Method for treating paint waste water

A treatment method and wastewater technology, which is applied in flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high wastewater lifting costs and filter blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

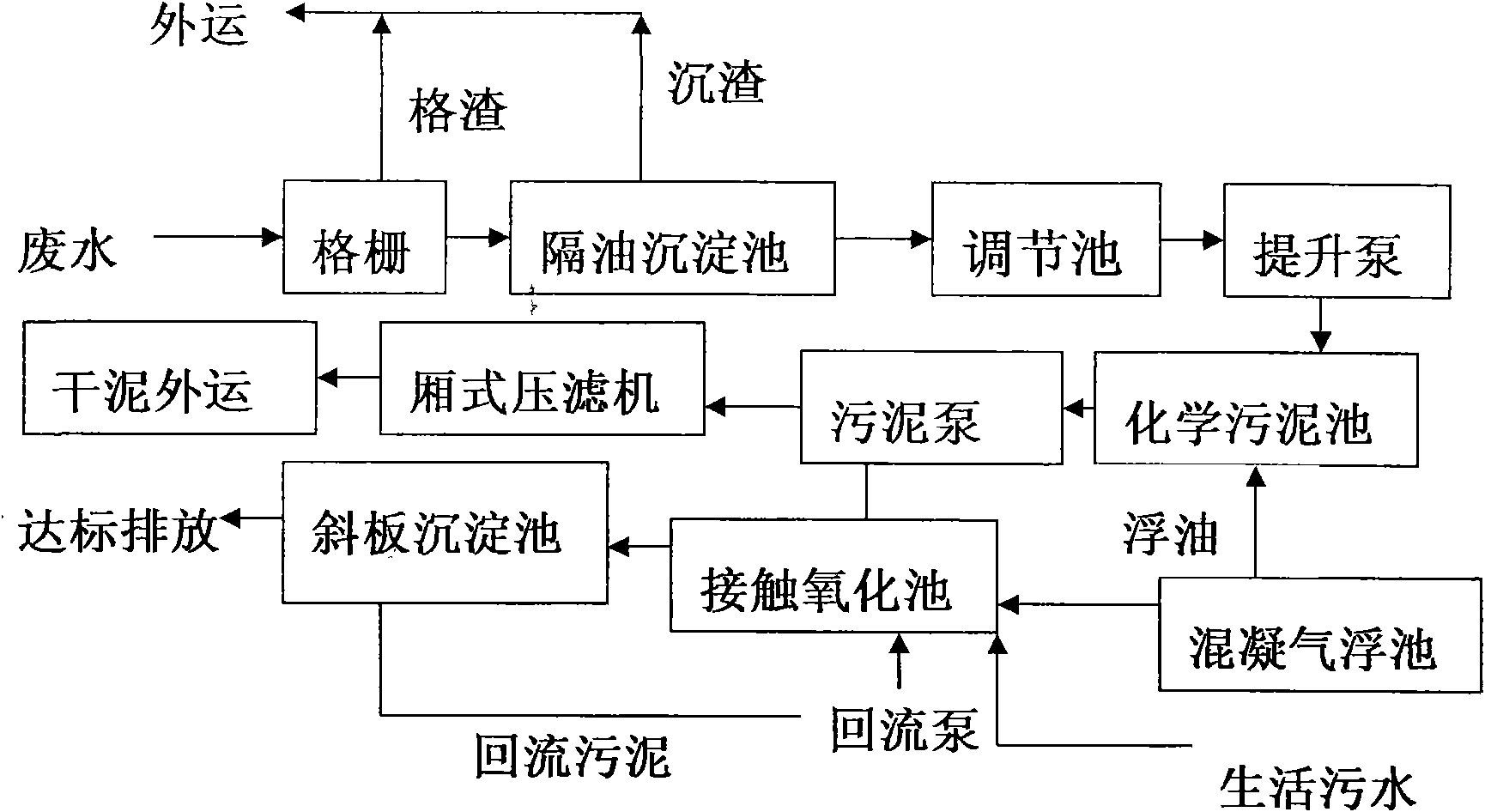

Image

Examples

Embodiment Construction

[0011] (1) The paint wastewater generated during the production process passes through the grid before entering the treatment system to intercept larger suspended and floating substances, so as to reduce the treatment load of subsequent treatment structures;

[0012] (2) After that, the wastewater enters the oil separation sedimentation tank to remove part of the slick oil and COD. The oil separation sedimentation tank adopts manual oil skimming to remove slag; the wastewater then enters the adjustment tank to adjust the water quality and quantity, and provide stable hydraulic load and organic load for subsequent treatment. , the residence time t of the wastewater in the regulating tank is 8 hours; the wastewater regulated by the regulating tank is pumped into the air flotation tank; in the air flotation tank, the paint wastewater is removed most of the oil by air flotation;

[0013] (3) The wastewater after air flotation treatment enters the biological contact oxidation tank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com