Assembled and combined cabin concrete structure of shallow-buried 0815-type underground comprehensive pipe gallery

A technology of concrete structure and comprehensive pipe gallery, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as low efficiency, difficult construction, and inability to be widely applied, so as to increase operating life, The effect of compact installation space and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to understand the content of the present invention more clearly, specific implementation methods will be described below in conjunction with the accompanying drawings.

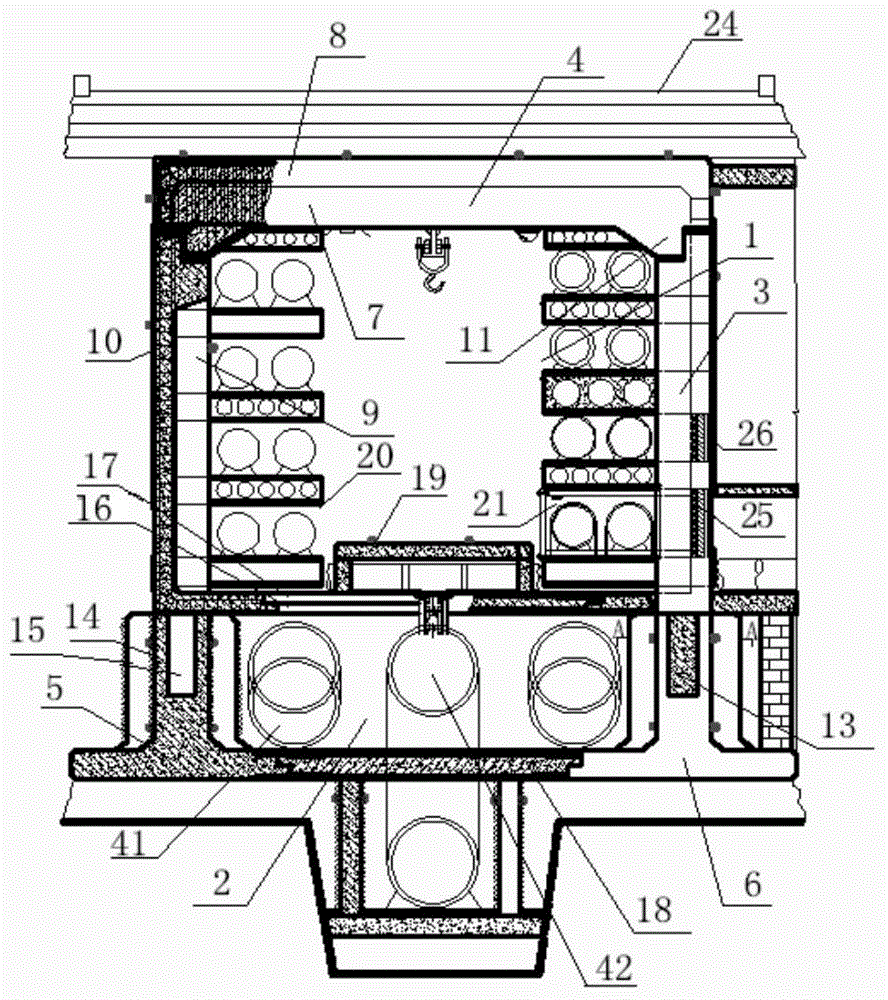

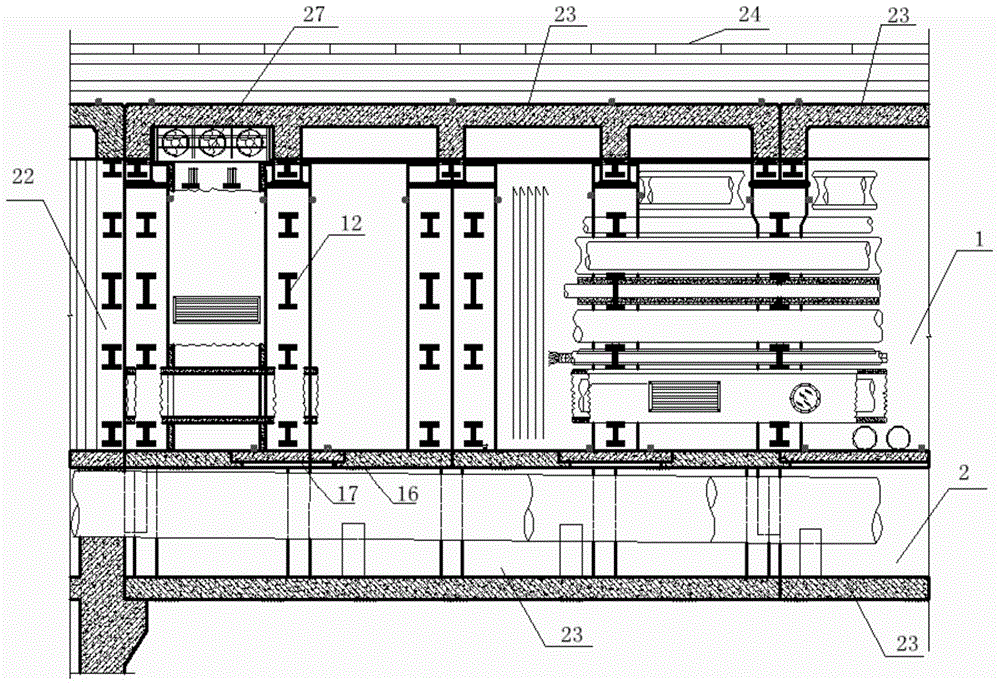

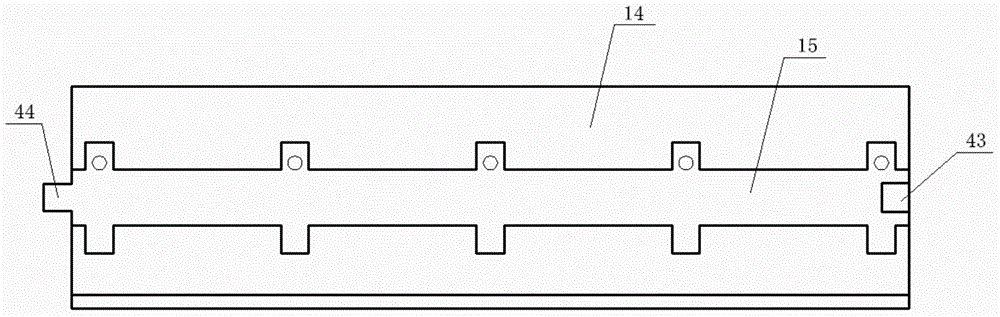

[0064] figure 1It is a vertical diagram of an embodiment of a shallow-buried 0815 type underground comprehensive pipe gallery assembly composite cabin concrete structure of the first-level main line comprehensive pipe gallery embodiment. As shown in the figure, the shallow-buried 0815 underground first-level main line pipe gallery 22 figure 2 shown in ) of a standard section 23 (in figure 2 shown in ), including the upper cabin 1 and the lower cabin 2, the upper cabin 1 is a concrete structure surrounded by three parts assembled components, the standard components are: two identical L-shaped Corbel column connecting plate side walls 3 and a riding beam connecting plate hatch cover 4, wherein the two side walls are symmetrically distributed on both sides of the upper cabin 1, and the middle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com