Complex vacuum deposition device

A technology of equipment and vacuum chamber, applied in the field of composite vacuum deposition equipment, can solve the problems of not realizing the optimal distribution of reaction gas, poisoning of magnetron sputtering source, etc., and achieve the effect of optimizing working range and reducing coating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

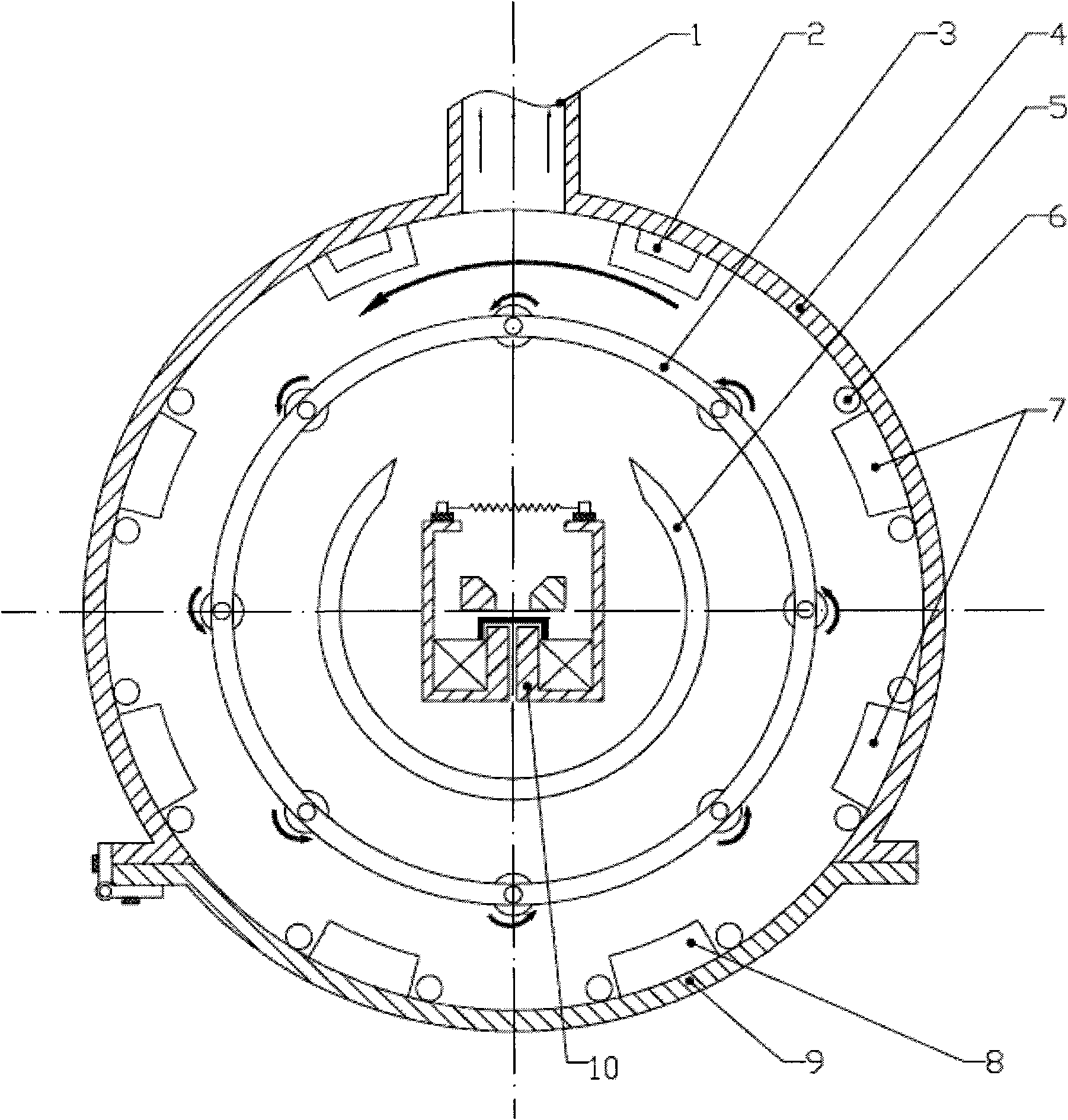

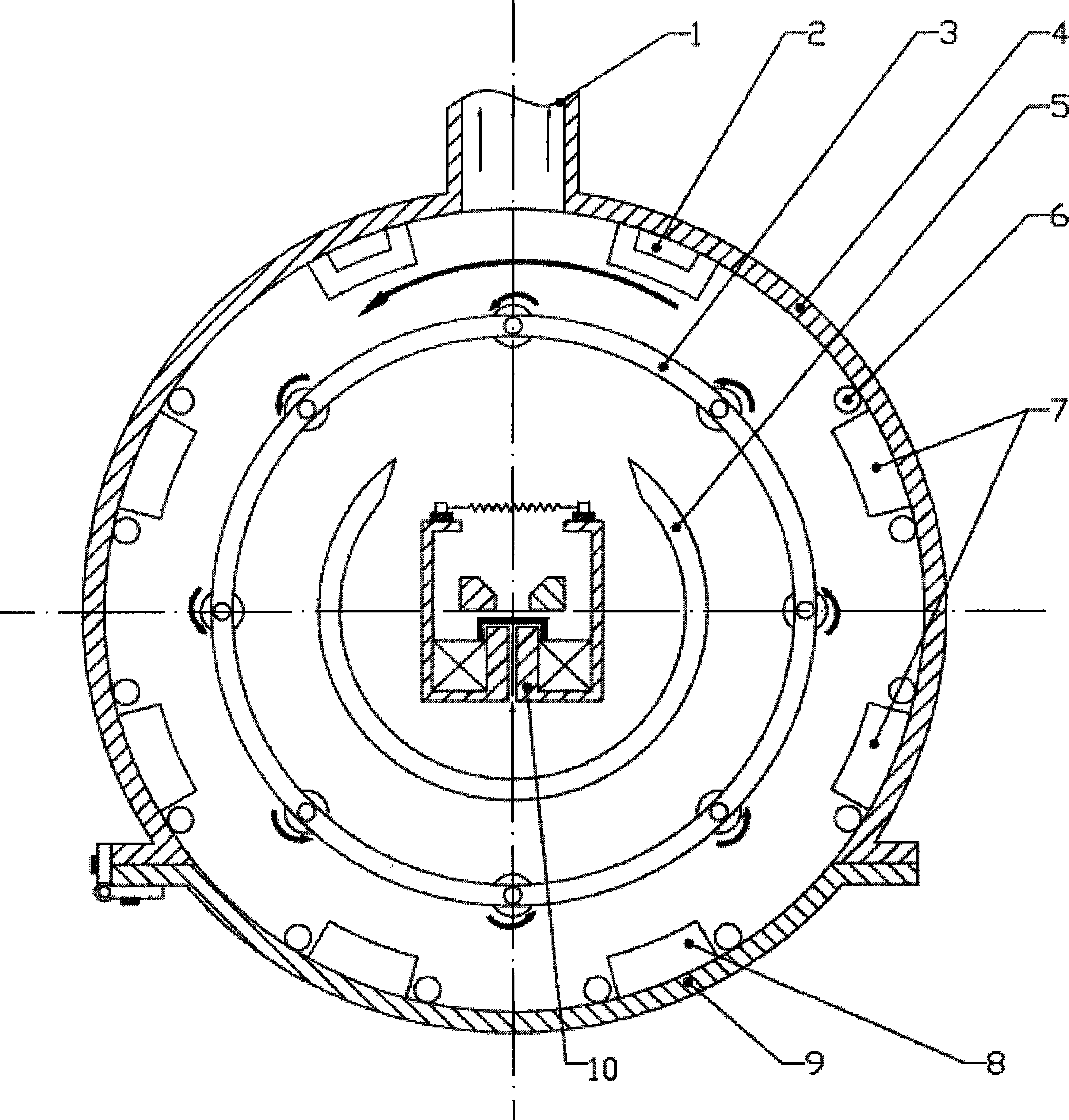

[0021] Below in conjunction with accompanying drawing, the patent of the present invention is described in detail.

[0022] A new type of composite vacuum deposition equipment, mainly composed of a coating chamber 4, a cathode arc evaporation source 2, an intermediate frequency magnetron sputtering source 7, a DC magnetron sputtering source 8, a gas ion source 10, a working gas inlet pipe 6, and a workpiece Frame 3 and vacuum acquisition system, vacuum measurement system, air intake system, power supply and control system, etc. The air extraction port 1 is installed on the rear side of the vacuum chamber and connected with the vacuum obtaining system. The cathodic arc evaporation source 2 is installed on the vacuum chamber wall near the two sides of the pumping port 1, the intermediate frequency magnetron sputtering source 7 is installed on the vacuum chamber wall in the middle of the left and right sides, and the DC magnetron sputtering source 8 is installed far away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com