Presorting device for waste disposal

A technology for waste treatment and pre-sorting, which is applied in grading, solid separation, transportation and packaging, etc. It can solve the problems of cumbersome operation, low efficiency, mixed with light strips, etc., and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

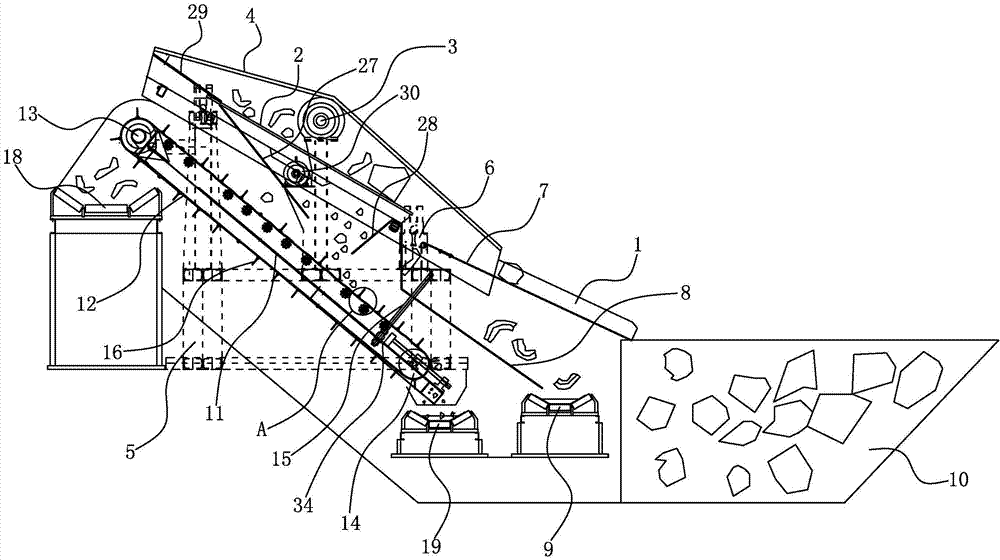

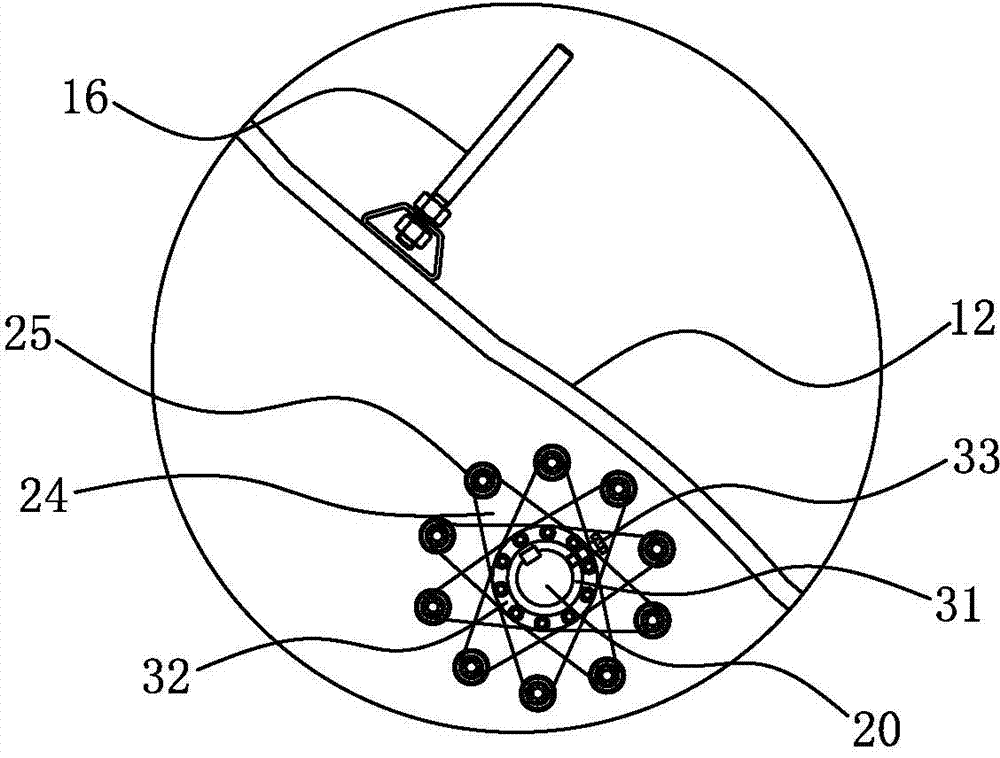

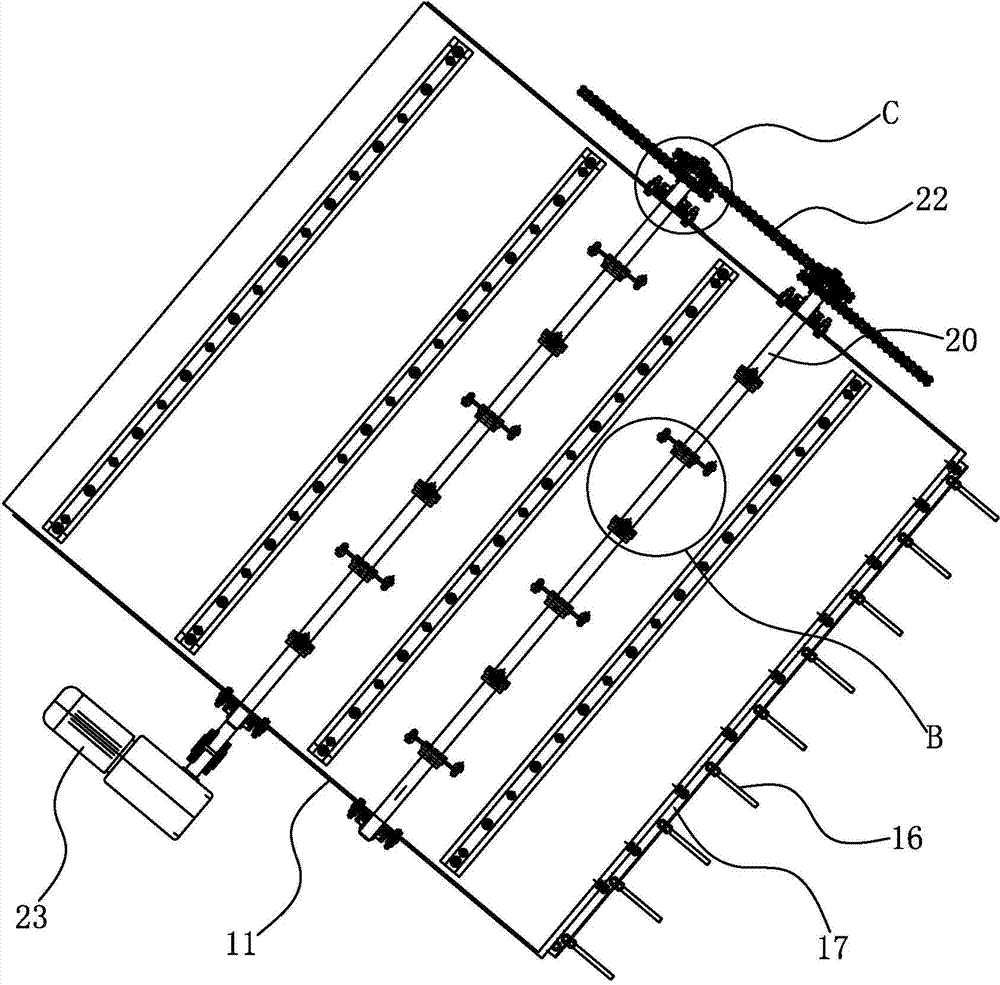

[0027] Such as figure 1 As shown, for the clarity of the view, the first bracket 5 in this figure is drawn with a dotted line, and the garbage treatment pre-sorting device of the present invention includes a rod parabolic sorting machine and a bouncing sorting conveyor. The bar parabolic separator includes a bar vibrating screen and a large heavy object chute 1, and the bar vibrating screen includes a bar screen 2, a vibrator 3, a baffle plate 4, and a damping spring (not shown in the figure) and the first bracket 5 . The bar screen 2 is installed on the first bracket 5 through a damping spring, and the front and rear sides of the bar screen 2 are respectively fixed with a said baffle plate 4 , and the baffle plates 4 are also fixedly arranged on the first bracket 5 . The vibrator 3 is installed on the first bracket 5, and the first motor 30 installed on the first bracket 5 makes the eccentric mass in the vibrator 3 rotate at high speed through the V-belt, and the running ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com