Patents

Literature

1396 results about "Sanitary sewer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

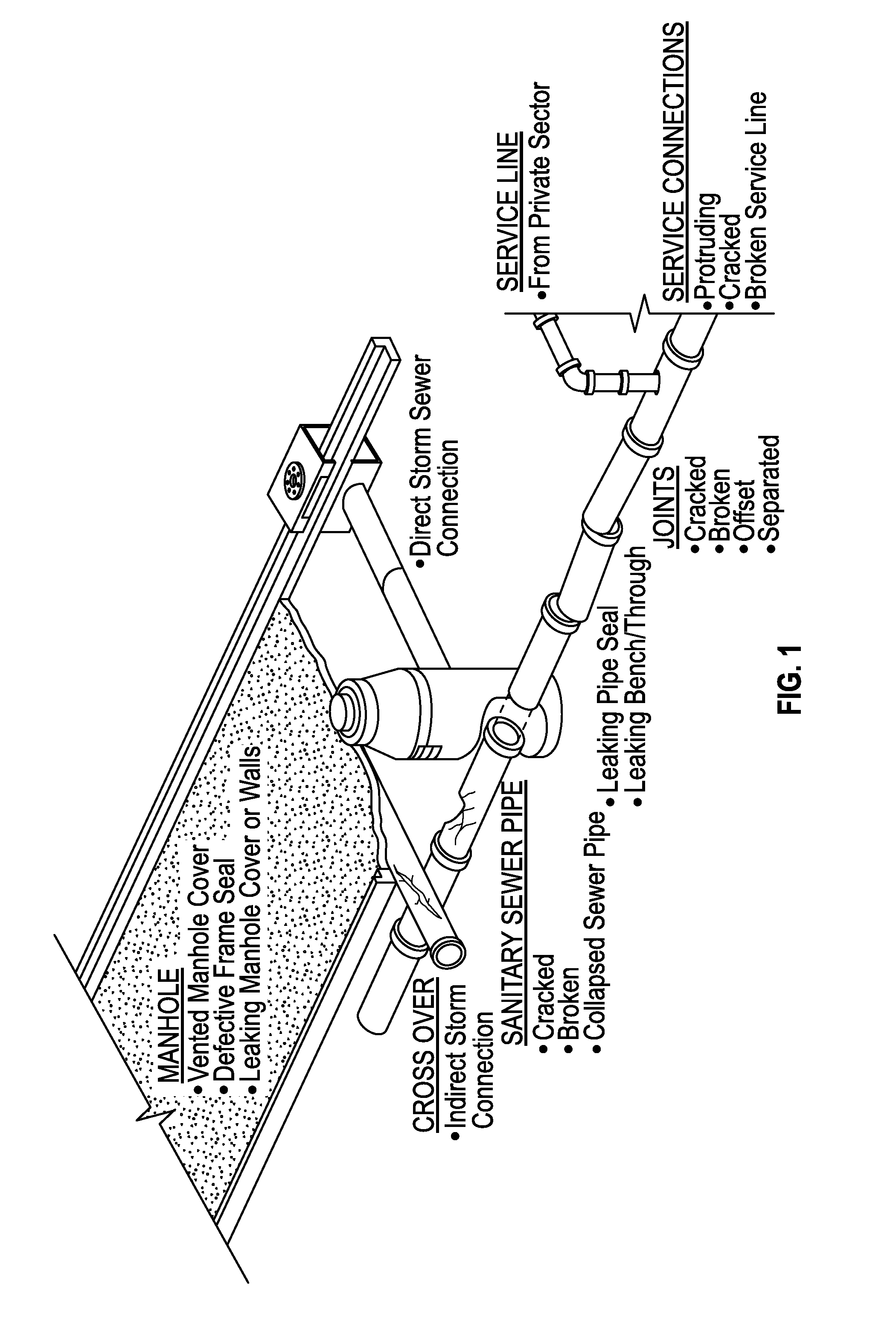

A sanitary sewer or foul sewer is an underground pipe or tunnel system for transporting sewage from houses and commercial buildings (but not stormwater) to treatment facilities or disposal. Sanitary sewers are part of an overall system called a sewage system or sewerage.

Recirculating marine aquaculture process

A high efficiency recirculating marine aquaculture process for producing fish at variable yield densities of up to 60 kg / meter3 of the aquaculture tank, including fish that spawn under short photoperiods such as gilthead seabream (Sparus aurata) as well as fish that spawn under long photoperiods such as striped bass (Morone saxatilis). The process involves broodstock conditioning, spawning / reproduction, larval growth, nursery, and adult grow-out operations. The process is characterized by high-rate growth at optimal process conditions requiring less than 10% daily water exchange, thereby enabling effluent waste from the system to be discharged to a municipal sewer after disinfection treatment, which in turn permits siting of the aquaculture process facility in urban / suburban locations where aquaculture processes have been previously infeasible.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

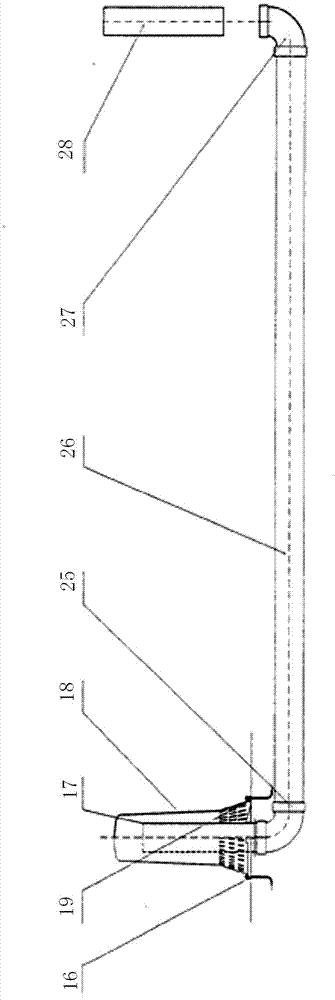

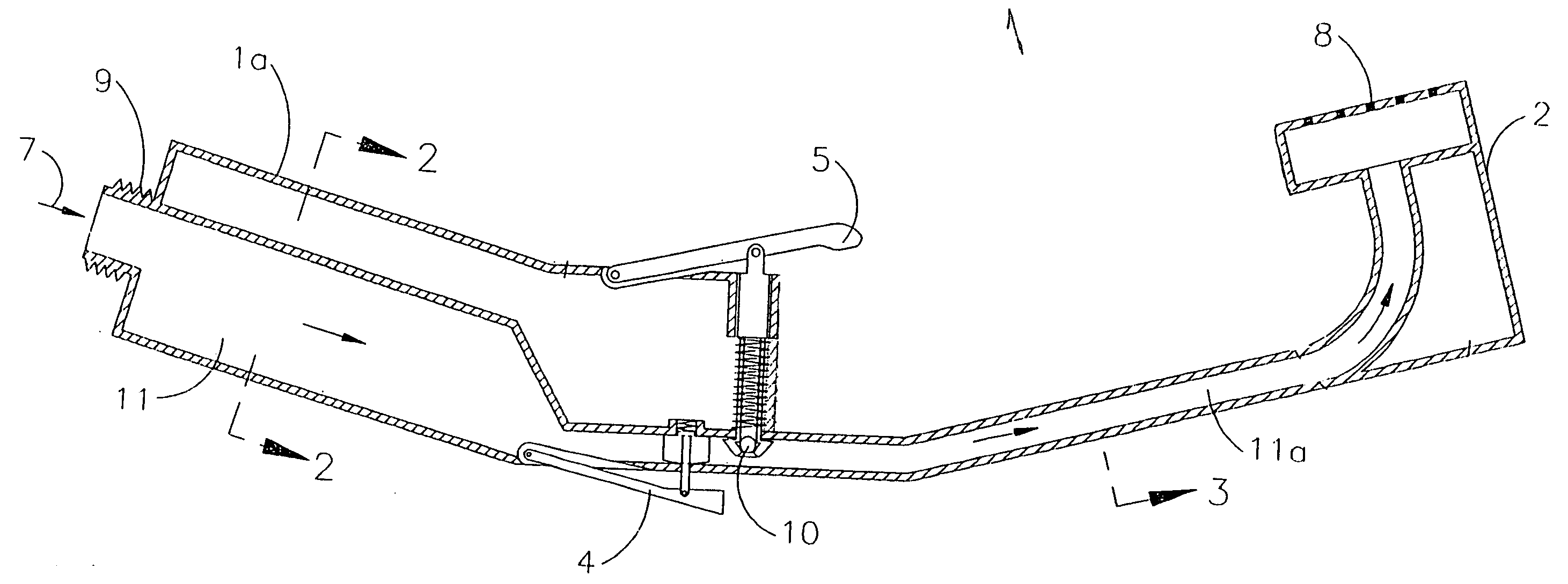

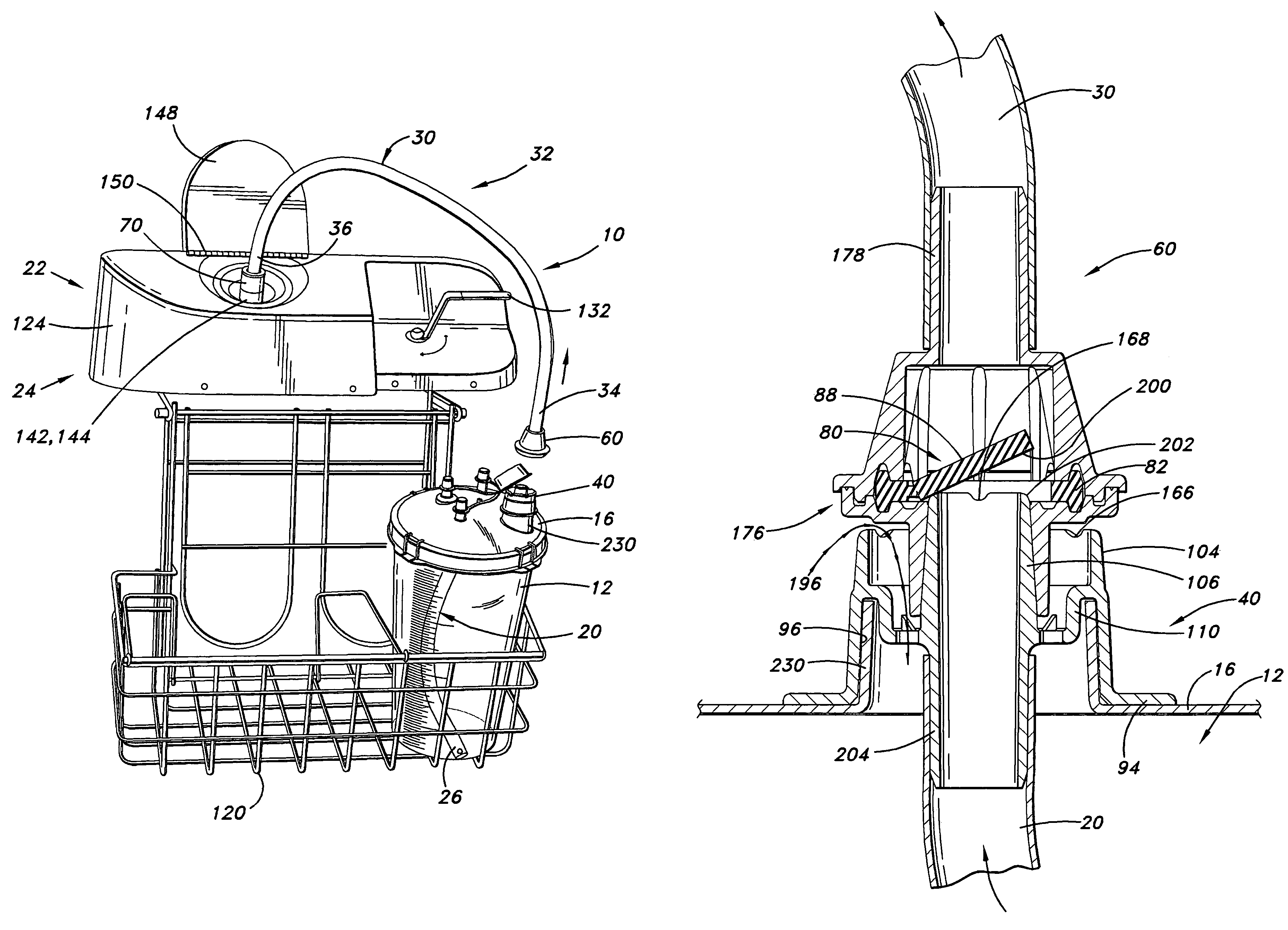

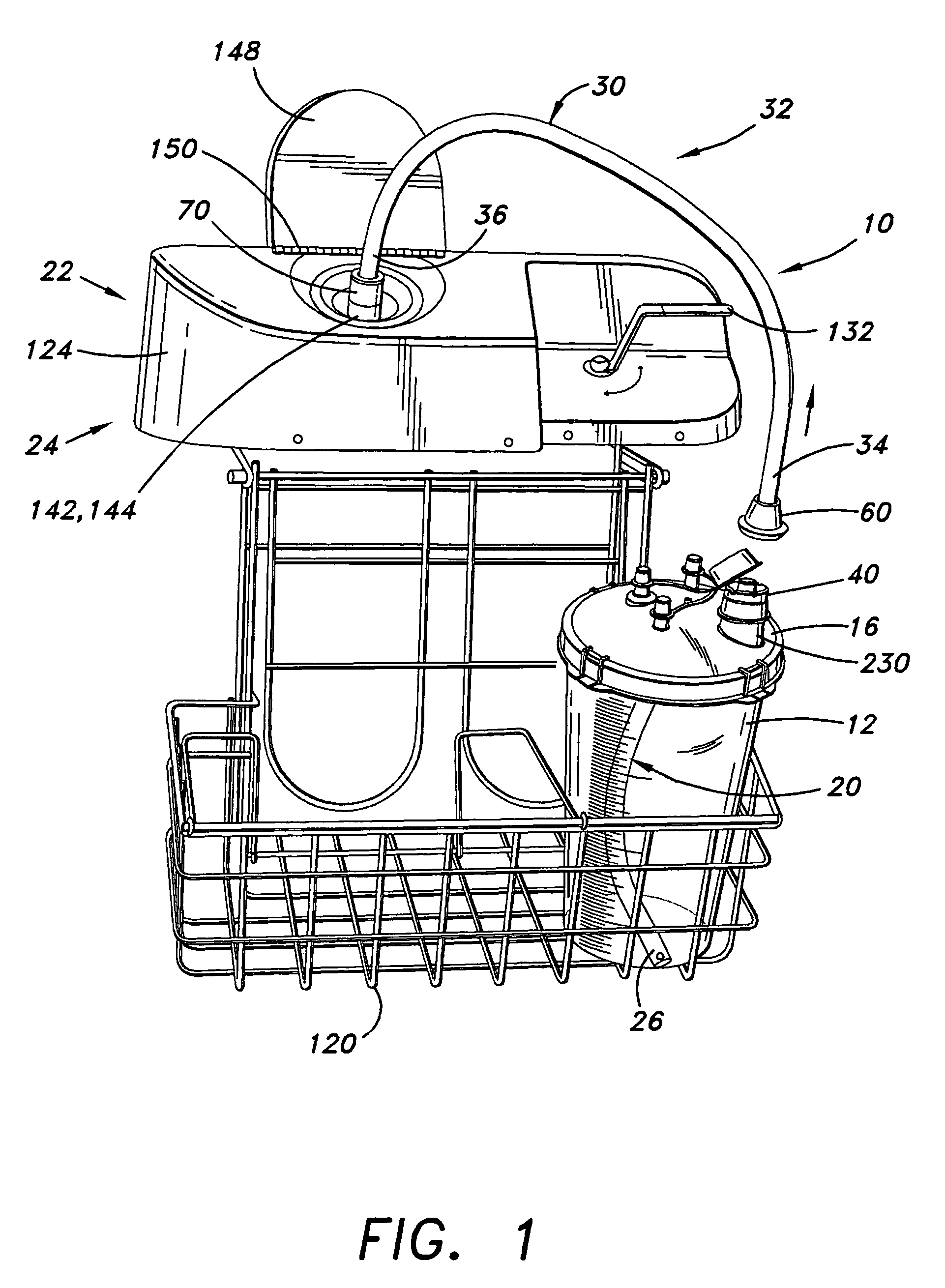

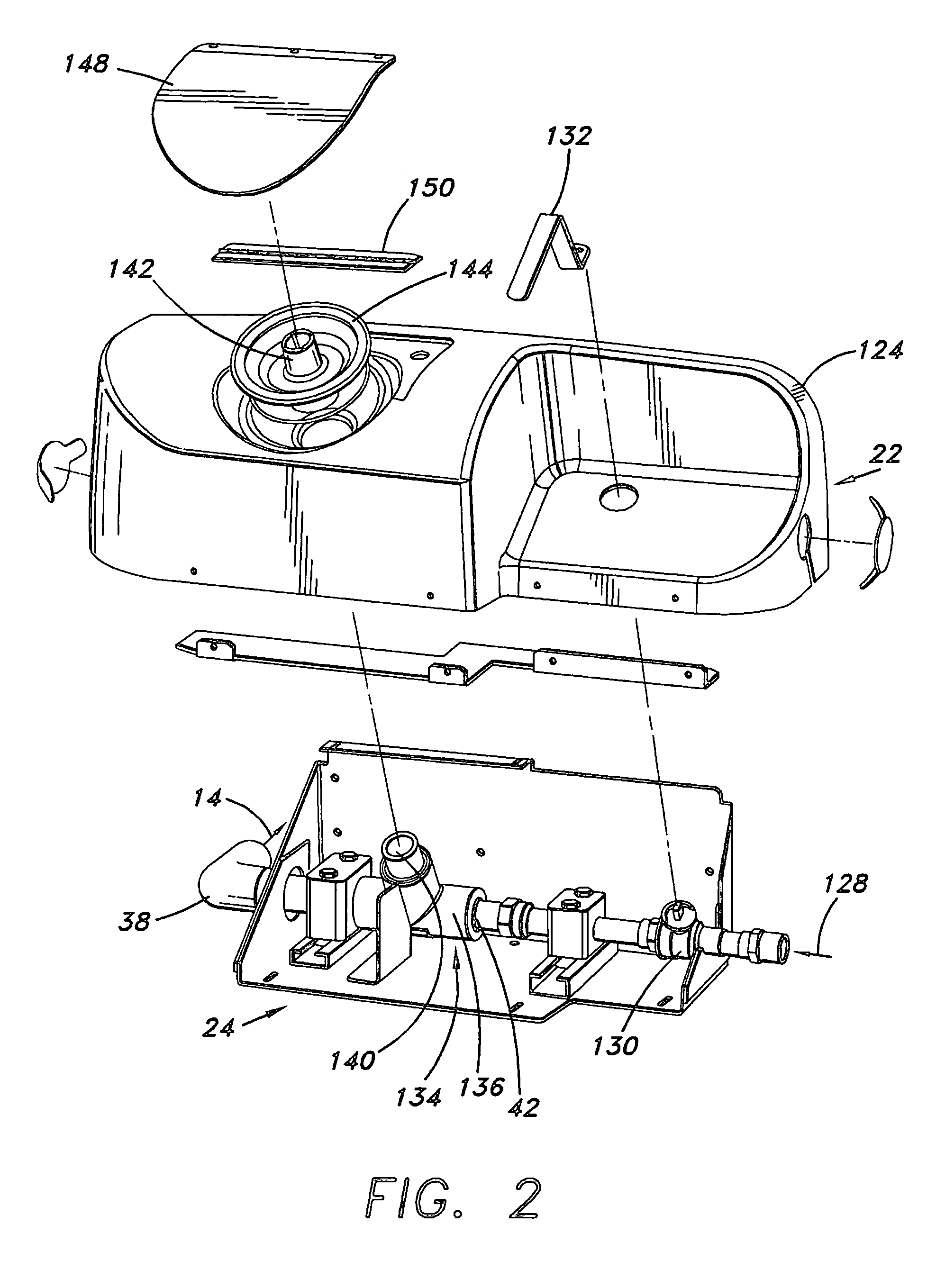

Method and apparatus for the disposal of waste fluids

An innovative method and apparatus for disposing of waste fluids, especially human body fluids such as are generated during surgery, into a hospital's sanitary sewer system is provided. A conduit system is adapted to transport waste fluid from a receptacle to a sanitary sewer using an eductor having a venturi device. The conduit system includes first and second conduits. First and second connectors are used to easily connect the first conduit to the second conduit. The second connector includes a flap that acts as a check valve.

Owner:ALLEGIANCE CORP

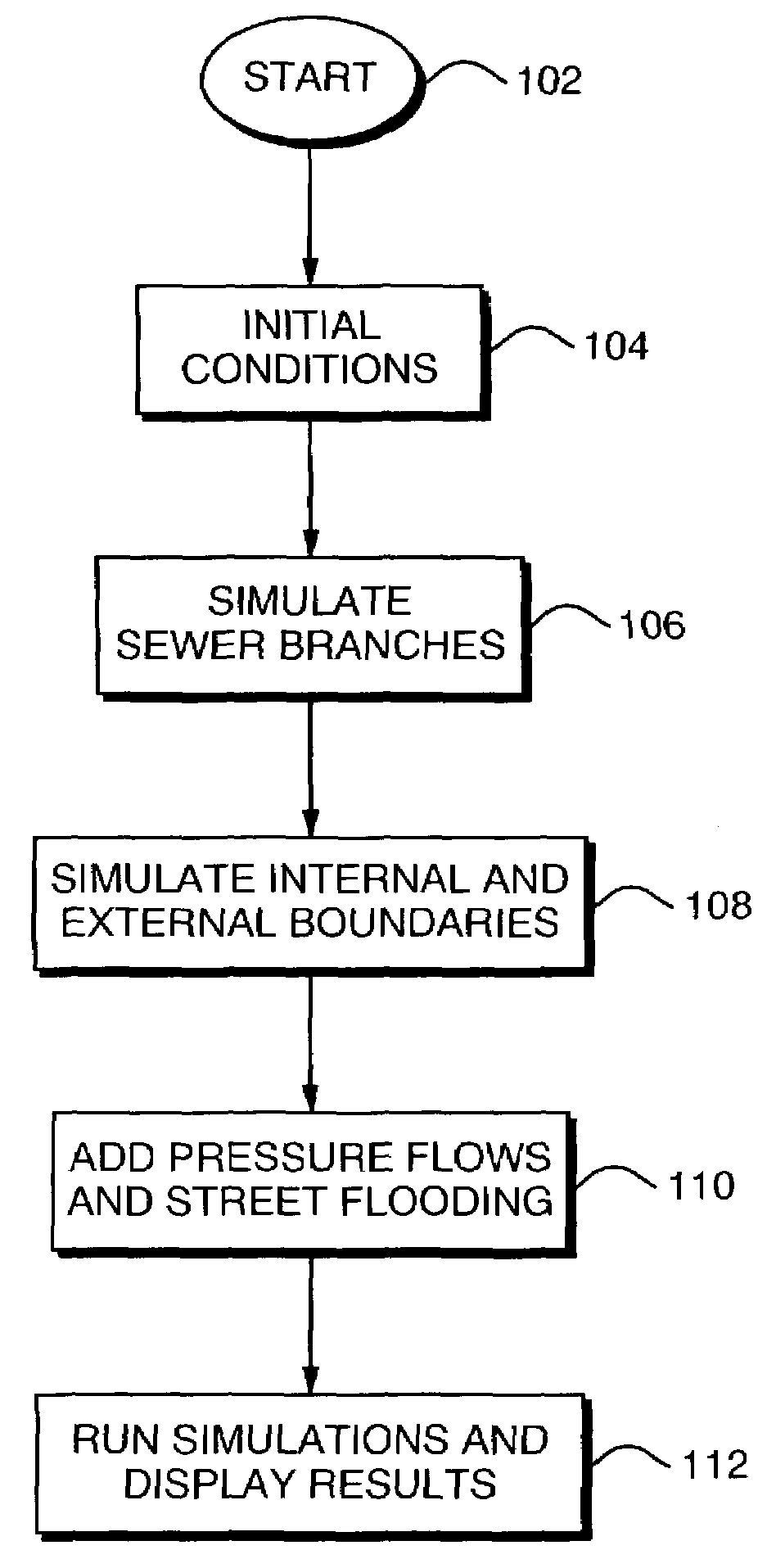

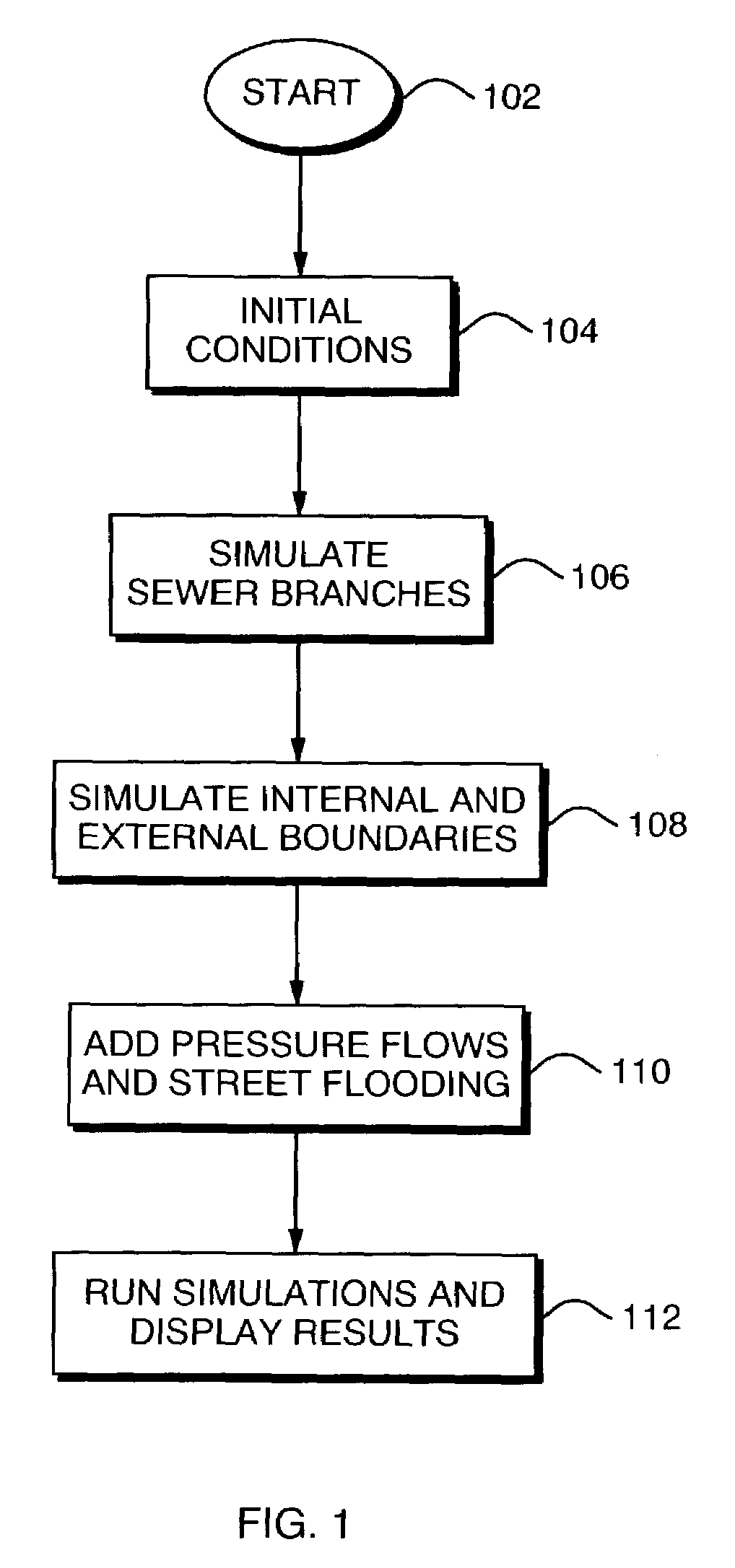

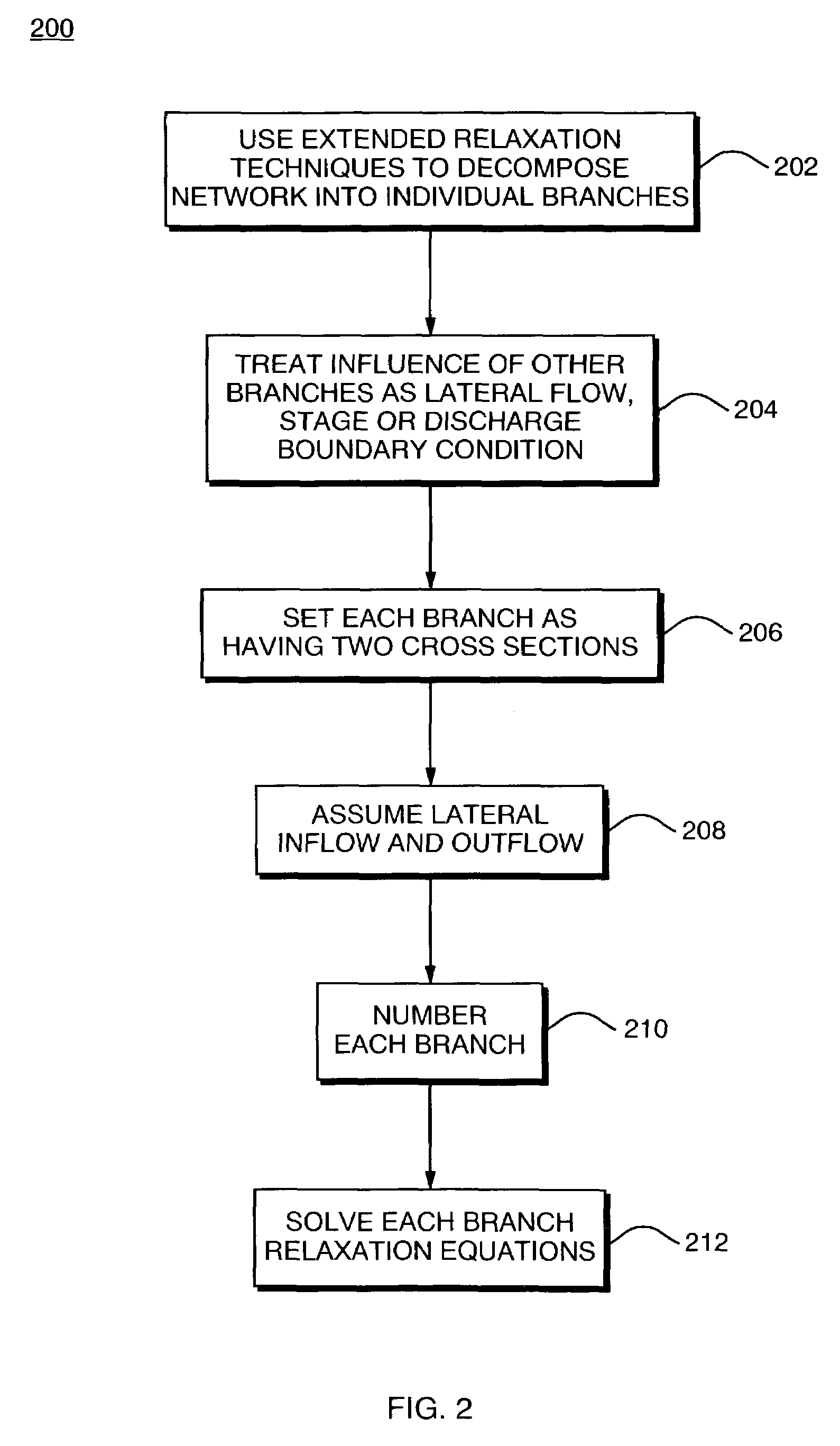

Method and system for developing a numerical dynamic sanitary sewer and storm water drainage simulation model

ActiveUS7039565B1Geometric CADComputation using non-contact making devicesSoftware systemCommercial software

An hydraulics software system for a one-dimensional hydrodynamic numerical model for modeling unsteady flows in sewer and storm water urban drainage systems is provided. The inventive software uses as a numerical model, an implicit four-point, finite-difference solution technique to solve the one-dimensional Saint-Venant equations. The software is designed to select that numerical model, or equation that best describes, or best exhibits the behavior of each of the various structures and flows encountered in complex hydrodynamic systems such as a sewer and storm water drainage systems. Local partial initial modification for subcritical and supercritical transcritical flows is provided. Relaxation for pipe / channel networks are included for achieving computational performance and robustness for commercial software for practical use in water resource engineering.

Owner:BENTLEY SYST INC

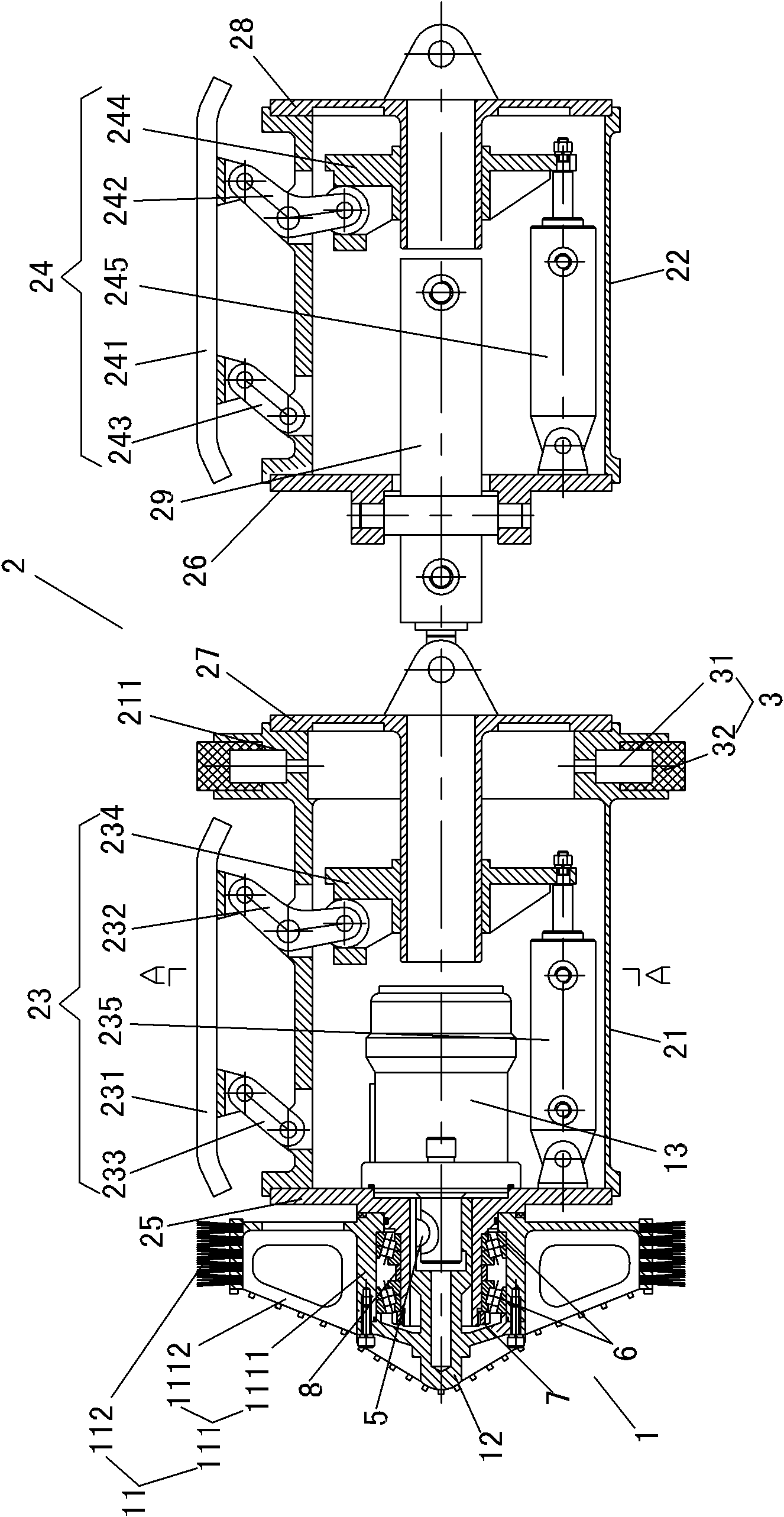

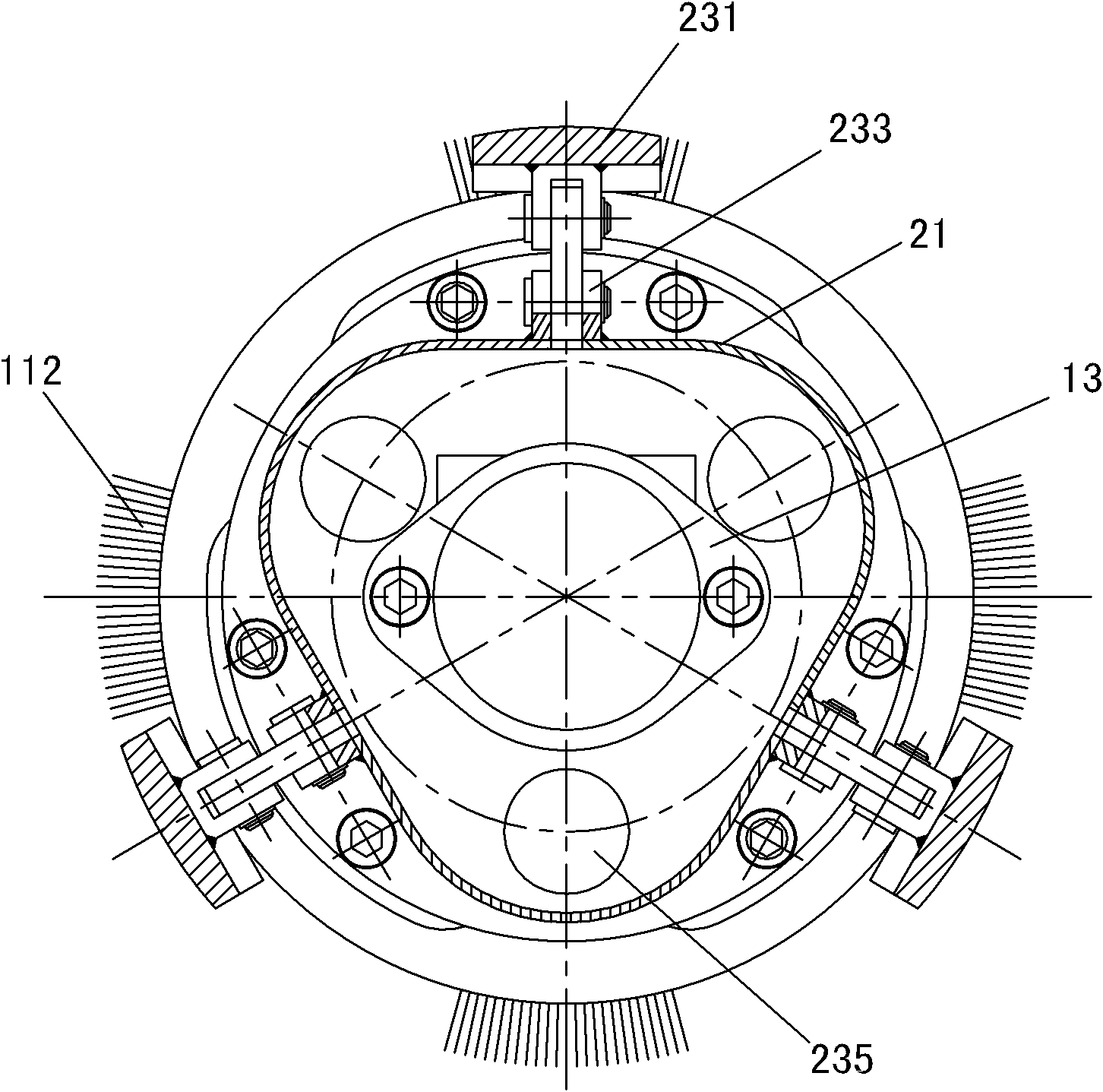

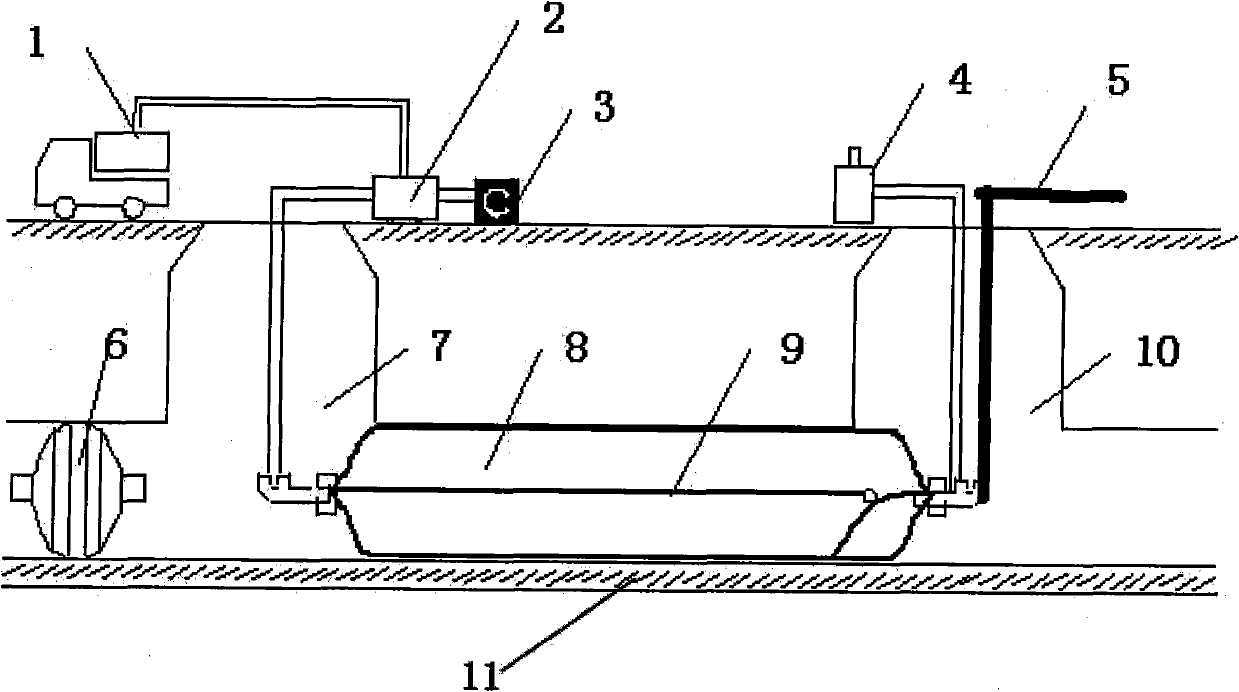

Sewage conduit cleaning and detection robot

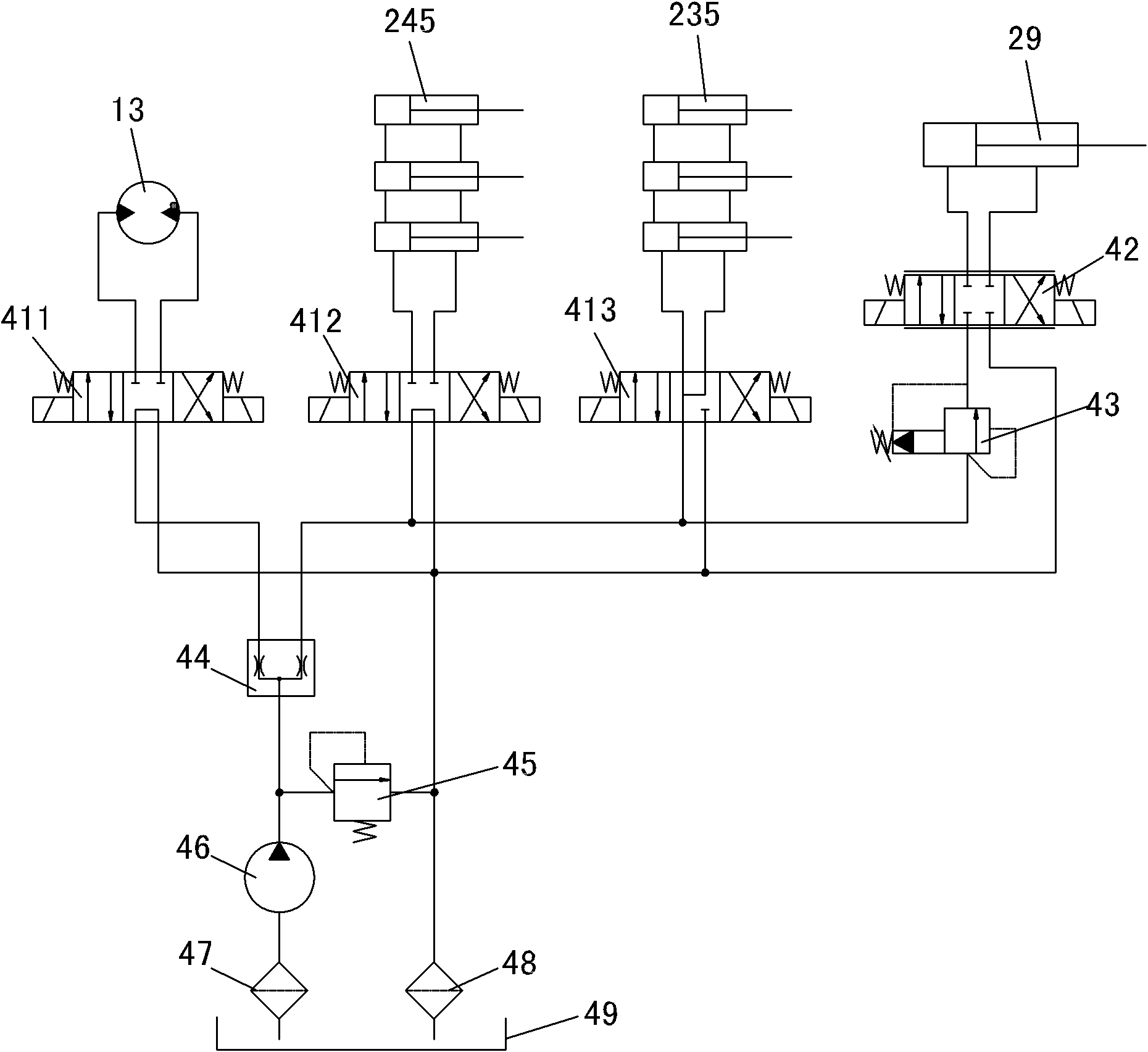

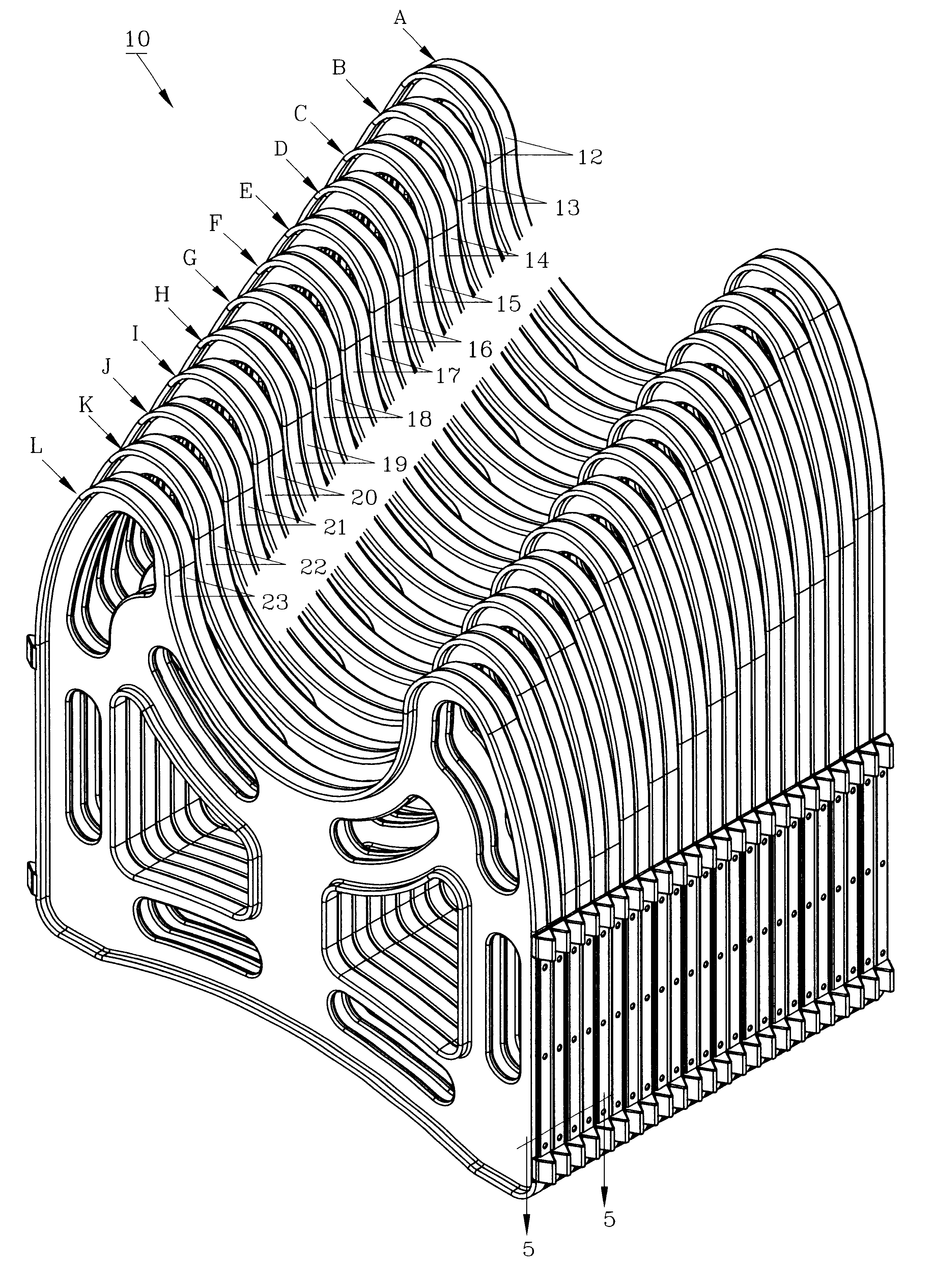

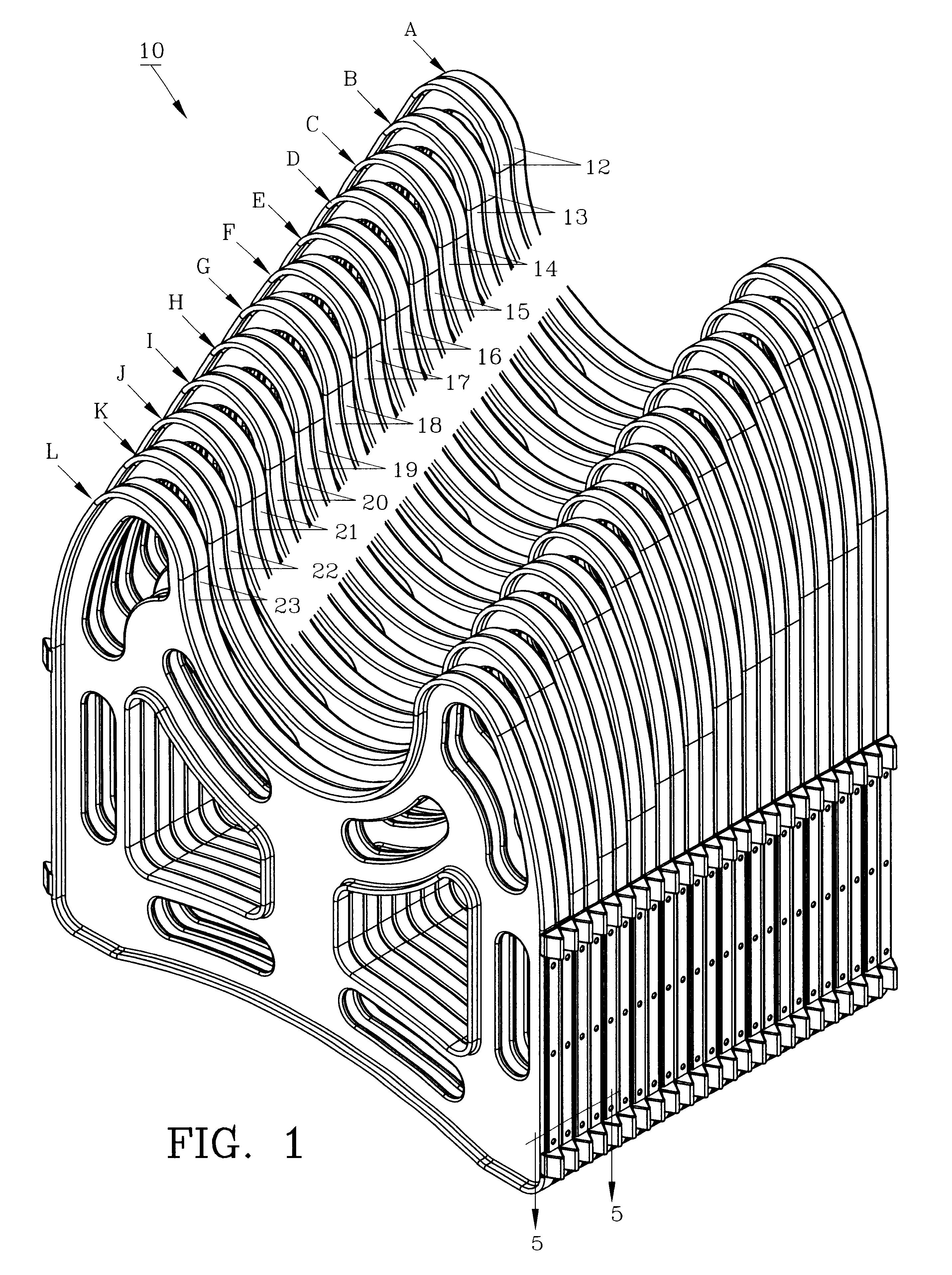

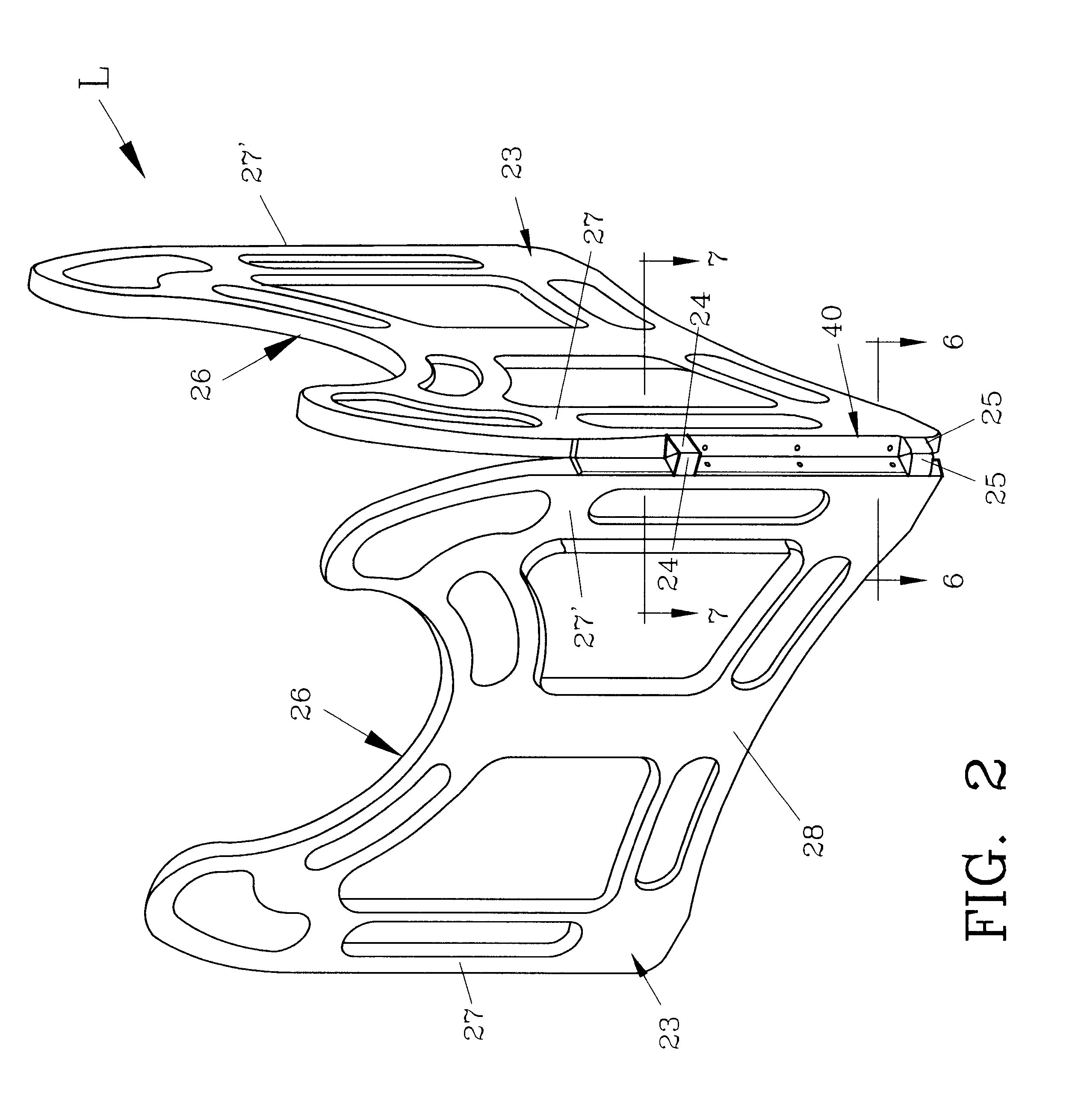

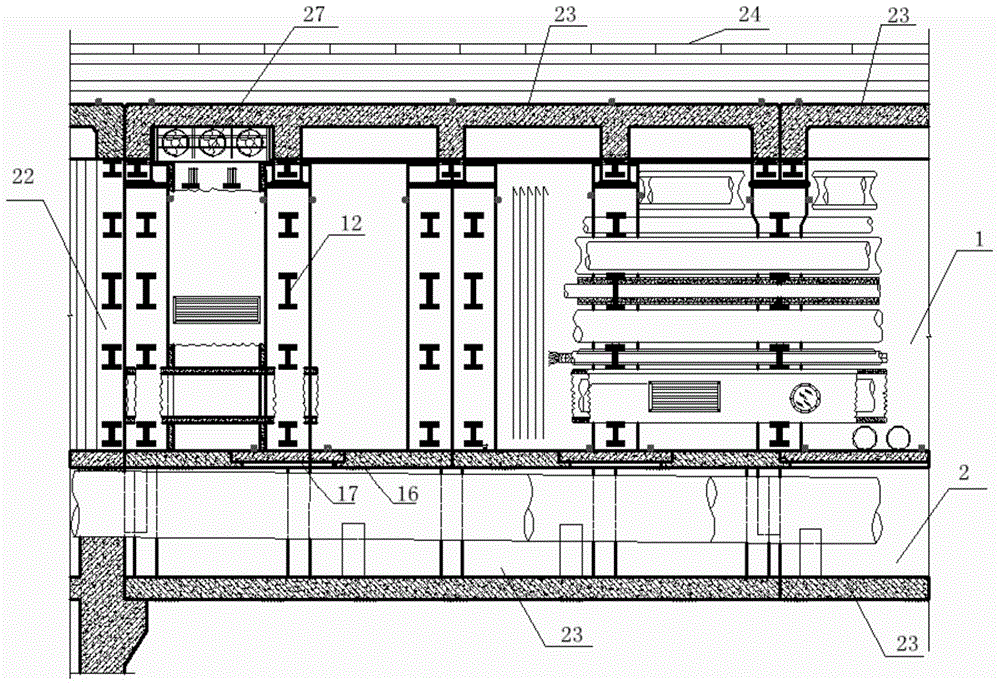

The invention relates to a sewage conduit cleaning and detection robot, which is mainly used in a sewage conduit and comprises a cleaning device, a traveling device, a detection device, a hydraulic power device and a control part used for controlling the operation of the hydraulic power device. The cleaning device is installed on the first front end cover of the traveling device. The detection device is installed on the first rear end cover of the traveling device. The hydraulic power device is hinged with the second rear end cover of the traveling device through a hinge pin. The control part controls the hydraulic power device to work. Through adjusting the opening and the closing of electromagnetic valves on the hydraulic power device, the robot travels to realize the cleaning of the entire sewage conduit. Moreover, through transmitting the field conduit detection conducted by the detection device to the control part, the situation in the conduit can be observed by the external world. The invention has the advantages that the volume is small, the structure is ingenious and compact, and the robot is suitable for cleaning and detecting all kinds of sewage conduits.

Owner:SHANDONG UNIV OF SCI & TECH

Pasty composition for sanitary ware

Owner:THE PROCTER & GAMBLE COMPANY

RV sewer hose support

InactiveUS6619596B1Easy to openEasy to usePipe supportsSpraying apparatusGravitational forceEngineering

A collapsible support is provided for a flexible RV sewer hose which includes in the preferred form, a plurality of pairs of identical arches. The height of each arch pair is different from the preceding arch pair to allow a sewer hose placed therein to properly flow by gravitational forces from the RV to a septic system. The arches of the support are hinged along the side so that each arch will cradle the sewage hose at an angle to the longitudinal axis of the sewer hose.

Owner:CAMCO MFG LLC

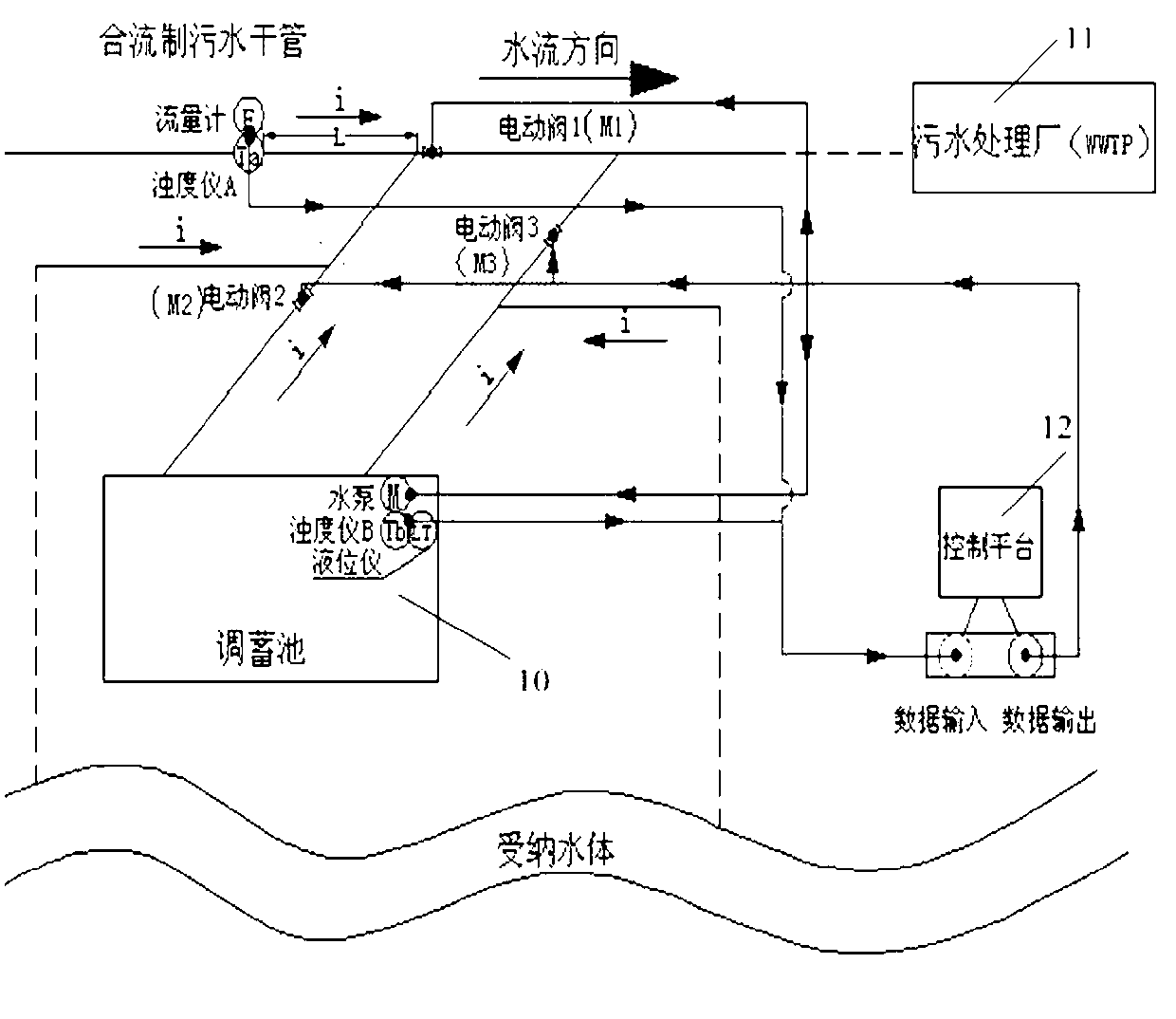

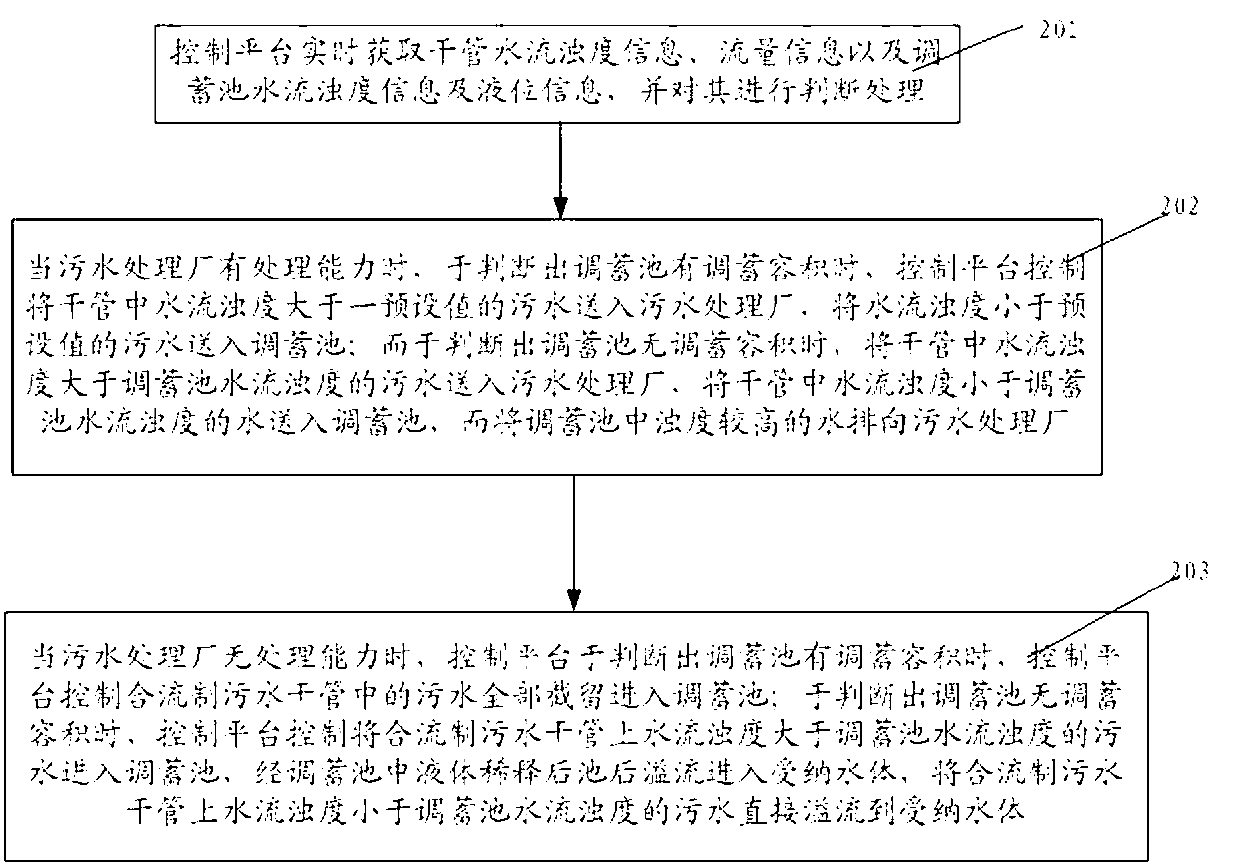

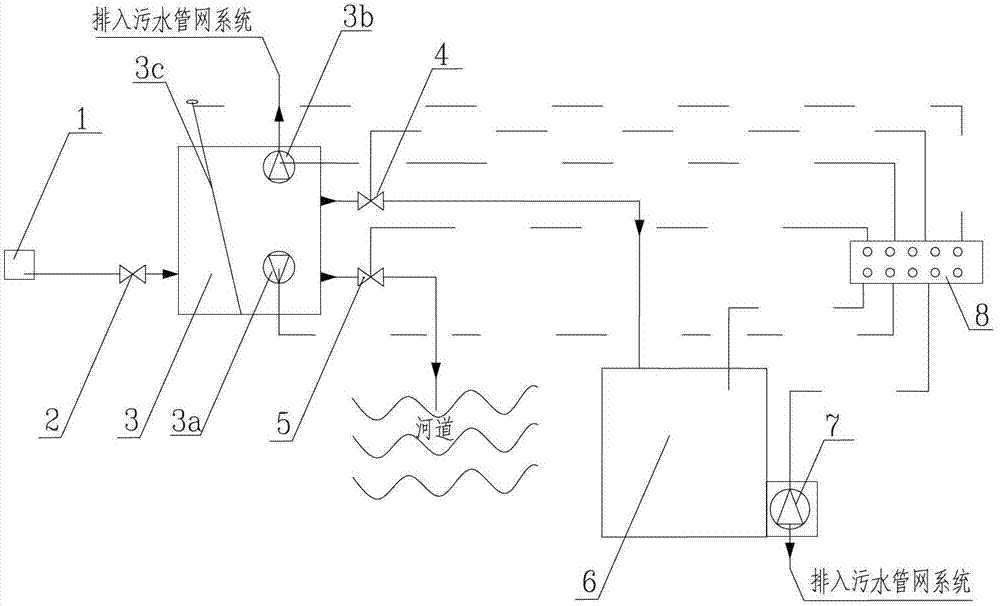

Flow combined system regulating storage tank real-time control system and control method thereof

InactiveCN103343570AReduce overflowRelieve water stressOperating means/releasing devices for valvesSewerage structuresReal-time Control SystemWater flow

The invention discloses a flow combined system regulating storage tank real-time control system and method. The method comprises the following steps that a control platform obtains water flow turbidity information and flow information of a flow combined system sewage conduit and water flow turbidity information and liquid level information of a regulating storage tank in real time and carries out judging processing on the information; the control platform carries out coordination control on each electric valve and a water pump according to judging results, water inlet positions, water outlet positions and overflow positions of the regulating storage tank are flexibly controlled, and direct overflowing pollution on receiving water from severely-polluted sewage is avoided. Priority processing on sewage with high load in a flow combined system drainage system is effectively achieved through flow and turbidity control and regulating storage, and meanwhile cutting storage or processing or using or discharging is carried out on lightly-polluted water in a flow combined system pipeline, and flow combined system overflowing pollution is effectively lowered.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

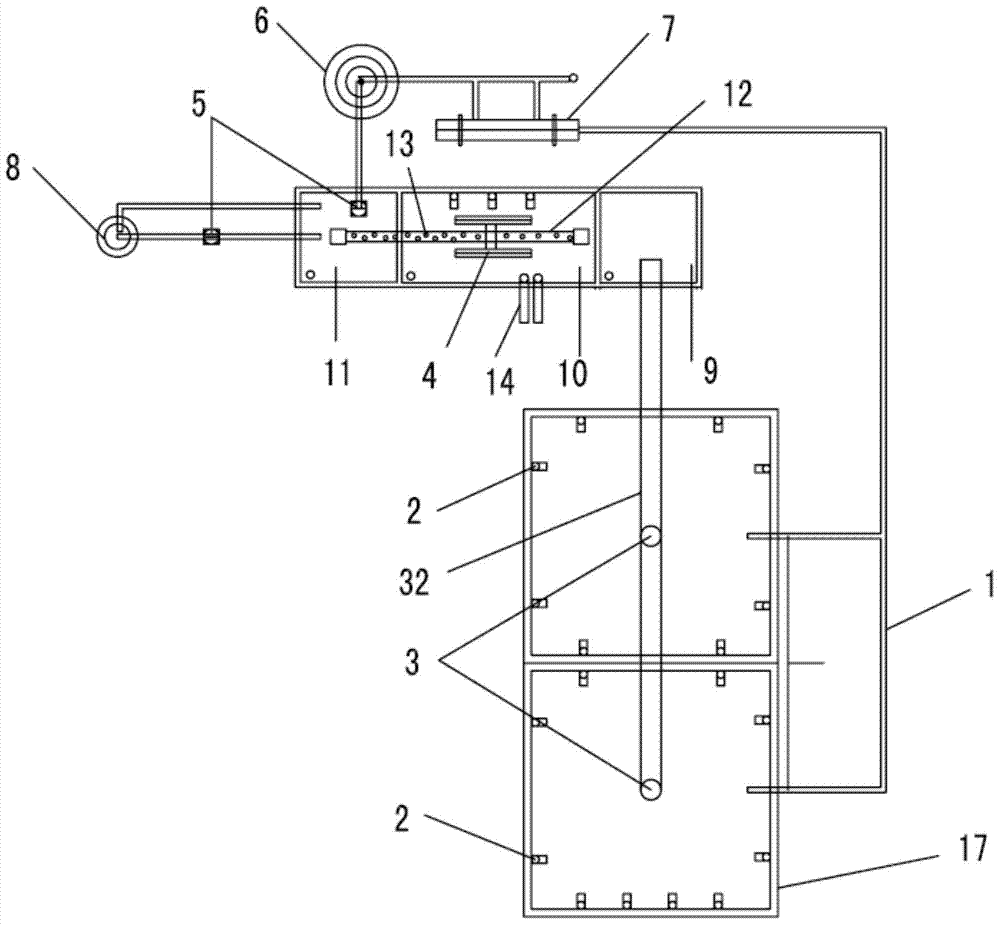

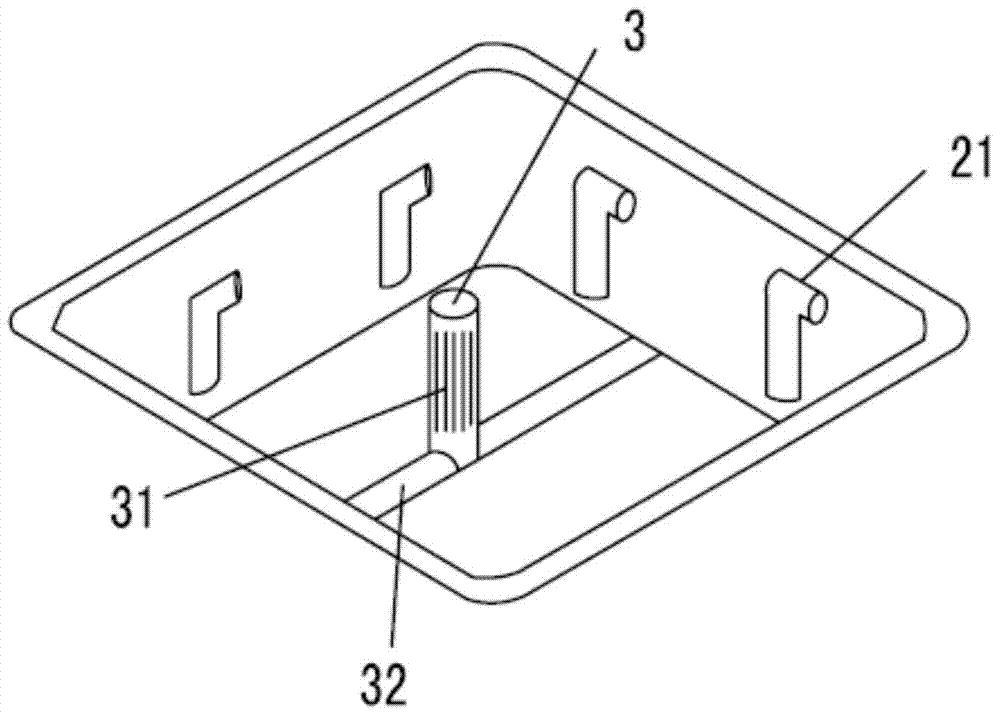

Indoor industrial penaeus vannamei culture device

InactiveCN103478055AReduce investmentEmission reductionClimate change adaptationPisciculture and aquariaWater useBiological filter

The invention discloses an indoor industrial penaeus vannamei culture device which comprises a plurality of culture ponds, a water inlet pipe and a culture water circulation system, wherein the culture water circulation system comprises a sedimentation pond, a floatation pond and a biological filter pond; the floatation pond is internally provided with an aerobiotic device, an aeration device and a foam sewage discharge device; the foam sewage discharge device comprises a foam guide pipe and a sewage pipeline; the foam guide pipe has a plurality of foam guide holes; the biological filter pond is connected with both protein separator and sand filtering tank; one end of the sand filtering tank is connected with the biological filter pond, and the other end of the sand filtering tank is connected with one end of an ultraviolet sterilizer; the other end of the ultraviolet sterilizer is connected with the water inlet pipe. The indoor industrial penaeus vannamei culture device disclosed by the invention has the advantages of simple structure, convenience in use and low investment cost, can be used for effectively pushing water inside a penaeus vannamei pond to flow so as to ensure that the water inside the penaeus vannamei pond is in a stable rotational flowing state, can effectively solve the problem that the sewage of the penaeus vannamei pond is effectively discharged in time in a low circulation volume state, is uniform in aeration, improves the utilization ratio of water used for culture, reduces the sewage discharge and reduces the medicine application.

Owner:HAINAN PROVINCIAL FISHERIES RES INST

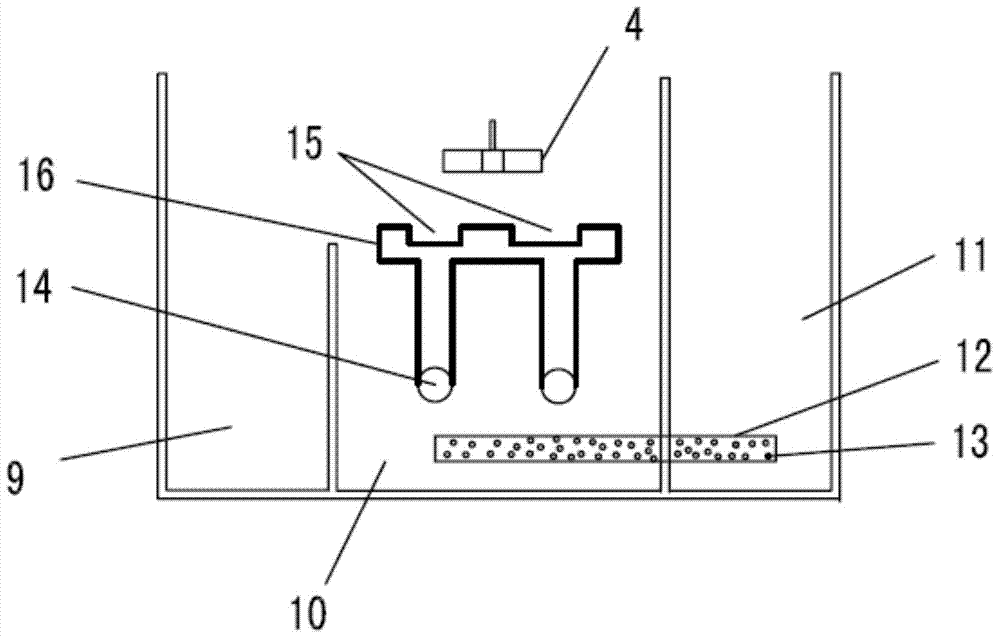

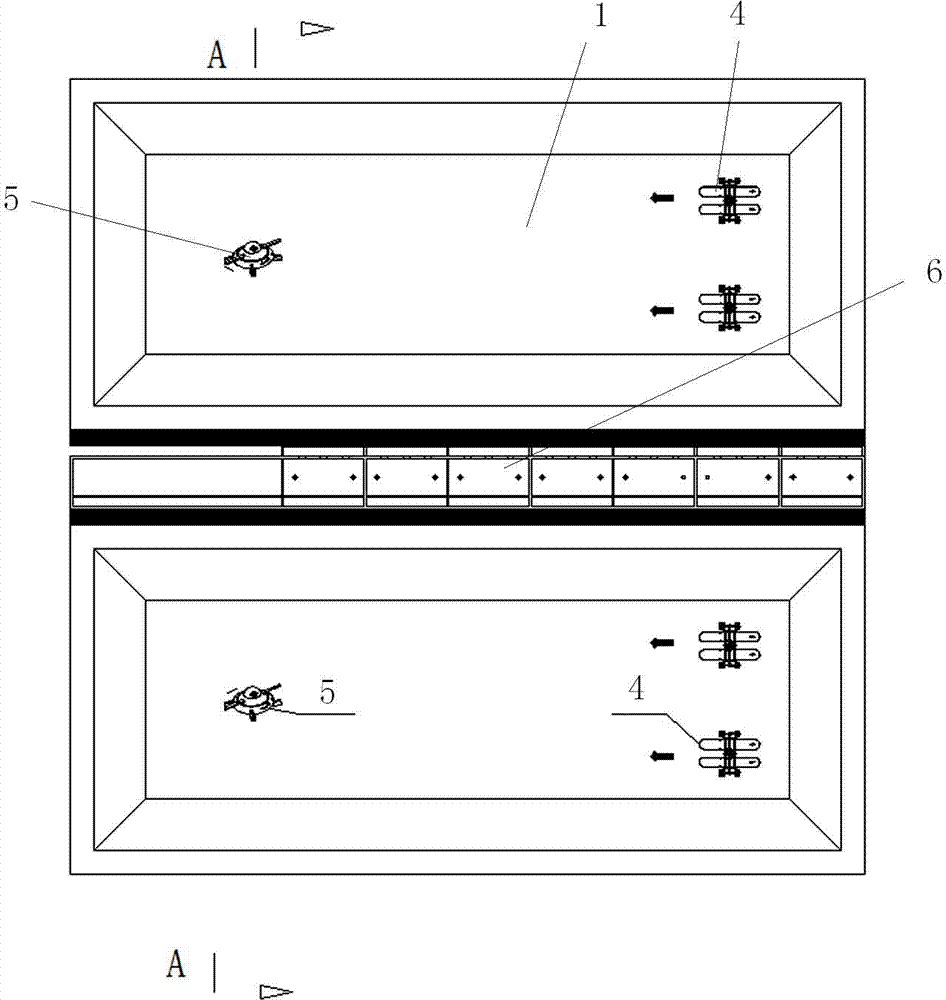

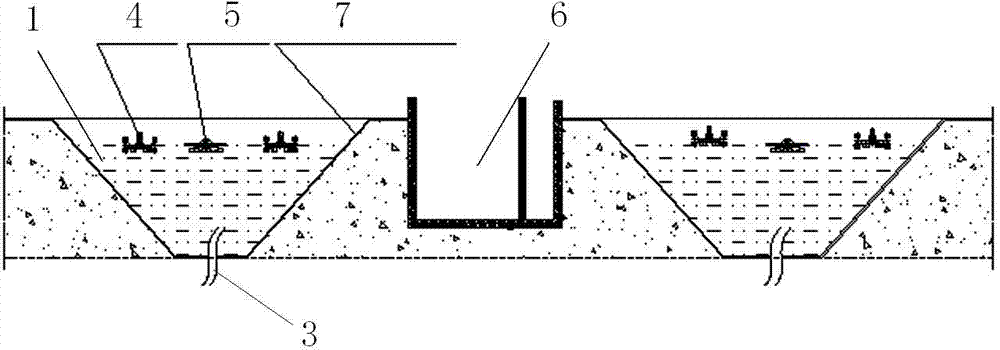

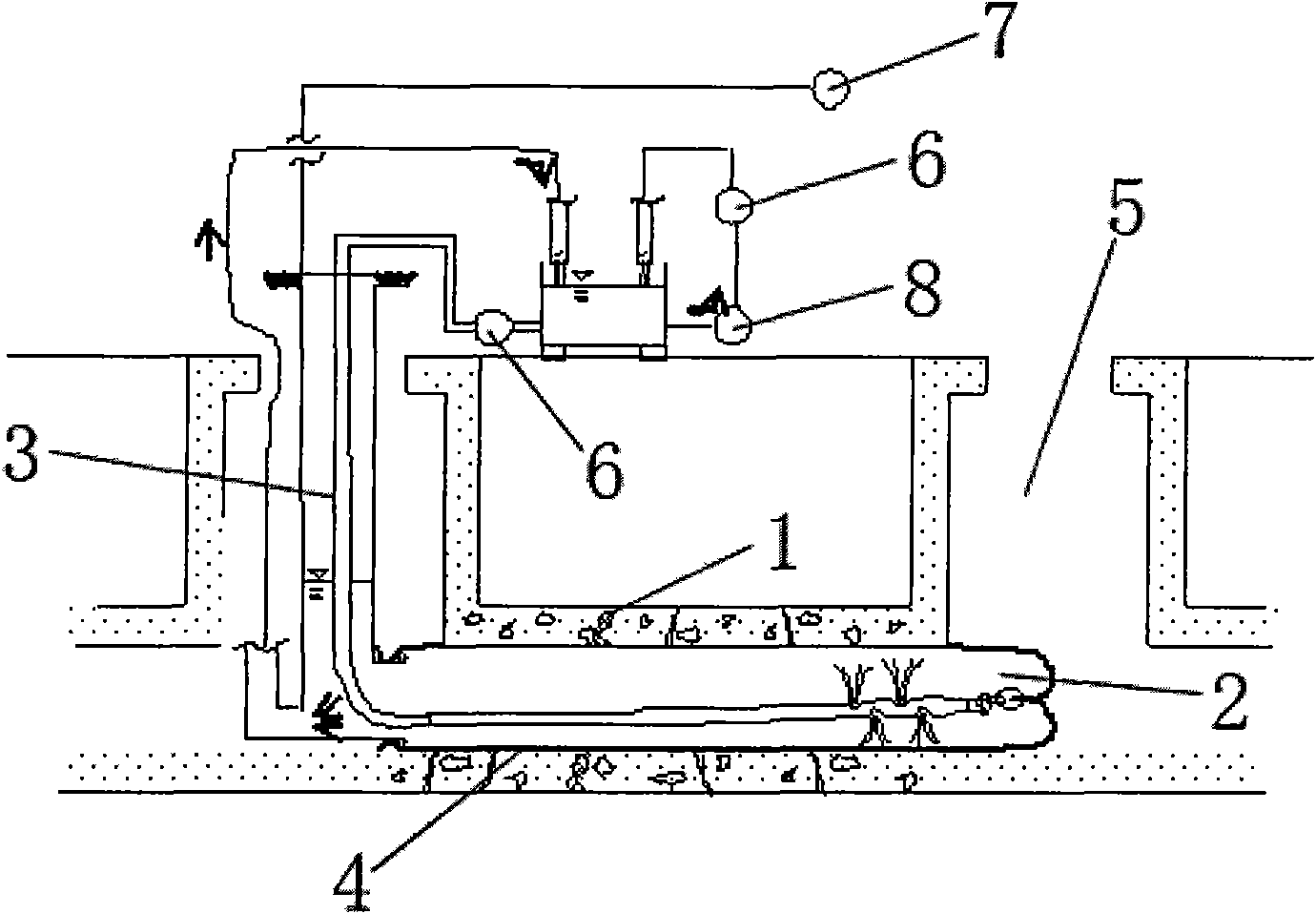

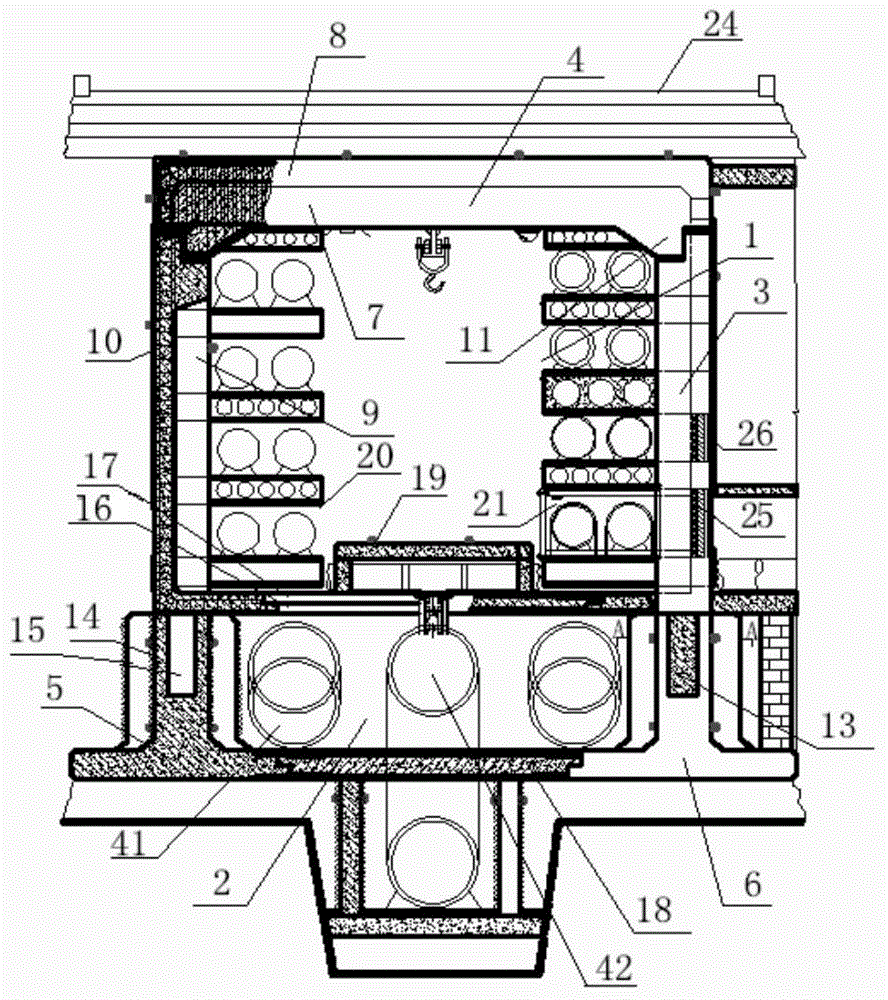

Centralization indoor constant temperature circulation aquaculture system

ActiveCN103081843ANo secondary pollutionFree from pollutionPisciculture and aquariaThermal insulationAquatic product

The invention discloses a centralization indoor constant temperature circulation aquaculture system which includes two aquaculture ponds arranged side by side. A water inlet and a water outlet are arranged in each aquaculture pond. An aerator and a swell machine are arranged in each aquaculture pond. The centralization indoor constant temperature circulation aquaculture system is characterized in that the two aquaculture ponds are made of thermal insulation materials. A sewage treatment system is arranged between the two aquaculture ponds. A suction sewage device is arranged at the end of water outputting of each aquaculture pond. The suction sewage device is connected with the sewage treatment system through a sewage pipe. A water outlet of the sewage treatment system communicates with each aquaculture pond. The centralization indoor constant temperature circulation aquaculture system has the advantage that circulation utilization of water for aquaculture is achieved so that the quality of aquaculture aquatic products is improved and pollution of sewage discharges to environment is reduced.

Owner:喃嵘实业(上海)有限公司

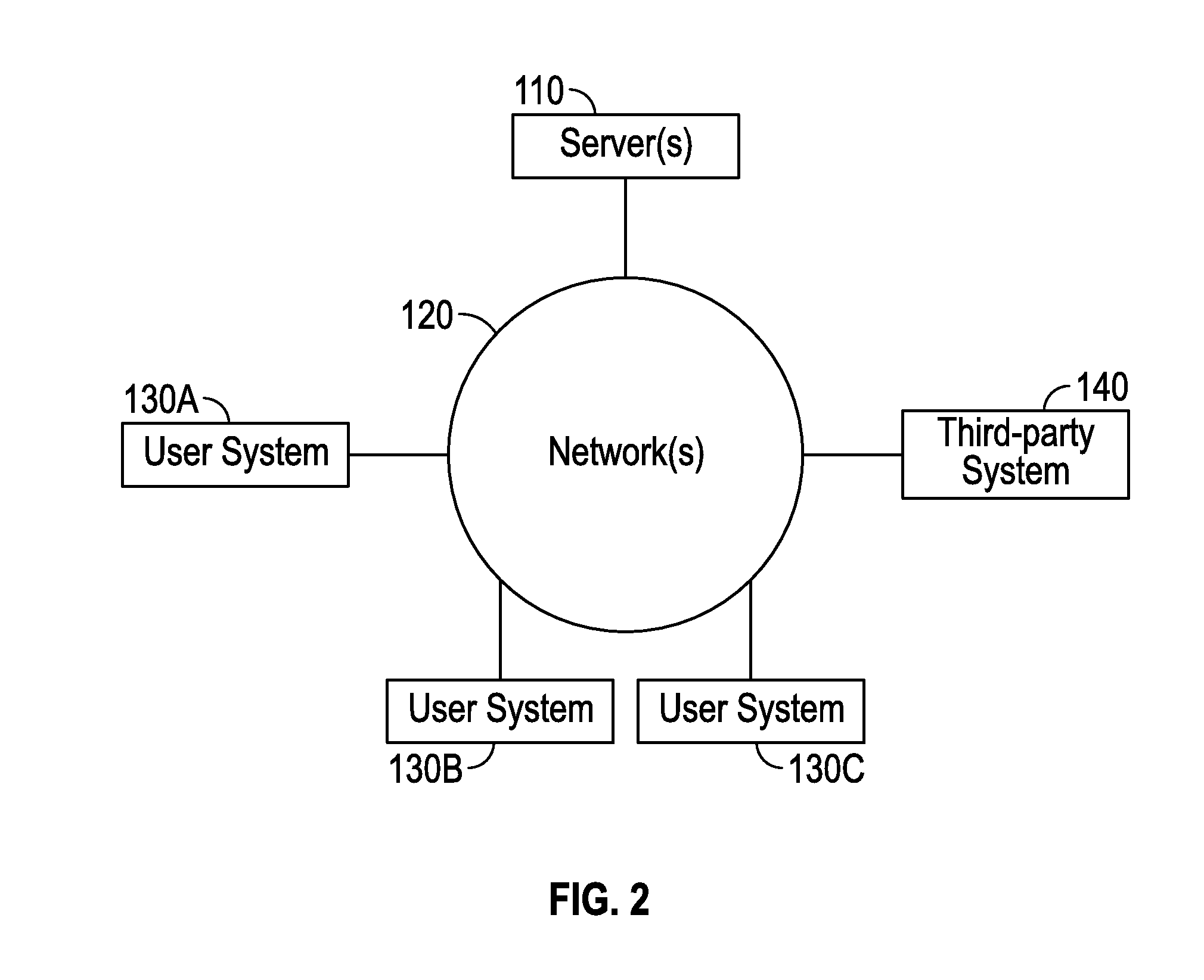

Systems and methods for advanced sanitary sewer infrastructure management

ActiveUS20150112647A1Efficient automationSave a lot of timeGeometric CADData processing applicationsUser deviceSanitary sewer

Systems and methods for managing a sanitary sewer infrastructure. In an embodiment, a plurality of representations of infrastructure assets are re-projected from a plane coordinate system into a geospatial coordinate system, such that each of the re-projected plurality of representations of infrastructure assets is associated with a geospatial coordinate. Each of the re-projected plurality of representations of infrastructure assets and its associated geospatial coordinate is stored in one or more databases. Subsequently, geospatial coordinates, collected in the field, may be received from one or more user devices, wherein each geospatial coordinate corresponds to a geospatial location of an infrastructure asset. A stored geospatial coordinate associated with one or more of the stored re-projected plurality of representations of infrastructure assets may then be adjusted based on the received geospatial coordinates.

Owner:T4 SPATIAL LLC

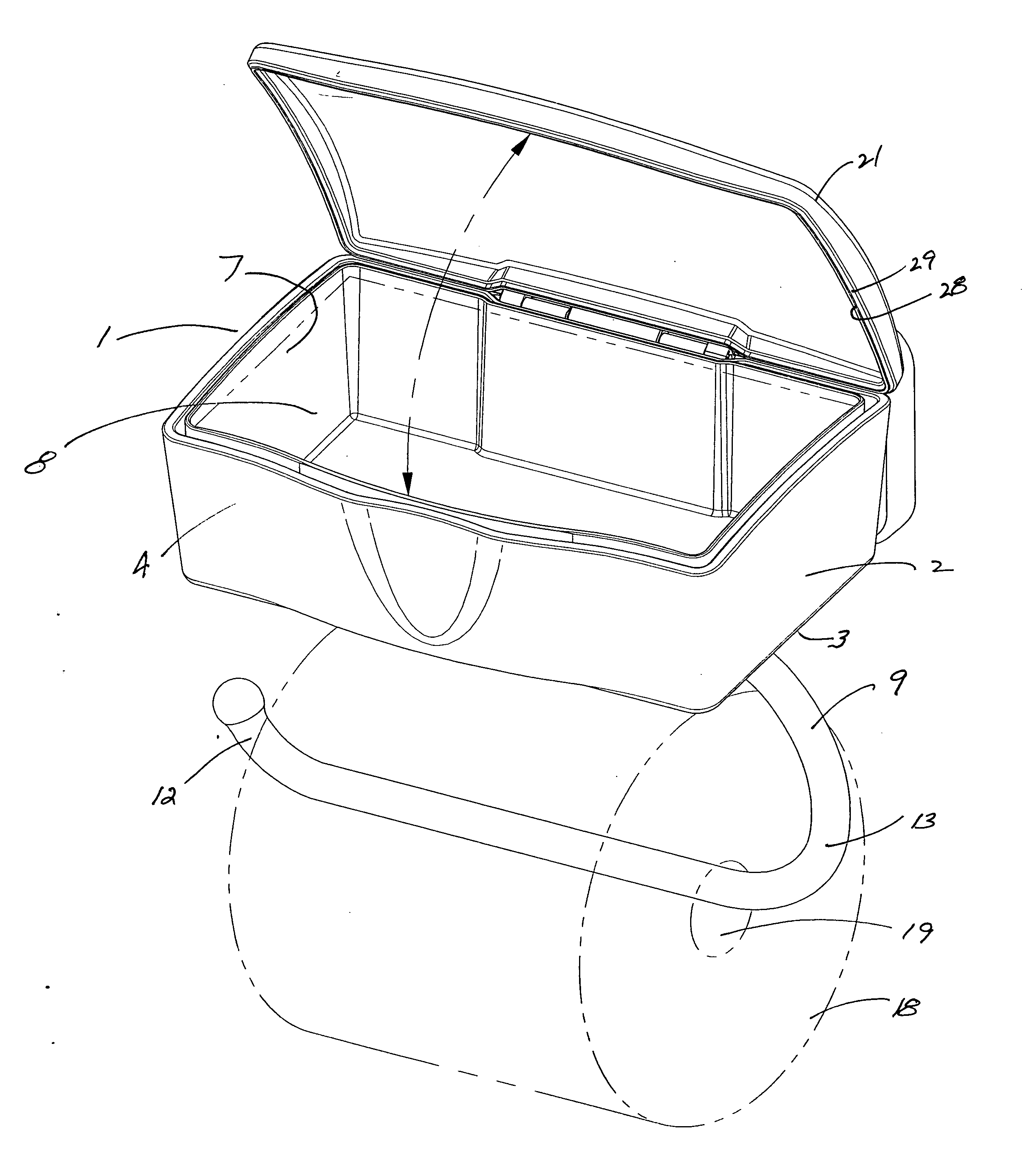

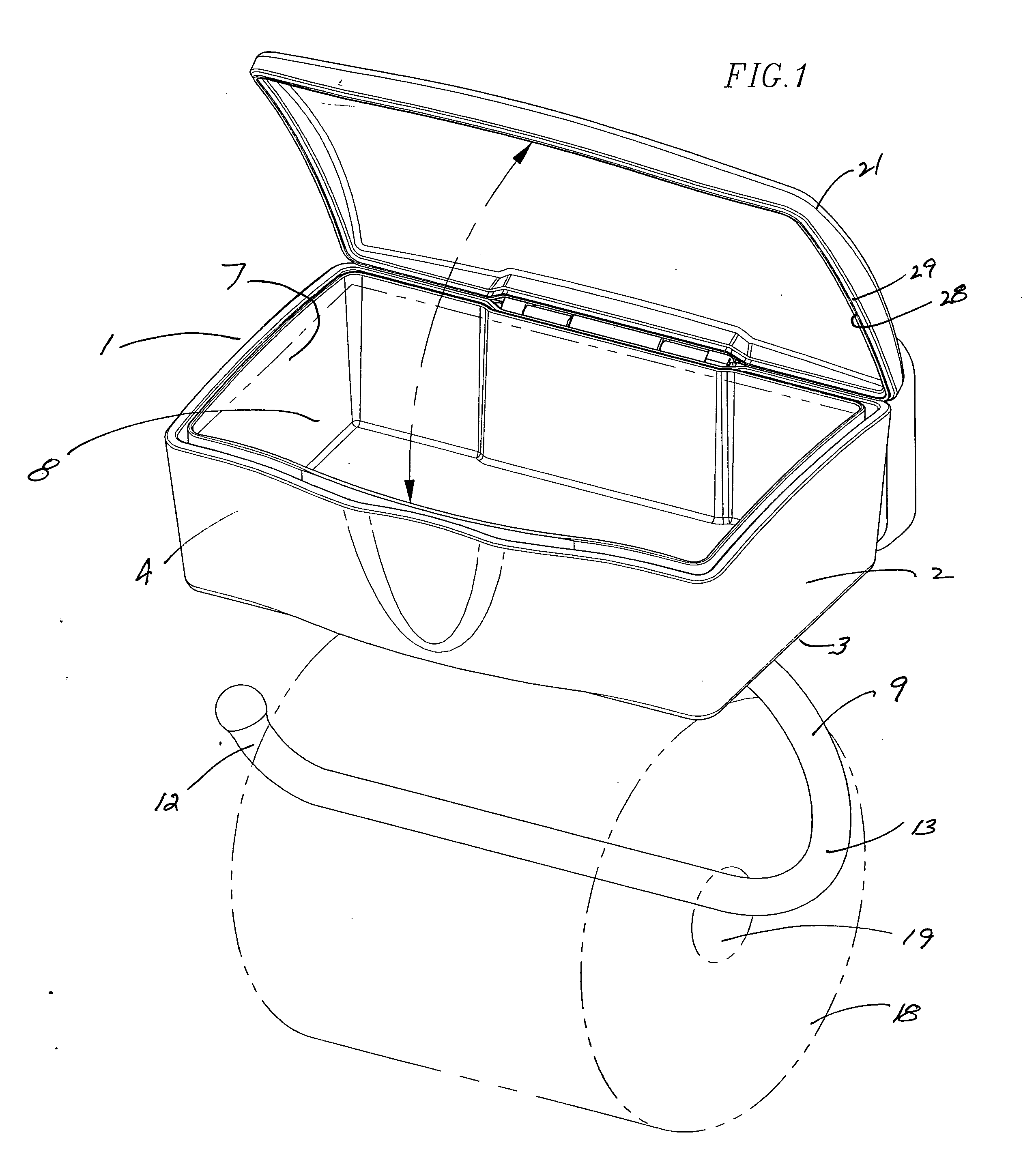

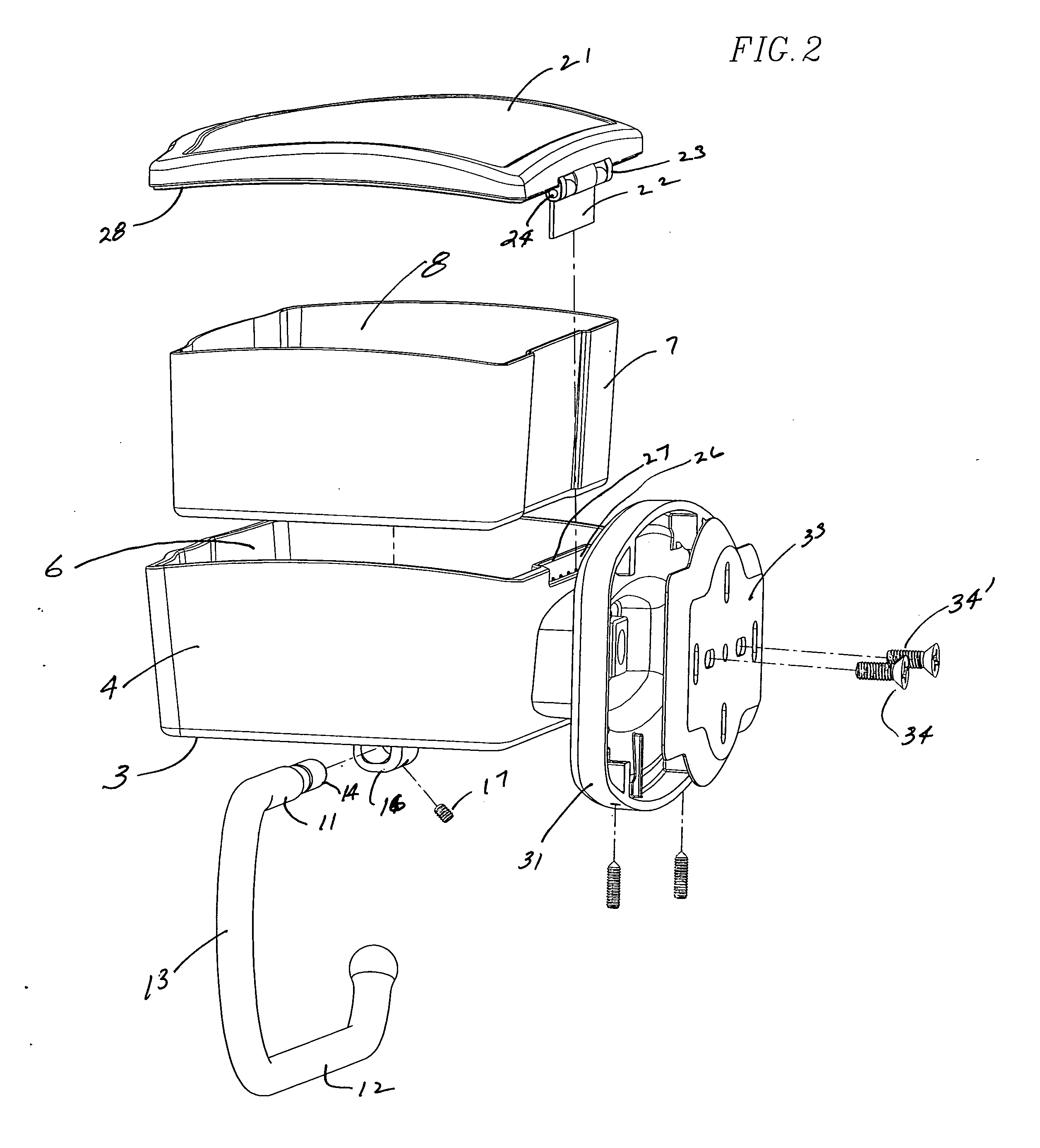

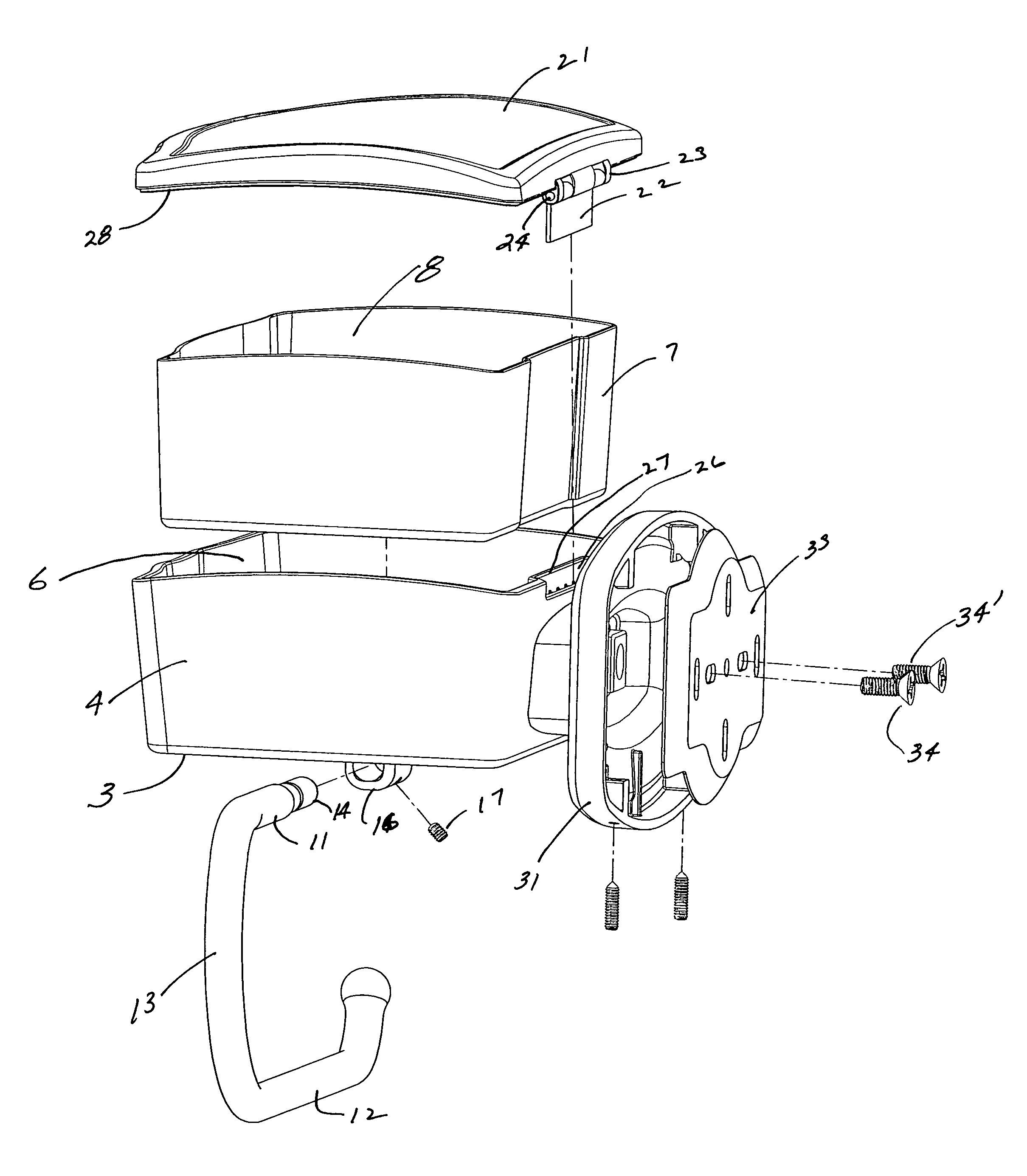

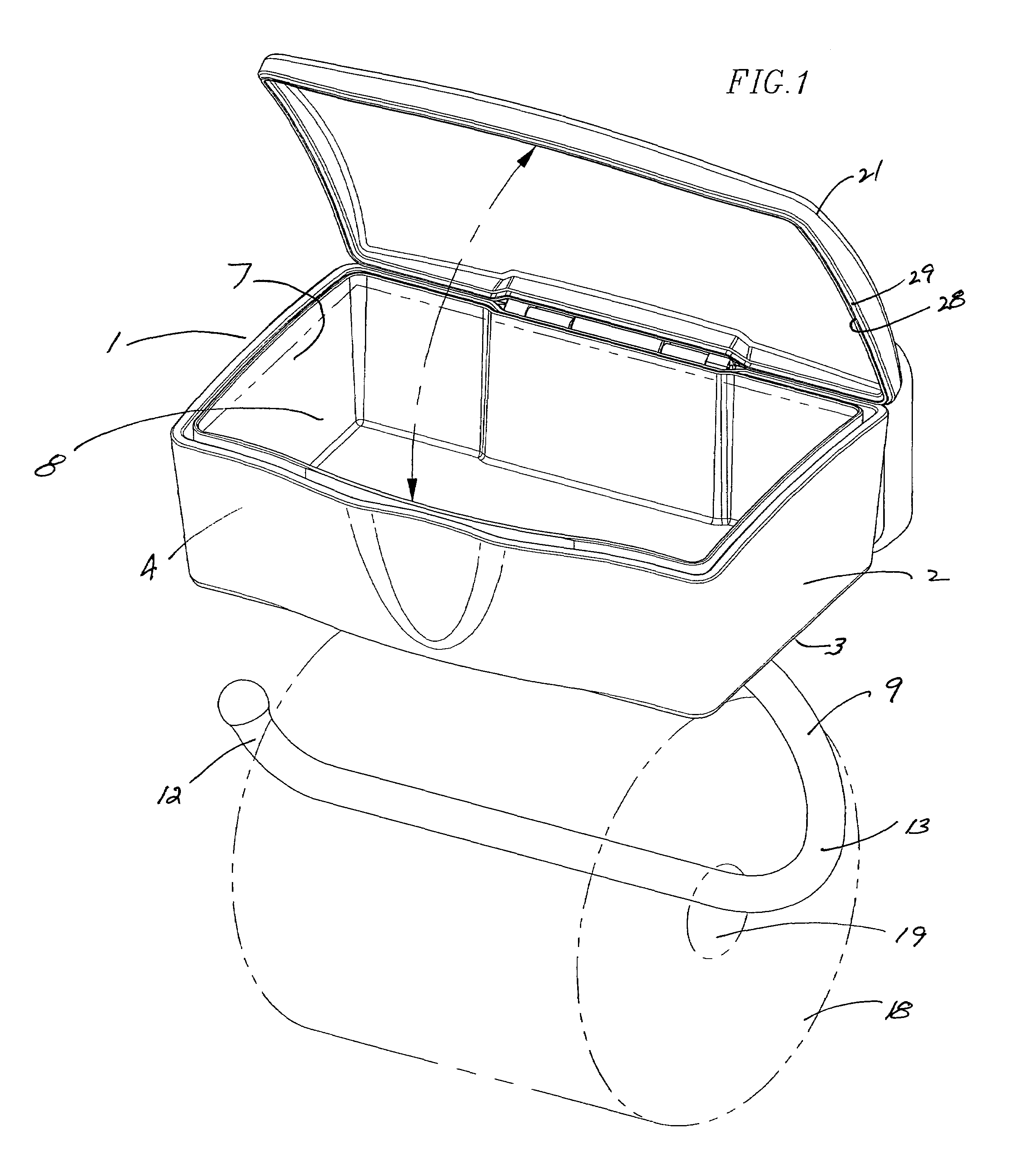

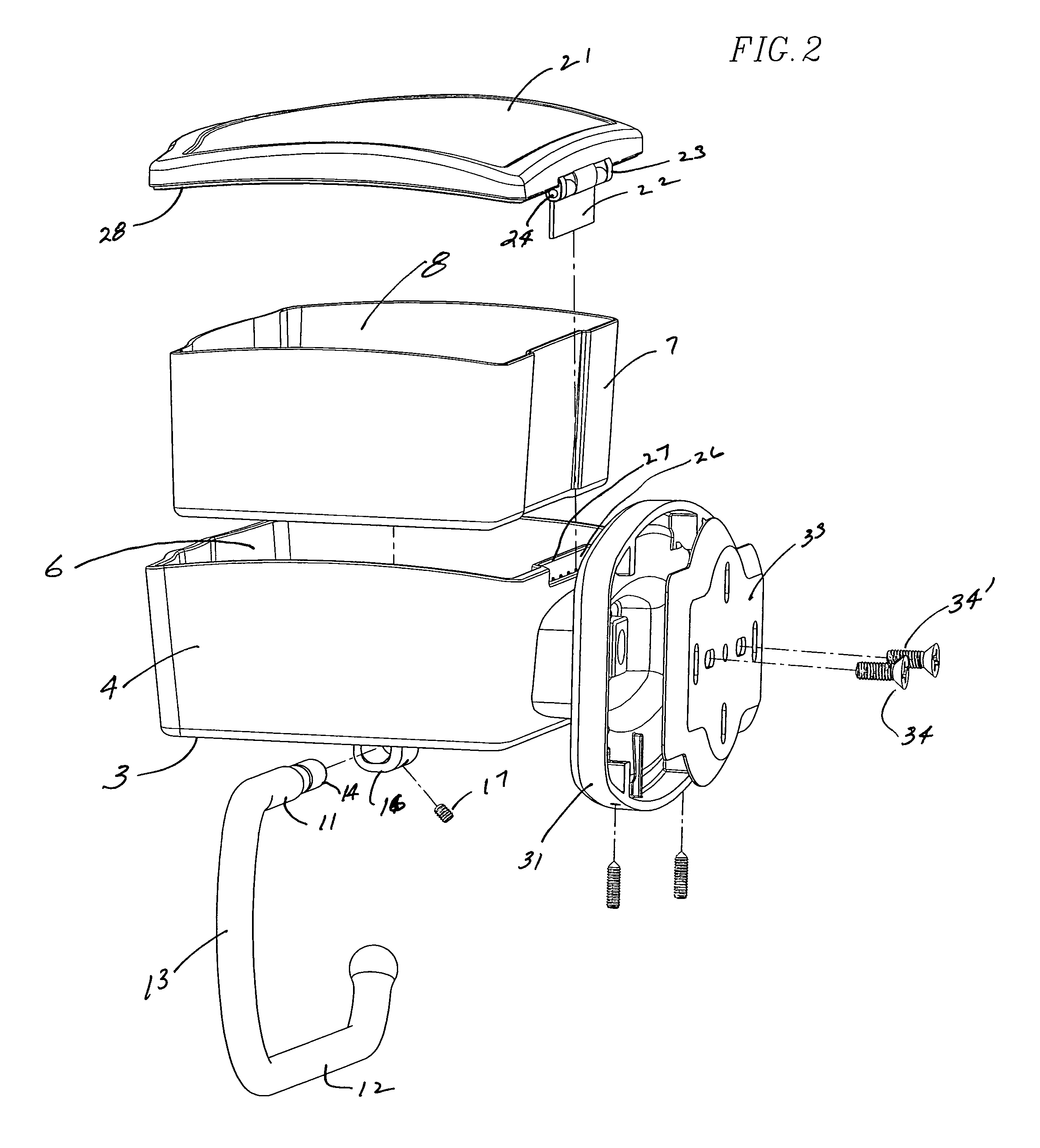

Combination sanitary wipe and toilet tissue holder

The invention relates to a combination hygienic device for holding sanitary wipes or toiletries and for dispensing a roll of toilet tissue paper. The device consists of a sanitary tray having a void region for receiving a sleeve member so dimensioned and proportioned to permit insertion of the sleeve into the void region. A cover is pivotally mounted to the sanitary tray for permitting access to a cavity contained in the sleeve member where the sanitary wipes or toiletries may be stored. A holder member is removably mounted to the bottom-wall of the sanitary tray for holding a roll of toilet tissue paper in telescopic and rotational relationship with the holder member to permit the dispensing of the toilet tissue paper.

Owner:BROWN AARON

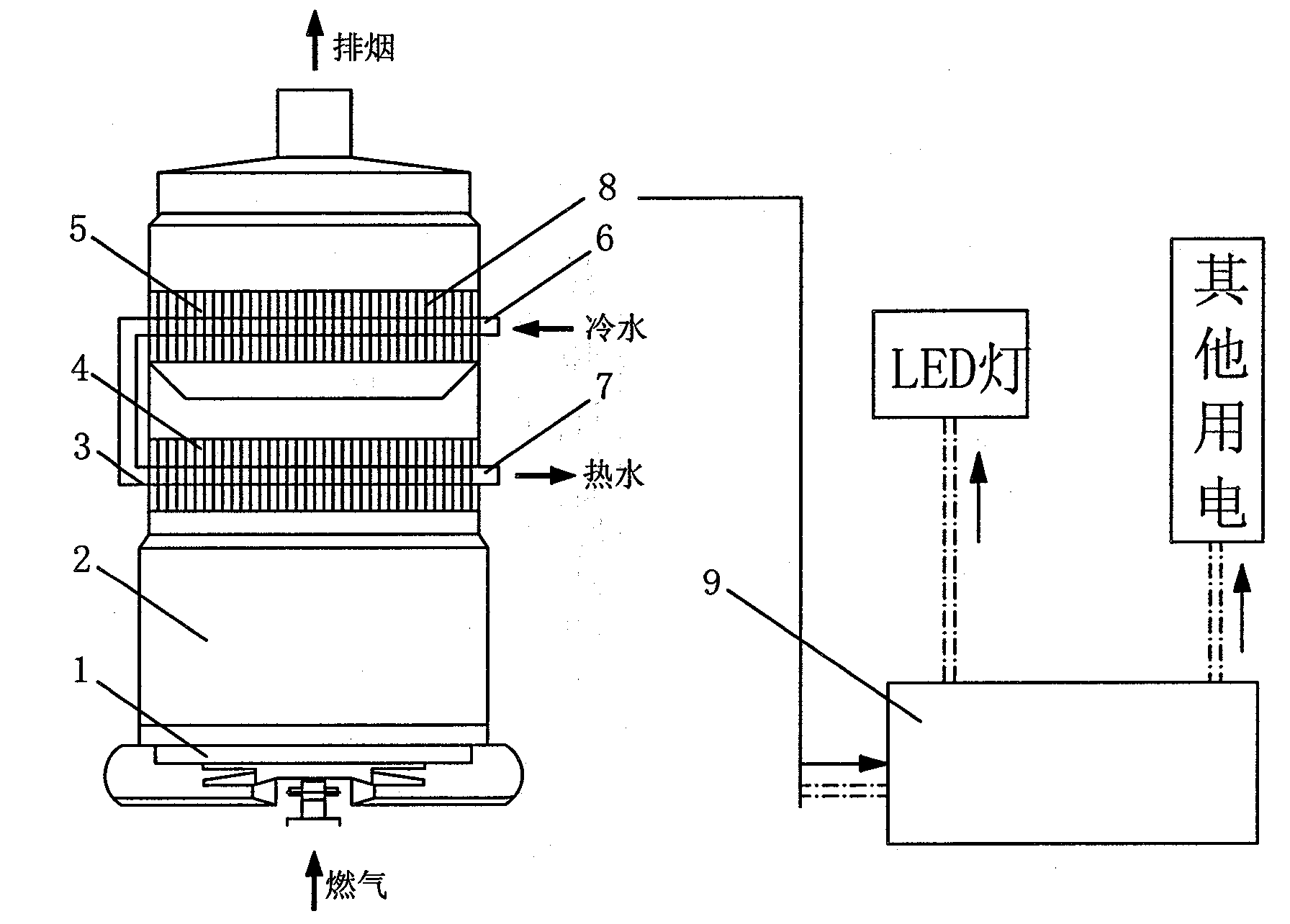

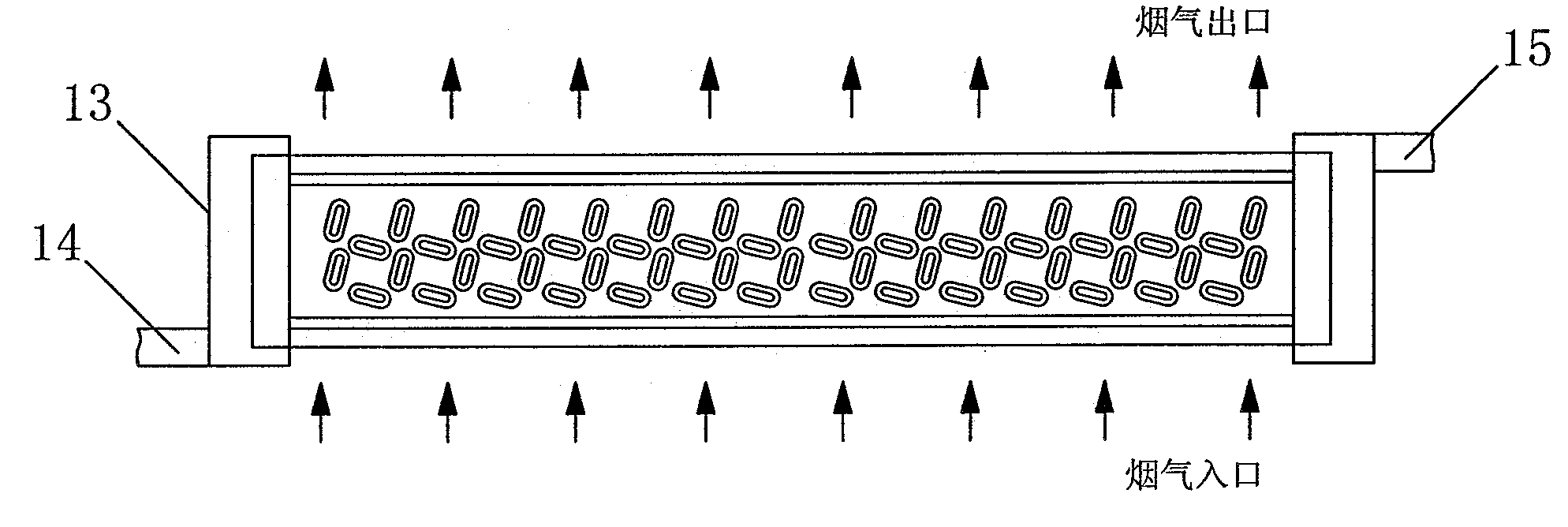

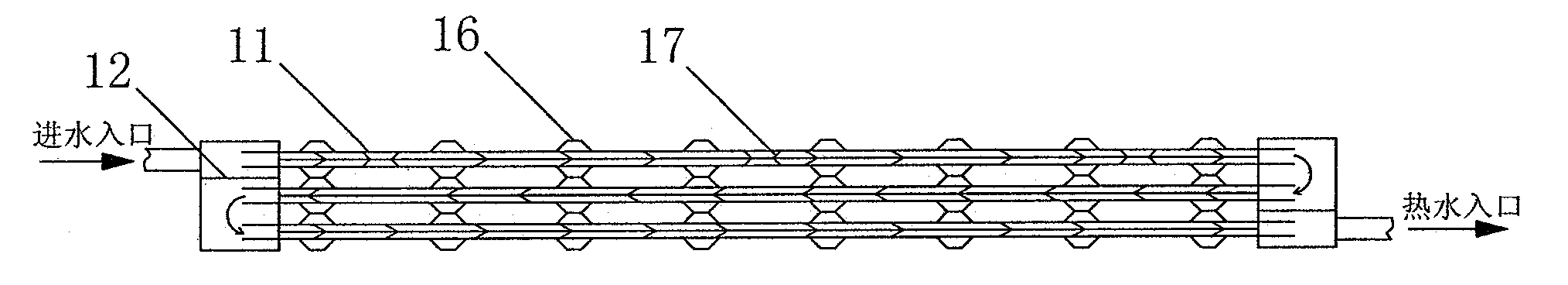

Power generation device by waste heat of gas water heater

InactiveCN102064744AImprove heat transfer efficiencyTypical original surface structureEnergy efficient heating/coolingAir heatersCombustion chamberEngineering

The invention discloses a power generation device by waste heat of a gas water heater, comprising a condensing gas water heater and a temperature difference power generation system, wherein the condensing gas water heater comprises a combustor, a combustion chamber, a heat-exchange coil, a high-temperature section heat exchanger and a condensing section heat exchanger; the combustion chamber is positioned below the heat-exchange coil; the combustor is positioned below the combustion chamber; the high-temperature section heat exchanger is positioned below the condensing section heat exchanger; the high-temperature section heat exchanger mainly comprises two corrugated plate bundles, a partition plate, a plate box, a water inlet connecting tube and a water outlet connecting tube arranged in a shell; the corrugated plate bundles comprise two metal plates which are oppositely and longitudinally arranged to form a water channel, convex corrugations and concave corrugations are machined on each metal plate, the convex corrugations are bulges machined on the metal plate towards the outside of the water channel; and the distance between the two corrugated plate bundles is 2-6mm. In the invention, the temperature difference between high-temperature fume and sanitary water is used, and thermoelectric conversion is carried out by a temperature difference chip power generation module, thus realizing efficient utilization of the fume waste heat of the gas water heater, and achieving the purposes of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

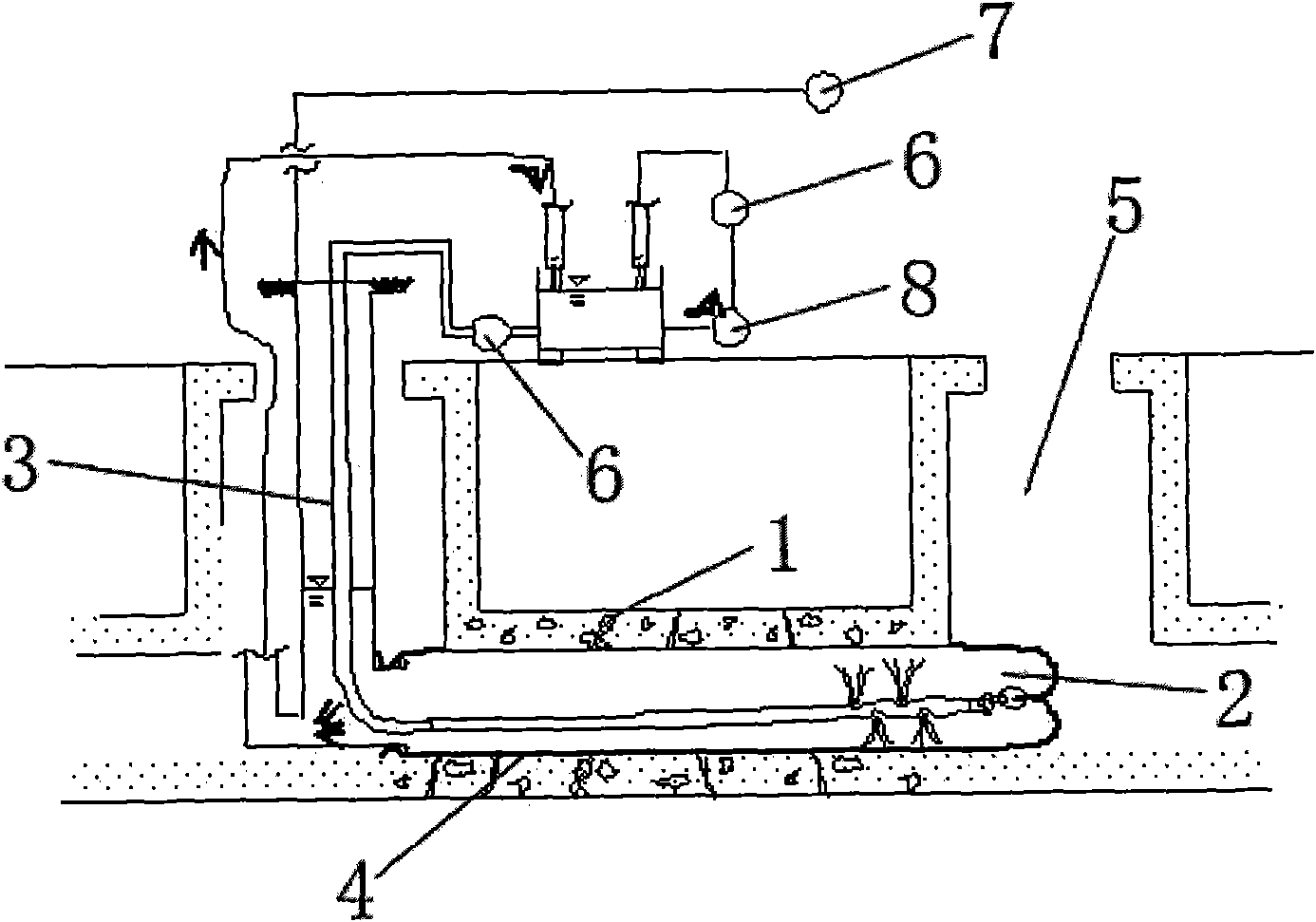

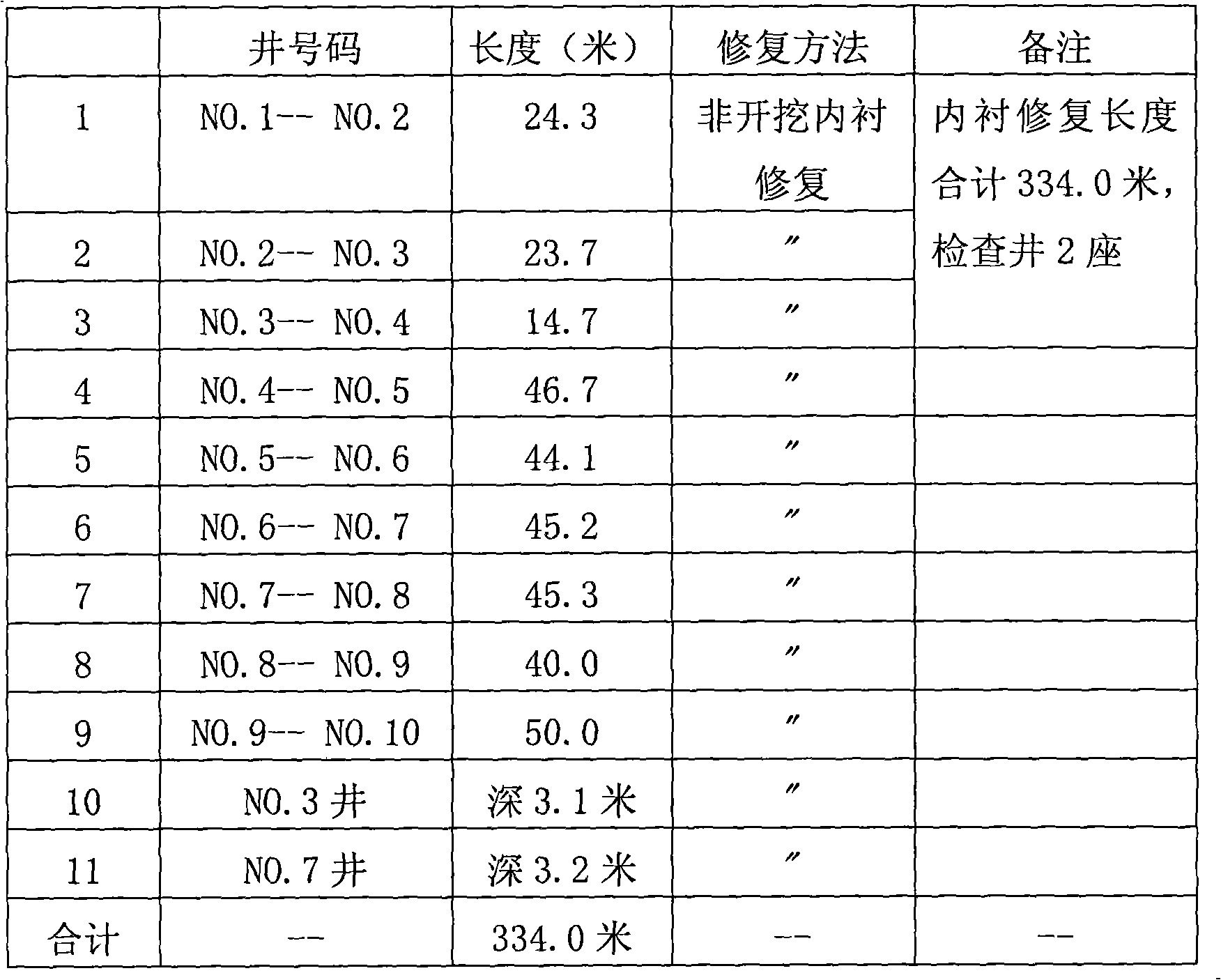

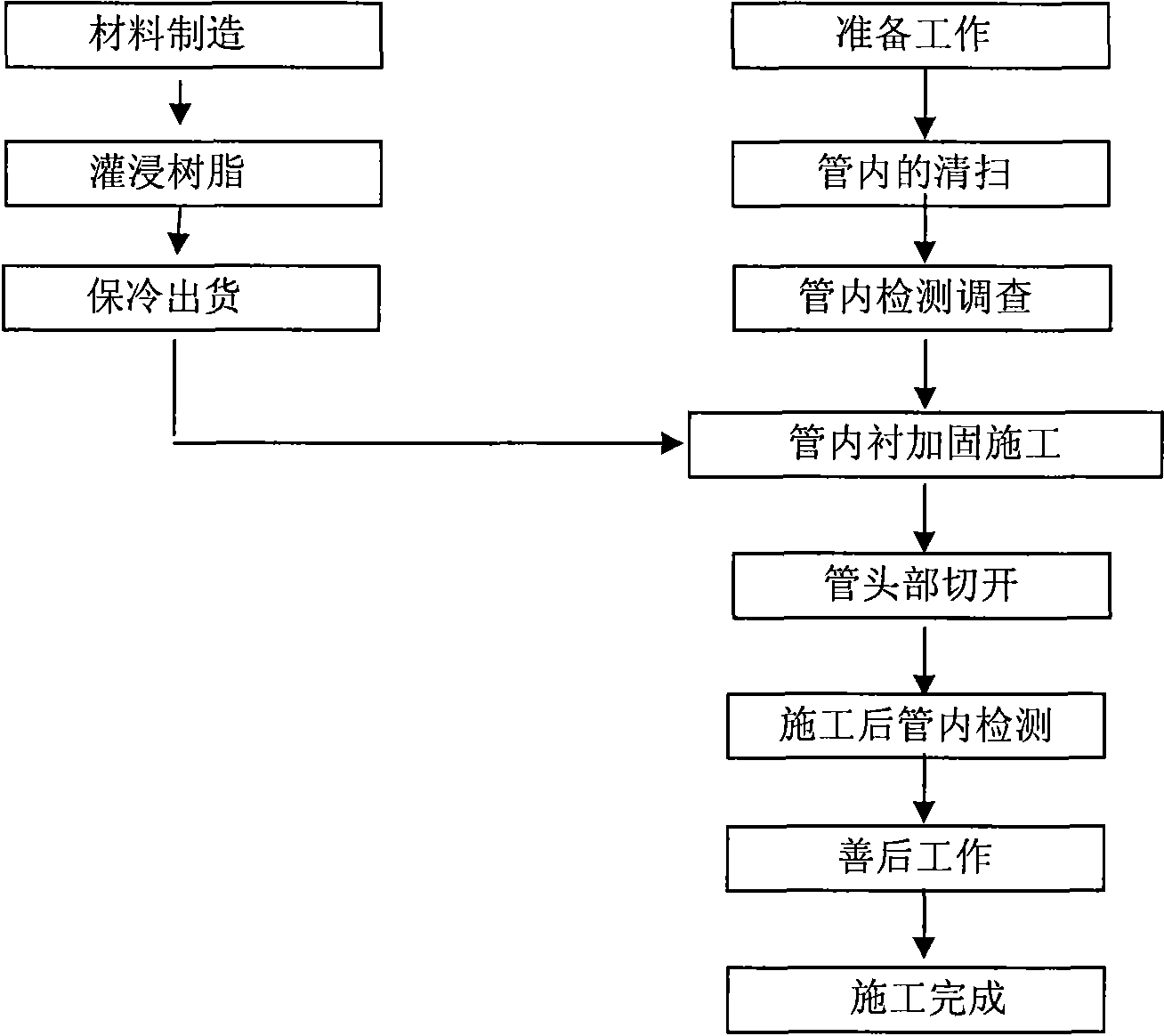

Method for repairing underground pipeline without digging

InactiveCN101649944AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a method for repairing an underground pipeline without digging, which comprises the following steps: (1) blocking and cleaning an old sewage pipeline needing repair and usingclosed circuit TV system (CCTV) equipment to detect the inner part of the pipeline; (2) delivering a waterproof barrel-shaped auxiliary lining hose pipe into the pipeline and injecting thermosetting resin to form a resin hose pipe; (3) turning over and inserting the resin hose pipe and a warm water delivery pipe for heating into the waterproof barrel-shaped auxiliary lining hose pipe; (4) expanding the resin hose pipe with water and compressed air so that the resin hose pipe is tightly attached to the inner wall of an old pipe, circularly heating by warm water and hardening and molding the thermosetting resin hose pipe so that the inner wall of the old pipe forms a new lining pipe with high strength; (5) opening pipe openings at both ends of the new lining pipe by cutting to smooth the pipeline; and (6) cutting at the extending positions of the pipe openings of the new lining pipe, which are positioned in the well wall of a check well. The method can prevent leakage, protect the pipe openings, prevent the thermosetting resin injected into the lining hose pipe from being mixed with underground water and prevent a poor phenomenon of lining material part hardening.

Owner:管丽环境技术(上海)有限公司 +1

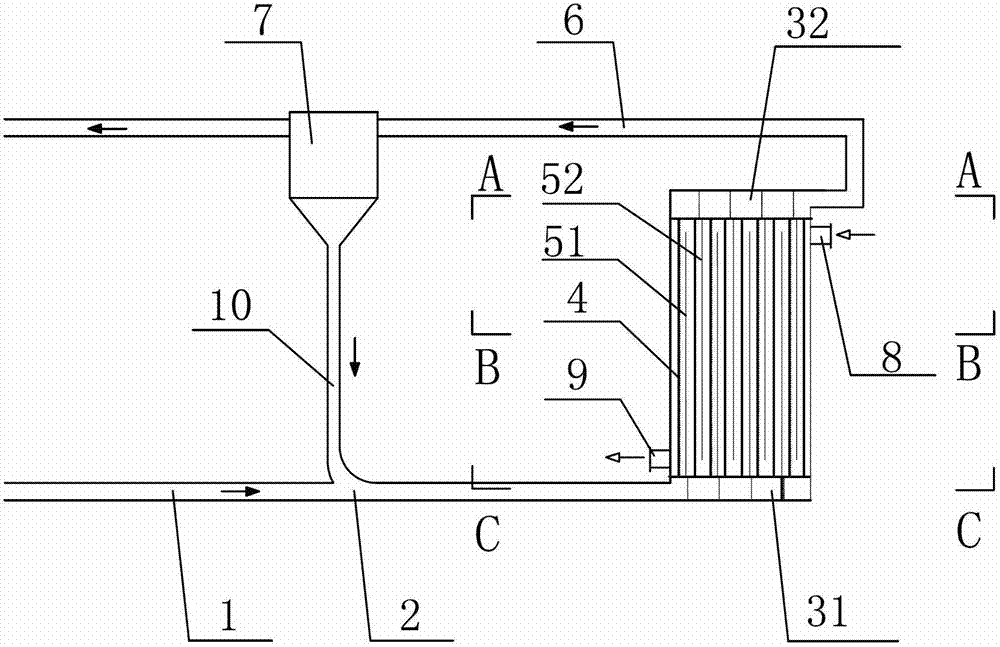

Sewage heat exchange device for large-diameter shell-tube type fluidized bed

InactiveCN102759289AImprove heat transfer efficiencyAnti-dirtCorrosion preventionHeat exchange apparatusSolid particleVolumetric Mass Density

The invention discloses a sewage heat exchange device for a large-diameter shell-tube type fluidized bed, which is provided with a sewage passageway and a clear water passageway, wherein an area for carrying out heat exchange through the tube wall exists between the sewage passageway and the clear water passageway. The sewage heat exchange device is characterized in that the sewage passageway is positioned in the heat exchange area, and a large-diameter pipeline with the diameter of 50-120mm is selected as a sewage pipeline; in addition, a solid particle introducing port is arranged at a water inlet of the sewage large-diameter passageway, and a solid particle storing and conveying assembly is connected to the rear end of the solid particle introducing port, wherein the diameters of the solid particles are 2-8mm, and the volume fraction of the solid particles is 2-8 percent; and the density of the solid particles is more than that of sewage. The sewage heat exchange device disclosed by the invention thoroughly overcomes the defects that a heat exchange is blocked by sundries and the heat exchange property is poor in the utilization of sewage or surface water cold and hot sources, can provide cold and hot sources for a heat pump, can be also used for cooling circulating water of large-size equipment or used for occasions, such as heating, air-conditioning and domestic water and has remarkable environment-friendly economic benefits.

Owner:DALIAN UNIV

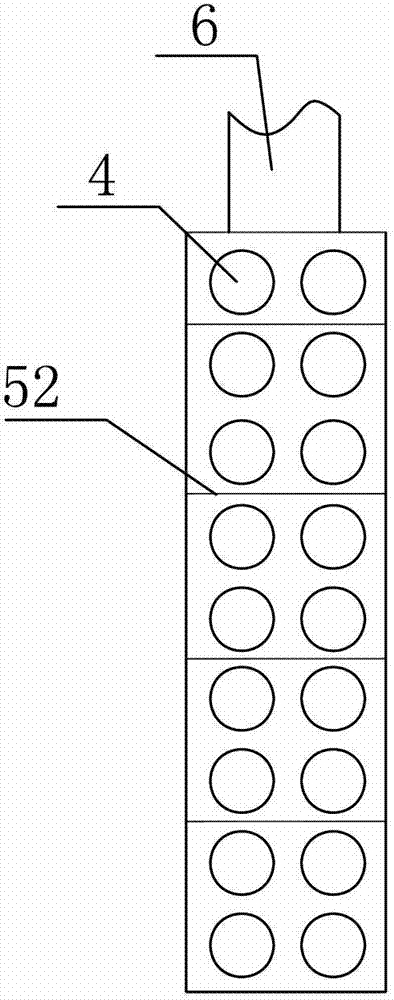

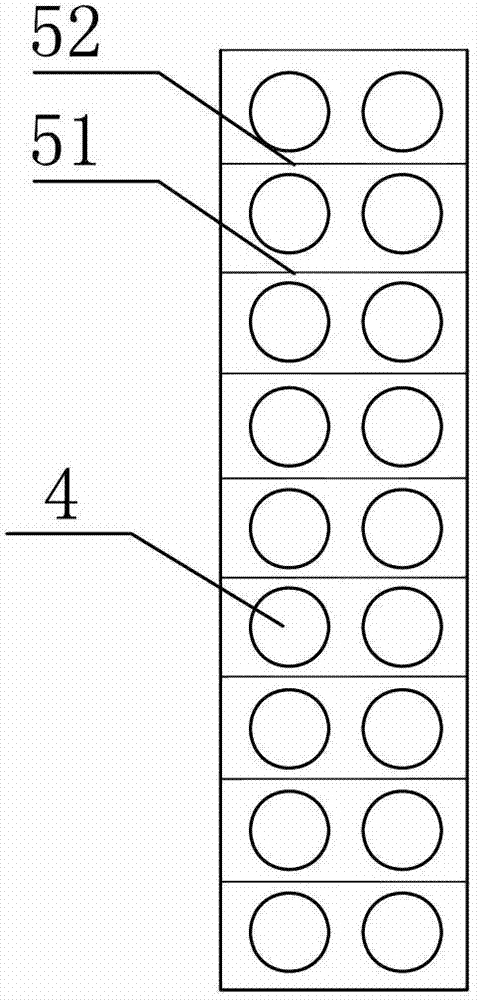

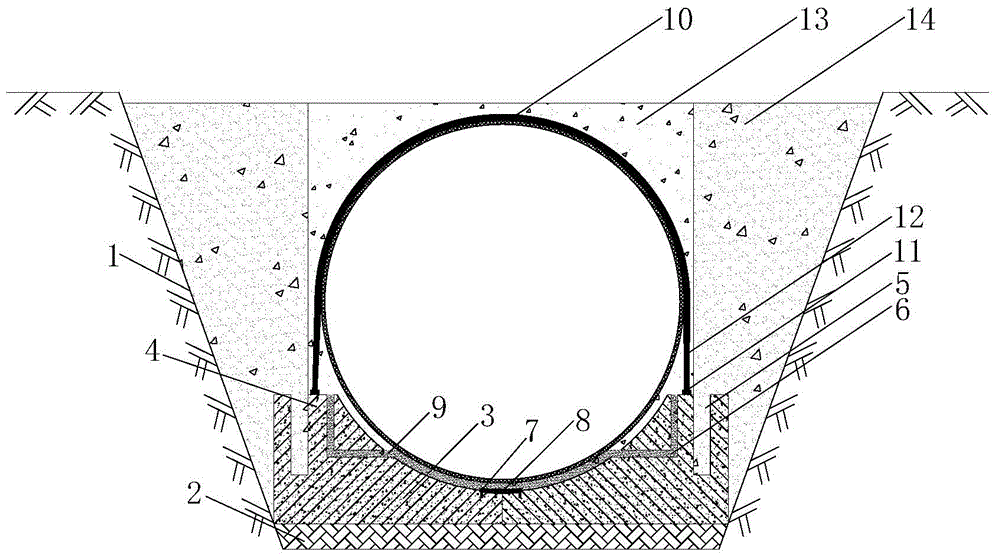

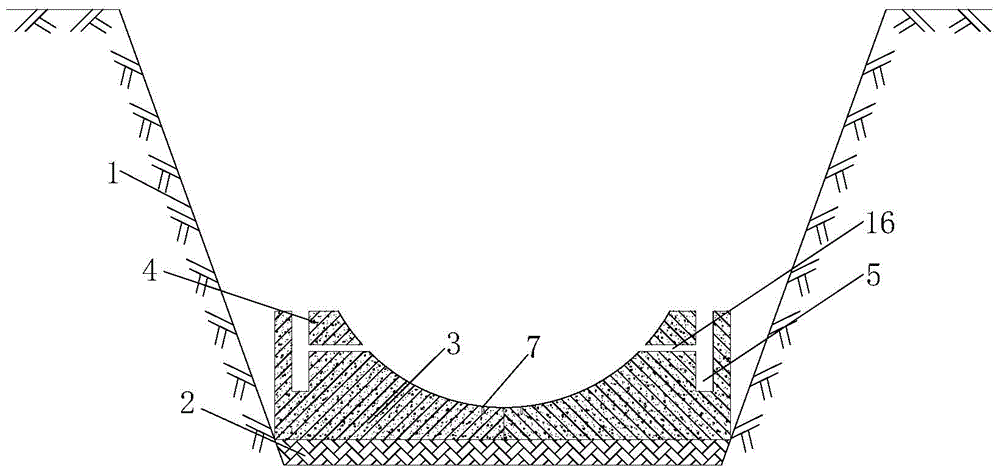

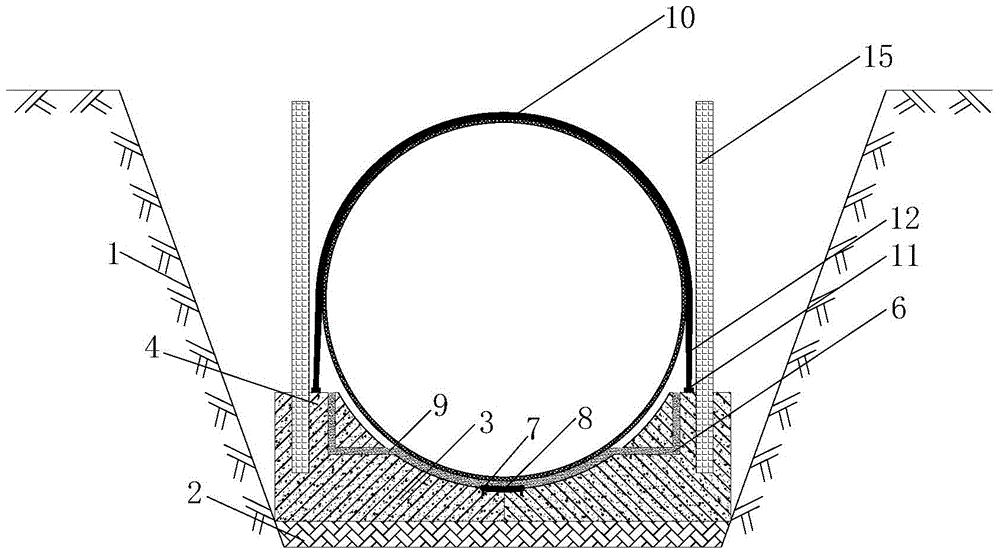

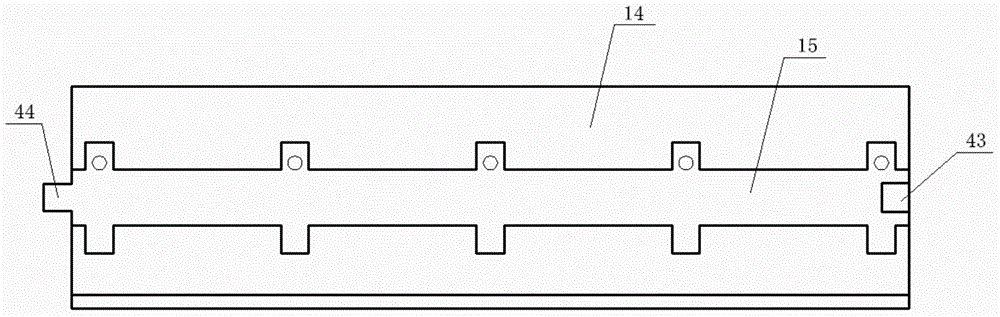

Construction method of large-diameter rain sewage pipeline assembling type component structure

The invention relates to a large-diameter rain sewage pipeline assembling type component structure. The large-diameter rain sewage pipeline assembling type component structure is characterized in that a shallow curing cement layer is disposed at the bottom of the groove of a pipeline, a prefabricated pipeline base is disposed on the upper portion of the shallow curing cement layer, the pipeline base is provided with hoisting holes, rear grouting holes, form board grooves and positioning fasteners, the pipeline is supported on the pipeline base, rear grouting sealing bodies are formed in the gaps between the pipeline and the pipeline base by grouting through the rear grouting holes, separated annular positioning bands are evenly disposed on the pipeline, two ends of the separated annular positioning bands are respectively connected with the positioning fasteners on two sides of the pipeline base, a concrete backfill layer is disposed on the periphery of the pipeline, and gravel backfill layers are disposed on two sides of the pipeline. The large-diameter rain sewage pipeline assembling type component structure has the advantages that the prefabricated pipeline base is used, pipeline mounting integrity and stability are effectively enhanced by a series of reinforcing measures, and the structure is convenient in hoisting and good in economic and technological benefits.

Owner:神州建设集团有限公司

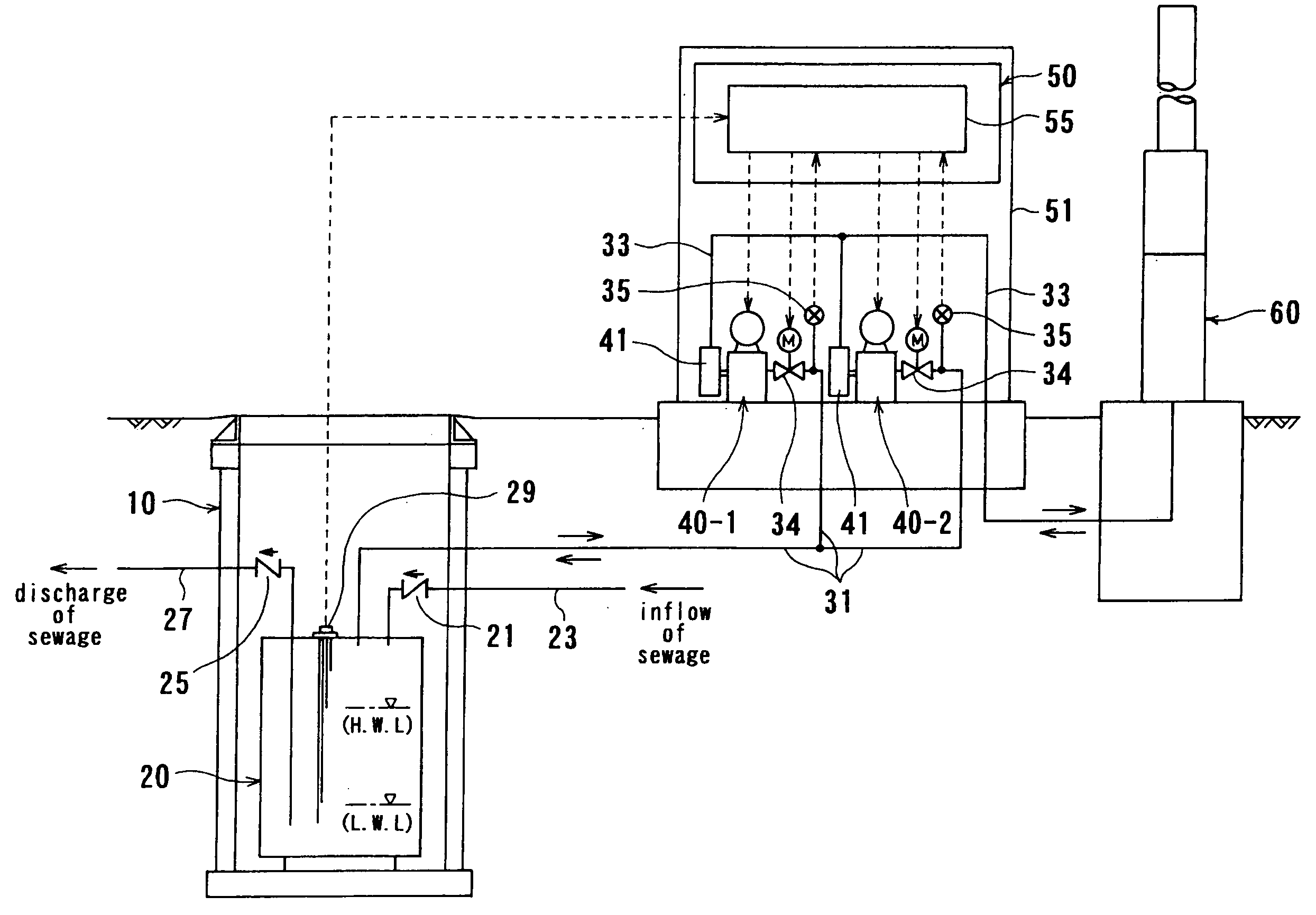

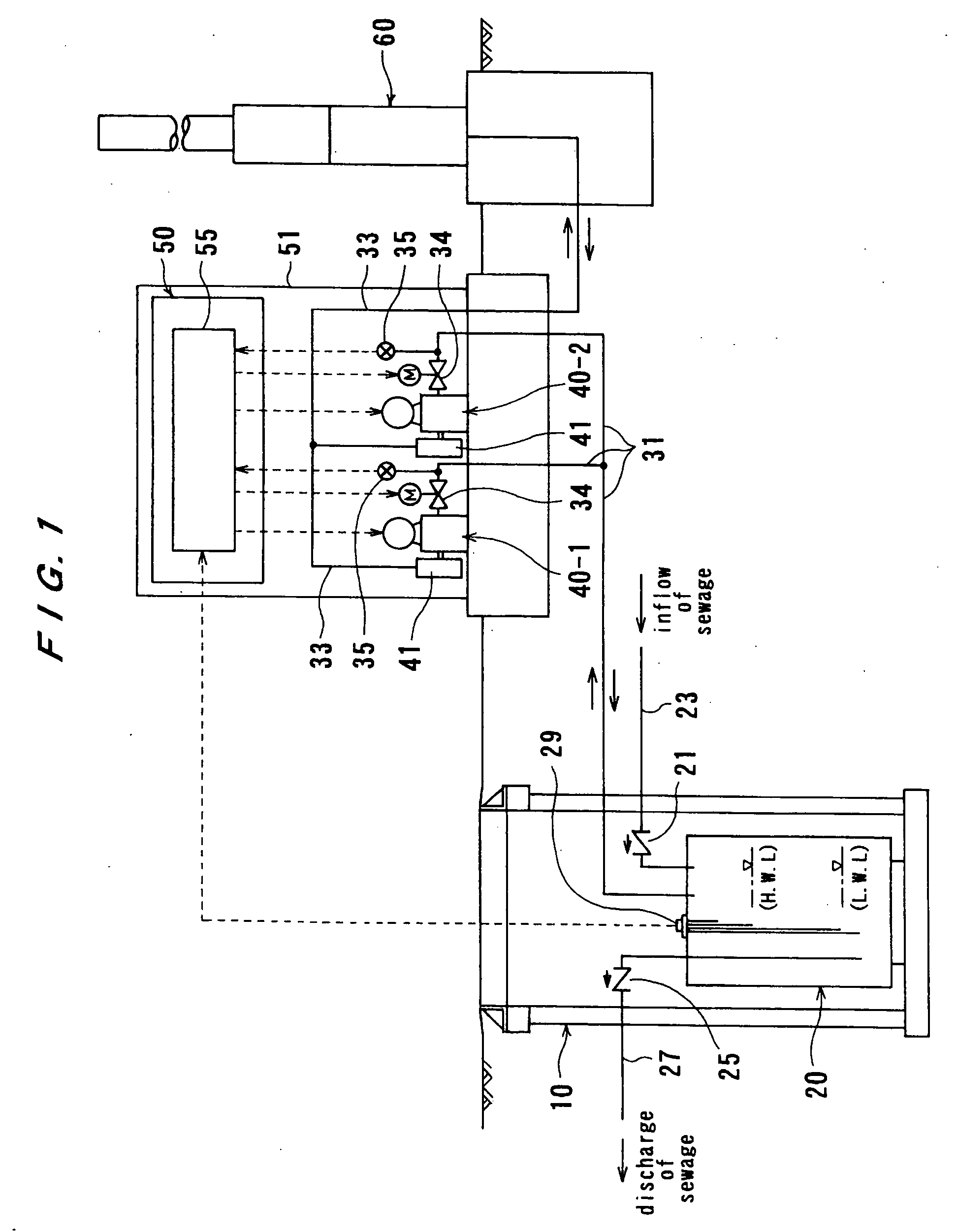

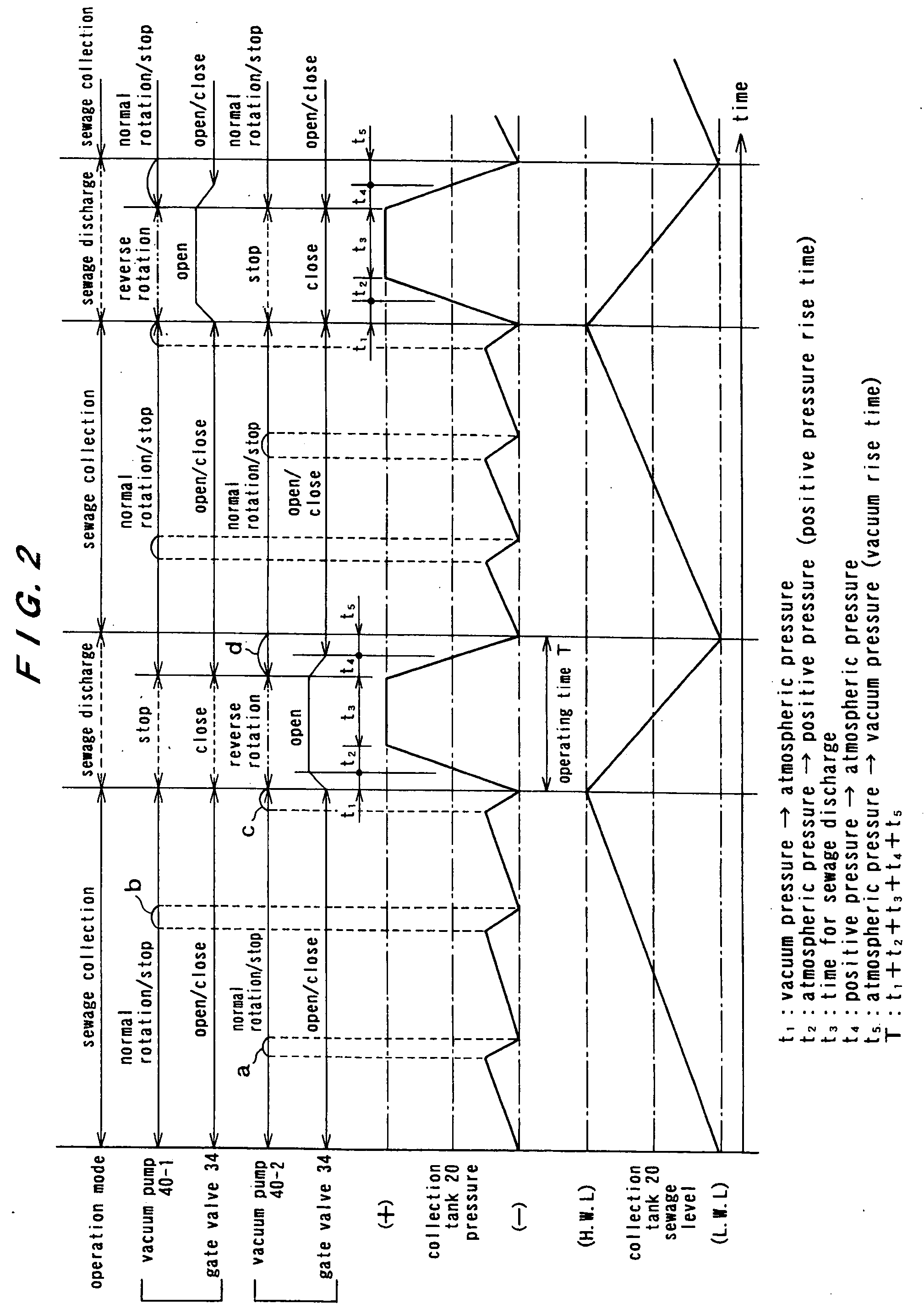

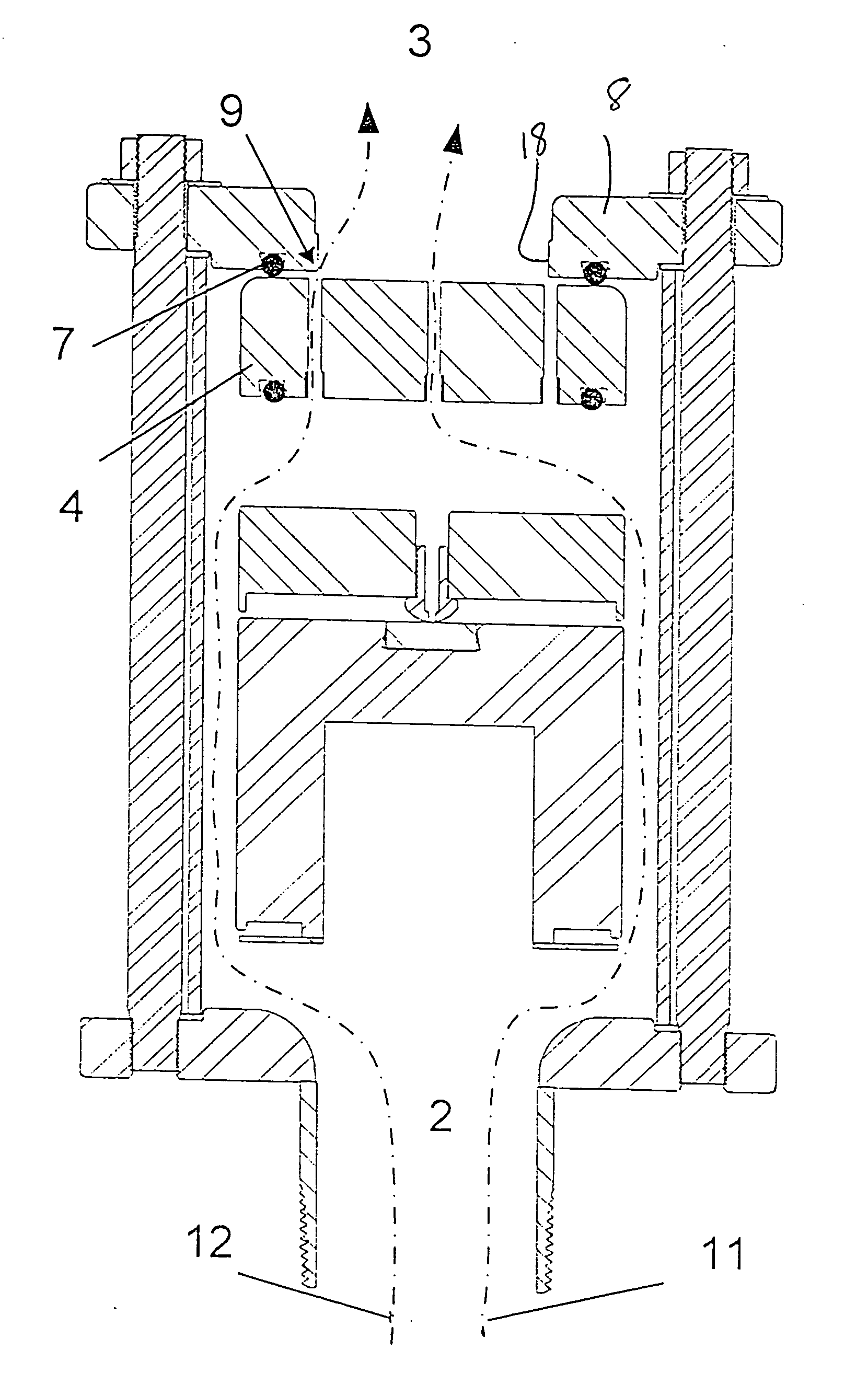

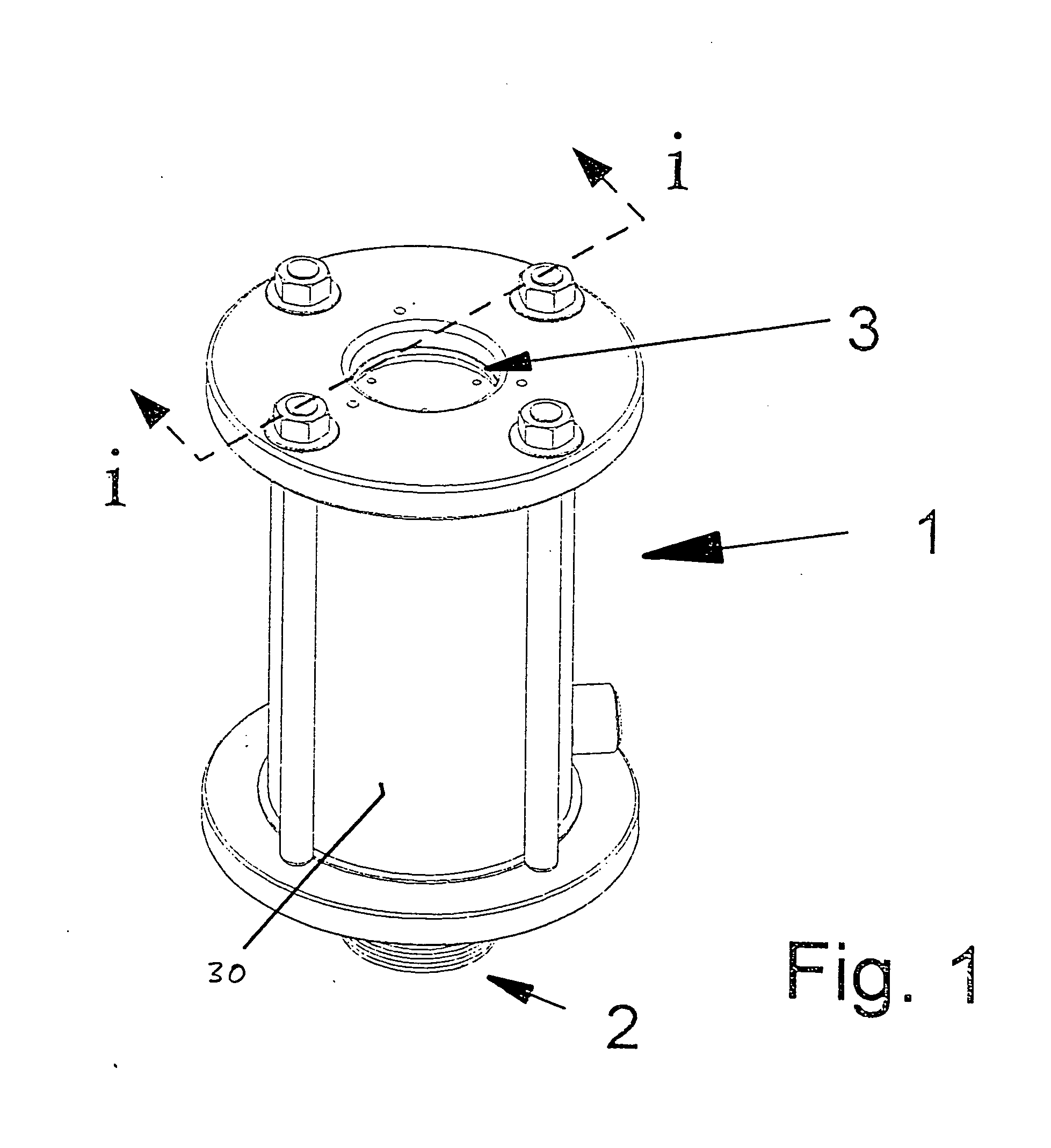

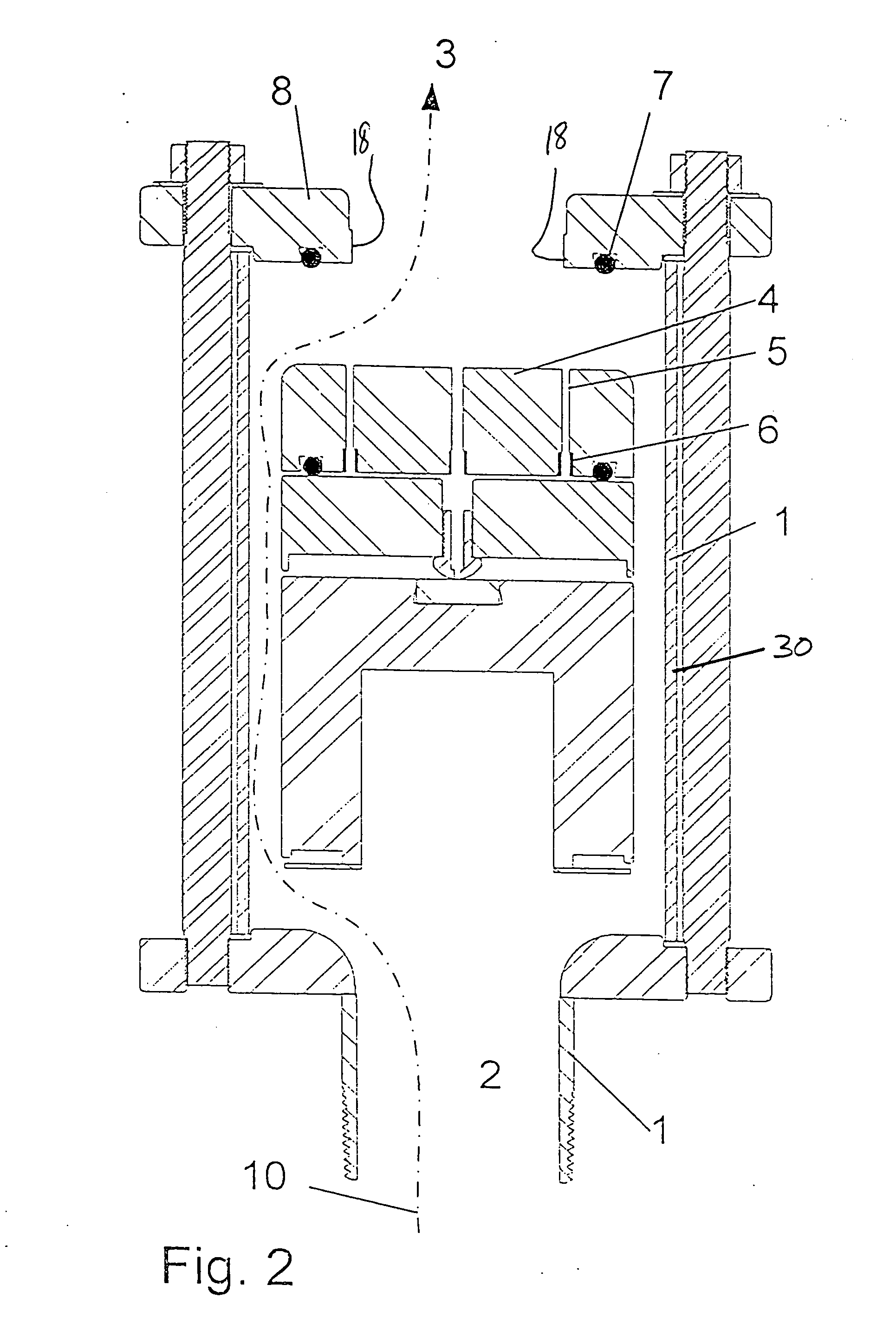

Vacuum station and the method for operating the same

ActiveUS20050016588A1Reduce facility costsImprove efficiencyFilling using suctionSewerage structuresSewageSewage treatment

A vacuum station is used for storing sewage from a vacuum sewage pipe and then delivering the sewage to a sewage treatment plant or the like. The vacuum station includes a collection tank for collecting sewage, a plurality of vacuum pumps for depressurizing and pressurizing an interior of the collection tank, and a controller for controlling the plurality of vacuum pumps. The controller controls at least one of the vacuum pumps so as to rotate in normal direction so that the interior of the collection tank is depressurized to collect sewage into the collection tank, and at least one of the vacuum pumps so as to rotate in reverse direction when the sewage in the collection tank reaches a predetermined sewage level so that the interior of the collection tank is pressurized to discharge the sewage from the collection tank.

Owner:EBARA CORP

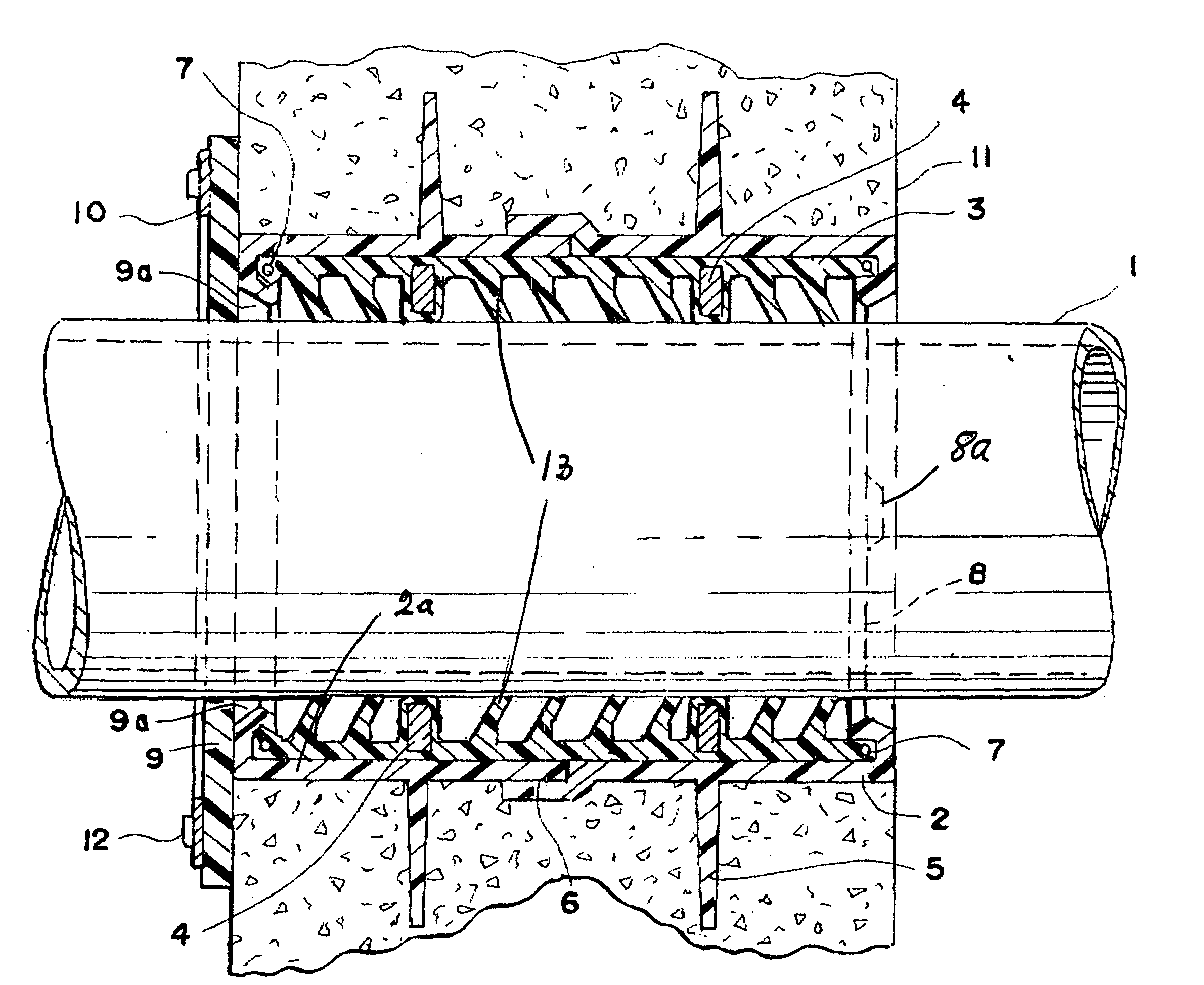

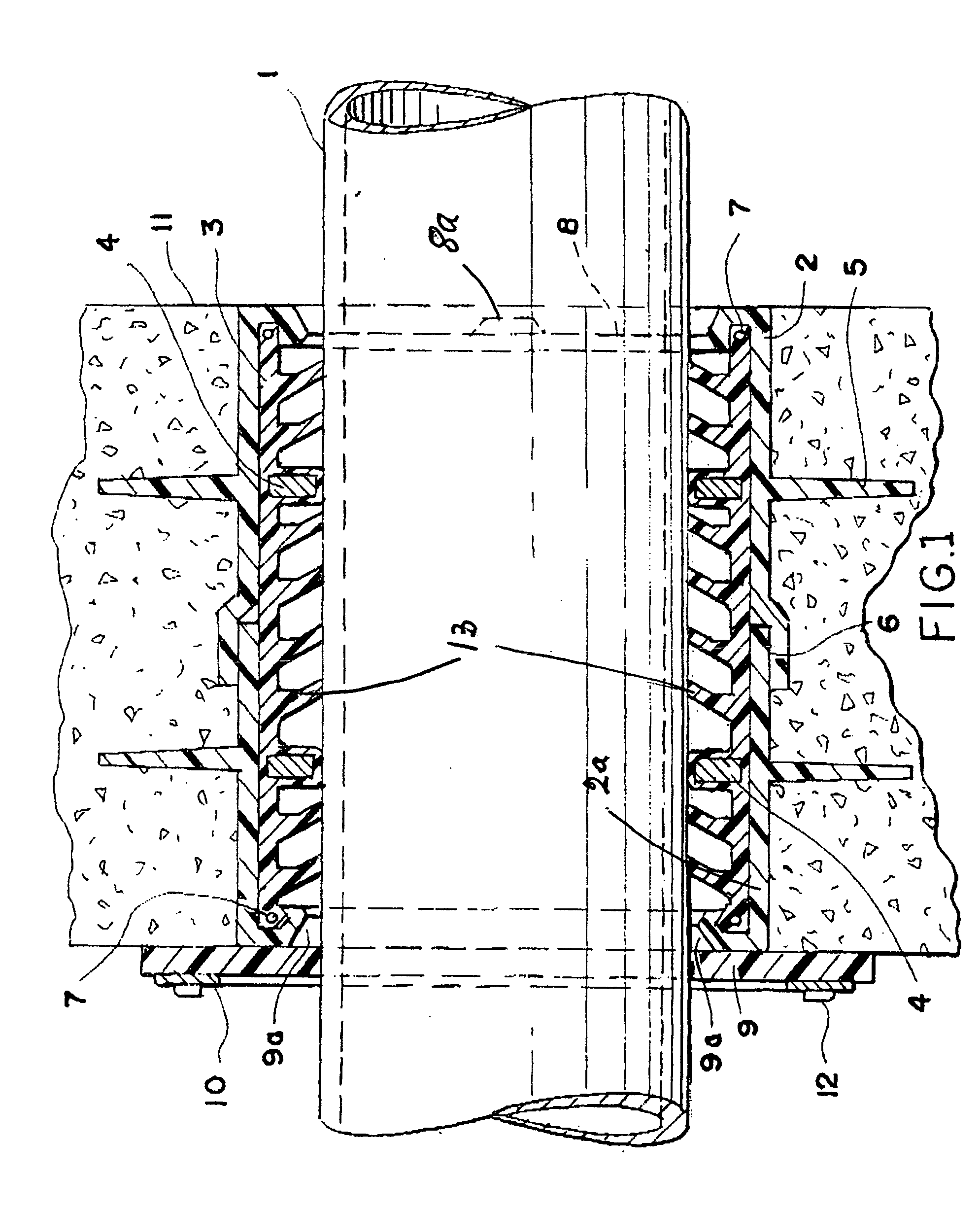

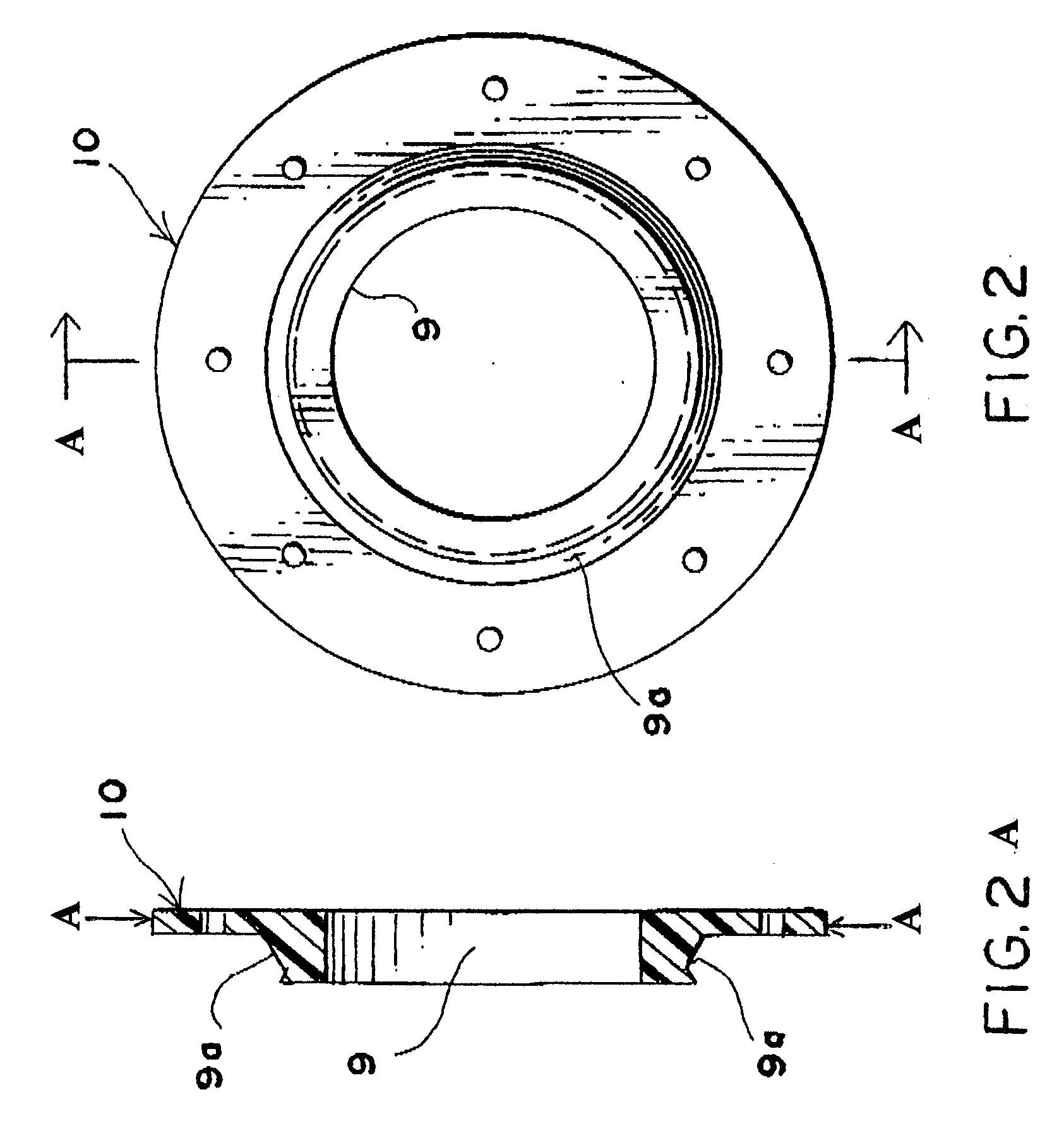

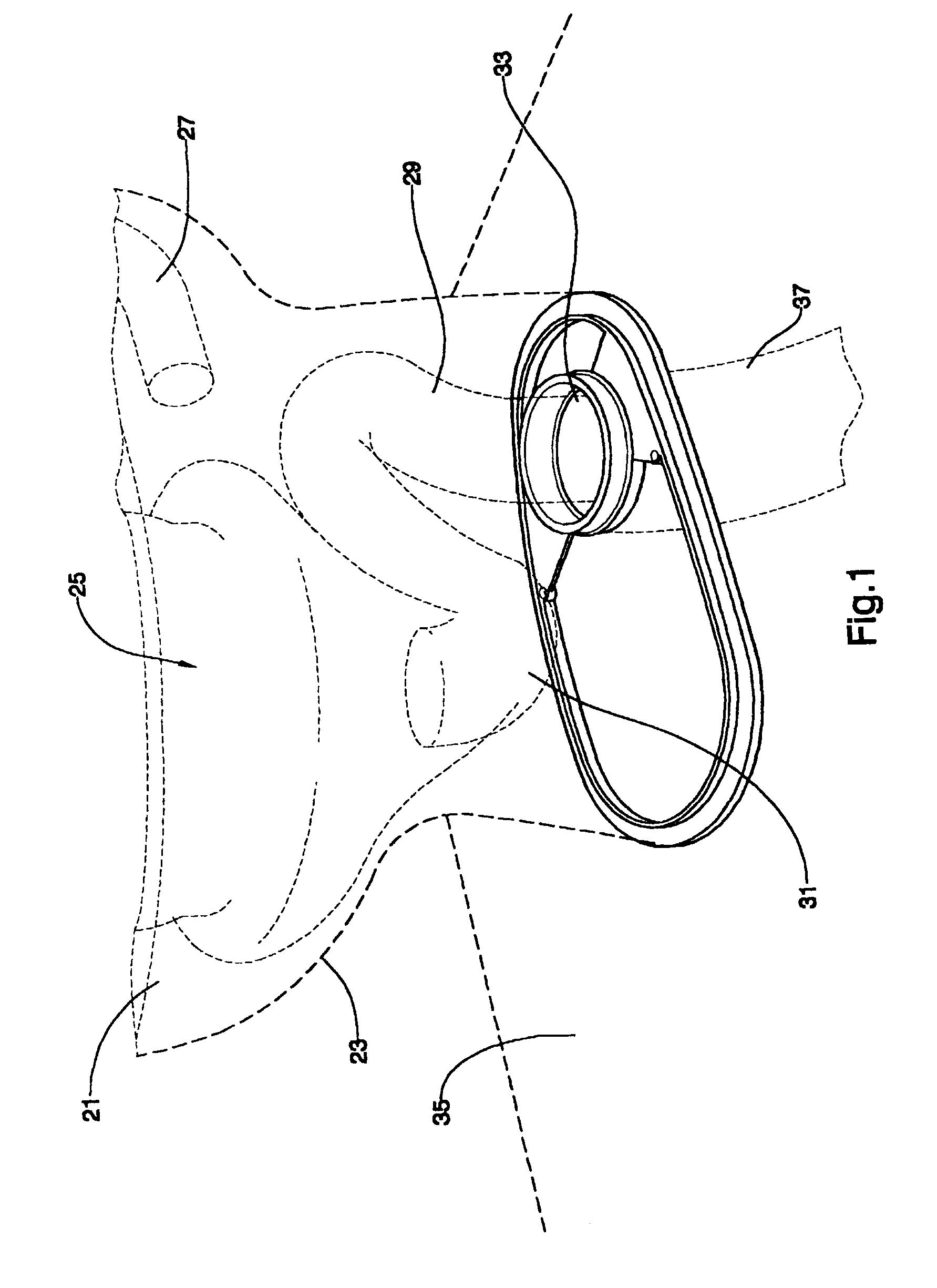

Hydro penetration prevention sleeve

A hydro penetration prevention sleeve is used when building a basement wall wherein said basement wall is subject to leakage from ground water especially pipes that have to be placed through the wall. The pipe, mostly a sewage pipe, has to placed into the wall at a height which is just above the sewage pipe located outside the building or house so that gravity can carry the sewage toward the outside pipe. A main sleeve is placed into a concrete casing that will form the wall just prior to casting the concrete into the casting. The sleeve consists of PVC and is made of two halves that interfit with each other and are glued together to accommodate any preset dimension that matches the preset dimension of the concrete forms prior to casting. The main sleeve has an interior hard rubber sleeve that has rings extending to an interior of the sleeve and the rings are slanted in the direction of the insertion of the pipe to be inserted therein. When the pipe is inserted therein, the slanted rings are compressed by the pipe. The pipe cannot be moved into the opposite direction because of the compression and friction of the rings. There are other elements used in sealing the ends of the main sleeve. One embodiment can be used to seal pipes against concrete in existing installations.

Owner:STASKAL JEFFERY GENE

Trenchless repairing method of underground pipeline with drawing-type liner pipe

InactiveCN101907213AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a trenchless repairing method of an underground pipeline with a drawing-type liner pipe. The method comprises the following steps of: (1) blocking and cleaning a worn sewage pipeline and detecting the interior of the pipeline; (2) drawing a watertight cylindrical auxiliary liner hose in the worn pipeline, preliminarily impregnating thermosetting resin in a non-woven hose to form a resin hose and well turning the resin hose; (3) drawing the well-turned resin hose and a warm water conveying pipe for heating in the watertight cylindrical auxiliary liner hose which is already arranged in the worn pipeline; and (4) expanding the resin hose by adopting compression air to tightly attach to the worn pipe, directly adding hot water to the resin hose to harden and form the thermosetting resin hose in the worn pipe and forming a new high-strength liner pipe on the inner wall of the worn pipe. The invention solves limitation caused by a construction site when repairing an underground pipeline through liner by using a turning method, solves the problem of uneven resin curing strength, simplifies the process flows of on-site construction and has the advantages of easy and simple operation, time saving and damage resistance.

Owner:管丽环境技术(上海)有限公司 +1

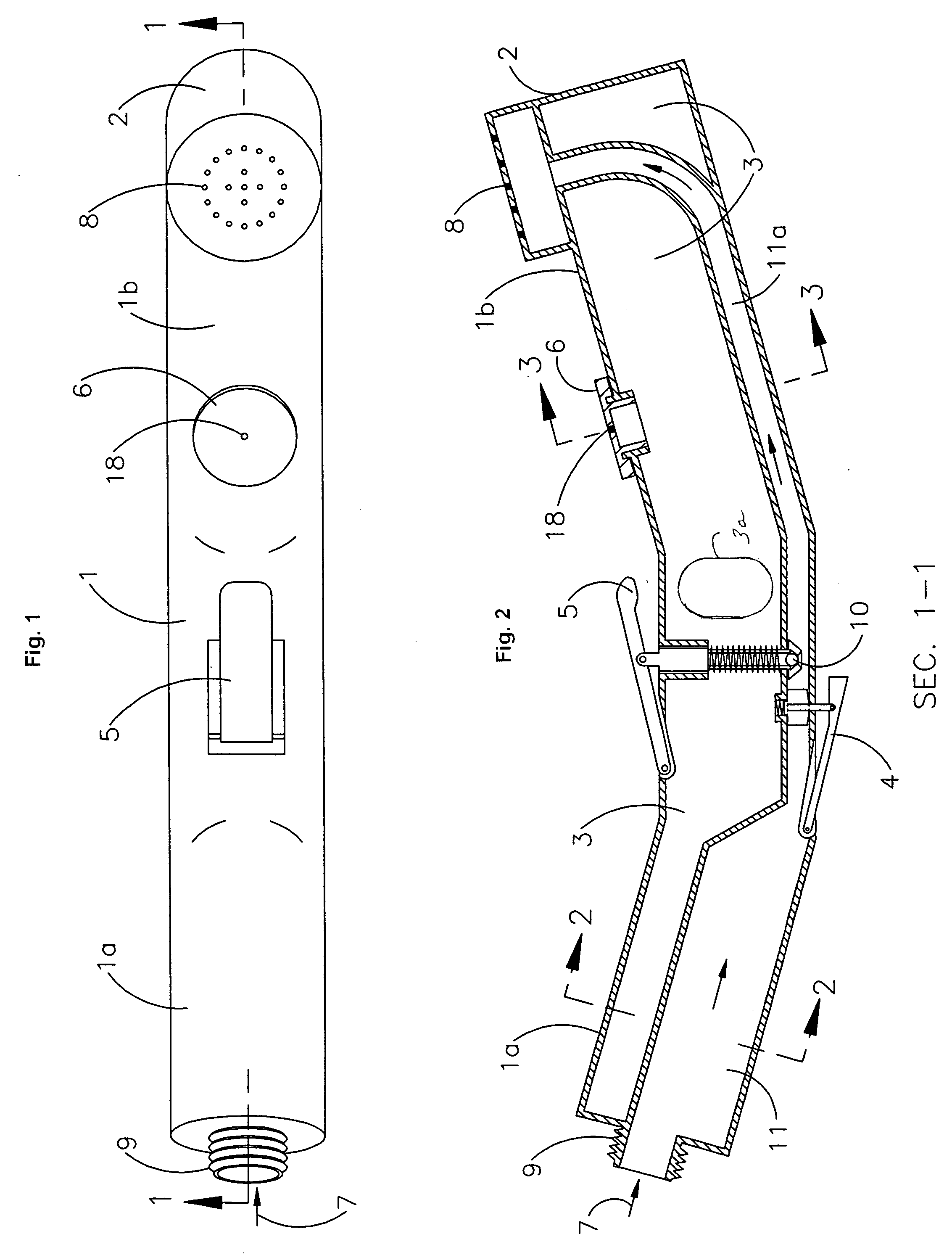

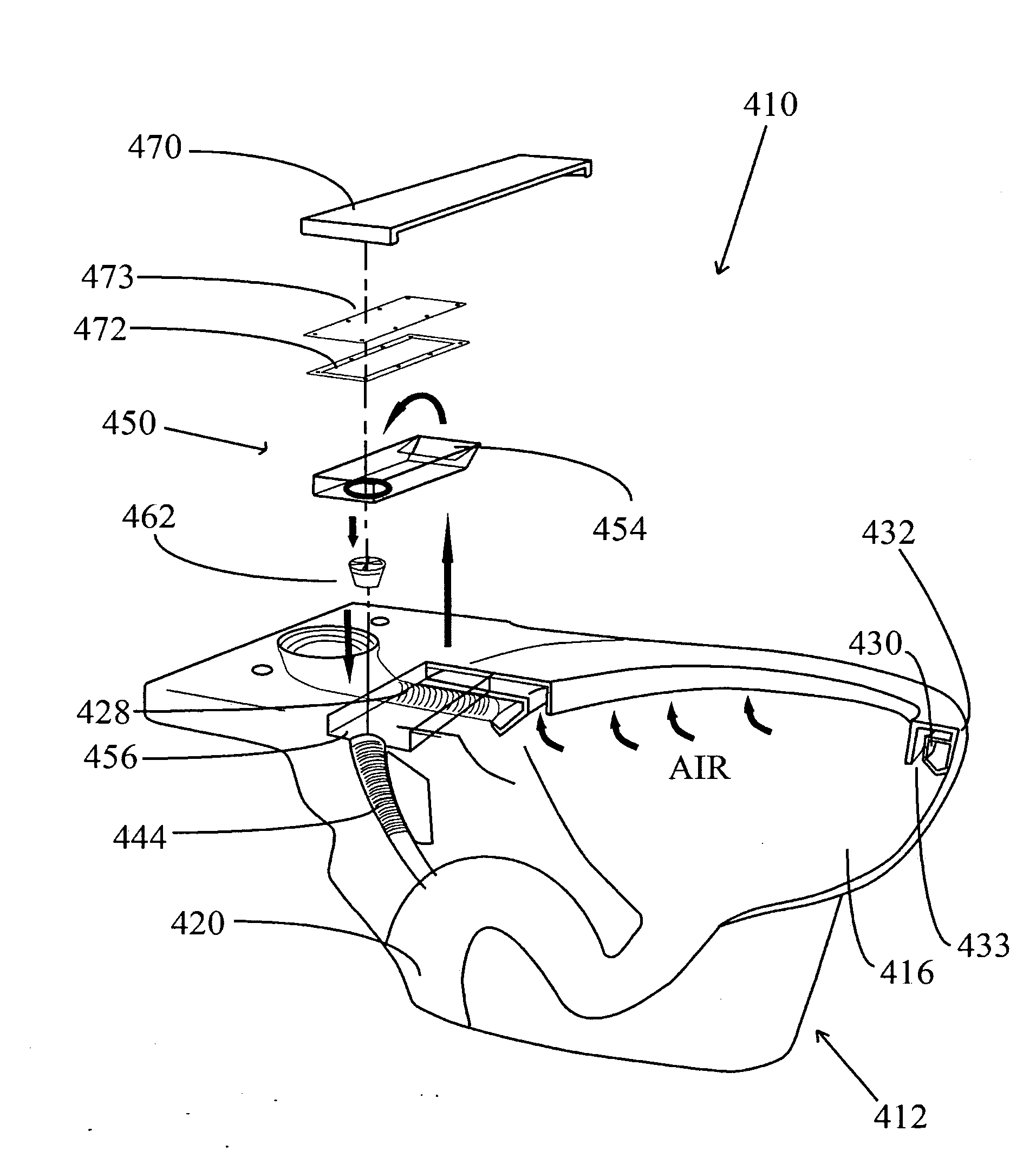

Hand held sanitary washer

InactiveUS20090121042A1Improve personal hygieneLow costSpray nozzlesDomestic plumbingTemperature controlHand held

The Hand Held Sanitary Washer provides a mechanism to deliver soap, water or a soap and water mixture. Soap delivery is accomplished through a venture mechanism or through compressive means. A soap reservoir may be detachable or included within the sanitary washer handle. Water aeration diminishes splashing as well as aiding in the mixture of soap and water. The addition of temperature controlled water is provided for and various attachment means to existing plumbing facilities are provided.

Owner:MITRY RAGAI

Underground pipeline excavation-restoration construction method of stage temperature-control field pipe-making

InactiveCN101634374ATo achieve anti-leakageAvoid crackingPipe laying and repairTemperature controlTelevision equipment

The invention relates to an underground pipeline excavation-restoration construction method of stage temperature-control field pipe-making, comprising the following steps: (1) an old sewage pipeline is plugged and cleaned, and closed-circuit television equipment is adopted to detect the inner part of the pipeline; (2) an impervious tubular auxiliary lining flexible pipe is arranged in the pipeline, and soaking hardened resin is filled to form a resin flexible pipe; (3) the resin flexible pipe and a hot water delivery pipe for heating are turned over and are inserted in the impervious tubular auxiliary lining flexible pipe; (4)the resin flexible pipe is expanded to be closely attached to the inner wall of the old pipeline by utilizing water and compression air, the hot water is heated in a circulating way, the resin flexible pipe is hardened, and a lining new pipeline is formed on the inner wall of the old pipeline; (5) the pipe orifices at two ends of the lining new pipeline are cut, so as to lead the pipeline to be smooth. The method is characterized in that: the heating circulation of hot water is divided into three steps: a first step is carried out for 40-45 minutes at the temperature of 73-75 DEG C; a second step is carried out for 55-60 minutes at the temperature of 82-84 DEG C, and a third step is carried out 30-35 minutes at the temperature of 25-30 DEG C. The method can prevent seepage, and can prevent the hardened resin which is soaked in the material and is solidified and not hard from cracking caused by sharp cooling.

Owner:管丽环境技术(上海)有限公司 +1

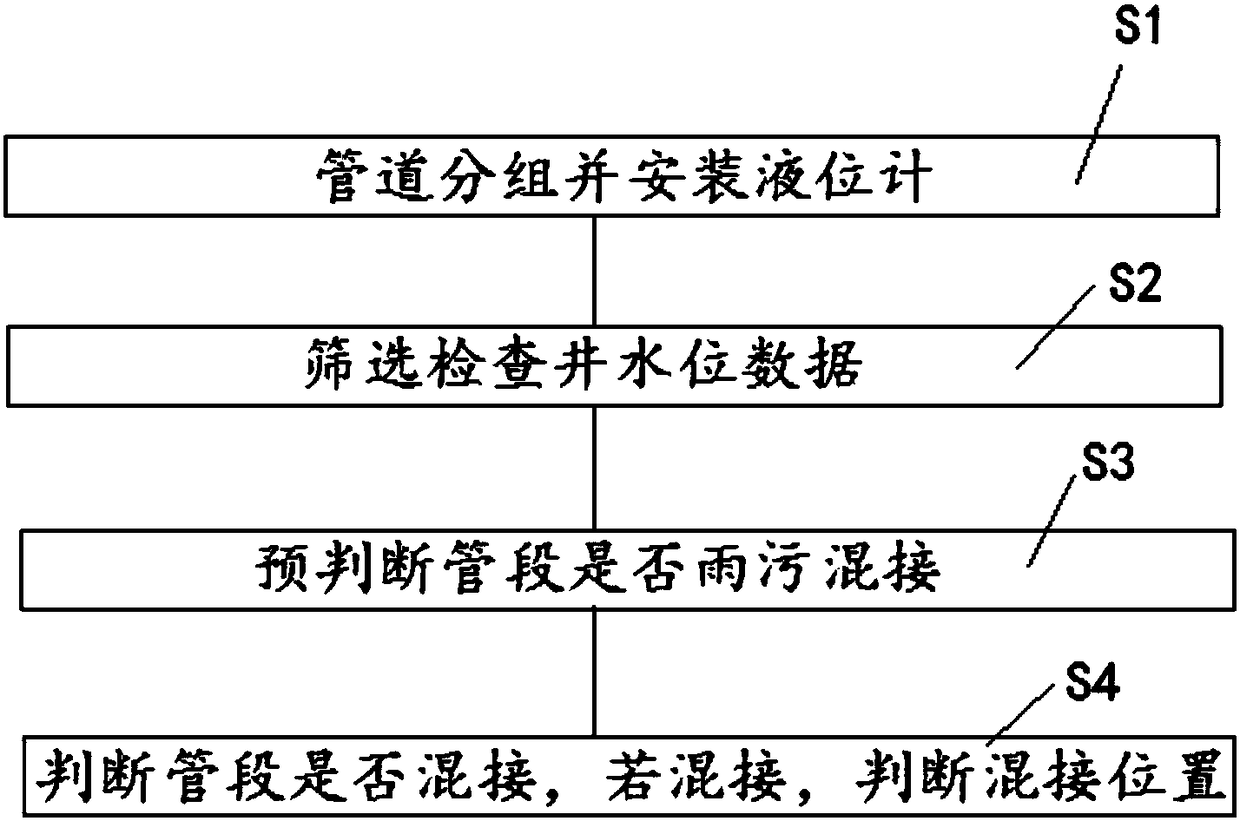

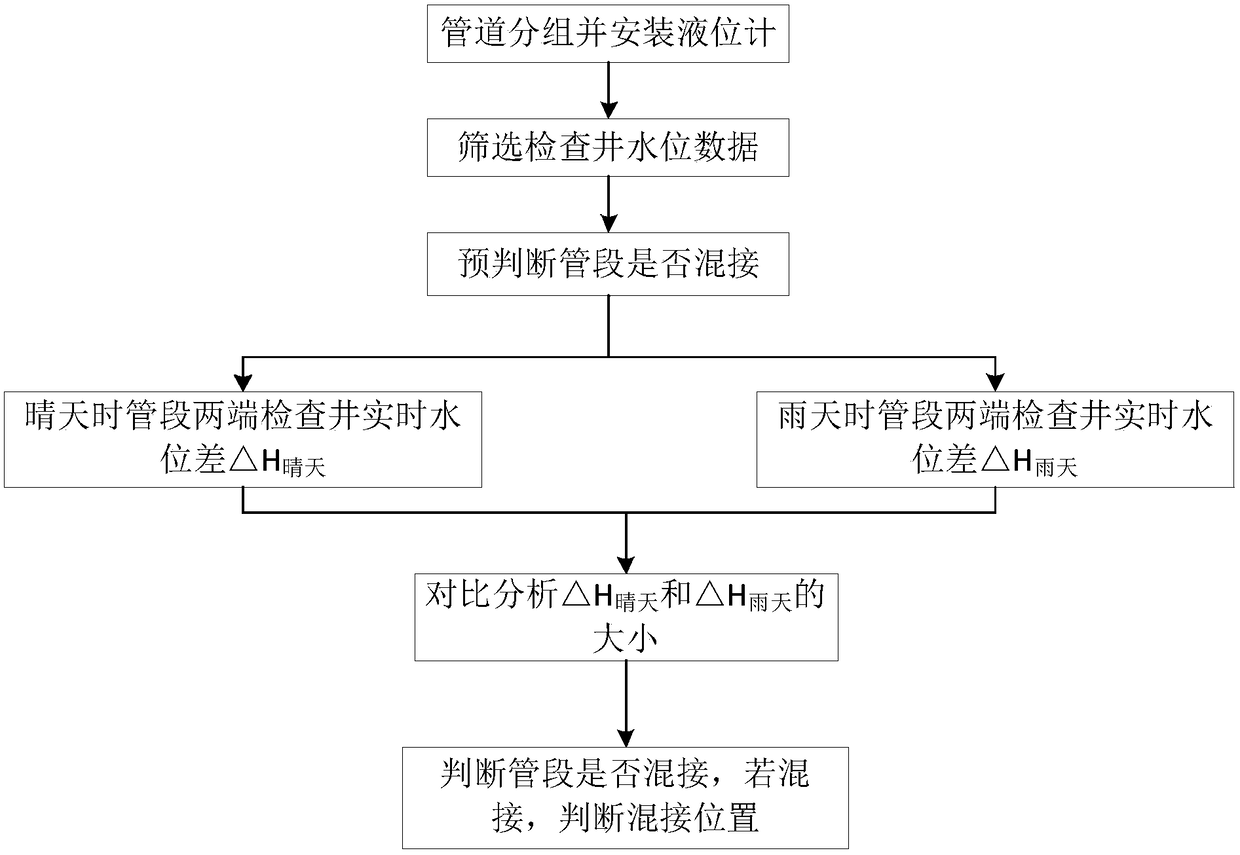

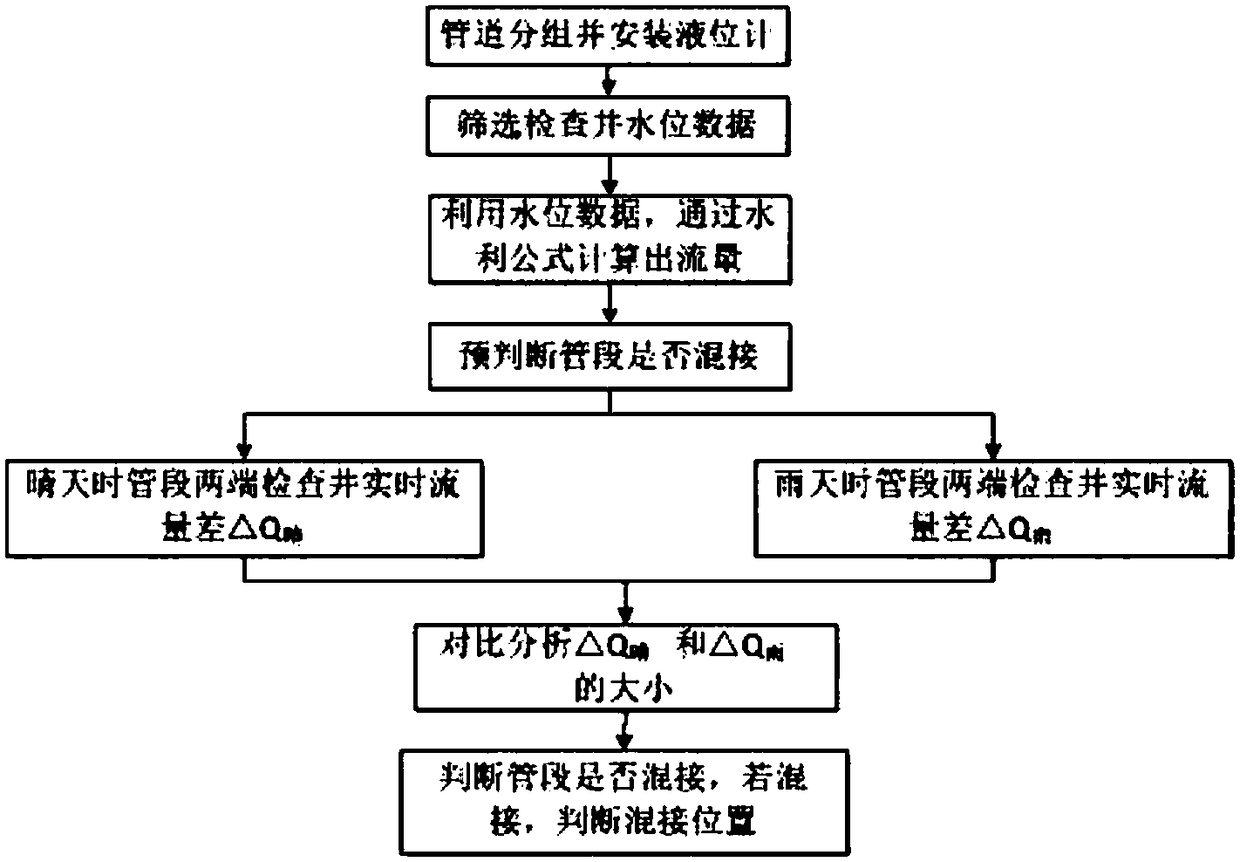

Method and system for analyzing pipe rainwater and sewage mixed collection distribution

The invention relates to a method and system for analyzing pipe rainwater and sewage mixed collection distribution. The method comprises the steps of S1, grouping pipes and installing a liquid level meter; S2, screening inspection well water level data; S3, prejudging whether pipe sections are subjected to mixed collection of rainwater and sewage or not; S4, judging whether the pipe sections are subjected to mixed collection or not, and if yes, judging the mixed collection position. According to the method, by arranging the liquid level meter in an inspection well and acquiring liquid level data for a long term, through the combination of hydraulic calculation and analysis and big data analysis, the status quo of whether the sewage pipes are pipes subjected to mixed collection of the rainwater or not and area characteristic distribution are obtained; moreover, through liquid level data, the data is processed, through hydraulic power, flow is calculated to judge whether the phenomenon of mixed collection of the rainwater and the sewage exists among pipe sections in a sewage pipe network or not, the distribution of the pipe sections subjected to mixed collection is obtained, the specific positions of the pipe sections subjected to mixed collection of the rainwater and the sewage are judged in a more economic and safer mode, and data support is provided for later pipe updating andimproving.

Owner:上海水顿智能科技有限公司

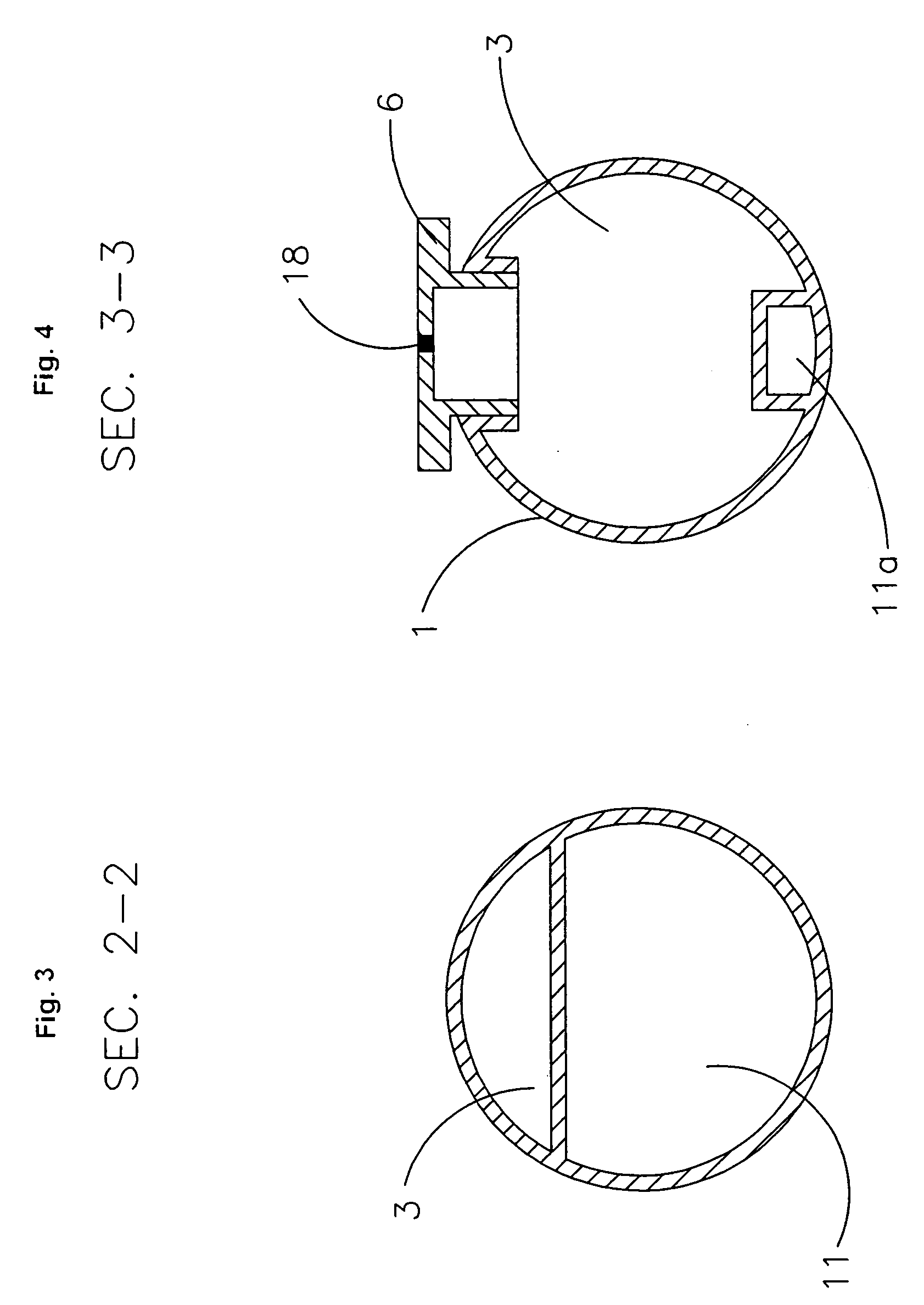

Method and apparatus for venting gas from liquid-conveying conduit

InactiveUS20120037834A1Increased durabilityReduce wear rateSewerage structuresVenting valvesExhaust valveHeat flow

A valve-venting method increases the durability of flow restrictors within gas venting valves used on large diameter water and sewer pipelines such that transient high pressure conditions that can cause rapid adiabatic heating of the discharging gases are prevented from causing flow erosion and debris wear induced by the high velocities and thermal softening of the valve components. The method utilizes wear resistant orifice inserts that are more conductive than the valve component to better distribute the heat, and dynamic surge control geometry to slow the heat flow and provide progressive water-hammering control during high pressure events.

Owner:INT VALVE MFG

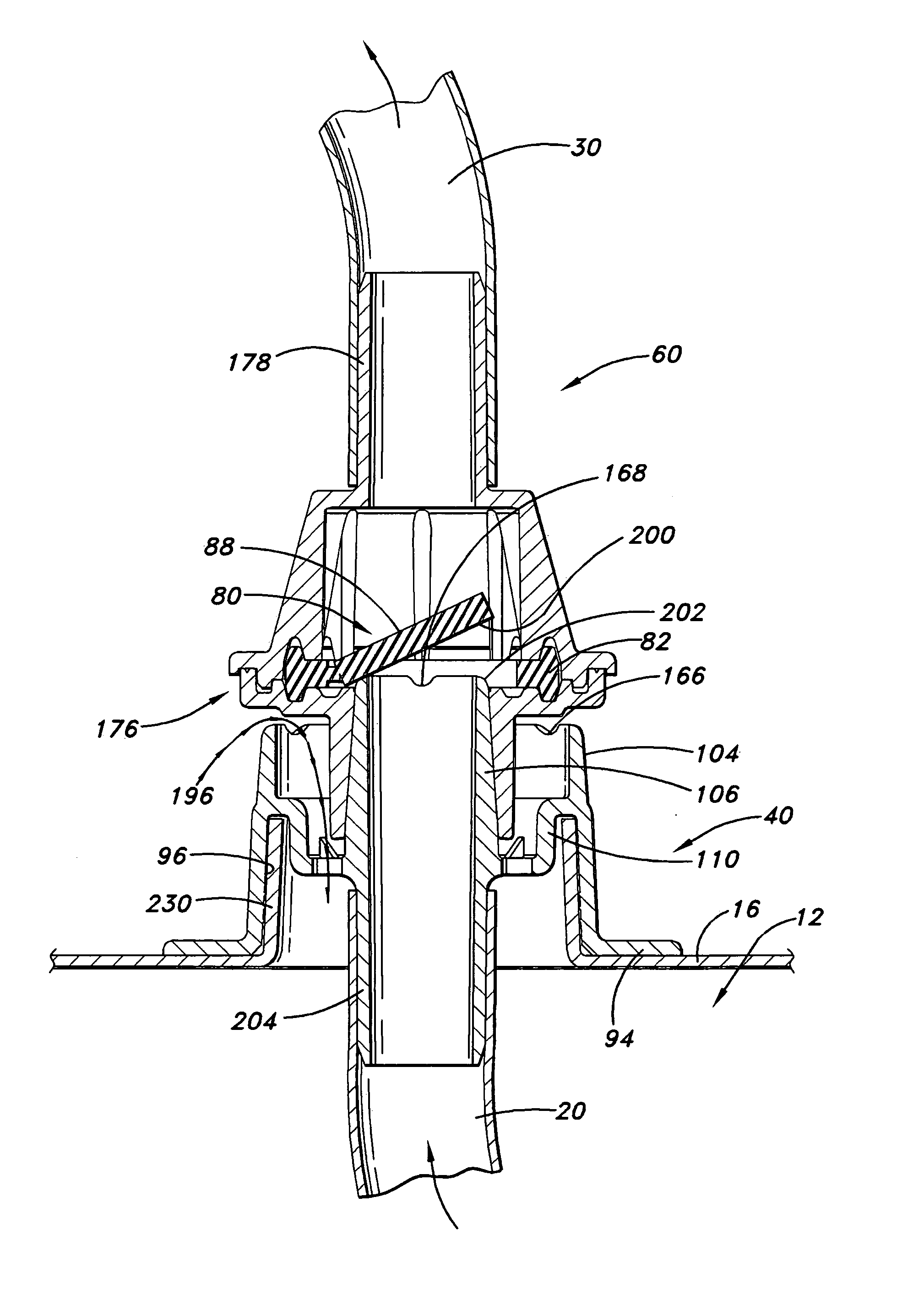

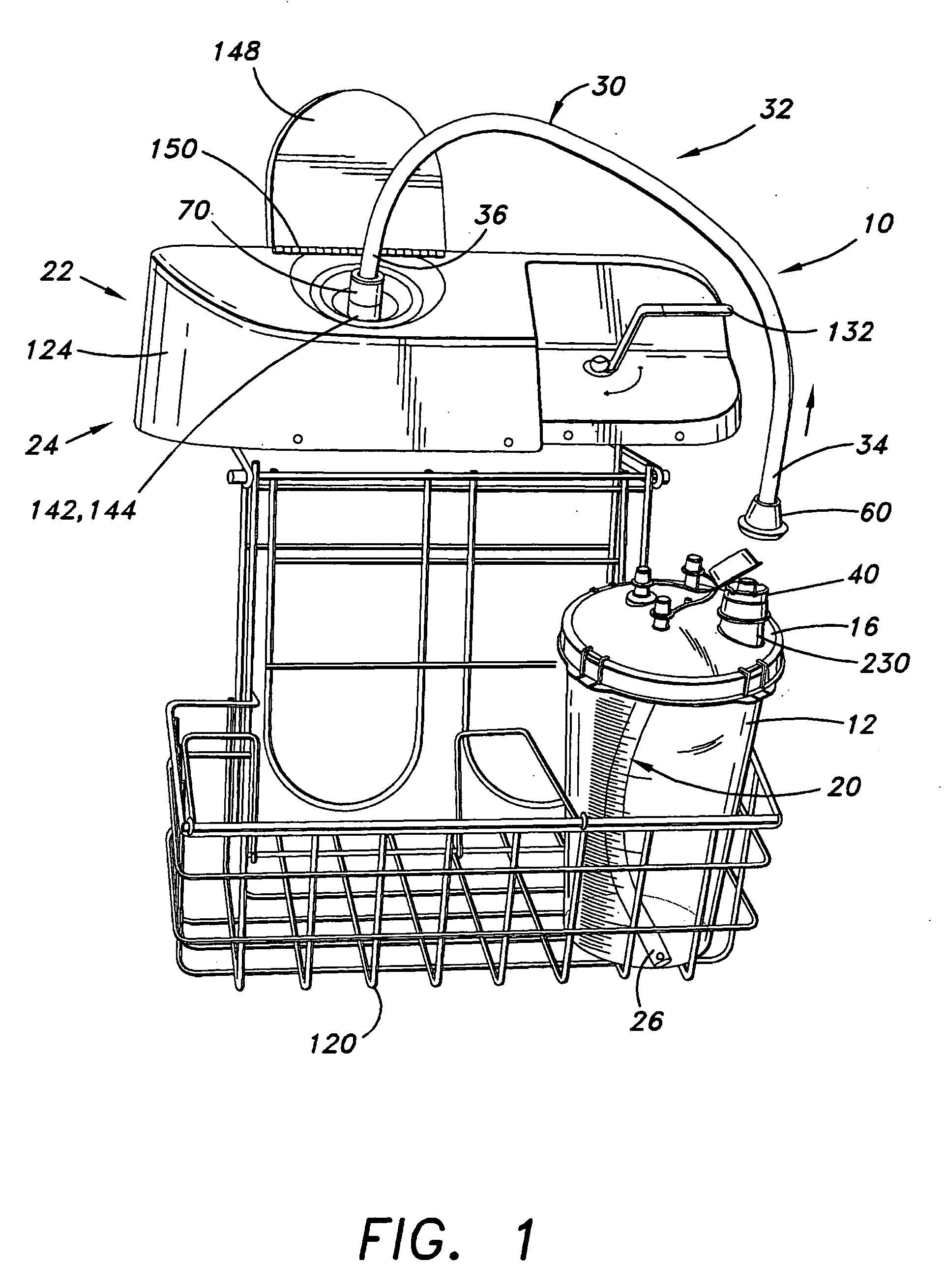

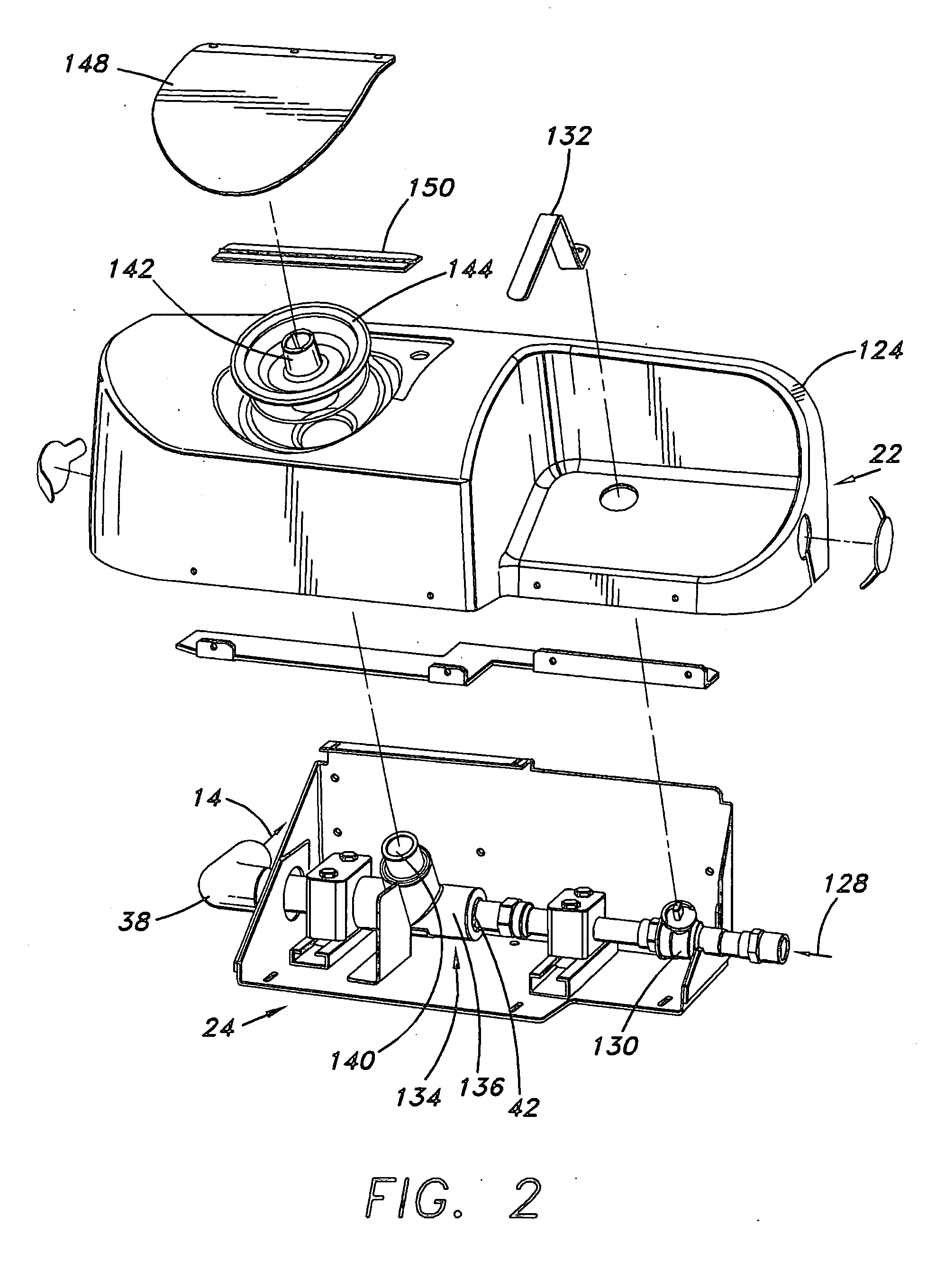

Method and apparatus for the disposal of waste fluids

An innovative method and apparatus for disposing of waste fluids, especially human body fluids such as are generated during surgery, into a hospital's sanitary sewer system is provided. A conduit system is adapted to transport waste fluid from a receptacle to a sanitary sewer using an eductor having a venturi device. The conduit system includes first and second conduits. First and second connectors are used to easily connect the first conduit to the second conduit. The second connector includes a flap that acts as a check valve.

Owner:ALLEGIANCE CORP

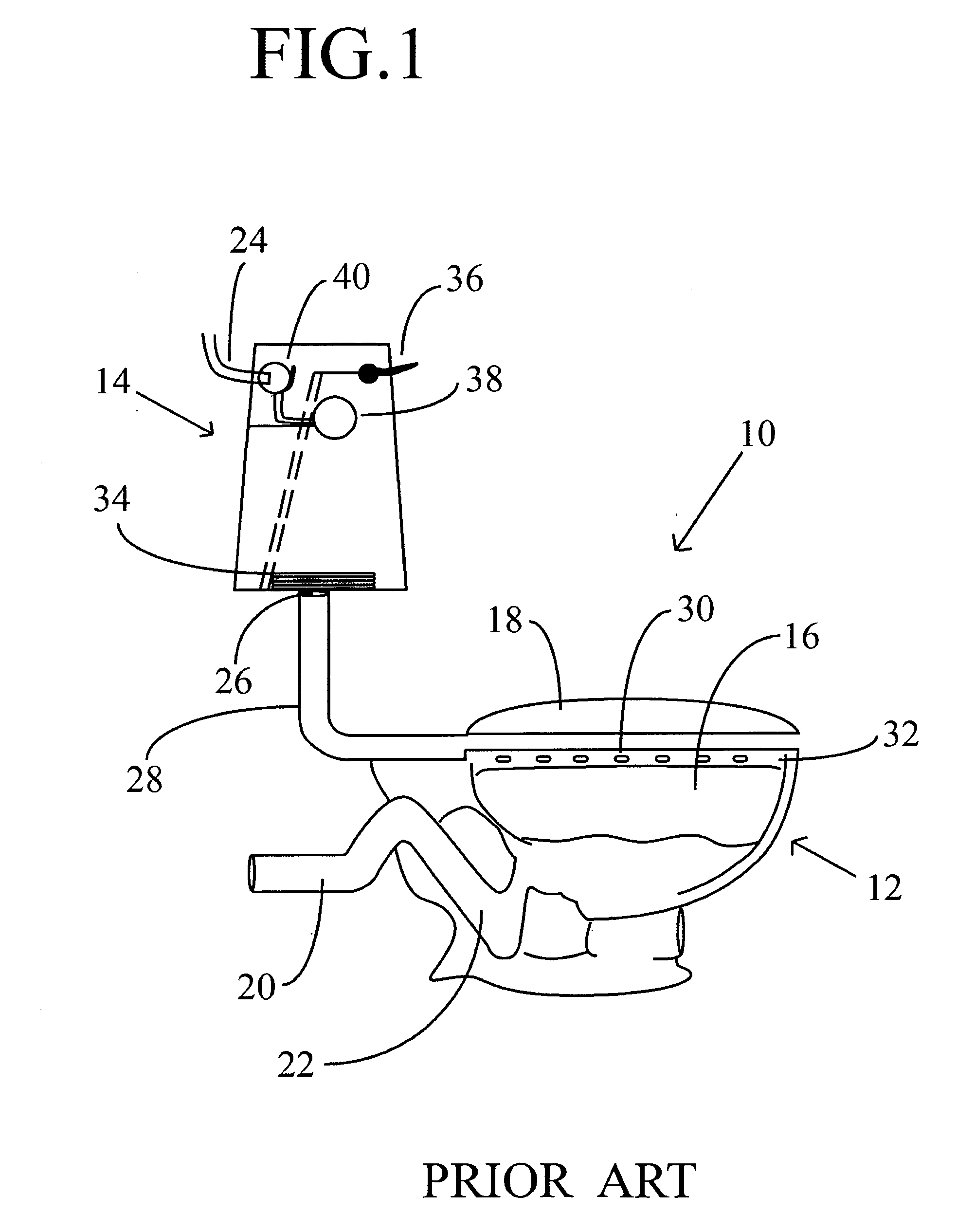

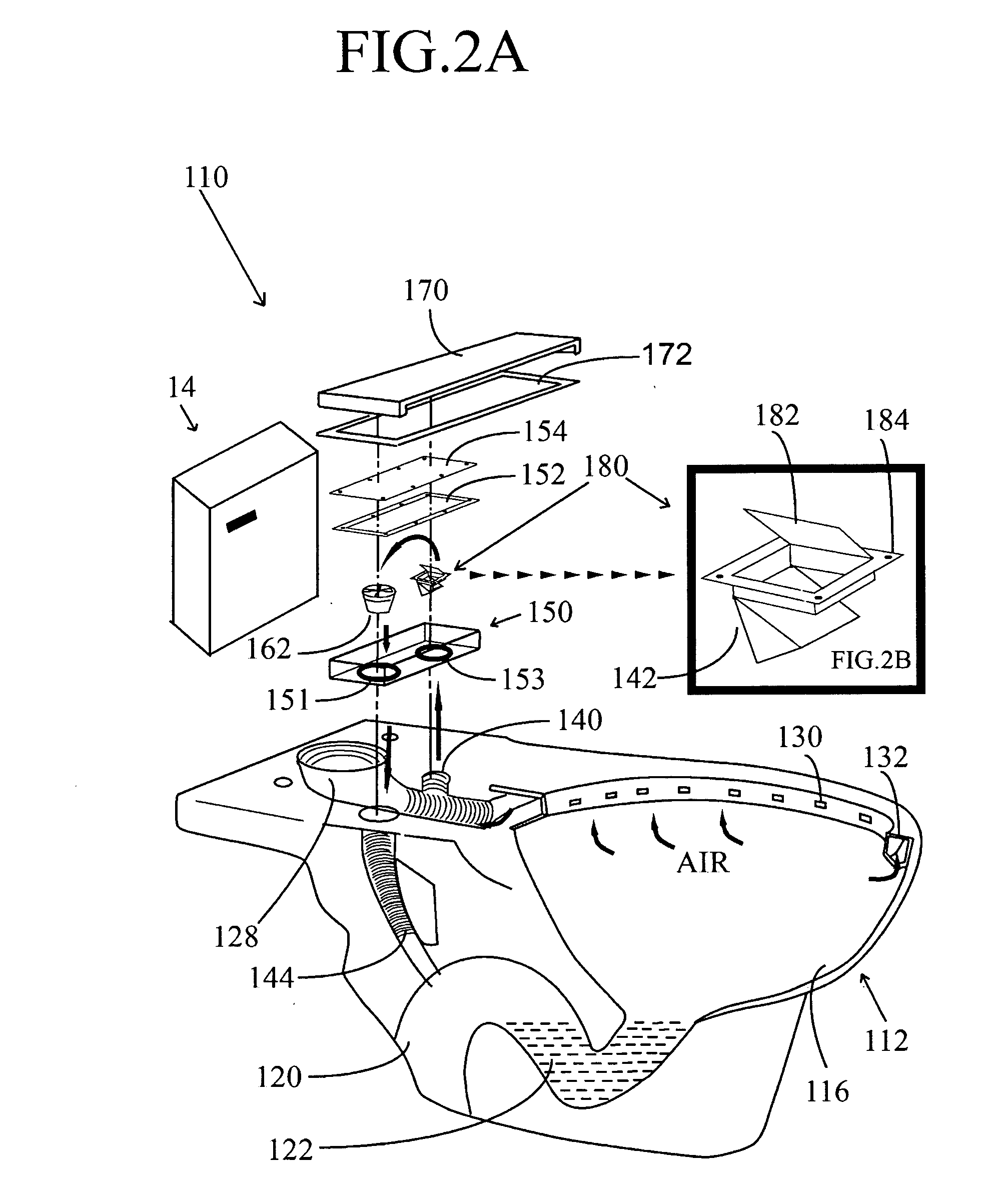

Odor-free toilet

InactiveUS20090307831A1Inherently reliableSimple valveBathroom coversLavatory sanitoryAir pumpSewage

An odor extracting system for a toilet bowl of a toilet pedestal, coupleable to a water supply via a flush conduit leading to flush outlets under a rim of the bowl; the bowl being coupleable to a sewage pipe via a U shaped trap; the odor extracting system comprising: an air bypass extending substantially through the pedestal, the air bypass for bypassing the U shaped trap, that is coupled to air intake ports around the toilet bowl, and to the sewage pipe downstream of the U shaped trap; an air pump for pumping air and vapors out of toilet bowl to sewage pipe via the air bypass, and a light weight air valve upstream of the air pump, the air valve to seal the air bypass when said pump is not in use to prevent escape of smells from the sewage pipe to the toilet bowl; said system further comprising a sealing lid coupled to the toilet pedestal, allowing access to the air valve and air pump, whilst preventing escape of odors from the bypass.

Owner:SHAHAR YEHEZKEL

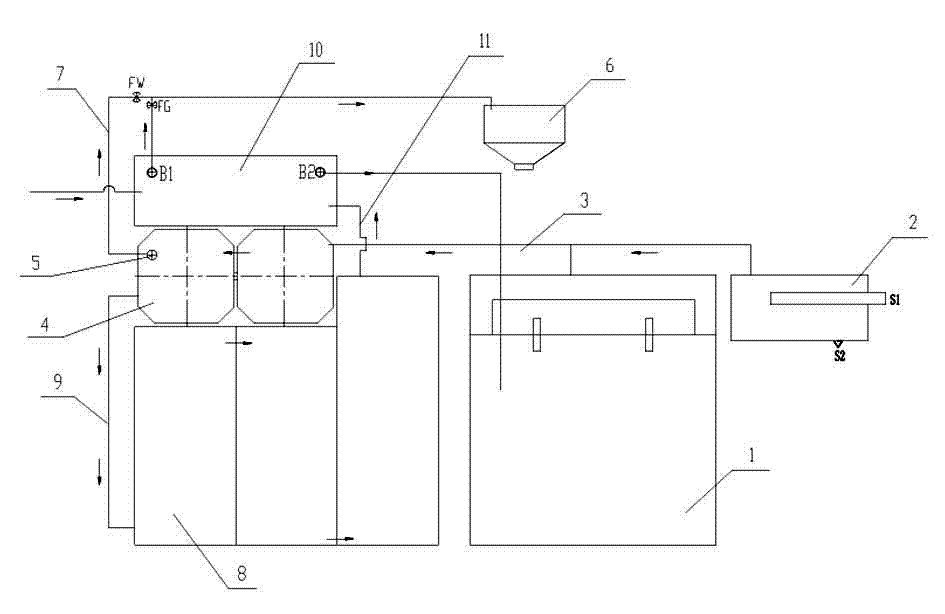

Recovering system for concrete cement mortar

InactiveCN102826668AReduce wearExtended service lifeMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationEngineeringSewage

The invention discloses a recovering system for concrete cement mortar. The recovering system comprises a service rack and a sand and stone separating machine, wherein a mortar water outlet of the sand and stone separating machine is communicated with a mixing tank; a sewage pipeline extending to the upper side of a metering hopper is connected to a sewage pump water outlet arranged in the mixing tank; a setting pond is arranged on one side of the mixing tank; the mixing tank is communicated with the setting pond through an overflowing pipeline; a clean water reservoir is arranged beside the mixing tank; a water outlet pipe of a clean water pump B1 arranged in the clean water reservoir is communicated with a sewage pipe through a one-way valve FG; a one-way valve FW is arranged on the sewage pipe on a front section at the intersection joint of the water outlet pipe of the clean water pump B1; a water outlet pipe of a clean water pump B2 arranged in the clean water reservoir extends to the service rack; and a water pouring pipe is arranged between the setting pond and the clean water reservoir. The recovering system disclosed by the invention has the advantages that the structure is simple and reasonable; and the clean water pump and the sewage pump are adopted for simultaneously supplying materials, so that the wear to the pump body is reduced, the service life of the pump body is prolonged, the recovering effect of mortar water generated by washing a vehicle is remarkably improved and the maintenance cost is greatly reduced.

Owner:郑州新水工机械有限公司

Assembled and combined cabin concrete structure of shallow-buried 0815-type underground comprehensive pipe gallery

ActiveCN105113543AAvoid hidden dangers in fire protection technologyEnsure safetyArtificial islandsUnderwater structuresUtility tunnelSewage

The invention discloses an assembled and combined cabin concrete structure of a shallow-buried 0815-type underground comprehensive pipe gallery. The assembled and combined cabin concrete structure comprises a first-class main line pipe gallery provided with multiple standard segments; each standard segment comprises an upper cabin and a lower cabin, the upper cabin is of an upper cabin concrete structure which is formed by assembling two same L-shaped bracket column connection plate side walls and an inspection beam connection plate cabin cover, the two side walls are symmetrically distributed on the two sides of the upper cabin to form a U-shaped connection body, and the cabin cover covers the top of the U-shaped connection body in a jointed mode to form the upper cabin to contain municipal pipelines; the lower cabin is of a boat-shaped groove concrete structure formed by assembling two same inverted-T-shaped structure ground beams, and the two structure ground beams are symmetrically distributed on the two sides of the lower cabin and connected to form an inverted-pi-shaped connection body for containing rainwater pipelines and sewage pipelines; the upper cabin is detachably installed on the lower cabin. Assembling moulds of the assembled and combined cabin concrete structure are easier to demould, hoist, transport and install, high in anti-seismic performance and commonality and mature in technology and can be applied to unified management of the municipal pipelines.

Owner:赵洪志

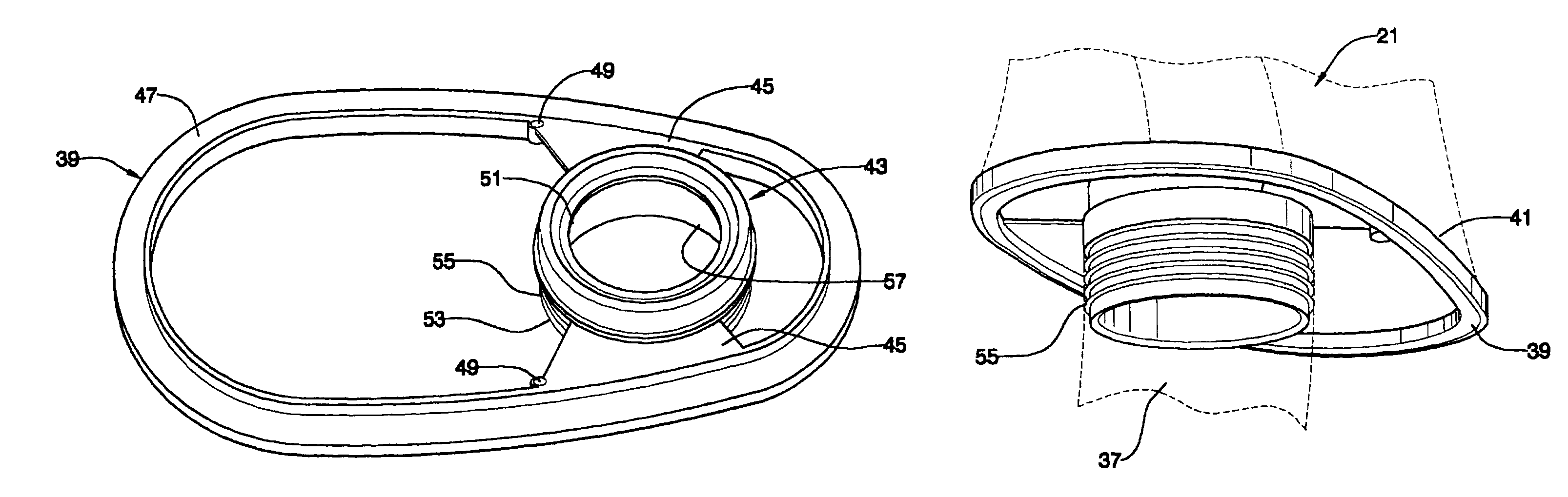

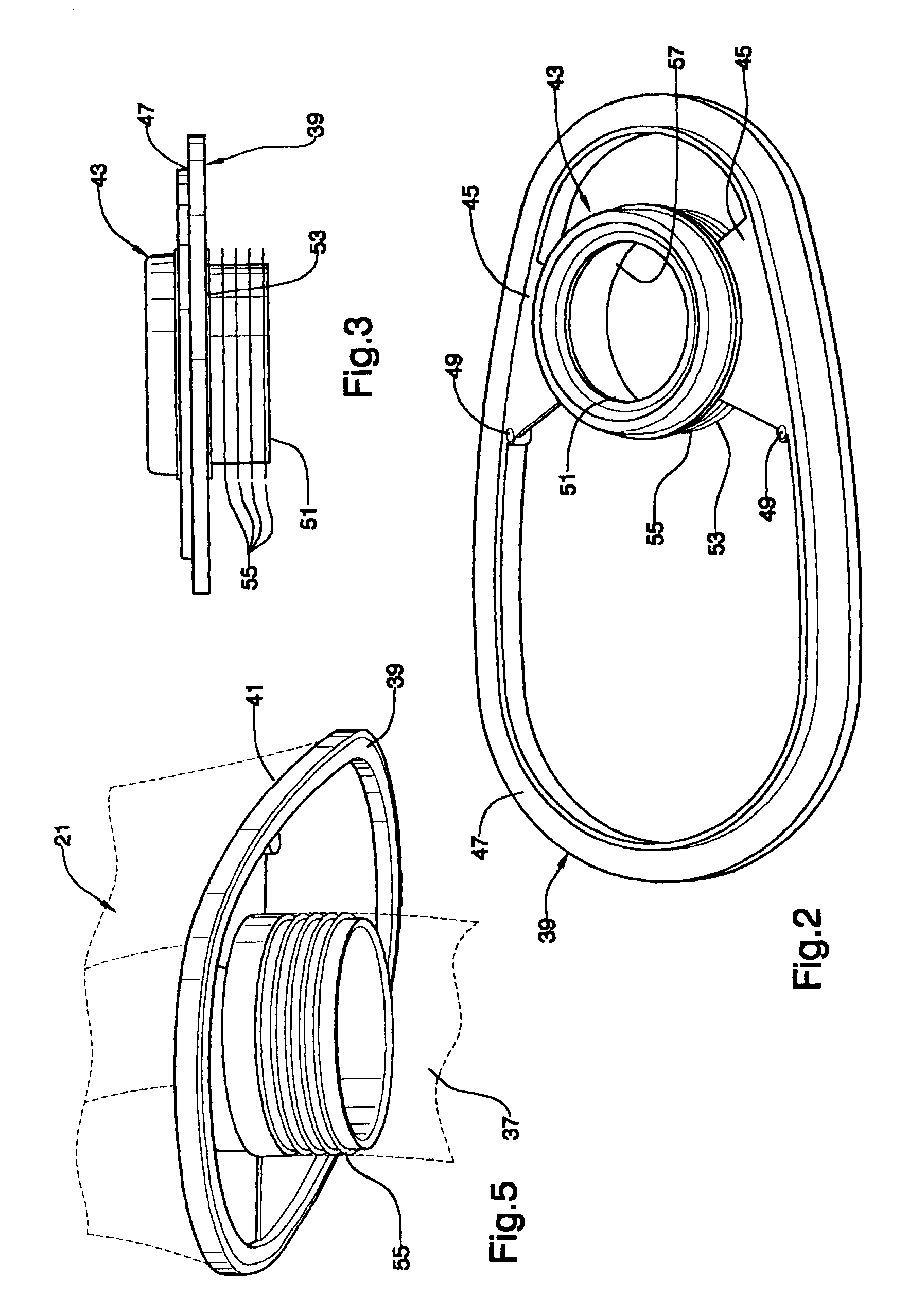

Water-closet compound gasket

A one-piece water-closet gasket (21) comprises an outer gasket (39) for the stand (41) and an inner gasket (43) for sealing the outlet of the water-closet drain-duct (29) to the sewage inlet duct (37). The latter gasket comprises a tube (51) having a lower span (53) for plugging into the sewage inlet and is provided with means (55, 57) elastically bearing and sealing against the inner wall surface of the sewage duct.

Owner:PEG

Combination sanitary wipe and toilet tissue holder

Owner:BROWN AARON

Microbial agent for purifying sanitary sewage and preparation method of microbial agent

InactiveCN105331565AEfficient removalGuaranteed removal effectFungiBacteriaMicrobial agentPropionibacterium acnes

The invention discloses a microbial agent for purifying sanitary sewage and a preparation method of the microbial agent. Active ingredients of the microbial agent is formed by mixing the following raw material bacteria including thiobacillus denitrificans, bacillus subtillis, bacillus licheniformis, bacillus polymyxa, lactic acid bacteria, nocardia amarae, denitrifying bacteria, rhodopseudomonas palustris, thiophilic red pseudomonas, rhodospirillum, saccharomycetes and propionibacterium. By means of the microbial agent, cellulose, saccharides, fat protein, pathogenic bacteria, viruses and parasitic ovum in sanitary sewage and pollutants, such as inorganic salt which is high in the contents of nitrogen, sulphur and phosphorus, the BOD and COD removal effect is guaranteed, meanwhile good bactericidal ability is achieved, high inhibiting ability is achieved especially for pathogenic bacteria, and the effect of treating sanitary sewage is remarkable.

Owner:孙娟

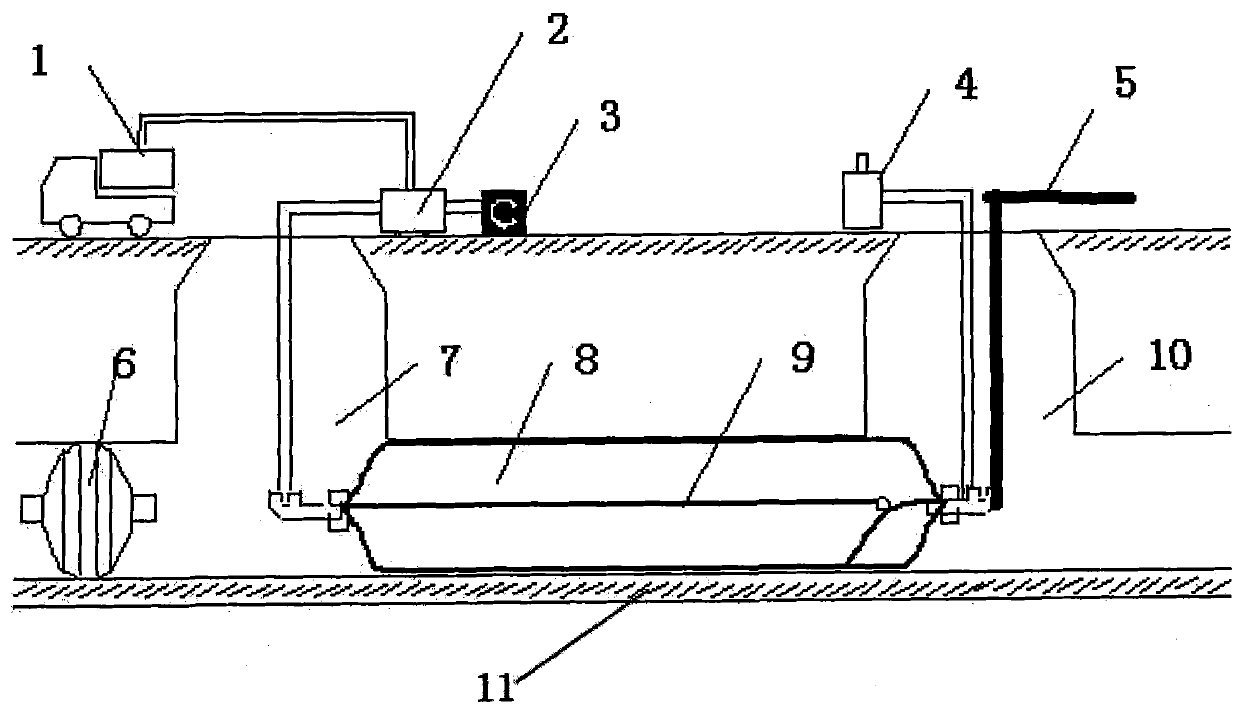

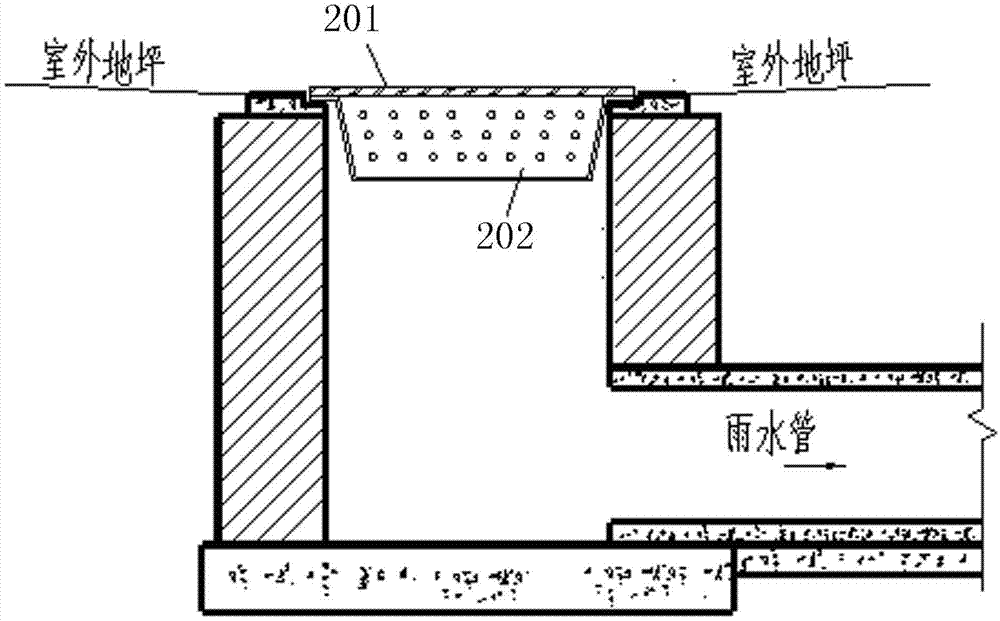

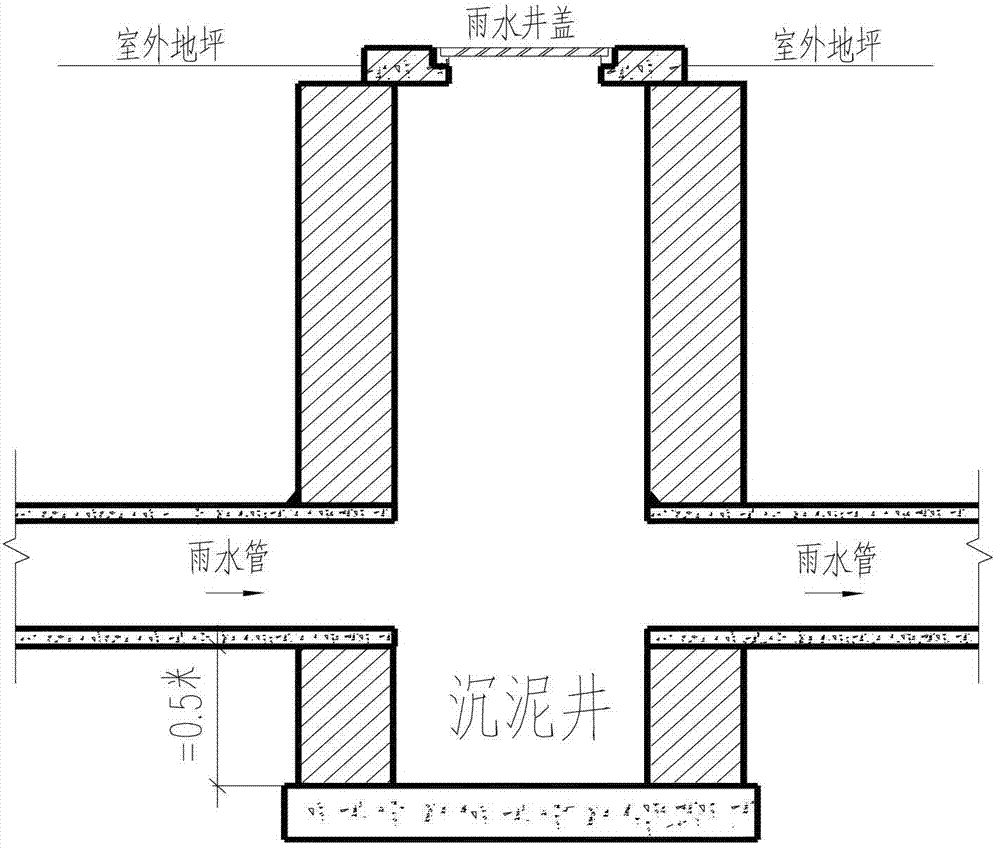

Municipal rainwater storage system

ActiveCN103046632ARealize manual integrationReduce pollutionSewerage structuresSewage drainingElectricityInlet valve

The invention provides a municipal rainwater storage system which comprises a rainwater pollutant intercepting facility, a rainwater lifting pump station and a rainwater storage pool. A bar screen, a rainwater lifting pump set, a submersible sewage pump and an electric room are arranged in the rainwater lifting pump station, a sewage pump is arranged in the rainwater storage pool and connected with a municipal sewage pipeline, a rainwater pump station water inlet pipe valve is arranged on a rainwater pipe between the rainwater pollutant intercepting facility and the rainwater lifting pump station, a rainwater storage pool water inlet valve is arranged on a rainwater pipe between the rainwater lifting pump station and the rainwater storage pool, a riverway water inlet valve is arranged on a rainwater pipe, connected to a riverway, of the rainwater lifting pump station, and the electric room is electrically connected with the rainwater storage pool water inlet valve, the riverway water inlet valve, the rainwater lifting pump set, the submersible sewage pump and the sewage pump. The municipal rainwater storage system can effectively control discharging of most surface pollutants and sewage and reduce pollution of rainwater at the early stage.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com