Pretreatment method of stale refuse

A pretreatment and garbage technology, applied in the direction of solid waste removal, etc., can solve the problems of rapid storage capacity consumption, closure, secondary pollution, etc., and achieve the effect of solving secondary pollution and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] Stale garbage pretreatment method of the present invention, its preferred embodiment is:

[0028] Include steps:

[0029] The first step, excavation: Excavate the old garbage with an excavator, transport it to the comprehensive garbage treatment plant with a closed garbage transport vehicle, and stack it at the loading place of the apron feeder;

[0030] The second step, feeding: the loading truck transports the garbage to the apron feeder, and the apron feeder feeds the rod sieve through the belt conveyor;

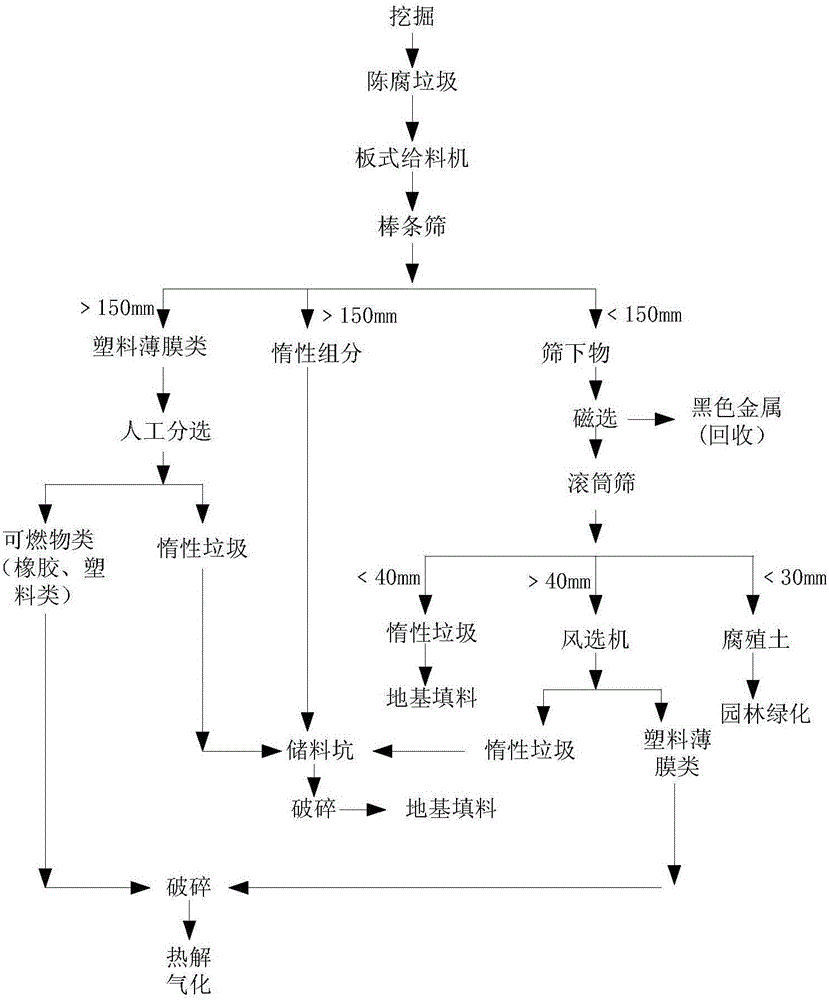

[0031] The third step, pre-screening: use the rod sieve to screen the garbage for the first time, and separate out three types of garbage with different densities or sizes;

[0032] The fourth step, magnetic separation: the undersize after the bar sieve is screened is separated by a magnetic separator to obtain ferrous metals;

[0033] The fifth step is the multi-stage screening of the trommel sieve: the undergrowth of the bar sieve enters the trommel sieve, and ...

specific Embodiment

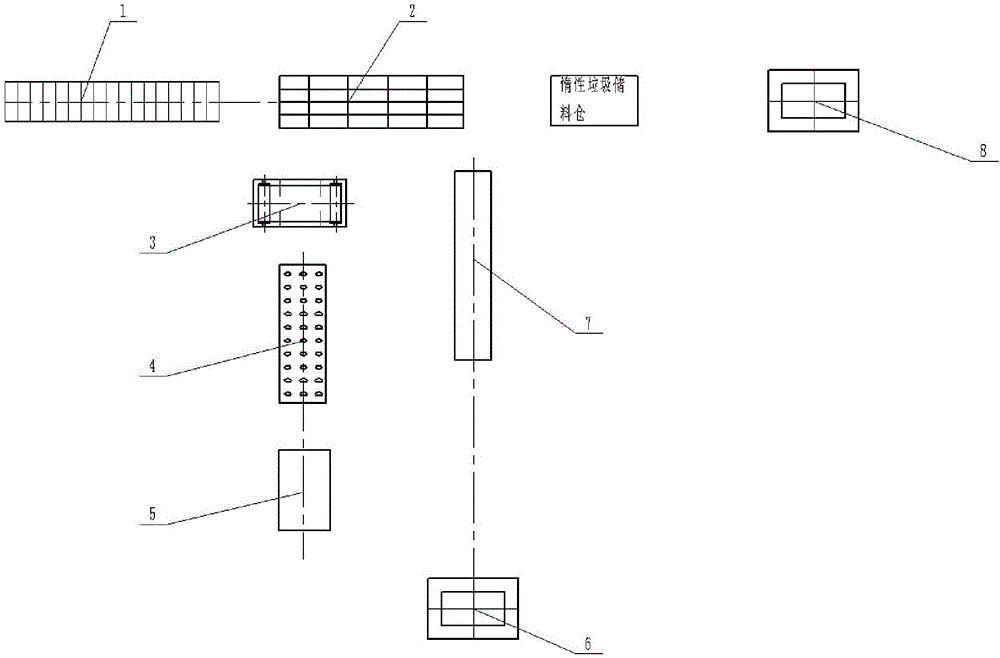

[0056] Please see attached figure 1 And attached figure 2 , a kind of obsolete garbage pretreatment method provided by the invention comprises the following processing steps:

[0057] The first step is to dig. Excavate the obsolete garbage, transport the obsolete garbage to the comprehensive garbage disposal site with a closed garbage truck, and stack it at the loading place of the apron feeder;

[0058] The second step is loading. The loading truck continuously lifts the garbage to the apron feeder, and the belt conveyor sends the garbage to the bar screen for the first screening;

[0059] The third step is pre-screening. Utilizing the difference in specific gravity and friction between the bar sieve and the sieve plate, when the sieve is transported to the lower end of the bar sieve, different ejection velocities are generated, and the two kinds of garbage with different specific gravity fall to different parts at the lower end of the bar sieve. At the distance, the ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com