Flow passage type sewage heat exchanger

A heat exchanger and runner type technology, which is applied in the field of runner type sewage heat exchangers, can solve the problems of large welding workload, high cost, fatigue damage of weld seams, etc., and achieves low manufacturing cost, reasonable structure, flow channel smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

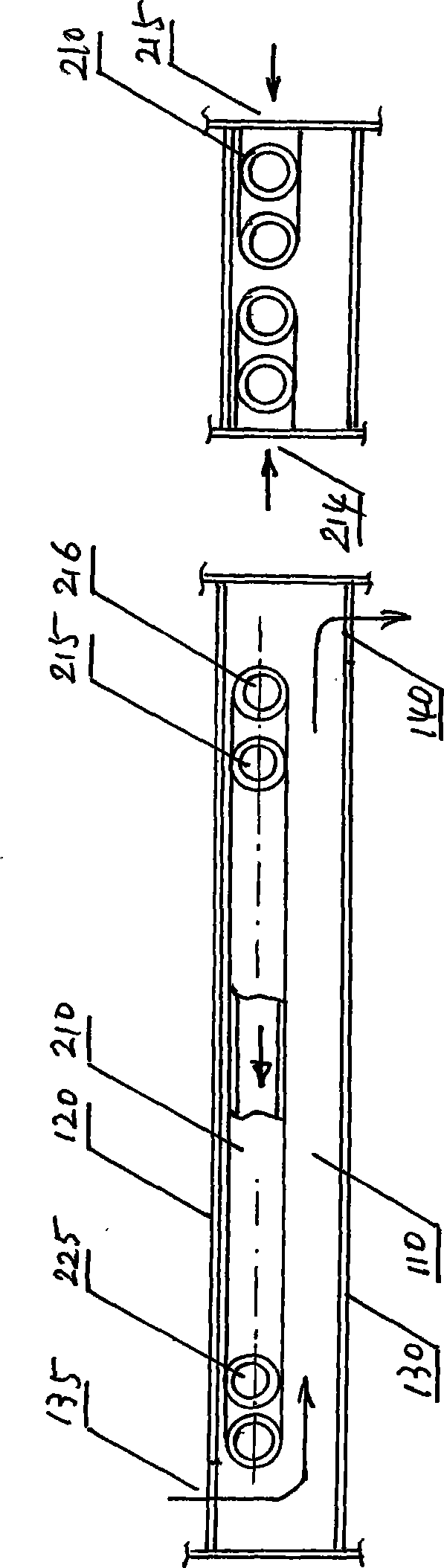

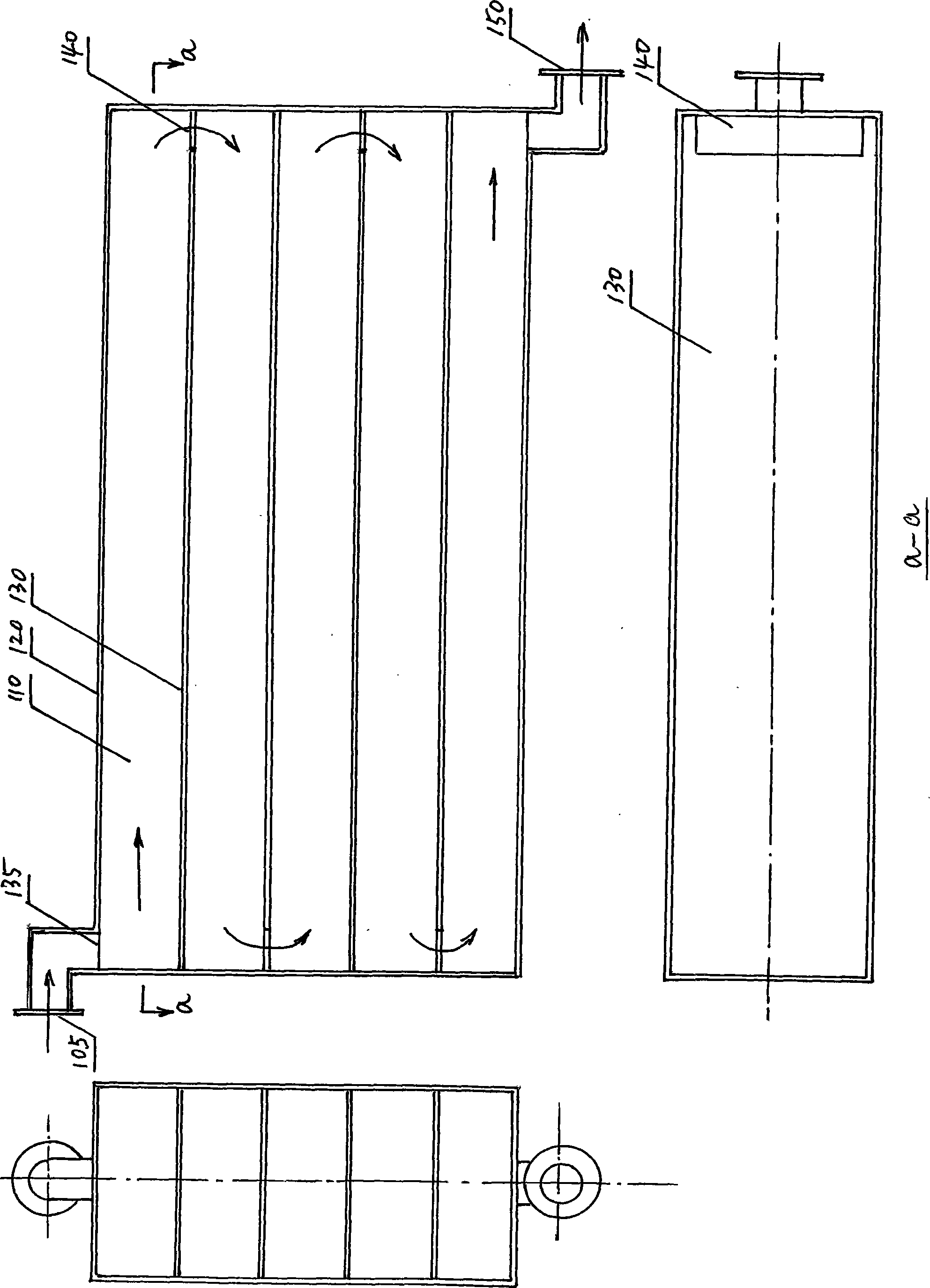

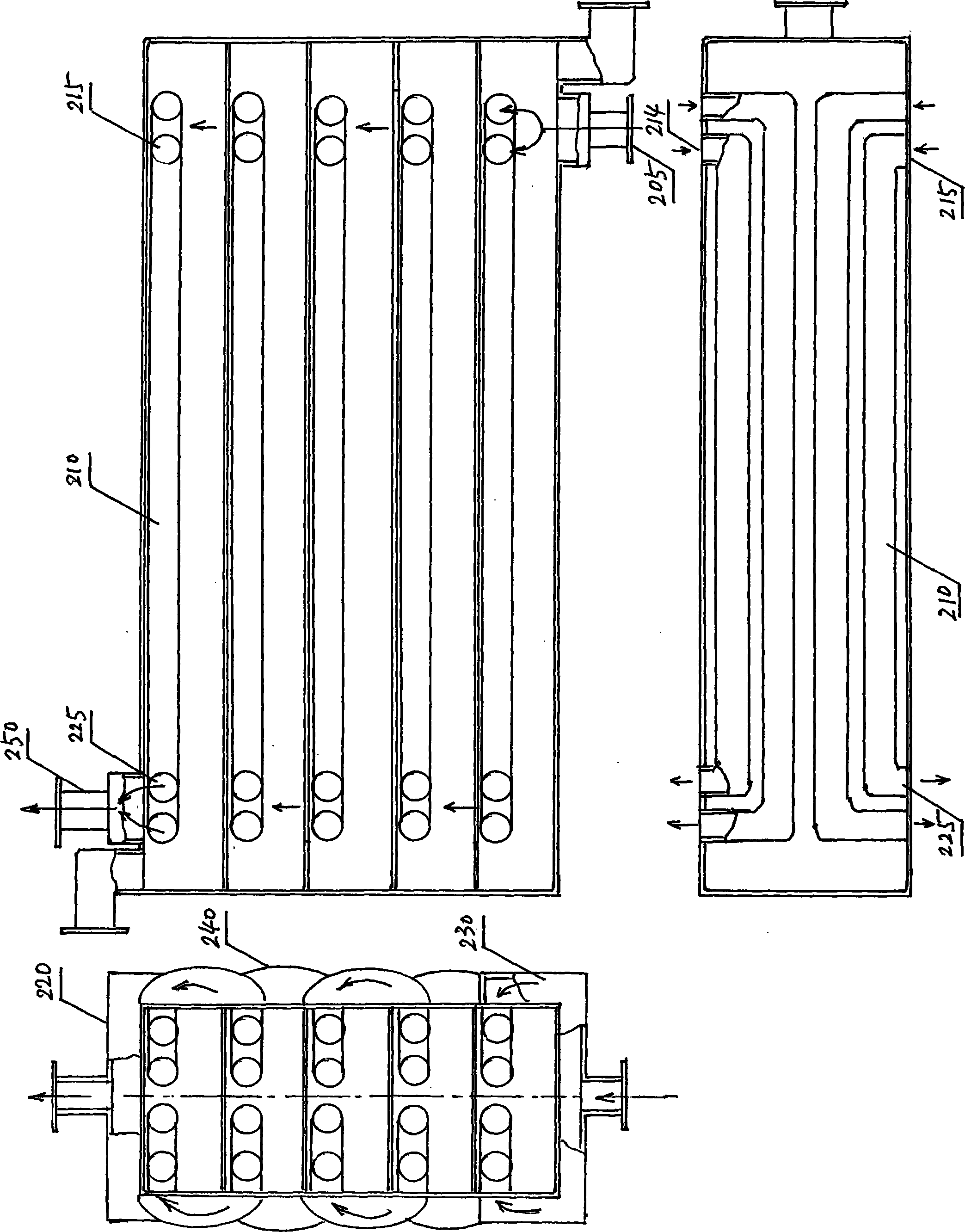

[0034] figure 1 The basic principle diagram of the embodiment of the channel type sewage heat exchanger of the present invention is given.

[0035] The basic principle of the embodiment of the flow channel type sewage heat exchanger of the present invention is as follows: figure 1 , indicating two channels of sewage and clean water, and the sewage and clean water conduct convective heat exchange.

[0036] The sewage flow channel is a sewage pipeline 110 with a rectangular cross-section formed by the top plate 120 and the bottom plate 130 of the flow channel, as well as side plates and end plates. The water inlet 135 of the sewage pipeline 110 is at one end of the top plate 120 , and the water outlet 140 of the sewage pipeline 110 is at the other end of the bottom plate 130 .

[0037] In the sewage pipeline 110, a clean water flow channel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com