System for separating high-temperature oil gas and carbon black obtained after thermal pyrolysis of waste rubber and plastic

A separation system and carbon black technology, applied in the direction of separation device, precipitation separation, separation method, etc., can solve the problems of oil and gas transmission pipeline blockage, mixing, shutdown, etc., and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

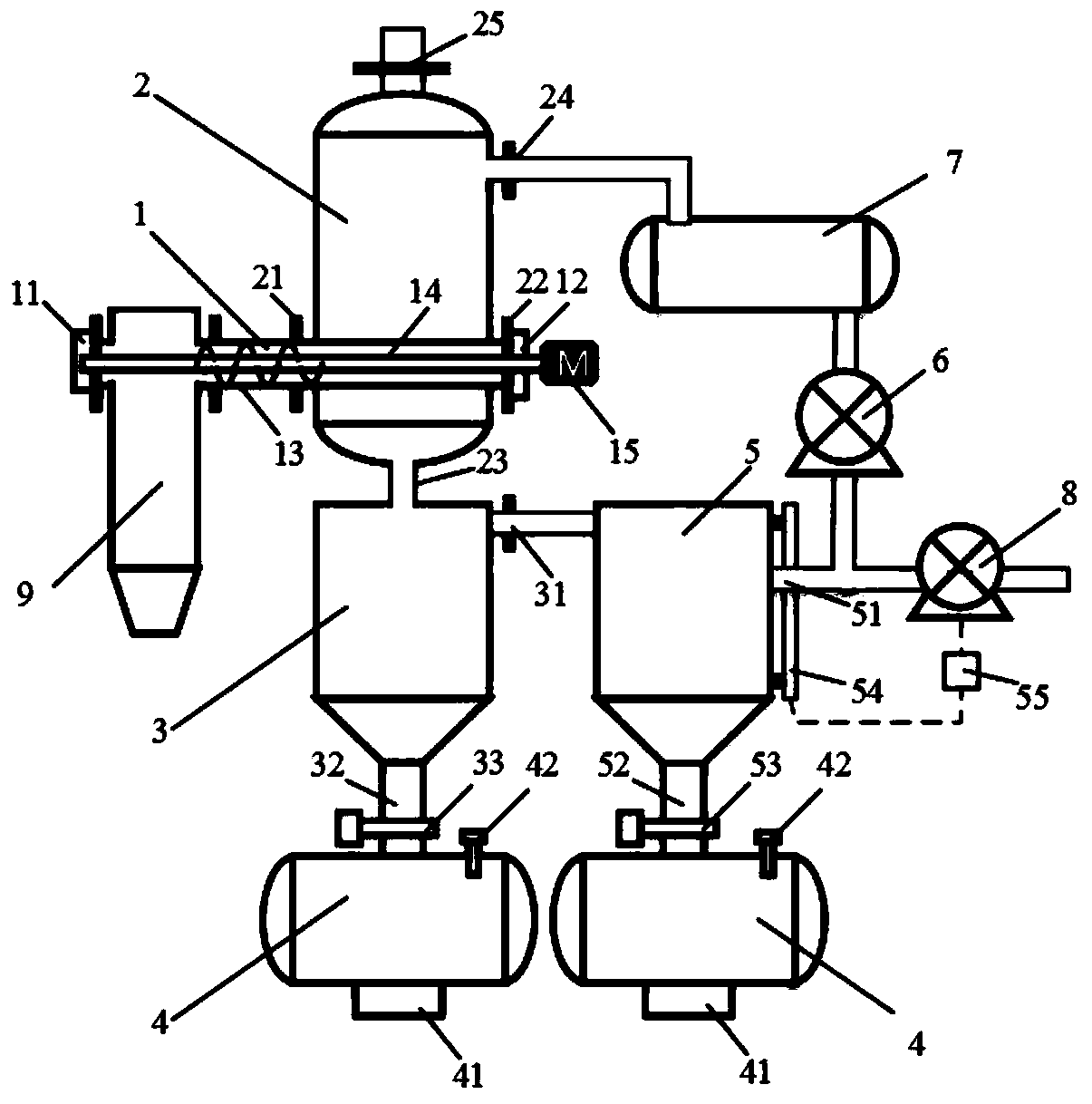

[0039] like figure 1 As shown, the waste rubber and plastic high-temperature oil gas and carbon black separation system disclosed in this embodiment includes an oil spray tower 2, a primary settling tank 3, a secondary settling tank 5, a circulating oil pump 6, and a cooling tank 7 connected sequentially in an annular manner. , the cooling tank 7 takes away the heat of the circulating oil through water-cooling or air-cooling heat exchange; the input end of the oil spray tower 2 is connected with a wall-scraping screw for transporting high-temperature oil and gas in the thermal cracking device 9 1, the primary settling tank 3 and the secondary settling tank 5 are respectively connected with two primary carbon black storage tanks 4 through the primary sedimentation carbon black outlet 32 and the secondary sedimentation carbon black outlet 52, and the primary carbon black storage tank The bottom of 4 is provided with a carbon black discharge port 41, and the top is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com