Processing machinery for red date

A processing machine and jujube technology, applied in metal processing, etc., can solve problems such as uneven slices, unsuitability for mechanized production, and heavy manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

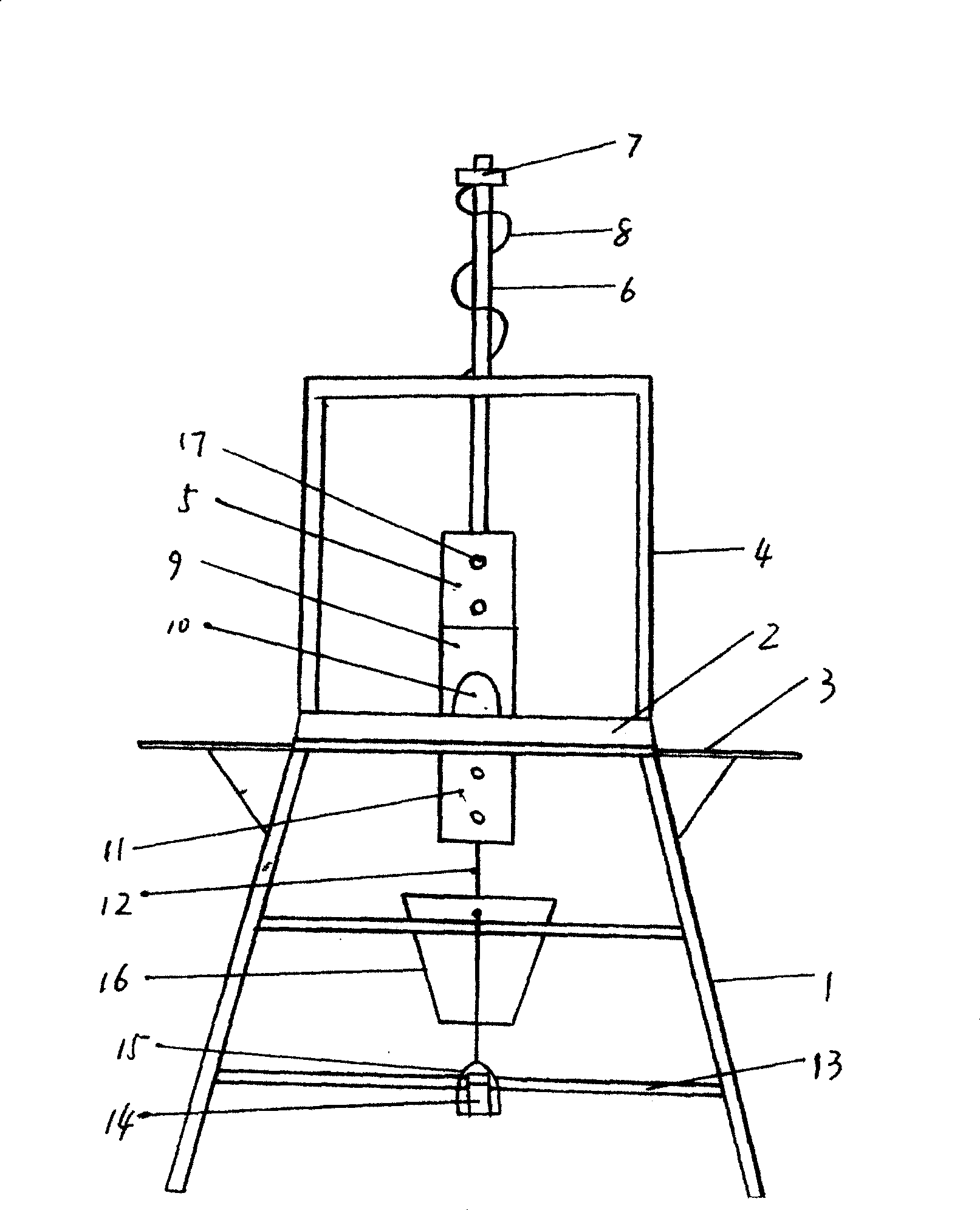

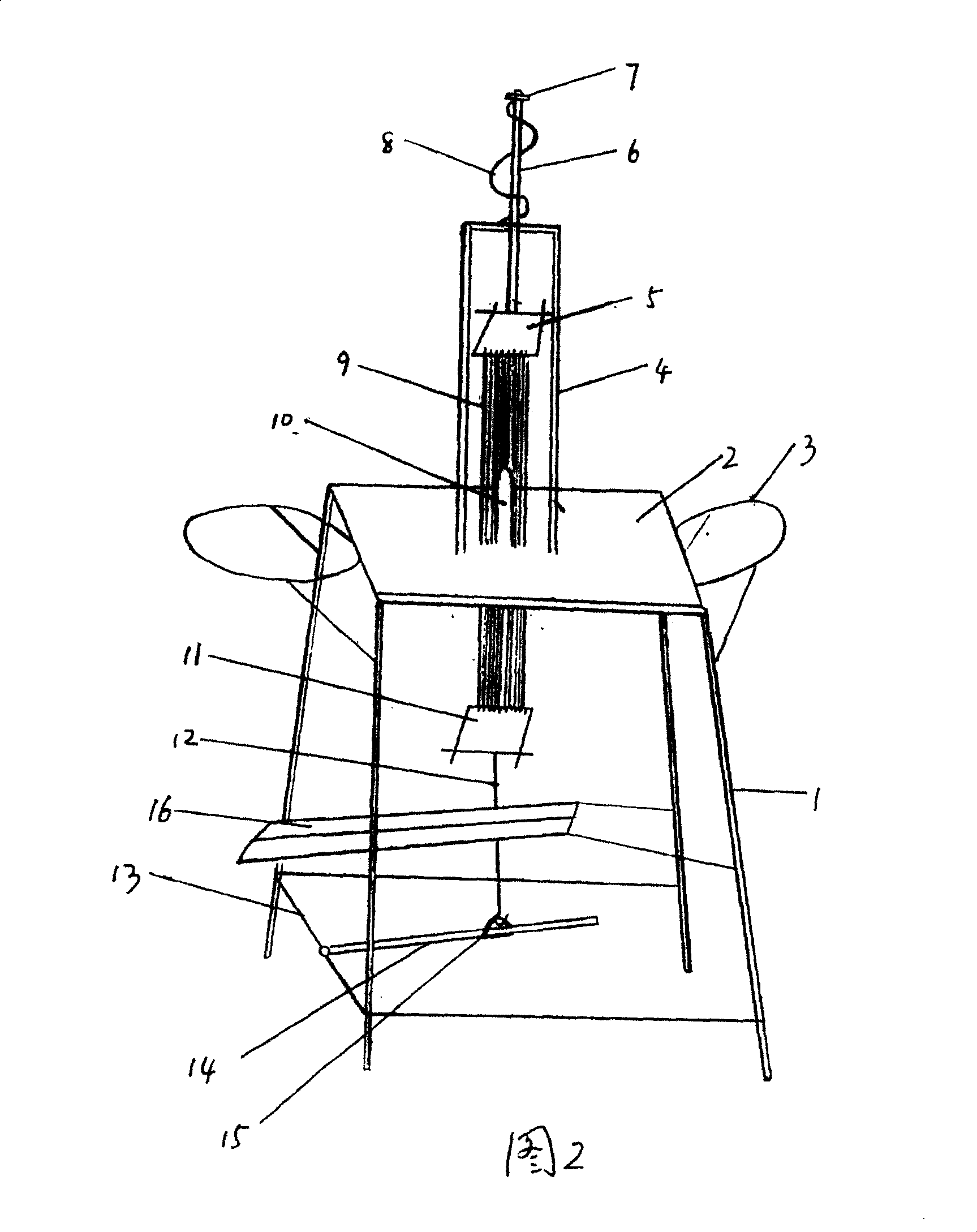

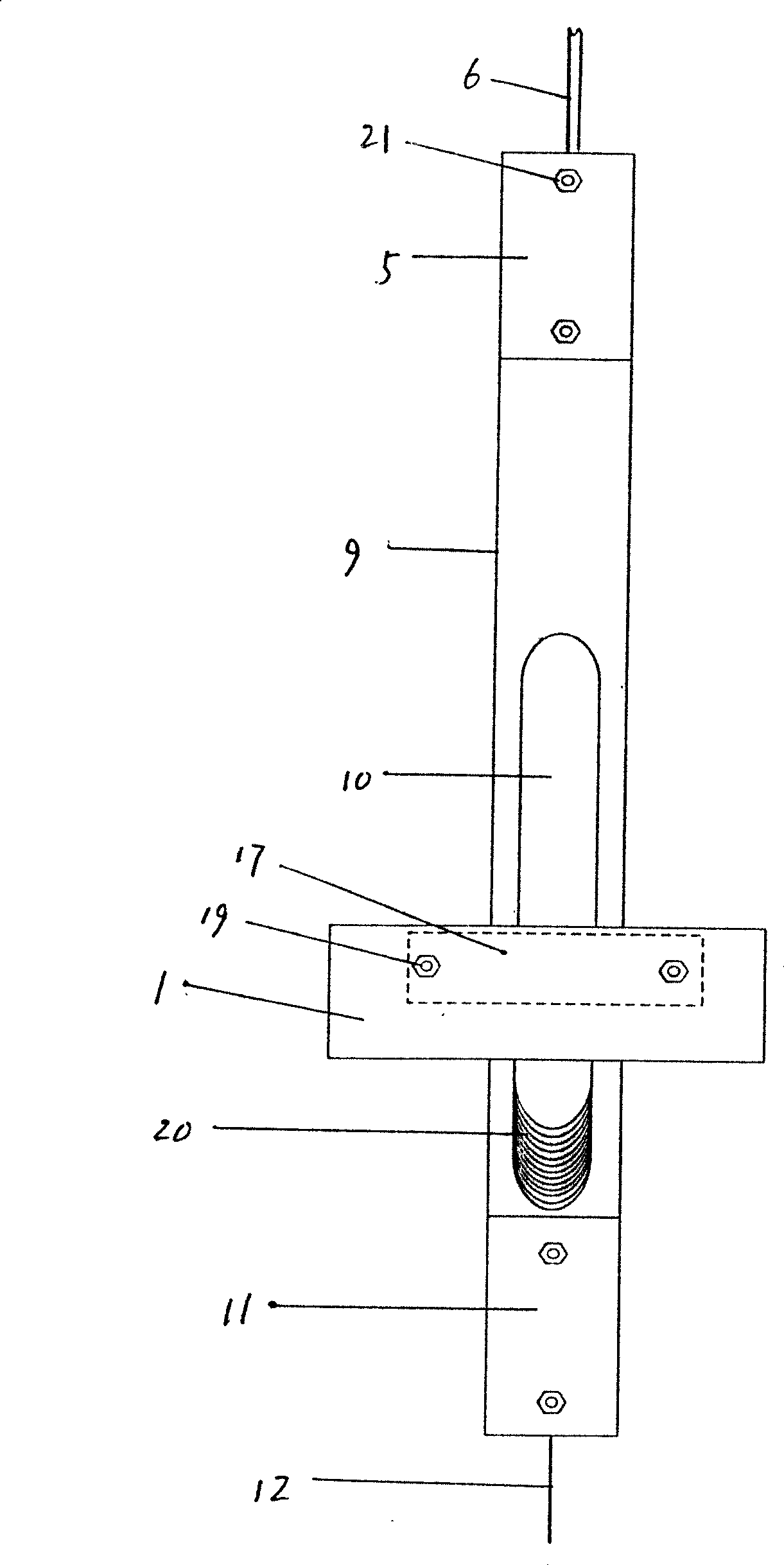

[0009] Depend on figure 1 , Figure 4 Given, the present invention comprises support 1 and workbench 2, and the middle part of support 1 is equipped with the slicing device that the thickness control plate 9 that moves up and down and blade 17 constitutes, and thickness control plate and blade are arranged alternately, and blade 17 is fixed through bolt rod 19 On the bracket 1, the two ends of the thickness control plate 9 are respectively equipped with a connecting frame and a connecting rod by bolts 21, and the connecting rod 6 of the upper connecting frame 5 passes through the upper bracket 4 and is mounted on the upper bracket 4 by a spring 8 and a fixing screw 7. The connecting rod 12 of the lower connecting frame 11 is installed on the pedal power plate 14 through the hanging ring 15, and one end of the pedal power plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com