Printing and dyeing wastewater treatment technique

A technology for treating process, printing and dyeing wastewater, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment and other directions, can solve the problems of unstable effluent quality, high energy consumption, short flow, etc., and achieve stable treatment effect. , the effect of high pollutant concentration and deep chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

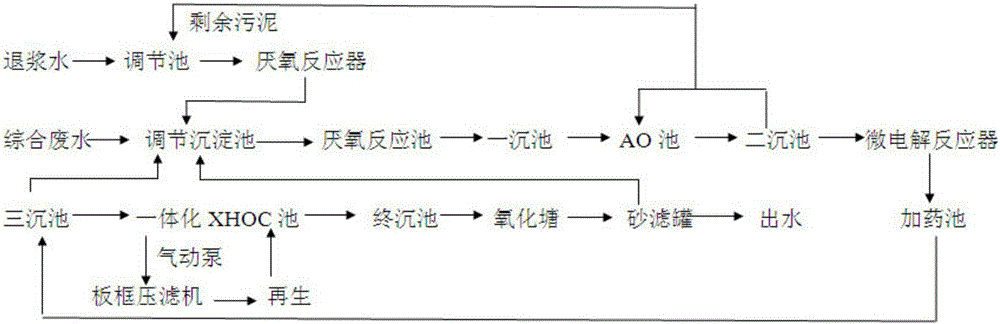

[0075] Embodiment 1 A kind of printing and dyeing wastewater treatment process, such as figure 1 As shown, the specific steps are as follows:

[0076] (1) The desizing wastewater first enters the adjustment tank, and acid is added to adjust the pH, so that the pH is between 6-8, and the pump is lifted to the anaerobic reactor. Under the action of anaerobic bacteria, the organic matter in the wastewater is converted into methane , carbon dioxide and water, and at the same time, the refractory macromolecular organic matter in the wastewater is opened and broken to become a small molecular organic matter, and then the supernatant flows to the regulating sedimentation tank by itself;

[0077] (2) After the other comprehensive wastewater except desizing wastewater is collected through the pipeline and the anaerobic desizing water enters the regulating sedimentation tank, it settles for 8 hours, and the supernatant is lifted to the anaerobic reaction tank by the pump. The function ...

Embodiment 2

[0082] Embodiment 2 handles the final sludge that printing and dyeing wastewater treatment process of the present invention produces

[0083] The final sludge produced by the whole treatment process is sent to the sludge thickening tank, dehydrated by the dehydrator, and the dehydrated sludge is incinerated without secondary pollution; the supernatant from the sludge thickening tank and the dehydrator come out The water is sent to the regulating sedimentation tank for treatment.

Embodiment 3

[0084] The anaerobic reactor in the treatment process of embodiment 3 of the present invention

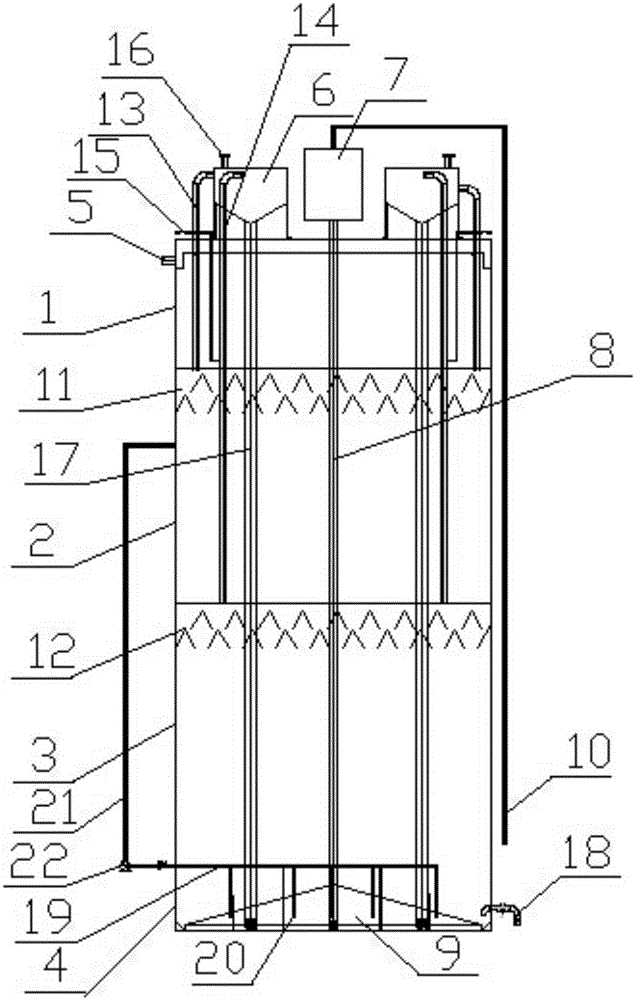

[0085] Such as figure 2 As shown, the anaerobic reactor includes a precipitation zone 1, an upper layer three-phase separation zone 2, a lower layer three-phase separation zone 3 and a swirling water distribution zone 4 from top to bottom. There are two gas-liquid separators 6 and a pulse water distributor 7 above the area 1, and the pulse water distribution pipe 8 is provided at the bottom of the pulse water distributor 7, and the pulse water distribution pipe 8 extends to the reflection cone 9 at the bottom of the swirl water distribution area 4 Inside, the top of the pulse water distributor 7 is connected to the water inlet pipe 10, the upper three-phase separation zone 2 is provided with an upper three-phase separator 11, the lower three-phase separation zone 3 is provided with a lower three-phase separator 12, and the upper three-phase The separator 11 is connected to the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com