Patents

Literature

218 results about "Bar screen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

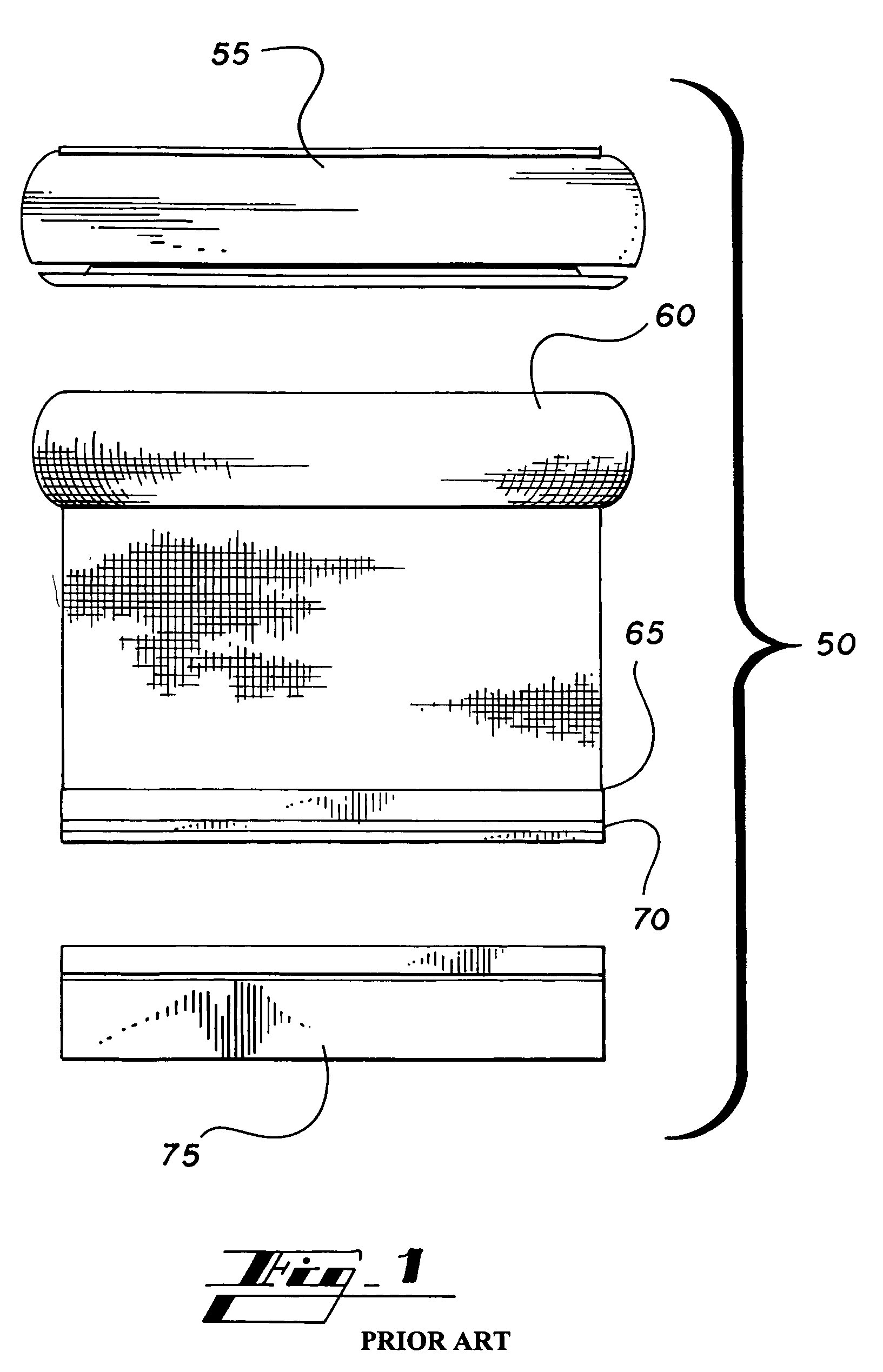

A bar screen is a mechanical filter used to remove large objects, such as rags and plastics, from wastewater. It is part of the primary filtration flow and typically is the first, or preliminary, level of filtration, being installed at the influent to a wastewater treatment plant. They typically consist of a series of vertical steel bars spaced between 1 and 3 inches apart.

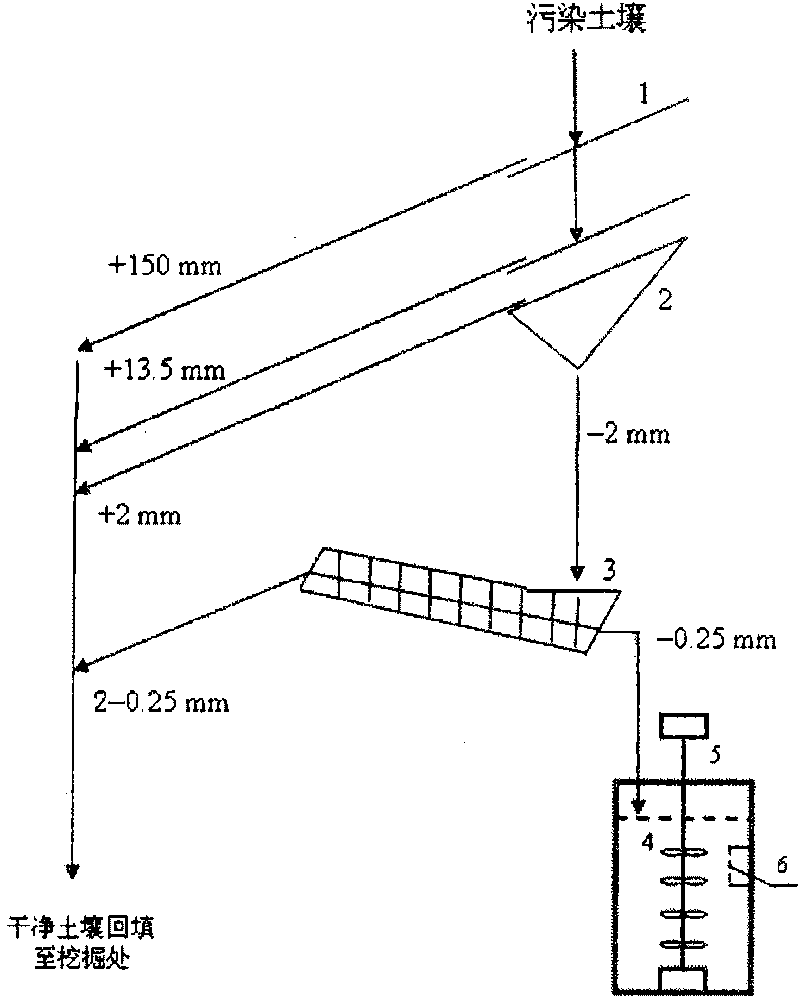

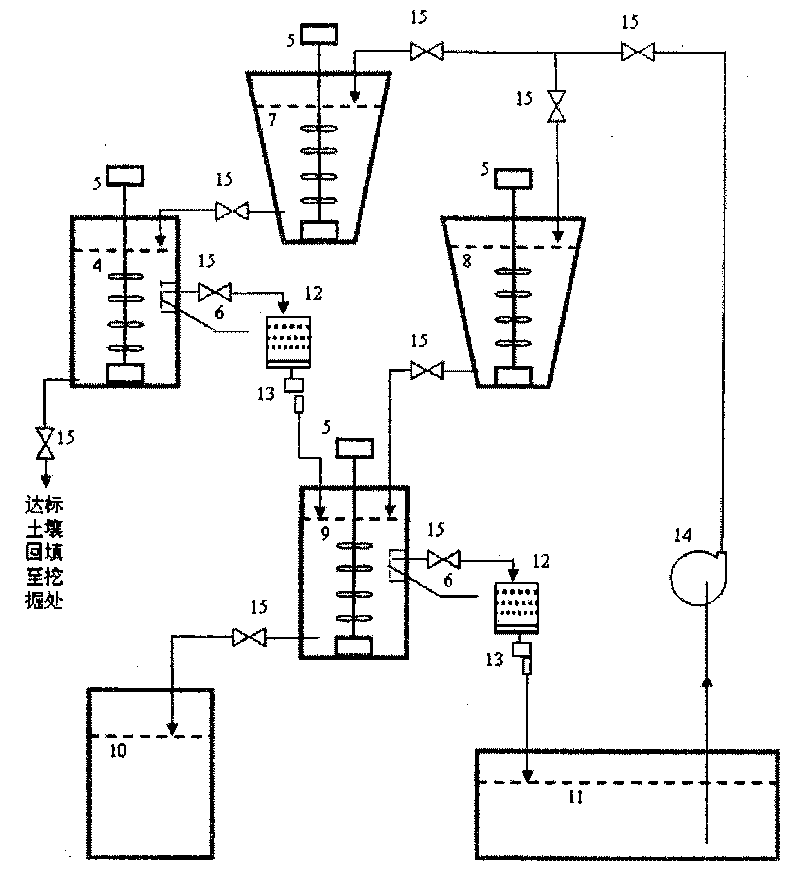

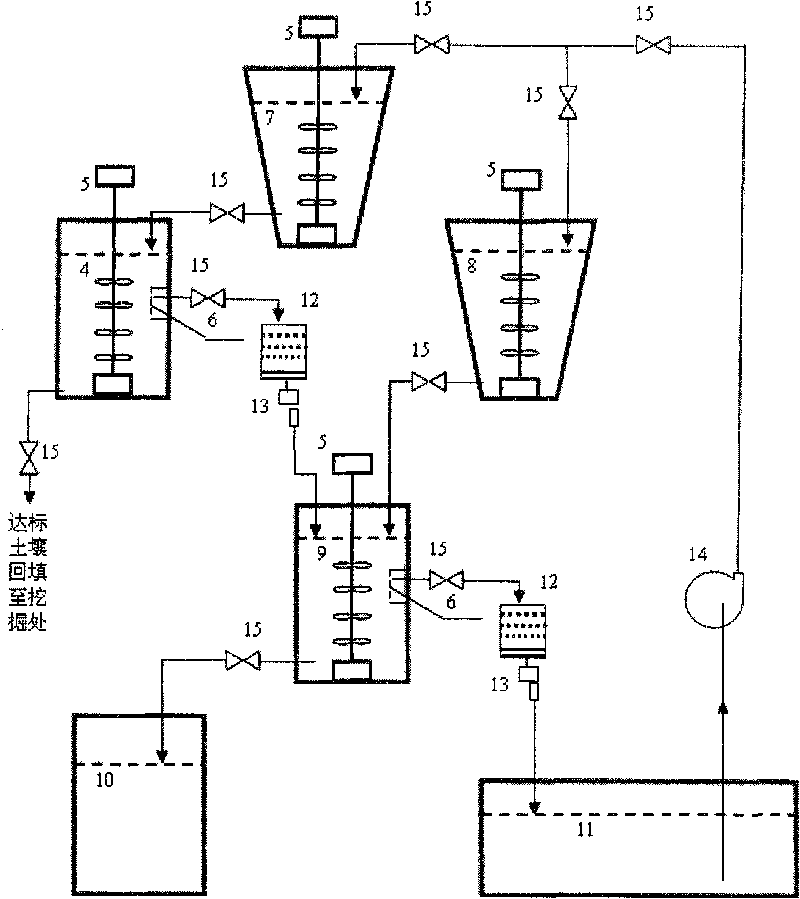

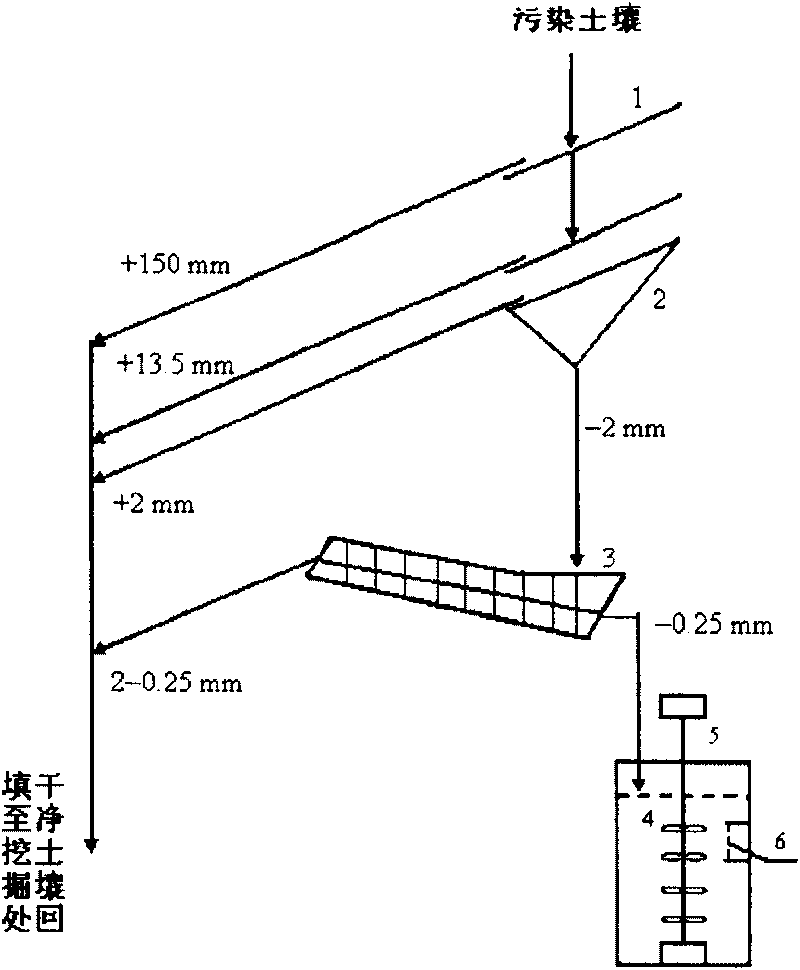

Treatment method of soil contaminated by uranium or cesium

InactiveCN101745528AQuick removalEfficient removalBacteriaContaminated soil reclamationSulfate-reducing bacteriaFiltration

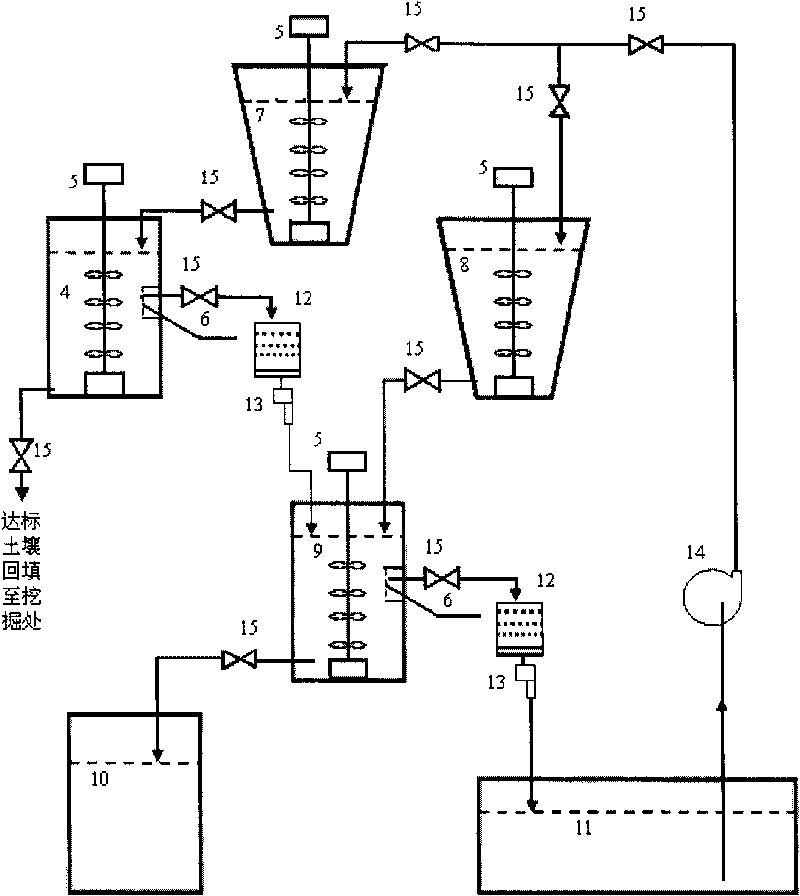

The invention belongs to the technical field of the microorganism, and in particular to a treatment method of soil contaminated by radioactive nuclide uranium or cesium. The invention adopts a bar screen, a double-plate screen and a spiral screen to screen the soil contaminated by uranium or cesium. The soil particles with the particle size more than 0.25mm are clean soil particles, the soil particles with the particle size less than 0.25mm are soil contaminated by uranium or cesium; and the soil particles with the particle size less than 0.25mm are mixed with active acidithiobacillus ferrooxidans for treatment, and the settlement is clean soil after filtration, the filtrate is transferred and mixed with active sulfate reducing bacteria for treatment, then the uranium or cesium is precipitated and can be recovered through filtering separation, and the water can also be recovered. The invention has the advantages of simple operation and low cost, and realizes the rapid and efficient removal of the uranium or cesium in the slightly contaminated soil.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

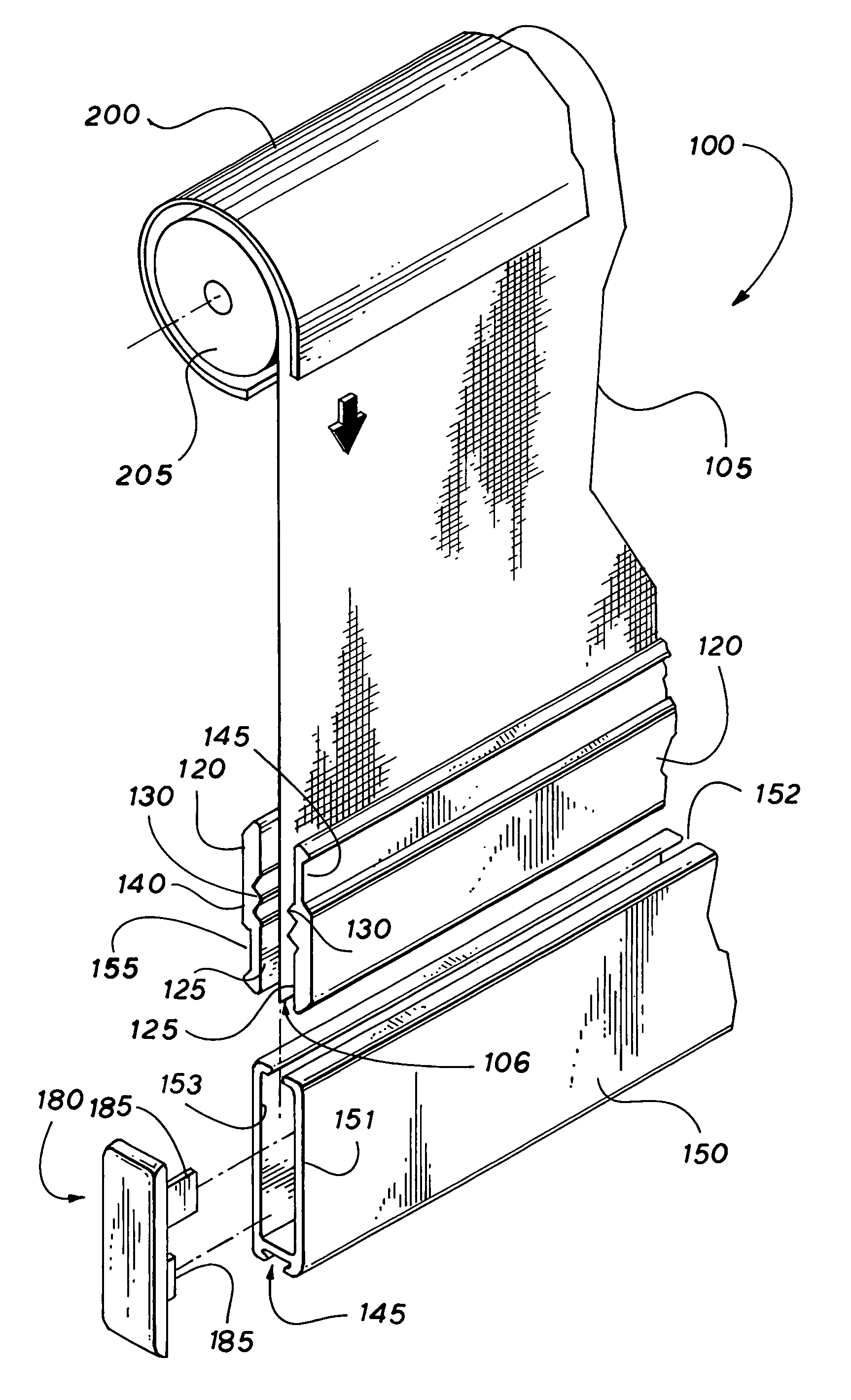

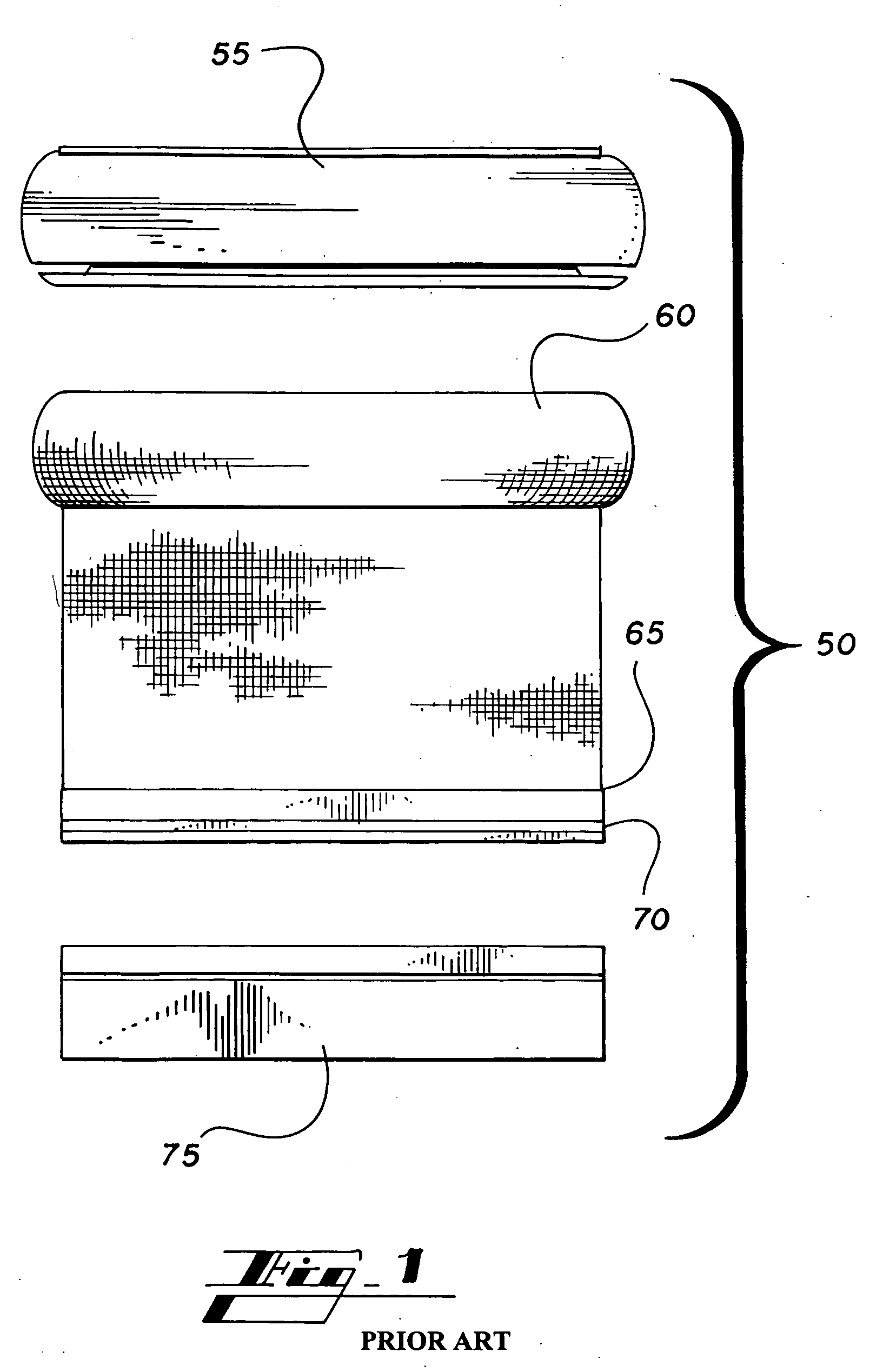

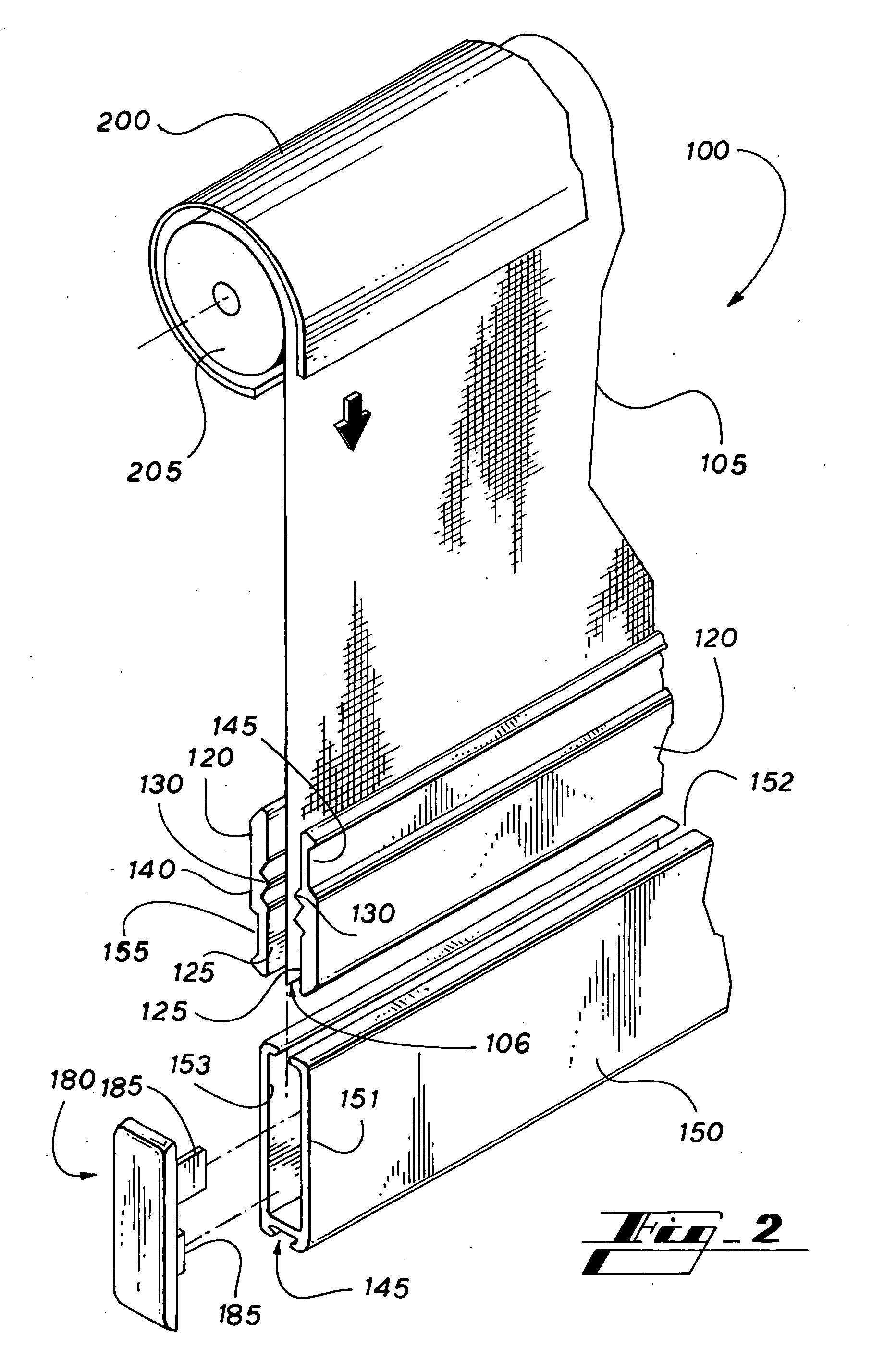

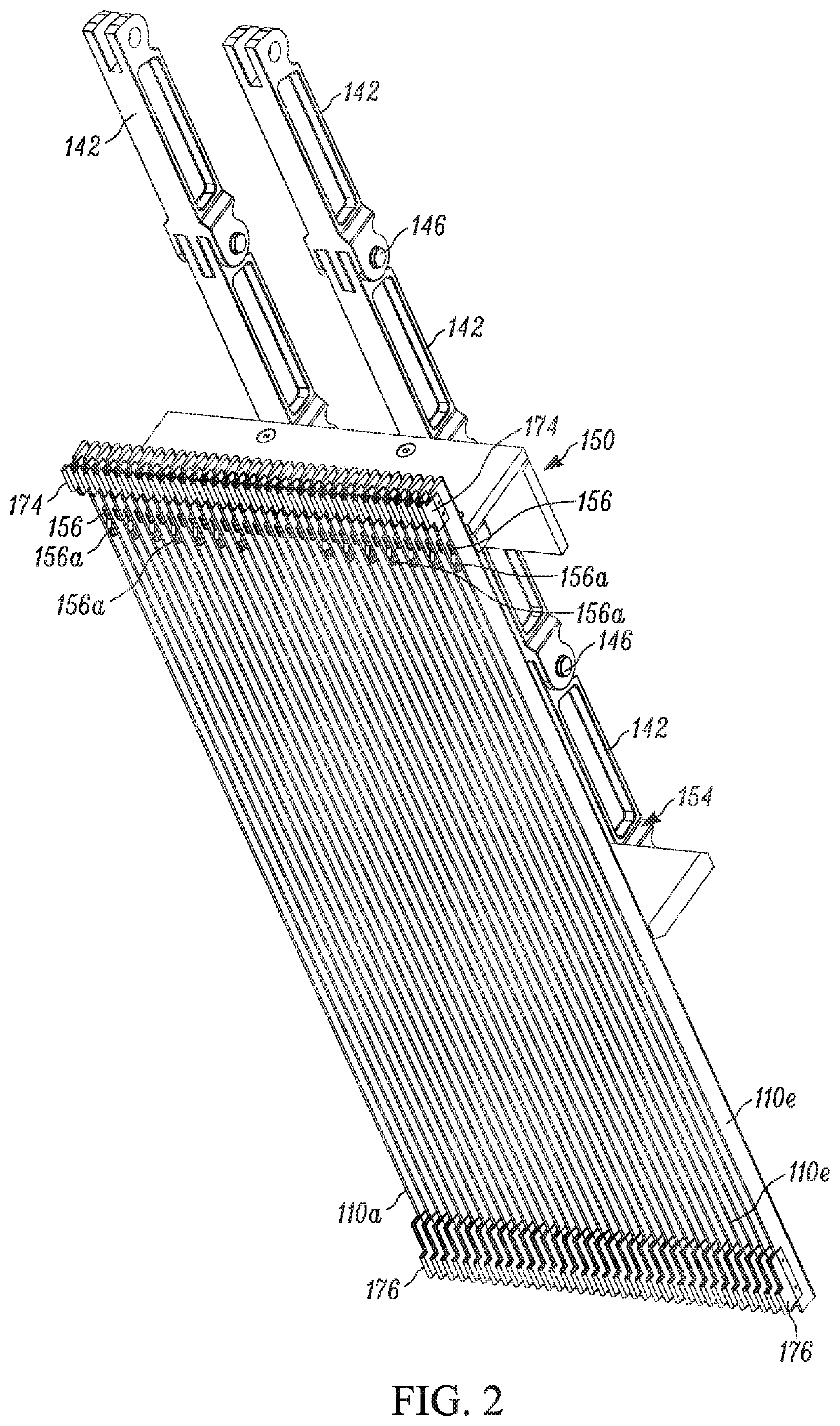

Pull bar screen apparatus and system

InactiveUS8016013B2For direct connectionEliminate needSunshadesShutters/ movable grillesEngineeringStructural integrity

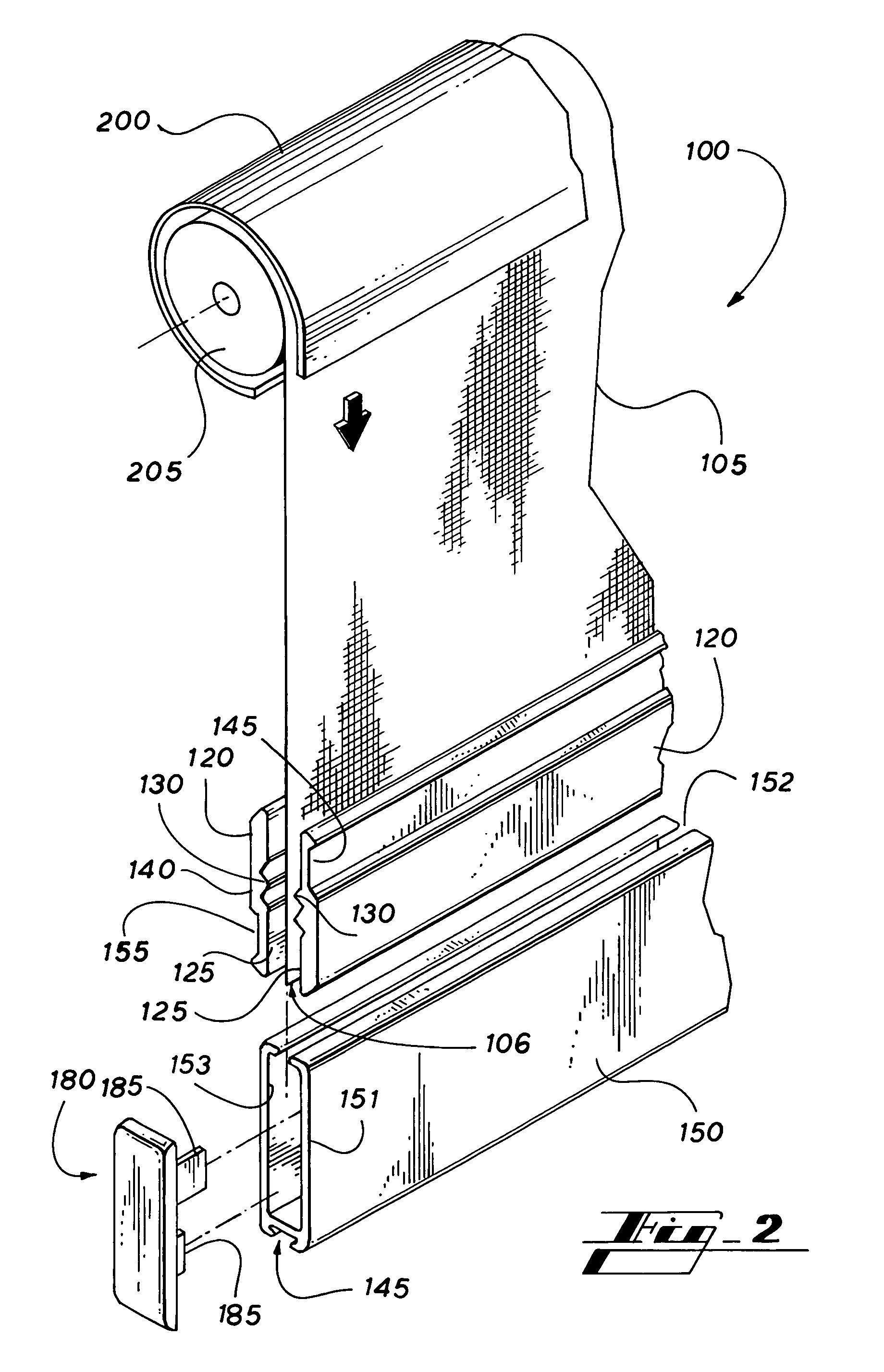

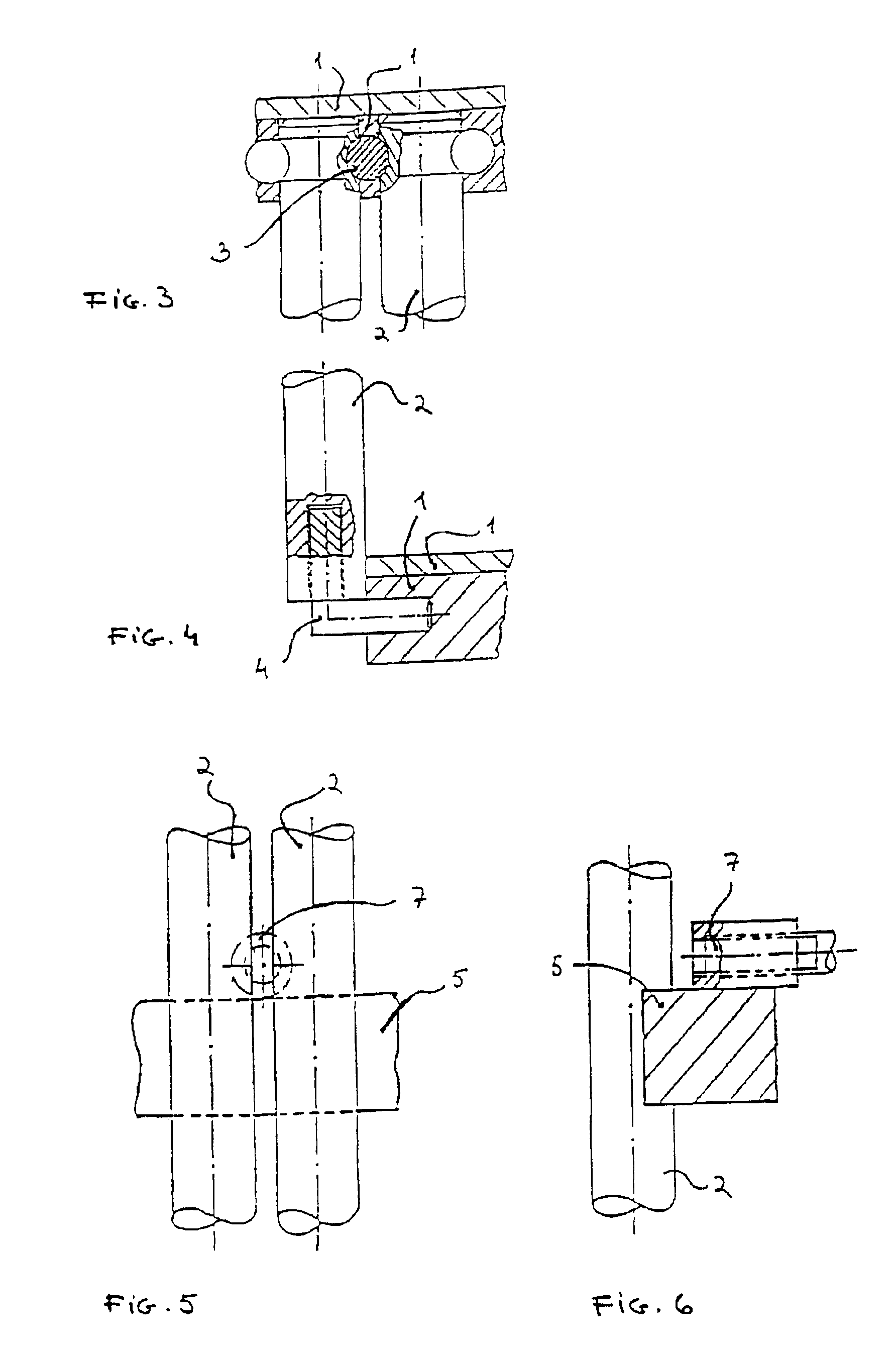

A pull bar screen apparatus and system in which screen is mechanically attached directly to a pull bar. Weld-less friction-lock cold-joining of screen and pull bar provides an improved pull-bar screen apparatus used in retractable pull screens. The pull bar screen apparatus and system remove the need for attaching a vinyl strip to the screen. Instead, the screen is flattened to retain its form and structural integrity. On one elongated end of the screen, an upper and lower lock bar are placed on either side of the screen. Corrugated ridges in the lock bars pinch the screen and hold it in place. A lock bar casing is placed under pressure around the upper and lower lock bars which hold the lock bars in position and thereby retain the screen.

Owner:HORVATH LOUIS

Bar screen

InactiveUS6889851B1Improve hydraulic performanceIncrease frictionDigestersSortingPulp and paper industryPressure vessel

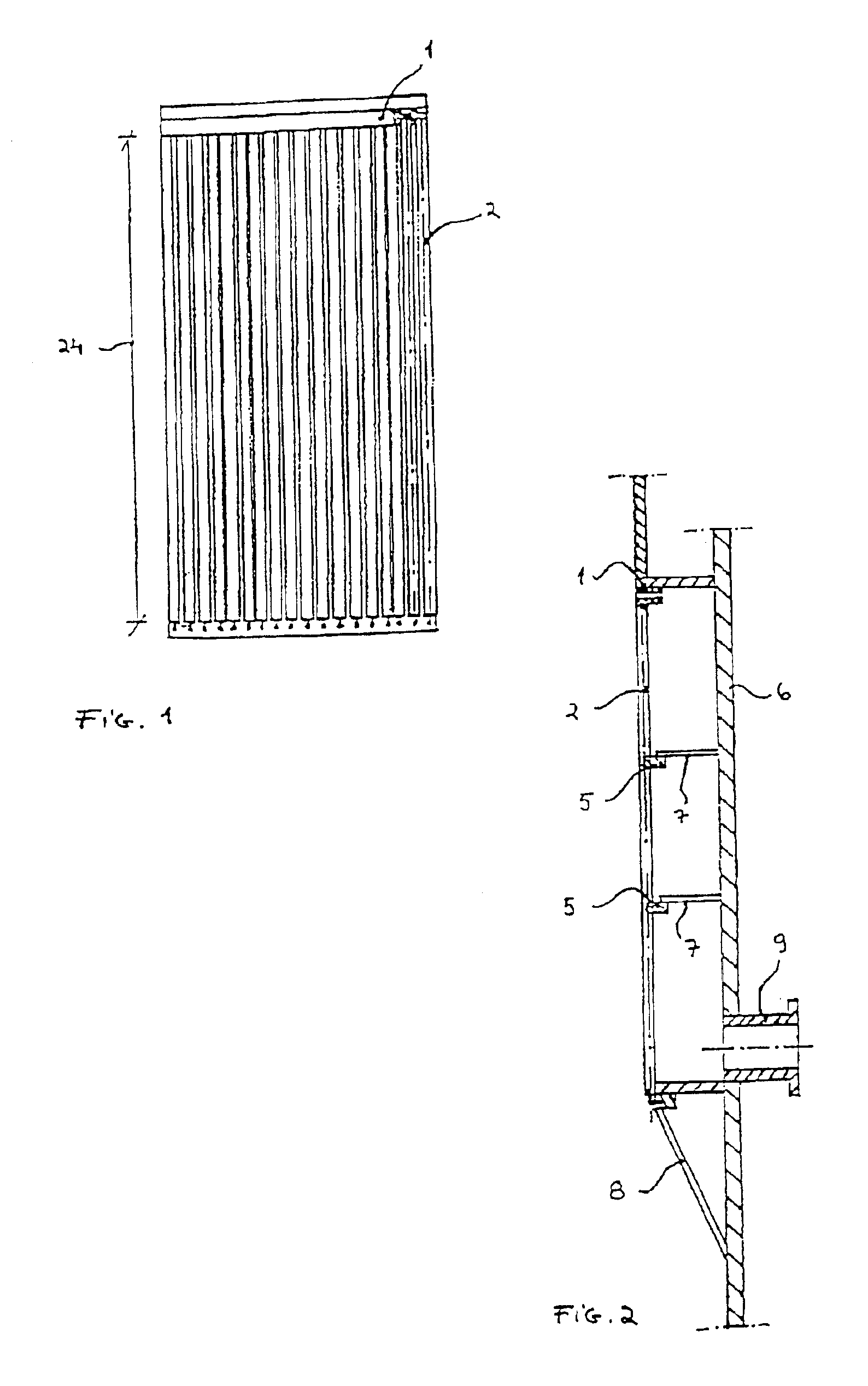

A bar screen is primarily intended for use in draining liquid from wood chips and pulp without blocking the bar screen. The area of use is especially a process area, in which cooking and circulation liquid is removed from a pressure vessel when making chemical pulp and paper pulp by continuous method. This type of bar screen is characterized in that behind the filtering gap of the screen bars, there is a flow space in which the liquid flows towards a discharge outlet. By adjusting the flow space, a flow rate of liquid which stops blocking due to accumulation is maintained in the background. The sturdiness of the screen structure is improved by adjustable support taps.

Owner:VALMET TECH INC

Municipal rainwater storage system

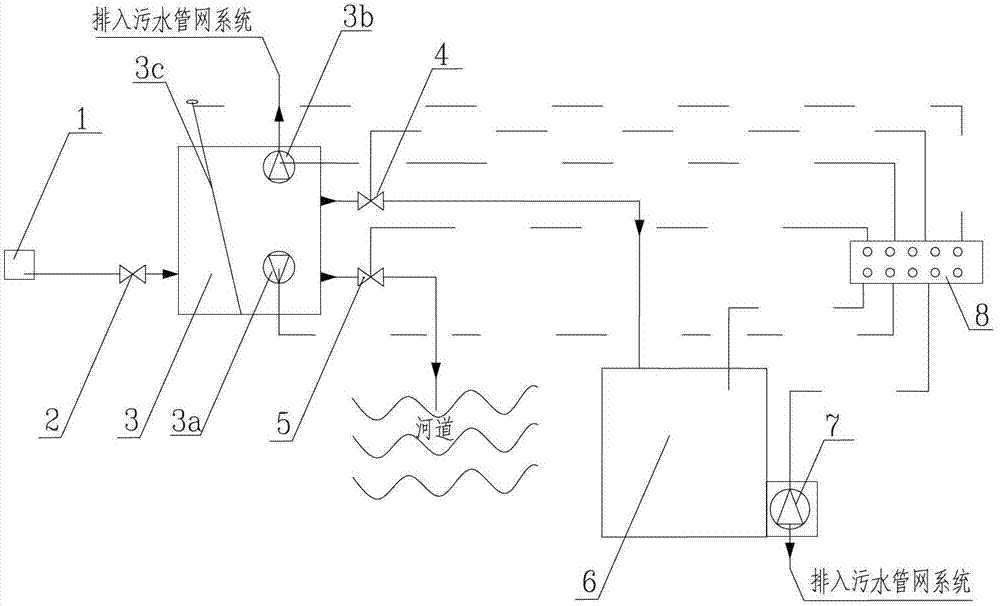

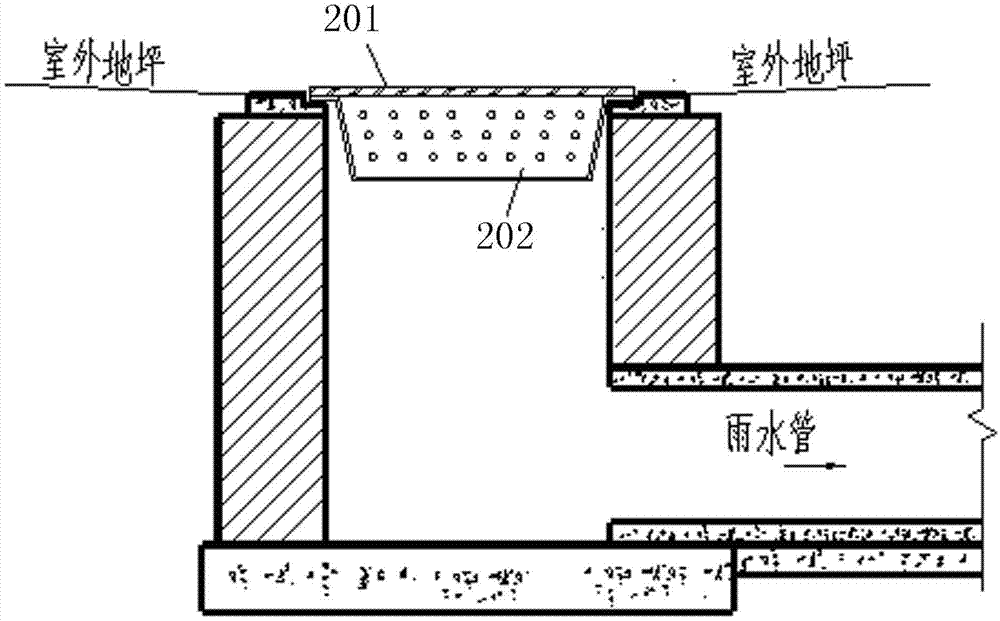

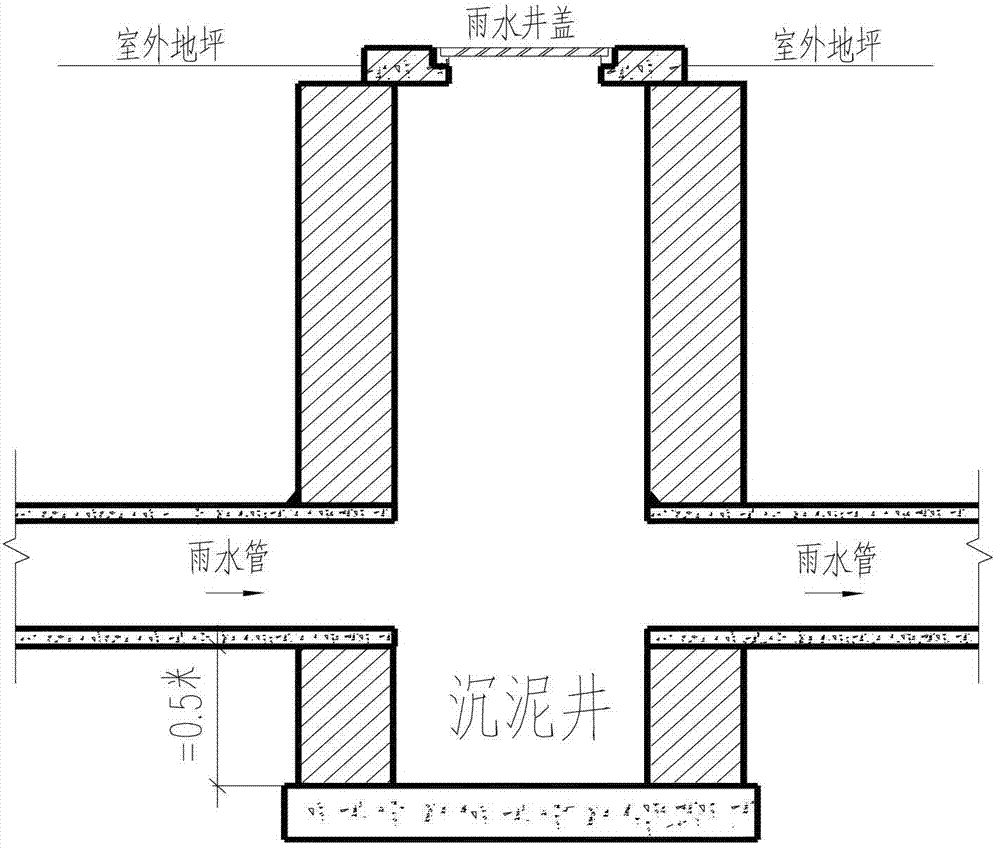

ActiveCN103046632ARealize manual integrationReduce pollutionSewerage structuresSewage drainingElectricityInlet valve

The invention provides a municipal rainwater storage system which comprises a rainwater pollutant intercepting facility, a rainwater lifting pump station and a rainwater storage pool. A bar screen, a rainwater lifting pump set, a submersible sewage pump and an electric room are arranged in the rainwater lifting pump station, a sewage pump is arranged in the rainwater storage pool and connected with a municipal sewage pipeline, a rainwater pump station water inlet pipe valve is arranged on a rainwater pipe between the rainwater pollutant intercepting facility and the rainwater lifting pump station, a rainwater storage pool water inlet valve is arranged on a rainwater pipe between the rainwater lifting pump station and the rainwater storage pool, a riverway water inlet valve is arranged on a rainwater pipe, connected to a riverway, of the rainwater lifting pump station, and the electric room is electrically connected with the rainwater storage pool water inlet valve, the riverway water inlet valve, the rainwater lifting pump set, the submersible sewage pump and the sewage pump. The municipal rainwater storage system can effectively control discharging of most surface pollutants and sewage and reduce pollution of rainwater at the early stage.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

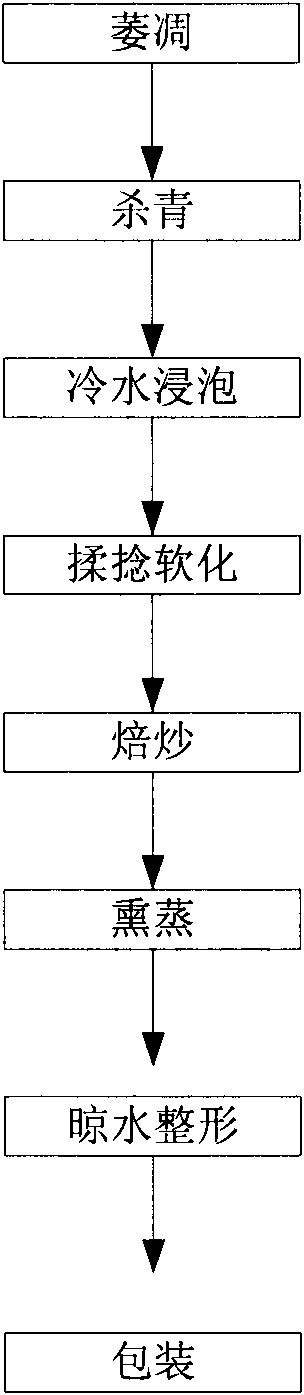

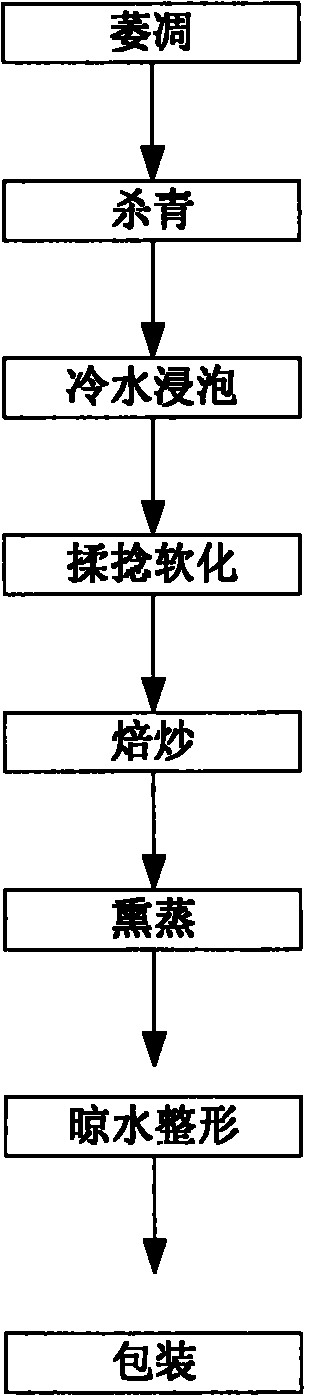

Persimmon leaf tea and preparation method

The invention relates to persimmon leaf tea and a preparation method. The preparation method for the persimmon leaf tea comprises the following steps of: deteriorating, namely deteriorating persimmon leaves serving as raw materials naturally at the aeration-drying position; performing green killing, namely scalding the deteriorated leaves in hot water to perform green killing for 15 to 20 minutes; immersing in cold water, namely immersing the scalded leaves subjected to green killing in the cold water for 3 to 5 hours; twisting and softening, namely draining the leaves immersed in the cold water, and kneading lightly, so that the persimmon leaves are softened and deformed; roasting, namely putting the twisted leaves in a pot and roasting quickly; fumigating, namely fumigating the roasted leaves in the pot; airing and reshaping, namely spreading the roasted and fumigated wet tea leaves at the cool and ventilating position uniformly by using a bar screen for airing and reshaping; and packaging, namely screening impurities in the tea leaves by using a mesh screen, packaging at different grades according to colors, shapes and taste, sealing and putting the packaged tea in a drying closed container for storage. In the persimmon leaf tea prepared by the method, the nutritional ingredients of the persimmon leaves can be maintained, and the persimmon leaf tea serving as a finished product has the ideal appearance.

Owner:山西析城山土特产开发股份有限公司

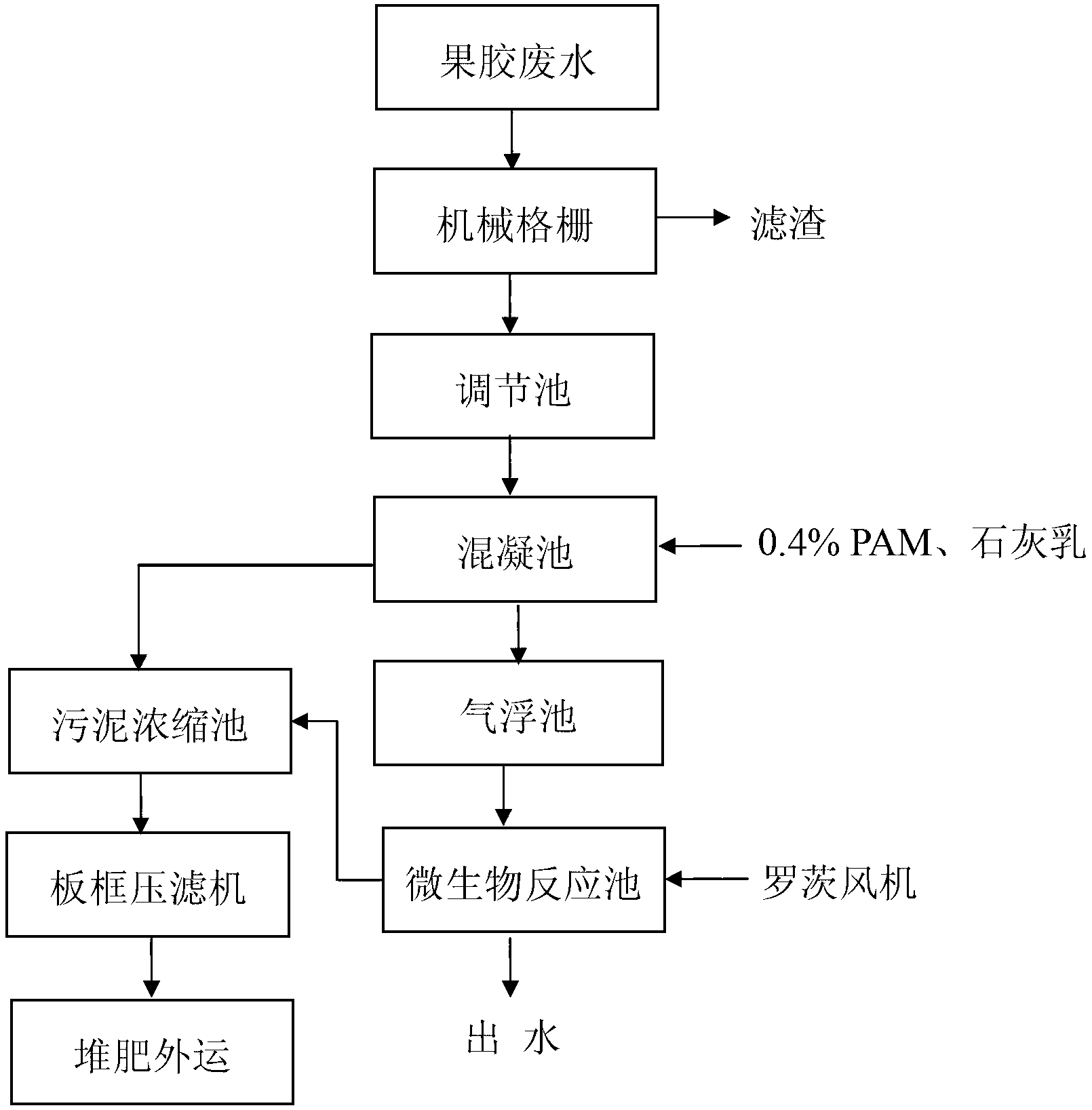

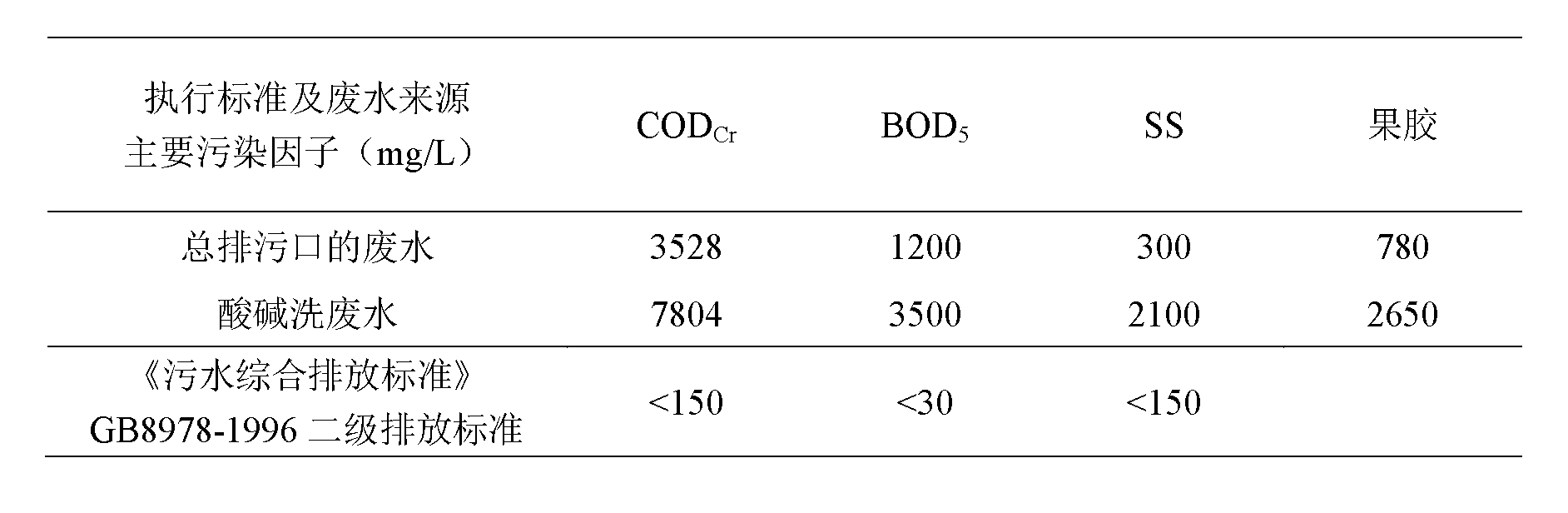

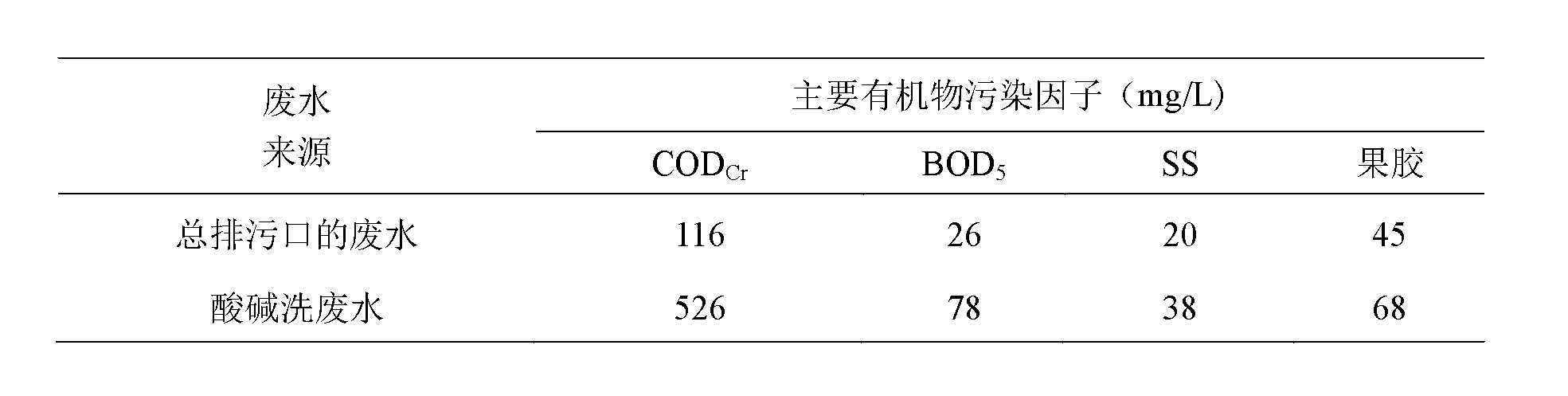

Method for treating canned citrus petal pectin wastewater

InactiveCN103304107AReduce contentAvoid secondary pollutionMultistage water/sewage treatmentPectinaseSecondary emission

The invention discloses a method for treating canned citrus petal pectin wastewater. By employing the method for combining mechanical bar screen and coagulating sedimentation, aerated air floatation and microbial advanced treatment, a mature strain of fungus penicillium simplicissimum is added into a microbial reaction pool in the microbial advanced treatment process, the pectin in the wastewater is degraded into low molecular weight organic matter galacturonic acid and methyl galacturonase under the catalytic action of pectinase generated by the mature strain of penicillium simplicissimum, and the highest degradation efficiency of the penicillium simplicissimum on the pectin is 97.4 percent; meanwhile, the penicillium simplicissimum has a good effect on the degradation of the CODCr in the wastewater, and the highest degradation efficiency on the CODCr is 89.9 percent; moreover, according to the process flow, the wastewater is extremely low in organic content and viscosity, the GB8978-1996 secondary emission standard of the integrated wastewater discharge standard is achieved, and emission on standard is realized. The process has the advantages that the energy consumption is low, the process is easy to operate, secondary pollution is not caused, and the like.

Owner:HUNAN UNIV

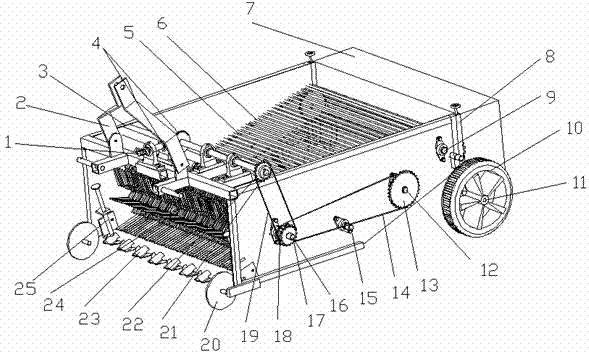

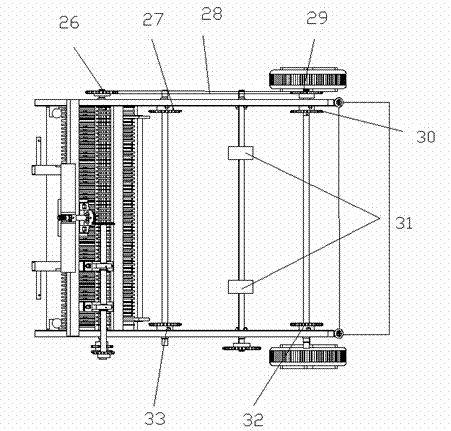

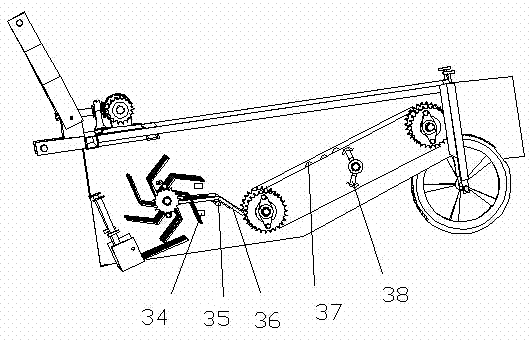

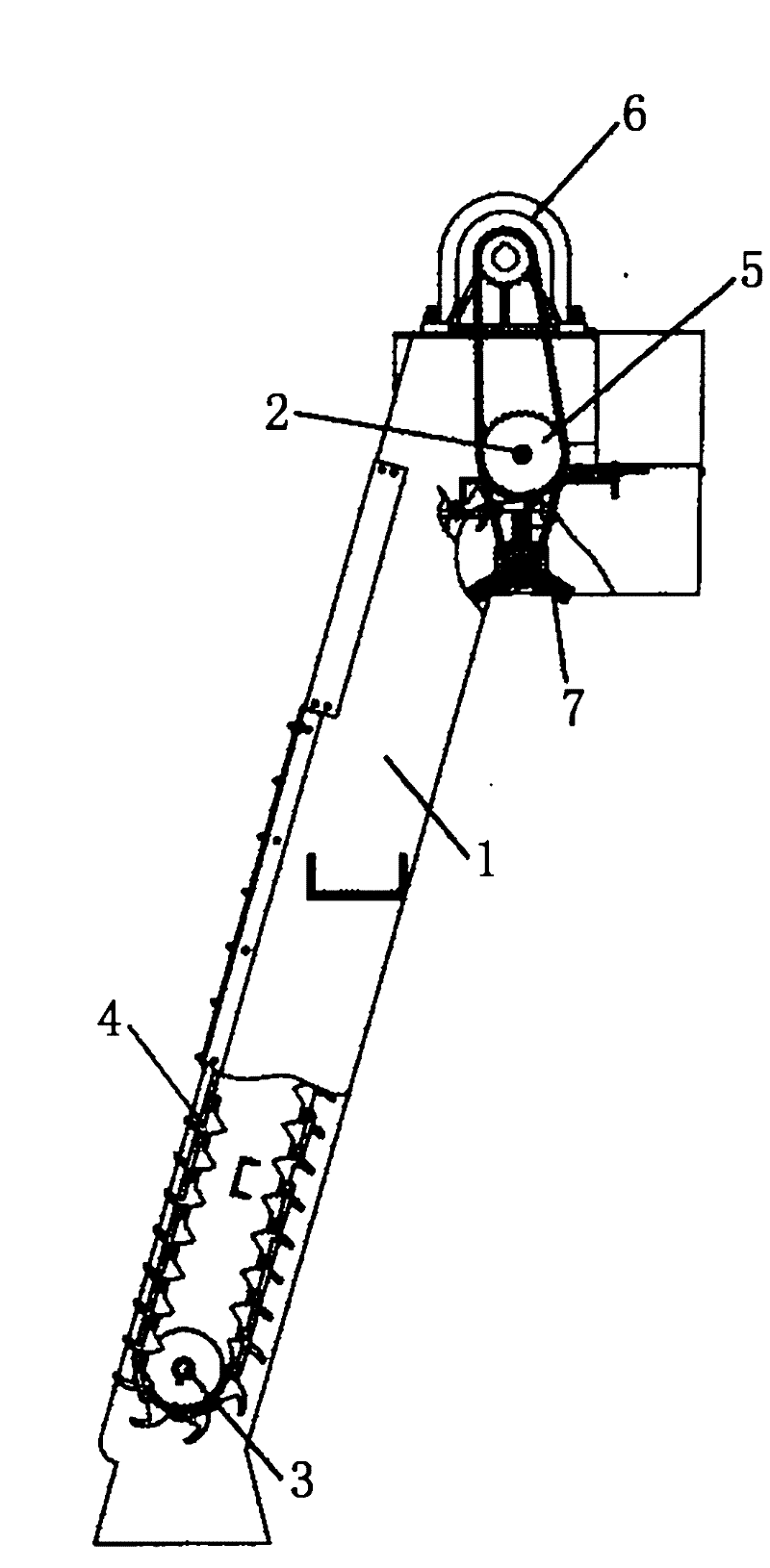

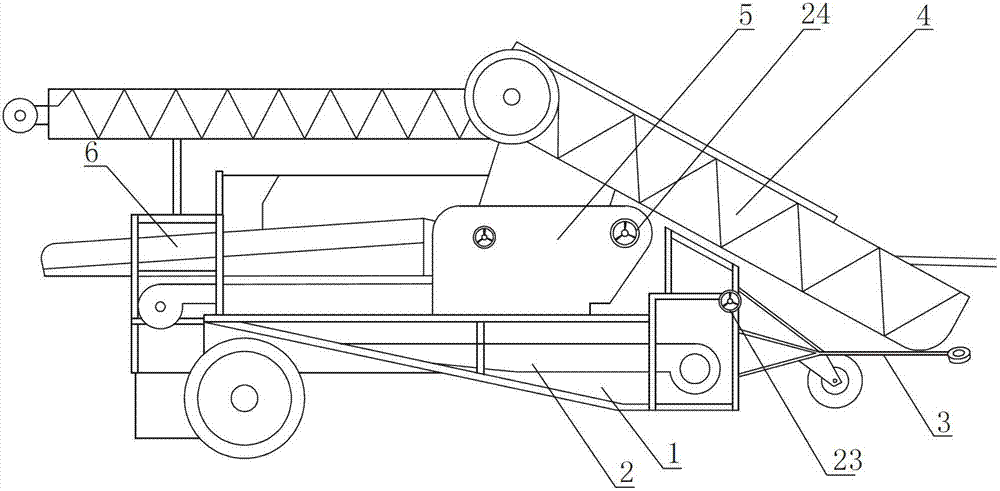

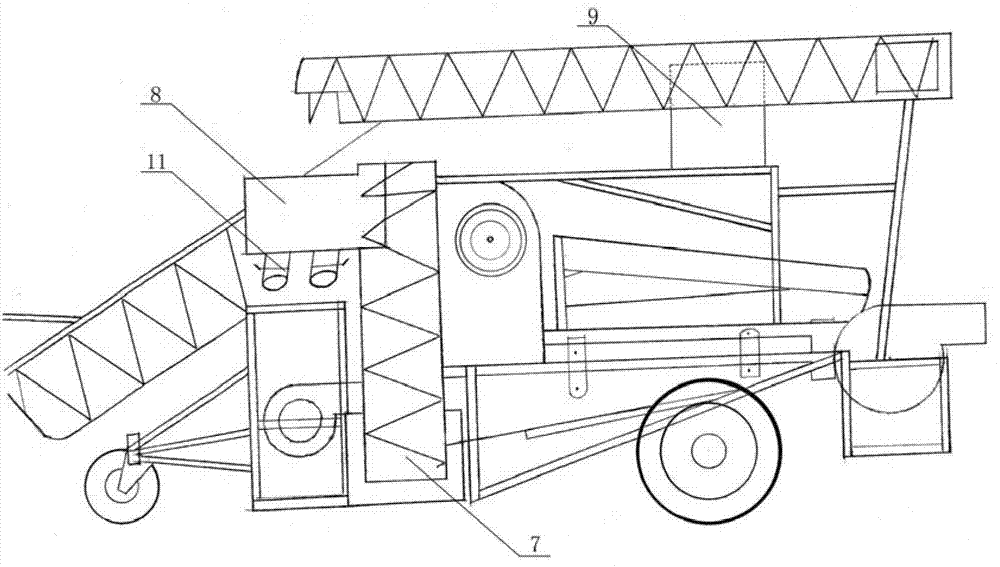

Rolling gate type pseudo-ginseng harvesting machine dragged by four-wheeled tractor

The invention relates to a rolling gate type pseudo-ginseng harvesting machine dragged by a four-wheeled tractor and belongs to the technical field of agricultural machinery. An adjusting wheel of the rolling gate type pseudo-ginseng harvesting machine is located under a machine frame and used for bearing the weight of the harvesting machine and walking. A traction frame is located in the front of the machine frame and used for dragging connection of the four-wheeled tractor to a harvesting system. A soil blocking plate and a digging shovel are located in front of the position under the machine frame and used for shoveling soil. A rolling gate is located above the back of the digging shovel, located inside the machine frame and used for first-time soil removal. A driven shaking gate is located behind the rolling gate, located inside the machine frame and used for receiving root-soil mixture and has certain soil removal effect. A rigid bar screen is located behind the driven shaking gate and used for secondary soil removal. An adjustable cam mechanism shaft is located inside a rigid bar screen space and used for improving the soil removal performance of the rigid bar screen. A collecting box is located behind the machine frame and used for collecting pseudo-ginseng roots. The pseudo-ginseng mechanization problem can be solved, and pseudo-ginsengs of different age stages can be harvested.

Owner:KUNMING UNIV OF SCI & TECH

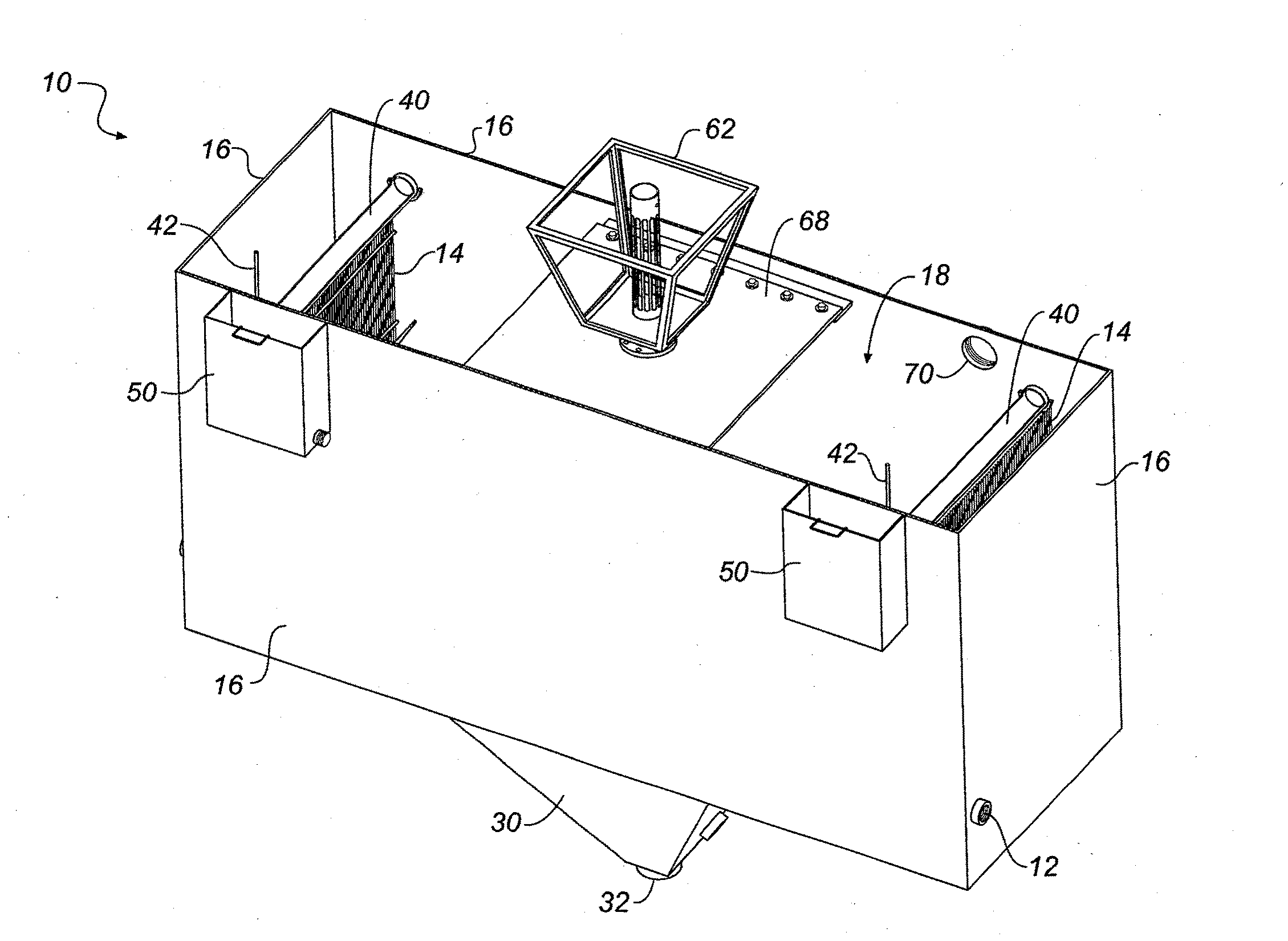

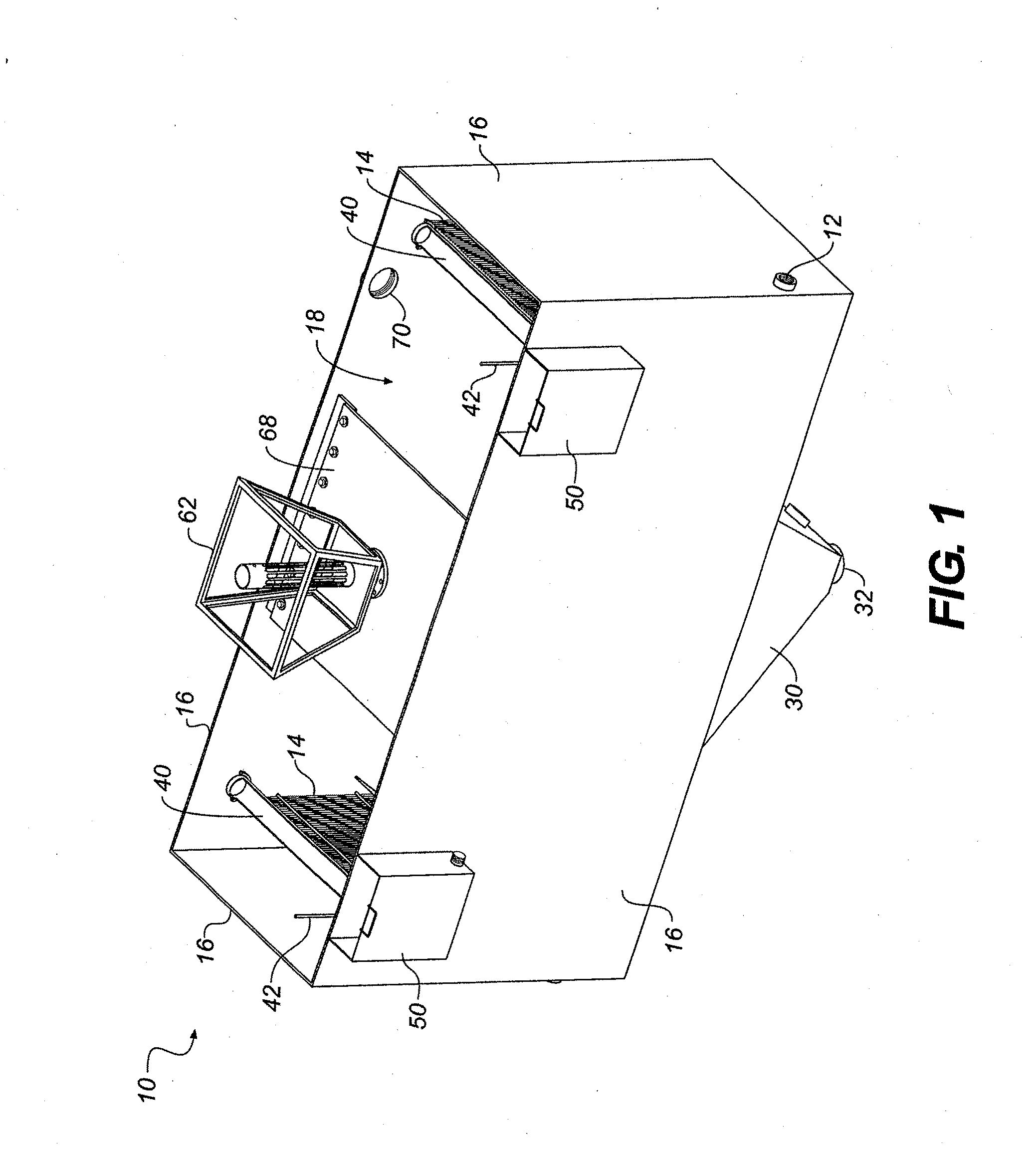

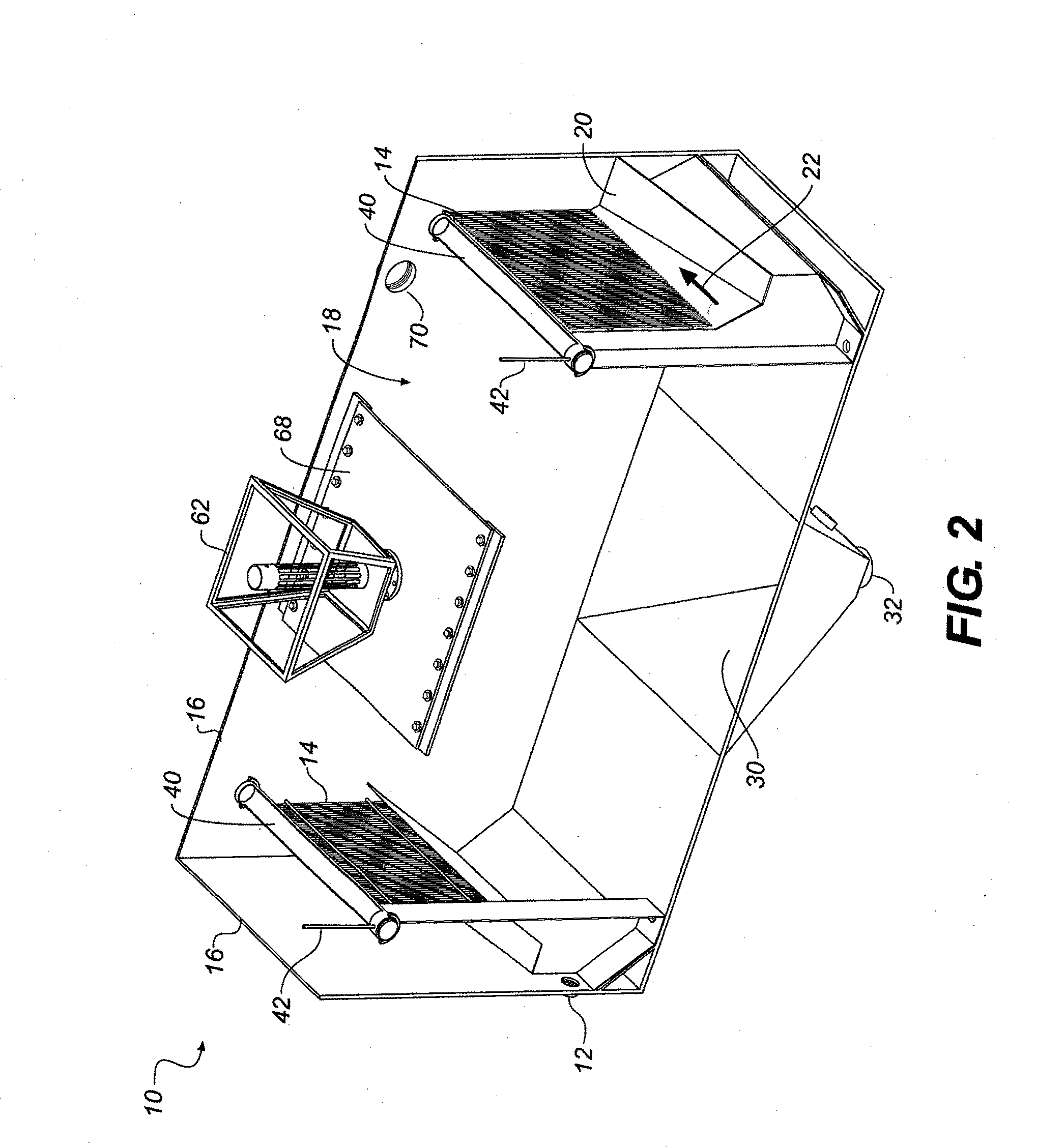

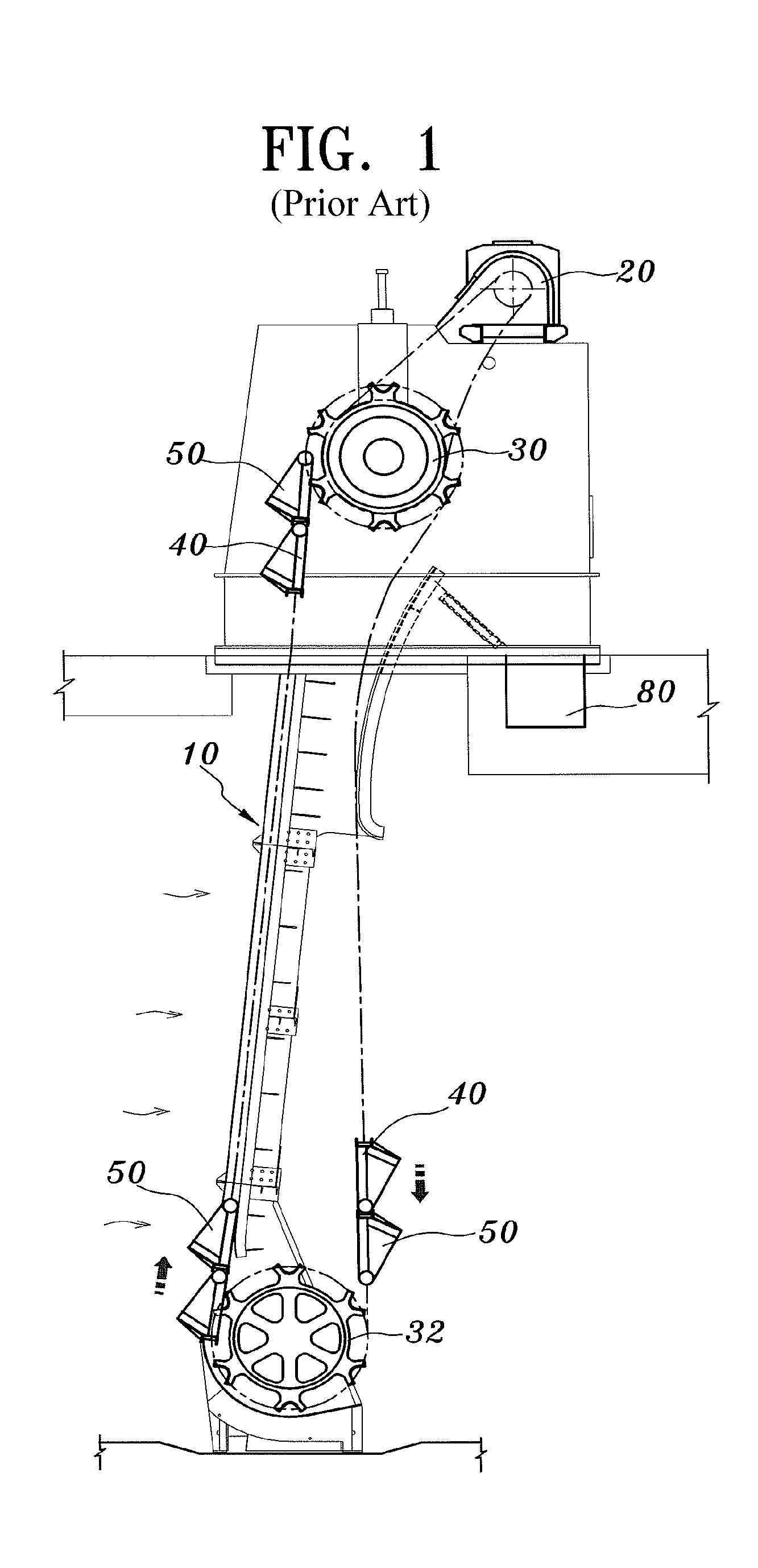

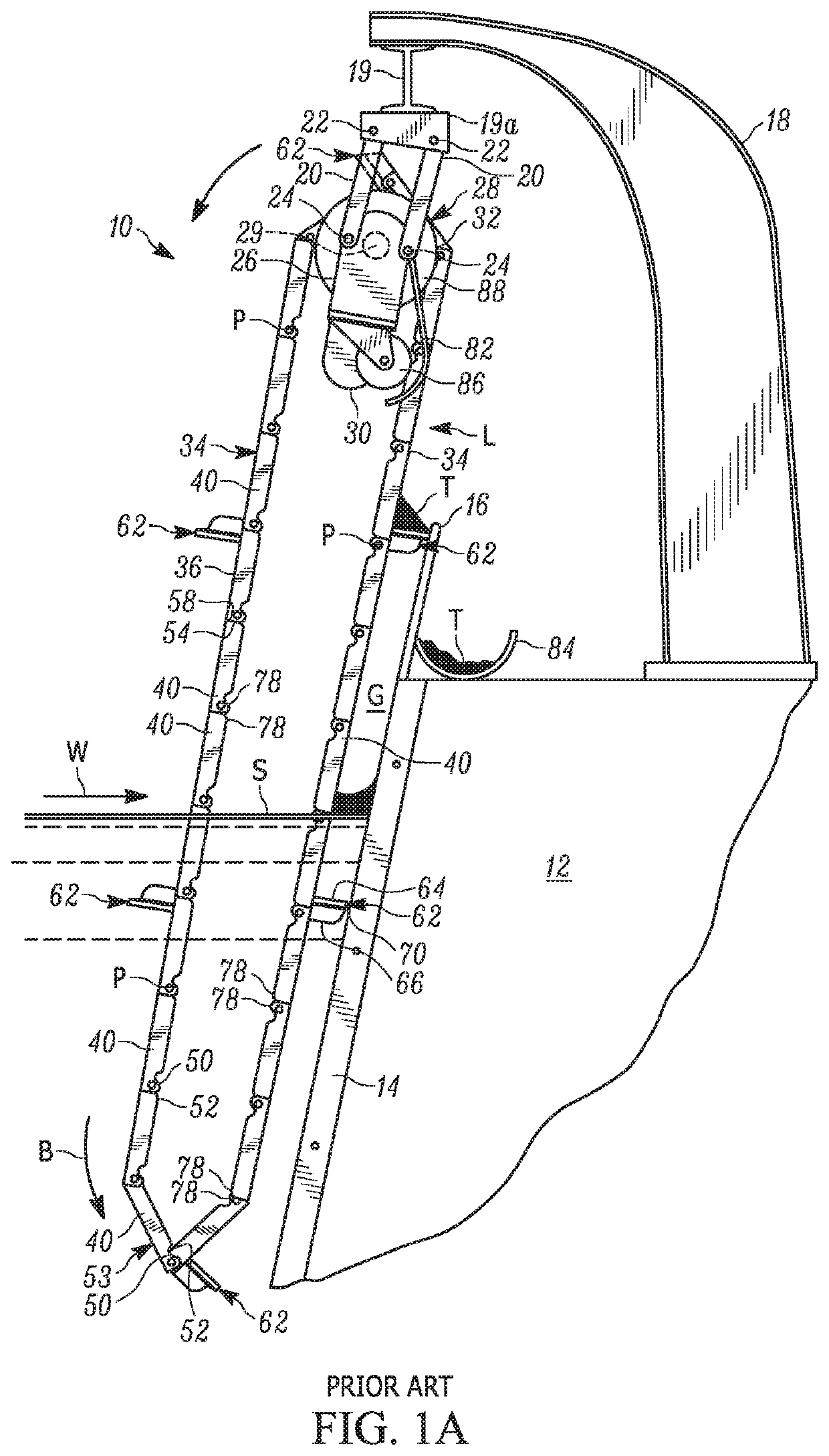

Floatables AMD scum removal apparatus for a waste water treatment system

InactiveUS20150182881A1Increase surface areaShorten speedTreatment involving sedimentationSedimentation settling tanksWater treatment systemEngineering

The invention provides a waste water treatment system including primary settling tanks. The waste water treatment system includes a trough which causes water to flow in a direction parallel to a bar screen placed in the trough with the base of the bar screen being at a lower elevation than the trough weir. Each primary settling tank has a fine screen box for screening waste water. Each primary settling tank has a scum and floatables trough for collecting scum and floatables which pass through or over a top edge of the bar screen. The scum and floatables troughs are in fluid communication with one. When a scum valve is open, scum, floatables and water in the scum and floatables trough flows from the scum and floatables trough of the first primary setting tank to the scum and floatables trough of the second primary settling tank into a collection container.

Owner:CLEARCOVE SYST

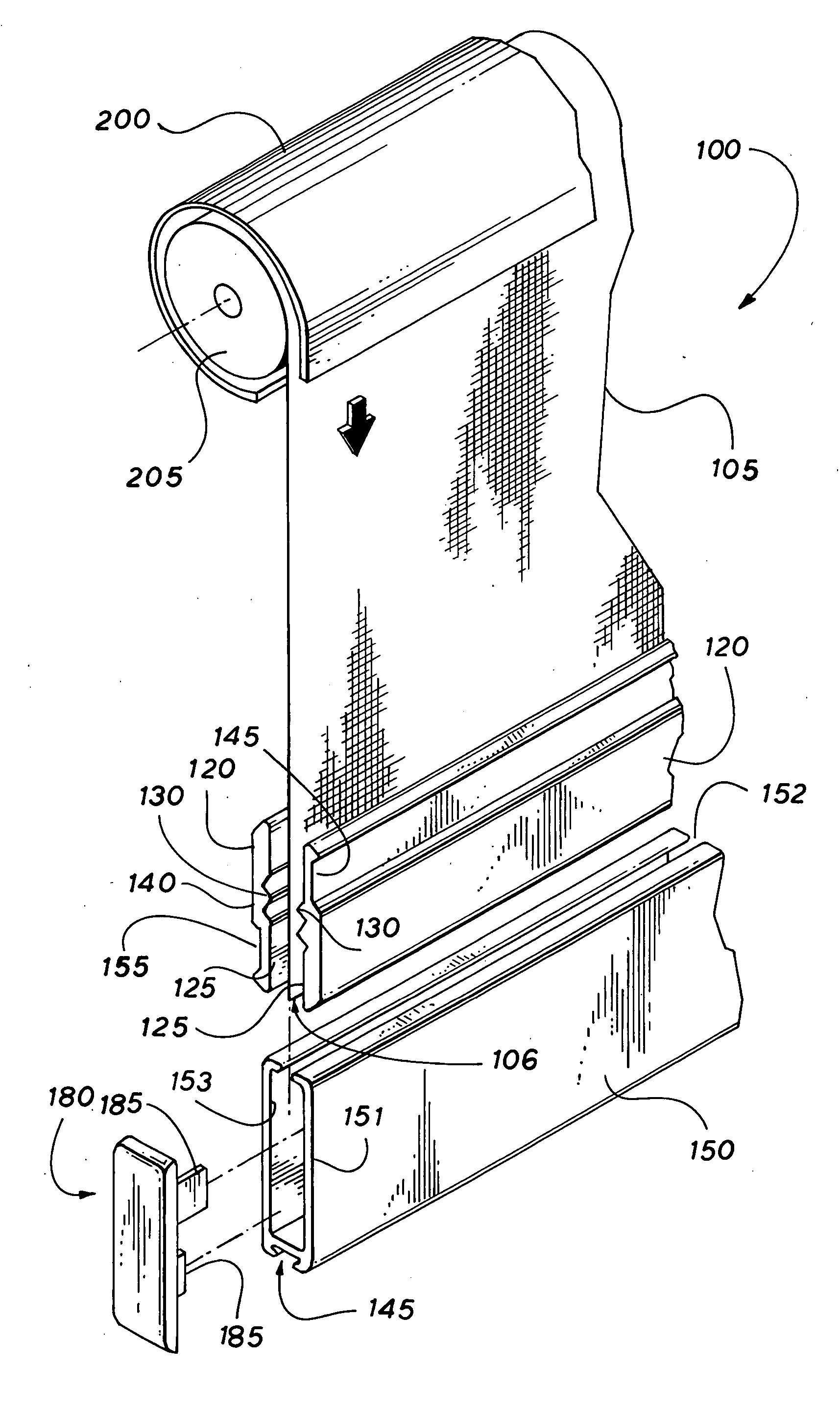

Pull bar screen apparatus and system

InactiveUS20070193697A1For direct connectionEliminate needSunshadesShutters/ movable grillesEngineeringStructural integrity

A pull bar screen apparatus and system in which screen is mechanically attached directly to a pull bar. Weld-less friction-lock cold-joining of screen and pull bar provides an improved pull-bar screen apparatus used in retractable pull screens. The pull bar screen apparatus and system remove the need for attaching a vinyl strip to the screen. Instead, the screen is flattened to retain its form and structural integrity. On one elongated end of the screen, an upper and lower lock bar are placed on either side of the screen. Corrugated ridges in the lock bars pinch the screen and hold it in place. A lock bar casing is placed under pressure around the upper and lower lock bars which hold the lock bars in position and thereby retain the screen.

Owner:HORVATH LOUIS

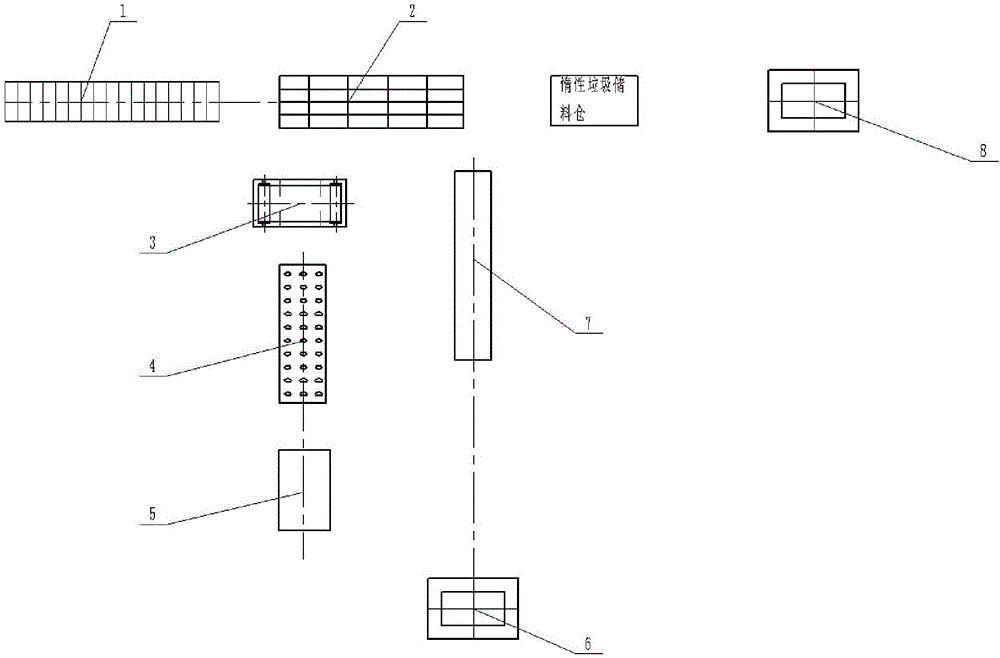

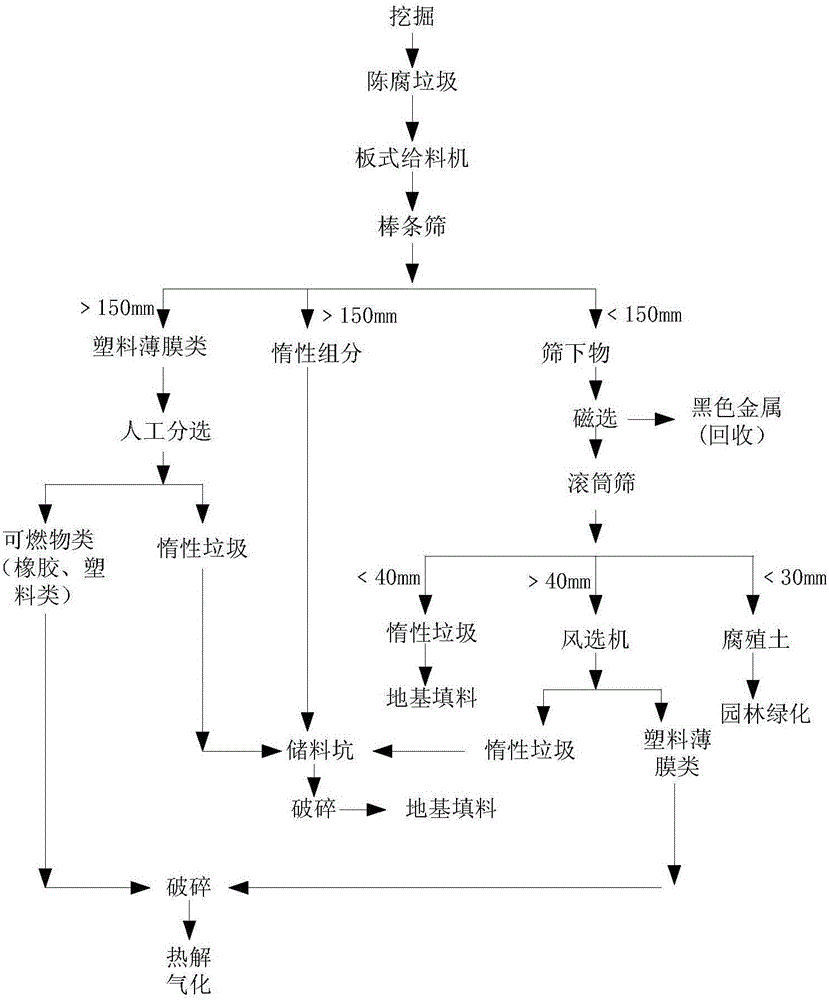

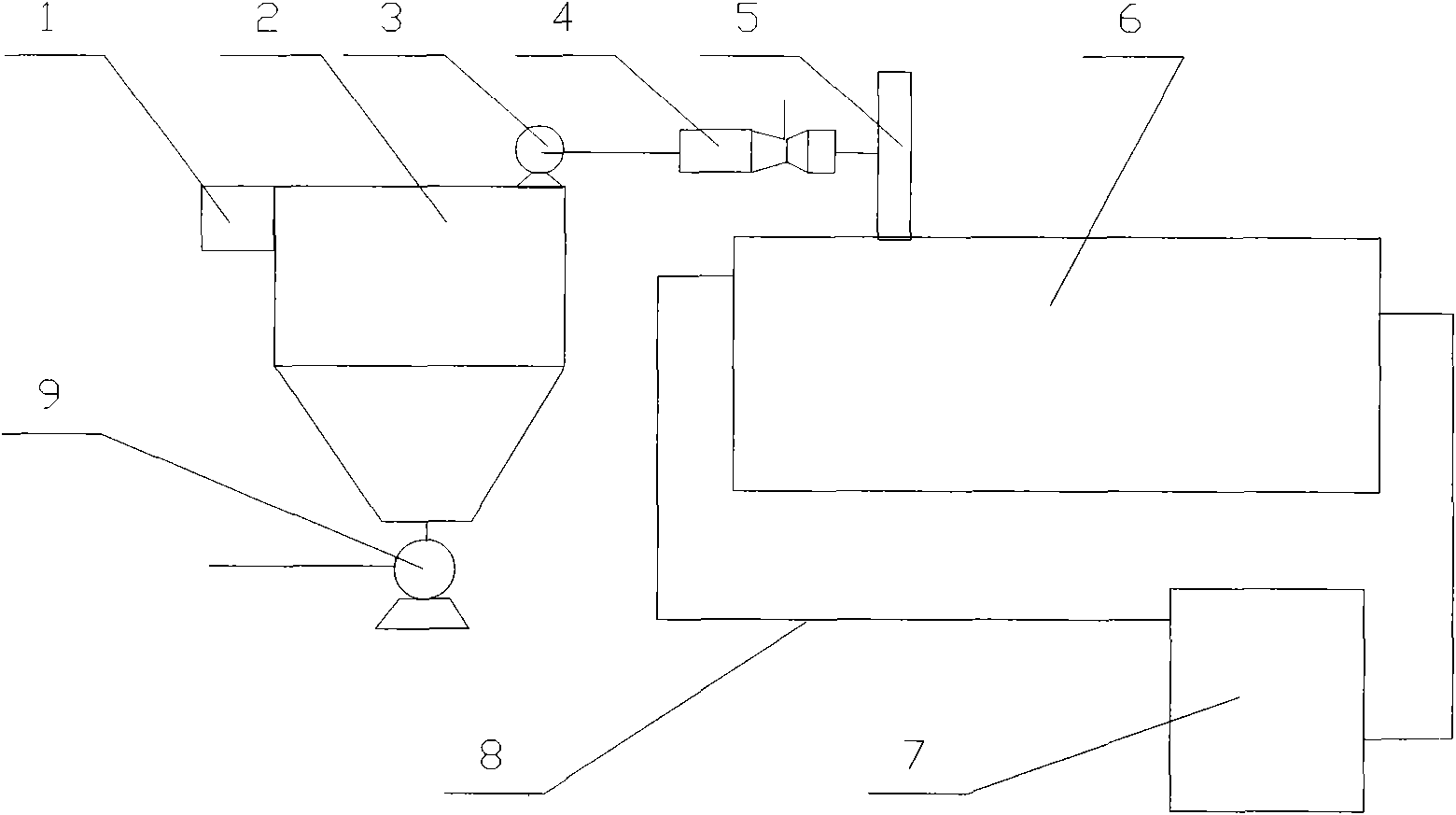

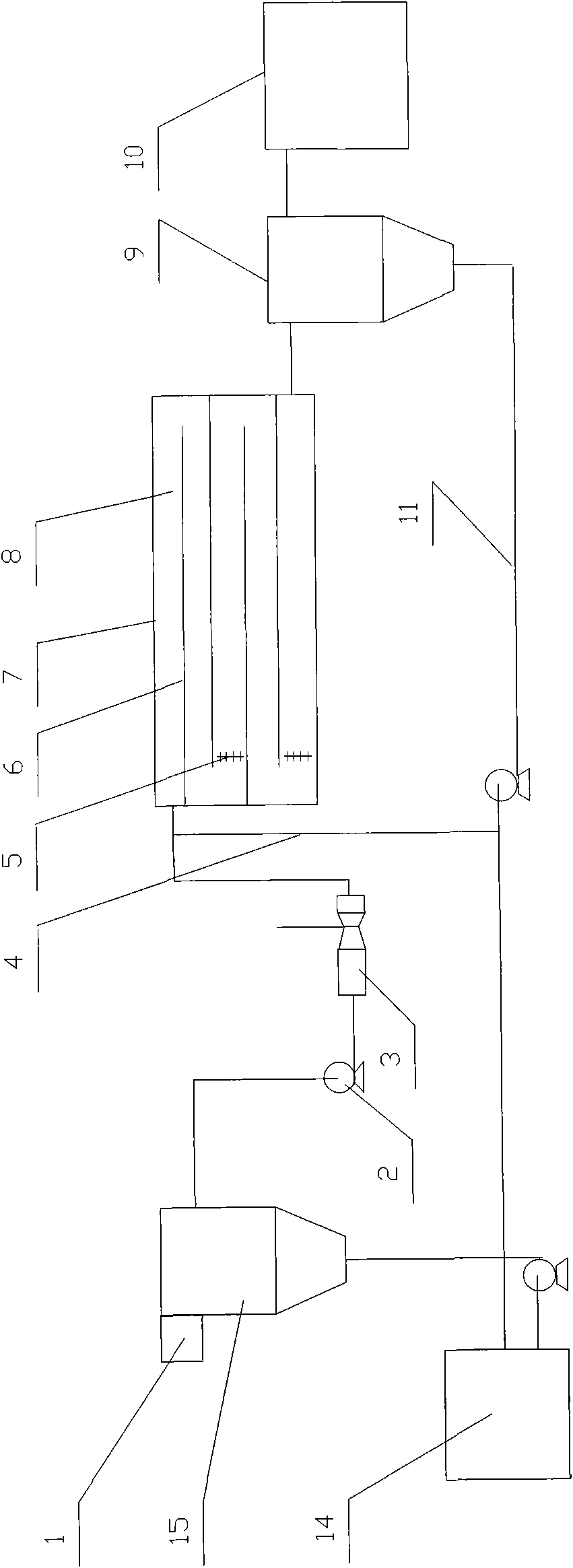

Pretreatment method of stale refuse

ActiveCN106040699AAchieve reductionRealize resourcesSolid waste disposalMagnetic separatorBar screen

The invention discloses a pretreatment method of stale refuse. The pretreatment method comprises the steps that the stale refuse is excavated by an excavator and is transported to a refuse comprehensive treatment plant through a closed refuse transport vehicle to be stacked at the feed position of a plate type feeding machine; the refuse is transported onto the plate type feeding machine through a loading vehicle, and the plate type feeding machine carries out feed on a bar screen through a belt conveyor; the bar screen is used for carrying out screening on the refuse for the first time, and three kinds of refuse different in density or size are separated out; black metal is separated out of screen underflow generated after screening of the bar screen through a magnetic separator; the screen underflow of the bar screen enters a roller screen, and three kinds of refuse different in density or size are separated out; screen overflow of the roller screen is subjected to winnowing; stone is picked out of screen overflow of the bar screen; and inert refuse and combustible refuse are broken. In the implementation process, the whole pretreatment process line operates in a totally closed manner. Reducing, recycling and harmless treatment of the stale refuse is achieved, secondary pollution and potential safety hazards of a refuse landfill, especially an informal landfill, are solved, reutilization of the refuse landfill is achieved, or land is emptied for other use, the whole pretreatment process is carried out in a closed manner, and no secondary pollution exists.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

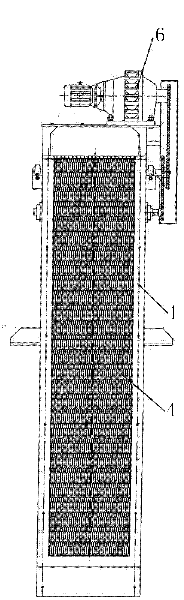

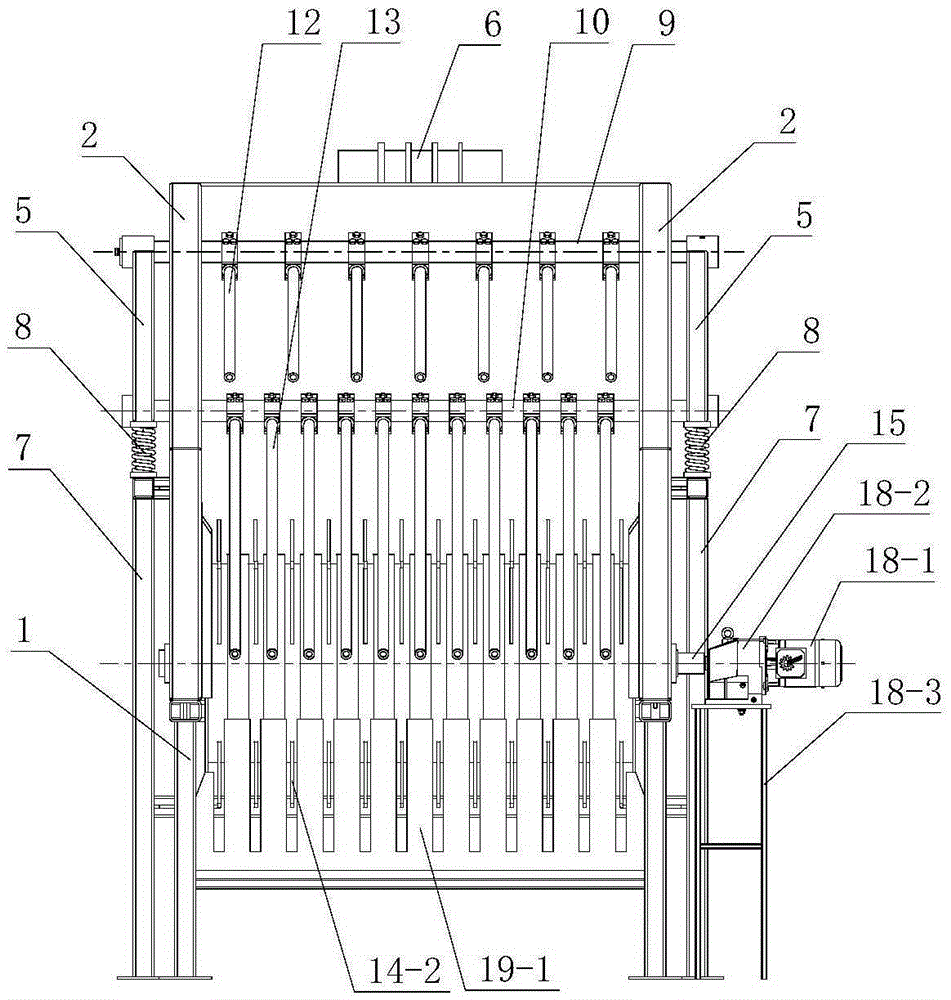

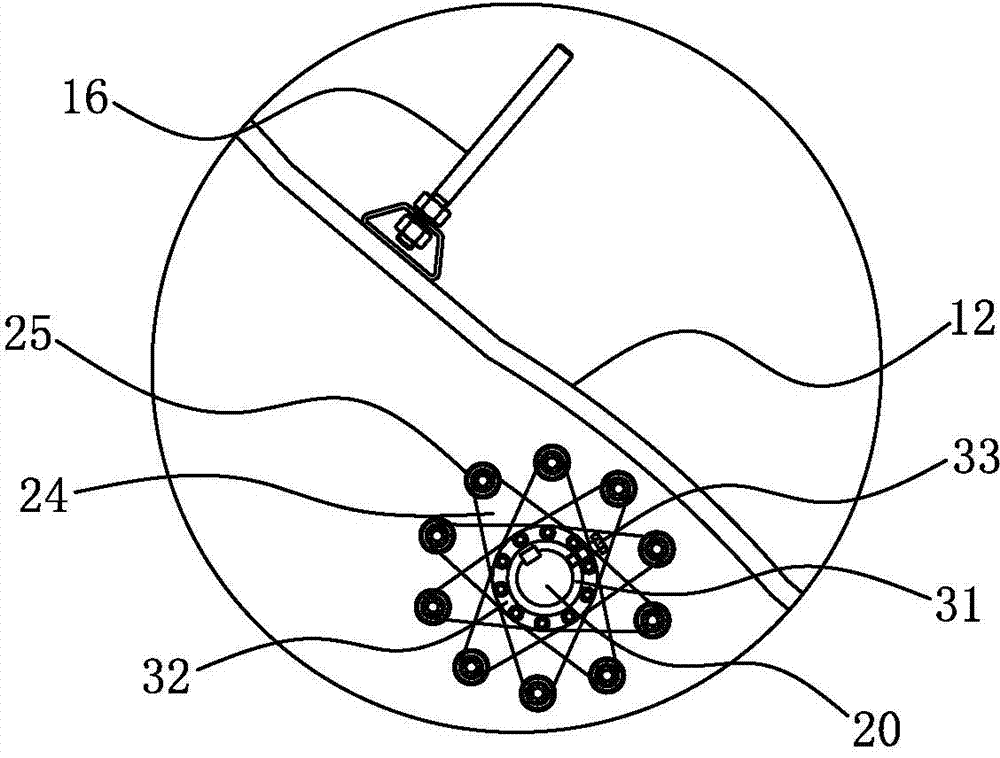

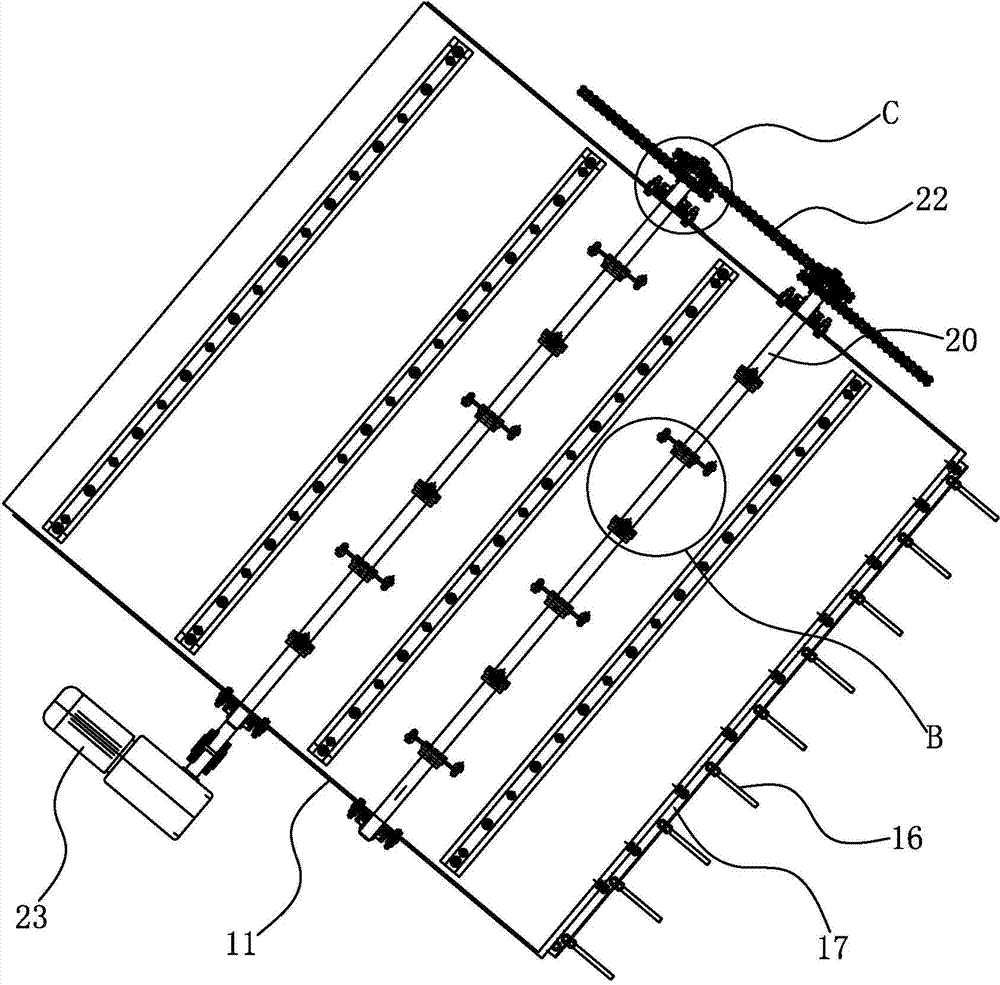

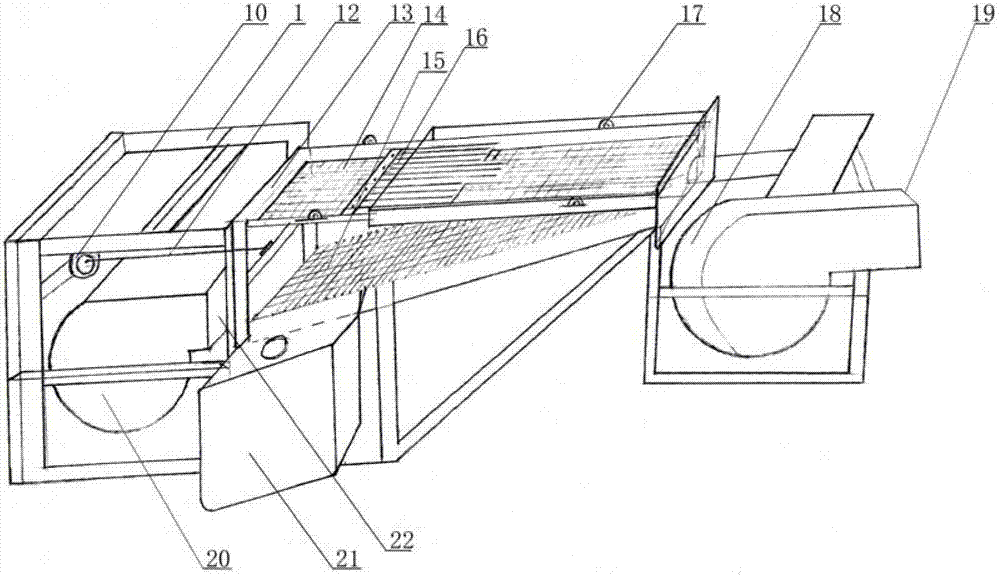

Rotary filter screen type bar screen cleaner

The invention discloses a rotary filter screen type bar screen cleaner. The rotary filter screen type bar screen cleaner comprises a frame, a driving device, a transmission chain, two main chain wheels, a main shaft, a cleaning brush, an air inlet pipe, an air nozzle, two traction chains, two secondary chain wheels, a filter frame, a filter screen, a mesh plate, a water stopping plate, and an air compressor; the driving device is fixedly connected to a top plate of the frame, the main shaft is fixed on a side plate of the frame; one end of the transmission chain is sleeved on a power output shaft of the driving device, and the other end is sleeved on a power input end of the main shaft; the main chain wheels are fixedly connected to the main shaft, and the secondary chain wheels are fixed to the lower part of the frame; two traction chains are respectively sleeved to one main chain wheel and one secondary chain wheel; the end part of the filter frame is fixedly connected to the traction chains, the filter screen and the mesh plate are arranged on the filter frame; the cleaning brush is fixed inside the side plate of the frame, brush bristle of the cleaning brush is contacted with the filter screen. By adopting the rotary filter screen type bar screen cleaner, fine floater and suspending solid matters in sewage can be intercepted; and furthermore, cleaning efficiency is high.

Owner:LANSHEN GRP CORP LTD

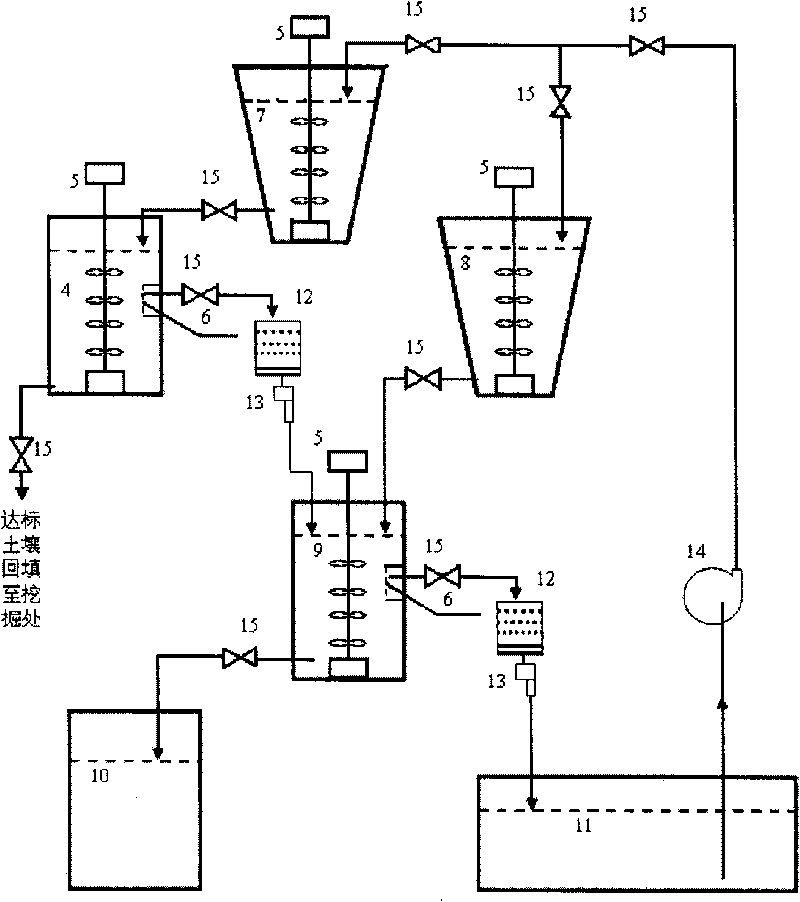

Method for treating radioactive cesium-137 polluted soil

InactiveCN101745530AReduce dependenceResidue reductionBacteriaContaminated soil reclamationEcological environmentSludge

The invention relates to a method for treating radioactive cesium micro-polluted soil. The method comprises the following steps: screening out coarse soil particles from the radioactive cesium micro-polluted soil by adopting a bar screen, a double-plate screen and a spiral screen, and then mixing the volume-reduced radioactive cesium micro-polluted soil and active bacteria liquid of acidithiobacillus ferrooxidans in a microbial dissolution promoting reactor to promote the dissolution of the radioactive cesium in the micro-polluted soil to a liquid phase; transferring the radioactive cesium containing solution to a microbial adsorption precipitation reactor, and further precipitating the radioactive cesium transferred to the liquid phase by adjusting the pH value and using active bacteria liquid of sulfate reducing bacteria; filtering the treated soil suspension and recycling the water; and reducing the volume of the sludge adsorbing the radioactive cesium. The method has the advantages of simple and convenient operation, economy, feasibility, high safety, no secondary pollution to the ecological environment, and capacity of efficiently and quickly removing the radioactive cesium from the micro-polluted soil.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Foreign substance eliminating apparatus

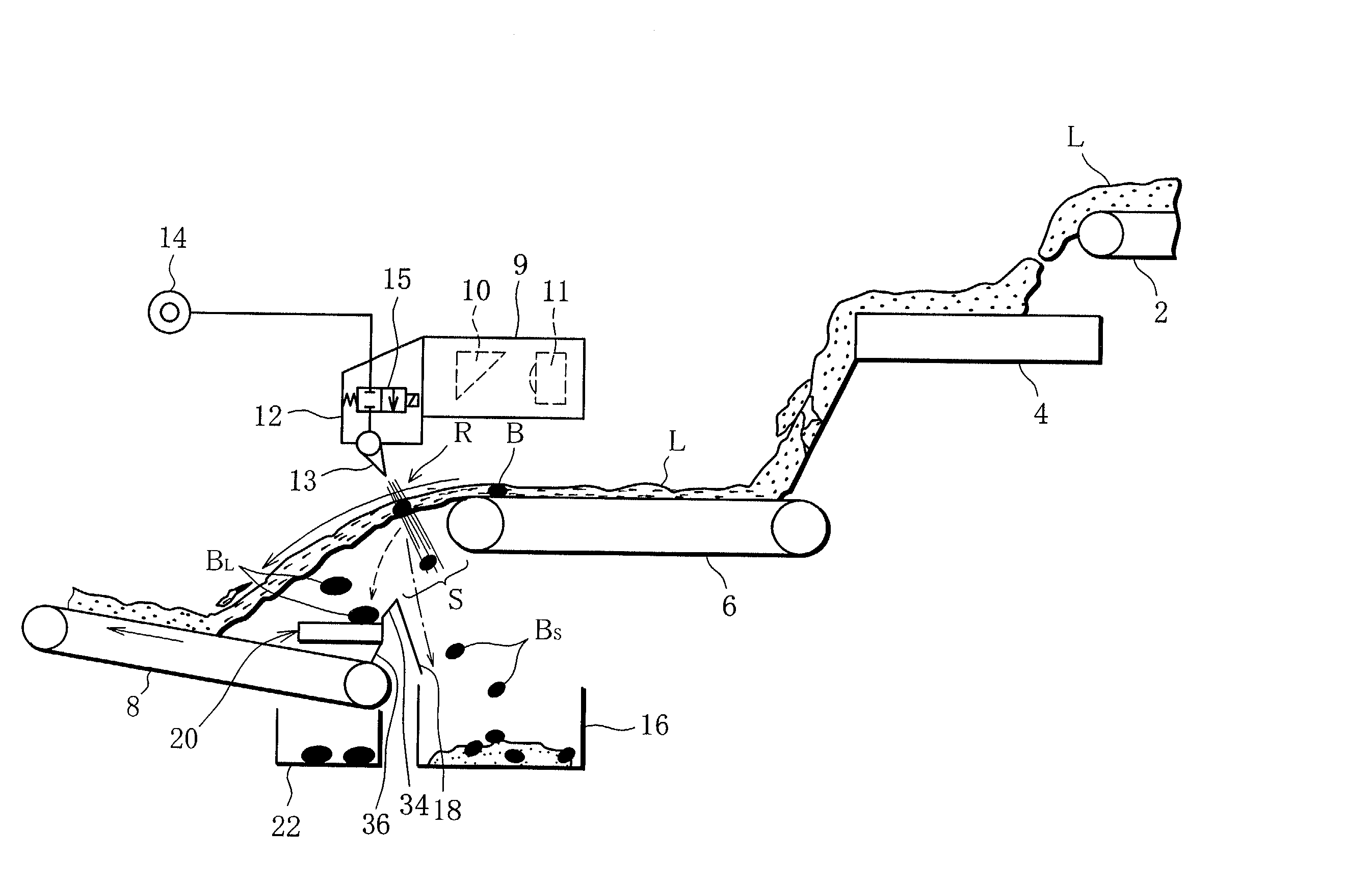

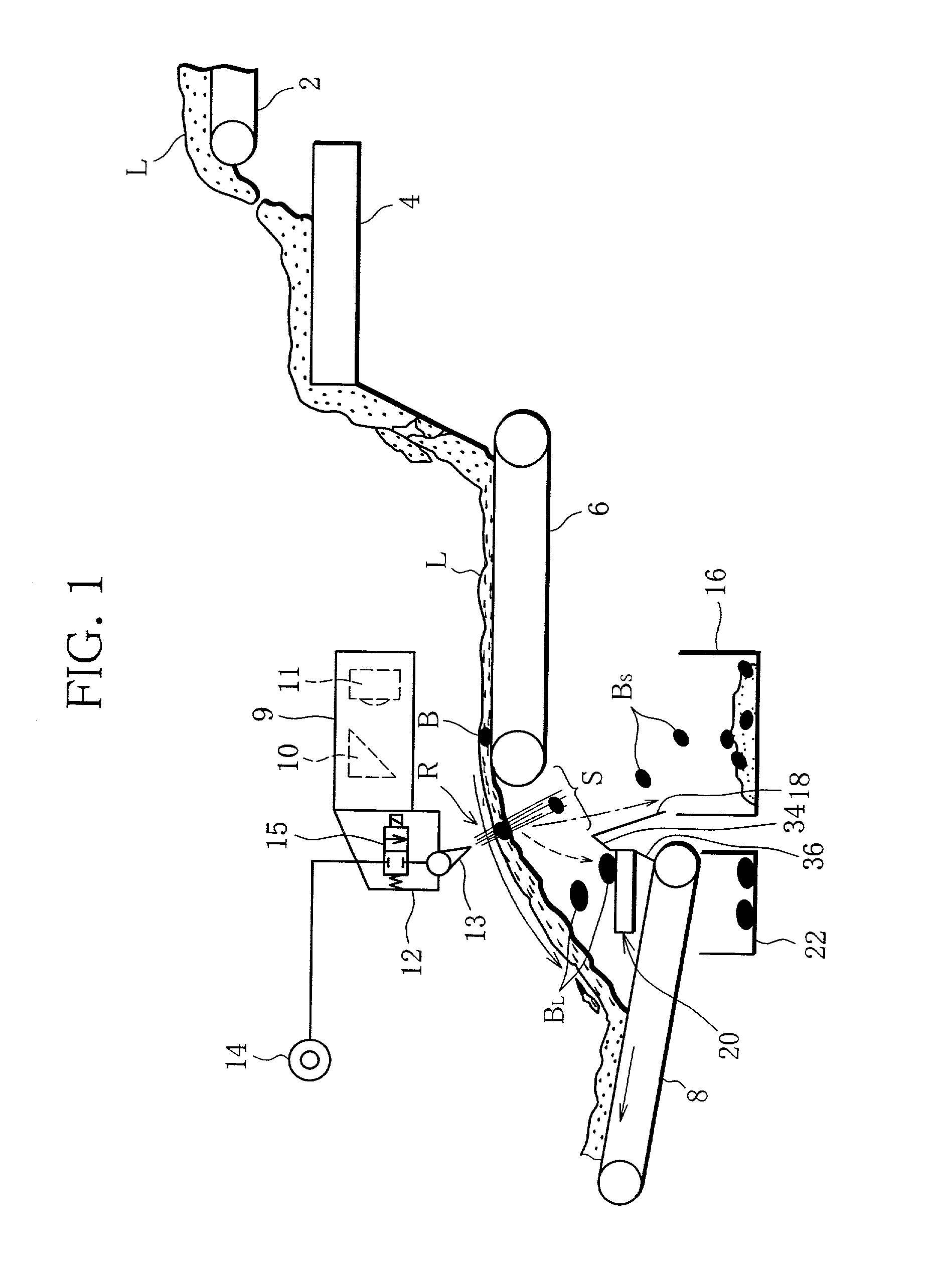

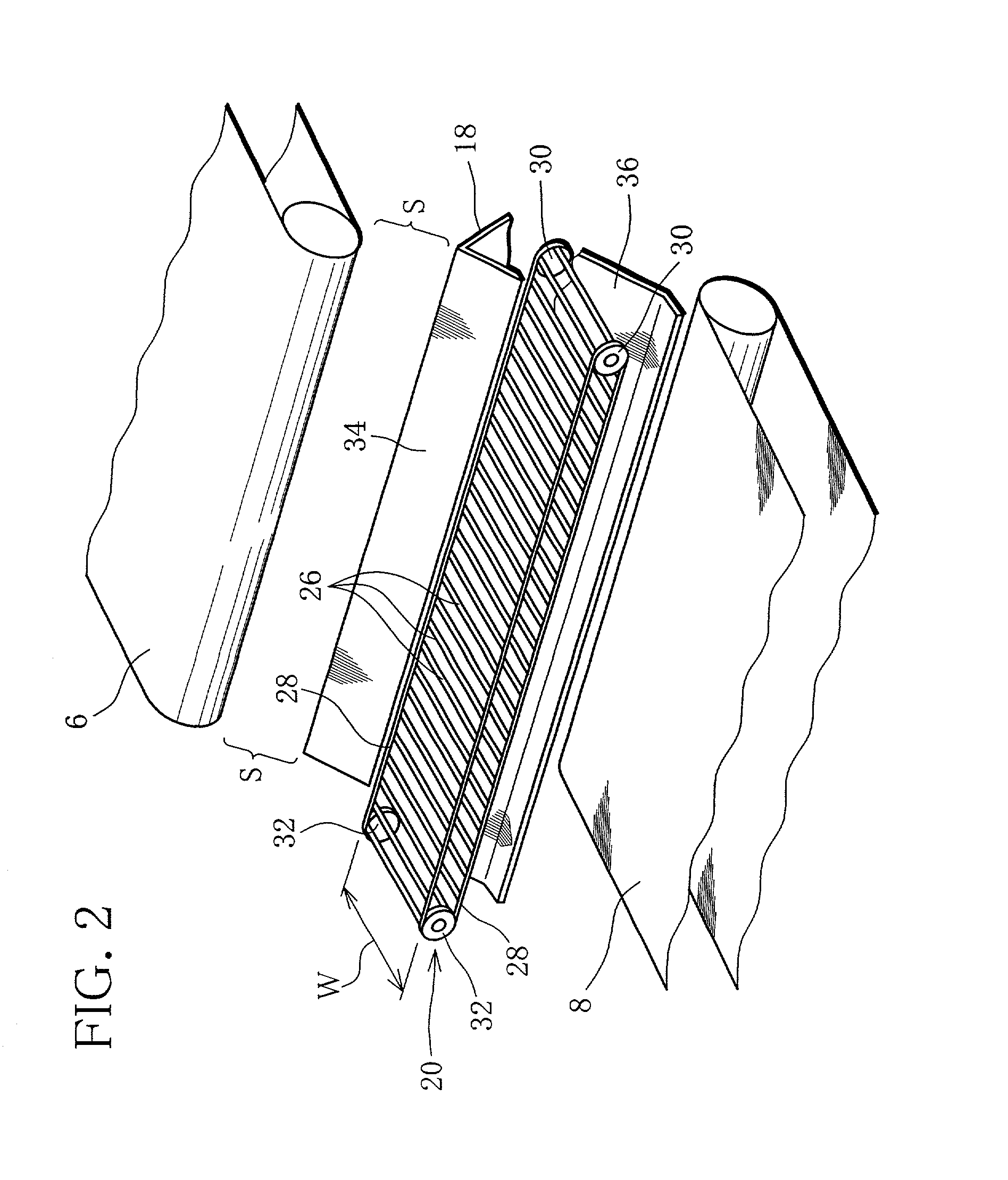

InactiveUS20020130067A1Quality improvementImprove efficiencyGas current separationSortingForeign matterEngineering

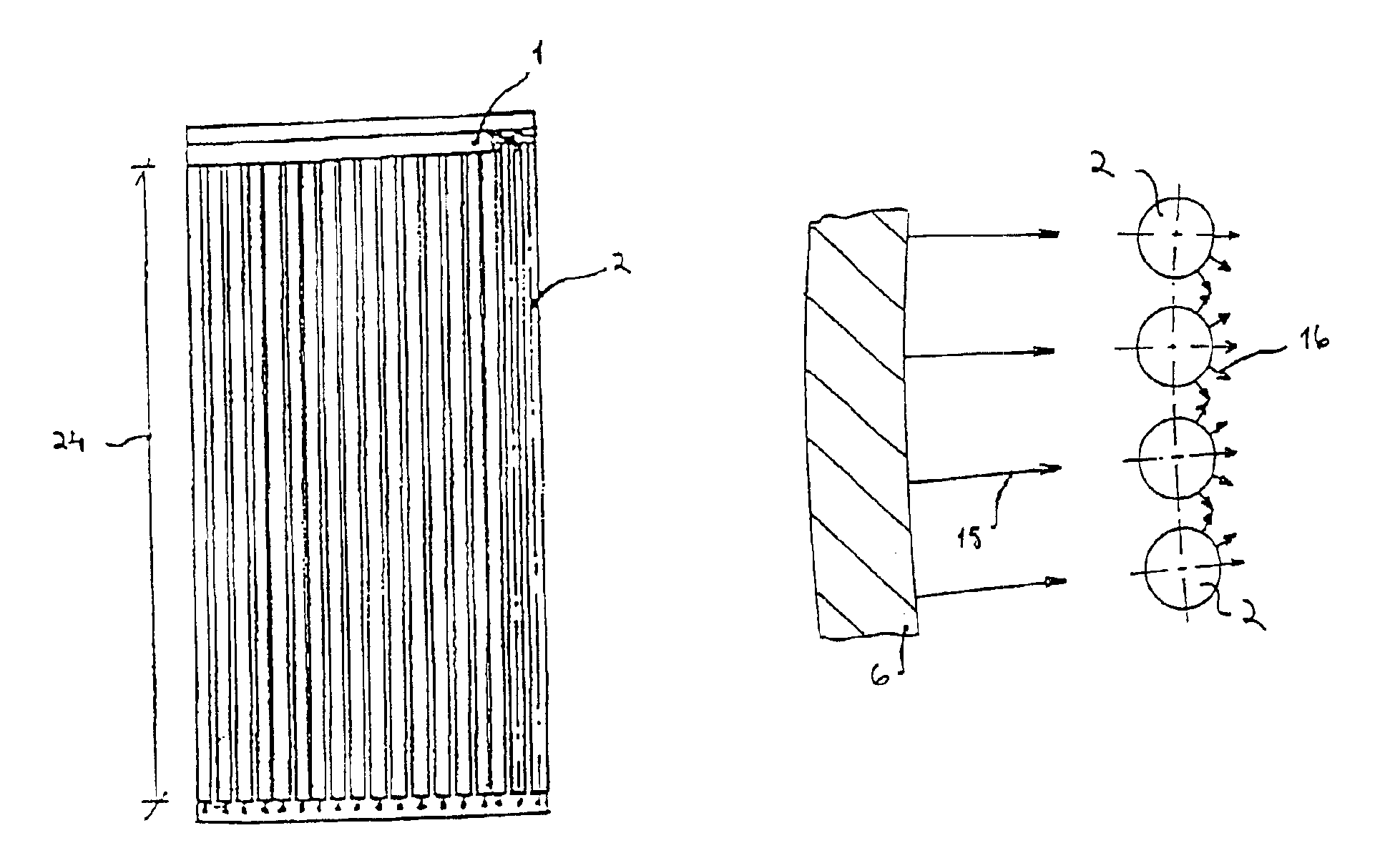

A foreign substance eliminating apparatus transfers raw material by passing the raw material between an upstream conveyor (6) and a downstream conveyor (8), and detects a foreign substance on the upstream transfer conveyor with a foreign substance detector (9). An eliminating airflow (R) is ejected from a row of air nozzles (13) when the detected foreign substance falls down, and deflects the falling direction of the foreign substance. At this point, a small foreign substance (B.sub.S) is blown off by the eliminating airflow, and sent to the foreign substancereceiving box (16). On the other hand, a large foreign substance (B.sub.L) goes across the eliminating airflow, and falls down onto the bar screen conveyor (20). The bar screen conveyor captures the large foreign substance, and removes it outside of the conveyor.

Owner:JAPAN TOBACCO INC

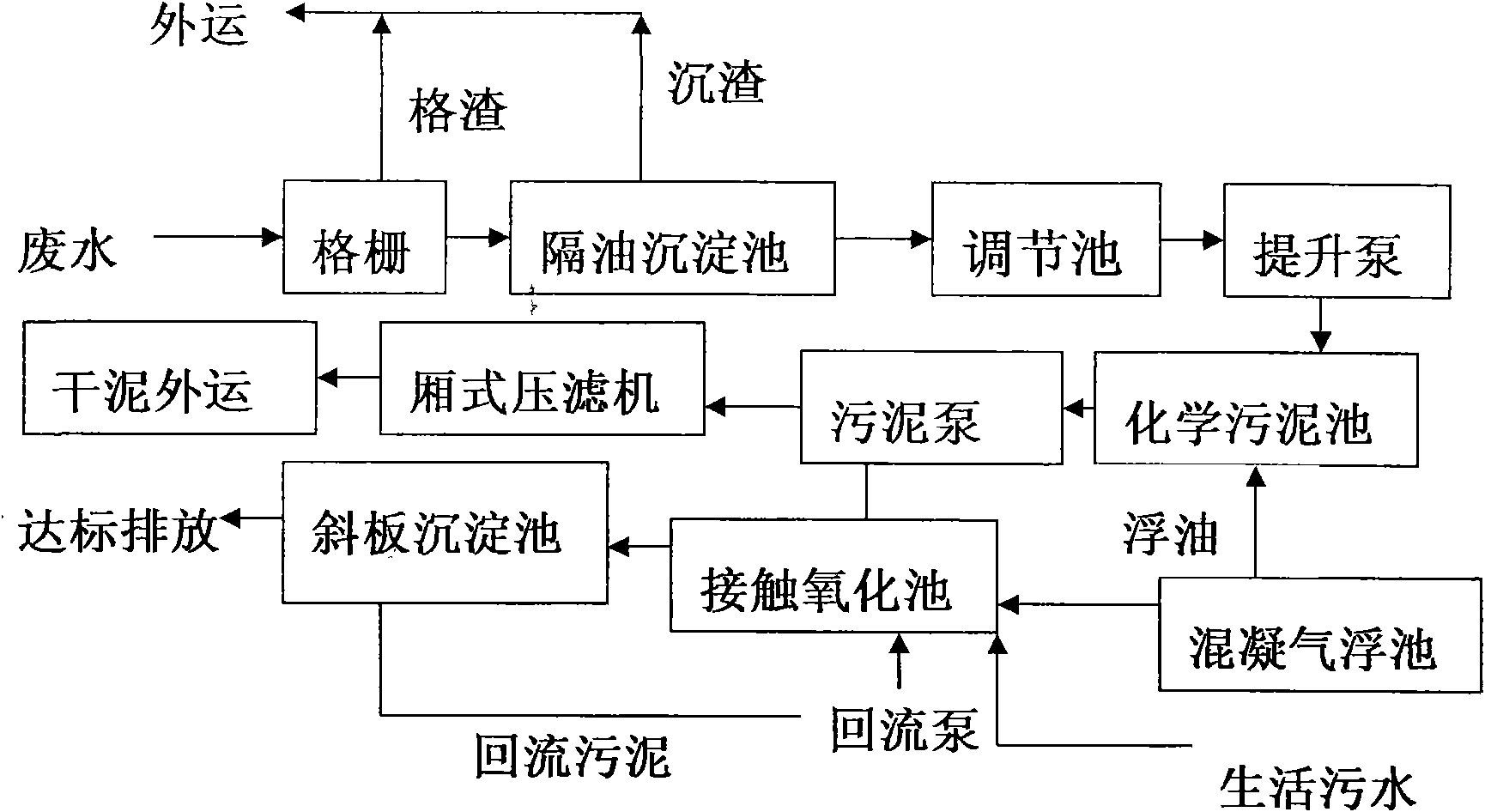

Method for treating paint waste water

InactiveCN101633540AFatty/oily/floating substances removal devicesTreatment using aerobic processesSludgeSewage

The invention discloses a method for treating paint waste water, which belongs to the technical field of waste water treatment, and particularly relates to the method for treating the paint waste water. The method for treating the paint waste water through oil isolation, coagulation air floatation and bio-contact oxidation has the advantages of low cost, small energy consumption, convenient operation management and good treatment effect. The method adopts the following technical scheme: (1) passing the paint waste water through a bar screen; (2) putting the waste water passing through the bar screen into an oil isolation sedimentation tank, and then in a regulating tank, and pumping the waste water regulated by the regulating tank into an air flotation tank by a pump; (3) putting the waste water after the air flotation treatment together with domestic sewage into a bio-contact oxidation tank to perform biochemical treatment, and performing mud-water separation on the waste water through an inclined plate sedimentation tank so that the waste water reaches the discharge standards; and (4) returning part of the sludge deposited in the inclined plate sedimentation tank to a primary bio-contact oxidation tank, putting the remaining sludge and the oil slick separated by the coagulation air floatation tank into a chemical sludge tank for concentration, and pumping the sludge after the concentration into a chamber press filter by a sludge pump to perform dewatering treatments.

Owner:刘倩

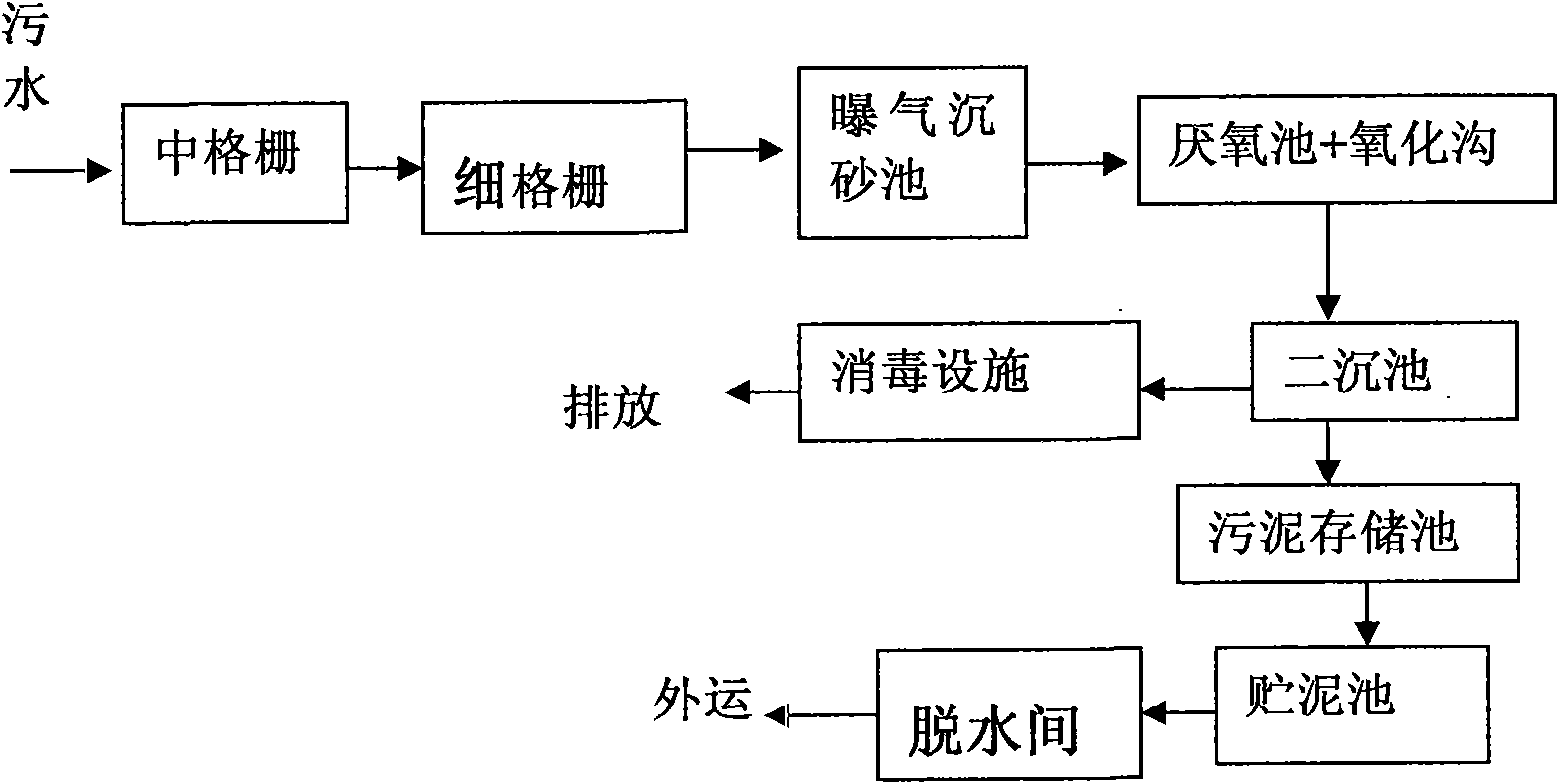

System and method for treating urban sewage

InactiveCN101659491AGood removal effectUnique hydraulic flowTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeTreatment effect

The invention belongs to the technical field of environmental protection, and in particular relates to a system and a method for treating urban sewage. The invention provides the system and the methodfor treating the urban sewage, which are simple in operation, good in treatment effect, simple in process and strong in adaptation to water quality and water amount and of which the effluent meets the discharge standard. The technical scheme is as follows: by adopting a treatment process of an anaerobic tank and an oxidation ditch, big and small suspended matters are substantially removed after the sewage passes through a middle bar screen and a fine bar screen; the effluent enters an aeration desilting basin so that inorganic particles with a big grain size, such as sands, gravels and coal slag, are precipitated; the effluent enters the anaerobic tank and the oxidation ditch, wherein in the oxidation ditch, the mixed liquid of the wastewater and activated sludge continuously and circularly flows under the action of an externally added driving force, organic substances are degraded under the functions of microorganisms, and the nitrogen and phosphor are well removed; the effluent enters a secondary settling tank; after the sludge and water in the effluent are separated, the sterilized and filtered effluent can be discharged after reaching the standard; and the left sludge is condensed, dehydrated and carried away.

Owner:王强

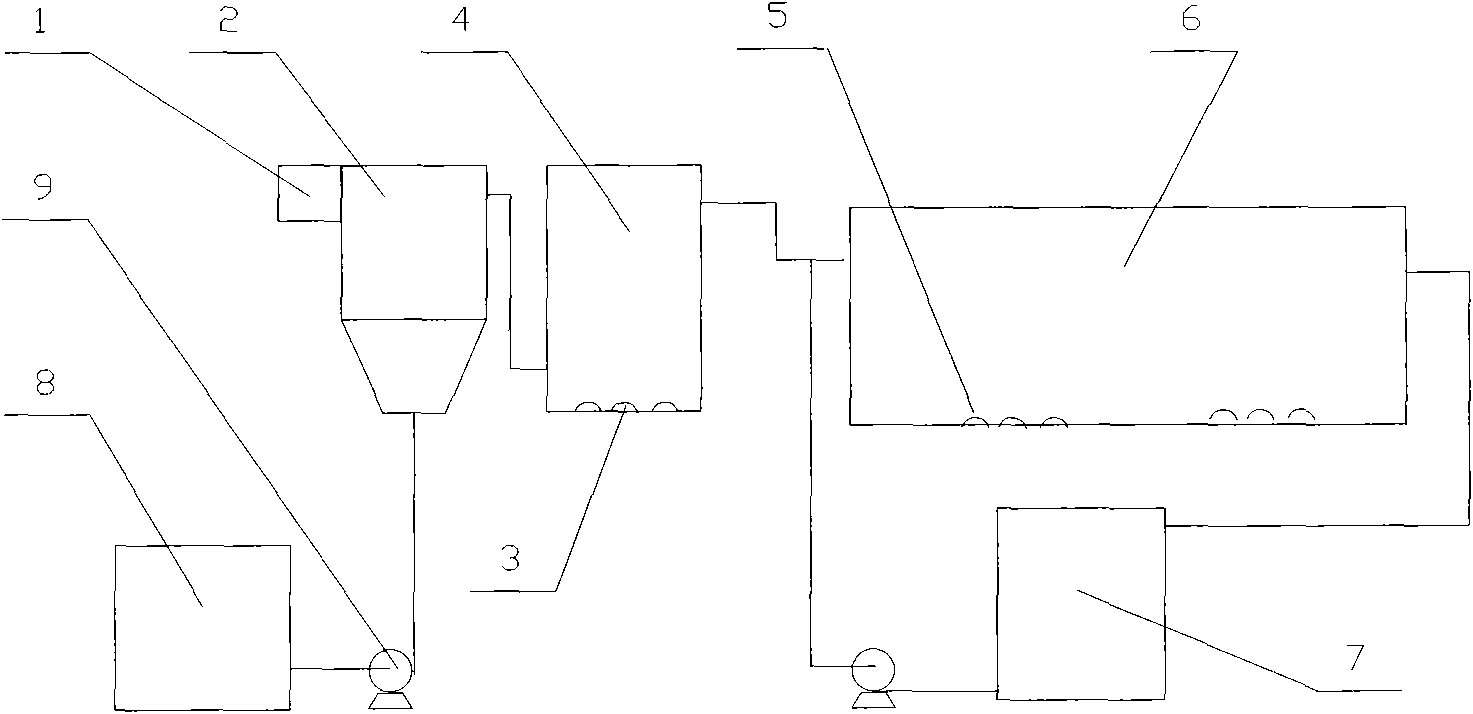

High-efficiency artificial wetland sewage treatment system

InactiveCN101585579AImprove the operating environmentImprove purification effectSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandSlag

The invention relates to a high-efficiency artificial wetland sewage treatment system, which comprises a bar screen, a water-collecting sedimentation tank, an aeration tank and an artificial wetland, wherein the bar screen is positioned in front of the water-collecting sedimentation tank, the yield water of the water-collecting sedimentation tank is pumped into the aeration tank by a sewage pump, a plurality of parallel horizontal traverse baffles are arranged in the artificial wetland and divide the artificial wetland into a plurality of parallel water flow passages which are communicated with each other in turn, and the bottoms of the water flow passages are distributed with a plurality of groups of aerators at intervals. The base material of the artificial wetland comprises sand soil mixture, crushed stone, zeolite, limestone, coal slag, steel slag, blast furnace slag, crushed stone, porcelain granules, melon seed piece and pebble and can be cultivated with mussels, and the water outlet end of the artificial wetland is provided with a water storage tank. The high-efficiency artificial wetland sewage treatment system has a simple structure, and can effectively improve the processing effect of the artificial wetland and the purification degree of the yield water of the artificial wetland.

Owner:HAISIBOTE BEIJING SCIENE & TECH

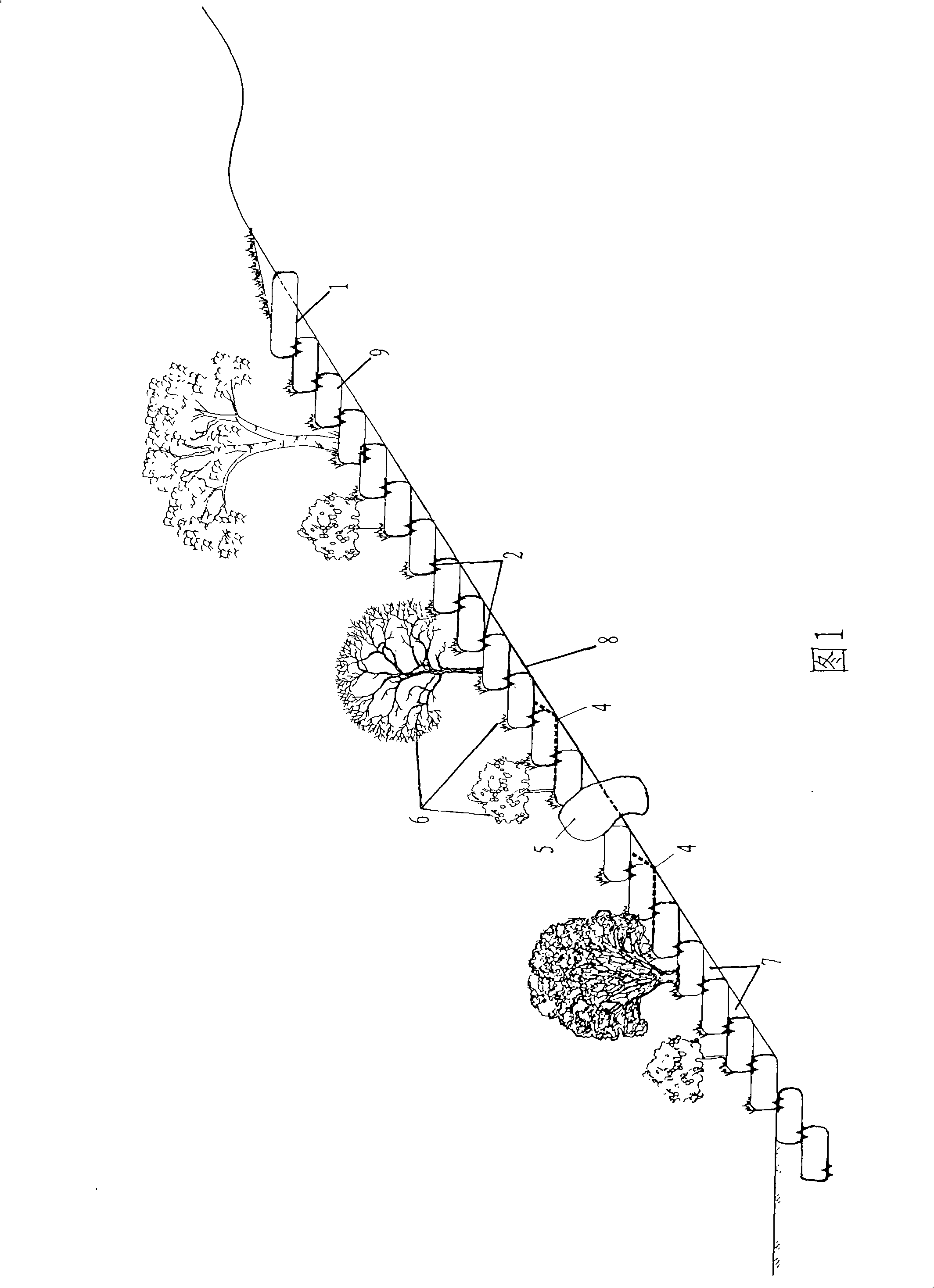

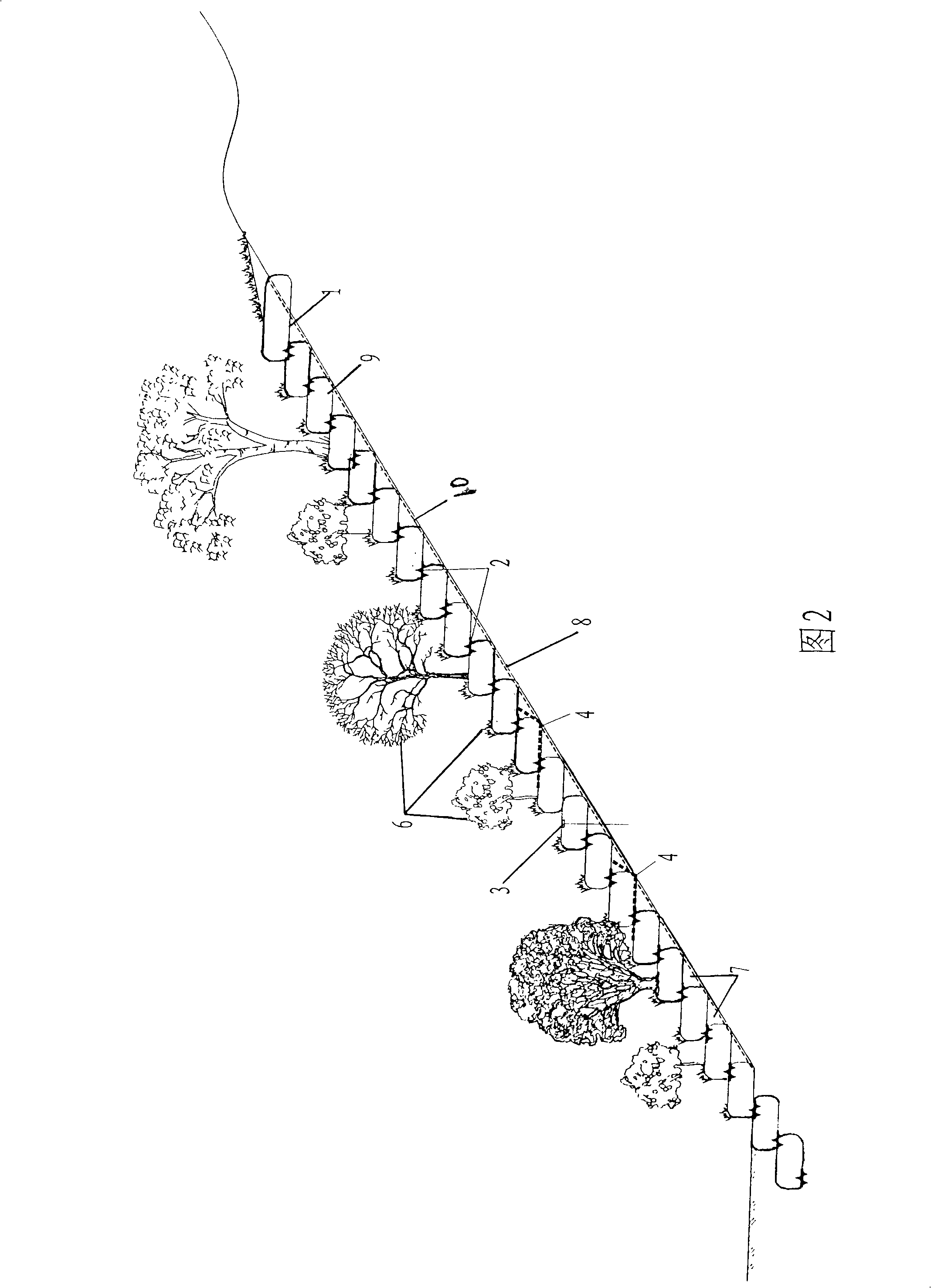

Method for greening infertile side slope fields

InactiveCN101313650ASolve the problem of safely and reliably restoring the ecological environmentSolve the problem of restoring the ecological environmentClimate change adaptationAfforestationEcological environmentGreening

The invention introduces a method for greening areas with barren side slopes. The method comprises the following steps: (1) by studying greening suitable planting conditions of a slope body(8), a greening plan is worked out; (2) the slope body(8) is cleaned and dressed; (3) ecological anti-sliding tenons (5) or systematic ecological anchor rods (3) or bar screens (10) and systematic ecological anchor rods (3) are arranged; (4) porous degradable ecological bags (1) are evenly arranged, and link buckles(2) of ecological bags and porous degradable plastic blind pipes (4) are arranged between the porous degradable ecological bags(1); and (5) grass and bushes (6) are planted. The method has the advantages that: 1. the method can effectively resolve the problem of restoring ecological environment in the areas with the barren side slopes and make an individualized ecological design; 2. the method can avoid water loss and soil erosion; 3. the method can greatly prolong ecological duration; and 4. the method is simple in construction, low in cost and wide in application range.

Owner:POWERCHINA ZHONGNAN ENG

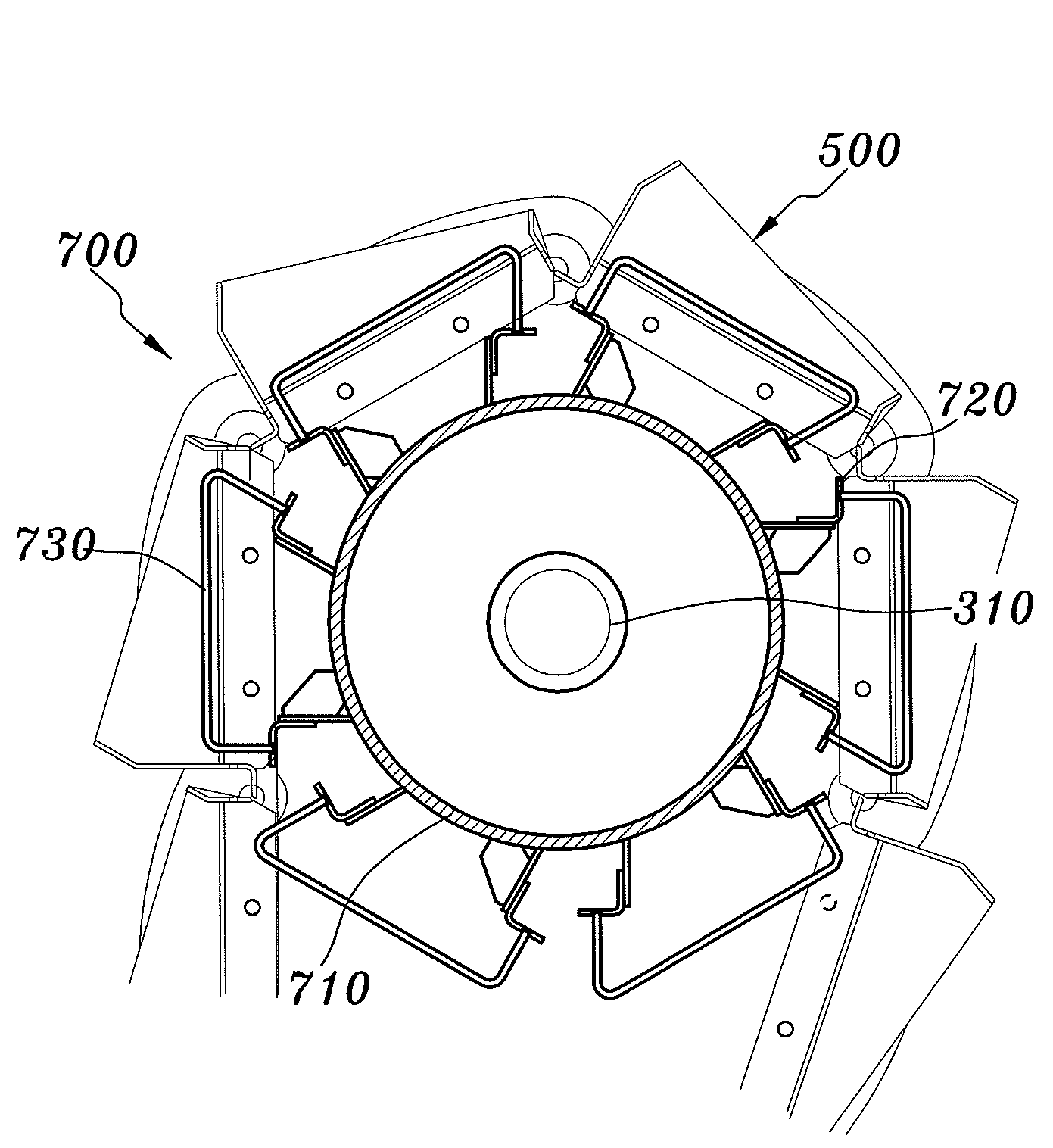

Rotary bar screen device

ActiveUS7575674B2Increase the effective areaEffective Area MaximizationFatty/oily/floating substances removal devicesSeawater treatmentBraced frameSprocket

Owner:COWAY ENTECH CO LTD

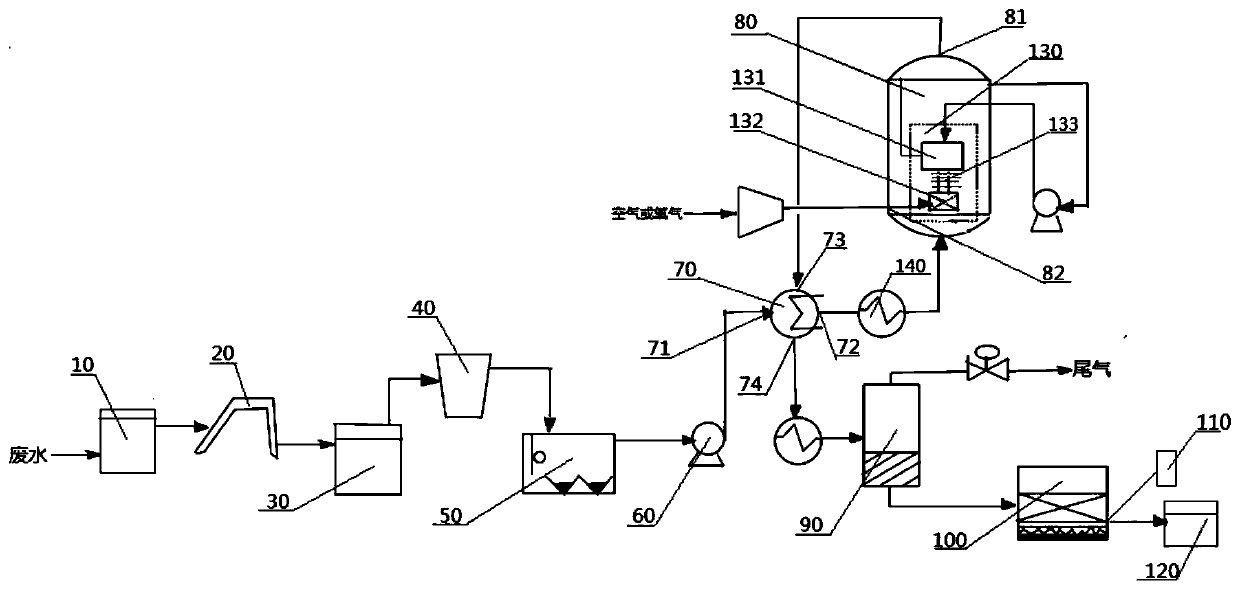

Built-in micro-interface papermaking wastewater treatment system and method

ActiveCN111573964AIncreased phase boundary areaImprove mass transfer effectWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationWater treatment systemVapor–liquid separator

The invention provides a built-in micro-interface papermaking wastewater treatment system and method. The treatment system comprises a papermaking wastewater tank, a bar screen machine, an adjusting tank, a centrifugal filter and a sedimentation tank which are connected in sequence, and further comprises a heat exchanger, a preheater, a wet oxidation reactor, a gas-liquid separator and a biodegradation tank, wherein a micro-interface unit used for dispersing broken gas into bubbles is arranged in the wet oxidation reactor, the micro-interface unit comprises a pneumatic micro-interface generator, a gas inlet is formed in the side wall of the wet oxidation reactor, and the gas inlet extends into the pneumatic micro-interface generator through a pipeline. According to the treatment system, the micro-interface unit is arranged in the wet oxidation reactor, so the temperature and the pressure of the papermaking wastewater treatment system are reduced, the consumption of air or oxygen is reduced, and the effects of low energy consumption and high treatment efficiency are achieved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

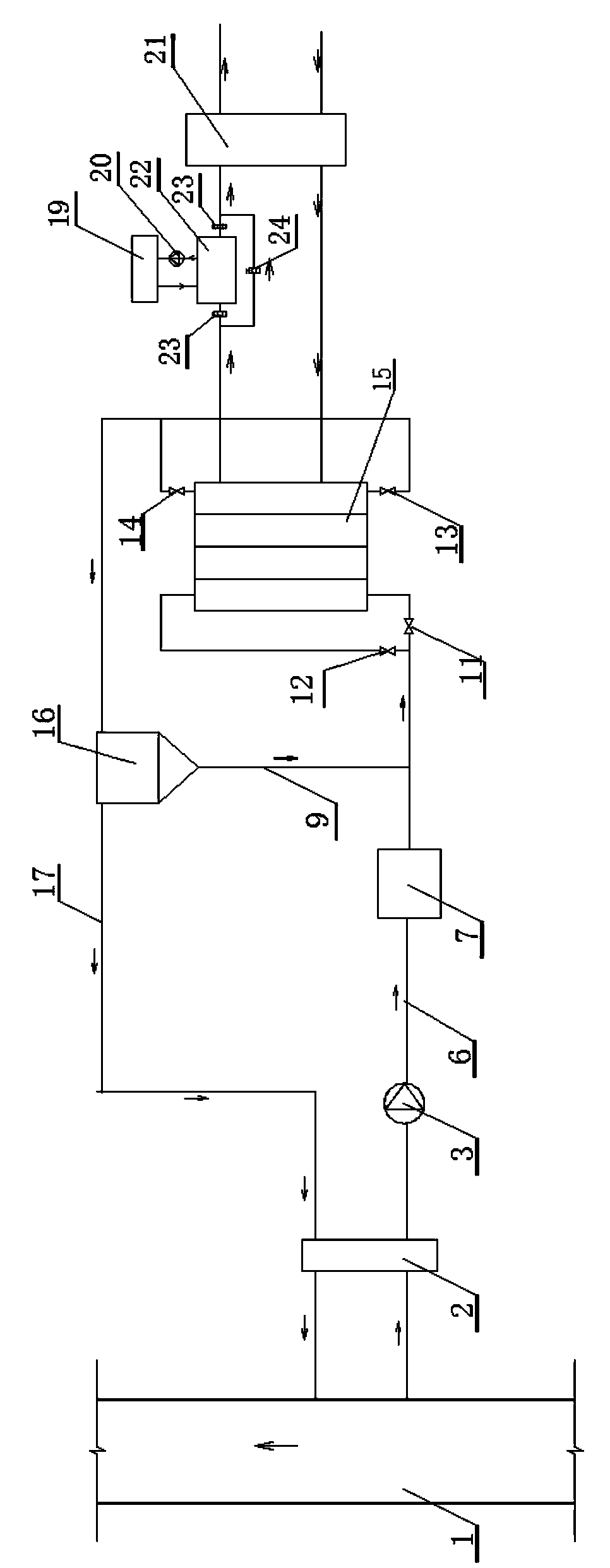

Self-cleaning heat transfer enhanced solar sewage source heat pump system

ActiveCN103615839AAvoid the situation of not being able to boot normallyIncrease water temperatureHeat pumpsEnvironmental resistanceWater source

Provided is a self-cleaning heat transfer enhanced solar sewage source heat pump system. Filtration is carried out on dirt impurities through a mechanical bar screen, a hair filter and other equipment, a control valve b, a control valve c, a control valve d and a control valve e are arranged in four sewage pipes connected to a sewage heat exchanger respectively, and back washing is carried out on a sewage pipeline through the switching of the opening and closing of the control valves. The problems that the dirt impurities block the pipeline, hair blocks heat-exchange equipment, the heat-exchange equipment is large in size due to dirt, the performance of the heat-exchange equipment is reduced and the heat-exchange equipment breaks down due to dirt water in the process that the sewage is used as cold and heat sources are solved thoroughly. Solar equipment is mounted on the water inlet of a water source heat pump to improve water temperature of inlet water, the problem that normal starting cannot be carried out due to the fact that the temperature of the inlet water is too low in winter, the heat exchange performance of the system is improved greatly, the safety, reliability and stability of the system are guaranteed, the self-cleaning heat transfer enhanced solar sewage source heat pump system can be applied to the field of carrying out cooling and heat supplying by using the sewage or surface water as low order cold and heat sources and using the heat pump technology, or be applied to cooling industrial equipment, and the self-cleaning heat transfer enhanced solar sewage source heat pump system is efficient and environmentally friendly.

Owner:大连葆光节能空调有限公司

Artificial wetland high-efficiency pre-aeration sewage treatment system

InactiveCN101585641AEasy processing conditionsImprove responseMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandWater storage tank

The invention relates to an artificial wetland high-efficiency pre-aeration sewage treatment system, which comprises a bar screen, a primary sedimentation tank, a venturi, a splash board and an artificial wetland connected in turn, wherein the bar screen is positioned in the front of the primary sedimentation tank; the inlet of the gradually reducing part of the venturi is connected with the upper part of the primary sedimentation tank through a high-pressure pump, the throat part is connected with the atmosphere through an air inlet pipe, and the outlet of the gradually expanding part is provided with a jet pipe extending forwards; and the splash board is positioned above the artificial wetland in front of the jet pipe. The artificial wetland adopts a horizontal baffling structure, the water outlet is provided with a water storage tank, and the water storage tank is provided with a backflow pipe connected with the water inlet end of the artificial wetland. The artificial wetland high-efficiency pre-aeration sewage treatment system has a simple structure and reasonable process, and through the high-efficiency aeration of the venturi and the splash board, the artificial wetland high-efficiency pre-aeration sewage treatment system improves the biochemical reaction types and the reaction speed in the artificial wetland, improves the surrounding environment, and is helpful to improve the purification degree of the yielding water of the artificial wetland. The artificial wetland high-efficiency pre-aeration sewage treatment system has the advantages of simple structure, convenient operation and good adaptability, allows the sewage quantity to have large range of variation, and is mainly adapted to the treatment of domestic sewage.

Owner:HAISIBOTE BEIJING SCIENE & TECH

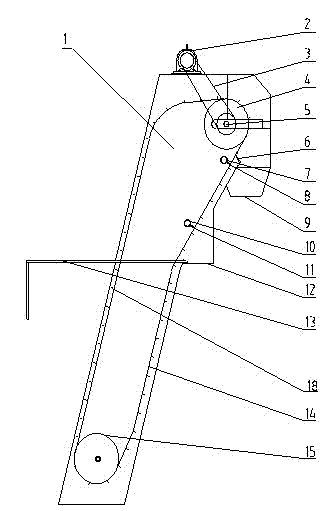

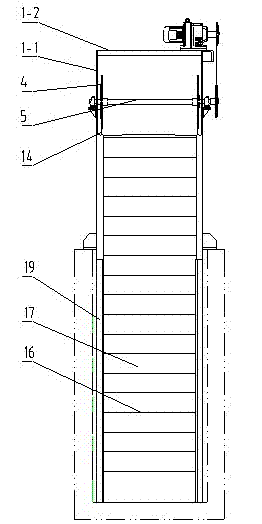

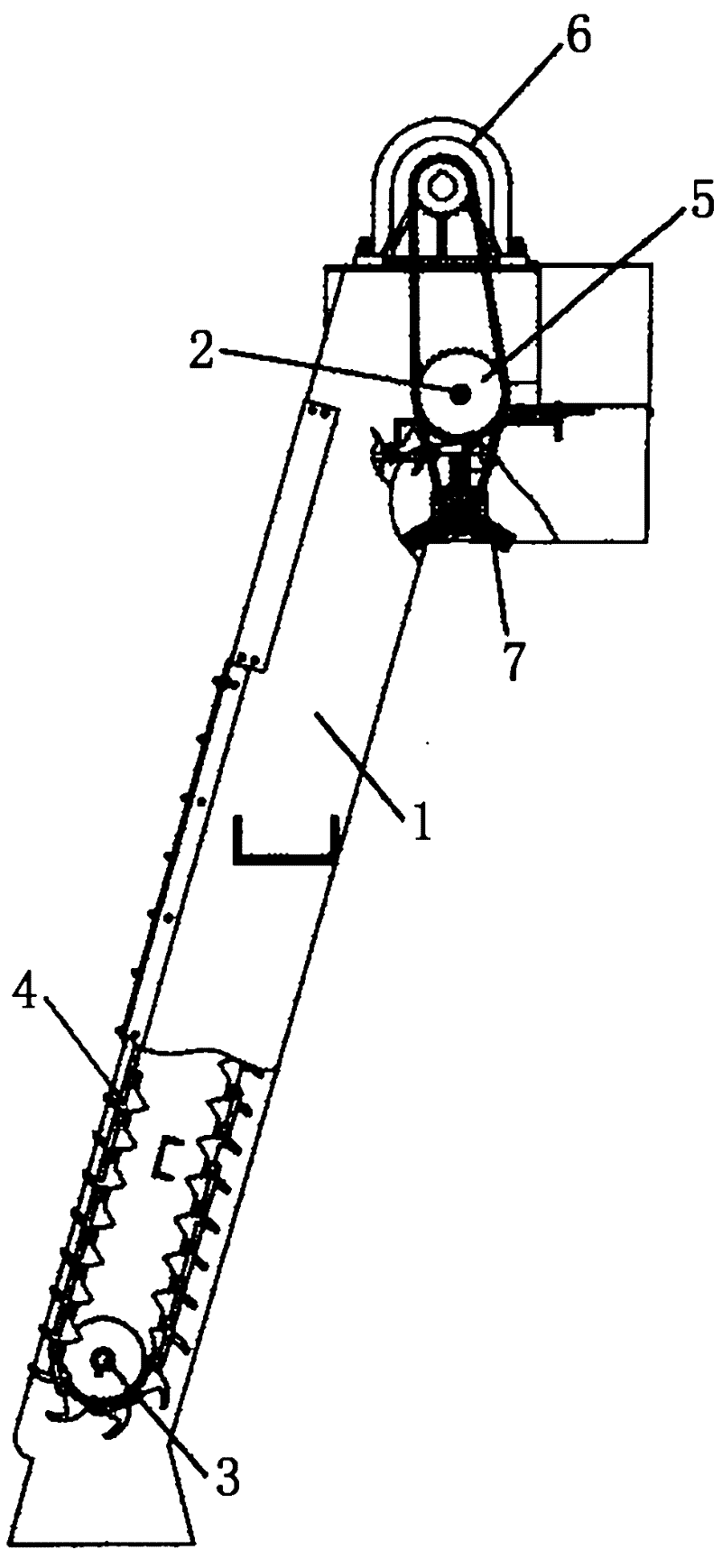

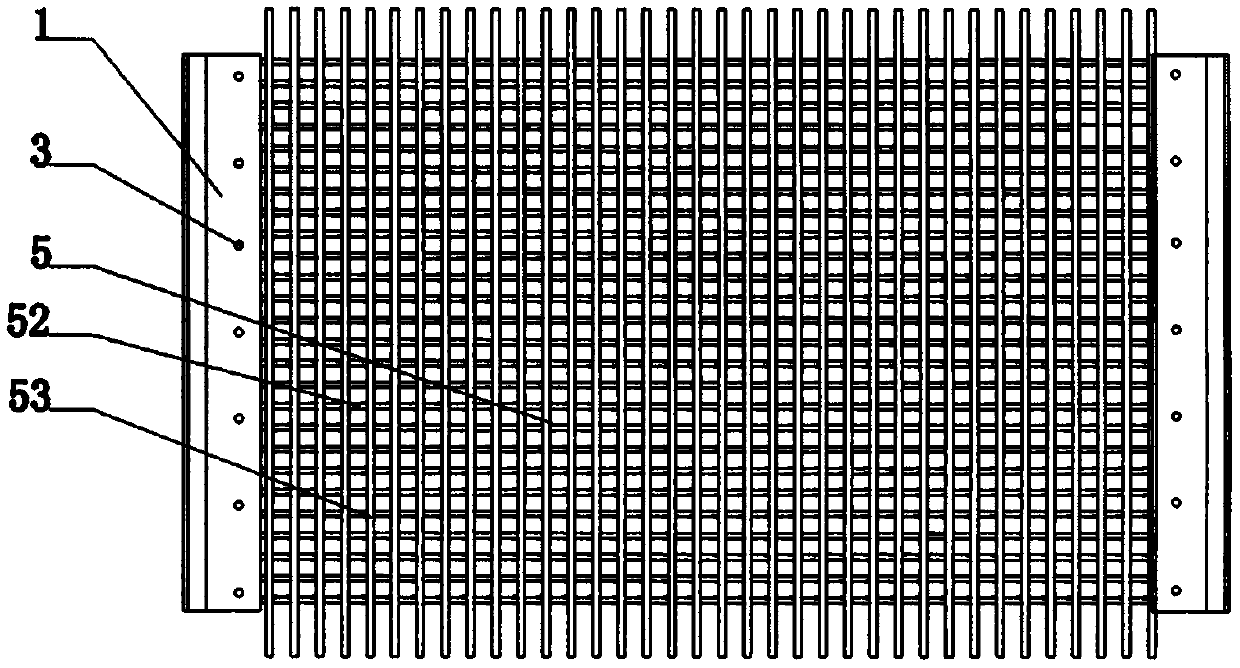

Rotary rake type bar screen machine

InactiveCN102398948ASimple structureLarge amount of treated water cubeWater/sewage treatmentBar screenSprocket

The invention discloses a rotary rake type bar screen machine. The rotary rake type bar screen machine is characterized in that: a circular rake tooth mesh belt is laid on the surface of a housing through an upper rotary shaft and a lower rotary shaft, two sprocket wheels are arranged side by side on one end of the upper rotary shaft, one of the sprocket wheels is connected with a transmission arranged on the top of the housing through a chain, and the other sprocket wheel is connected with a rotary removing brush arranged on the bottom of the upper end of the circular rake tooth mesh belt through a chain. By means of the arrangement, the rotary rake type bar screen machine can thoroughly fish litters in flowing water, the structure is simple, a large cubic amount of water can be treated, and labor can be saved.

Owner:山东金昊三扬环保机械有限公司

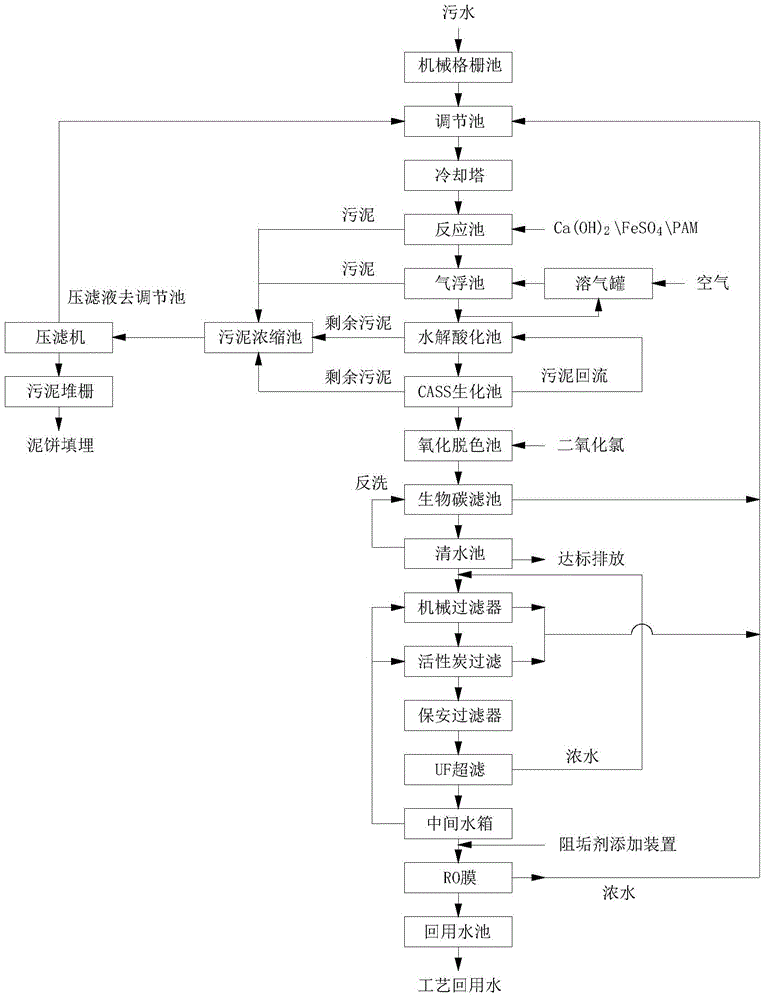

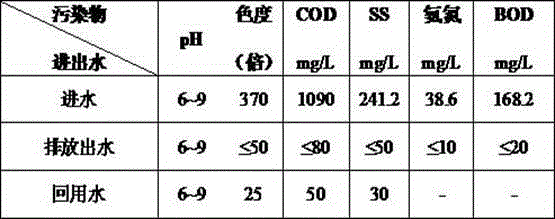

Method and device for treatment of high-temperature printing and dyeing wastewater

InactiveCN104370426ALow costProcess stabilityMultistage water/sewage treatmentWaste water treatment from textile industryActivated carbonCooling tower

A device for treatment of high-temperature printing and dyeing wastewater comprises a mechanical bar screen pool, an adjustment pool, a cooling tower, a reaction pool, a flotation pool, a hydrolysis acidification pool, a CASS biochemical pool, an oxidation decoloring pool, a biochar filter pool, a clean water pool, a mechanical filter pool, an activated carbon filter, a cartridge filter, a UF ultrafilter, a middle water tank, an RO (reverse osmosis) membrane and a recycling water pool. A wastewater treatment method which is low in cost, high in efficiency and technically stable is provided for treatment of high-temperature printing and dyeing wastewater. Effluent quality can meet the standard requirement of recyclability to production after treatment.

Owner:SHOURONG ENVIRONMENTAL TECH

Jet-pipe pre-aeration oxidation ditch sewage treatment system

InactiveCN101591088AImprove the airIncrease oxygen contentMultistage water/sewage treatmentSustainable biological treatmentNitrationEngineering

The invention relates to a jet-pipe pre-aeration oxidation ditch sewage treatment system, comprising a bar screen, a catchment sedimentation tank and an oxidation ditch, which are connected in turn; wherein, a Venturi is arranged between the catchment sedimentation tank and the oxidation ditch; the entrance of a converging part of the Venturi is connected with the upper part of the catchment sedimentation tank via a high-pressure pump; the throat of the Venturi is connected to atmosphere via an intake pipe; the exit of a diverging part of the Venturi is connected with the bottom of the oxidation ditch; the front end of the oxidation ditch is provided with a deep water area; the water in the deep water area is 2-2.5 times deeper than that in other areas of the oxidation ditch; the oxidation ditch is internally provided with a plurality of parallel baffle plates which divide space in the ditch into a plurality of parallel ditches connected end to end; a plurality of aeration rotary brushes are arranged at intervals in the parallel ditches connected end to end, therefore, an aerobic zone and an anoxic zone can be transformed in turn, wherein, oxidization and nitration reactions mainly take place in the aerobic zone and hydrolysis and denitrification reactions mainly take place in the anoxic zone. The system features good aeration effect, is provided with the efficiently oxidized deep water area, can eliminate organic pollution, has certain functions of denitrification and dephosphorization and is mainly applicable to treating domestic sewage and other similar organic sewages.

Owner:HAISIBOTE BEIJING SCIENE & TECH

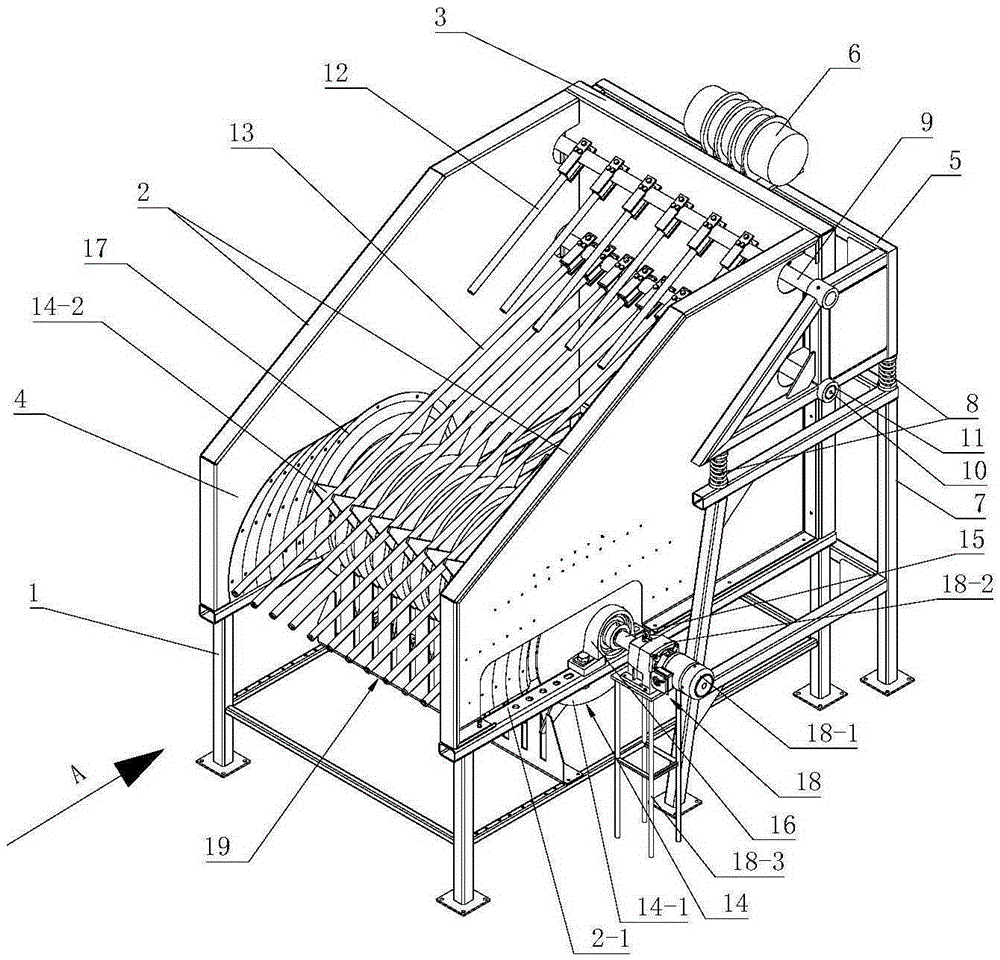

Adjustable vibration type bar screening equipment

The invention discloses adjustable vibration type bar screening equipment. The adjustable vibration type bar screening equipment comprises a frame, wherein two side plate and a back baffle plate are arranged at the upper end of the frame; the front ends of the two side plates are large material discharge ends; a vibration frame is arranged at the outer peripheries of the two side plates and the back baffle plate, and is supported on a vibration support frame in a floating manner through multiple vibration reducing springs; a vibration motor and first and second shafts, vertically arranged, are mounted on the vibration frame; multiple short bars are mounted on the first shaft to form an upper-layer bar screen; multiple long bars are mounted on the second shaft to form a lower-layer bar screen; poking drums consisting of drum bodies and multiple sets of poking teeth are arranged in the positions of the large material discharge ends, and are fixedly supported on the frame in a front-back adjusting manner; the two ends thereof are respectively provided with baffle plates; a driving mechanism is arranged outside the side plate at one side; and the lower ends of the multiple long bars are freely arranged on the drum bodies, and are inserted between the axially arranged poking teeth one by one. The equipment prolongs the service life of the bar screens, reduces the exciting force, the vibration frequency and the power of the vibration motor, and improves the large material discharge speed of the bar screens.

Owner:天津百利阳光环保设备有限公司

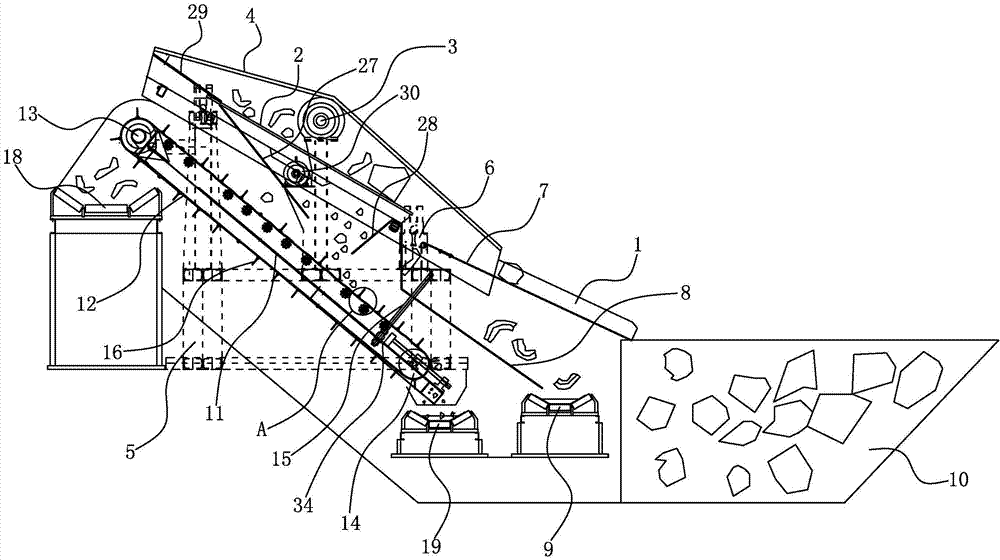

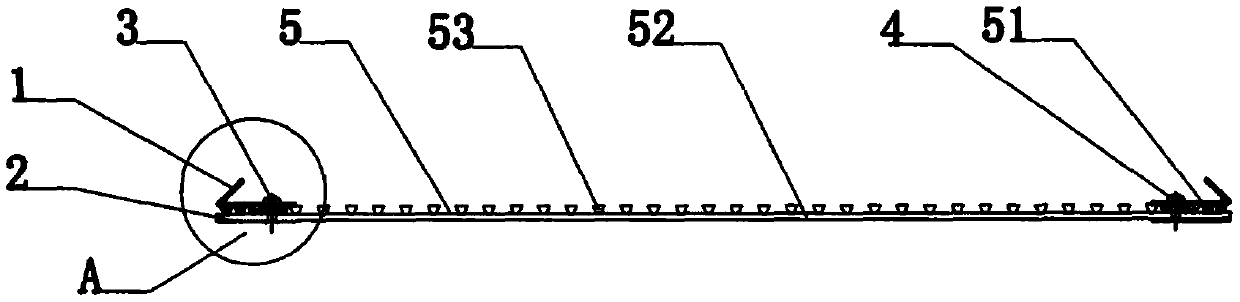

Presorting device for waste disposal

ActiveCN103934204AConducive to screeningSimple and fast operationSievingConveyorsEngineeringVibration exciter

The invention prelates to a separating device for solid waste, in particular to a presorting device for waste disposal. The purpose is to provide the presorting device for waste disposal, wherein the presorting device is easy and convenient to operate and high in efficiency and can perform fine screening processing on waste. The presorting device comprises a bar waste throwing sorting machine and a bouncing sorting conveyor. The bar waste throwing sorting machine comprises a bar type vibration screen and a big heavy sliding chute (1), the bar type vibration screen comprises a bar screen (2), a vibration exciter (3), a baffle (4), a vibration reduction spring and a first support (5). The upper end of the big heavy sliding chute is fixed to the baffle, and a gap is formed between the upper end of the big heavy sliding chute and the lower end of the bar screen. The bouncing sorting conveyor is located below the bar waste throwing sorting machine and fixed to a second support (11), the bouncing sorting conveyor comprises a conveying belt (12), and a drive roller (13) and a driven roller (14). The drive roller and the driven roller are installed at the two ends of the second support respectively and sleeved with the conveying belt.

Owner:BEIJING GREEN USE ENVIRONMENTAL PROTECTION SCI & TECH

Blowing and sucking type dust removal corn thresher with fork type screening

The invention relates to a blowing and sucking type dust removal corn thresher with fork type screening. The corn thresher comprises a diesel engine, a loading packing auger, a threshing host machine, vibrating screens, a blower, a lifting packing auger and a rack, wherein the host machine of the thresher is fixed on the rack, a slag charge screen moving in a reciprocating manner is arranged at the front end of the threshing host machine, three layers of vibrating screens, namely, a fork bar screen, a macroporous screen and a microporous screen, are sequentially arranged on the rack below the threshing host machine, and are fixed on a screen frame, the blower is arranged at the left ends of the vibrating screens, and a suction blower is arranged at the right ends of the vibrating screens, roller wheels are arranged on the screen frame, a lower collector is arranged at the lower end of the side surface of the threshing host machine, the lifting packing auger is arranged on the lower collector, and an upper collector and a bagging mechanism are arranged at the top end of the lifting packing auger. The blowing and sucking type dust removal corn thresher with fork type screening has the advantages that the threshing speed is quick, the yield is high, the suction blower and the fork type screening are adopted, the phenomenon of screen blocking is solved, the environmental protection and no raising dust in the whole course are realized, the corn threshing quality is good, and the service life of the thresher is prolonged.

Owner:王显铎

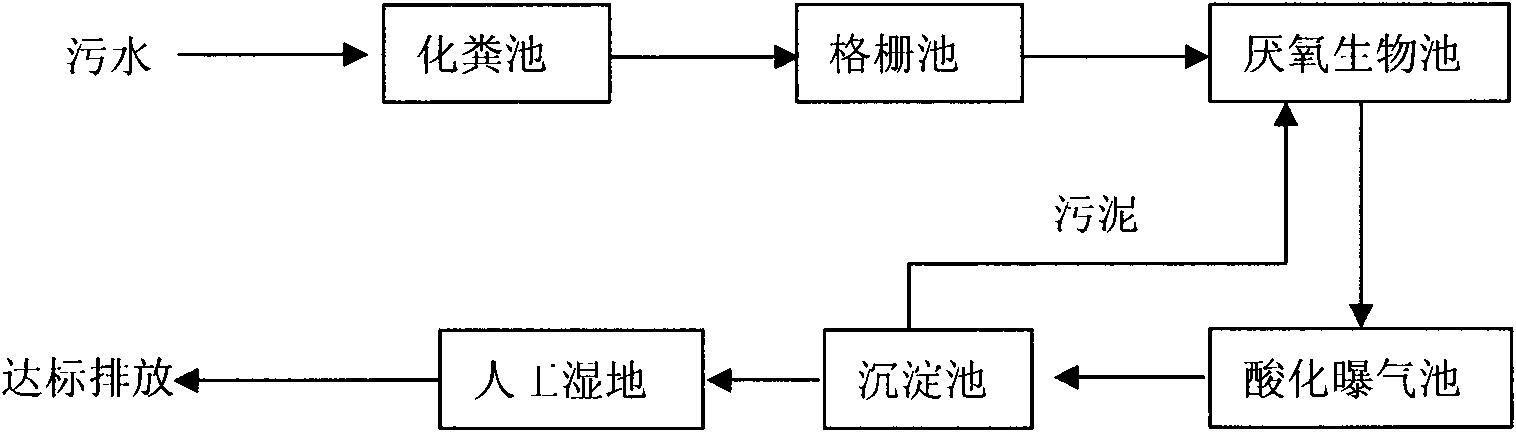

Purifying process of domestic sewage in residential centralized area

InactiveCN103449657AIncrease oxygen contentFacilitate subsequent aerobic treatmentMultistage water/sewage treatmentConstructed wetlandSmall footprint

The invention relates to a purifying process of domestic sewage in a residential centralized area. The purifying process is composed of a plurality of parts: a septic tank, a bar screen tank, an anaerobic biological tank, an acidification aeration tank, a sedimentation tank and a constructed wetland. The purifying process has high sewage purification efficiency, can effectively reduce the contents of BOD and COD in the sewage, has small occupied area and low running cost, and is not limited by air temperatures. The purifying process can be widely applied in rural domestic sewage treatment, small town domestic sewage treatment and tourist area sewage treatment.

Owner:TIANJIN BEIFANG LANDSCAPE ECOLOGY INST OF SCI & TECH

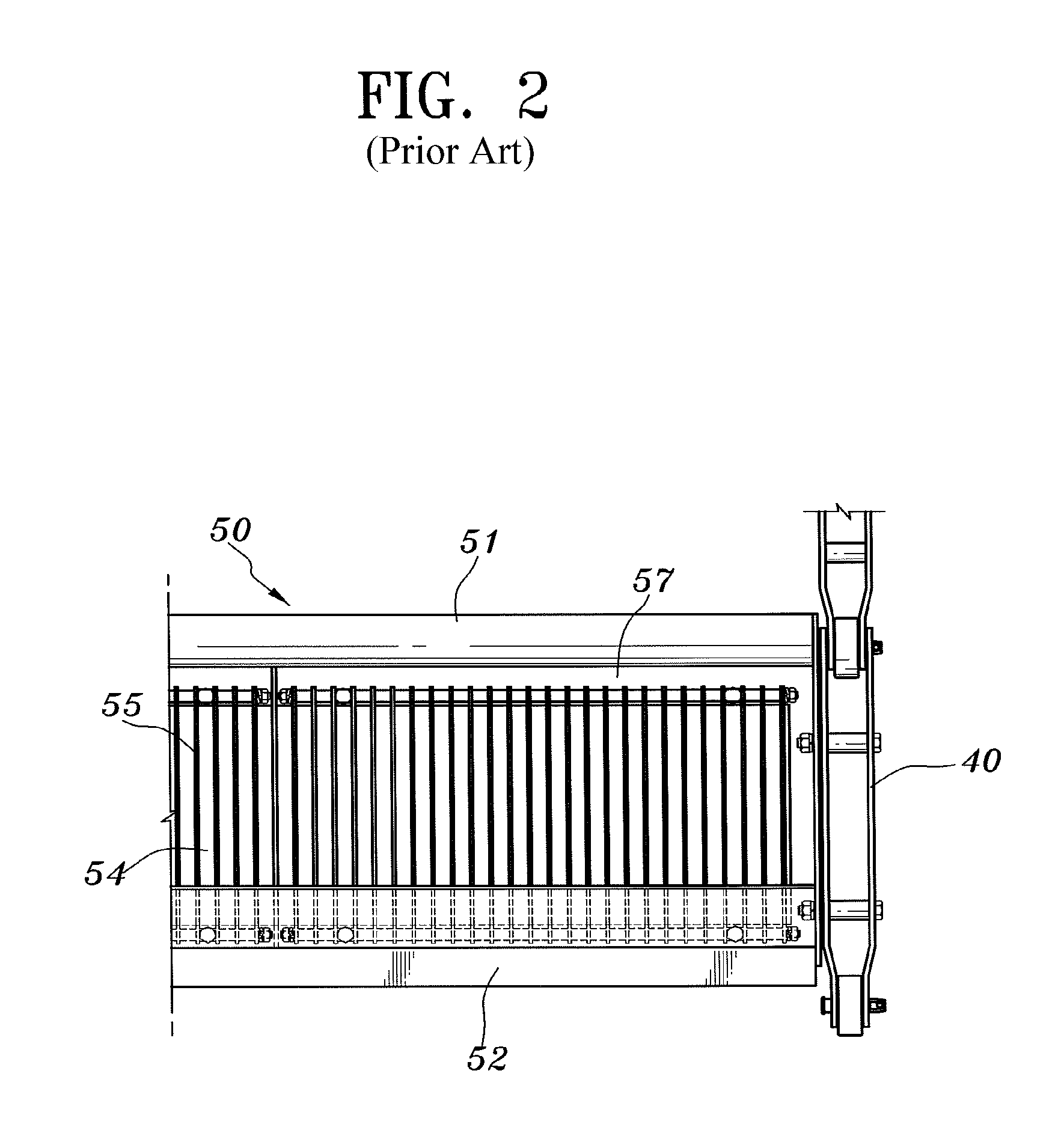

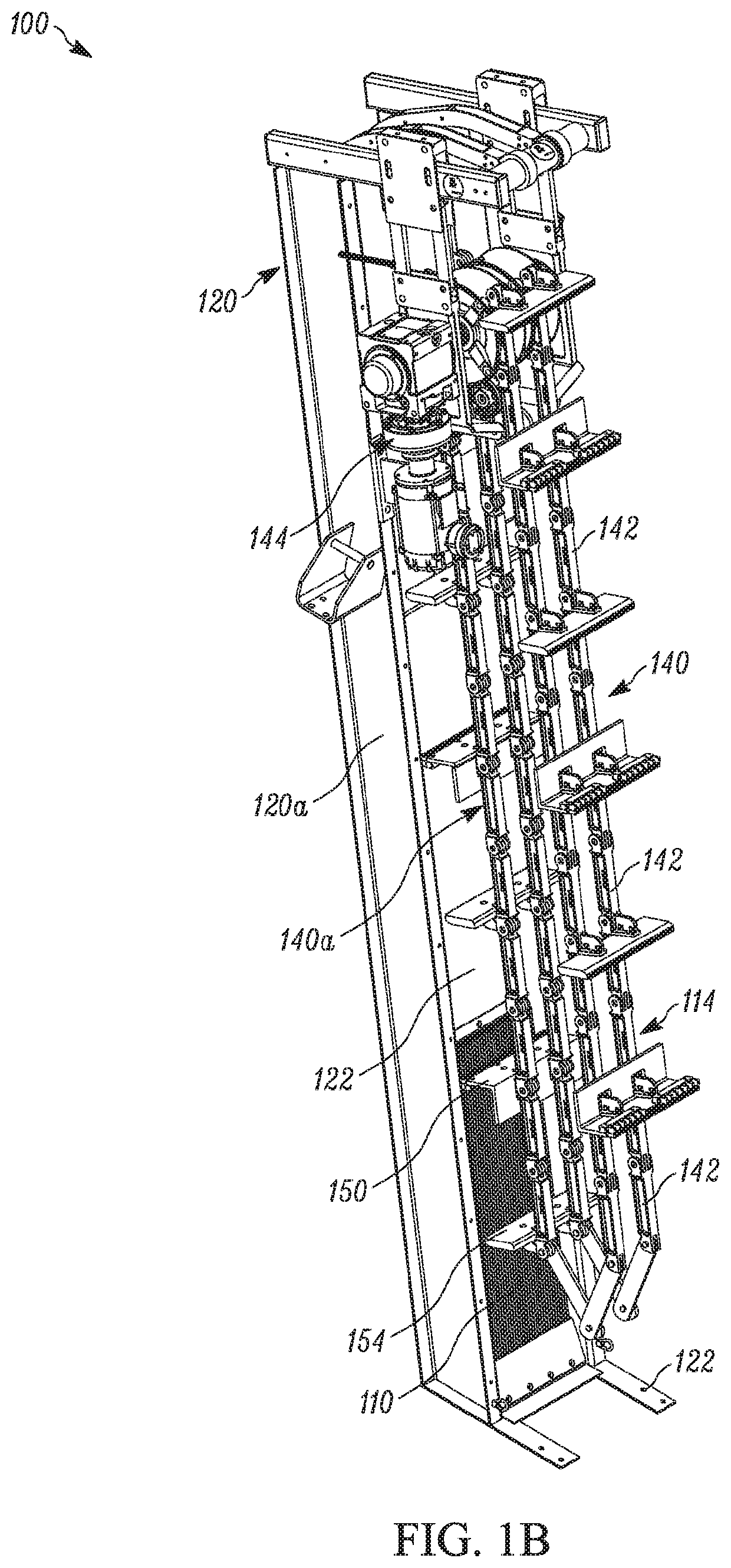

Bar screen filter apparatus and method

ActiveUS20200149239A1Clearance can be providedGood removal effectBarrages/weirsSewerage structuresBar screenEngineering

Apparatus for removing debris from channeled water that includes a bar screen assembly. The assembly includes a plurality of spaced apart screen bars, each bar having an upstream edge and a downstream edge and distal ends to which U-shaped clips are attached. Each of the clips has a bar engaging portion and a cross member engaging portion that attaches to an associated cross member. The clips operate to space the trailing edge of the screen bars a predetermined distance from associated cross members and allow easy replacement of a bar. A continuous conveyor carries a plurality of rakes having a plurality of spaced apart tines which are adapted to fit between the screen bars as the rake is moved along the bars by the conveyor. The tines of the rake have a length that substantially spans the distance between the leading edge and trailing edge of a bar, so that tips of the rake tines extend to at least the trailing edge of an associated bar. Intermediate clips may be used to support the intermediate section of the screen bars.

Owner:PARKSON

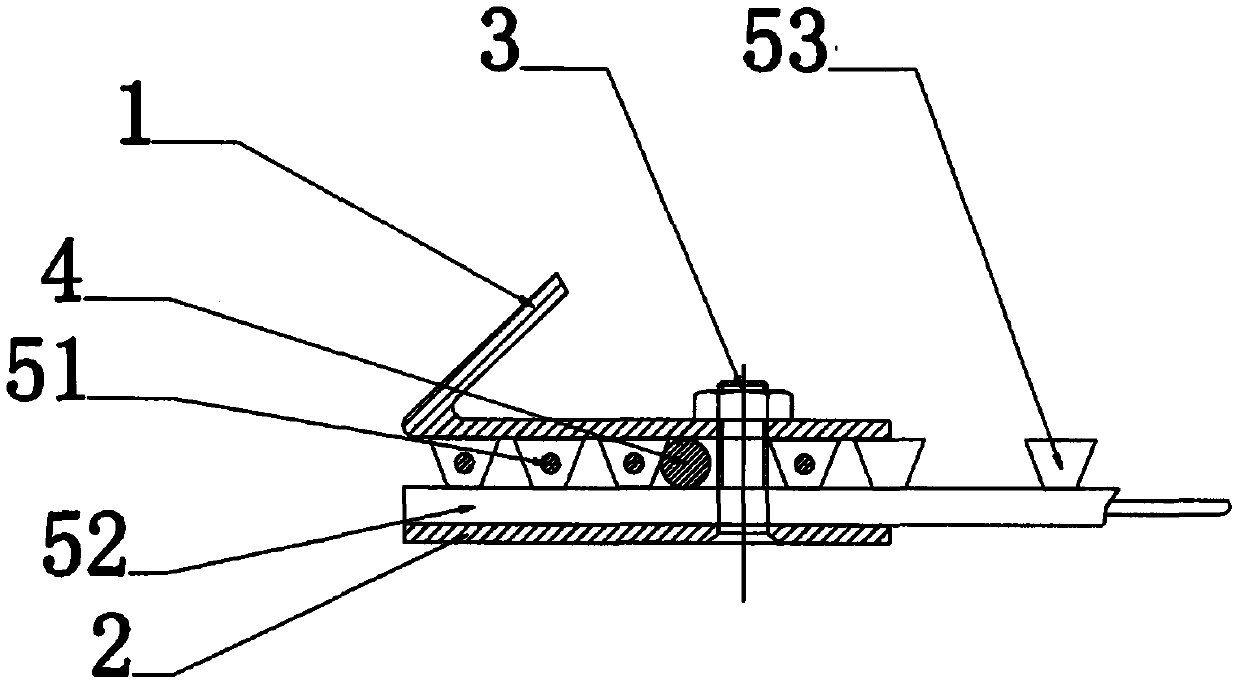

High-resilience anti-blocking polyurethane bar screen and preparation method thereof

InactiveCN111014028AWear-resistantStrong toughnessSievingScreeningPolymer scienceHigh wear resistance

A high-resilience anti-blocking polyurethane bar screen is composed of tensioning hooks, a fixing plate, bolts, round steel and a polyurethane bar screen surface. The polyurethane bar screen surface is characterized in that a steel wire rope core polyurethane coated rubber bar is used as a reinforcing area, aramid fiber rope core polyurethane coated rubber bars are used as warps, frameless polyurethane coated rubber bars are used as wefts, and joint points are subjected to hot melting welding to form screening areas; and all screen pores of the screen surface are inverted-cone-shaped. The production process comprises the following steps: firstly, trapezoidal-section coated rods are produced on an extruder by taking a steel wire rope, an aramid rope or frameless different materials as corewires; secondly, hot melting welding is conducted on screen mesh joint points according to hole pattern requirements, the steel wire rope core polyurethane coated bar is arranged at the installation position of a tensioning hook, the aramid fiber rope core polyurethane coated rubber bars are set as the warps, the frameless polyurethane coated rubber bars are set as the wefts; and thirdly, the tensioning hook, the round steel and a fixing plate are tightened through bolts at the edge of the screen. The high-resilience anti-blocking polyurethane bar screen has the characteristics of high wear resistance, good elasticity, strong toughness, strong screen pore deformability and excellent self-cleaning effect.

Owner:ANHUI FANGYUAN PLASTIC & RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com