Double-solid-phase suspended bed reactor used for heavy oil hydrocracking and application thereof

A heavy oil hydrogenation and reactor technology, which is applied in the field of coal chemical industry, can solve problems such as deactivation, easy loss, and complicated equipment, and achieve the effect of improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

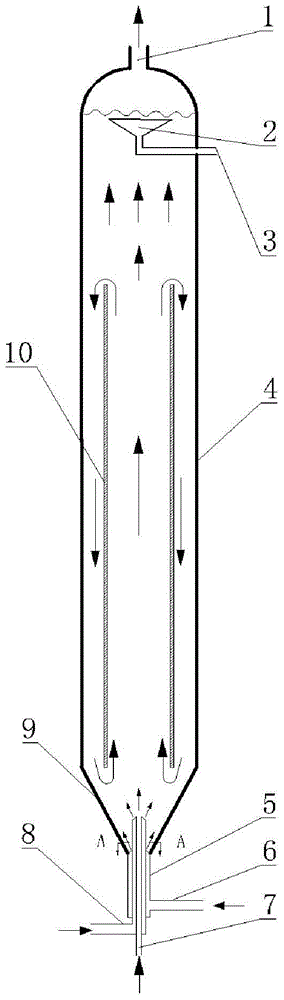

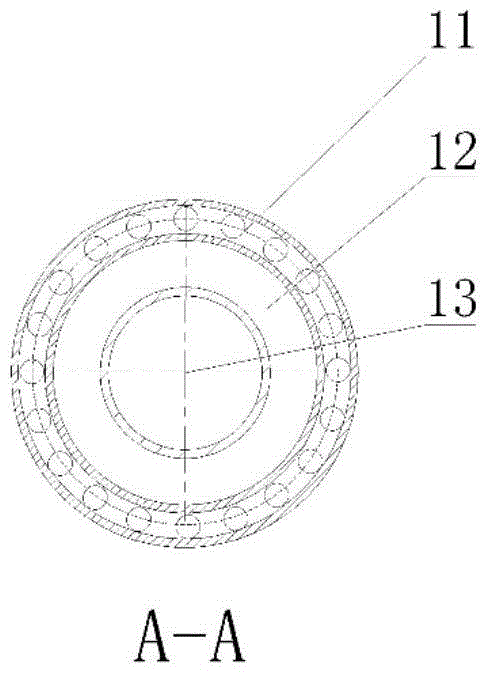

[0049] refer to figure 1 , the cold model experiment of double solid phase suspended bed reactor was carried out. In the experiment, the inner diameter of the shell was 1.21m, the height of the shell was 12m, the cone angle of the conical bottom was 60°, and the height of the conical bottom was 1.05m. The liquid outlet of the nozzle and the loose gas outlet were located at On the same horizontal plane and located 0.35m directly above the driving gas outlet, the bottom of the guide tube is 0.7m above the liquid outlet of the nozzle, concentric with the casing, the diameter of the guide tube is 0.8m, the length of the guide tube is 8.4m, and the gas-liquid material is sprayed Feed.

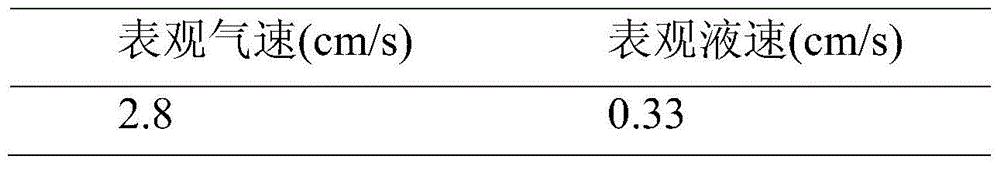

[0050] Operating conditions: see Table-1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com