Rolling gate type pseudo-ginseng harvesting machine dragged by four-wheeled tractor

A technology for tractors and harvesters, applied in the field of agricultural machinery, can solve the problems of high labor intensity, high operating costs, large losses, etc., and achieve the effect of increasing the adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

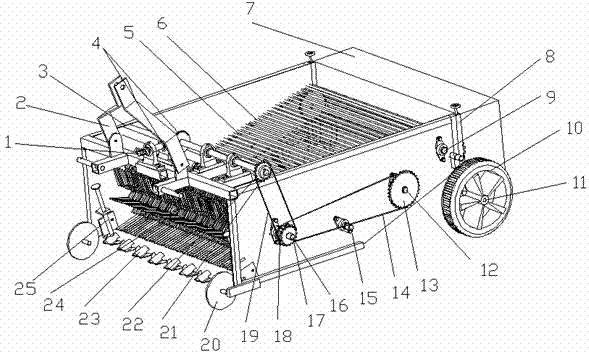

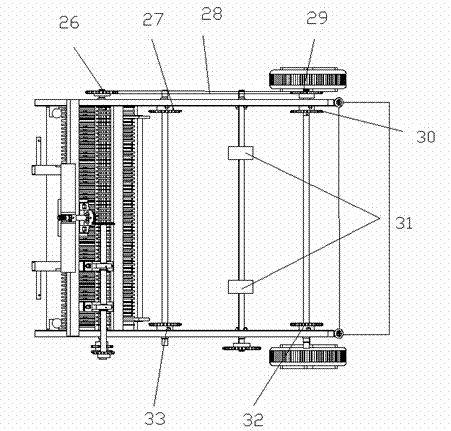

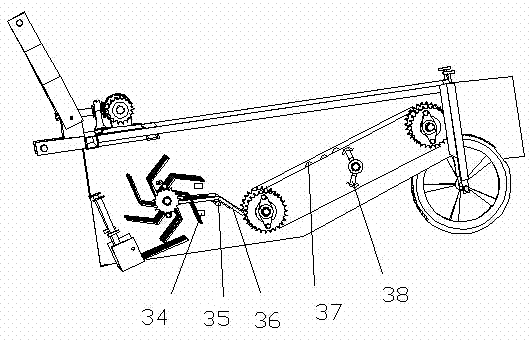

[0024] Embodiment 1: as Figure 1-3 As shown, a rolling grid type notoginseng harvester pulled by a four-wheel tractor includes a power input shaft 1, a traction frame 2, a frame 3, a bevel gear drive 4, a chain I 5, a steel bar screen 6, a collection box 7, an adjustment Lead screw 8, steel bar screen rear shaft 9, adjusting wheel 10, adjusting wheel shaft 11, adjustable cam mechanism shaft 12, auxiliary drive sprocket IV13, chain II14, steel bar screen front axle 15, auxiliary drive sprocket I16, rolling grid Main shaft 17, secondary transmission sprocket Ⅱ18, chain Ⅲ19, retaining plate 20, transmission main shaft 21, main transmission sprocket 22, excavating shovel 23, rolling grid 24, excavating shovel adjustment lever 25, secondary transmission sprocket Ⅲ26, secondary transmission chain Wheel Ⅷ 27, chain Ⅳ 28, secondary drive sprocket Ⅴ29, secondary drive sprocket Ⅵ30, arc plate 31, secondary drive sprocket Ⅶ32, secondary drive sprocket Ⅸ 33, block 34, driven jitter grid ...

Embodiment 2

[0033] Embodiment 2: as Figure 1-3 As shown, it is basically similar to Embodiment 1, except that the grid gaps of the excavating shovel 23 and the rolling grid 24 are interlaced, and the grid gaps of the driven shaking grid shaft 35 and the rolling grid 24 are mutually interlaced. staggered.

Embodiment 3

[0034] Embodiment 3: as Figure 1-3 As shown, a rolling grid type notoginseng harvester pulled by a four-wheel tractor includes a power input shaft 1, a traction frame 2, a frame 3, a bevel gear drive 4, a chain I 5, a steel bar screen 6, a collection box 7, an adjustment Lead screw 8, steel bar screen rear shaft 9, adjusting wheel 10, adjusting wheel shaft 11, adjustable cam mechanism shaft 12, auxiliary drive sprocket IV13, chain II14, steel bar screen front axle 15, auxiliary drive sprocket I16, rolling grid Main shaft 17, secondary transmission sprocket Ⅱ18, chain Ⅲ19, retaining plate 20, transmission main shaft 21, main transmission sprocket 22, excavating shovel 23, rolling grid 24, excavating shovel adjustment lever 25, secondary transmission sprocket Ⅲ26, secondary transmission chain Wheel Ⅷ 27, chain Ⅳ 28, secondary drive sprocket Ⅴ29, secondary drive sprocket Ⅵ30, arc plate 31, secondary drive sprocket Ⅶ32, secondary drive sprocket Ⅸ 33, block 34, driven jitter grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com