High-resilience anti-blocking polyurethane bar screen and preparation method thereof

A polyurethane, high-resilience technology, applied in chemical instruments and methods, nets, filters, etc., can solve the problems of affecting the screening effect, failure of the screening area, affecting the screening efficiency, etc., and achieve excellent self-cleaning effect. The effect of strong hole deformation ability and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described.

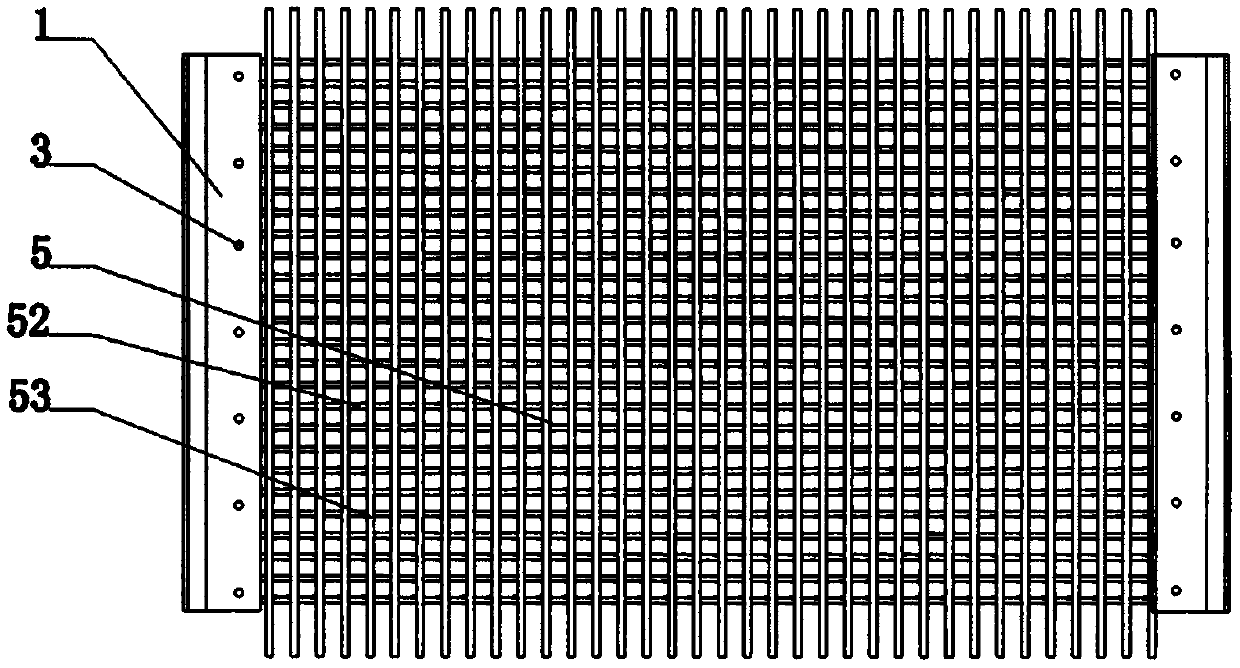

[0014] Such as figure 1 As shown, the present invention is a high-resilience anti-blocking polyurethane bar screen, which includes a useful tension hook 1, a fixing plate 2, a bolt 3, a round steel 4 and a polyurethane bar screen surface 5, and is characterized in that The screen surface of the polyurethane bar is composed of a steel cord polyurethane coated rubber bar 51 as a reinforcement area, an aramid rope core polyurethane coated rubber bar 52 is a weft, and a skeletonless polyurethane coated rubber bar 53 is a screening area for the weft ; The warp and weft joints of the screening area are integrated by hot-melt welding.

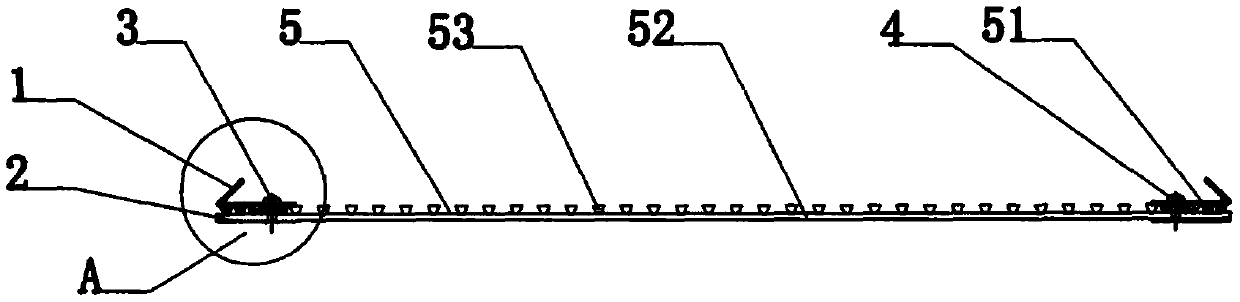

[0015] Such as figure 2 As shown, the cross-sections of the warps and wefts of the polyurethane screen surface 5 are all inverted trapezoids, so that all screen holes are inverted cones.

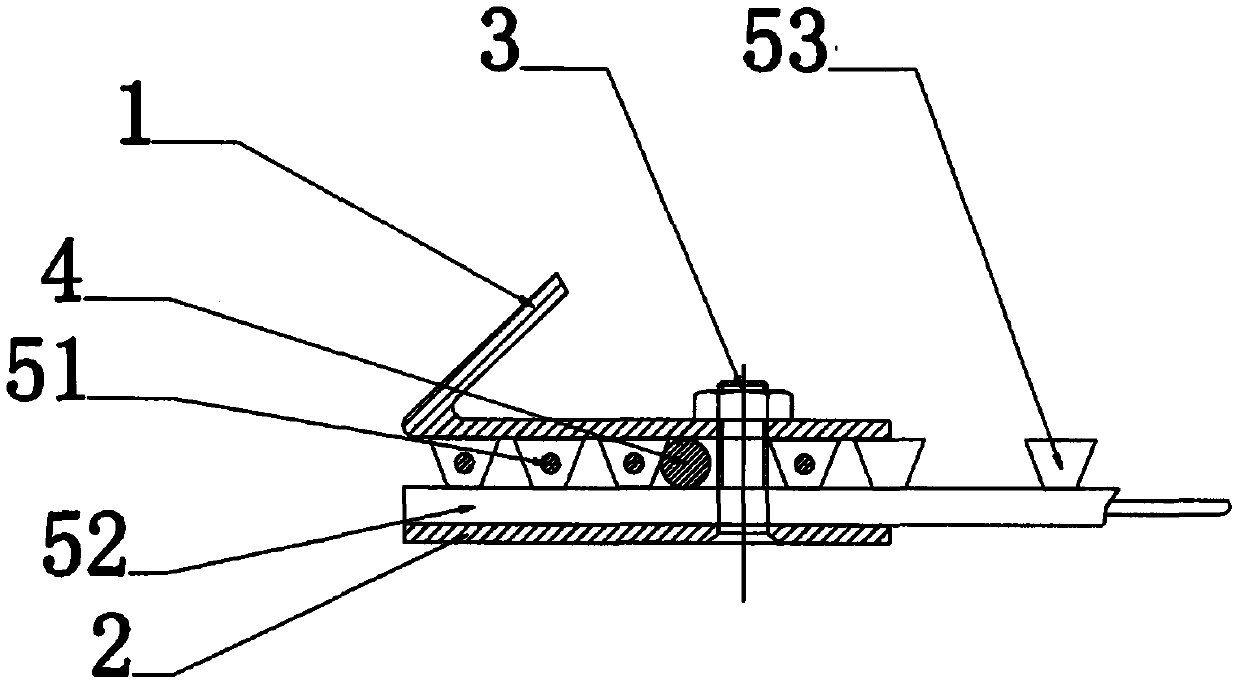

[0016] Such as image 3 As shown, the edge portion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com