Novel slit type spray head and spray coating machine head

A slit type nozzle technology, applied in the field of new type slit type nozzle and its spraying machine head, can solve problems such as unstable gap, unstable response speed, and increased electrode manufacturing cost, so as to delay the appearance of streaks and improve the response speed Fast, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

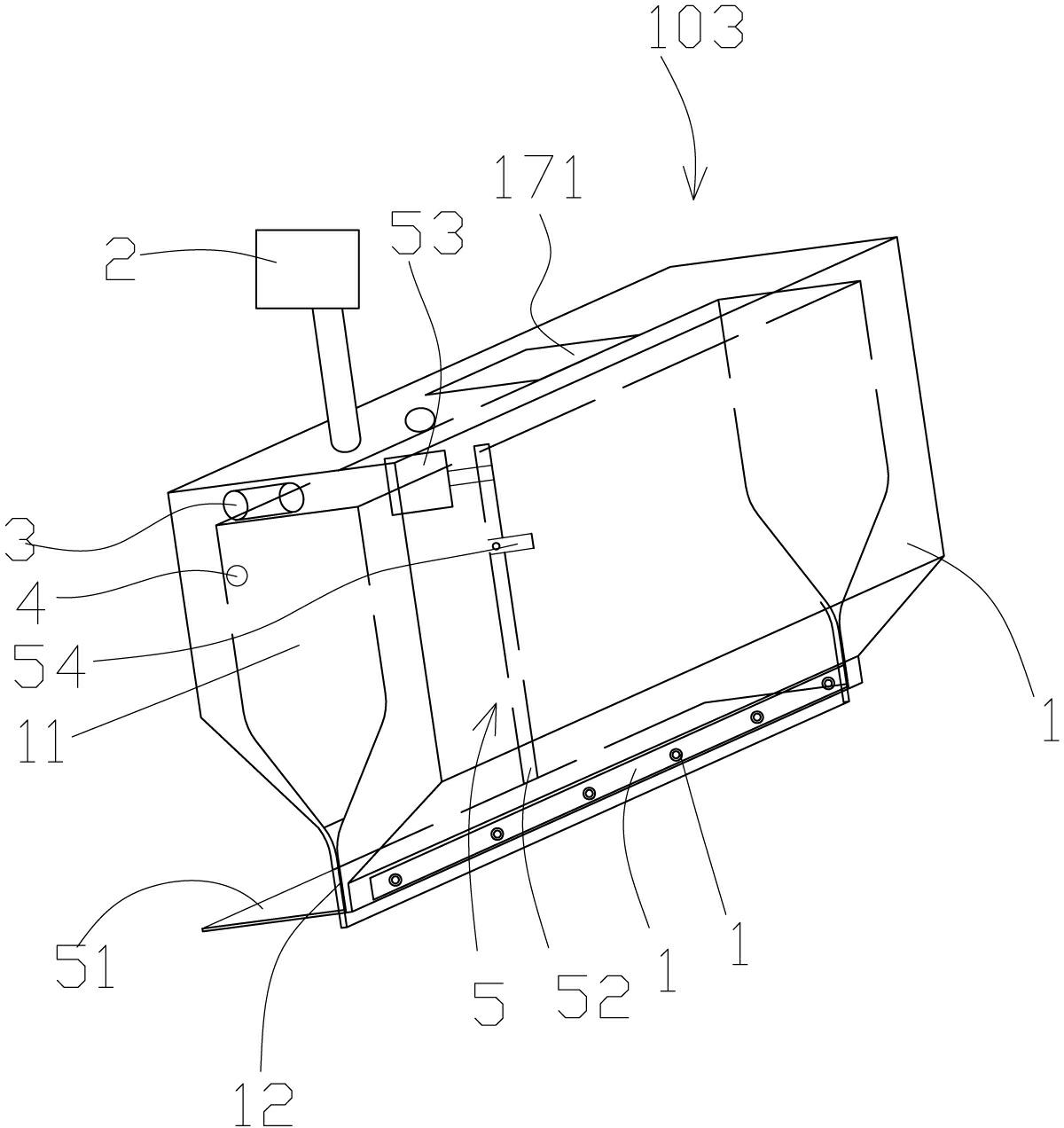

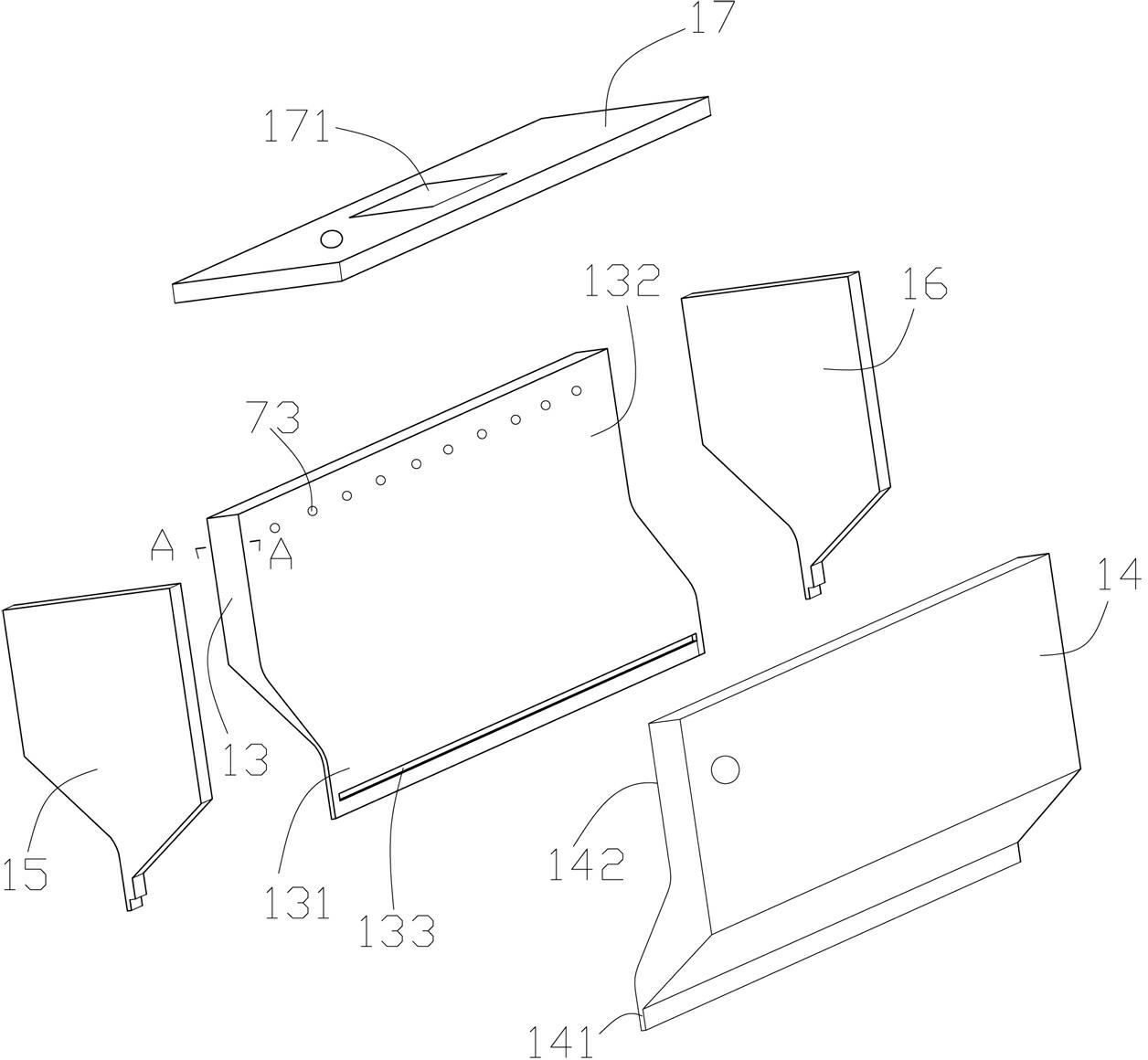

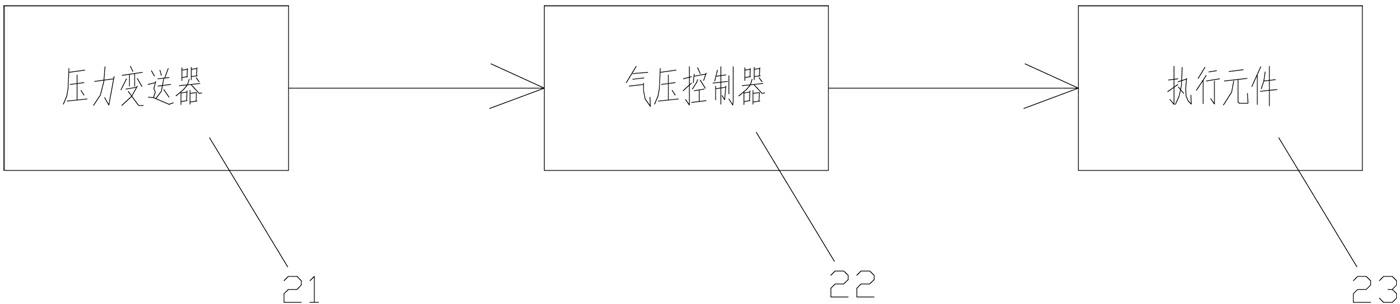

[0037] See figure 1 , figure 1Disclosed is a novel slit nozzle 103, comprising a nozzle main body 1, in which a content cavity 11 and a slit nozzle 12 are arranged, and the content cavity 11 and the slit nozzle 12 Communication; constant pressure gas supply system 2, to provide constant pressure gas in the container chamber 11; slurry supply control system 3, including slurry supply device (not shown in the figure) and liquid level control system 4, the liquid level The control system 4 controls the working state of the slurry supply device according to the slurry liquid level height in the storage chamber 11, and keeps the liquid level height in the storage chamber 11 constant; the slit nozzle switch control device 5, according to the main control device Signal to open or close the slit nozzle 12. In this way, the air pressure and liquid level in the container chamber 11 are constant, so that the purpose of constant material pressure and fast response can be achieved, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com