Novel draft-tube and preparation method thereof

A draft tube and a new type of technology, applied in the field of draft tubes, can solve the problems of aquatic weed deposition, limitation, increase local resistance of draft tubes, etc., and achieve the effects of uniform flow direction speed, avoid pressure pulsation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

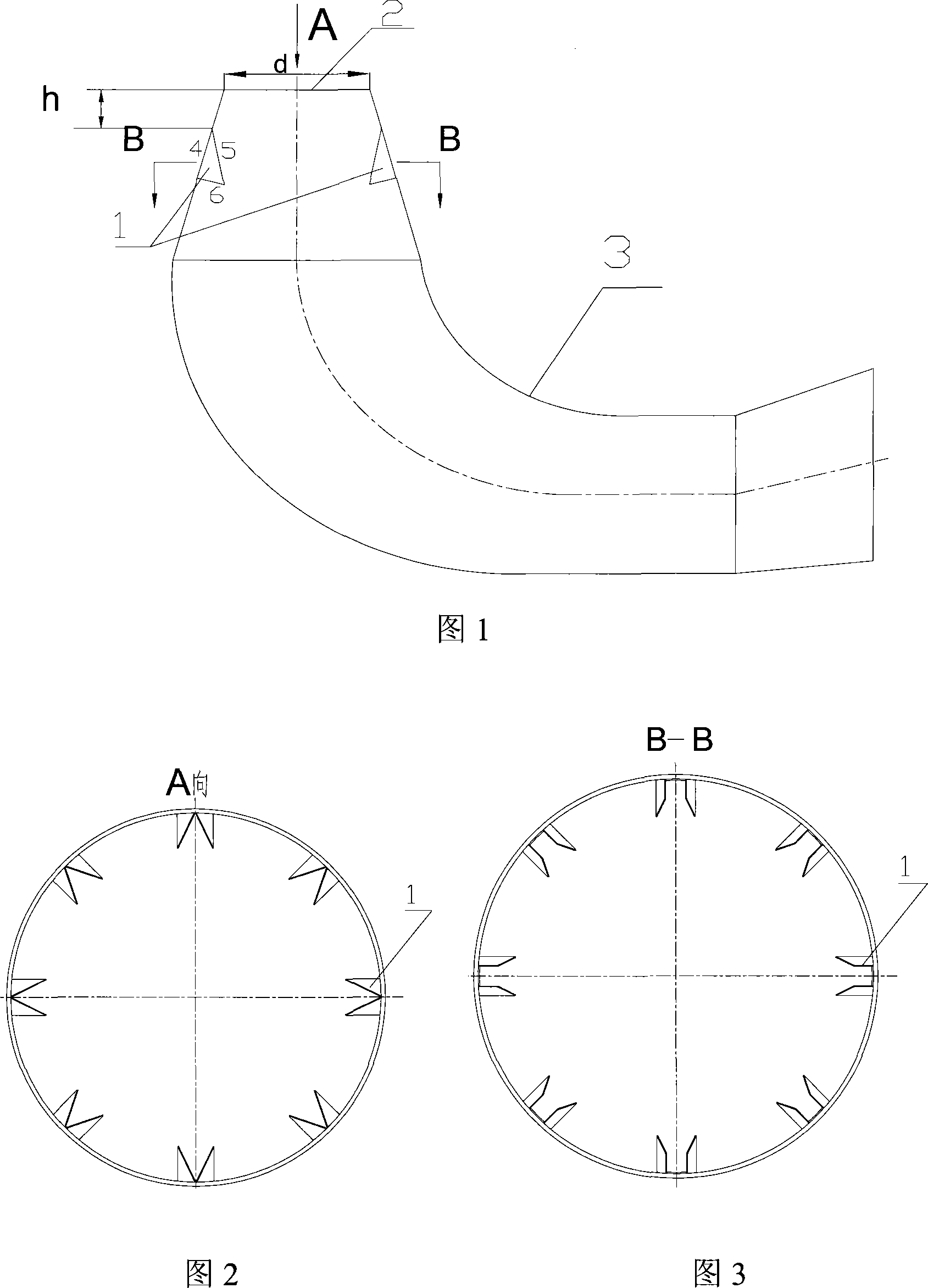

[0022] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

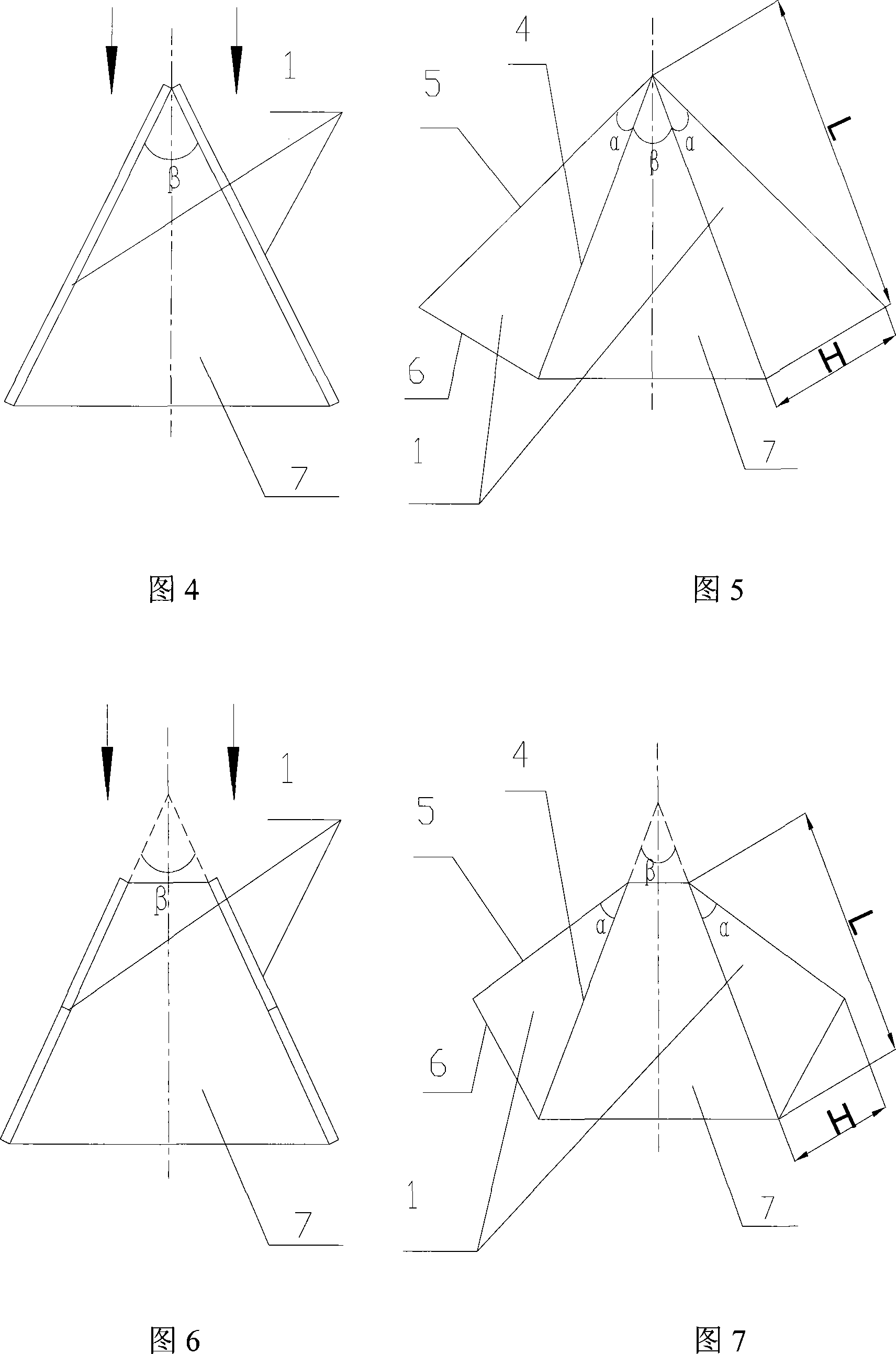

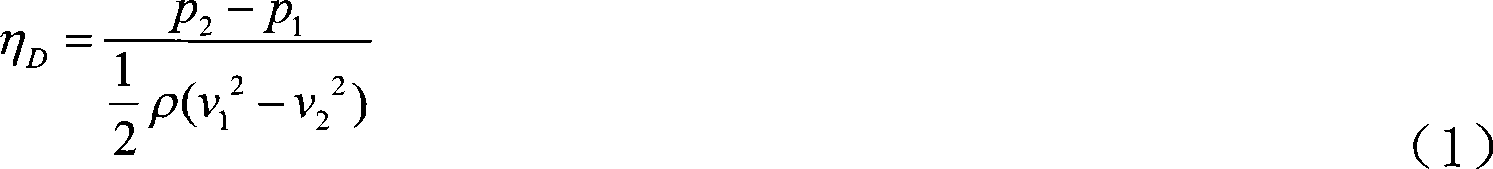

[0023] As shown in Fig. 1, Fig. 2 and Fig. 3, the structure of the novel draft tube is specifically that eight pairs of triangular blades are uniformly and fixedly arranged on the inner wall of the water inlet of the pipe body 3 along the circumferential direction. Each pair of triangular blades includes two symmetrically arranged triangular blades 1, and each triangular blade 1 includes a long side 5, a short side 6 and an installation side 4, wherein the long side 5 is arranged on the side close to the end face 2 of the water inlet, and the short side 6 It is arranged on the side away from the end surface 2 of the water inlet, and the installation side 4 is connected to the inner wall of the water inlet on the whole side. The included angle between the mounting side 4 and the long side 5 is α, and α is 2°, 10°, 30°, etc. The included a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com