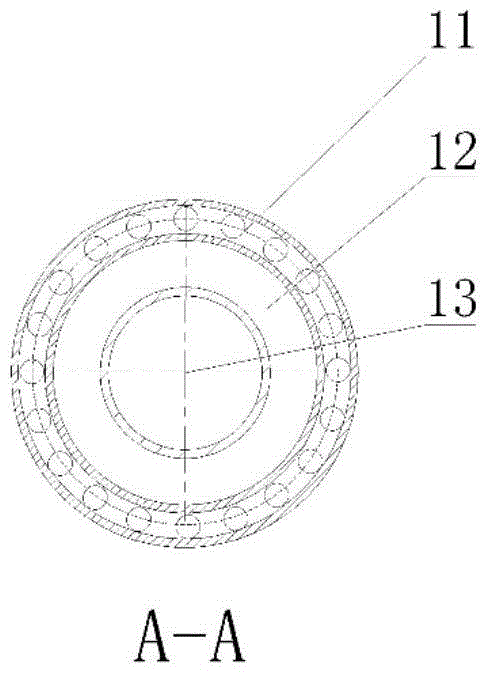

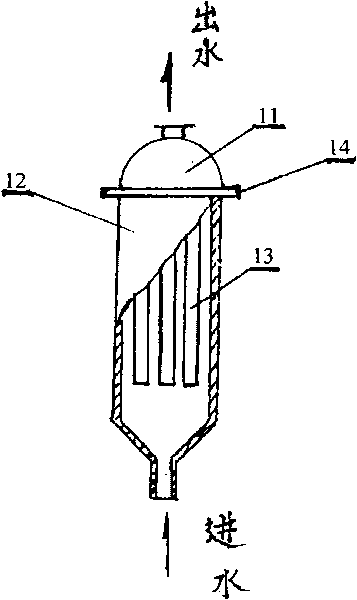

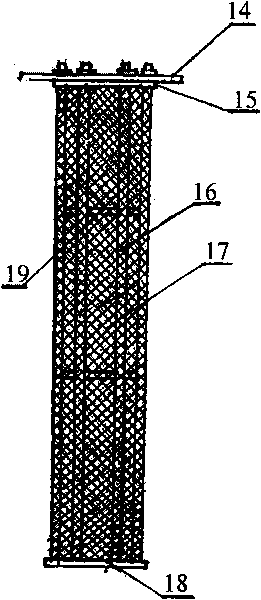

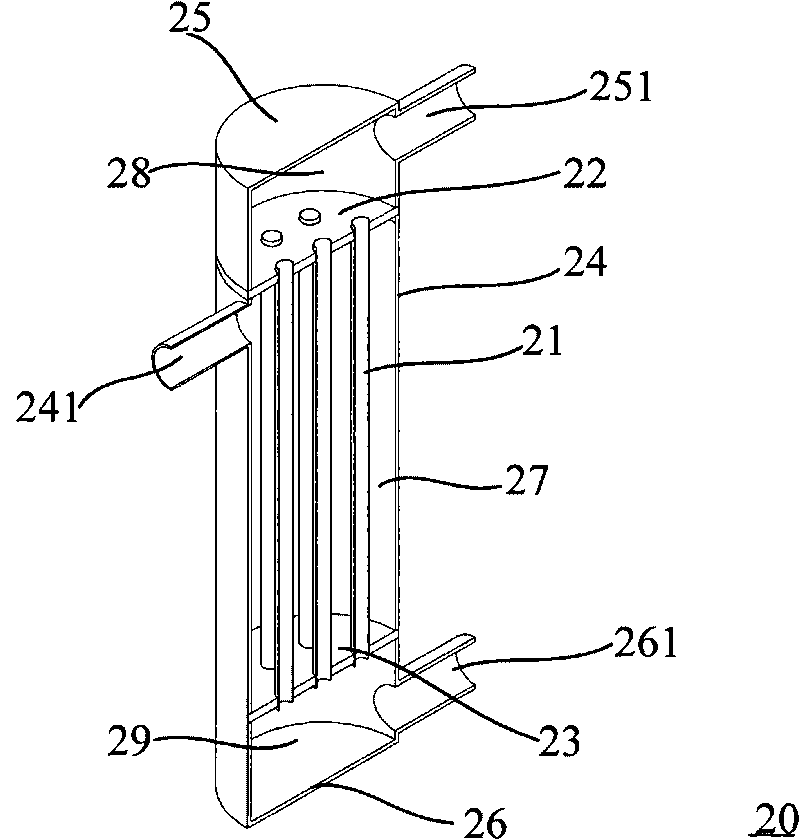

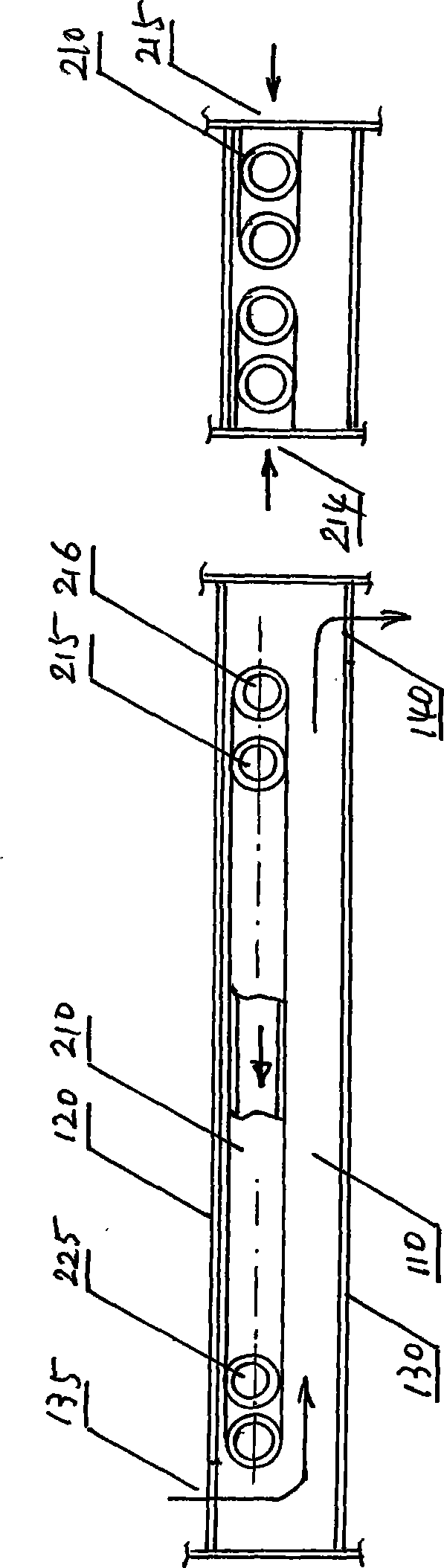

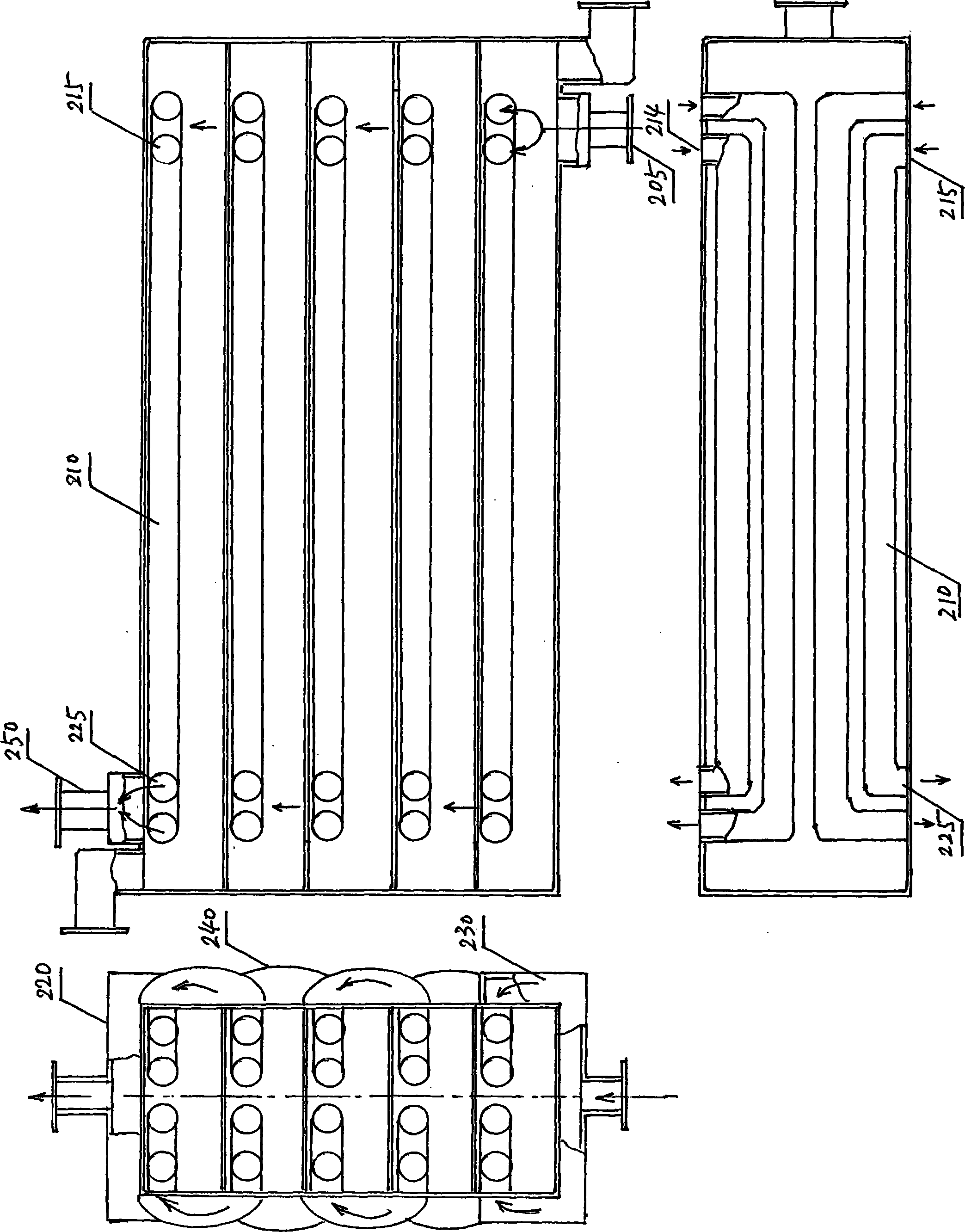

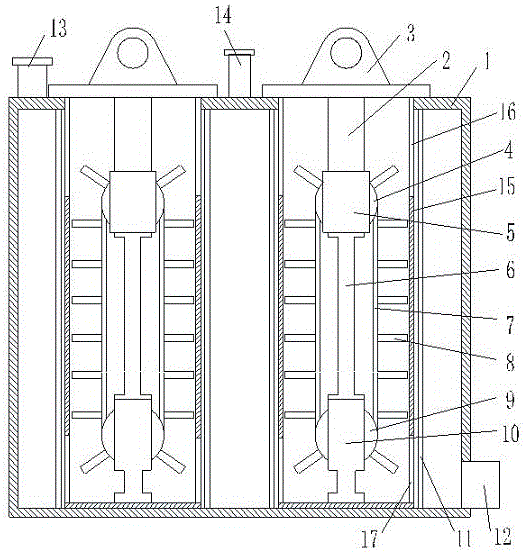

Multi-pipe internal pressure mechanical circulation forced cross current solid-liquid separation dynamic membrane system and device thereof

InactiveCN101757854AIncrease water pressureUniform thicknessSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisVena contracta diameterWork period

The invention relates to a multi-pipe internal pressure mechanical circulation forced cross current solid-liquid separation dynamic membrane system and a device thereof; wherein the dynamic membrane comprises a tubular shape internal pressure supporting body with plural number of large aperture nets, an upper orifice plate and a lower orifice plate, a shell, an upper cover and a lower cover; the upper orifice plate and the lower orifice plate are respectively provided with plural number of jack sockets, the tubular shape internal pressure supporting body is connected with the jack sockets; the shell is connected with the upper orifice plate and the lower orifice plate to form a water purification chamber; the upper cover and the upper orifice plate are connected to form a cross current backflow chamber, and the upper cover is provided with an water outlet for the cross current backflow water; the lower cover and the lower orifice plate are connected to form a water inlet chamber and the lower cover is provided with a raw water inlet thereupon. The dynamic membrane device of the invention has the advantages of no water power dead angle, short pre-coating time, convenient back wash, continuous work, improved dynamic membrane flux, stable water yield and long work period.

Owner:上海臻泓环境科技工程有限公司

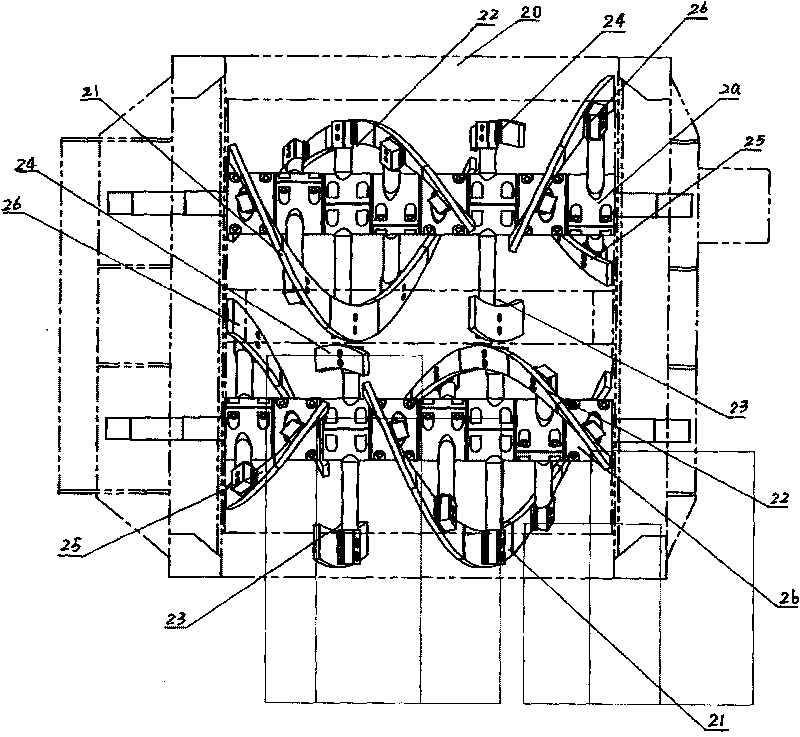

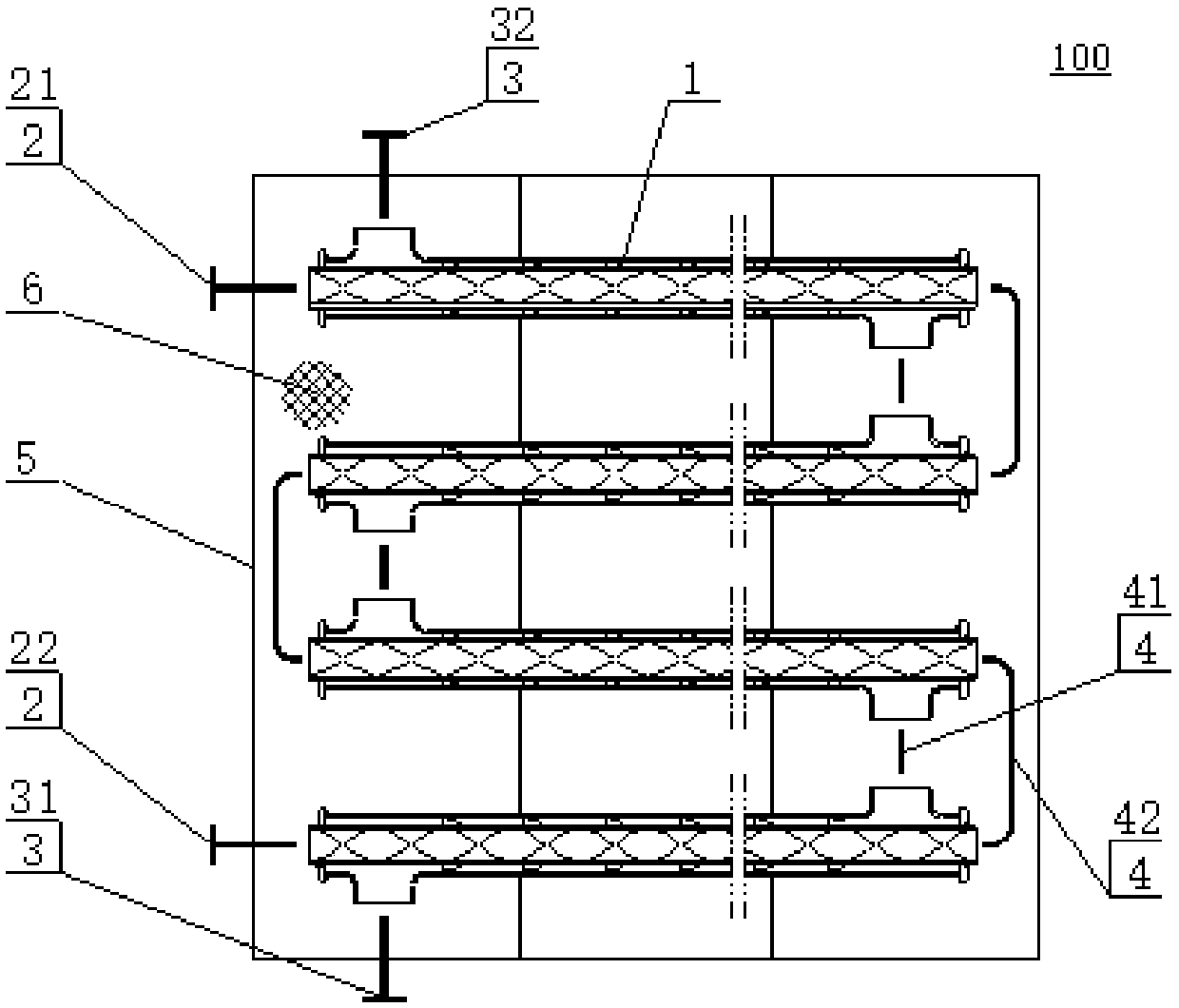

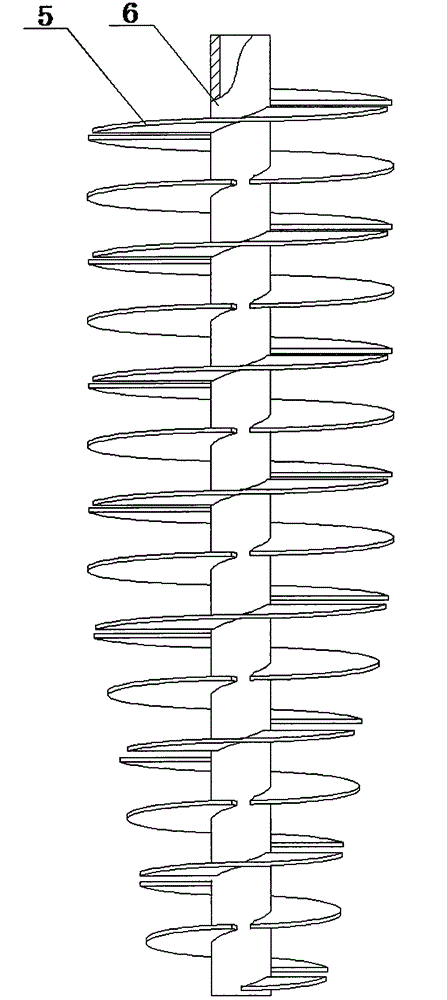

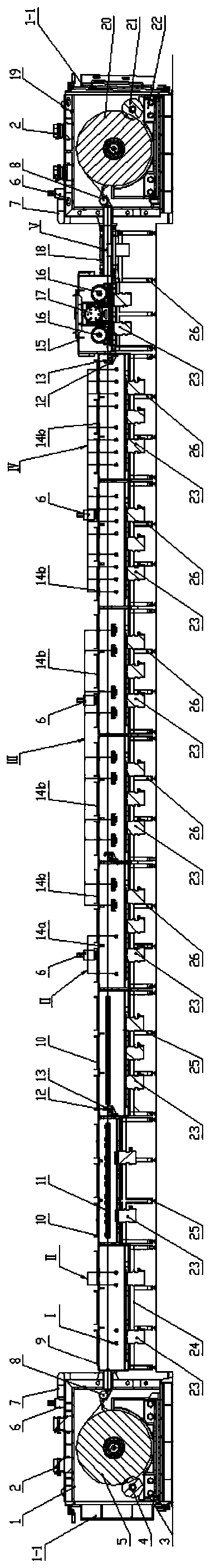

Horizontal four-axis blender

InactiveCN101757866ANo depositionNo unstirred homogeneous depositionTransportation and packagingRotary stirring mixersHorizontal axisCoaxial line

The invention discloses a horizontal four-axis blender, and relates to a blender for high-sticky materials, or cement or other light materials which runs along a horizontal or basically horizontal axis. The invention provides a horizontal four-axis blender with the advantages of high blending efficiency, lower energy consumption, and broader applicable scope, in which materials can flow more smoothly. The horizontal four-axis blender is provided with a body, a left blending system, and a right blending system; the left blending system is provided with a left outer blending mechanism, and a left inner stirring mechanism which are horizontally arranged; the left inner blending mechanism is internally arranged in the left outer blending mechanism, and is axial with the left outer blending mechanism; the right blending system is provided with a right outer blending mechanism, and a right inner stirring mechanism which are horizontally arranged; the right inner blending mechanism is internally arranged in the right outer blending mechanism, and is axial with the right outer blending mechanism; and the left outer blending mechanism and the right outer blending mechanism are crossly arranged along different axial directions, with different rotating directions and consistent rotating speeds.

Owner:蔡达棋

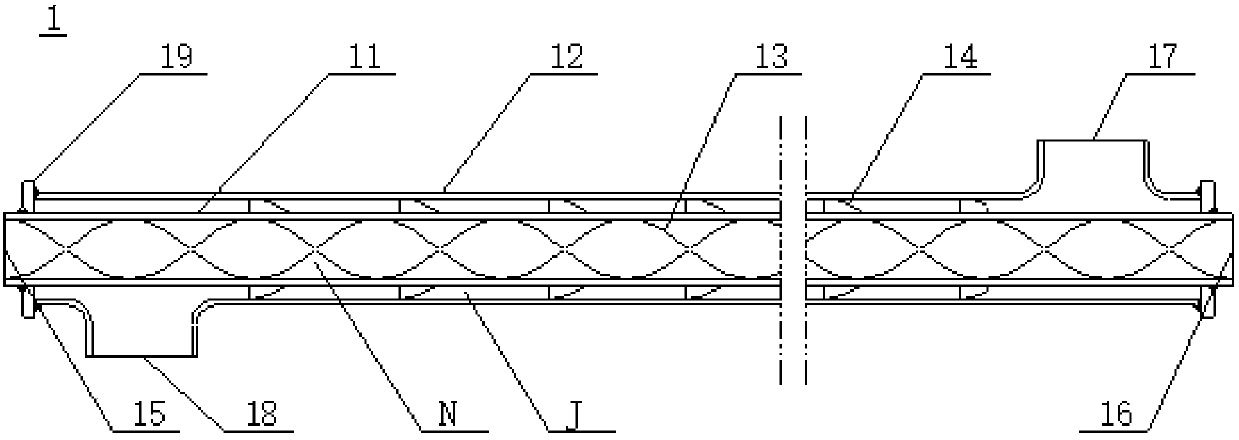

Double-pipe heat transfer enhancement unit component and penetrating hybrid cyclone efficient double-pipe heat exchanger

ActiveCN107764099AReduced delivery power consumptionReduce heating energy consumptionHeat exchanger casingsStationary tubular conduit assembliesCycloneSocial benefits

The invention discloses a double-pipe heat transfer enhancement unit component and a penetrating hybrid cyclone efficient double-pipe heat exchanger. The double-pipe heat transfer enhancement unit component comprises an inner pipe, an outer pipe, an inner pipe twisting reinforcement part and an inter-pipe twisting reinforcement part, wherein an inner cavity allowing sludge to circulate therein isdefined in the inner pipe; the outer pipe sleeves the inner pipe; an outer cavity allowing sludge to circulate therein is defined between the outer pipe and the inner pipe; a first circulation openingis formed in the inner pipe twisting reinforcement part; and a second circulation opening is formed in the inter-pipe twisting reinforcement part. According to the double-pipe heat transfer enhancement unit component of the embodiment, two heat exchange fluids can conduct complicated flowing including spirally rotary flowing and porous penetrating hybrid flowing, so that the heat exchange fluidsare prevented from bias flowing, precipitation, cementation and blockage, mud-mud long-term stable and efficient heat exchange can be realized, the sludge conveying flow resistance and the pumping power dissipation are remarkably reduced, and accordingly, remarkable energy-saving economic benefits and environment-friendly social benefits can be achieved in sludge treatment.

Owner:TSINGHUA UNIV

Glyphosate assistant and preparation method thereof

InactiveCN103109801AReduce manufacturing costImprove liquidityBiocideGroup 5/15 element organic compoundsSulfite saltGlyphosate

The invention discloses a glyphosate assistant and a preparation method thereof. The glyphosate assistant comprises the following raw materials in percentage by weight: 15-30% of anhydrous sodium sulfite, 10-15% of sulphamic acid or sodium borate, 40-60% of ammonium bicarbonate, 5-10% of catalyst and 4-15% of surfactant; the glyphosate assistant can convert glyphosate active compound into glyphosate soluble powder under the condition of normal temperature and normal pressure; the prepared soluble powder is dry, and the expanding or moisture absorption is avoided; the preparation method mainly comprises the steps of preparing surfactant, catalyst and product; and the preparation method is simple and practicable.

Owner:段凤羽

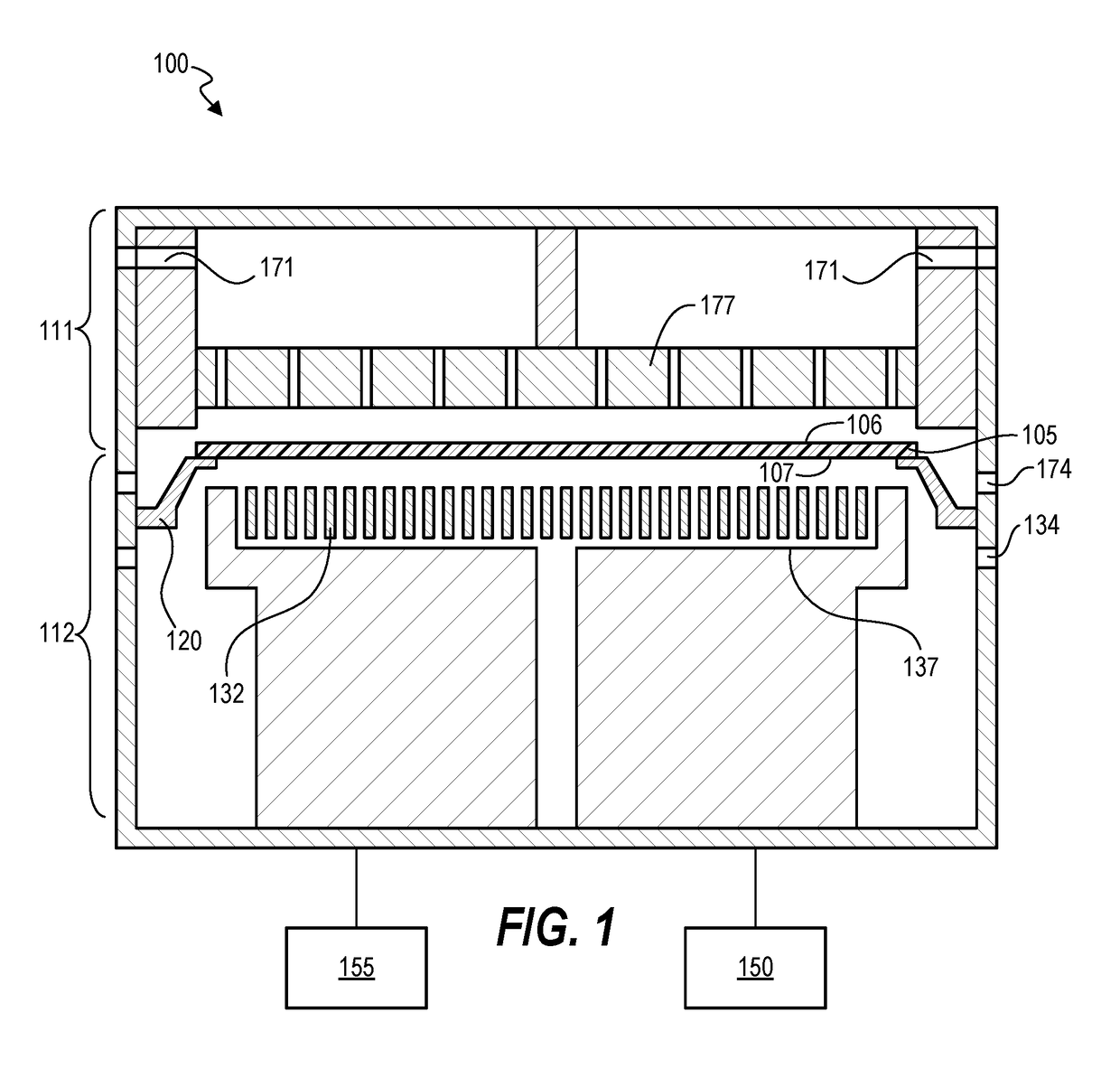

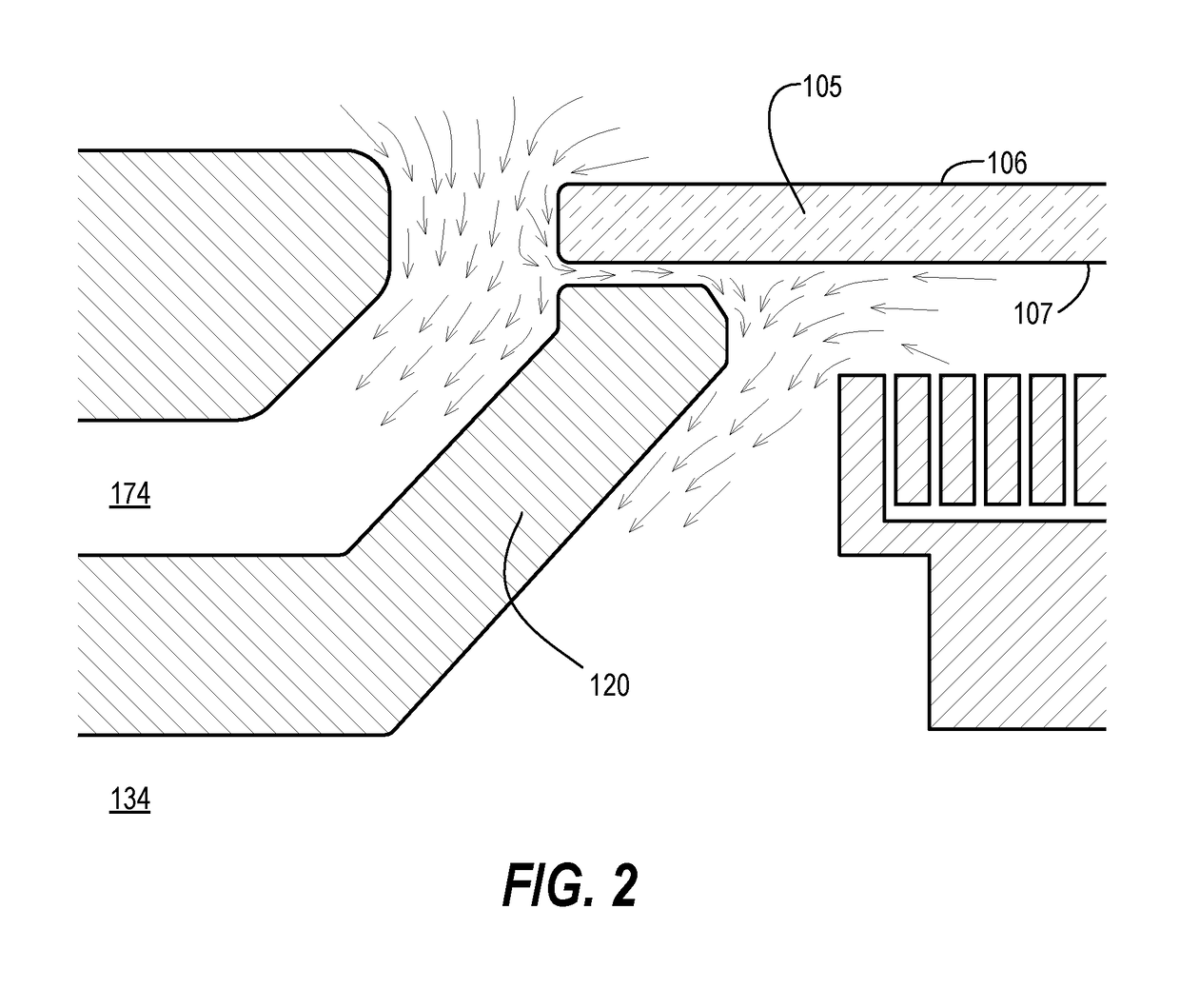

System and method for backside deposition of a substrate

PendingUS20190035646A1Small feature sizeImprove device densityElectric discharge tubesSemiconductor/solid-state device manufacturingDifferential pressureEngineering

Techniques herein include a process chamber for depositing thin films to backside surfaces of wafers to reduce wafer bowing and distortion. A substrate support provides an annular perimeter seal around the bottom and / or side of the wafer which allows the majority of the substrate backside to be exposed to a process environment. A supported wafer separates the chamber into lower and upper chambers that provide different process environments. The lower section of the processing chamber includes deposition hardware configured to apply and remove thin films. The upper section can remain a chemically inert environment, protecting the existing features on the top surface of the wafer. Multiple exhausts and differential pressures are used to prevent deposition gasses from accessing the working surface of a wafer.

Owner:TOKYO ELECTRON LTD

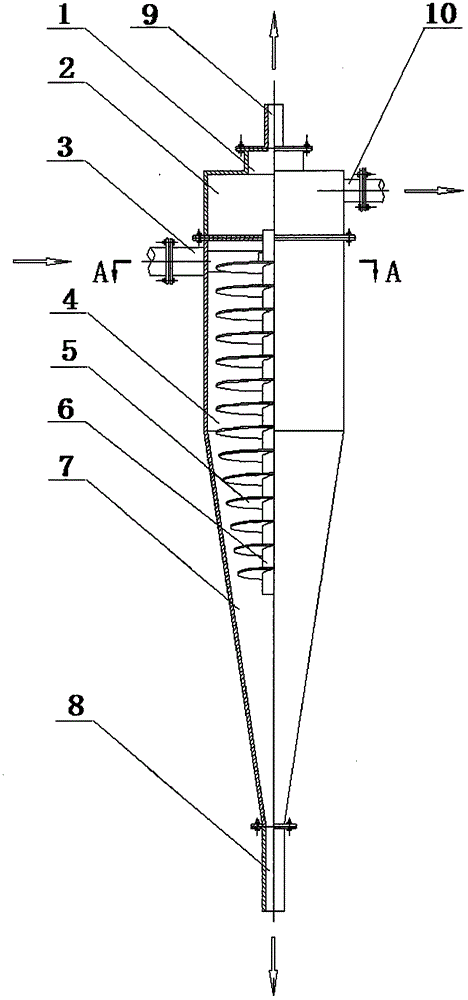

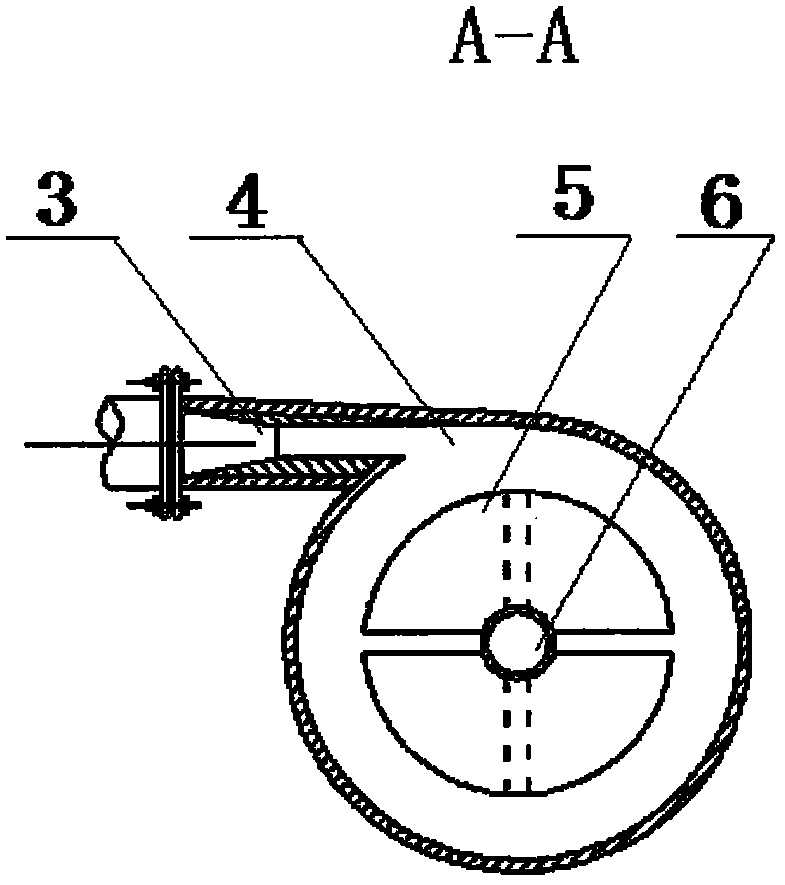

Spiral-flow type electric dehydrator for crude oil

InactiveCN104531204AImprove dehydration efficiencyReduce volumeDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansCycloneElectricity

The invention discloses a spiral-flow type electric dehydrator for crude oil. The spiral-flow type electric dehydrator is characterized by comprising an air collection chamber, an oil collection chamber, an oil inlet pipe, a cylindrical section, plate electrodes, an overflow pipe, a conical section, a dehydrated water discharging pipe, an exhaust pipe, a dehydrated oil discharging pipe, wherein the plate electrodes are arranged in a spiral mode along the periphery of the overflow pipe, and every two adjacent plate electrodes are installed in a staggered mode. According to the spiral-flow type electric dehydrator for crude oil, the hydraulic cyclone technique is adopted, crude oil dehydrating efficiency is improved, the size of the dehydrator is reduced, and crude oil dehydrating time is shortened.

Owner:承德石油高等专科学校

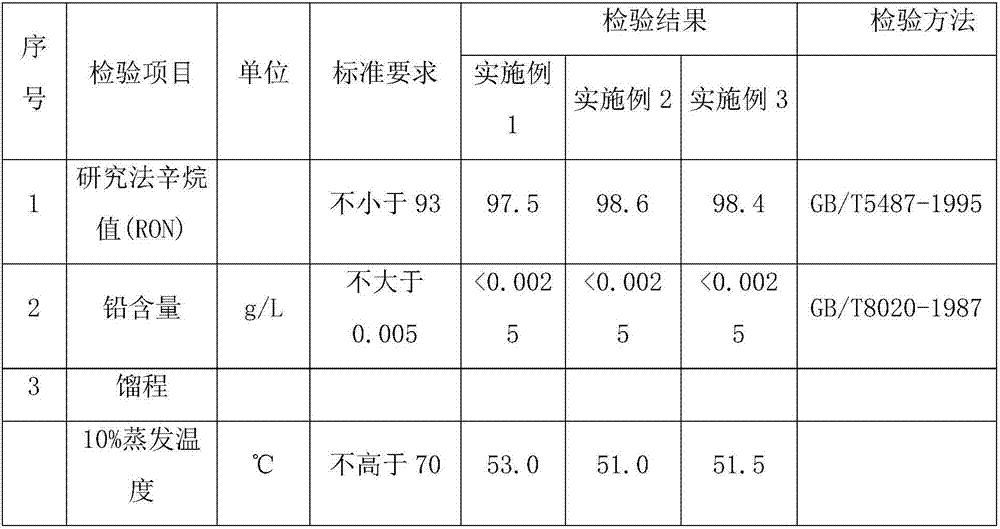

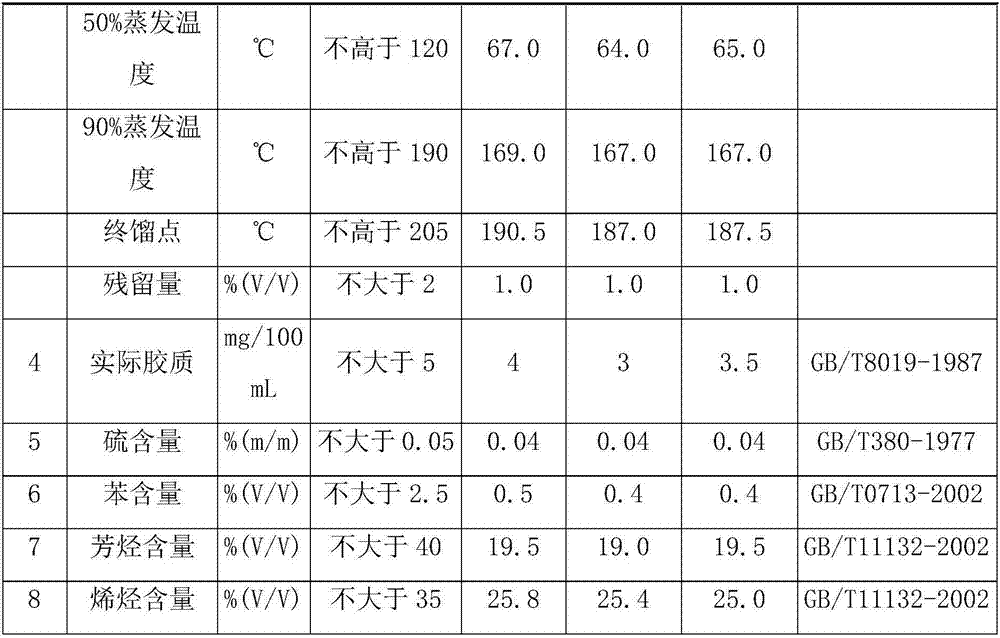

Gasoline additive and production method thereof

InactiveCN107987903AGood miscibilityNo delaminationLiquid carbonaceous fuelsFuel additivesOil additiveMethanol

The invention provides a gasoline additive and a production method thereof. The gasoline additive is prepared from the main components as follows: 0.01 to 0.5 percent of nano particle complex, 4 to 15percent of surfactant, 20 to 35 percent of combustion aid, 1 to 3 percent of octane value improver, 5 to 10 percent of methanol, and 40 to 65 percent of ethanol. The invention also provides a preparation method of nano gasoline additive. The preparation method comprises the following steps: adding nano particles into an ethanol solution of a complexing agent, heating to 35 to 55 DEG C, stirring for 30 to 60 minutes at a stirring speed of 100 r / min, uniformly mixing, cooling to the room temperature, and preparing a nano particle complex; and adding the obtained nano particle complex into anhydrous ethanol, then successively adding methanol, surfactant, combustion aid and octane value improver, stirring for 60 to 120 minutes at the room temperature at a stirring speed of 100r / min, uniformlymixing, thus obtaining the nano gasoline additive. The raw materials used in the gasoline additive of the invention are low in price, the gasoline additive is economical, practical, easy in popularization, and the economic benefit and the social benefit are significant.

Owner:宁波高新区州致科技有限公司

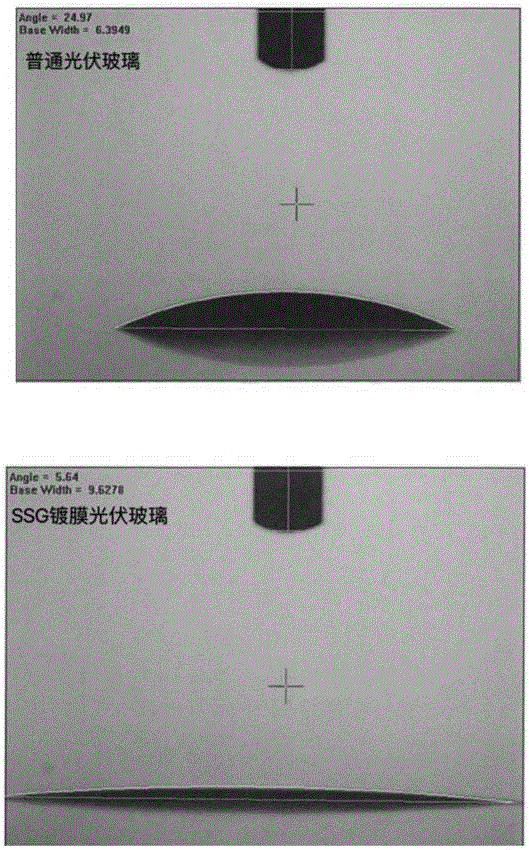

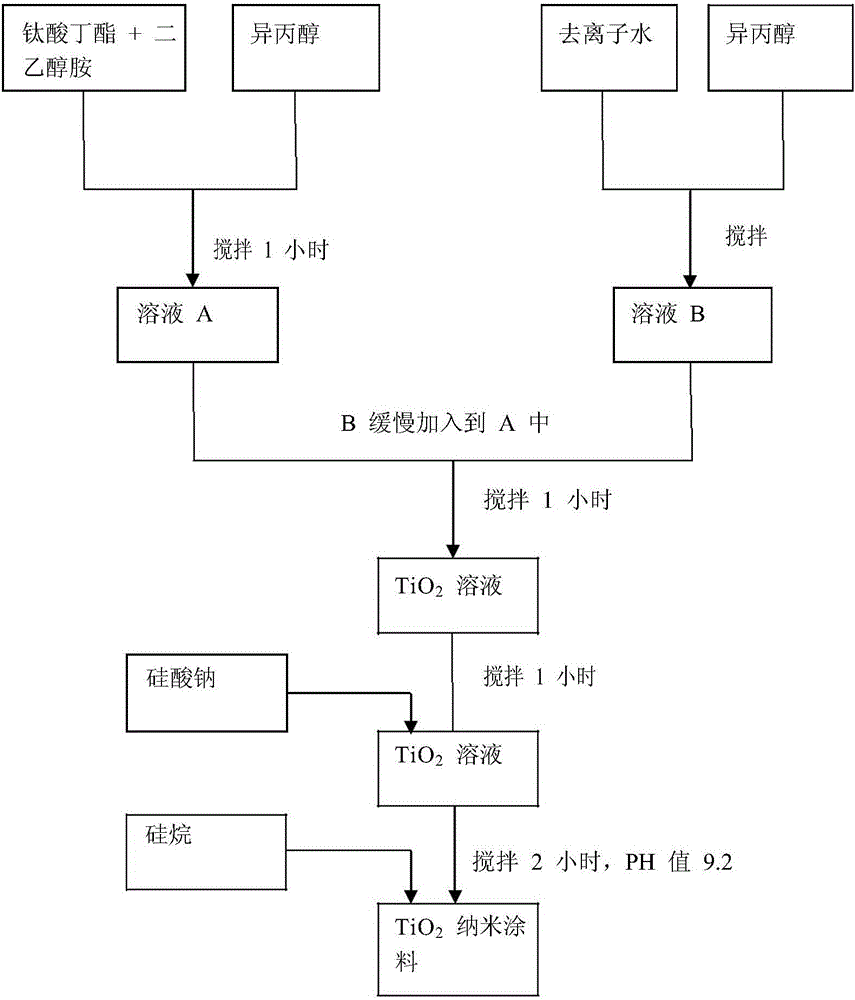

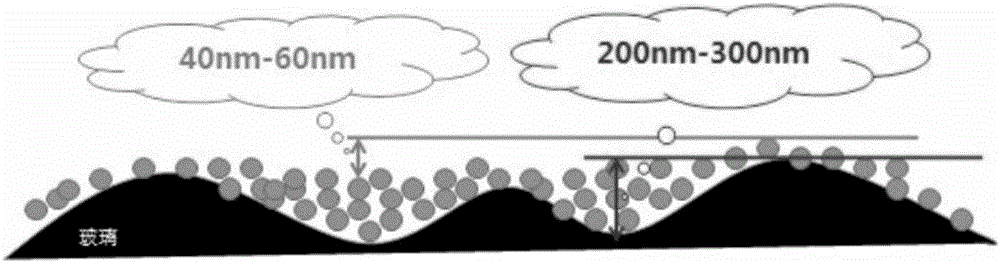

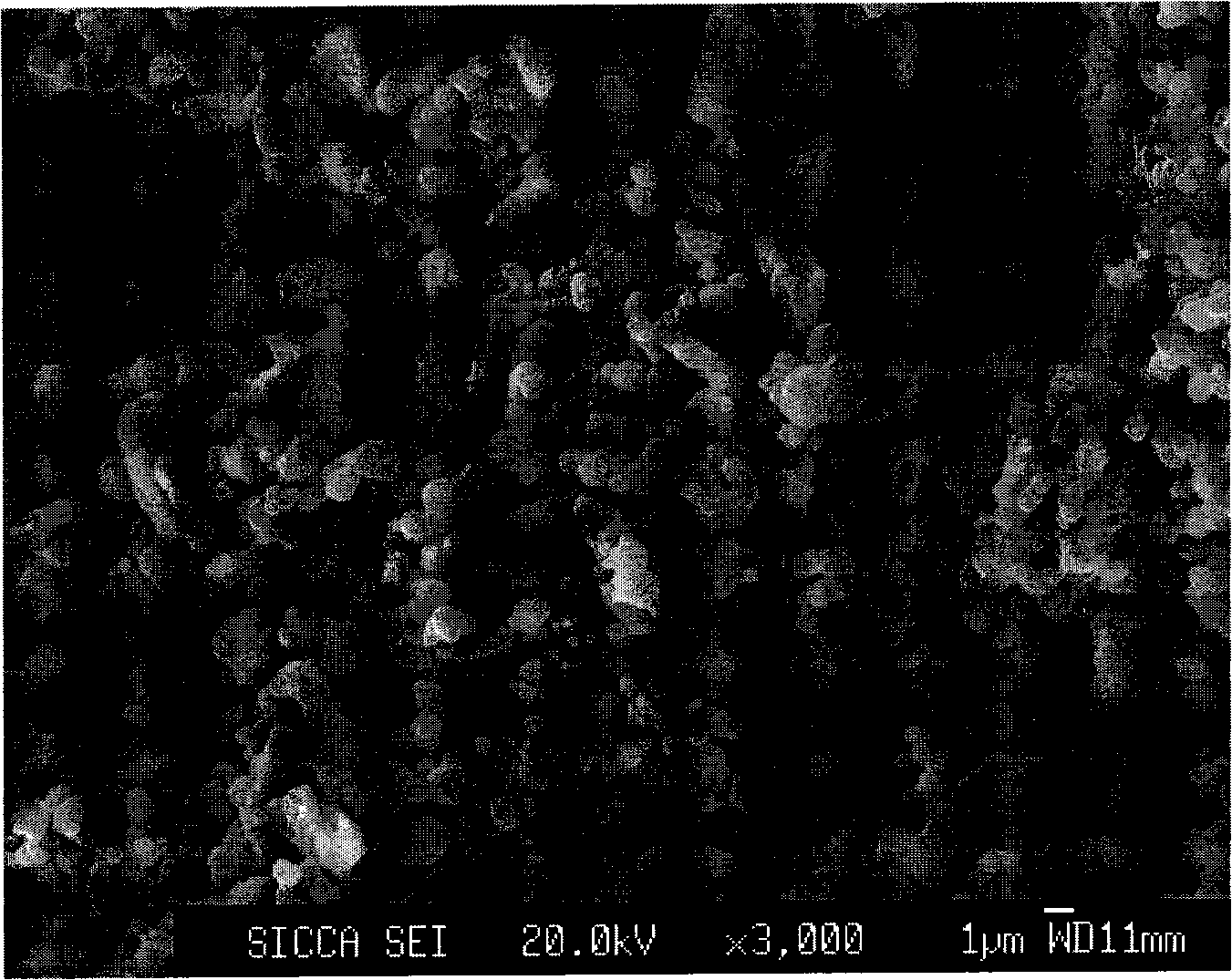

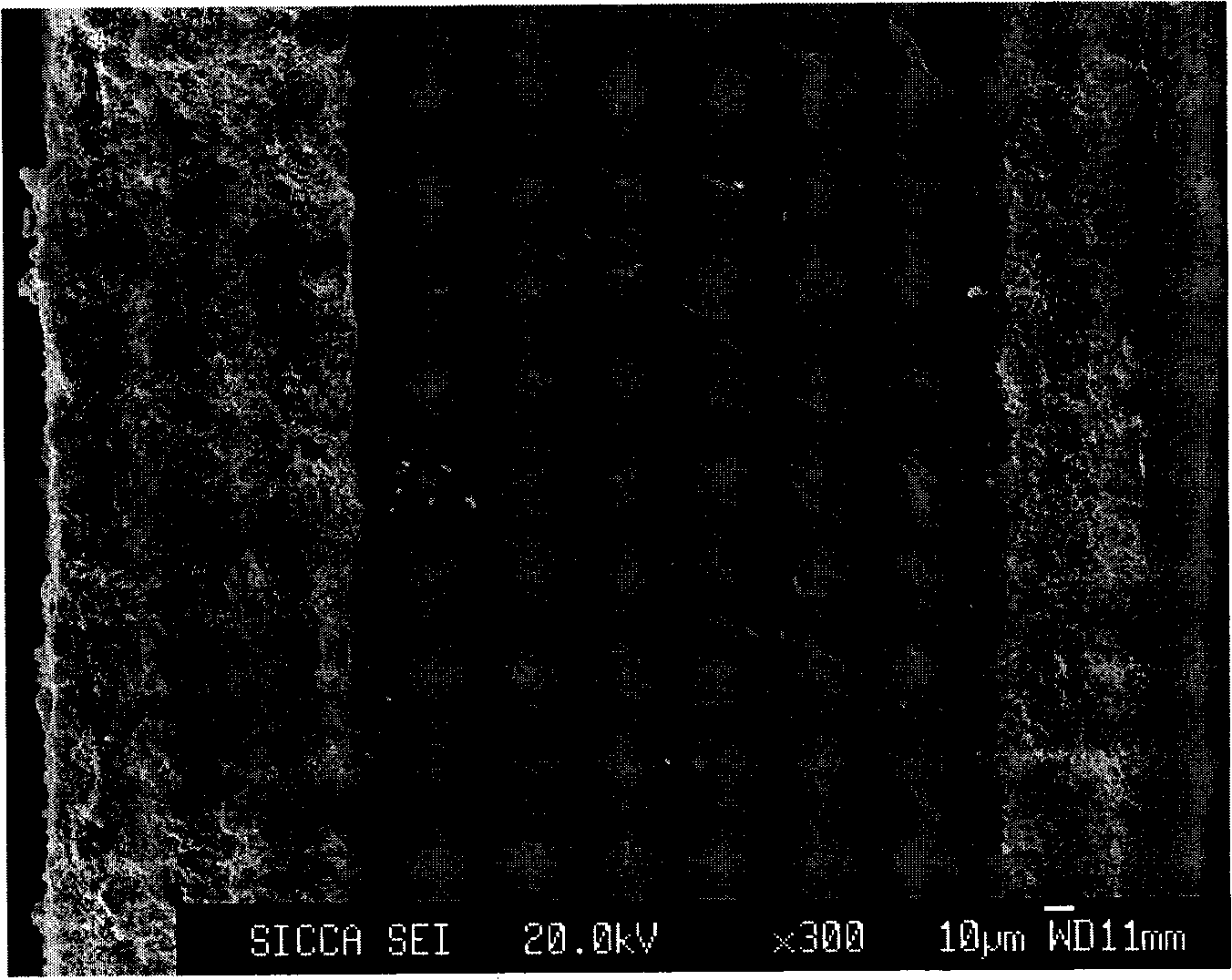

Preparation method for multifunctional TiO2 nano-paint

InactiveCN106046863AAvoid interactionImprove photoelectric conversion efficiencyAntifouling/underwater paintsPaints with biocidesSilanesSurface cleaning

The invention provides a preparation method for a multifunctional TiO2 nano-paint. The preparation method comprises the following steps: preparation of a TiO2 solution with butyl titanate as a titanium source, isopropanol as a solvent and diethanolamine as a hydrolysis inhibitor; and dispersion and surface modification of the TiO2 nano-solution: carrying out TiO2 surface modification on the obtained TiO2 solution with sodium silicate as a dispersing agent and silane as a coupling agent so as to obtain the multifunctional TiO2 nano-paint. The multifunctional TiO2 nano-paint prepared in the invention can be directly sprayed on the surface of a substrate at normal temperature and has good bonding action on the substrate; surface cleanness of a photovoltaic assembly is maintained mainly in virtue of super hydrophilicity and self-cleaning performance of a formed coating; and the photoelectric conversion rate of the photovoltaic assembly is improved.

Owner:BEIJING LION TRUNK NEW MATERIAL TECH CO LTD

Direct hydrocarbon fuel solid oxide fuel cell anti-carbon deposition anode and a preparation method thereof

InactiveCN101515647AStable structureMeet the requirements of conductivityCell electrodesSolid electrolyte fuel cellsHydrogenFuel cells

The invention relates to an anti-carbon deposition solid oxide fuel cell anode material and a preparation method thereof. The composition of the anode material is xSr (1-1.5y) My TiO3-(1-x) CeO2. In the formula, x is equal to 0.3-0.7, and y is equal to 0.04-0.4; M is La, Y or Sm. The adulteration amount of La, Sr and Y is respectively 0.2-0.4mol%, 0.1-0.3mol% and 0.02-0.08mol%. Compared with the traditional nickel- yttrium oxide stabilized zirconia anode taking hydrogen as fuel, the anode material can take hydrocarbon having low price and rich reserve volume as fuel, so as to reduce the cost of a solid oxide fuel cell and be beneficial to accelerating the commercial development of the solid oxide fuel cell.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

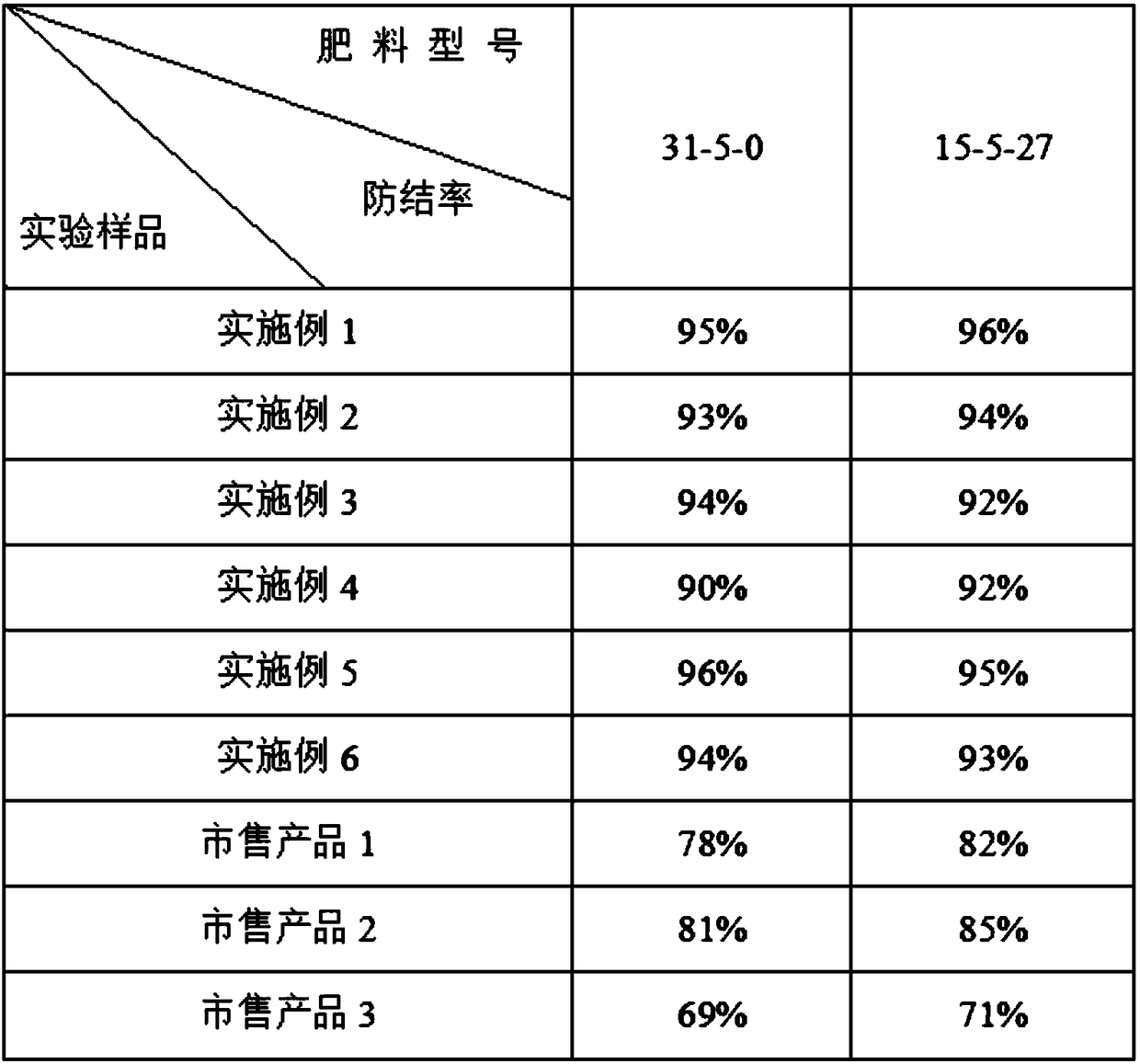

Microemulsion type water-soluble fertilizer anti-blocking agent and preparation method thereof

The invention discloses a microemulsion type water-soluble fertilizer anti-blocking agent and a preparation method thereof. The anti-blocking agent comprises the raw materials of a surfactant and anti-blocking oil, wherein the surfactant comprises one or a plurality of anionic surfactant, nonionic surfactant and zwitterionic surfactant; the HLB of the surfactant is 7-14; the anti-blocking oil comprises one or a plurality of vegetable oil, modified vegetable oil, vegetable wax and aliphatic ester. The preparation method of the anti-blocking agent comprises the step of preparing basic anti-blocking oil and the step of preparing an anti-blocking agent. The prepared microemulsion type water-soluble fertilizer anti-blocking agent is good in anti-blocking effect; after a water-soluble fertilizerwrapped with the prepared microemulsion type water-soluble fertilizer anti-blocking agent is dissolved in water, the microemulsion type water-soluble fertilizer anti-blocking agent can be completelydissolved in water together with the water-soluble fertilizer; floating oil and precipitate are avoided; the solution is uniform in phase and is smoothly and uniformly sprayed during use; pollution precipitating in a farmland is avoided; and the soil and the soil texture cannot be damaged.

Owner:SUZHOU FENGBEI BIOTECH CO LTD

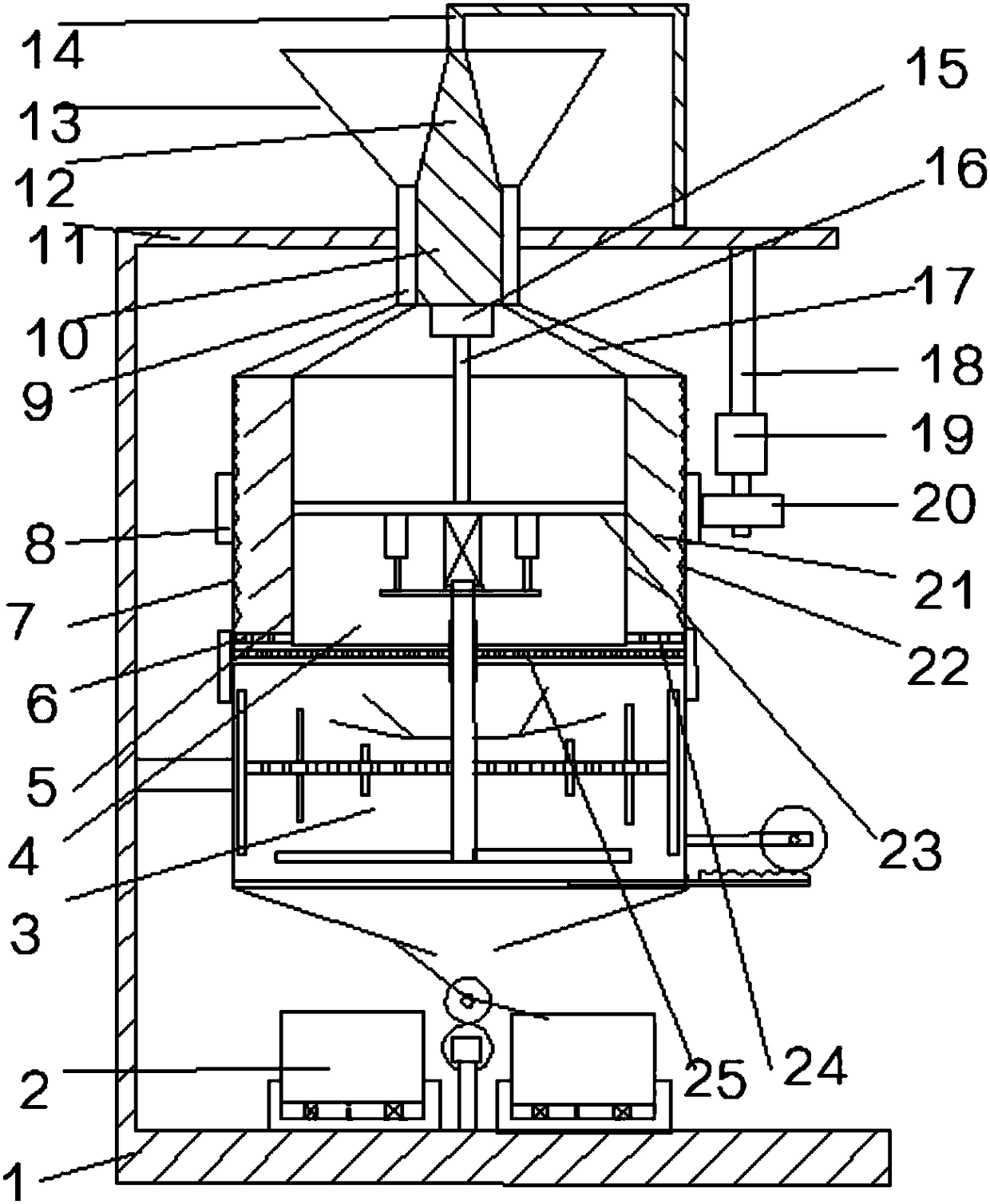

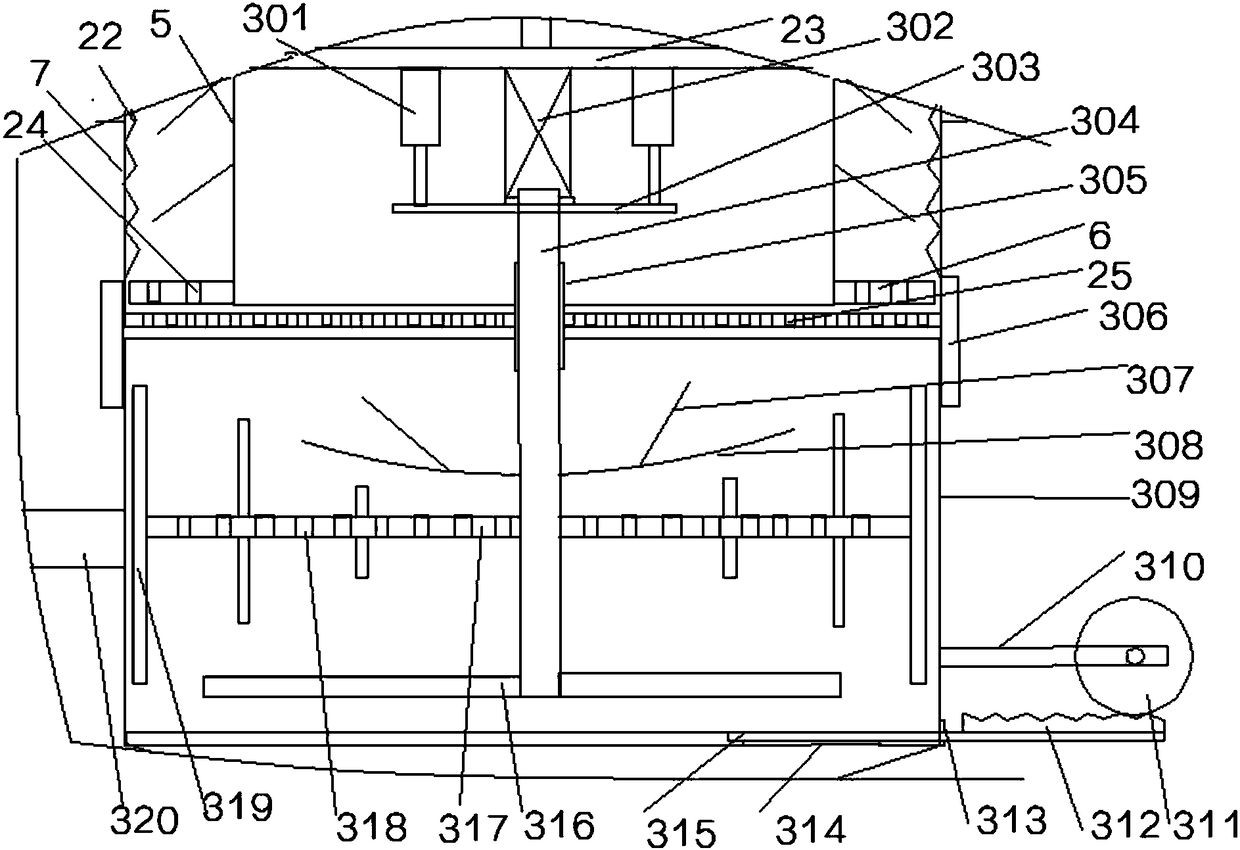

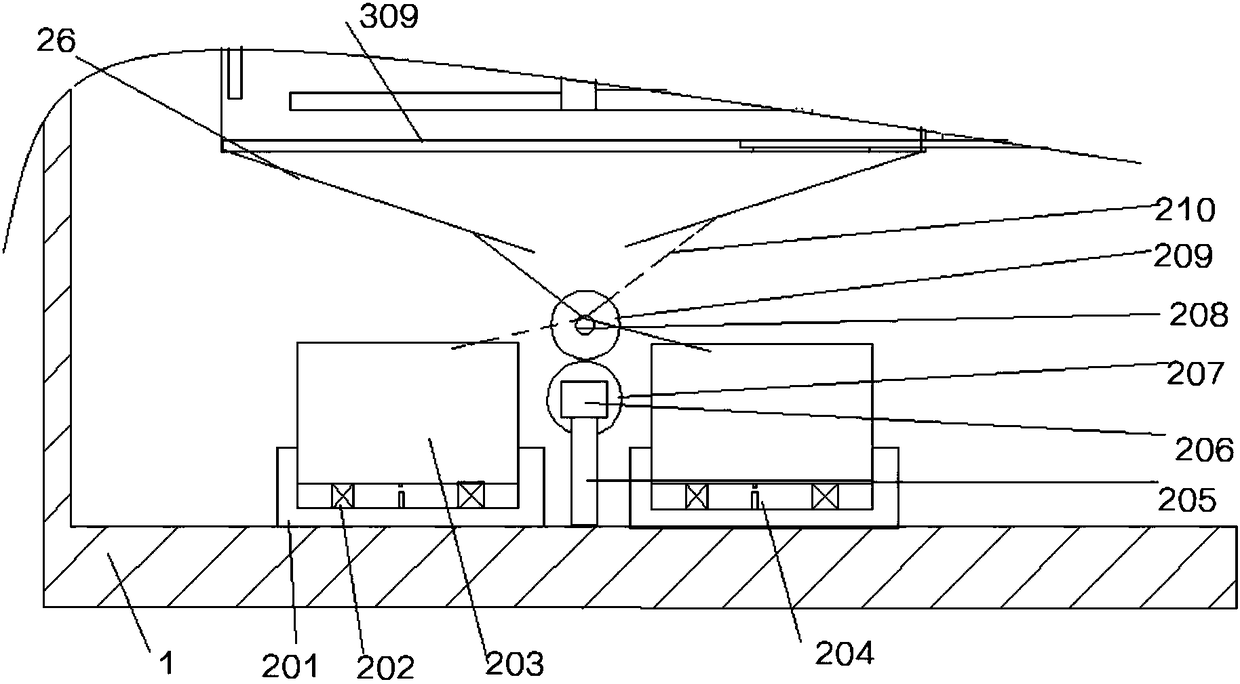

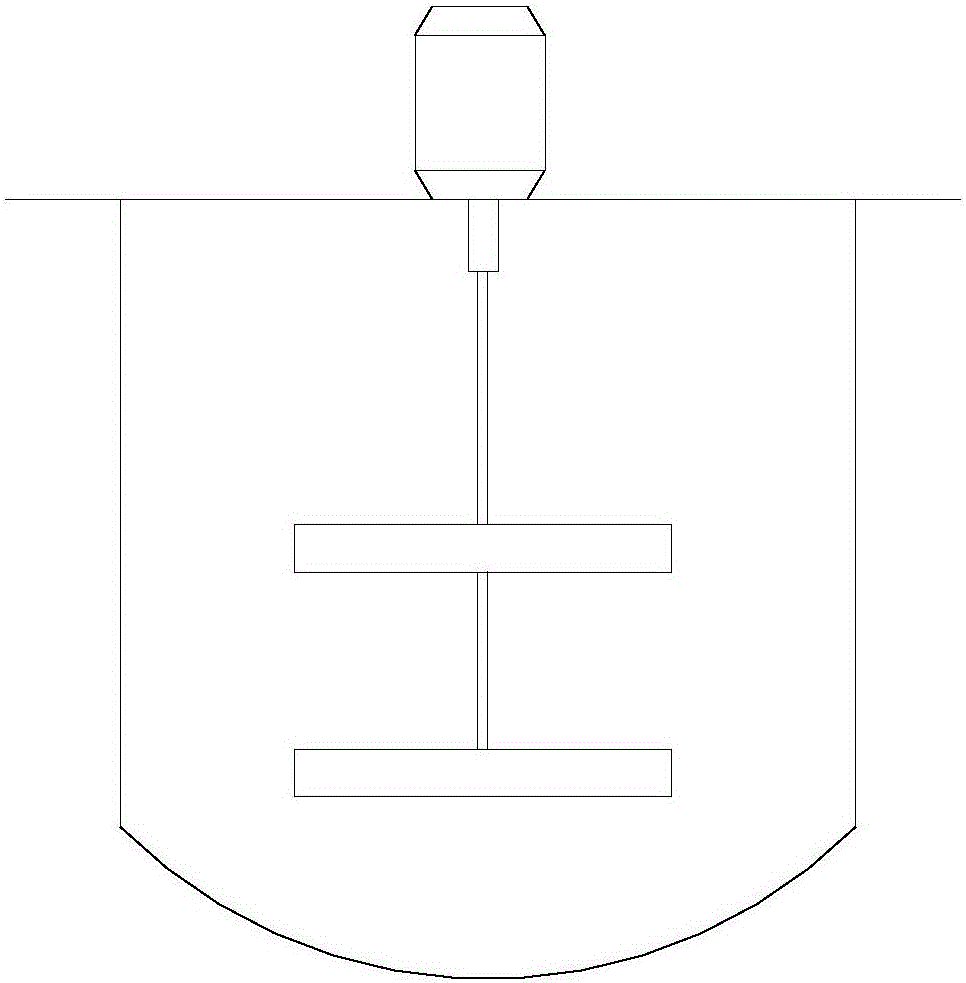

Solid and liquid chemical raw material mixing tank

PendingCN108144530AGuaranteed uniformityStable outputTransportation and packagingMixer accessoriesEngineeringSolid particle

The invention provides a solid and liquid chemical raw material mixing tank which comprises an L-shaped support. A cross plate is arranged at the top of the L-shaped support, a feeding hopper penetrates the cross plate arranged at the top of the L-shaped support, a material distributing shaft is arranged at an inner axis center of the feeding hopper, an annular pipe is placed at the bottom of thefeeding hopper, a plurality of material distributing pipes are distributed on the upper periphery of a material guide cavity, a crushing cylinder is arranged at one end, far away from the feeding hopper, of the annular pipe, a crushing shaft is concentrically, reversely and rotatably connected into the crushing cylinder, a cross rod is connected on the inner wall of the crushing shaft, a stirringmechanism is rotatably connected at the bottom of the crushing cylinder, and a quantitative discharging mechanism is arranged at an outlet corresponding to the stirring mechanism. By simple structuralmatching, a special mixing tank for solid and liquid chemical raw materials is implemented, the size uniformity of solid particles is ensured, the solid particles and liquid can be sufficiently mixed, discharging is stable, processing efficiency is improved, device use is decreased, processing cost is reduced, the working efficiency of workers is improved, mixing quality is better, and market competitiveness is improved.

Owner:TIANJIN XINYUAN GUANGTAI NEW MATERIAL TECH CO LTD

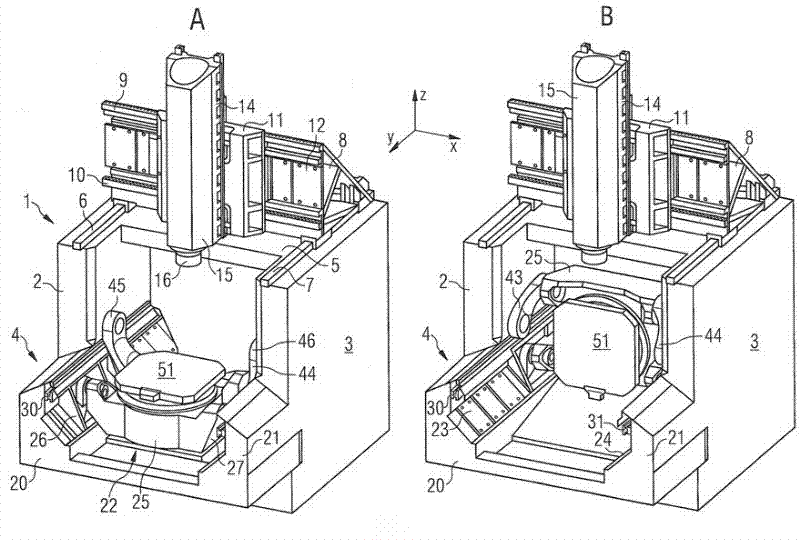

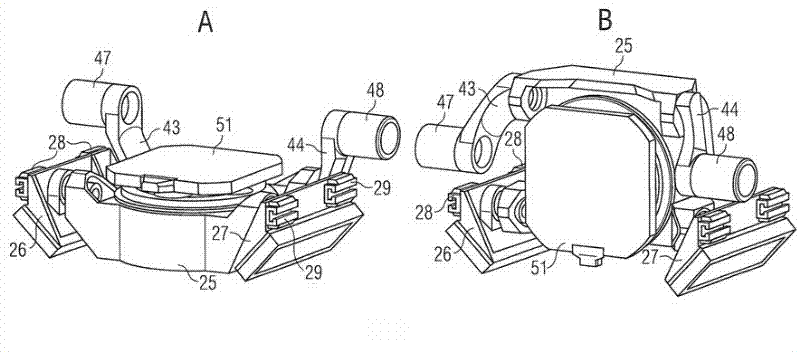

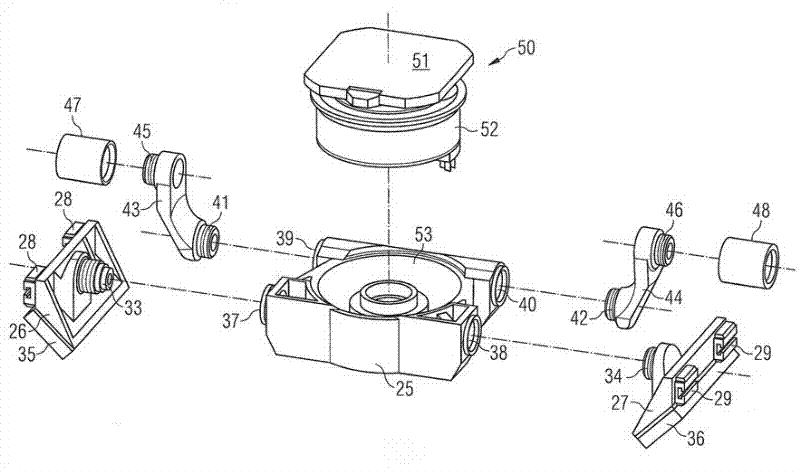

Machine tool having a carrier device for work pieces or tools

InactiveCN102056708ASave spaceSimple structureSleeve/socket jointsLarge fixed membersMachine partsEngineering

The invention relates to a machine tool having a carrier device for work pieces or tools or tool spindles, comprising a console that can be pivoted about a first axis from the horizontal into the vertical position and that is housed on two carriages guided in the machine stand. A carrier for a work piece or a tool spindle is arranged on the console, and a drive device is provided for the synchronous displacement of both carriages on guide rails fixed on the machine. According to the invention, the console is hinged via two crank-like arms to a stationary machine part in addition to being supported on both carriages.

Owner:DECKEL MAHO SEEBACH GMBH

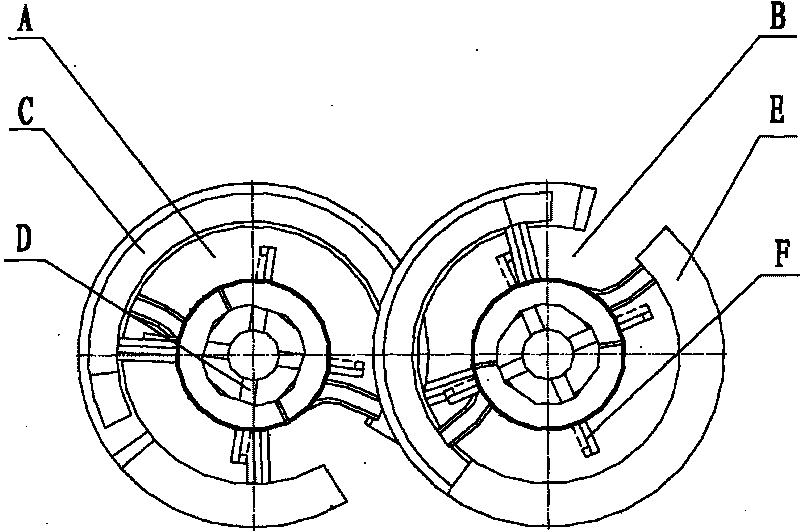

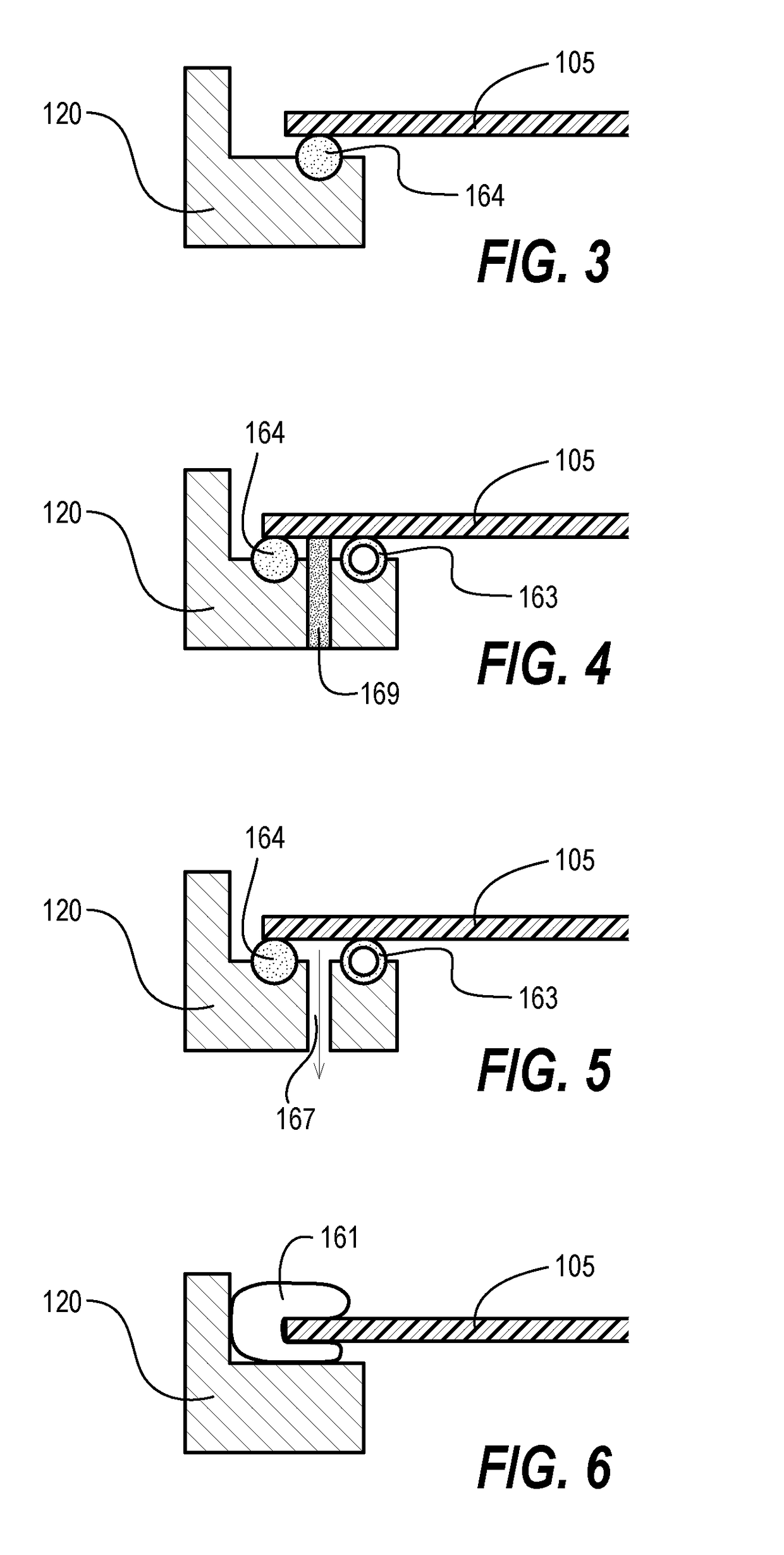

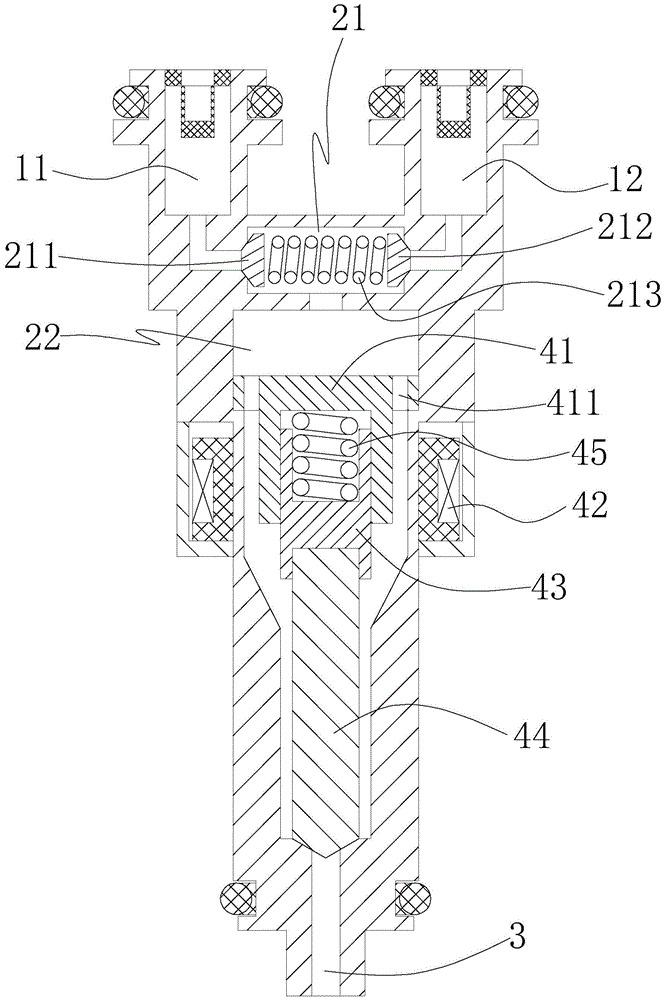

Integrated ejector

ActiveCN105041533ASmooth switchingNo depositionFuel injection apparatusMachines/enginesEngineeringControl switch

The embodiment of the invention discloses an integrated ejector. The integrated ejector comprises an ejector body. The ejector body is provided with a first fuel inlet, a second fuel inlet, a first control cavity communicated with the first fuel inlet and the second fuel inlet, a second control cavity communicated with the first control cavity, a fuel ejecting port communicated with the second control cavity, a fuel switching control valve arranged in the first control cavity and used for controlling switch between first fuel feeding and second fuel feeding, and a fuel ejection control valve arranged in the second control cavity and used for controlling the second control cavity to be communicated with or disconnected from the fuel ejection port. The integrated ejector is simple in structure and convenient to install, and fuel switching can be conducted smoothly. Furthermore, the integrated ejector can directly replace an original automotive ejector to be installed at the position where the original automotive ejector is located, the optimal ejection angle can be obtained, and oil consumption can be reduced. Besides, oil film deposition and covering can be avoided.

Owner:KUANGYUE TECH (LINYI) CO LTD

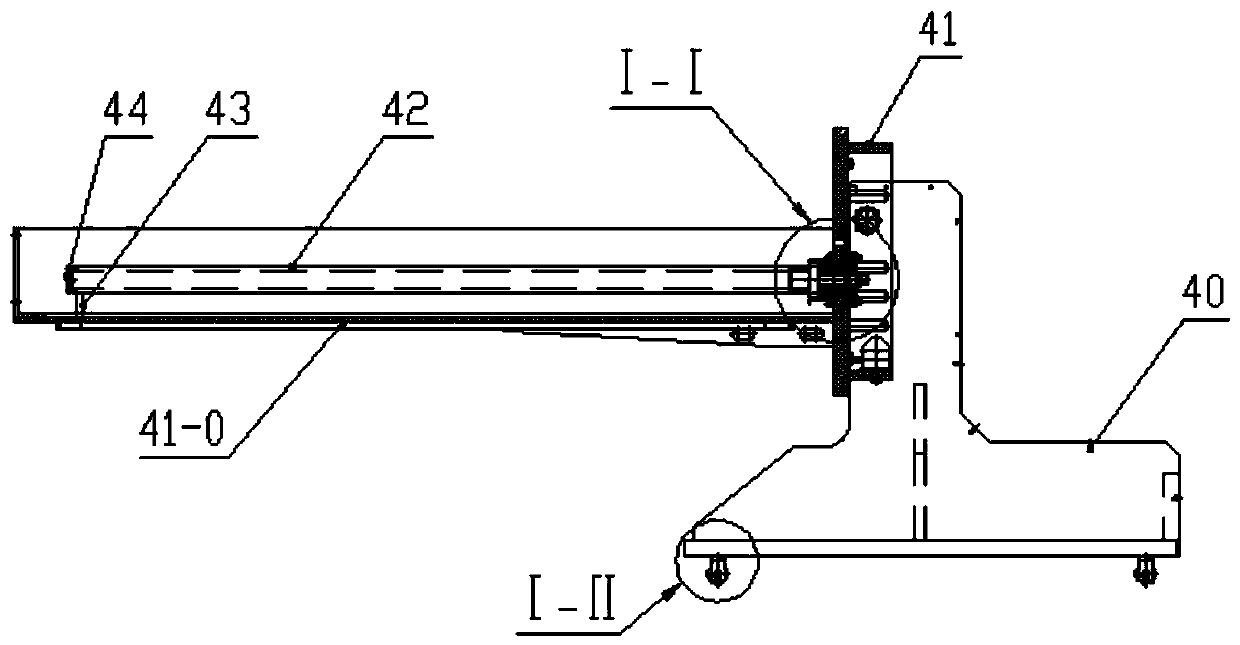

Continuous acid leaching device

The invention relates to vanadium oxide production equipment and discloses a continuous acid leaching device. The continuous acid leaching device comprises supports, a rotary cylinder and a driving mechanism, wherein the rotary cylinder is horizontal, the supports are arranged at two ends of the rotary cylinder, two ends of the rotary cylinder are connected with shaft barrels, material holes communicated with the rotary cylinder are formed in the shaft barrels, bearings are arranged on the supports, the shaft barrels are mounted on the supports through the bearings, and the driving mechanism is in driving connection with the rotary cylinder; a feeding end and a discharging end are arranged at two ends of the rotary cylinder, a feeding main pipe is arranged at the feeding end, a discharging main pipe is arranged at the discharging end, the feeding main pipe and the discharging main pipe are connected with the corresponding shaft barrels though rotary seal rings respectively, and a discharging control valve is mounted on the discharging main pipe. The continuous acid leaching device can cooperates with continuous roasting of a rotary kiln for production, so that operation is simplified, and the production efficiency is improved.

Owner:攀钢集团西昌钒制品科技有限公司

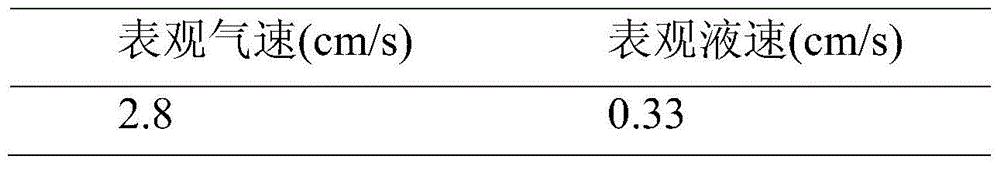

Method for preparing ferrous nitrate solution by adopting liquid-solid phase moving bed reaction device

The invention discloses a method for preparing ferrous nitrate solution by adopting a liquid-solid phase moving bed reaction device. In the method, iron sheets, water and nitric acid are taken as raw materials, reaction is carried out in the liquid-solid phase moving bed reaction device, the reaction time is 4 hours-12 hours, the reaction device comprises a reactor and a circulating pump; the reactor comprises a shell, an inner drum, a partition board, a circulating outlet, a material inlet, an acid inlet and a material outlet, wherein the acid inlet is arranged between the shell and the inner drum; the shell is formed by connecting a cylindrical section and a conical section; the partition board is arranged at the lower part of the cylindrical section; the inner drum is fixed on the partition board; the partition board at the bottom of the inner drum is provided with distributing holes; the material inlet is arranged at the upper part of the cylindrical section; the circulating outlet is arranged on the shell above the partition board; the material outlet is arranged at the bottom of the conical section; an inlet of the circulating pump is connected with the circulating outlet; and an outlet of the circulating pump is connected with the material outlet. In the method, the generation of high-valence iron and nitric oxides can be reduced, no slag and iron scrap are deposited, the system temperature is convenient to control, and the reaction time is shortened.

Owner:SHANGHAI YIPIN PIGMENTS CO LTD

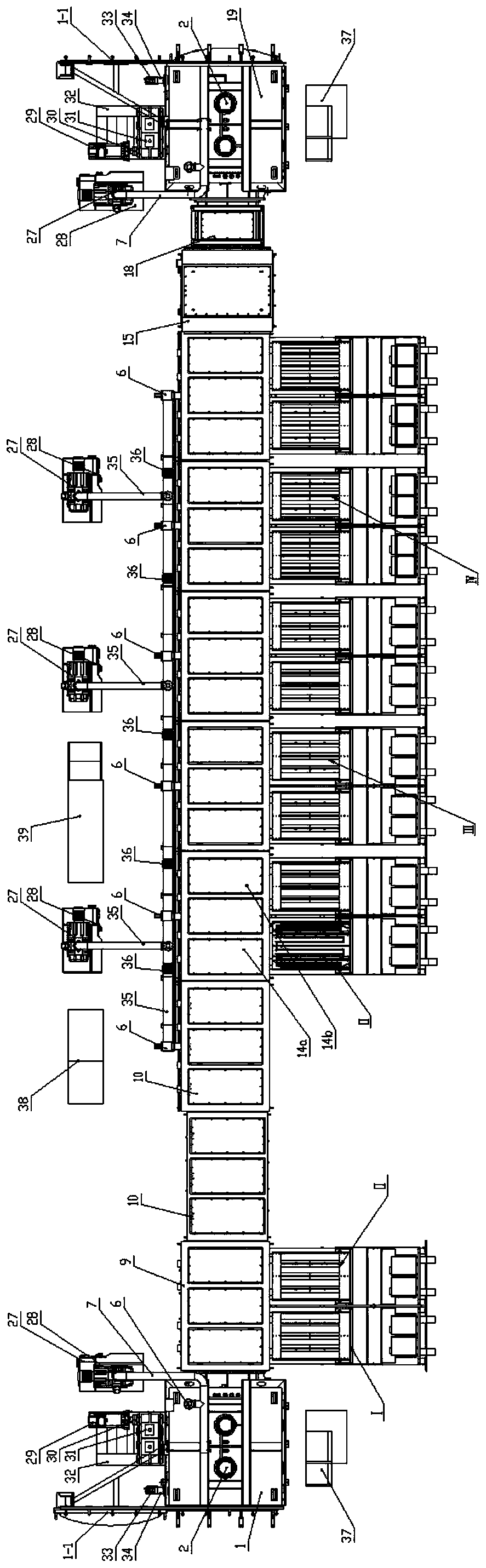

Metal foil winding type vacuum coating continuous production line

PendingCN111058009ATimely correction of process parametersGuaranteed color uniformityVacuum evaporation coatingSputtering coatingProduction lineMetal foil

The invention relates to a metal foil winding type vacuum coating continuous production line. The continuous production line comprises a coating chamber, the coating chamber is divided into a front section and a rear section, windows are correspondingly disposed on one sides of cavities at the front section and the rear section, and rails perpendicular to racks are arranged on one sides of the racks corresponding to the windows; a planar rectangular cathode arc source device is disposed in the front section, and comprises a target material and a moving trolley, and the target material is fixedon a vertical panel of the moving trolley and is positioned in a supporting drawer box; the moving trolley walks on the vertical rail, a sealing door bracket composed of a frame and a vertical panelis arranged on the moving trolley, a side of the vertical panel facing the window is a seal surface and is in seal design correspondingly with a window frame of the window, and a groove-shaped supporting drawer extending to the window is fixed on the vertical panel. A rotary columnar medium-frequency magnetron sputtering target device is disposed in the rear section, and comprises a sputtering target and a moving trolley assembly, the sputtering target is fixed on the vertical panel and is located in the supporting drawer box; and the target material and the sputtering target are respectivelypushed into or pulled out of each chamber by the moving trolley. The coating layer is uniform and stable in color, and the technological process is reliable.

Owner:DONGGUAN HUICHENG VACUUM TECH

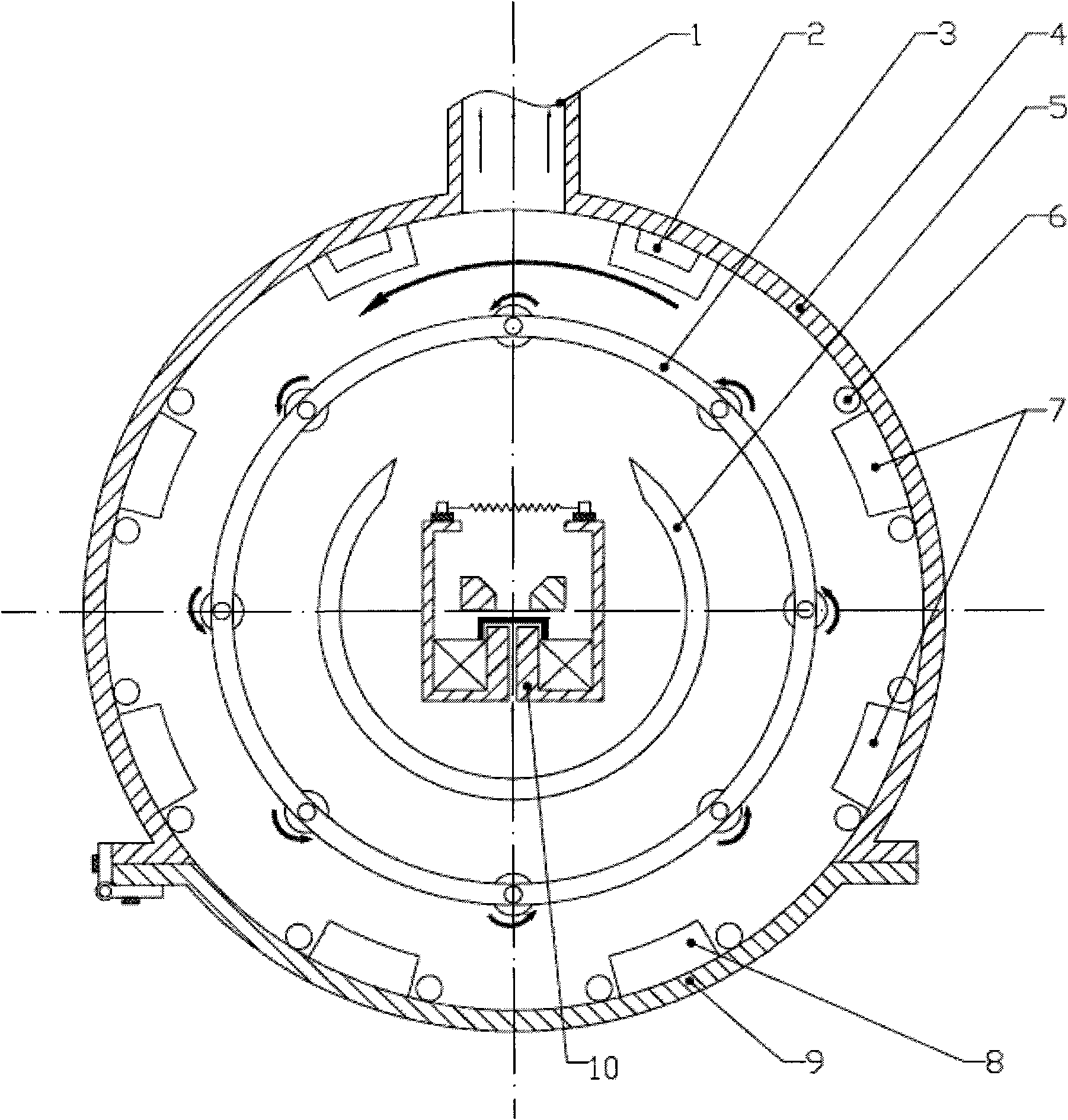

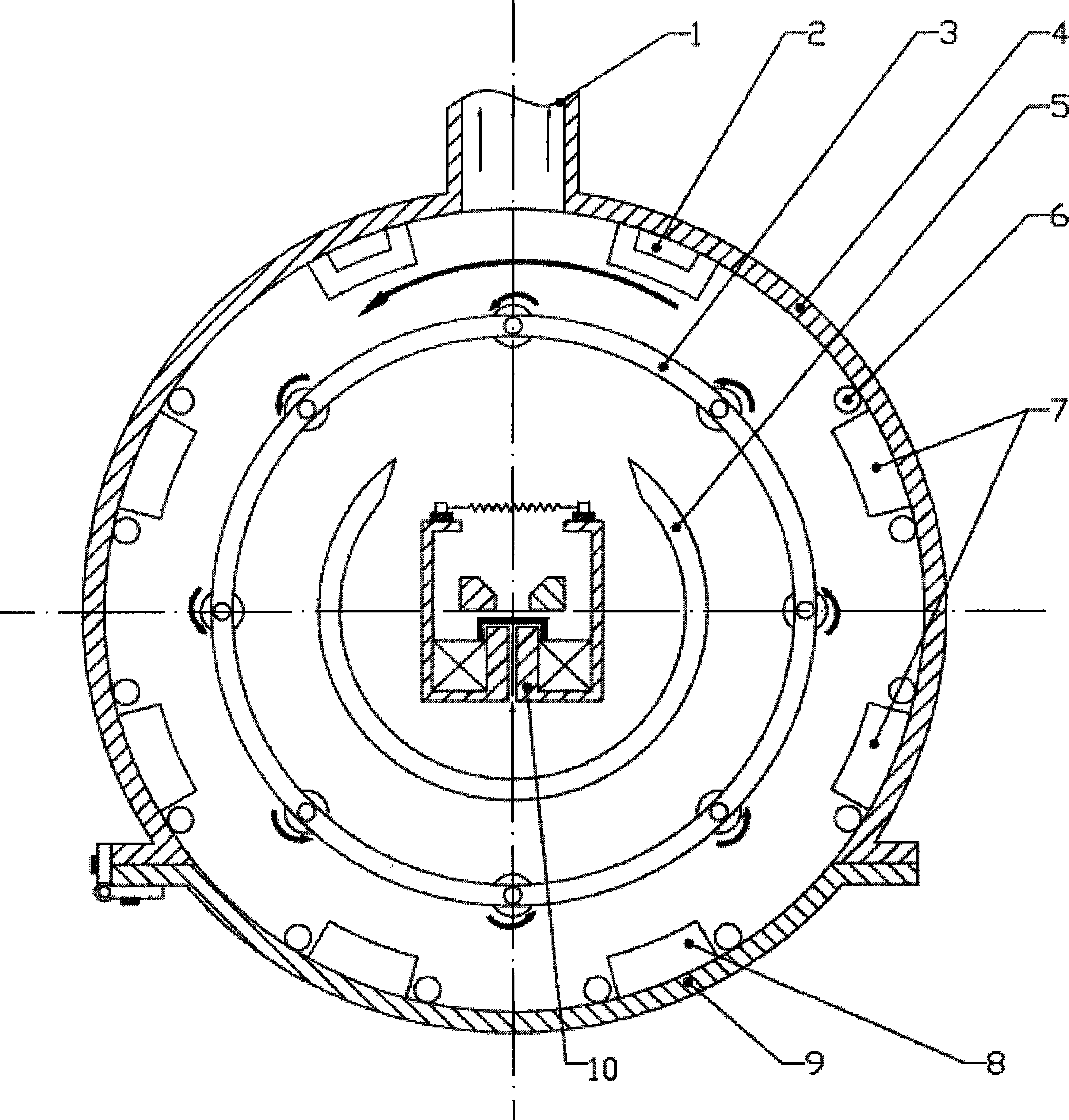

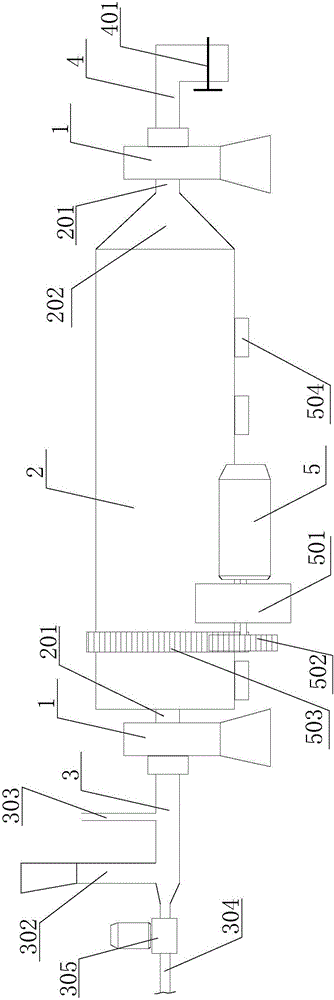

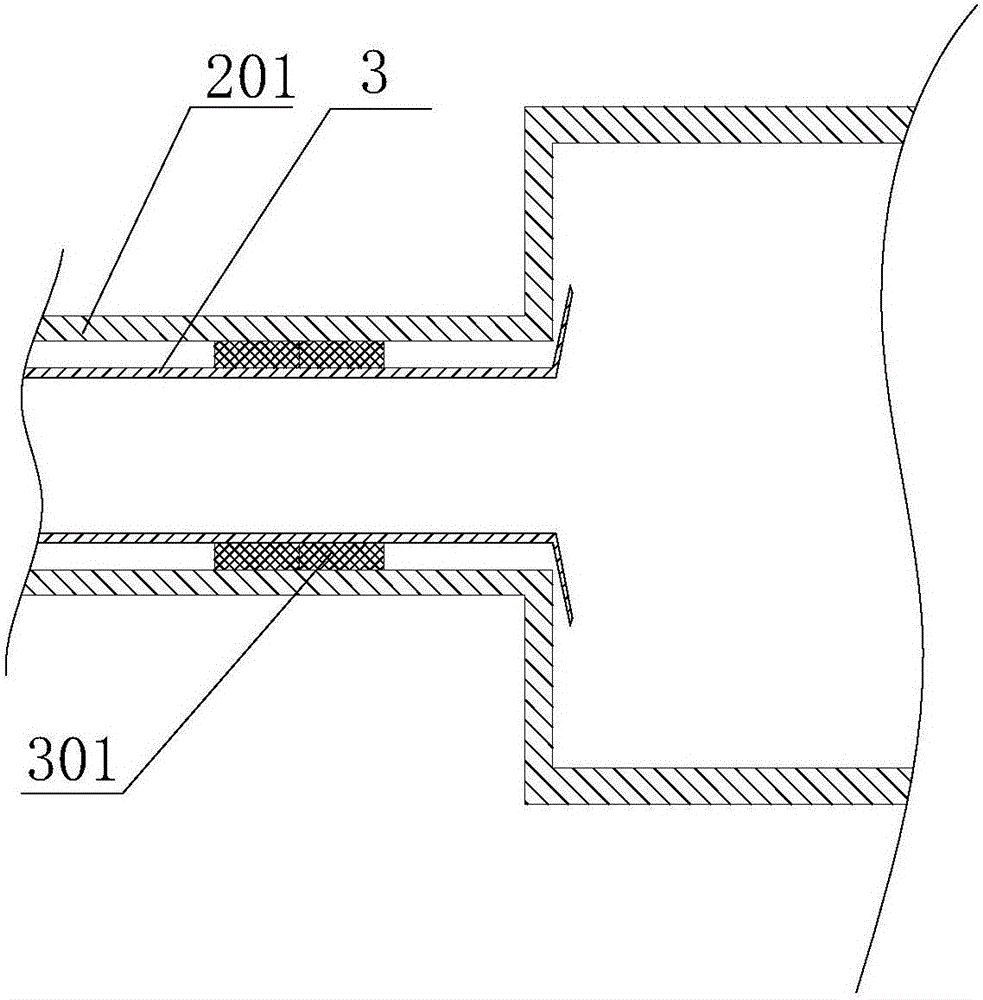

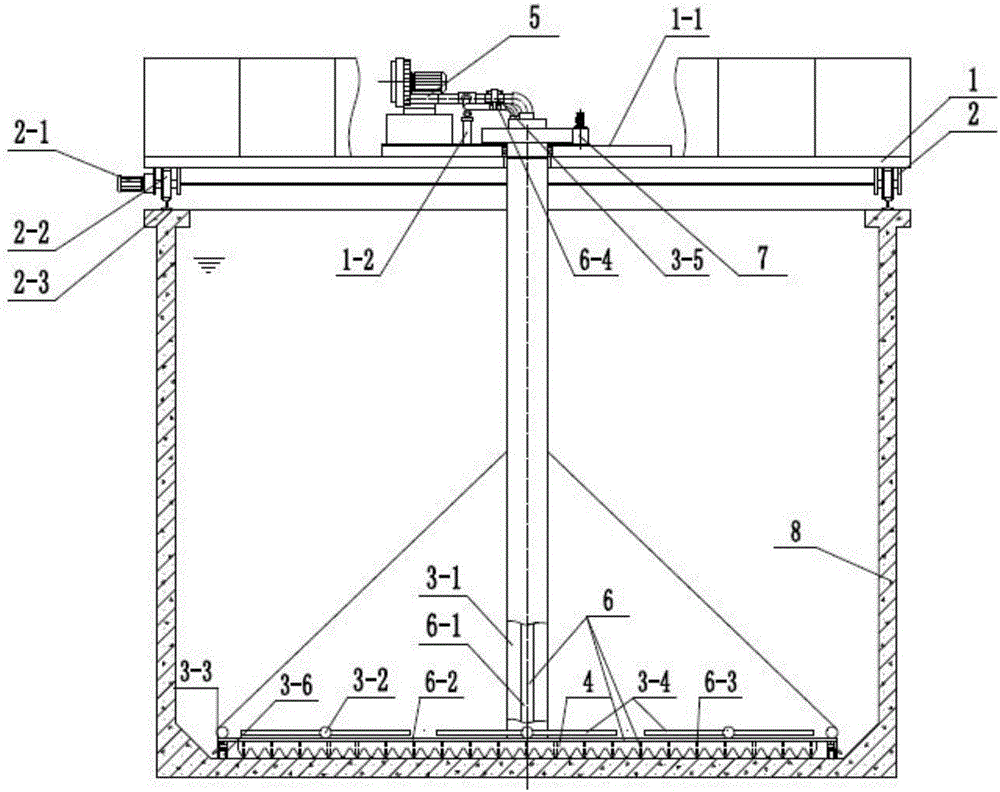

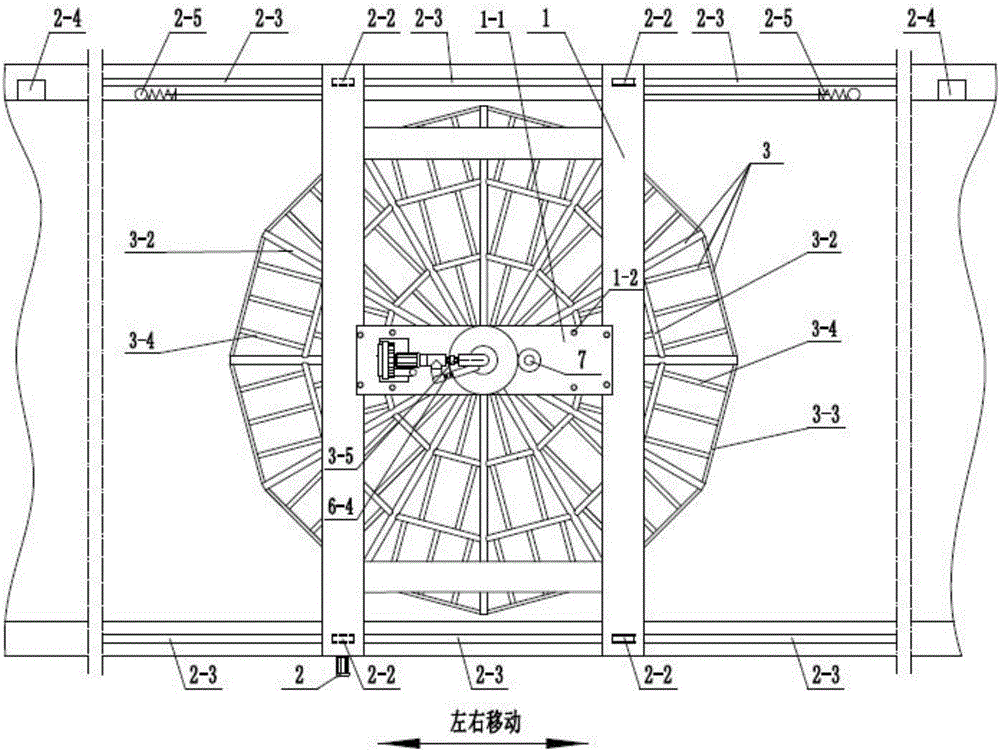

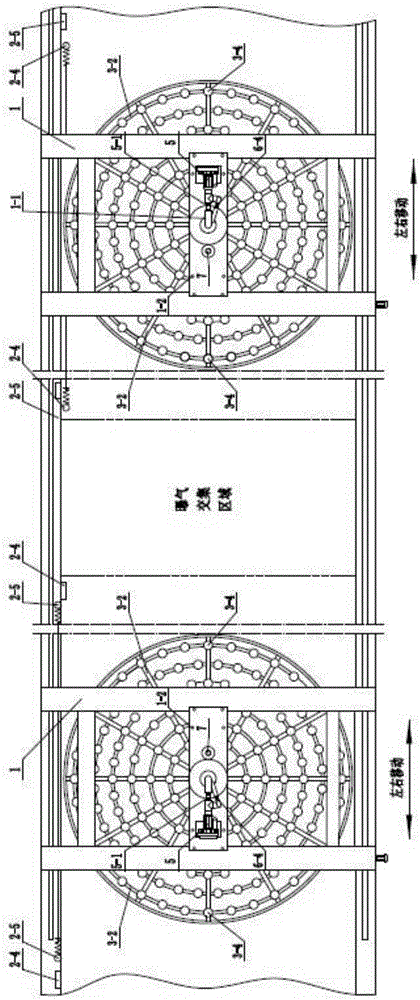

Dynamic bottom aeration system and aeration method thereof

PendingCN106517498AEliminate oxygenation blind spotsEvenly oxygenatedSustainable biological treatmentBiological water/sewage treatmentAeration systemNozzle

The invention provides a dynamic bottom aeration system and an aeration method. The system comprises two trusses, a truss moving unit, an aeration component, a scraper, a fan, a blow-brushing unit and a second driving device, wherein a bridge is arranged between the two trusses; the truss moving unit comprises a guide rail, truss rollers, a first driving device and limiting devices; the first driving device drives the truss to move on the guide rail; the aeration component comprises an aeration air supply pipe, aeration air supply branch pipes, a fixed support and aerators; the aeration air supply branch pipes are radially connected on the aeration air supply pipe; the aerators are communicated with the aeration air supply branch pipes; the scraper is arranged below the fixed support; the fan is communicated with the aeration air supply pipe and a blow-brushing air supply pipe; the blow-brushing unit comprises the blow-brushing air supply pipe, a blow-brushing air supply branch pipe and air nozzles; the blow-brushing air supply pipe and the aeration air supply branch pipes are concentric; one end of the blow-brushing air supply pipe is communicated with an air outlet of the fan and the other end is connected with the blow-brushing air supply branch pipe; the blow-brushing air supply branch pipe is installed on the fixed support; the air nozzles are arranged on the blow-brushing air supply branch pipe; the second driving device drives the aeration component and the blow-brushing unit to rotate. The system has the advantage of no blind area and dead center dynamic aeration oxygenation.

Owner:HUATIAN ENG & TECH CORP MCC

Niobium-based Josephson junction etching method

PendingCN110635022AAvoid damageEtch selection is smallSuperconductor device manufacture/treatmentNiobiumReactive-ion etching

The invention relates to a niobium-based Josephson junction etching method, and belongs to the technical field of superconducting device preparation. The specific method is as follows: the sample to be etched is sent to a reactive ion etching cavity through a conveying device in the vacuum state, etching gas is introduced and the Nb layer of the sample to be etched is etched; then the sample afterreactive ion etching is sent to an ion beam etching machine through the conveying device in the vacuum state, inert gas is introduced and the AlOx / Al layer is etched; and the Nb-based superconductingdevice is obtained by vacuum extrusion of the sample. The etching method is simple and good in effect, the prepared superconducting device has high yield and productivity, and the device has organicmatter or metal deposition.

Owner:JIANGSU LEUVEN INSTR CO LTD

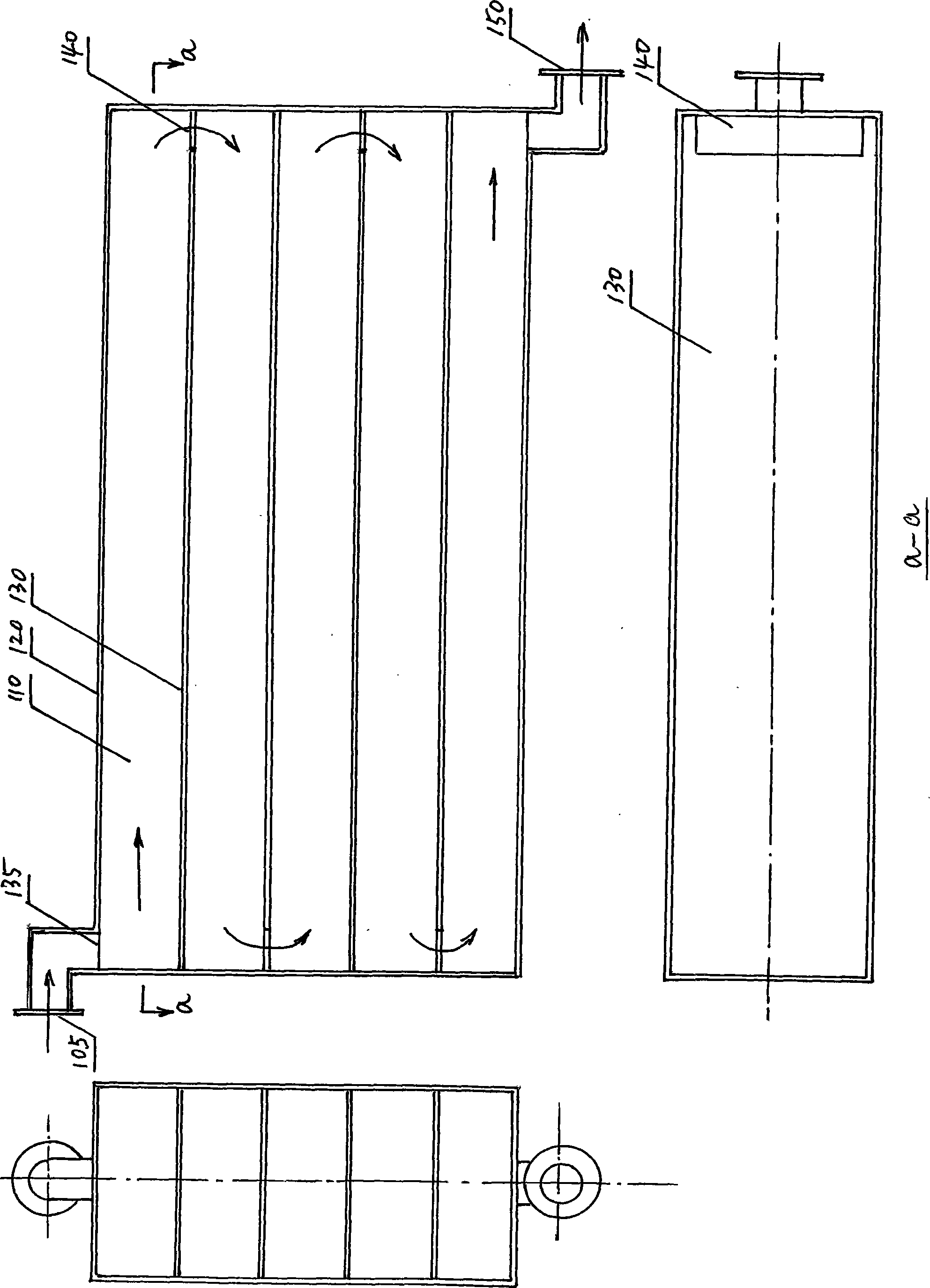

Flow passage type sewage heat exchanger

ActiveCN103134352ANo depositionNot cloggedStationary tubular conduit assembliesHeat exchange apparatusHeat transmissionWater flow

The invention provides a flow passage type sewage heat exchanger which structurally comprises a box body, a sewage flow passage, a clear water flow passage, a dirt removing door and a base. Sewage and clear water respectively flow in the flow passages arranged inside the box body and heat is exchanged through a dividing wall. The clear water flow passage is composed of a plurality of circular heat transmission tubes, arranged inside the sewage flow passage with a rectangular cross section, and tightly attached to the lower surface of a top plate of the sewage flow passage. The sewage flow passage comprises a sewage inlet, a sewage pipeline and a sewage outlet. The sewage enters the heat exchanger from the sewage inlet, enters the sewage pipeline from a water inlet at one end of the top plate of the sewage pipeline, flows out from a water outlet at the other end of a bottom plate, and finally flows out from the sewage outlet. The clear water flow passage comprises a clear water inlet, an inlet water distributive tank, clear water pipelines, a tile-shaped plate, an outlet collection tank and a clear water outlet. The clear water enters the heat exchanger from the clear water inlet, passes the inlet water distributive tank, enters the clear water pipeline, passes the tile-shaped plate, enters another clear water pipeline, and finally passes an outlet collection tank and flows out from the clear water outlet.

Owner:HIT HARBIN INST OF TECH KINT TECH

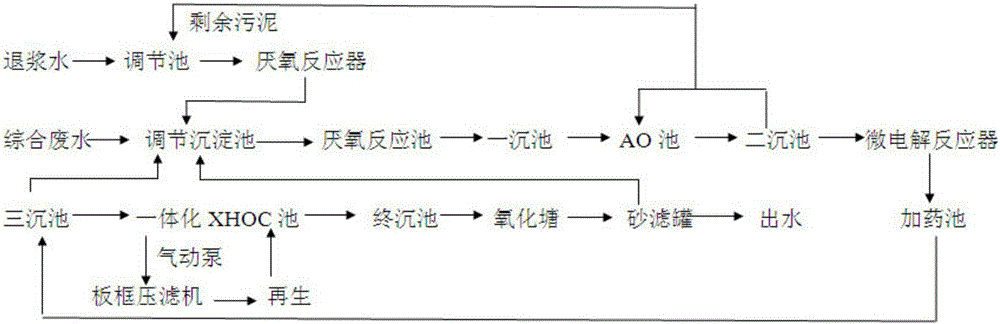

Printing and dyeing wastewater treatment technique

ActiveCN106315977AEasy to handleDeep colorBiological treatment apparatusTreatment involving filtrationWater flowAnaerobic reactor

The invention relates to a printing and dyeing wastewater treatment technique. The printing and dyeing wastewater treatment technique includes: feeding desizing wastewater into an adjusting pool prior to lifting to an anaerobic reactor through a pump, and allowing supernatant to flow into a settling pool after the desizing wastewater is treated in the anaerobic reactor; allowing comprehensive wastewater to enter the adjusting pool for settling via a pipeline, lifting the supernatant to the anaerobic reactor via the pump, and allowing the wastewater subjected to treatment of the anaerobic reactor to flow into an A / O pool via a primary settling pool; allowing the wastewater to flow into a secondary settling pool via the A / O pool, arranging a micro-electrolytic reactor in a water outlet of the secondary settling pool, allowing the treated wastewater to flow into a dosing pool and then into a tertiary pool via the dosing pool, sending sludge in the tertiary pool into the adjusting settling pool, and allowing the supernatant to enter an integrated XHOC pool, then a wastewater end settling pool prior to a sand filter tank via an oxidation pond, wherein treated water flowing from the sand filter tank is standard discharge water. The printing and dyeing wastewater treatment technique has the advantages of low energy consumption, high efficiency and stable effluent quality, and the technique is suitable for treatment of organic pollutants with various concentrations, simple in operation and convenient in running.

Owner:HUAFANG

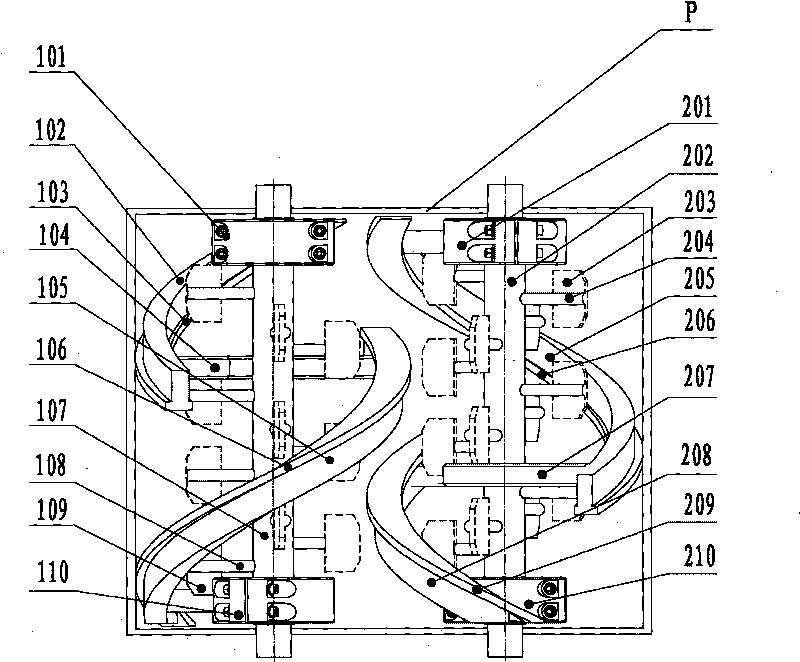

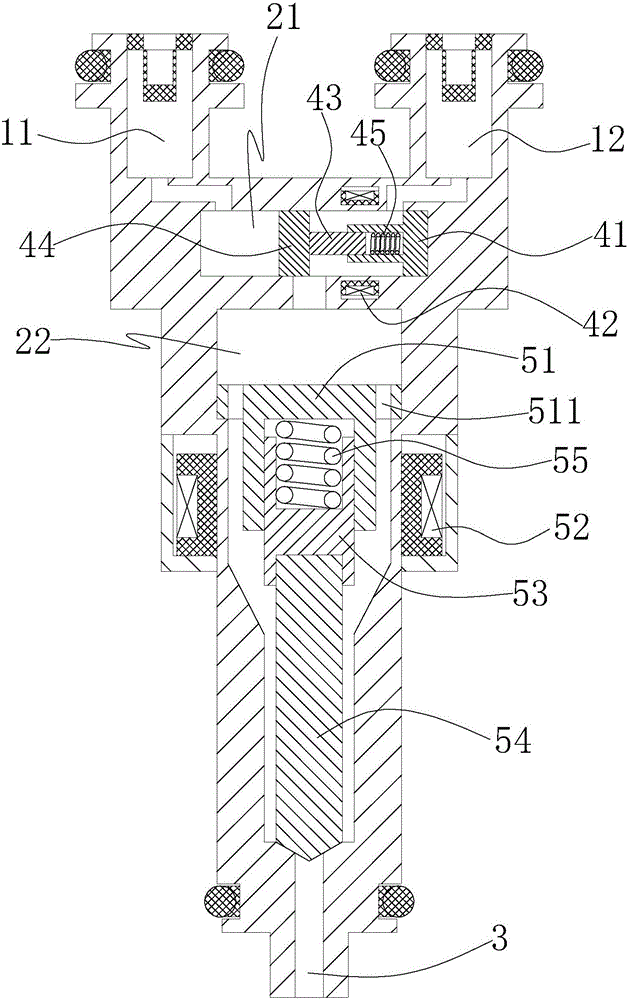

Double-fuel integrated electronic control ejector

ActiveCN105003370ASmooth switchingNo depositionFuel injection apparatusMachines/enginesControl valvesFuel injection

The embodiment of the invention discloses a double-fuel integrated electronic control ejector, which comprises an ejector main body, wherein the ejector main body is provided with a first fuel inlet, a second fuel inlet, a first control cavity, a second control cavity, a fuel injection outlet, a fuel switch control valve and a fuel injection control valve; the first control cavity is communicated with the first fuel inlet and the second fuel inlet; the second control cavity is located under the first control cavity and is communicated with the first control cavity; the fuel injection outlet is communicated with the second control cavity; the fuel switch control valve is used for controlling the supply switch of a first fuel and a second fuel; and the fuel injection control valve is arranged in the second control cavity, and is used for controlling the communication or stop of the second control cavity and the fuel injection outlet. According to the embodiment of the invention, the double-fuel integrated electronic control ejector has the advantages that the structure is simple; the installation is convenient; the smooth switch between different fuels can be realized; an original vehicle ejector can be directly replaced by the double-fuel integrated electronic control ejector, and the double-fuel integrated electronic control ejector is mounted at the position of the original vehicle ejector, so that an optimal injection angle can be reached, and fuel consumption can be reduced; and in addition, no oil film sedimentation and coverage occur.

Owner:中胄能源控股集团有限公司

Composition for light absorption film formation containing blocked isocyanate compound and antireflection film formed therefrom

InactiveCN1273590AImprove performanceDoes not spread and invadeRadiation applicationsPolyurea/polyurethane coatingsResistOrganic solvent

A composition for forming a radiation absorbing coating which comprises an organic solvent, a radiation absorbing polymer or a radiation absorbing material dissolved therein and a crosslinking agent having blocked isocyanate groups. Since the isocyanate groups of the crosslinking agent have been blocked, the composition containing the crosslinking agent has excellent storage stability. When the composition applied to a substrate and then baked, crosslinking proceeds to give an antireflective coating, which does not intermix with a resist layer to be formed thereon by coating and is free from diffusion of a photo-generated acid thereinto from the resist layer. As a result, a resist image free from footing or scum can be formed.

Owner:AZ ELECTRONIC MATERIALS (JAPAN) KK

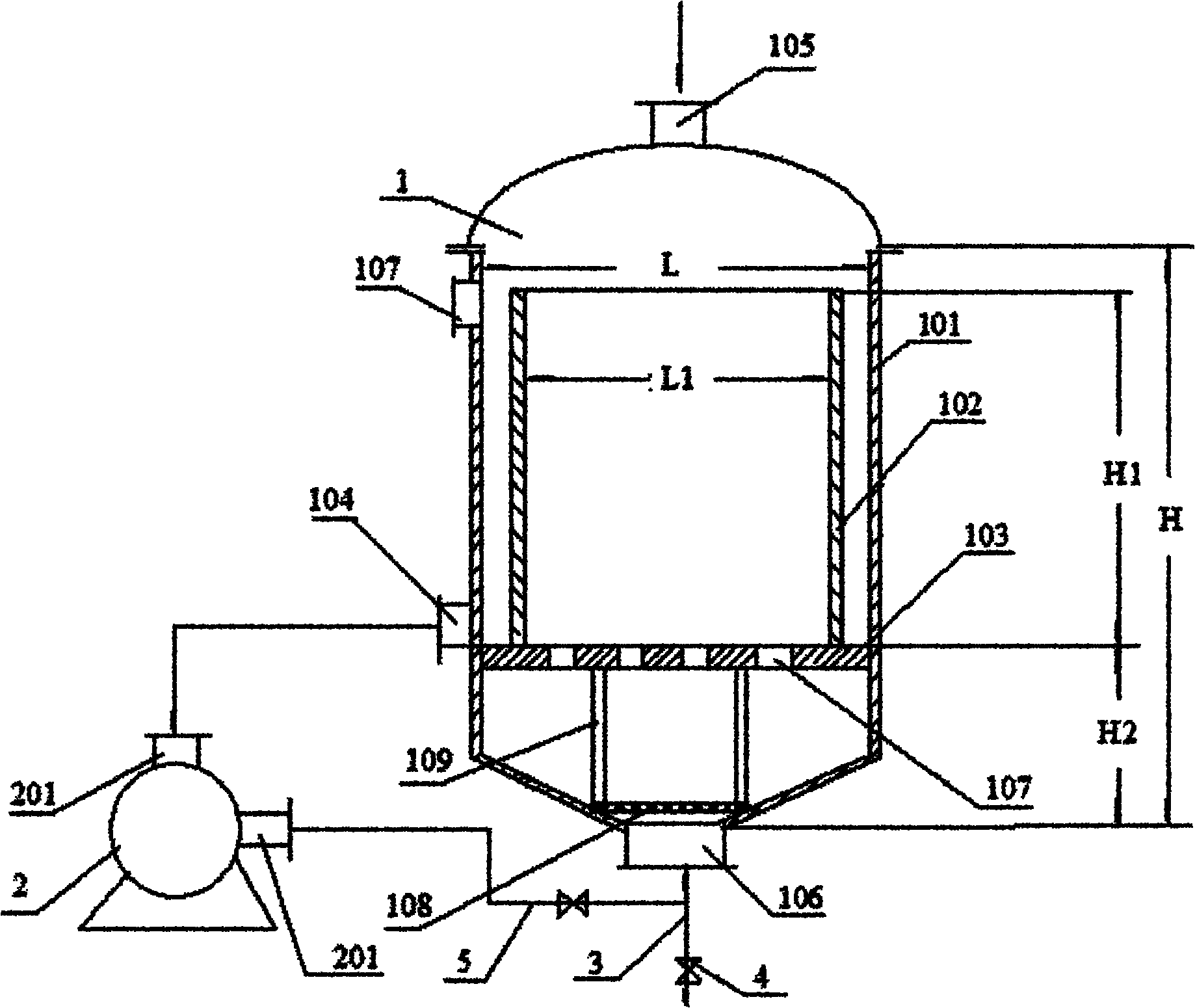

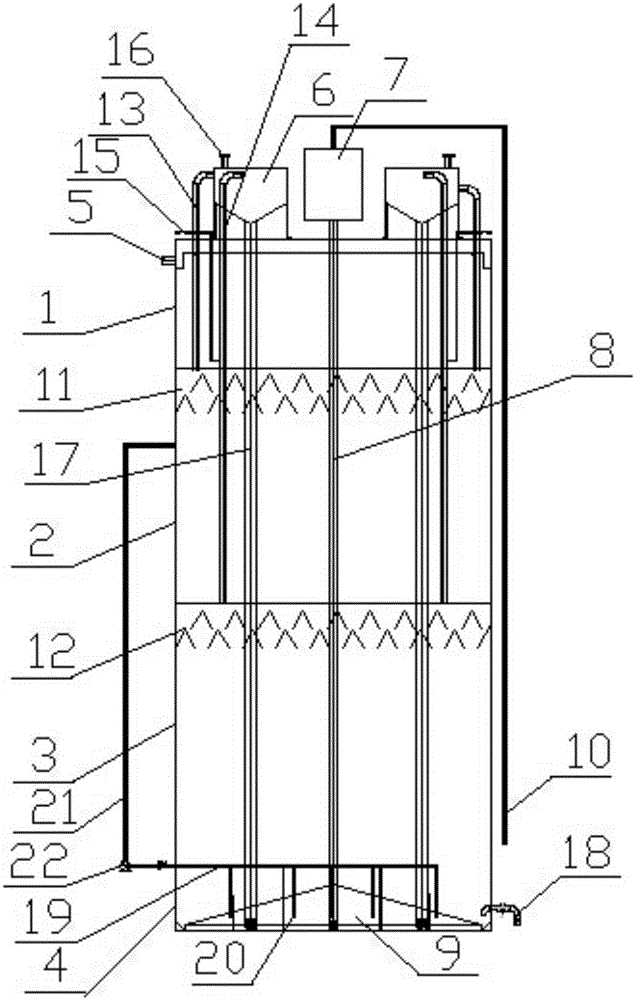

High-solid circulating anaerobic reactor

InactiveCN106281988AStir wellNo depositionBioreactor/fermenter combinationsBiological substance pretreatmentsDrive wheelAnaerobic reactor

A high-solid circulating anaerobic reactor comprises a tank body and at least one turning and lifting unit, wherein each turning and lifting unit is arranged in the tank body and comprises a driving wheel, a transmission device, a support and a driven wheel, the transmission device is mounted at the upper part of the support, a guiding barrel is arranged on the transmission device, a discharge port and a feed port are formed in the upper part and the lower part of the guiding barrel respectively, the driving wheel is connected with the output end of the transmission device, the driven wheel is mounted at the lower part of the support, a transmission belt is connected between the driving wheel and the driven wheel, and turning and lifting pieces are distributed on the transmission belt. According to the high-solid circulating anaerobic reactor, the circulating lifting disturbance units are arranged in the tank body, a material in the tank body is lifted from bottom to top and drops, so that whole rolling and stirring of the material are formed along the tank body from bottom to top, and the high-solid circulating anaerobic reactor is particularly suitable for fermentation treatment of muddy and highly-pasty solid waste with higher viscosity or higher solid content and is high in adaptability and convenient to manufacture and maintain, and the phenomenon of raw material sedimentation on the wall surface and at the bottom of the tank body can be prevented.

Owner:山东许中华环保科技有限公司

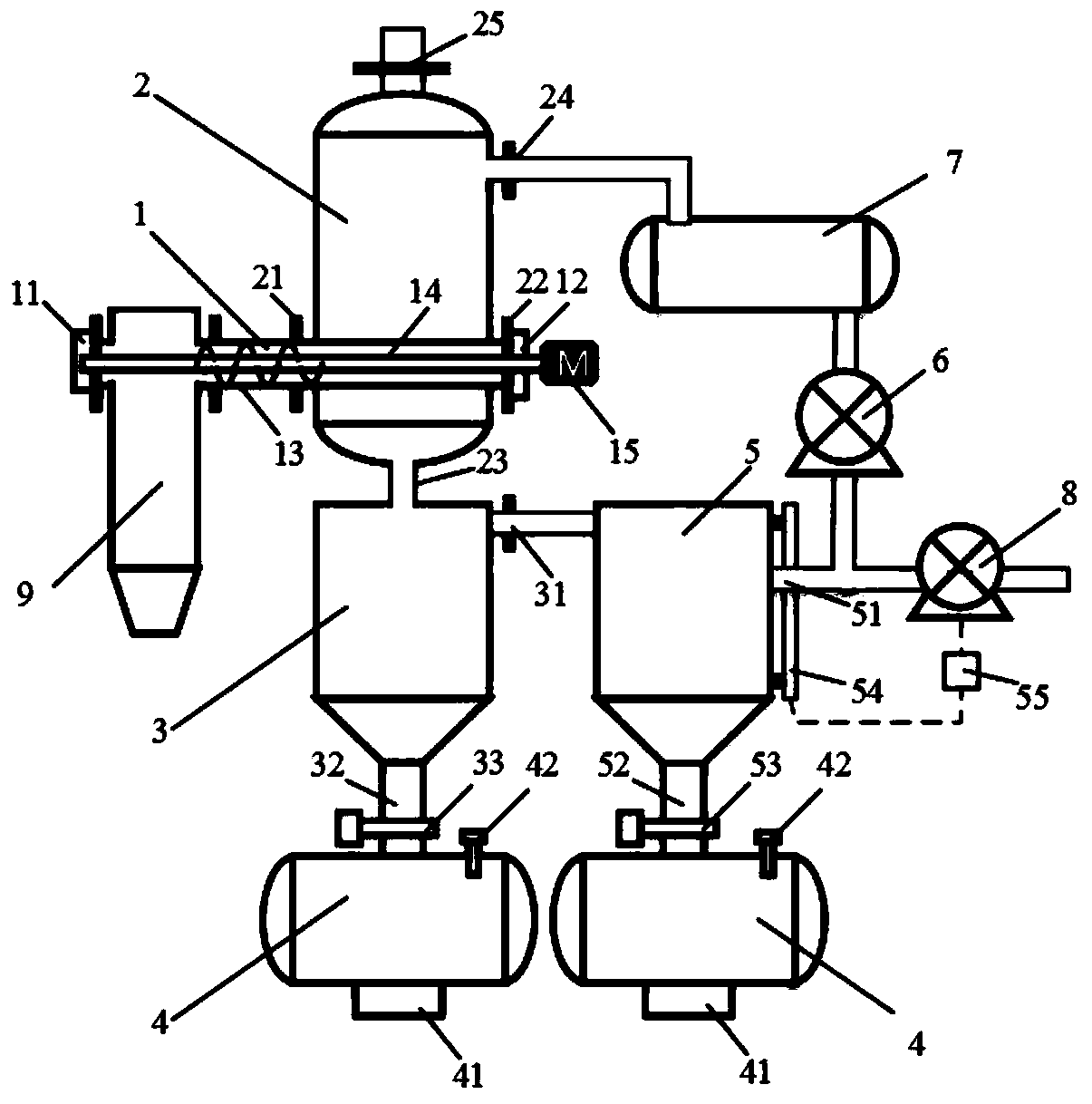

System for separating high-temperature oil gas and carbon black obtained after thermal pyrolysis of waste rubber and plastic

PendingCN109603376AAchieve separationAchieve recyclingUsing liquid separation agentSettling tanks feed/dischargeSolid carbonWaste rubber

The invention belongs to the field of waste rubber and plastic pyrolysis treatment, and relates to a system for separating high-temperature oil gas and carbon black obtained after thermal pyrolysis ofwaste rubber and plastic. By means of the system for separating the high-temperature oil gas and the carbon black obtained after thermal pyrolysis of the waste rubber and plastic, the technical problems that in the outputting process of the high-temperature oil gas, the carbon black is mixed in the high-temperature oil gas, and an oil gas conveying pipeline is blocked as the carbon black is accumulated for a long time are solved. The system comprises an oil spraying tower, a primary settling tank, a secondary settling tank, a circulating oil pump and a cooling tank, all of which are sequentially connected annularly. The input end of the oil spraying tower is connected with a wall scraping screw for conveying the high-temperature oil gas in a thermal pyrolysis device, the primary settlingtank and the secondary settling tank are connected with two primary carbon black storage tanks through a primary settling carbon black outlet and a secondary settling carbon black outlet respectively,and a secondary settling oil outlet of the secondary settling tank is connected with an oil drainage pump. By means of the system, no carbon black is deposited in a whole process channel of the high-temperature oil gas, and blockage is avoided; the carbon black and the high-temperature oil gas are separated, the solid carbon black and the pure high-temperature oil gas are obtained, and meanwhilespraying oil is recycled.

Owner:QINGDAO EXCEL INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com