Patents

Literature

33results about How to "Effective Area Maximization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

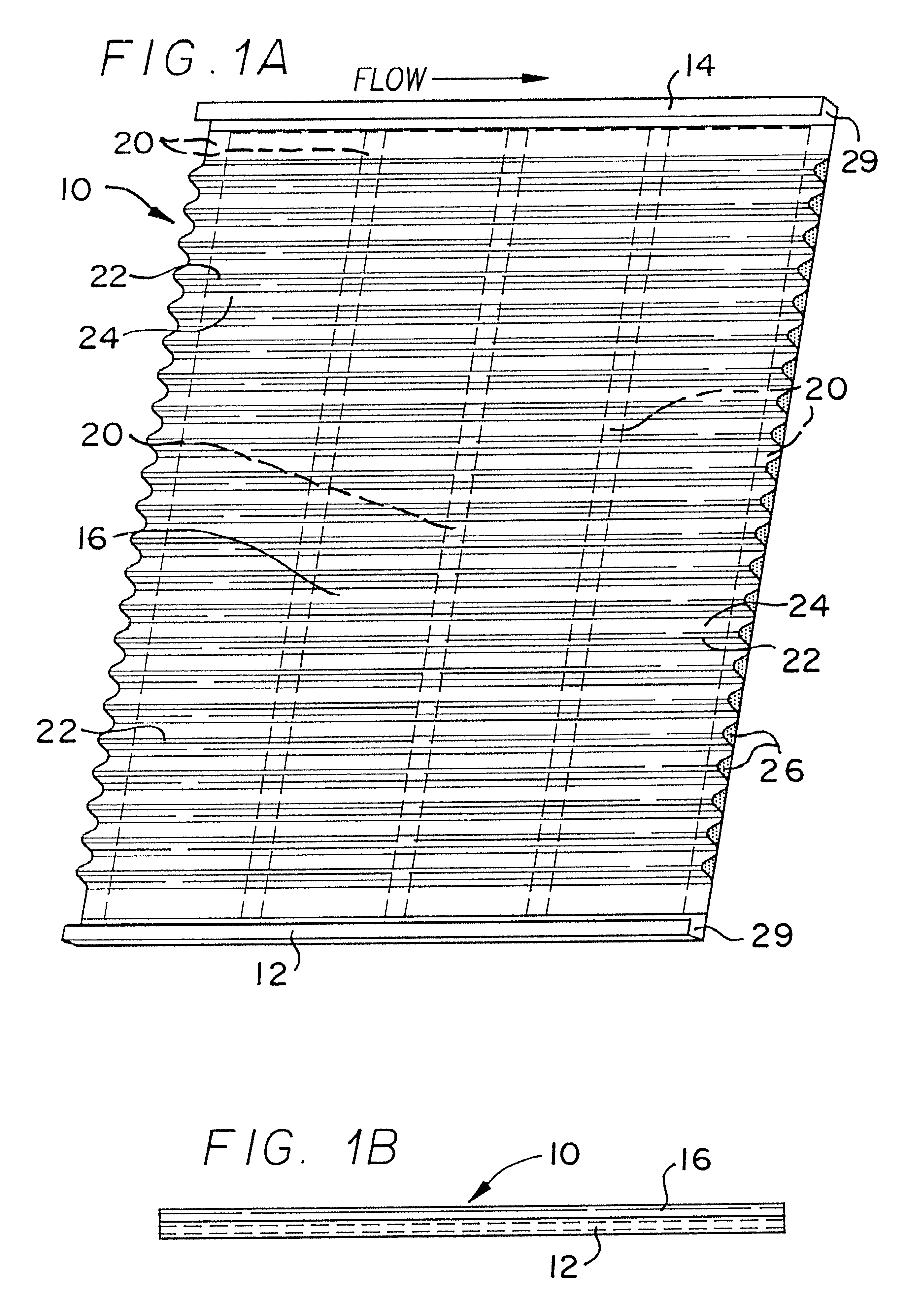

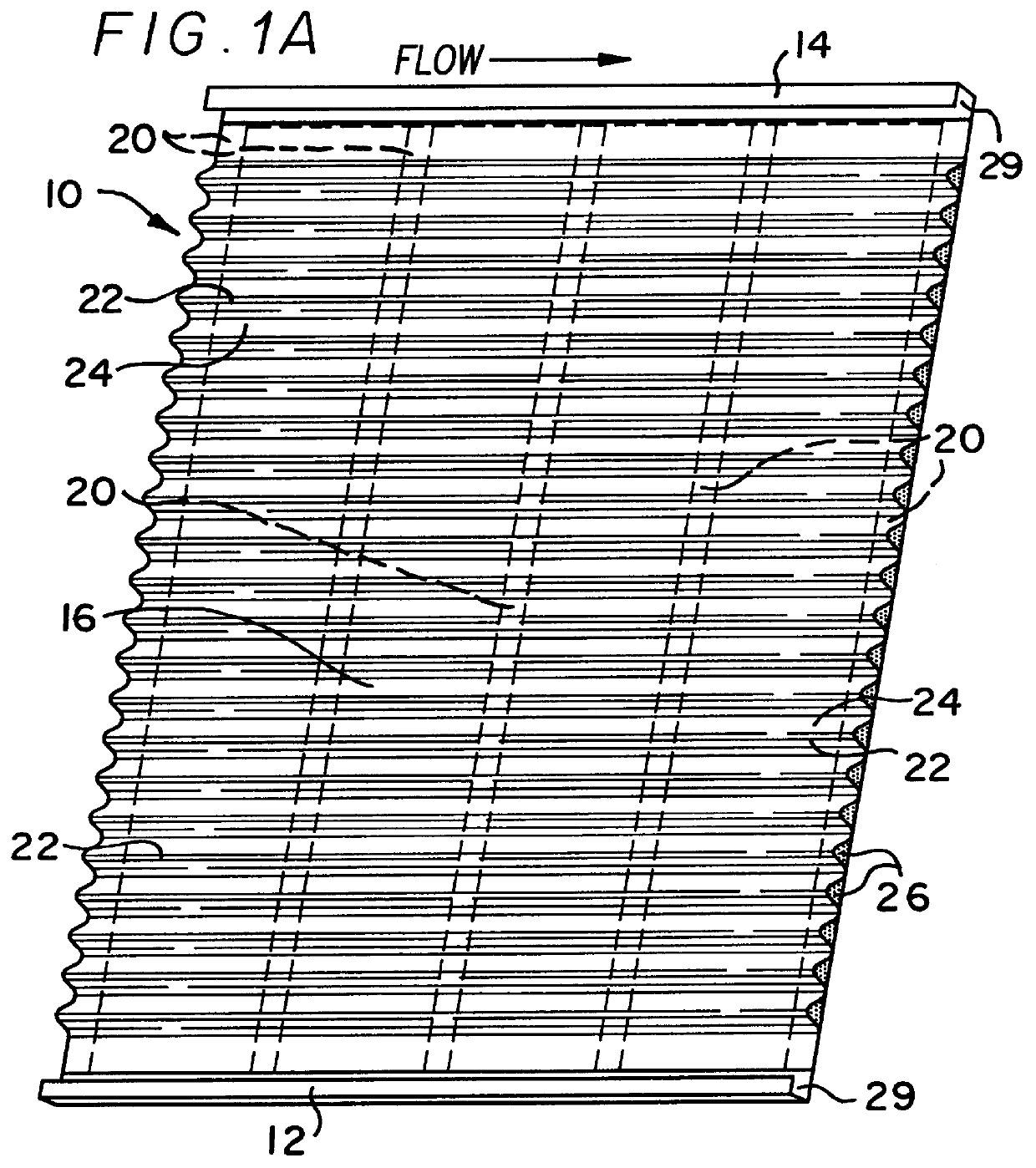

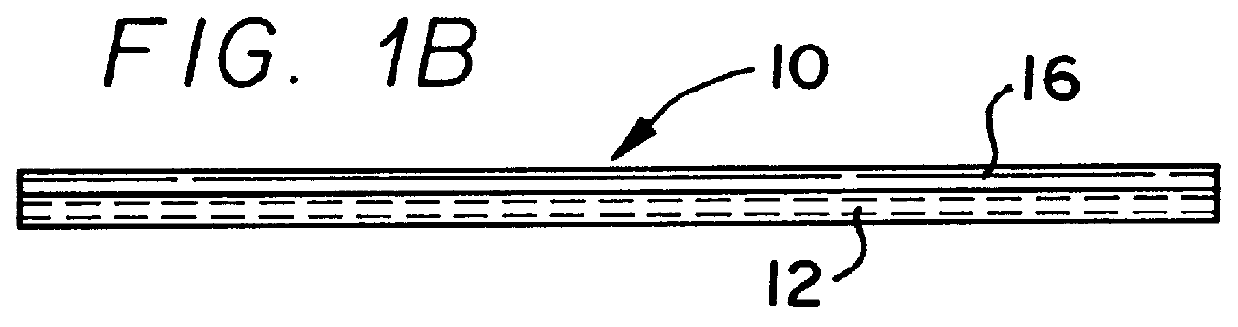

Method for making vibratory separator screens

InactiveUS6565698B1Easy to insertQuickly and easily repairedAdhesive processesSievingEngineeringMechanical engineering

A method for making a screen assembly for a vibratory separator, which, in certain aspects, includes placing a first layer of screening material below a glue application apparatus, and applying with the glue apparatus an amount of glue in a pattern to a portion of the first layer of screening material, unrolling part of a second layer from a second roll and positioning the part of the second layer adjacent part of the first layer to which glue has been applied, moving the part of the second layer and the part of the first layer between opposed rotatable spaced-apart rollers to press together the part of the second layer and the part of the first layer to form a pressed-together layer of first and second layers of screening material. In certain aspects hot glue is used and is cooled following application of the second layer on the first layer.

Owner:TUBOSCOPE IP

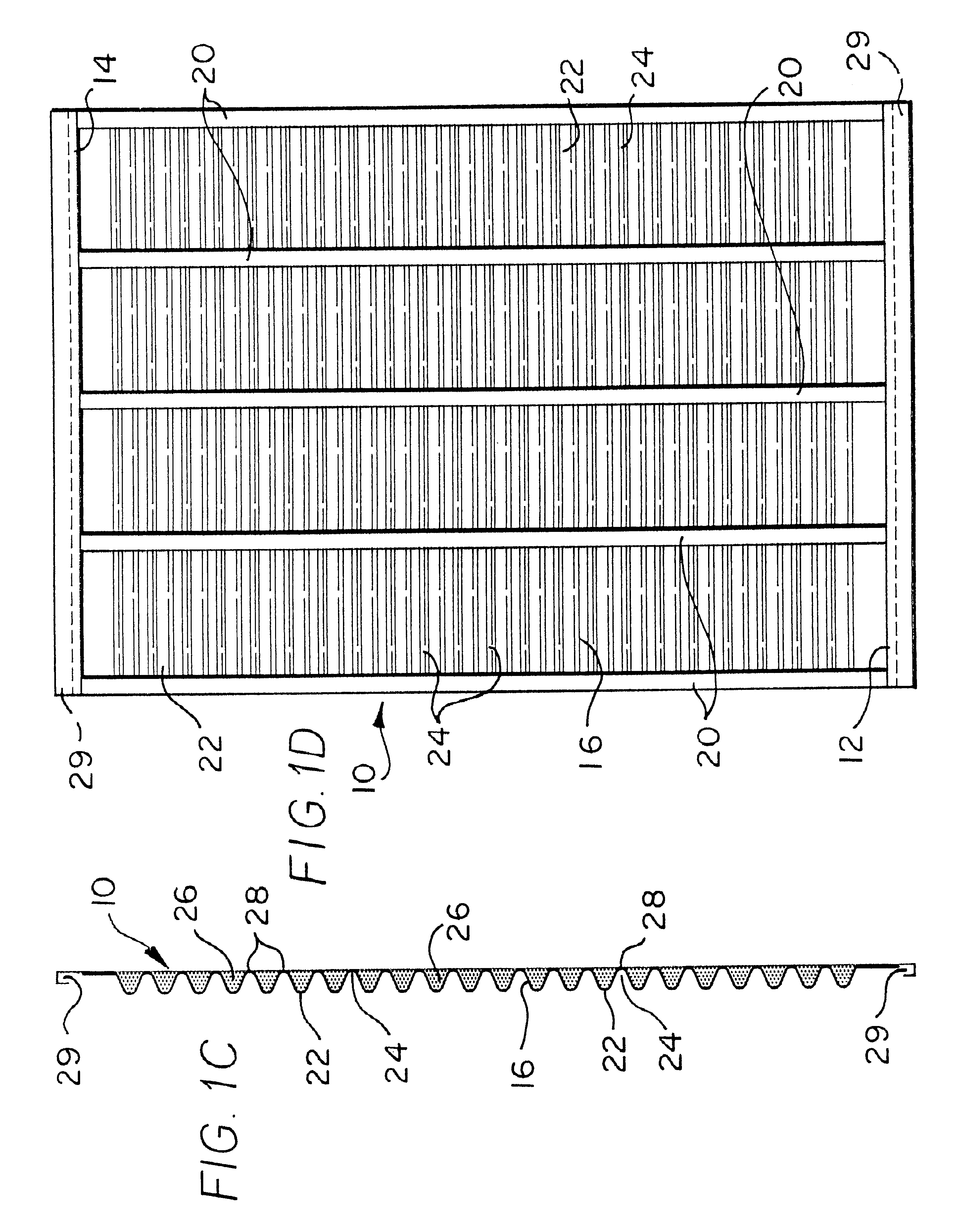

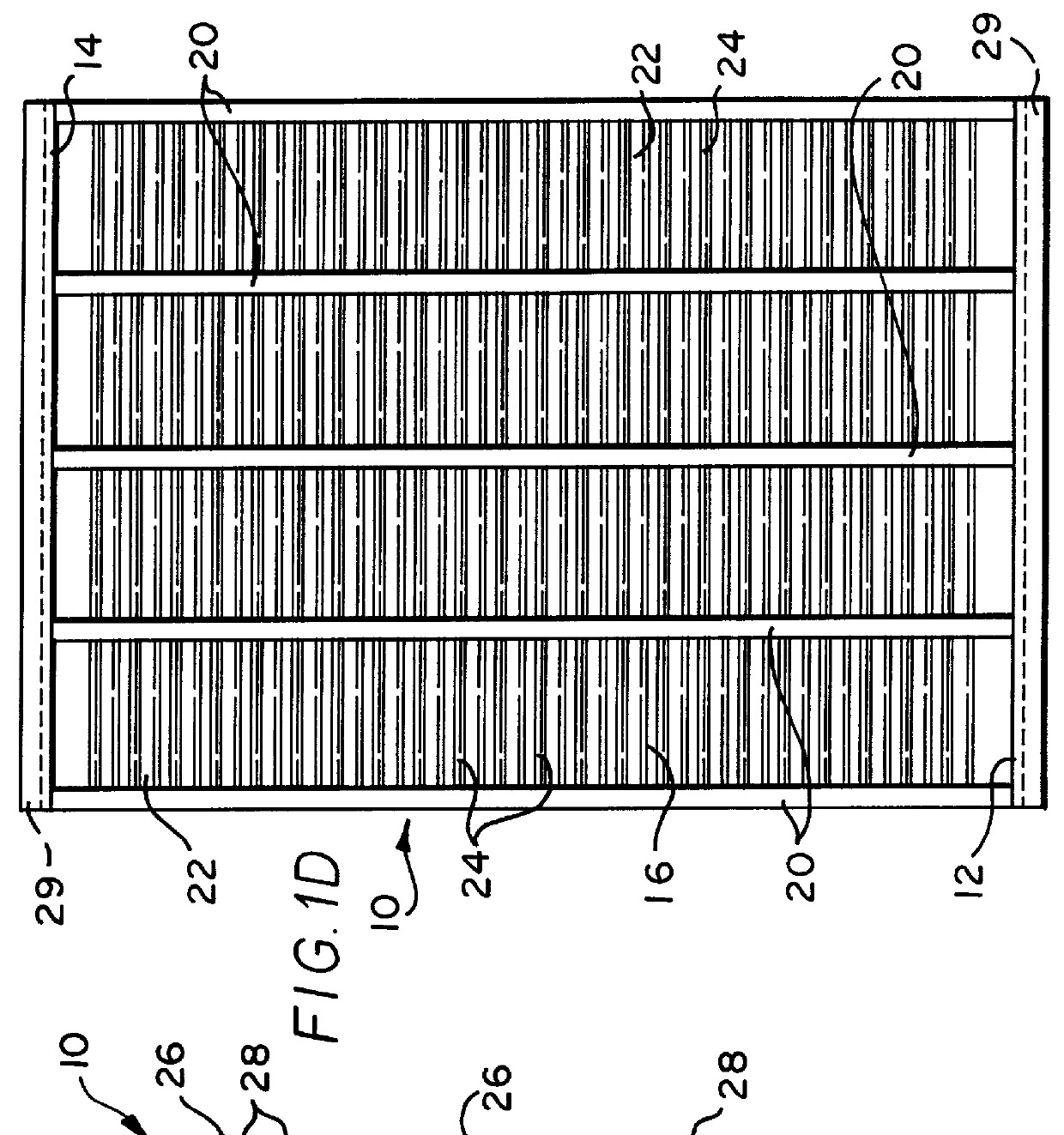

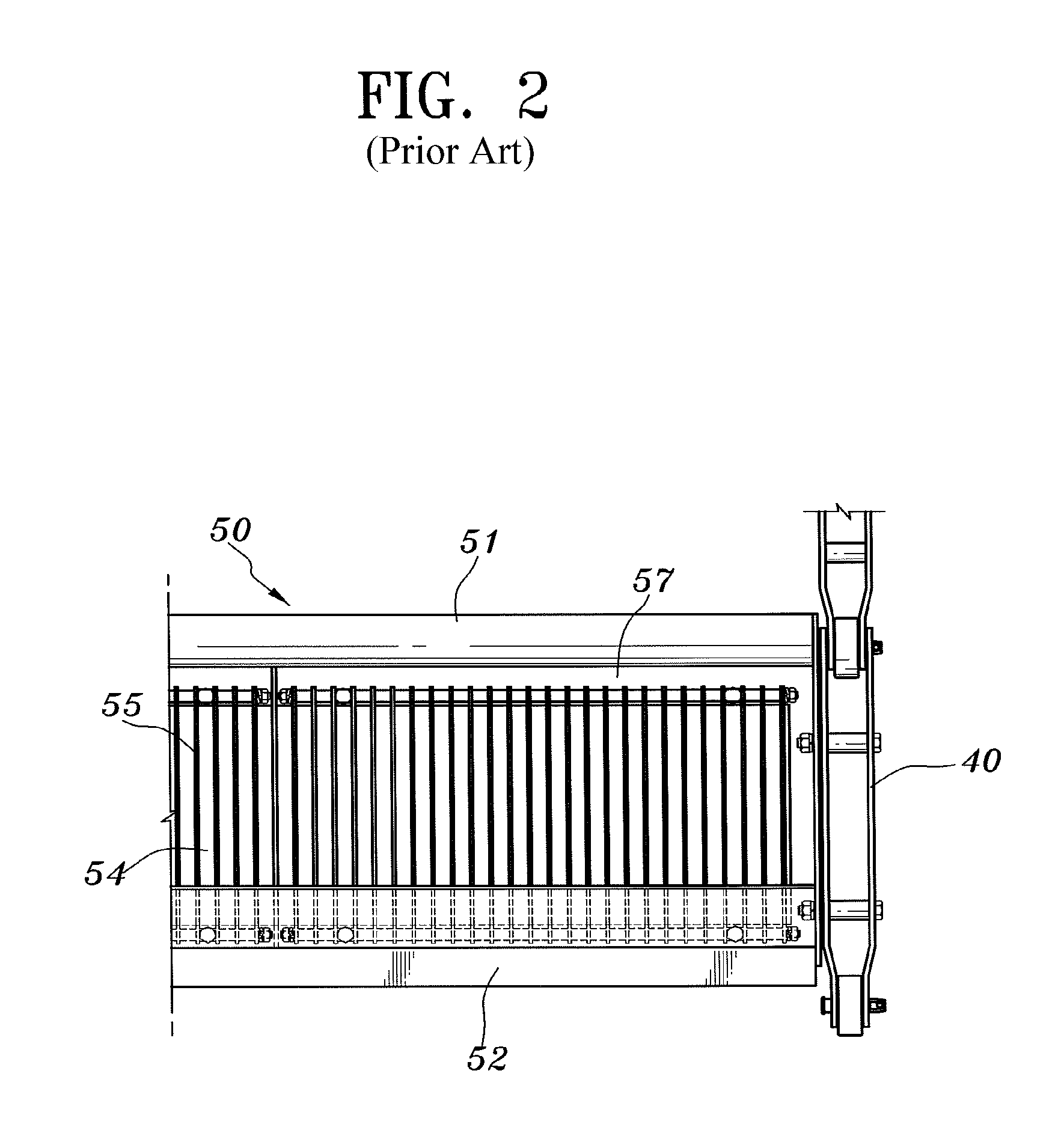

Screen apparatus for vibratory separator

InactiveUS6032806AEasy to insertQuickly and easily repairedSievingScreeningEngineeringMechanical engineering

A screen is disclosed which, in certain aspects, has screening material between opposed frame sides and one or more lower strips beneath the screen. In one aspect these strips are only inteconnected via their ends and not along their lengths. In certain aspects, a plurality of lower strips are bonded to the screen and extend across the screen from one frame side to the other. In one aspect one or more of the strips has one, two, or more humps or ridges corresponding to one or more corrugations in a corrugated perforated plate and / or corrugated screen assembly which is on the plate or, with no plate present, on the strips. In another aspect instead of the strips a solid corrugated perforated plate is used. In one aspect openings or perforations through the plate are triangular. In one aspect the screen is undulating screening material and lower portions of the screening material are bonded to a plate or to strips. Optionally screen mounting hooks or frame edges or screen edges may be used with such screens. A screening apparatus or shale shaker is disclosed which uses such plates and screens.

Owner:VARCO I P INC

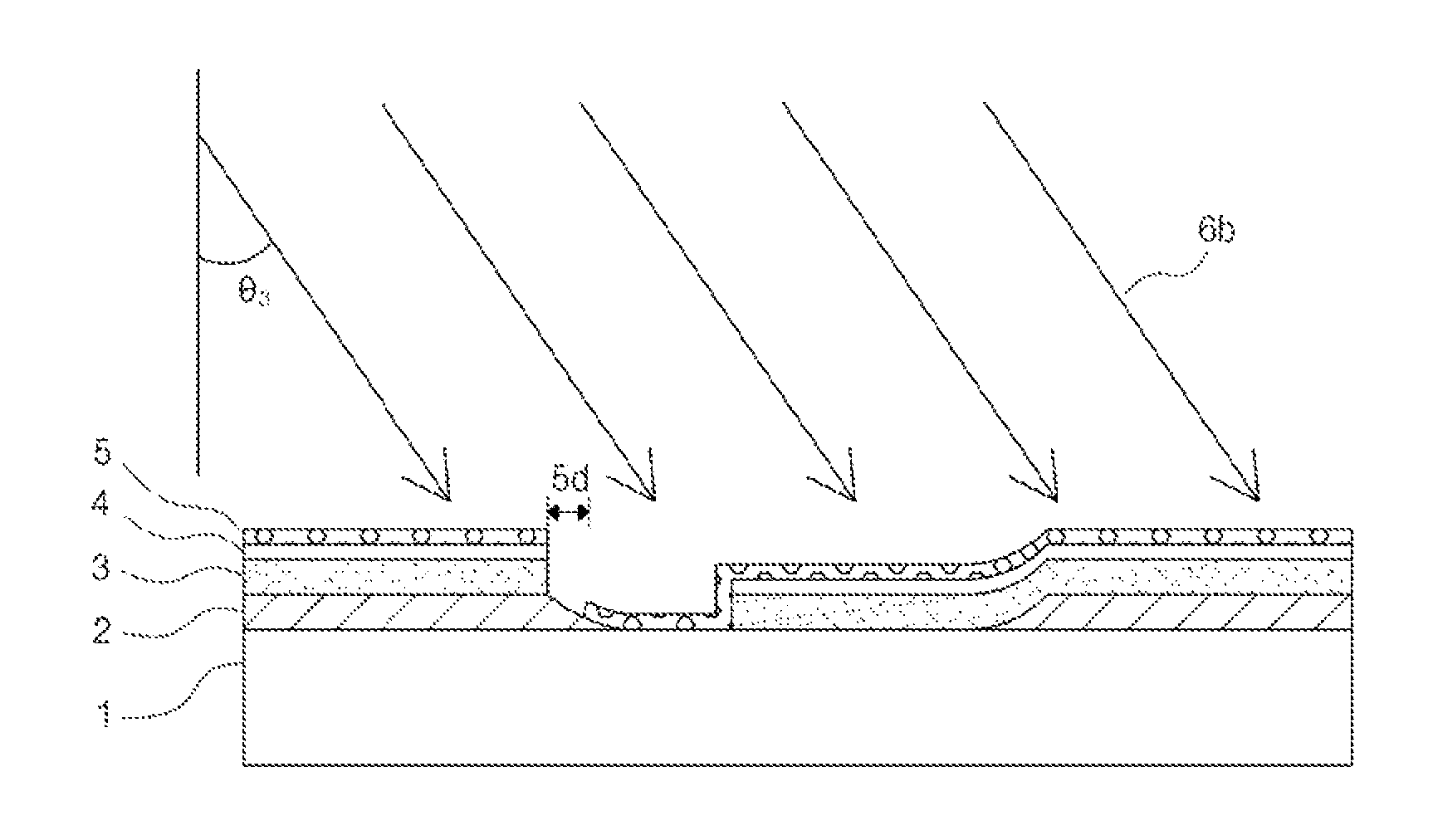

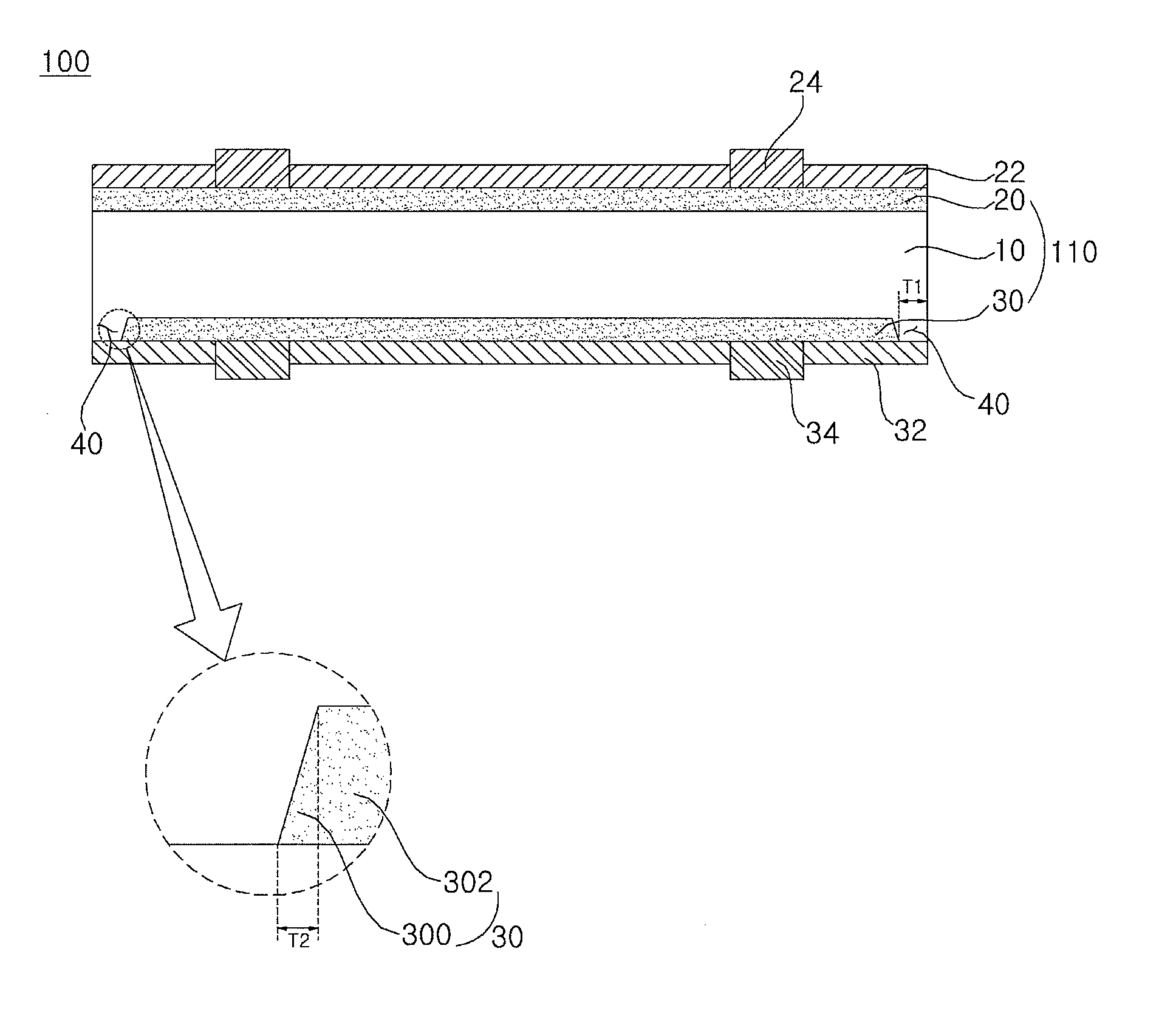

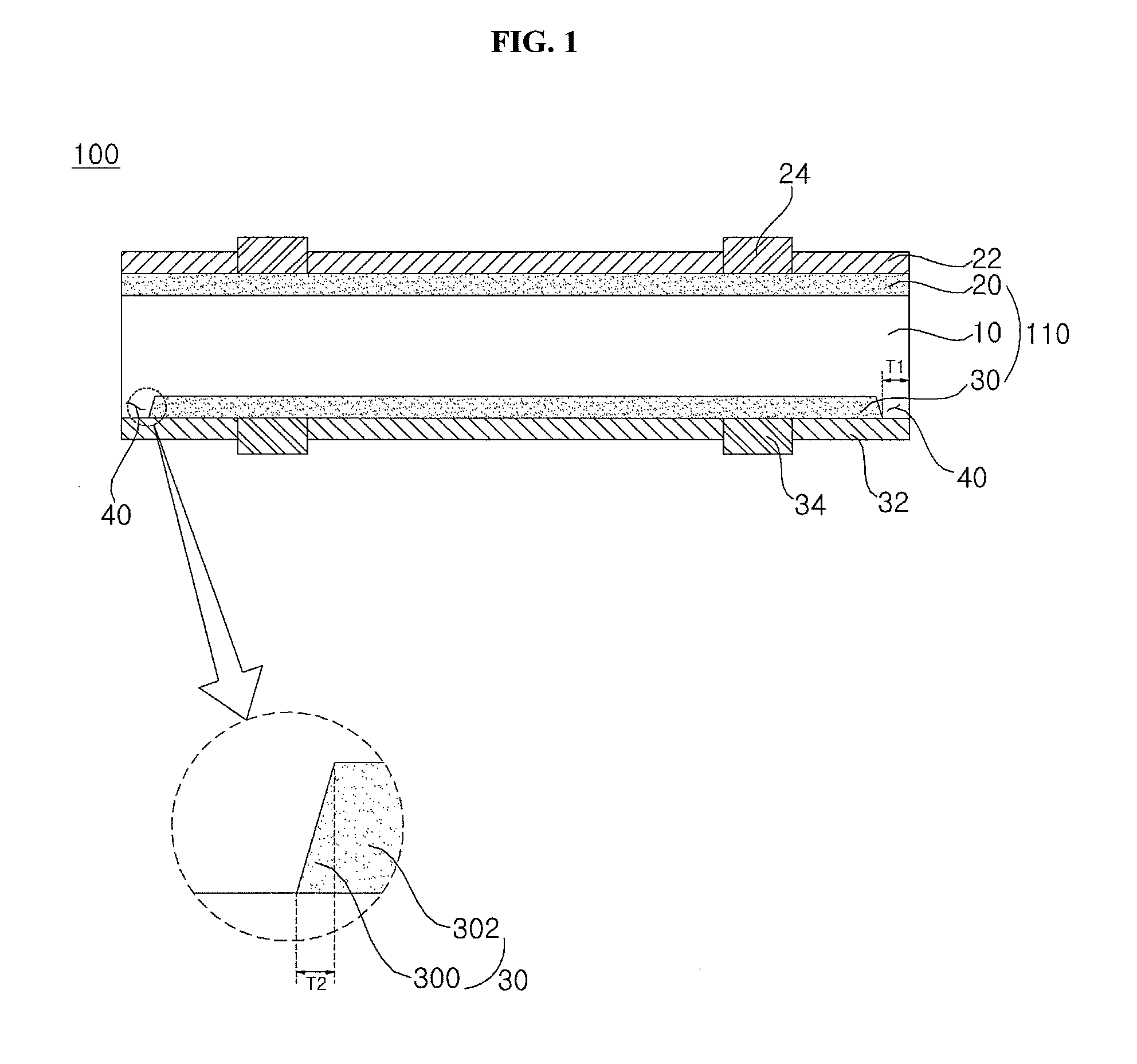

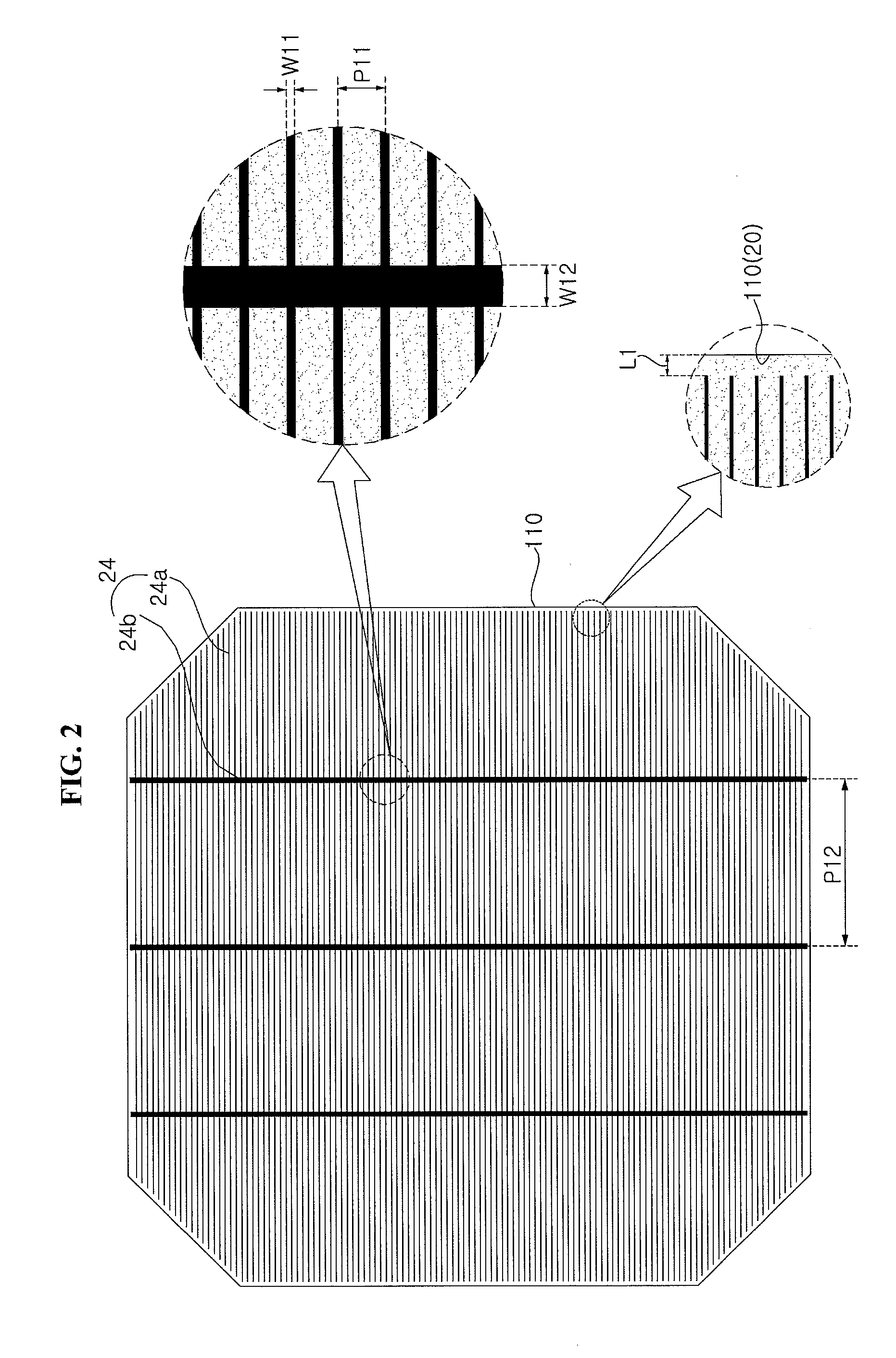

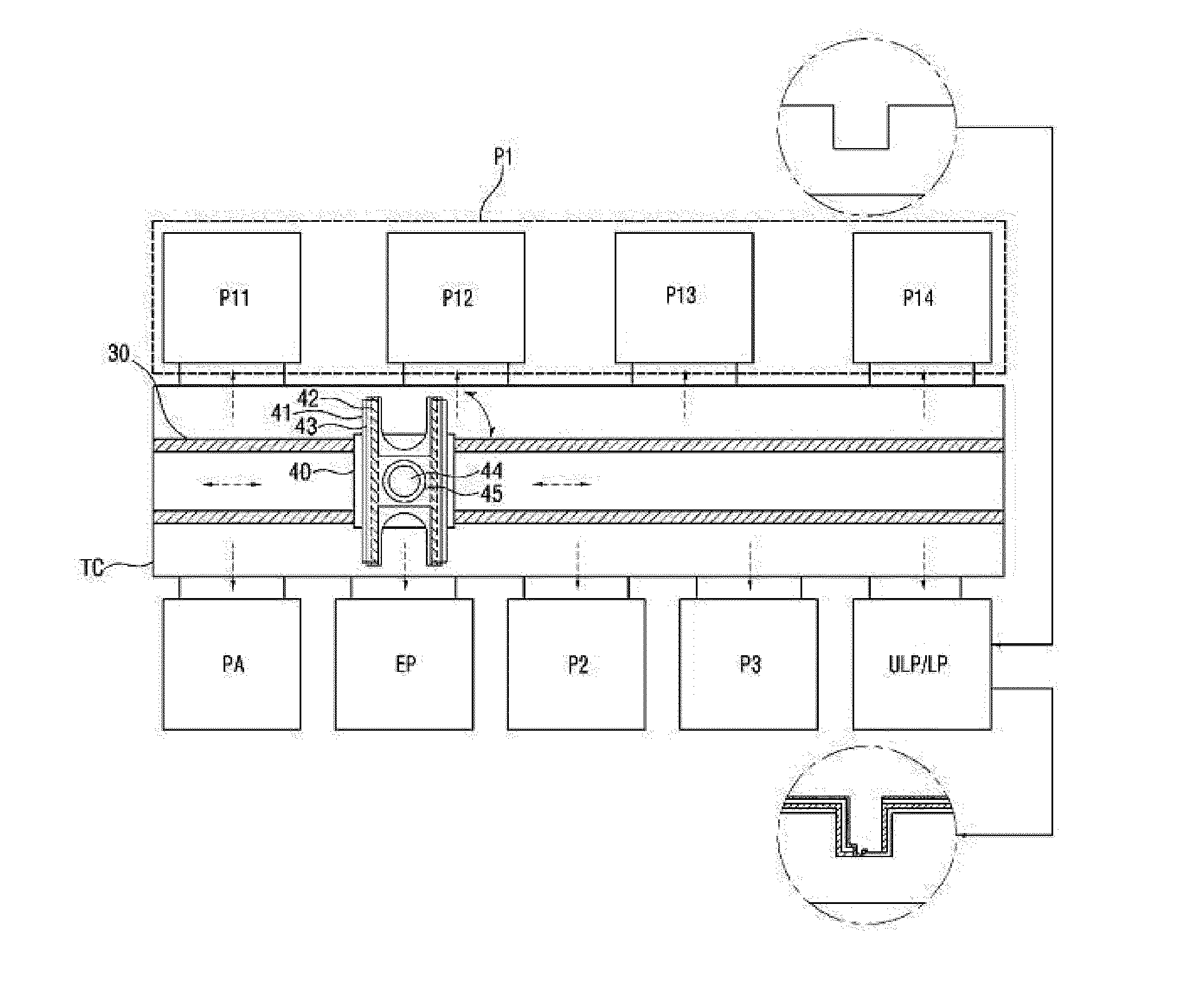

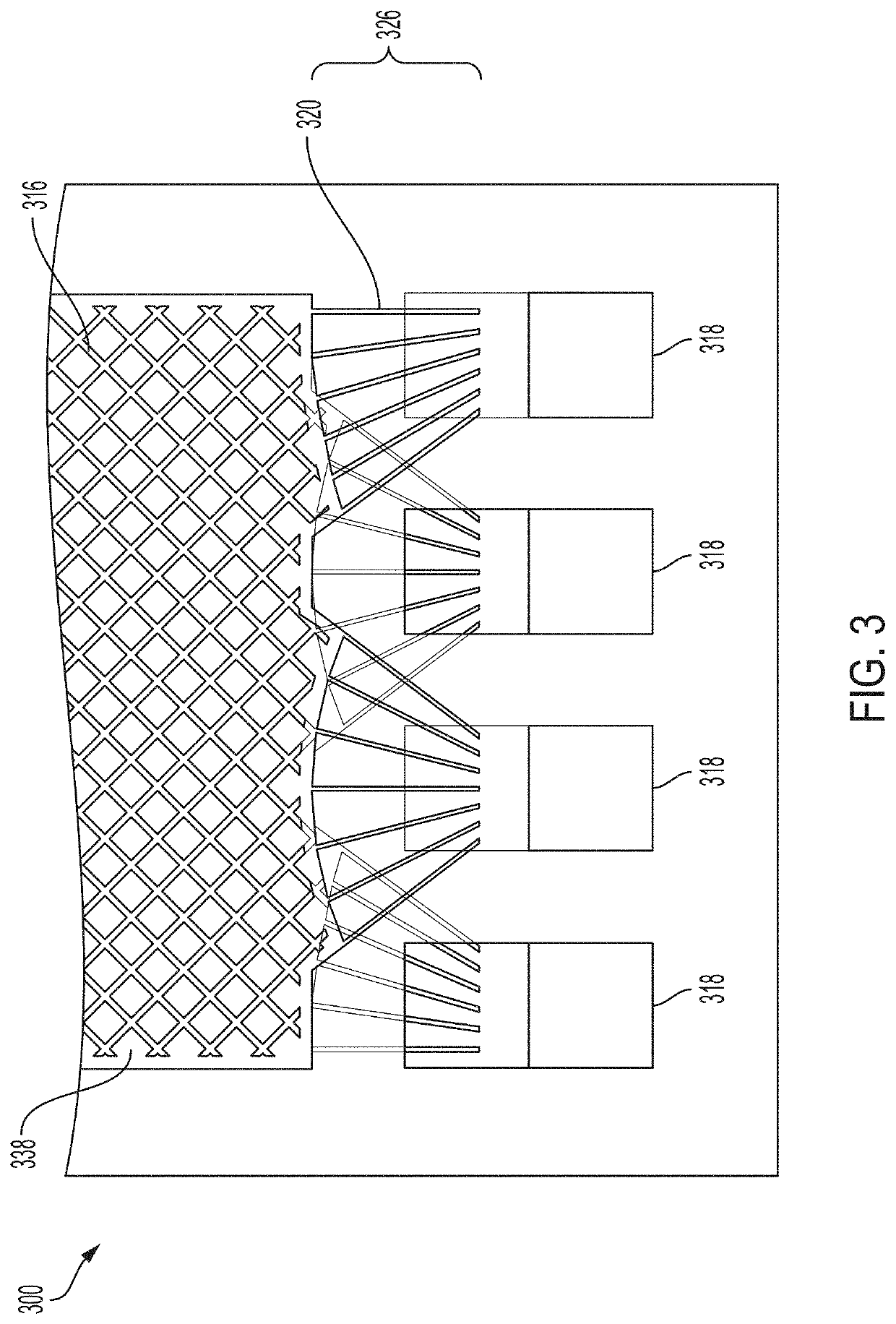

Integrated thin-film solar cells and method of manufacturing thereof and processing method of transparent electrode for integrated thin-film solar cells and structure thereof, and transparent substrate having processed transparent electrode

InactiveUS7927497B2Effective Area MaximizationImprove performanceFinal product manufactureOptical articlesManufacturing cost reductionEngineering

Owner:KOREA ADVANCED INST OF SCI & TECH

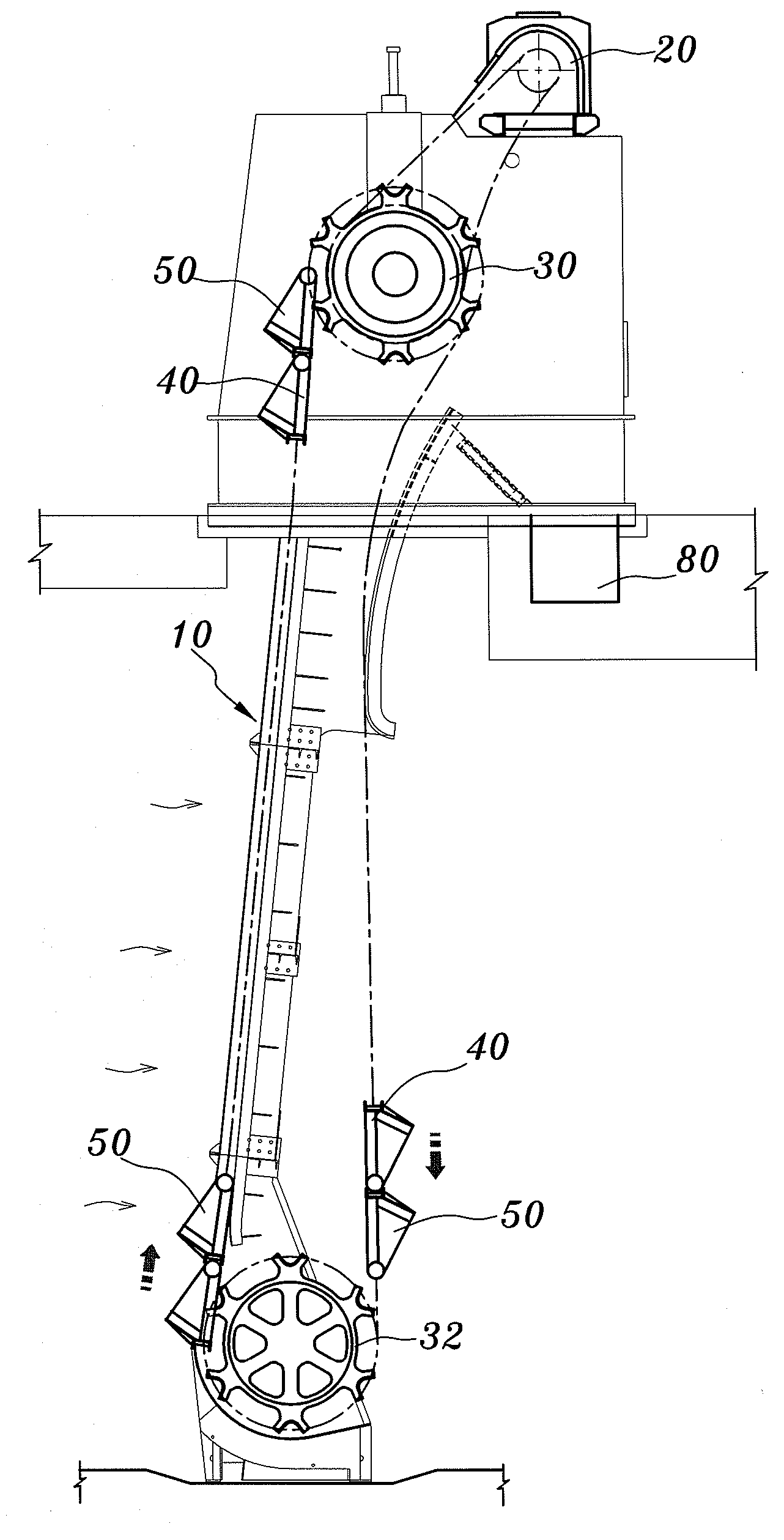

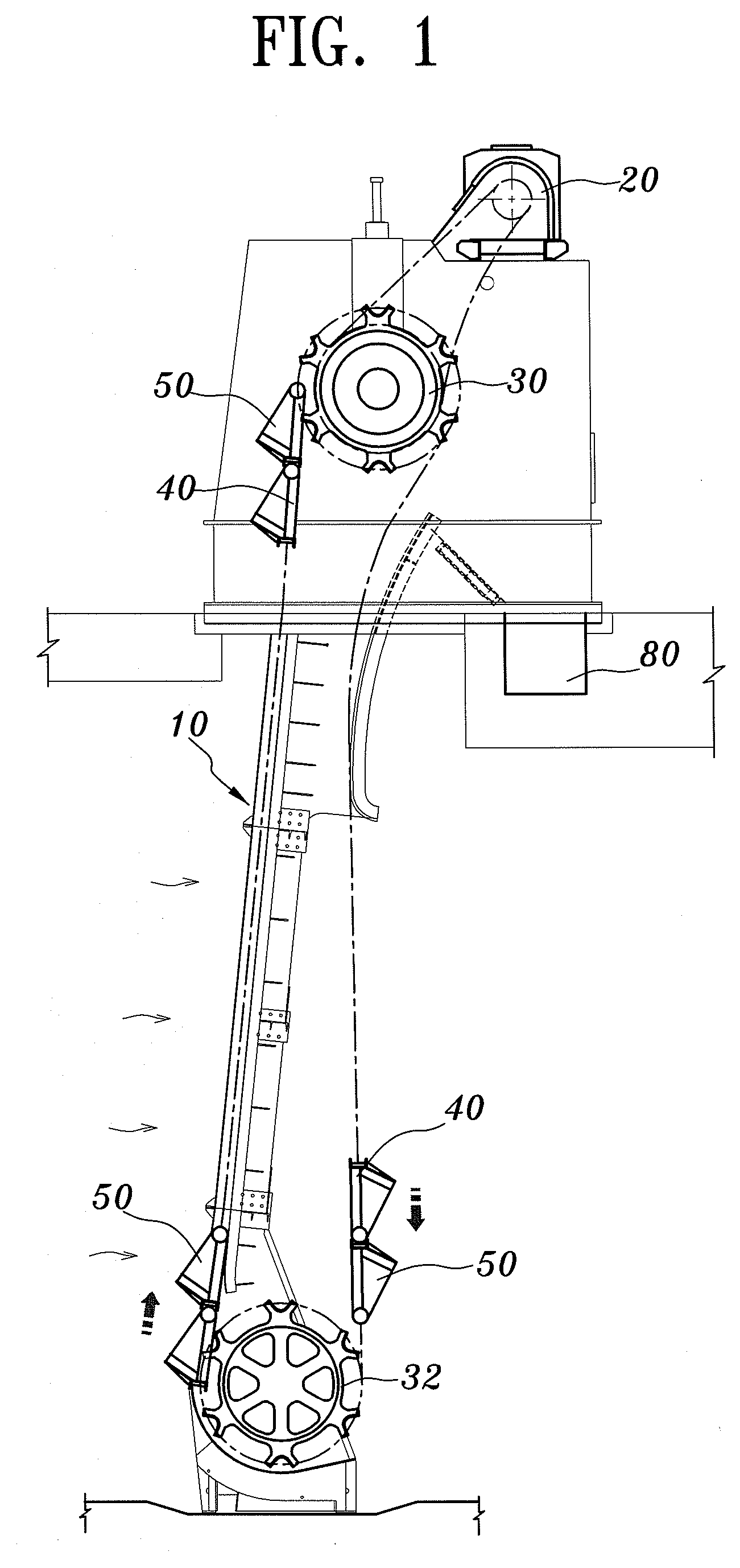

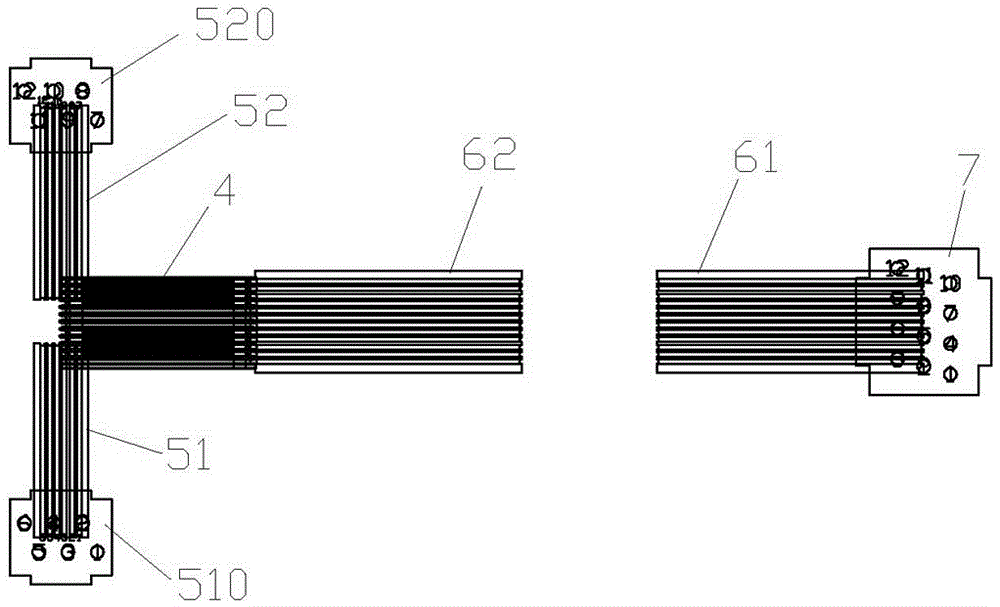

Rotary bar screen device

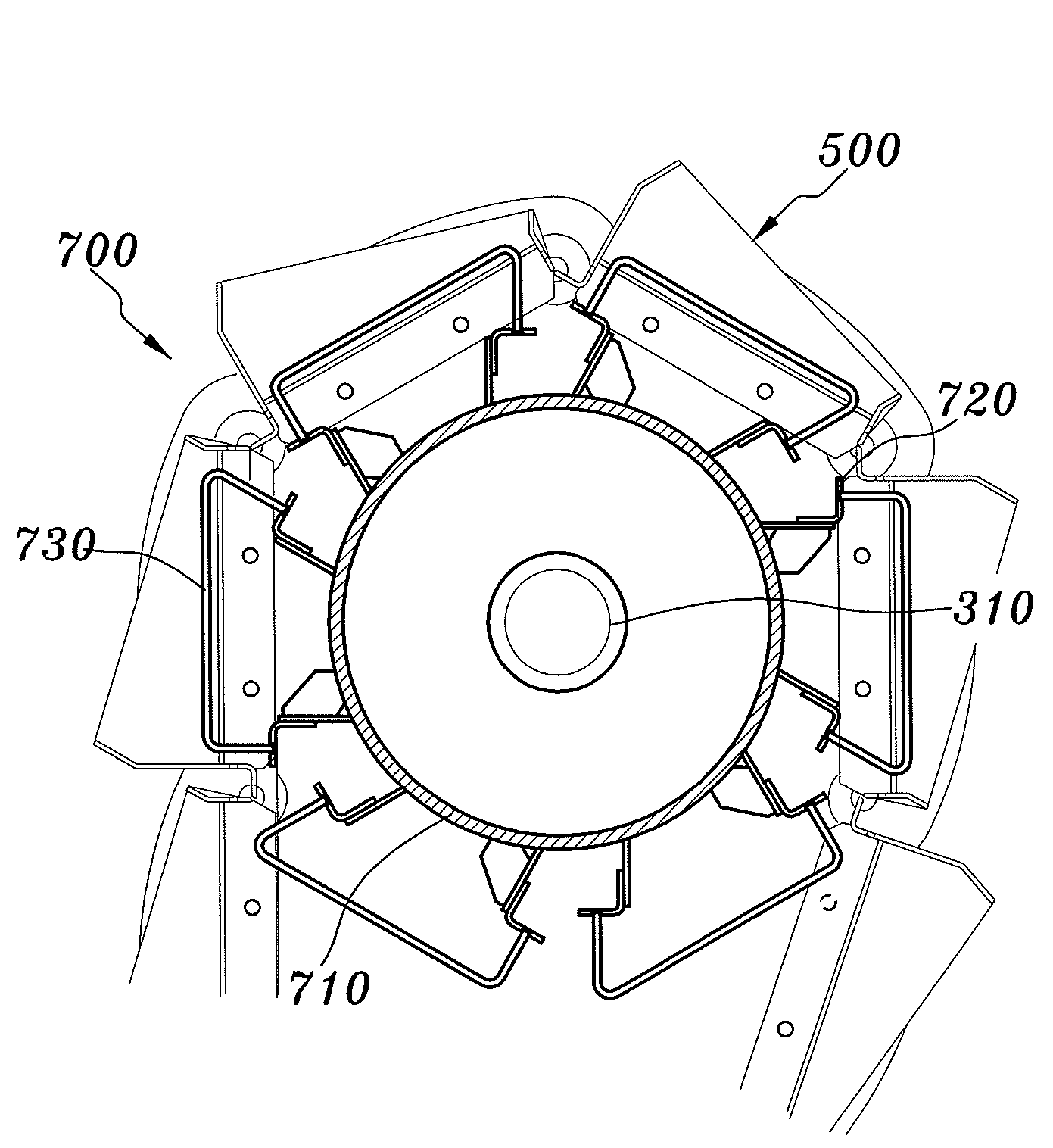

ActiveUS7575674B2Increase the effective areaEffective Area MaximizationFatty/oily/floating substances removal devicesSeawater treatmentBraced frameSprocket

Owner:COWAY ENTECH CO LTD

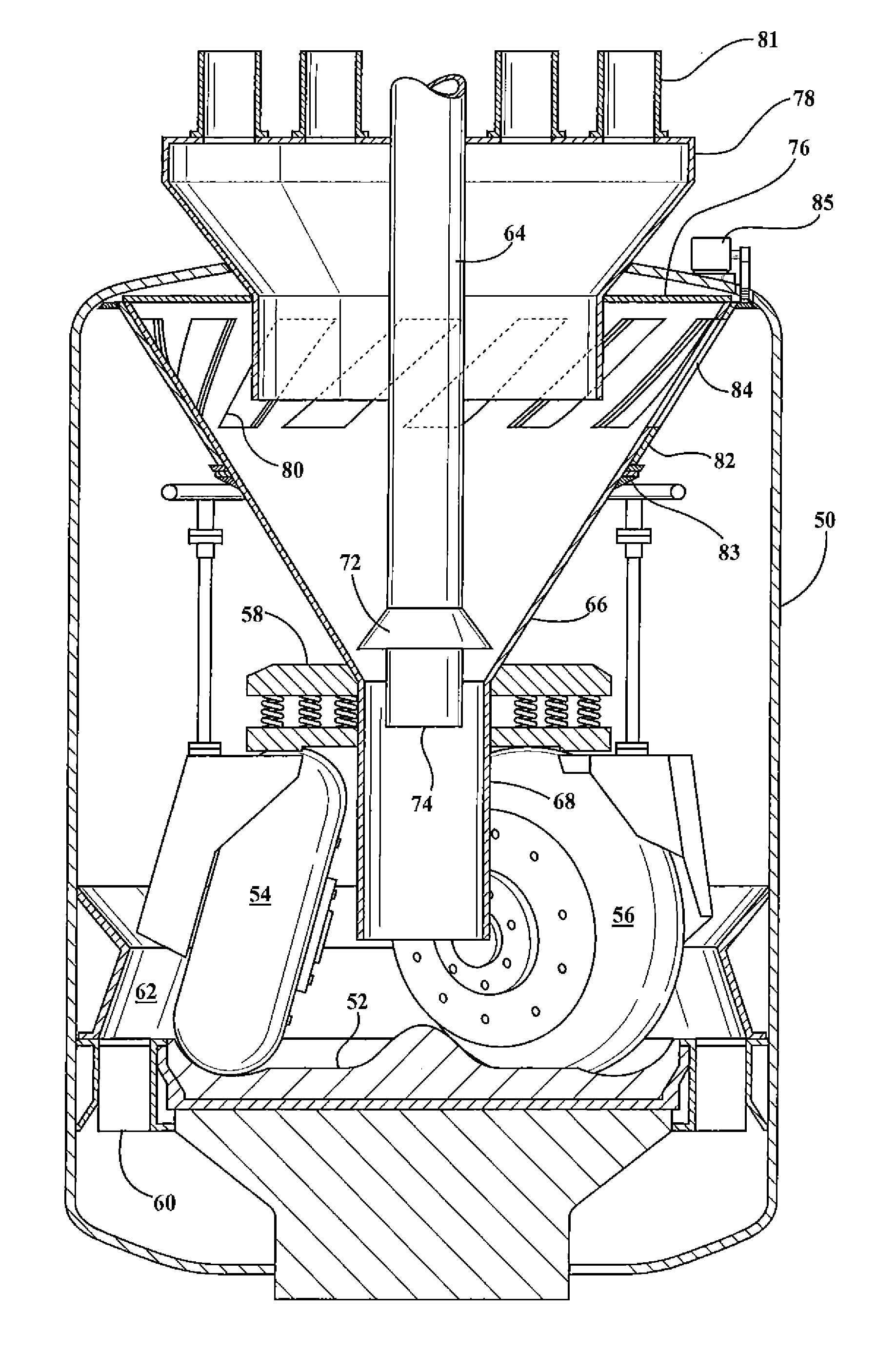

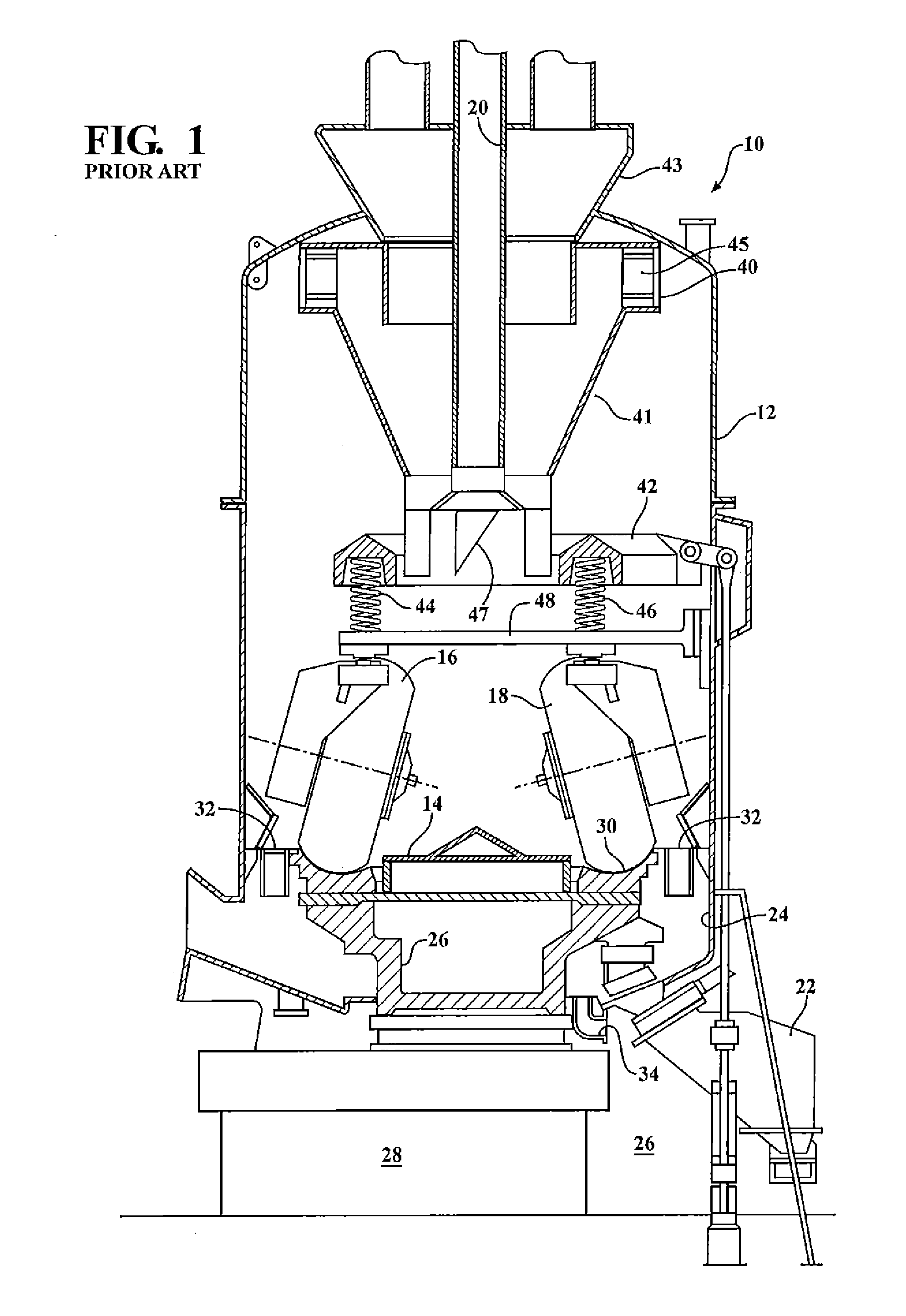

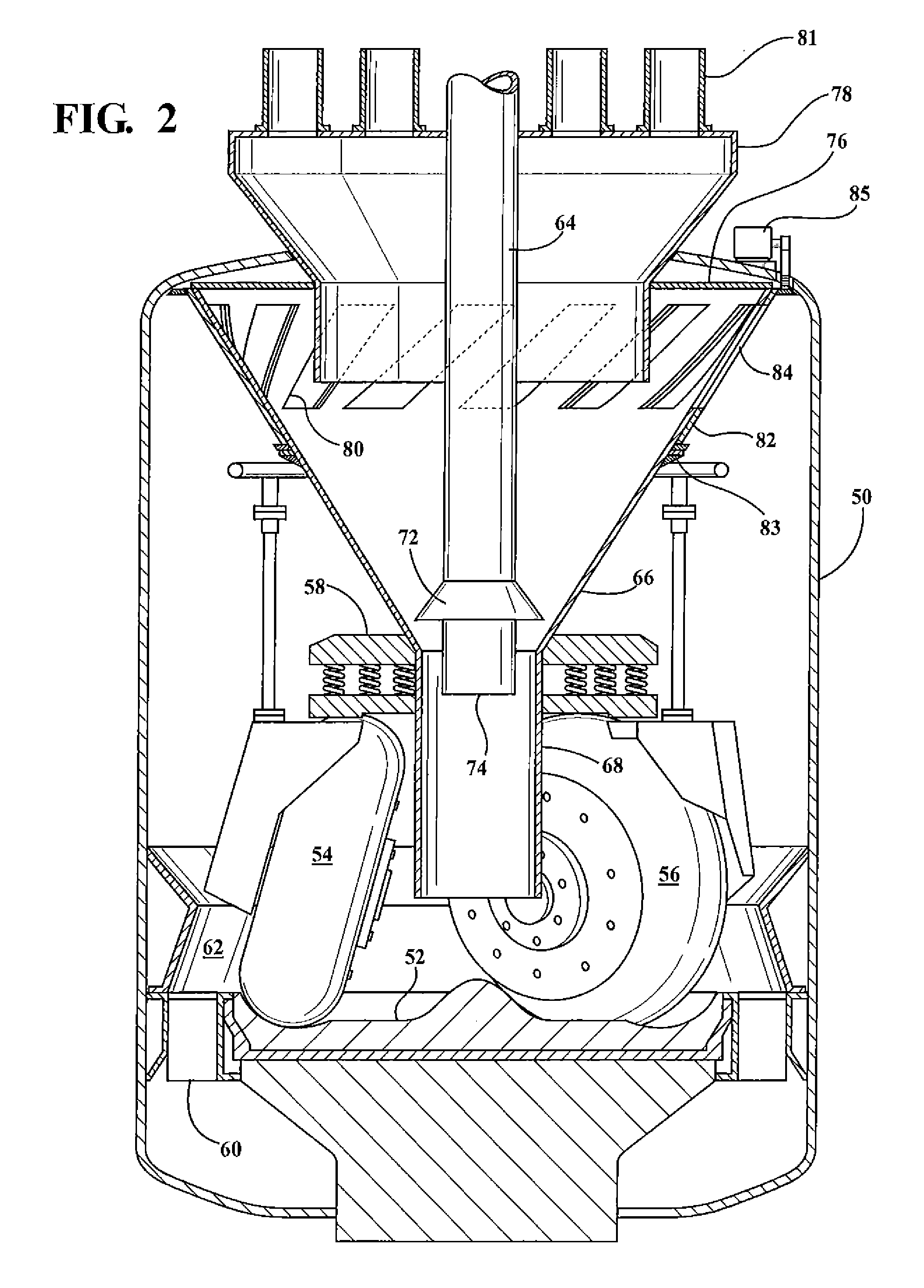

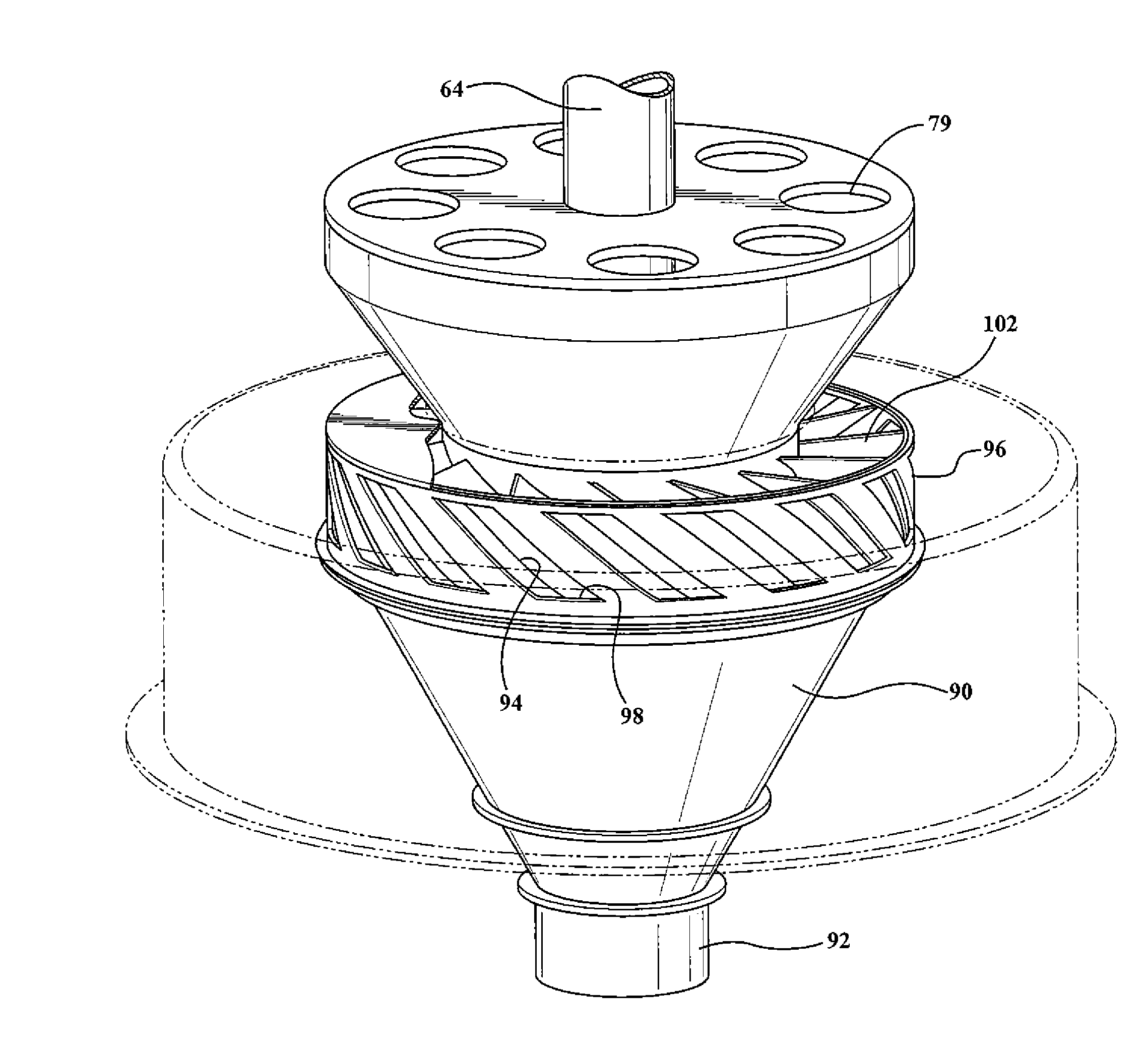

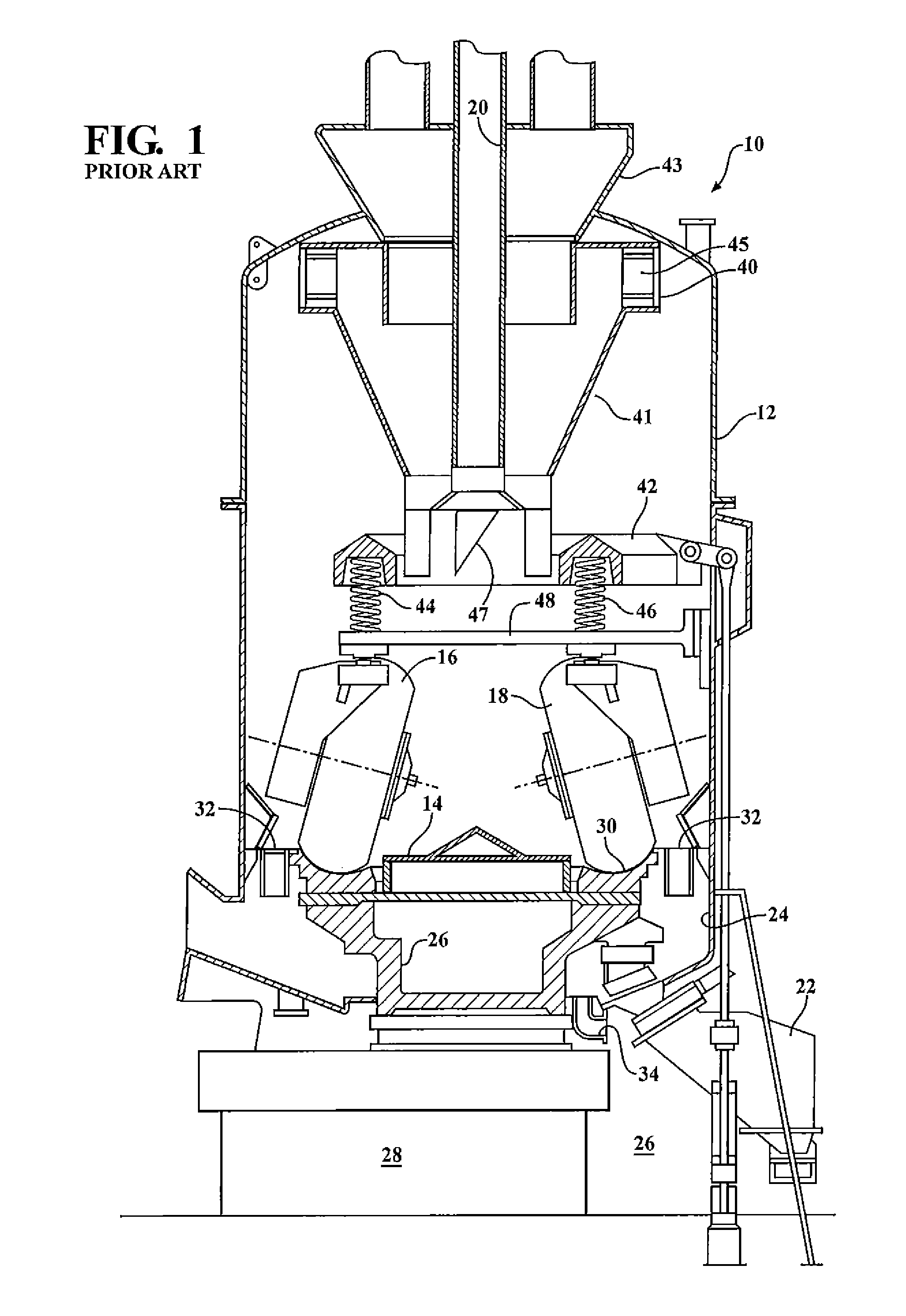

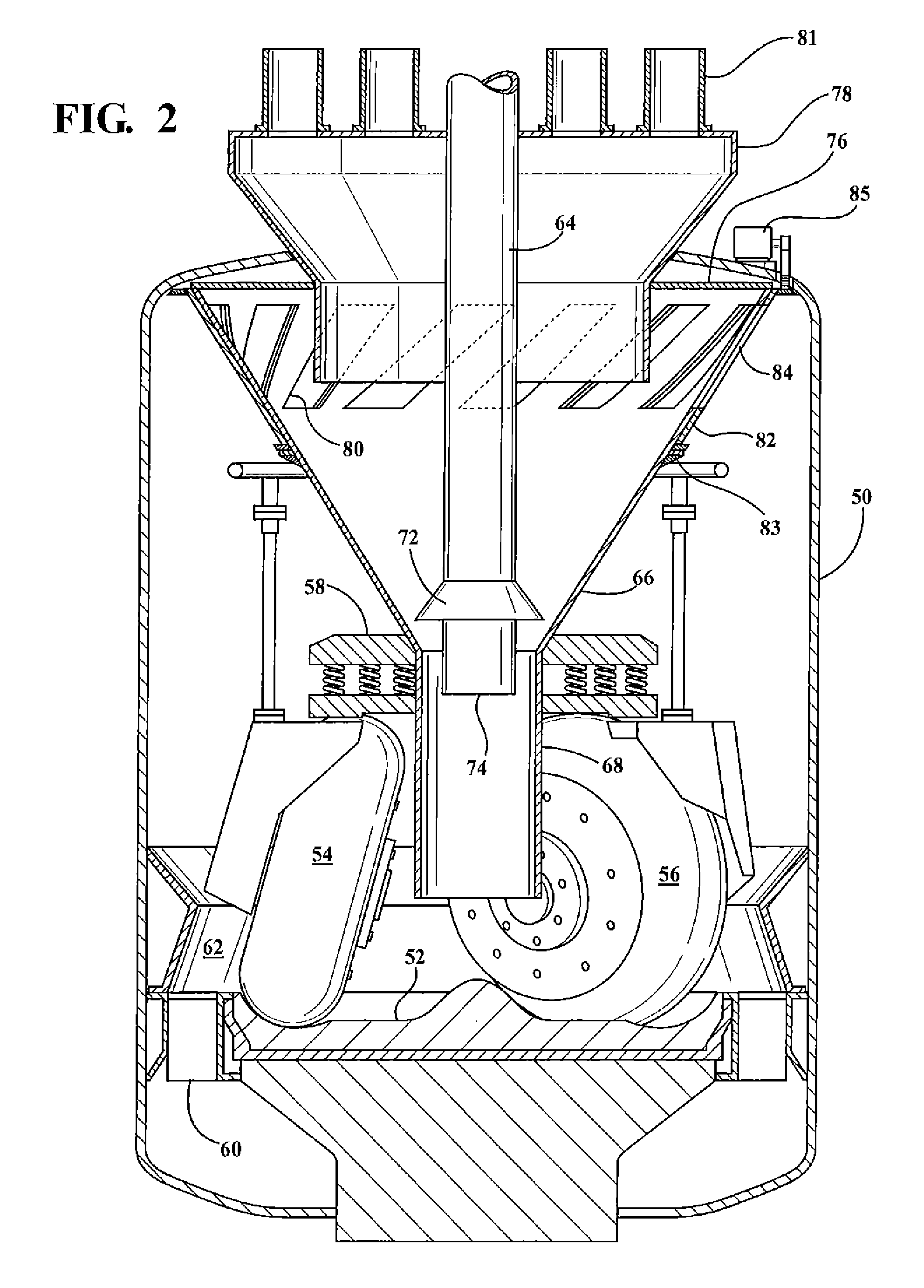

Classifier with variable entry ports

InactiveUS20130200187A1Effective areaEffective Area MaximizationGas current separationSortingEngineeringCoal

Multiple embodiments of a variable flow classifier for vertical air-swept coal pulverizers are disclosed. In all embodiments, a classifier structure includes a cone with means for providing a pattern of inlet ports for introducing airborne coal to the cone wherein said means allows for selective variation in the size of the ports.

Owner:WARK RICKEY E

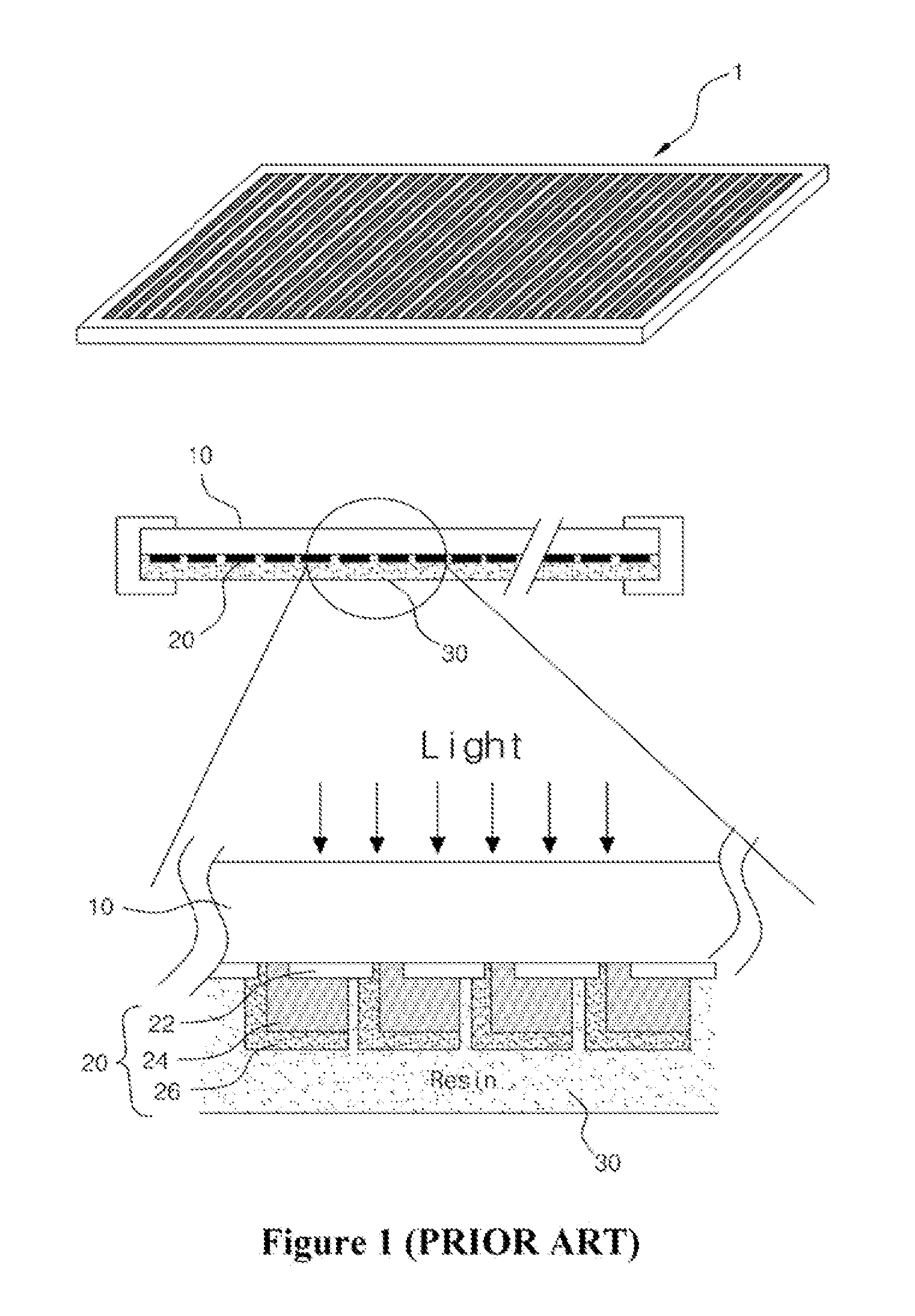

Solar cell and method for manufacturing the same

ActiveUS20140352770A1Improve reliability and productivityHigh efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsSemiconductor

Discussed is a solar cell including a semiconductor substrate, a first conductive type region formed on a surface of the semiconductor substrate, a second conductive type region formed on the other surface of the semiconductor substrate, the second conductive type region being spaced from an edge of the semiconductor substrate and having a conductive type different from that of the first conductive type region, an isolation portion formed at a perimeter of the second conductive type region on the other surface of the semiconductor substrate, a first electrode connected to the first conductive type region, and a second electrode connected to the second conductive type region, wherein the second conductive type region has a boundary portion in a part adjacent to the isolation portion, and in which a doping concentration or a junction depth varies over a width of the boundary portion.

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

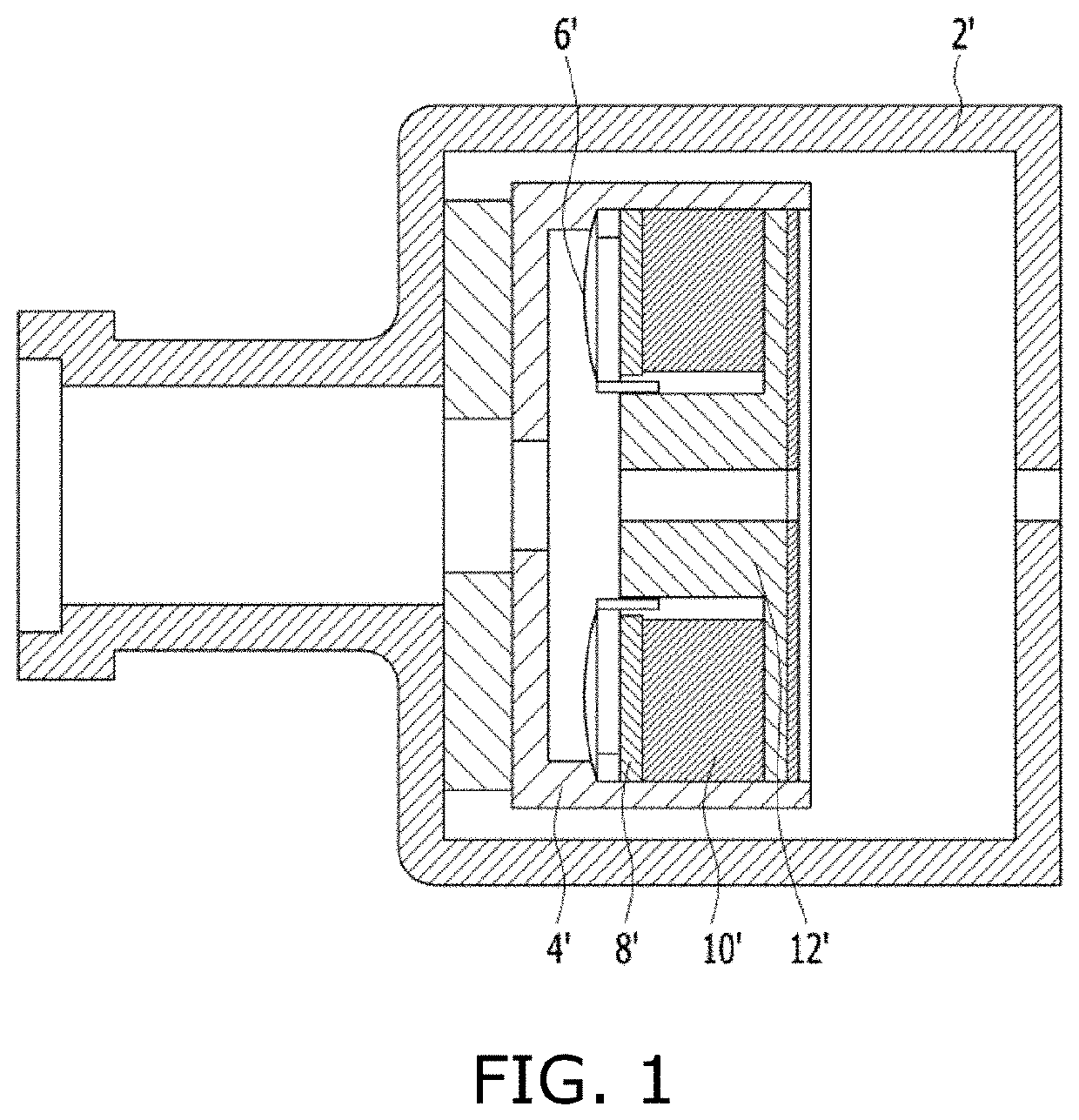

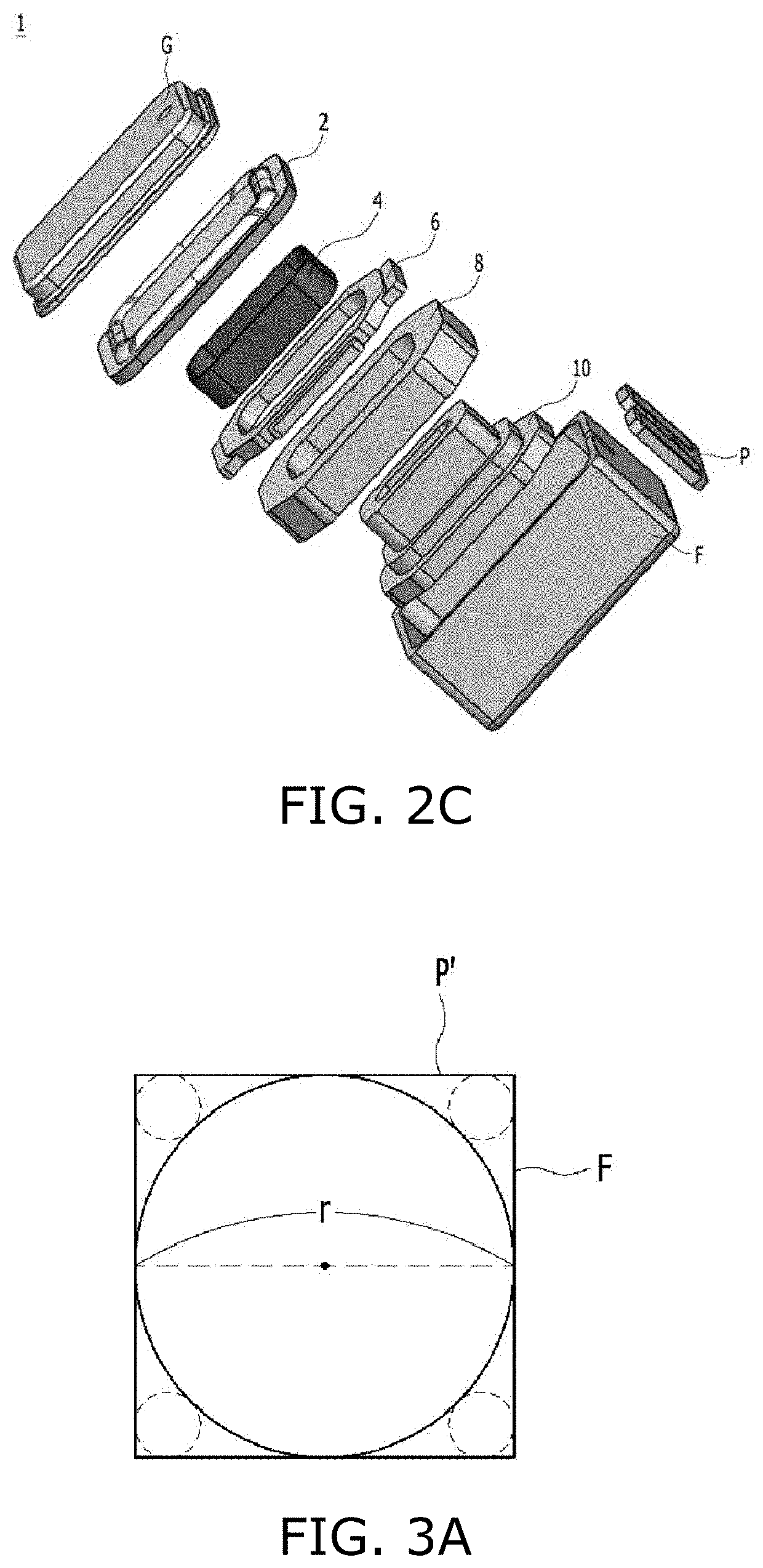

A thin receiver

InactiveCN109104663AHigh frequency responseImprove the sound effectEarpiece/earphone attachmentsPlane diaphragmsEngineeringSound production

The invention provides a thin-type receiver, comprising a housing, a diaphragm module and a coil. A diaphragm assembly includes a frame, Diaphragm and seal film, since a mounting area is formed between a part of the side wall of the frame and an inner wall surface of the housing, the coil seal is secured to the mounting area and the seal is sleeved outside the frame, and the sealing film is spreadto seal all first gaps between the frame and the diaphragm, thereby dividing the mounting cavity of the housing into two chambers that are side-by-side and do not communicate with each other, boundedby the diaphragm assembly. When the coil is energized and the electromagnetic field generated by the coil interacts with the fixed magnetic field of the permanent magnet in the receiver, the whole diaphragm vibrates, so that when a thin diaphragm is formed on the diaphragm module by snare on line, the diaphragm covered with the sealing diaphragm participates in the sound production, the effectivearea of the diaphragm vibration is maximized, and the frequency response of the receiver is improved.

Owner:SUZHOU YICHUAN TECH CO LTD

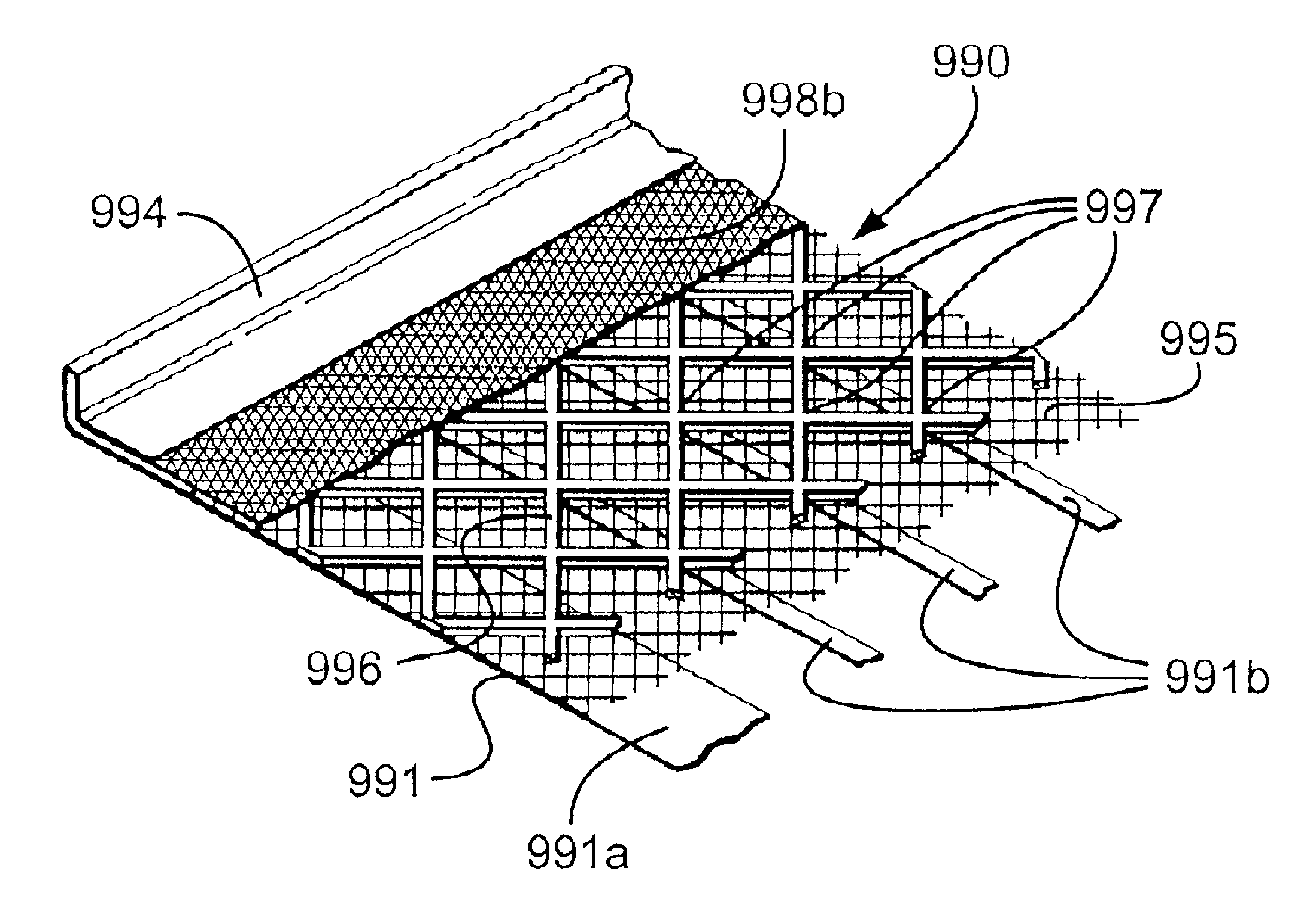

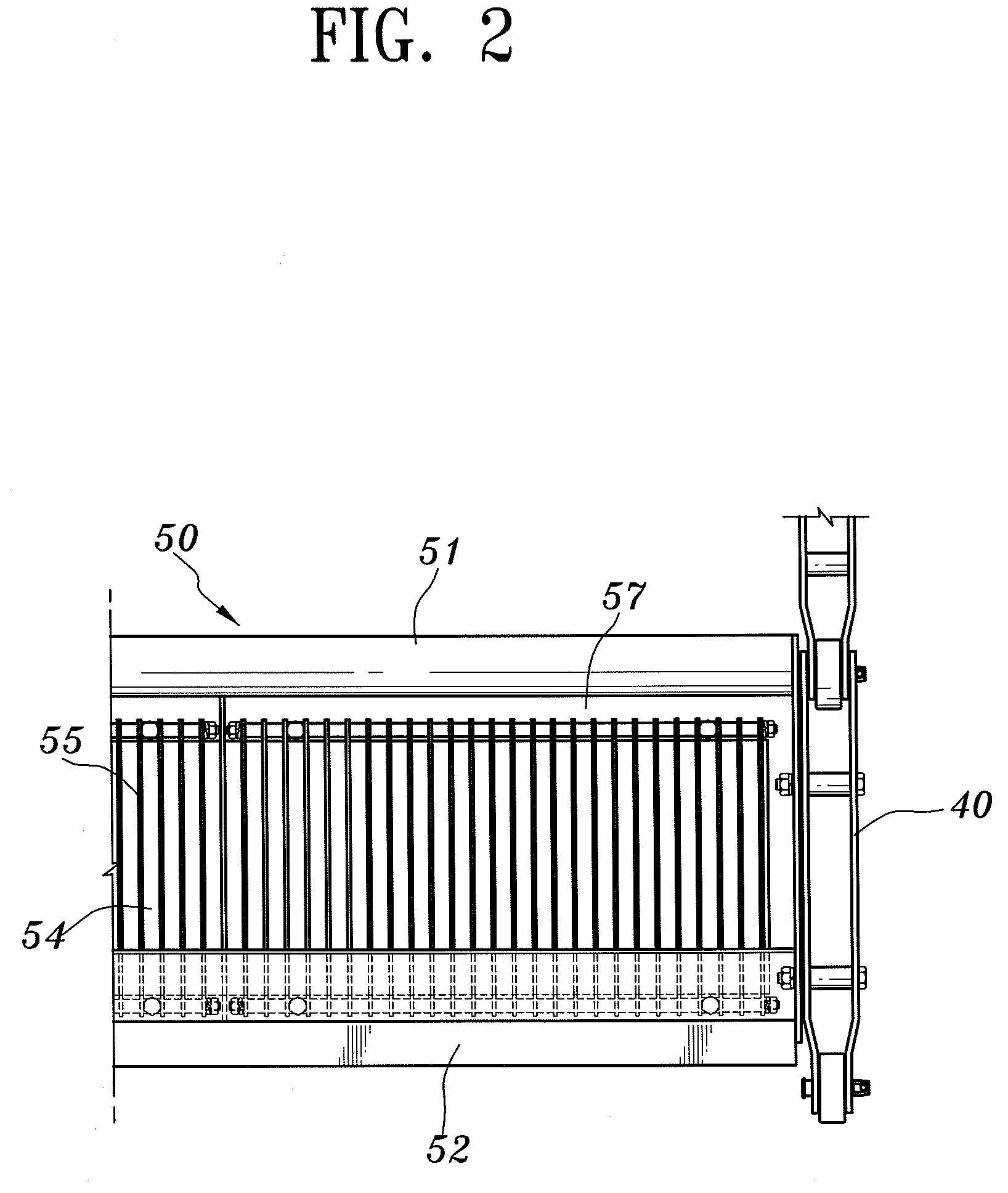

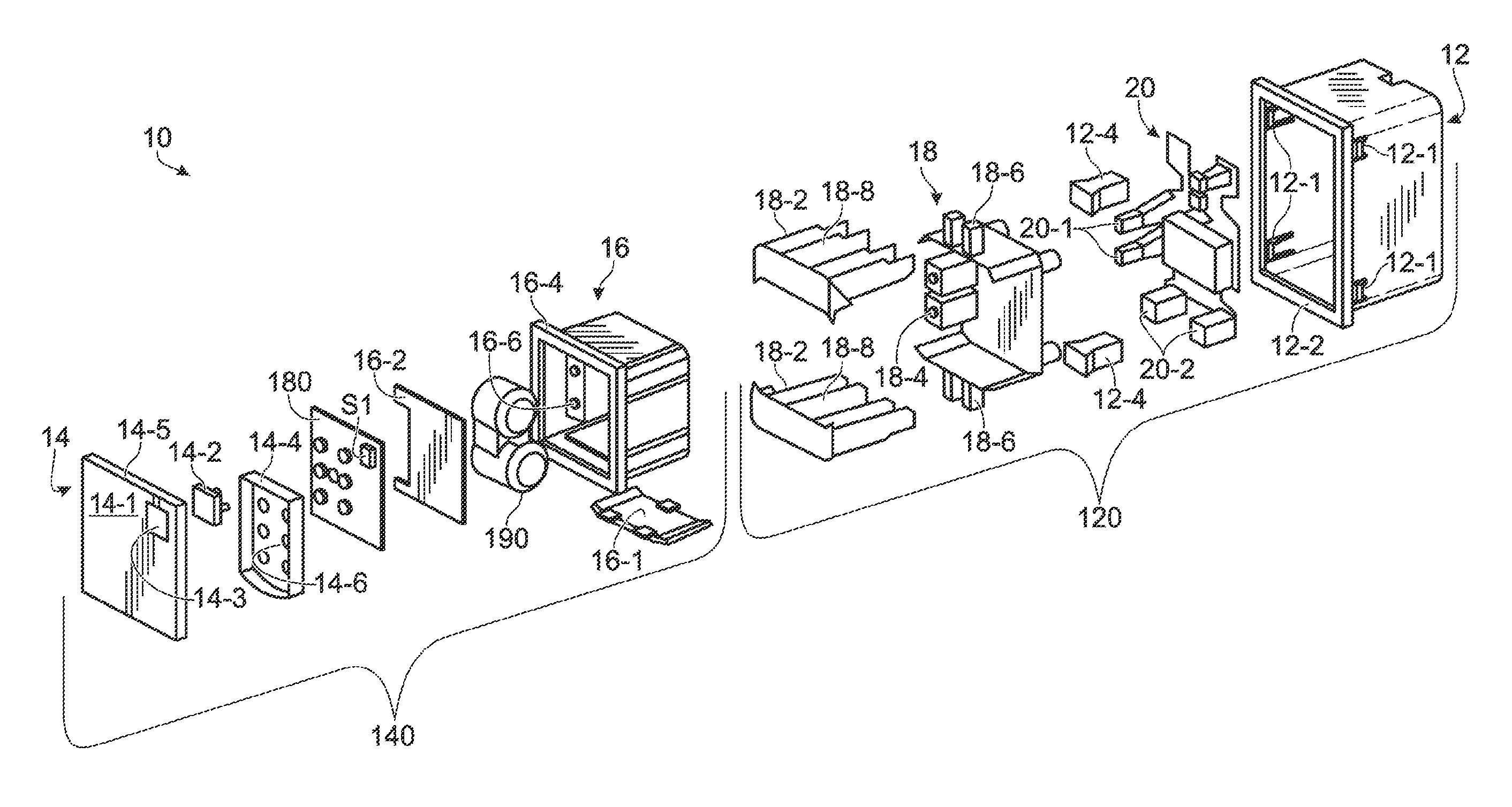

Rotary bar screen device

ActiveUS20070163928A1Increase the effective areaEffective Area MaximizationFatty/oily/floating substances removal devicesSeawater treatmentSprocketDrive motor

Provided is a rotary bar screen device. The device includes a driving motor, an up / down pair of driving and driven sprockets, left and right transfer chains, a plurality of screen buckets, a removal unit, and a slide plate. The driving motor is provided over a support frame, and transmits a driving force. The driving and driven sprockets are driven by the driving force. The left and right transfer chains connect the driving and driven sprockets with each other while circulatively moving. The plurality of screen buckets are provided between the left and right transfer chains. The removal unit is provided between the left and right driving sprockets. The slide plate guides the foreign materials dropping from the screen buckets.

Owner:COWAY ENTECH CO LTD

Classifier with variable entry ports

InactiveUS8820535B2Effective areaEffective Area MaximizationGas current separationSortingEngineeringCoal

Multiple embodiments of a variable flow classifier for vertical air-swept coal pulverizers are disclosed. In all embodiments, a classifier structure includes a cone with means for providing a pattern of inlet ports for introducing airborne coal to the cone wherein said means allows for selective variation in the size of the ports.

Owner:WARK RICKEY E

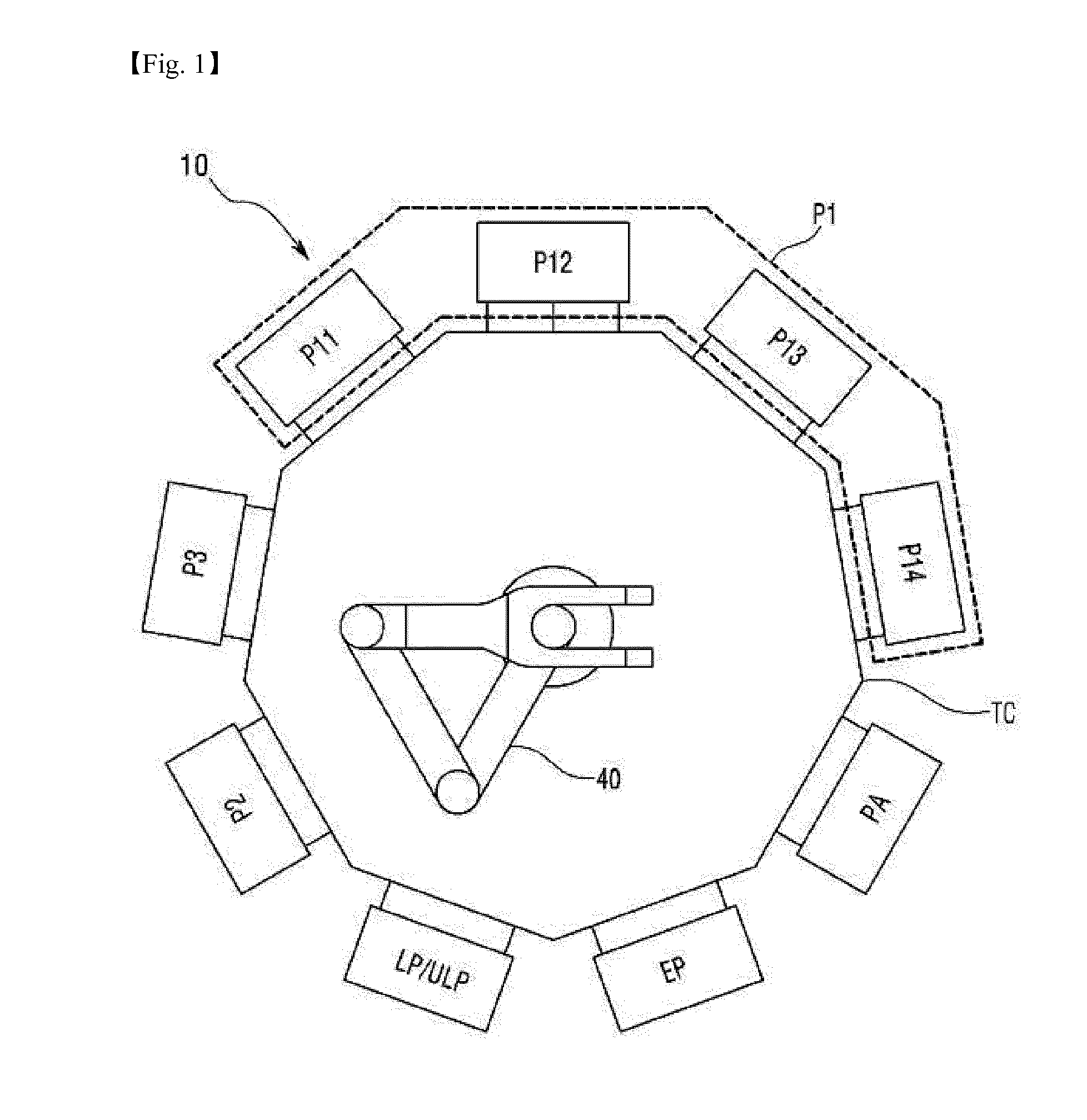

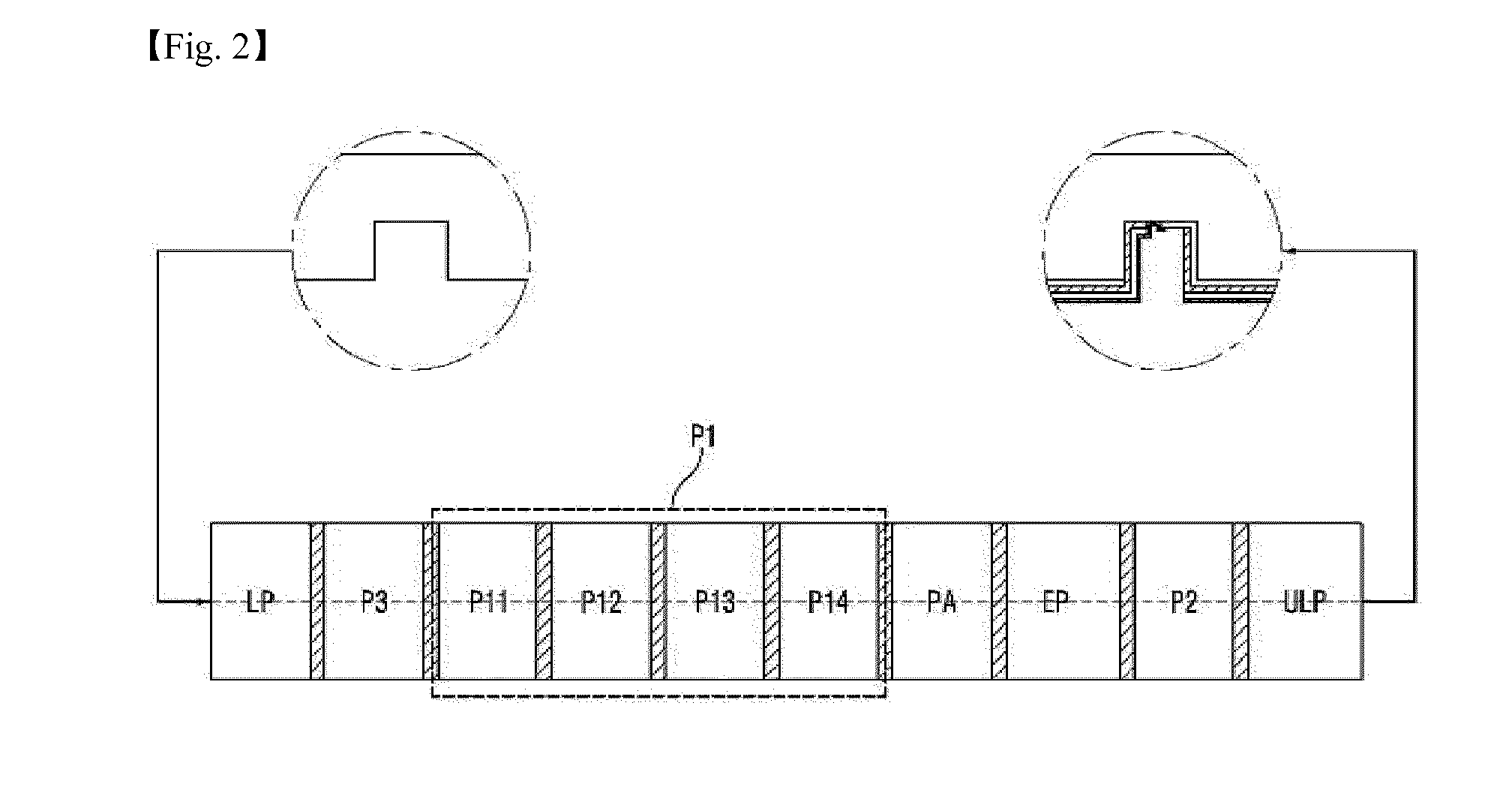

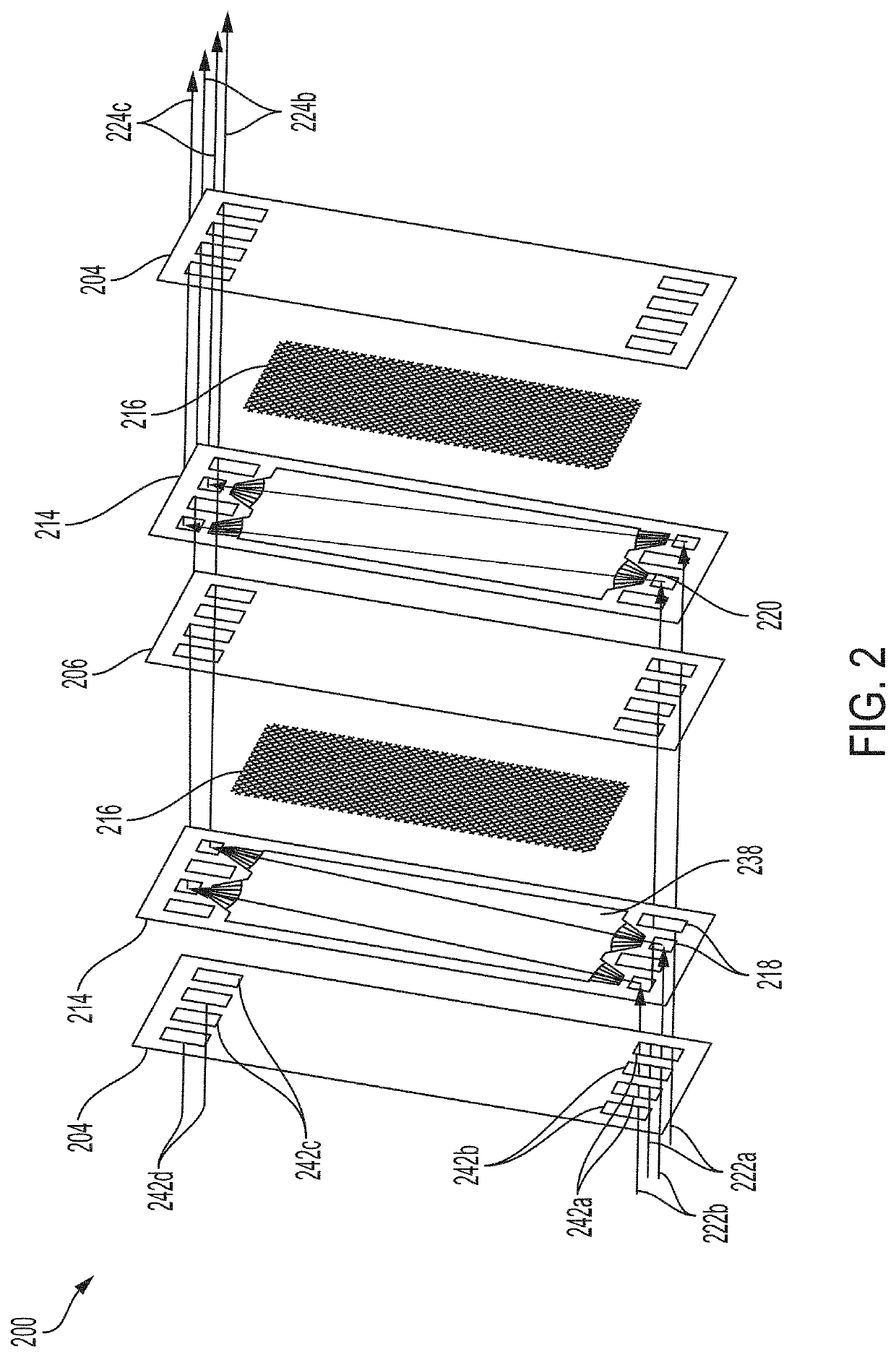

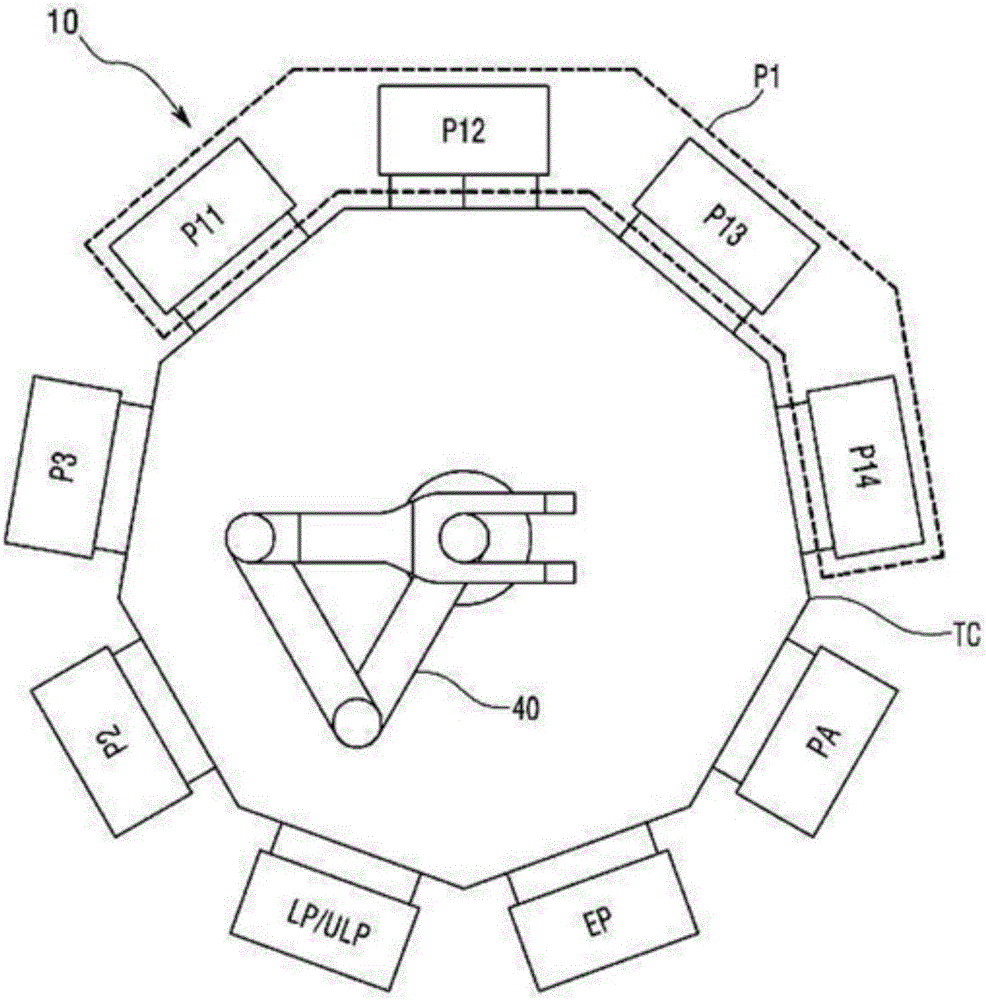

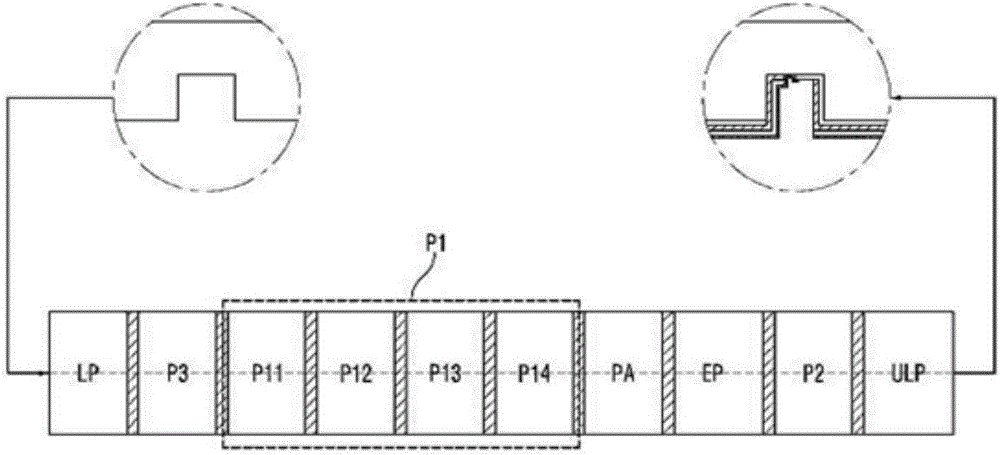

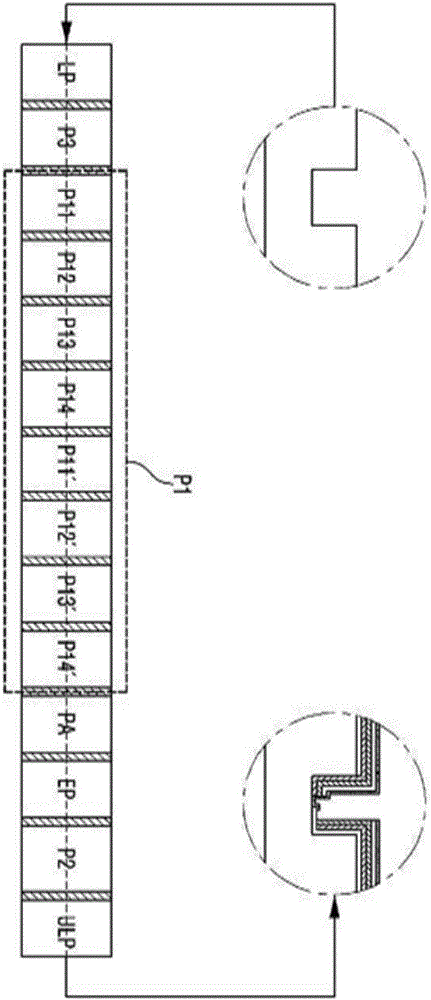

Device for manufacturing integrated thin film solar cell

InactiveUS20160329446A1Effective Area MaximizationMaximize power productionPhotovoltaic energy generationSemiconductor devicesPhotoelectric conversionForming processes

An apparatus for manufacturing an integrated thin film solar cell in which a plurality of unit cells are electrically connected in series to each other in vacuum may be provided that includes: a photoelectric converter forming process chamber which forms a photoelectric converter by emitting a photoelectric conversion material on a substrate where a first conductive layer has been formed from one basic line within each of a plurality of trenches formed in the substrate to a bottom of each of the trenches, to one side continuous from the bottom, and to a protruding surface of the substrate, which is continuous from the one side; and a second conductive layer forming process chamber which forms a second conductive layer from another basic line within each of the trenches to the bottom of each of the trenches, to the other side continuous from the bottom, and to a protruding surface of the substrate, which is continuous from the other side. The photoelectric converter forming process chamber and the second conductive layer forming process chamber perform the respective processes in vacuum.

Owner:KOREA ADVANCED INST OF SCI & TECH

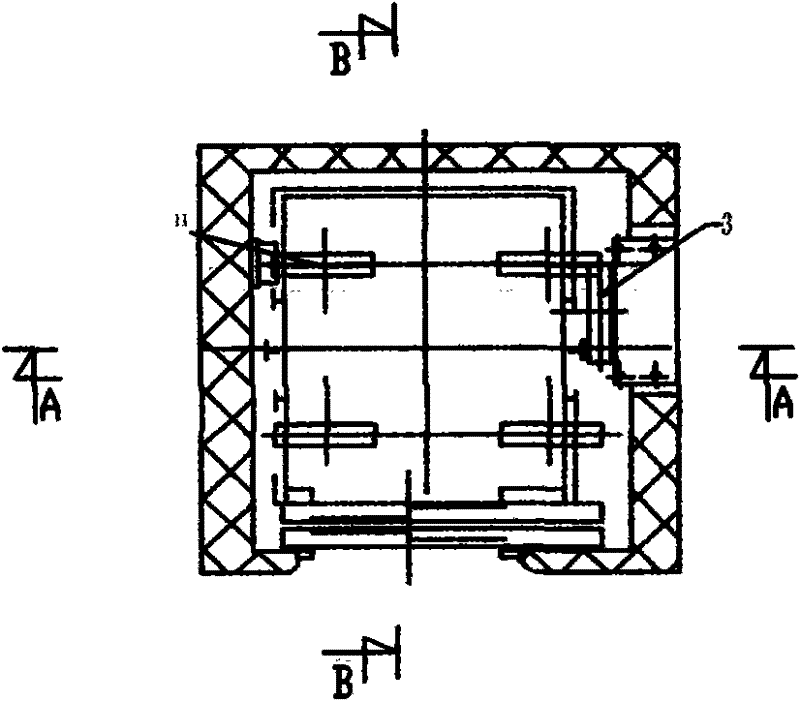

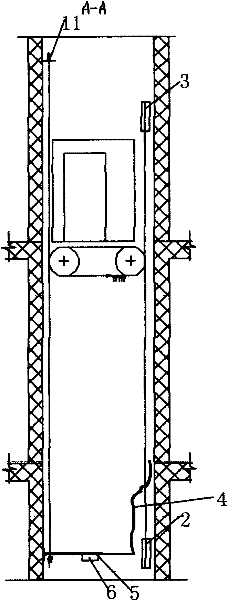

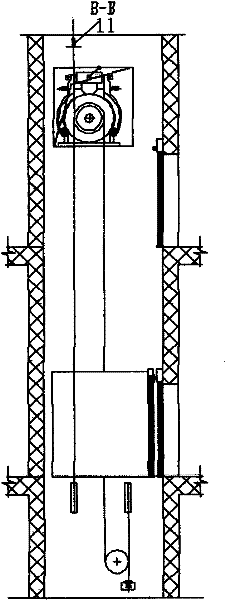

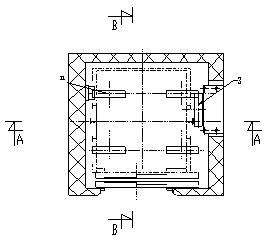

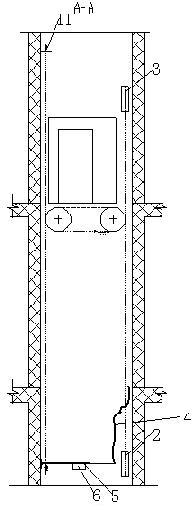

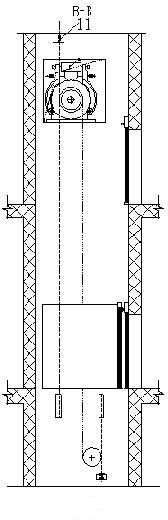

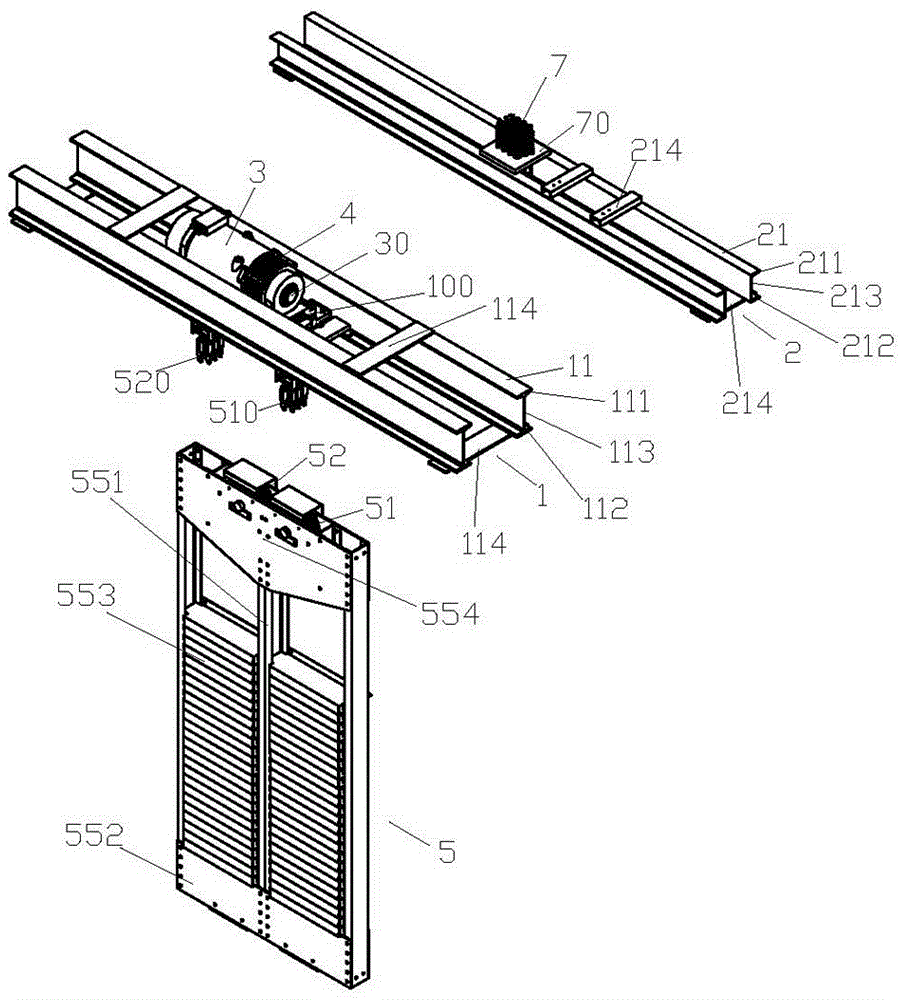

Counter-weight-free traction type passenger elevator

InactiveCN102408052AEffective Area MaximizationImprove area utilizationBuilding liftsEngineeringGantry crane

The invention discloses a counter-weight-free traction type passenger elevator, which relates to an elevator structure, in particular to a counter-weight-free traction type elevator structure. The counter-weight-free traction type passenger elevator comprises a steel structure, a lift car, a guide wheel, a traction wheel, a traction machine, a traction steel wire rope, a gantry crane, a landing door device, a buffer, a guide rail, a speed limiter steel wire rope and a speed limiter tensioning wheel, wherein the steel structure consists of vertical framework beams and transverse framework beams, the lift car, the guide wheel, the traction wheel, the traction machine, the traction steel wire rope, the gantry crane, the landing door device, the buffer, the guide rail, the speed limiter steel wire rope and the speed limiter tensioning wheel are arranged in the steel structure, a pair of guide rails are arranged at the left side and the right side of the inner side of the steel structure, the lift car is arranged in the steel structure and is glidingly matched with the guide rails, the traction steel wire rope is arranged on the lift car, the traction wheel, the traction machine and the guide wheel, the gantry crane and the landing door device are arranged on the lift car, the bottom of the steel structure is provided with a buffer, and one side of the traction steel wire rope is provided with the speed limiter tensioning wheel. The invention provides the counter-weight-free traction type passenger elevator with the advantages that the area utilization rate of hoistways is improved, the matched facility cost of buildings is reduced, and the installation and the debugging are convenient.

Owner:ANHUI ZHONGLING ELEVATOR

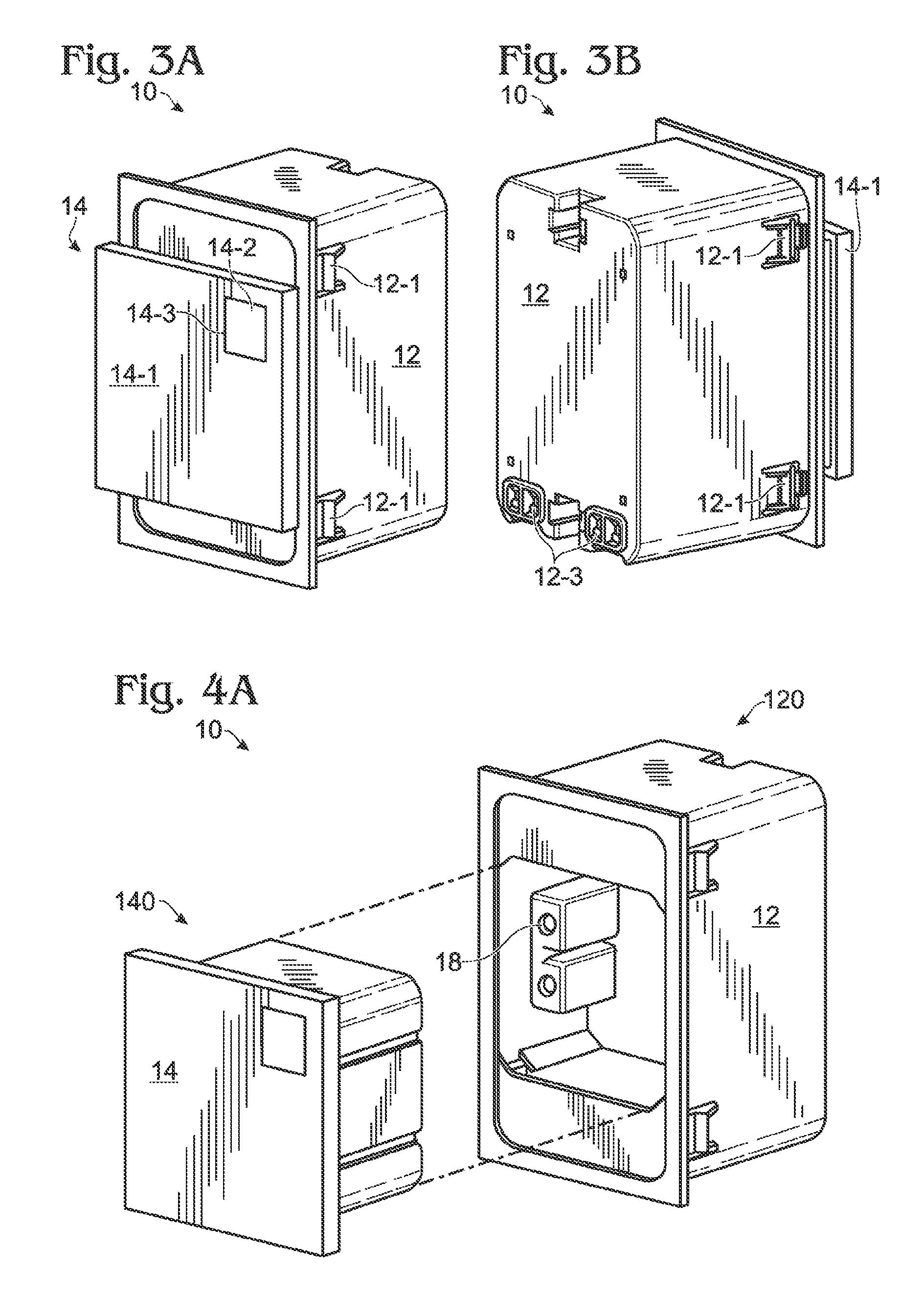

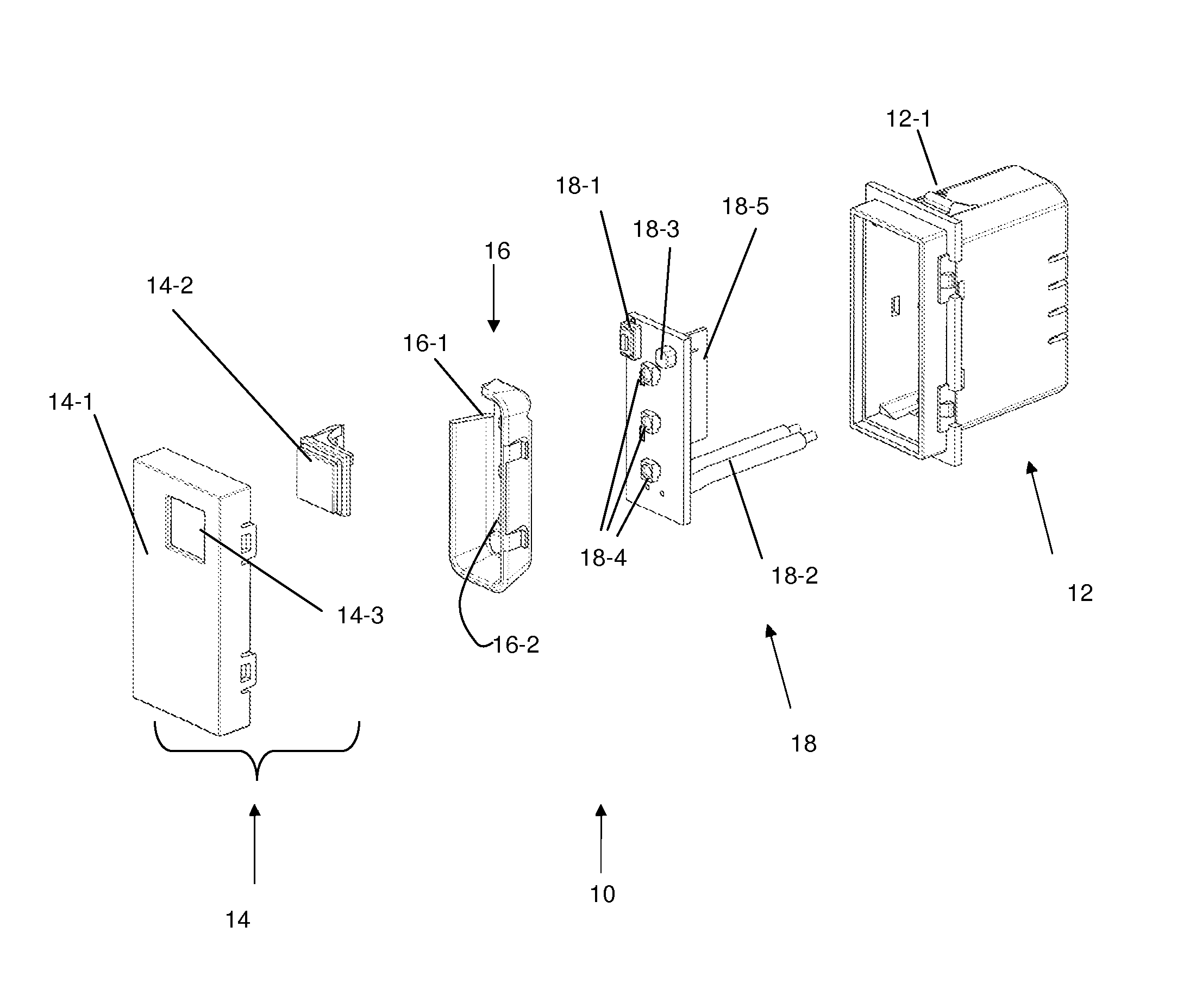

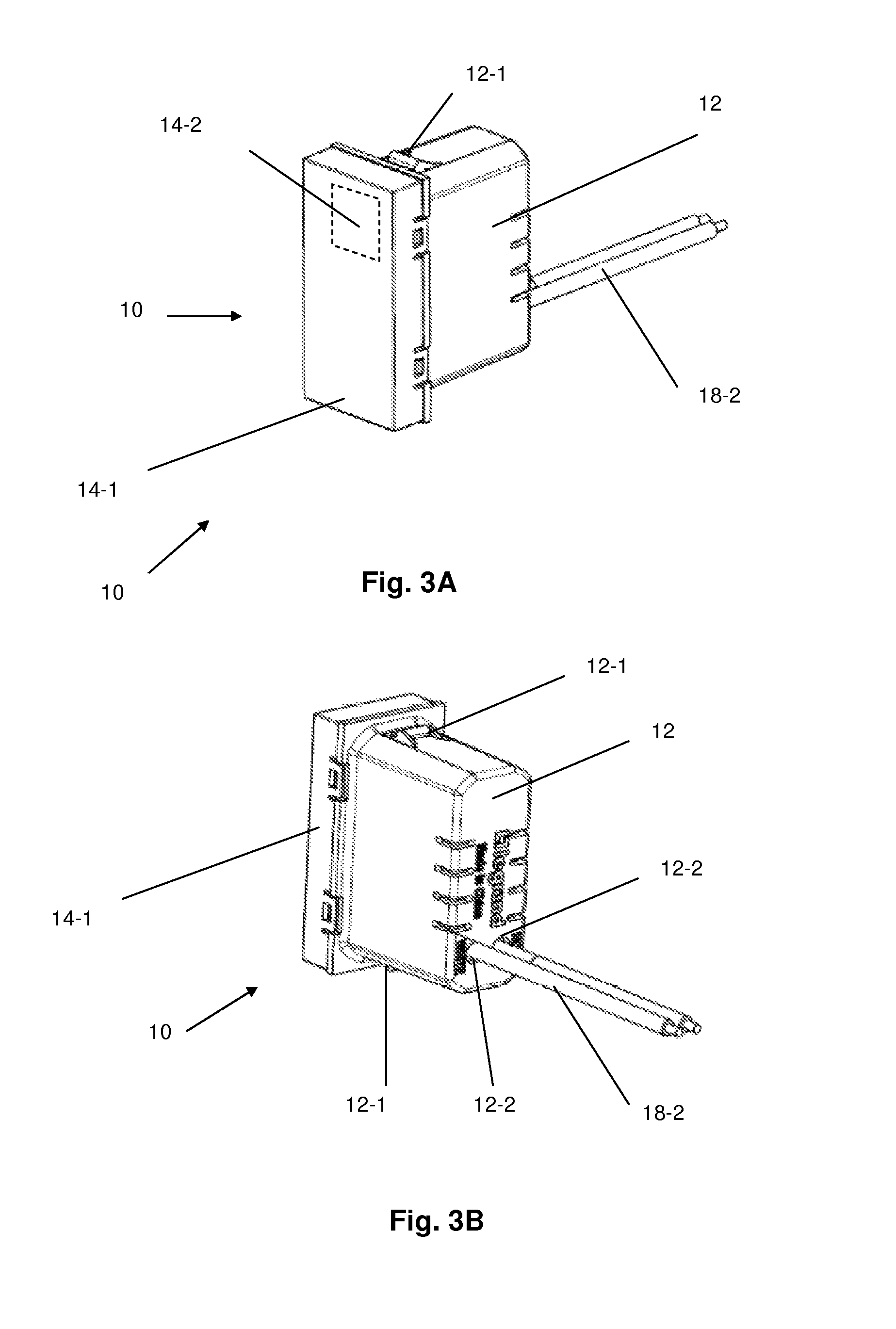

Removable night light

ActiveUS9167667B2Effective Area MaximizationSacrificing sensor isolationElectrical apparatusElectric light circuit arrangementLight beamEngineering

The present invention is directed to an electrical device that includes a lighting circuit is disposed in the second housing and coupled to the voltage output terminals. The lighting circuit includes a control circuit coupled to a plurality of first light elements and at least one second lighting element. The plurality of first light elements is configured to provide a relatively wide illumination beam when energized by the control circuit in a first operational state, and the at least one second lighting element being configured to provide a relatively narrow illumination beam when energized by the control circuit in a second operational state. The control circuit is configured such that the first operational state and second operational state do not simultaneously occur.

Owner:PASS SEYMOUR

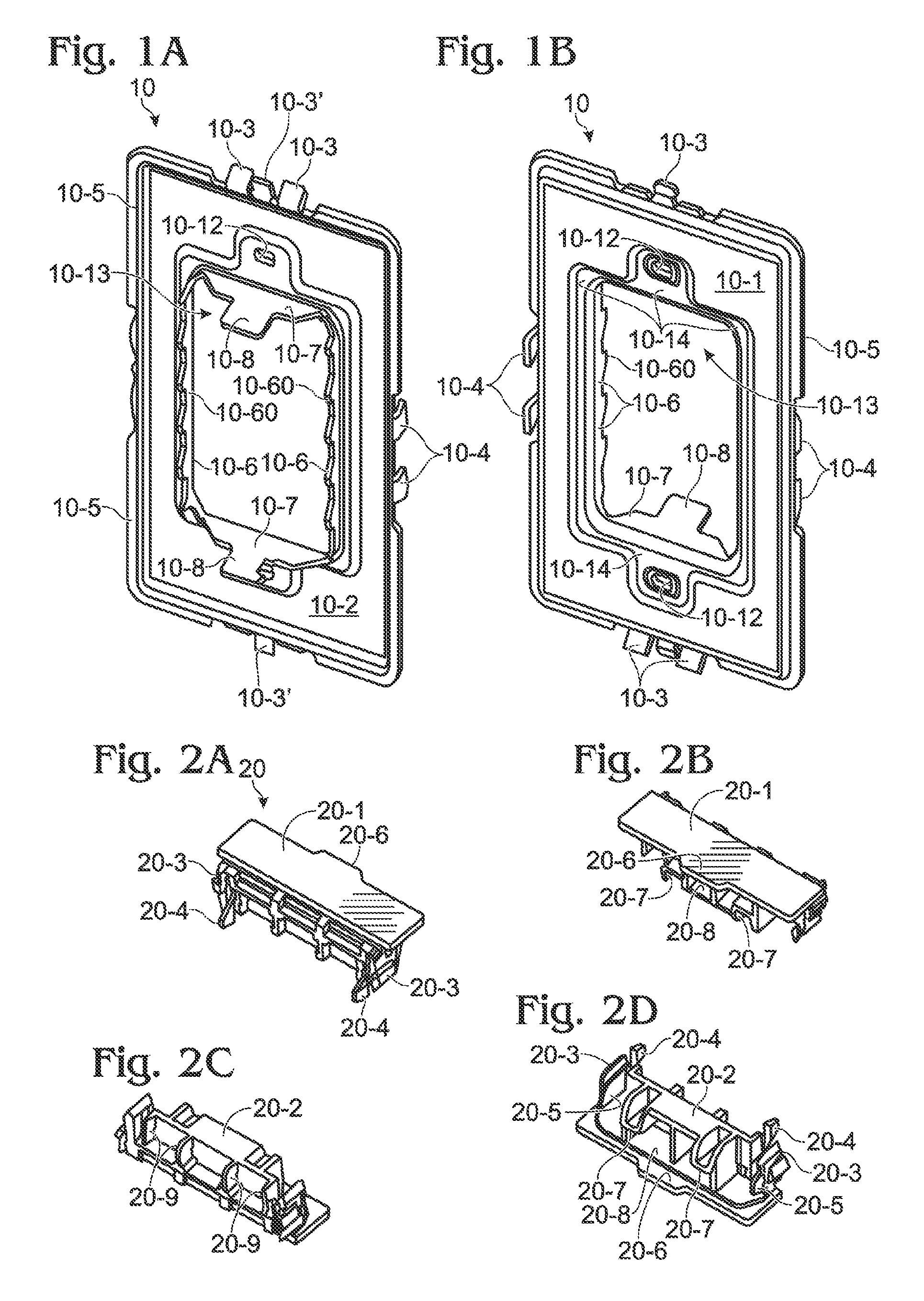

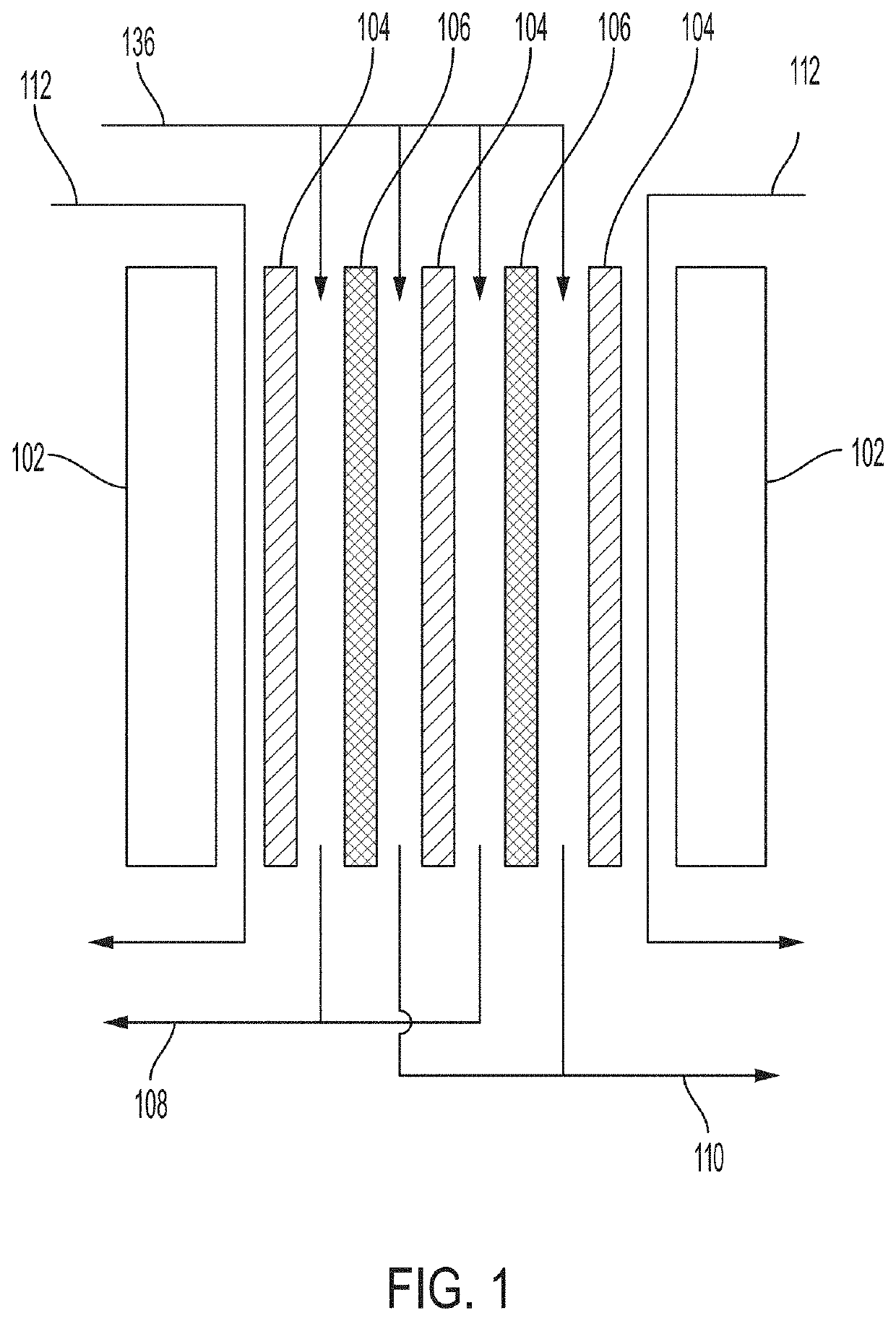

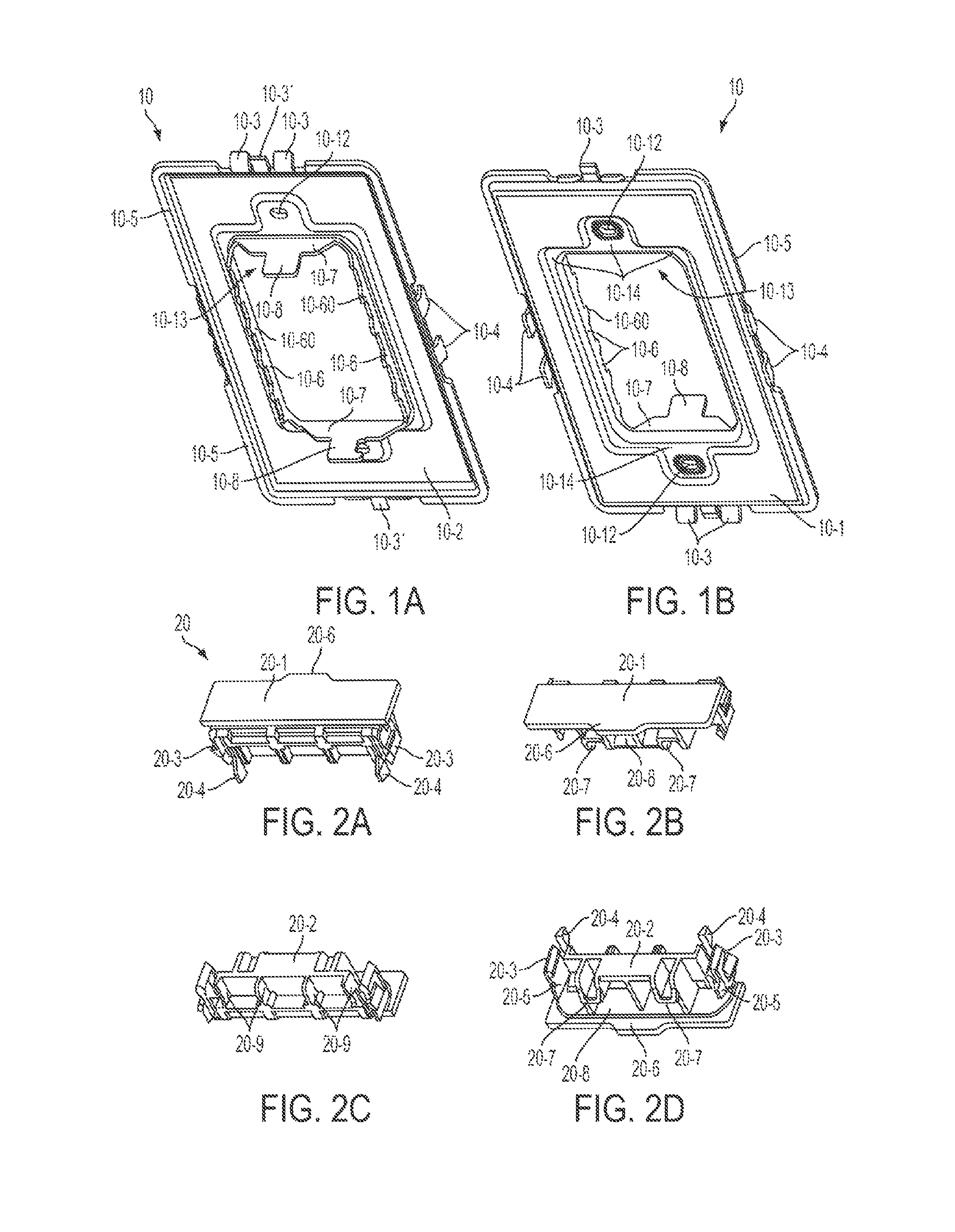

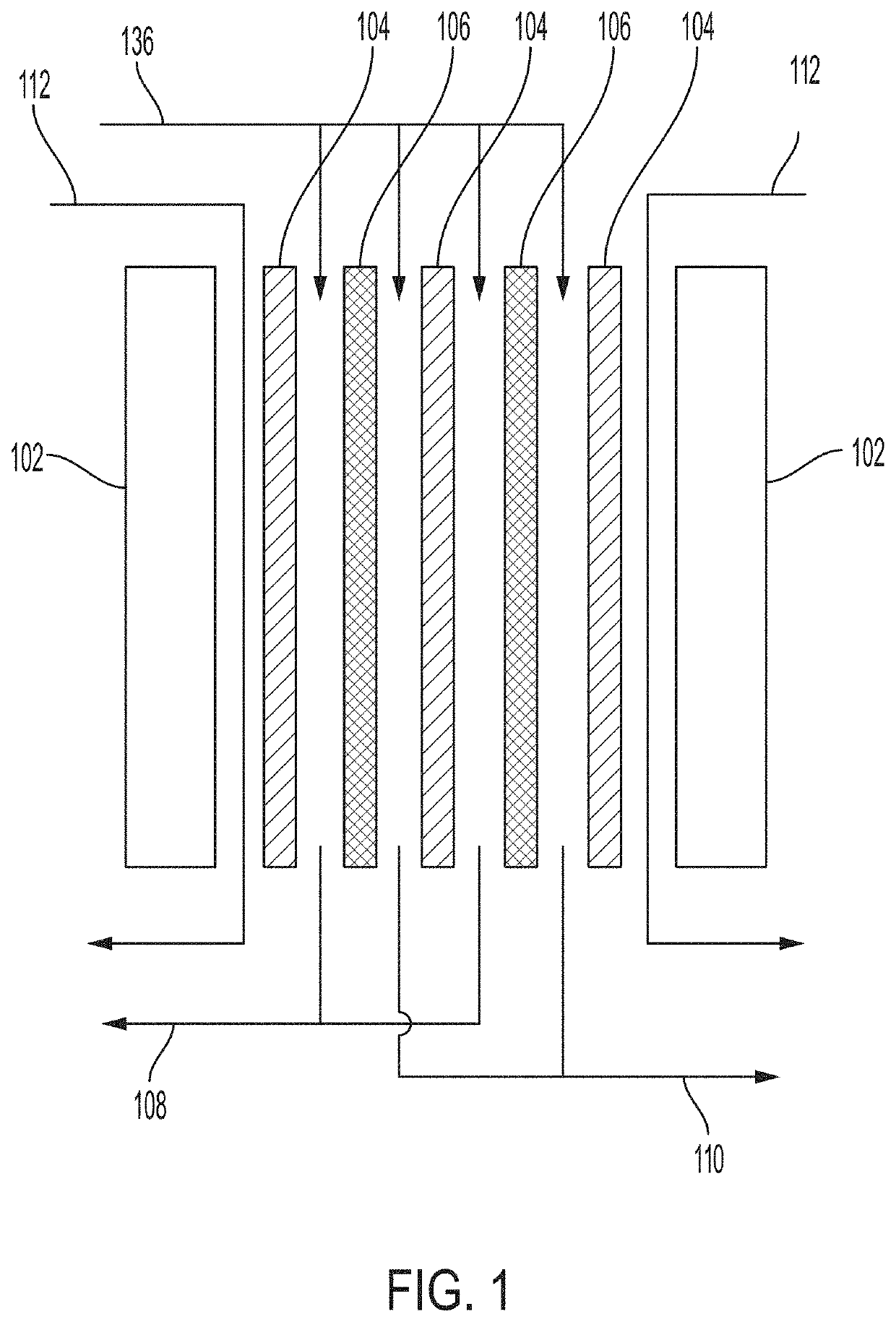

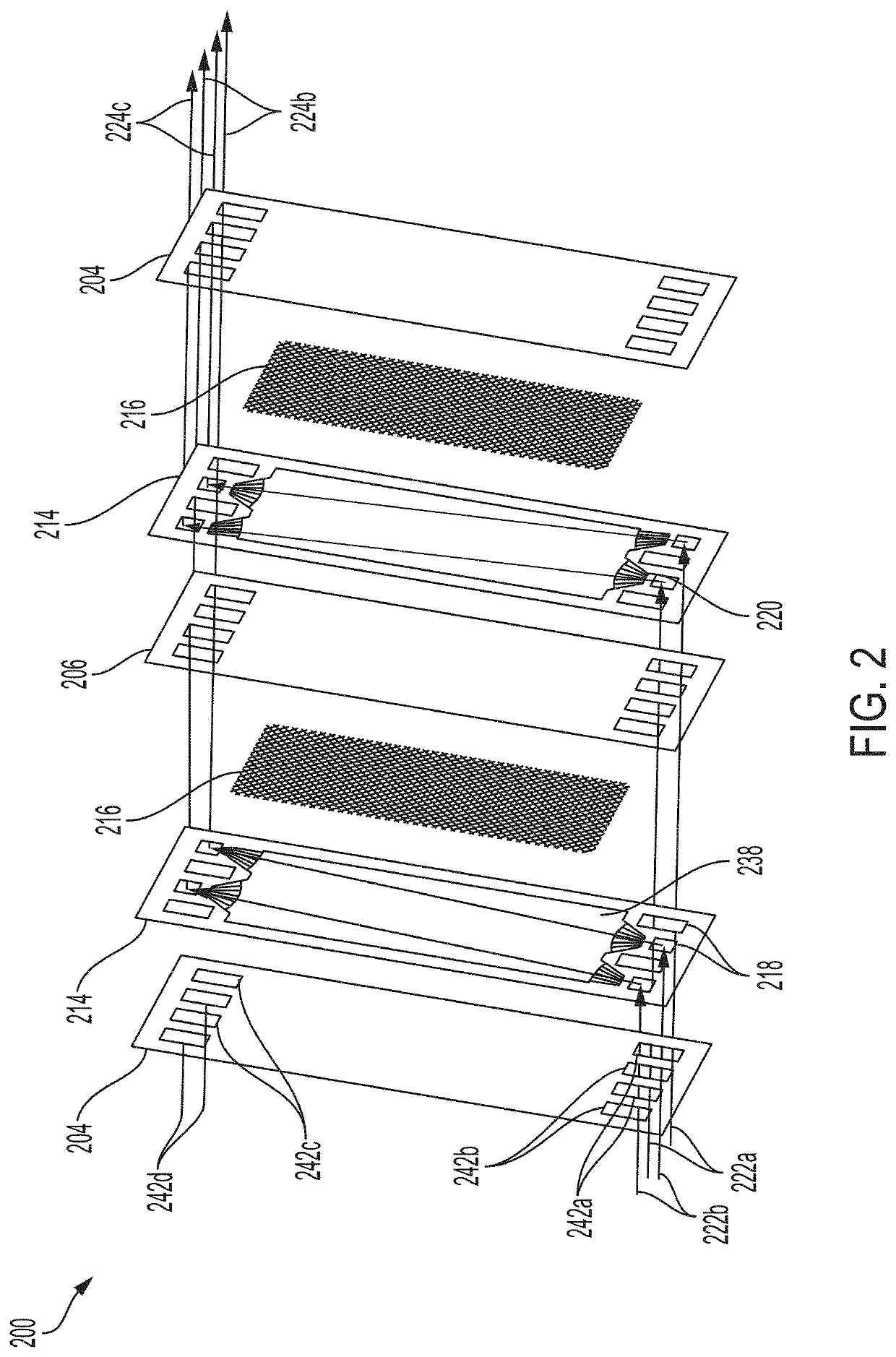

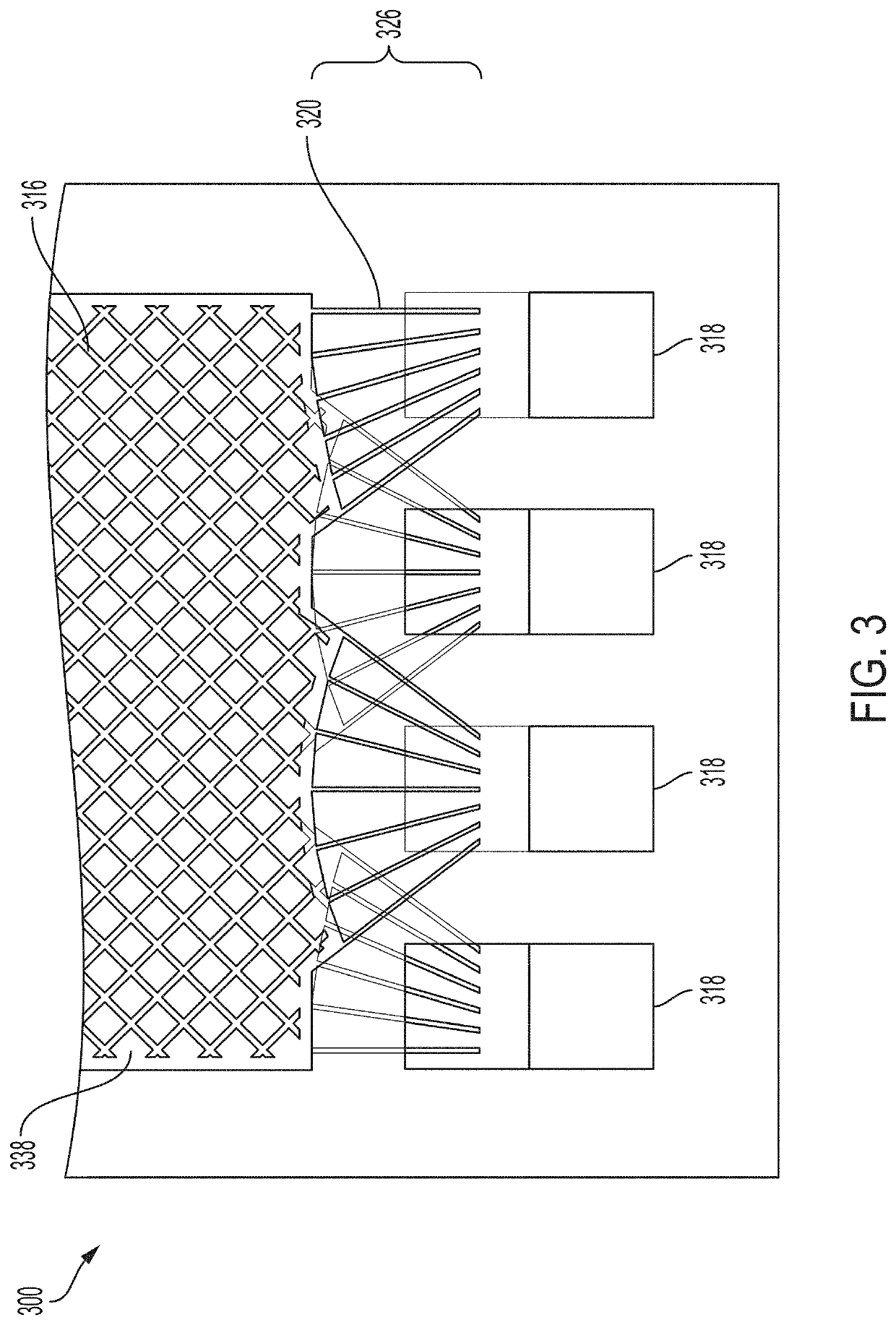

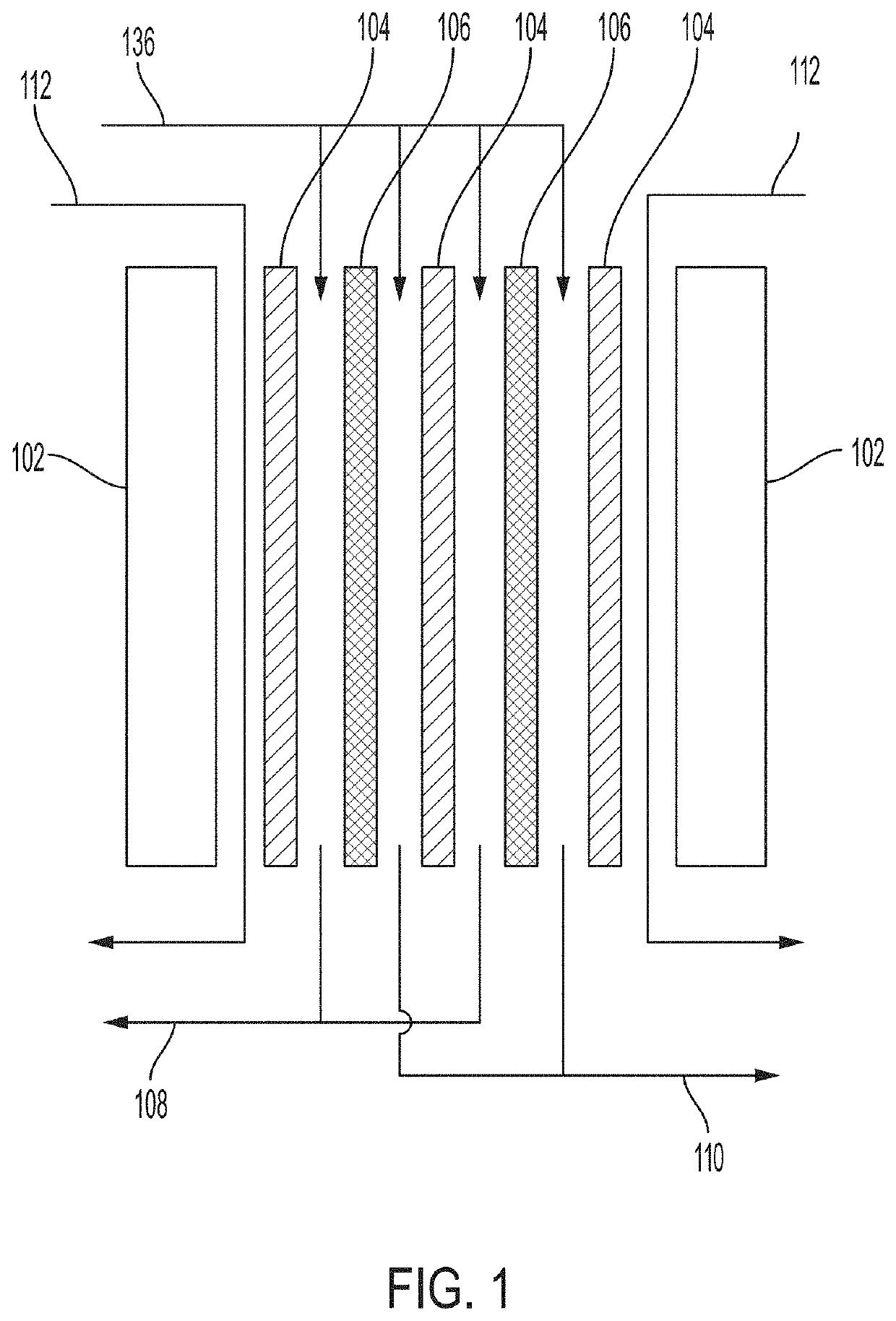

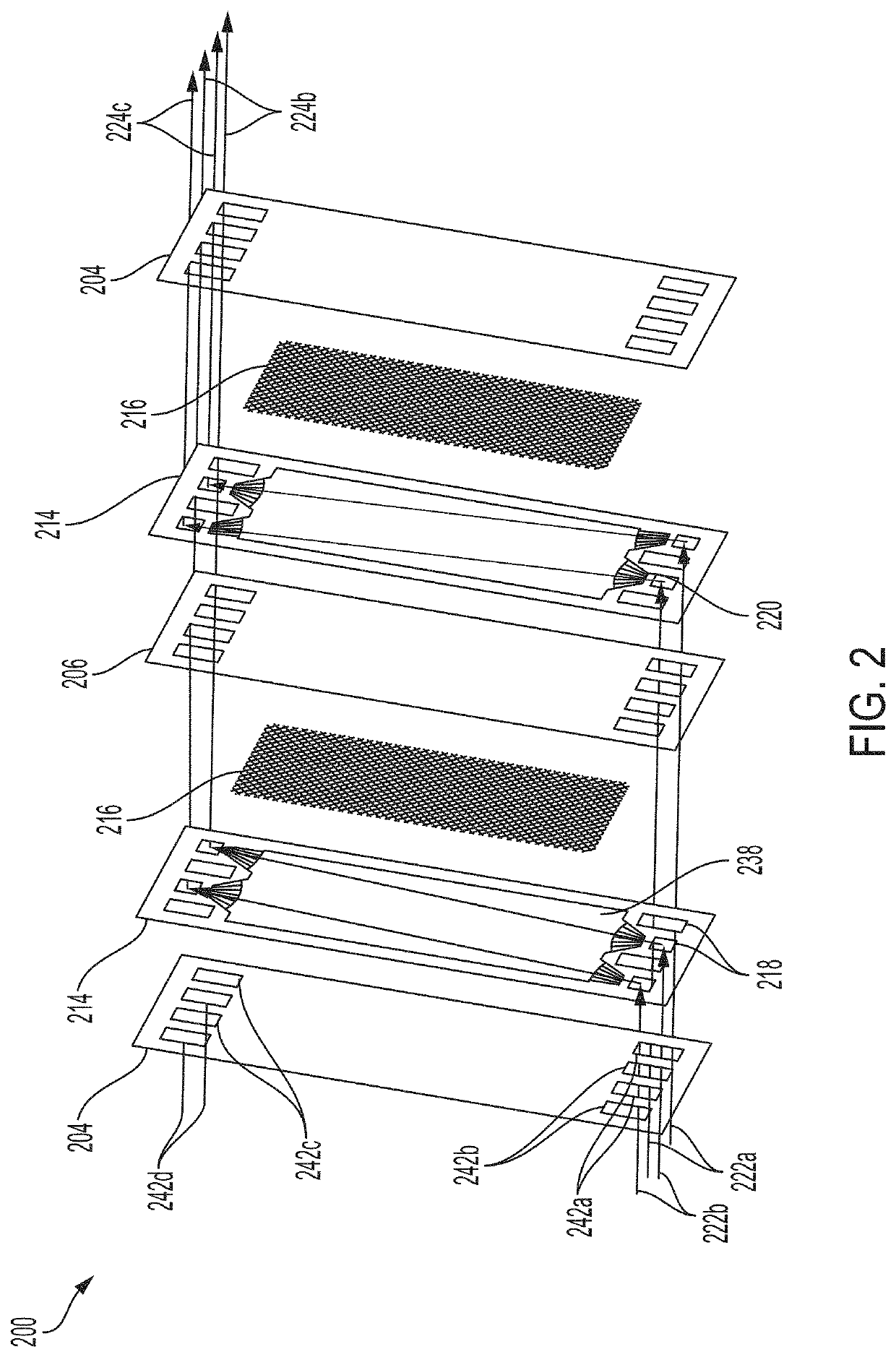

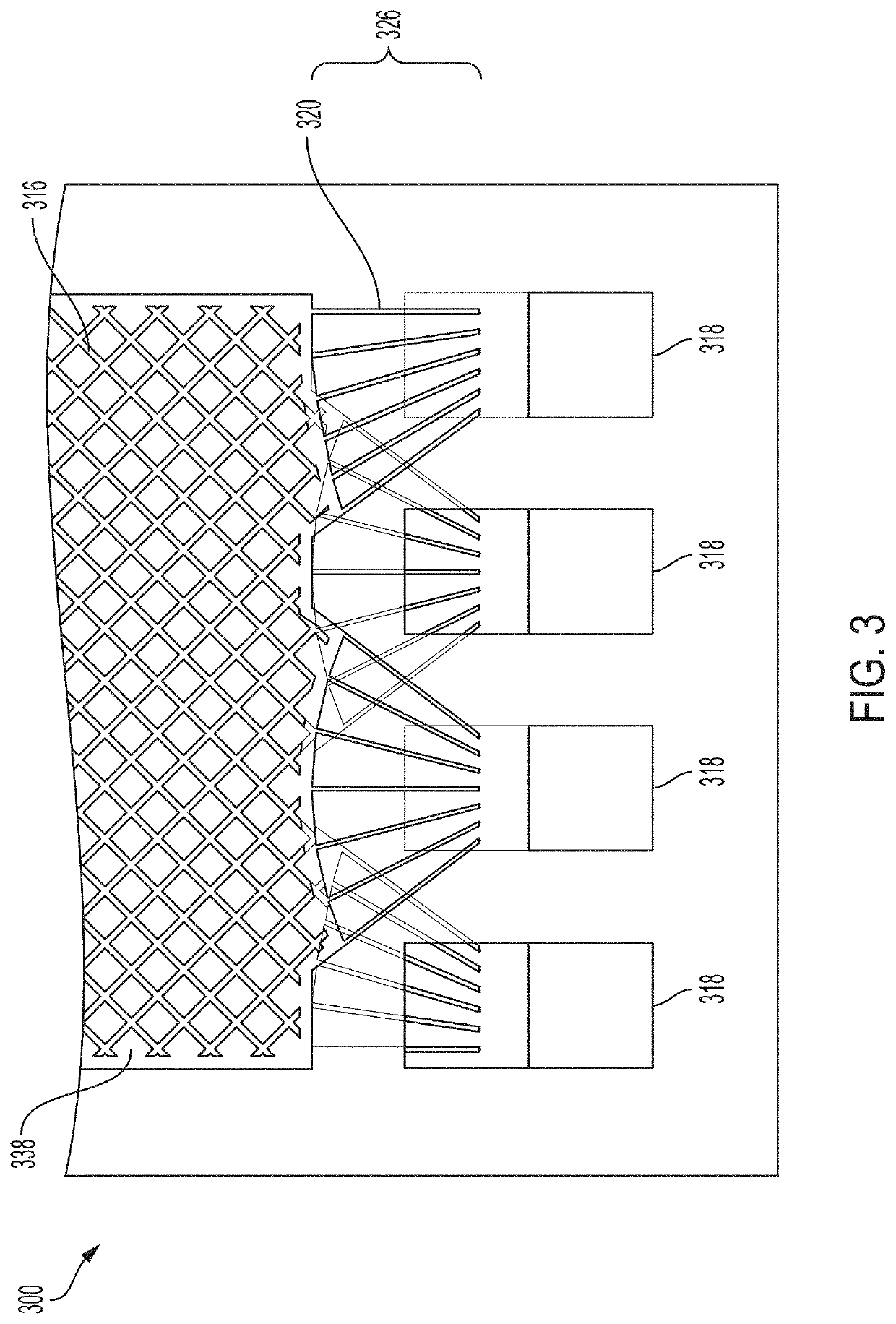

Spacers for ion-exchange device

ActiveUS20200155967A1Maximize recoveryMinimize safety hazardMembranesCation exchanger materialsPhysicsIon exchange

Provided are spacers, ion-exchange devices comprising spacers, and methods of preparing spacers for improved fluid distribution and sealing throughout an ion-exchange device. These spacers can include an internal cavity surrounded by a perimeter of the spacer. The perimeter can have a first opening and a second opening within the perimeter, and the first opening and the second opening can be located on opposite sides of the internal cavity. The spacers can also have a first and second plurality of channels located within the perimeter, wherein each channel of the first and second plurality of channels extends from the internal cavity towards the first opening or the second opening.

Owner:MAGNA IMPERIO SYST

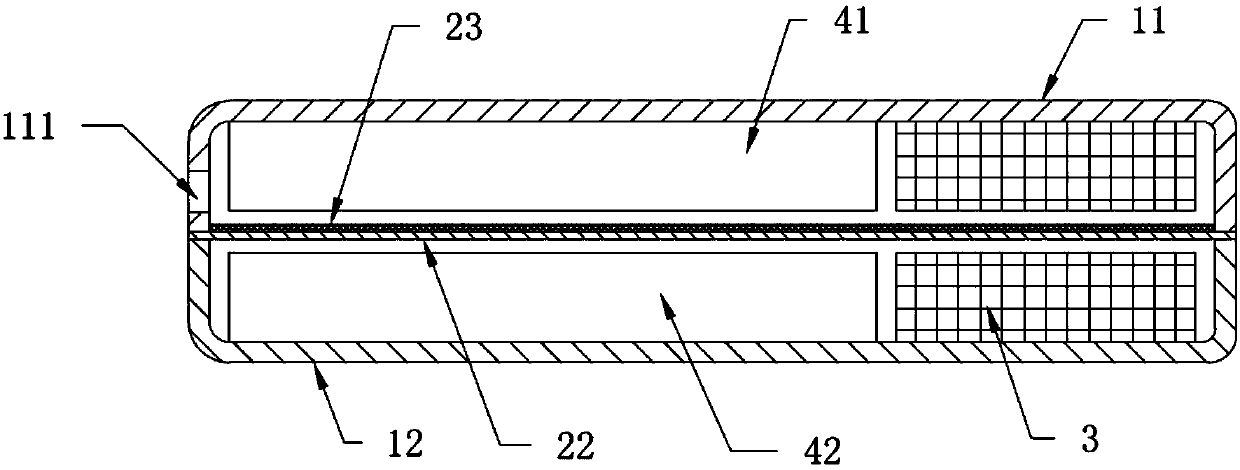

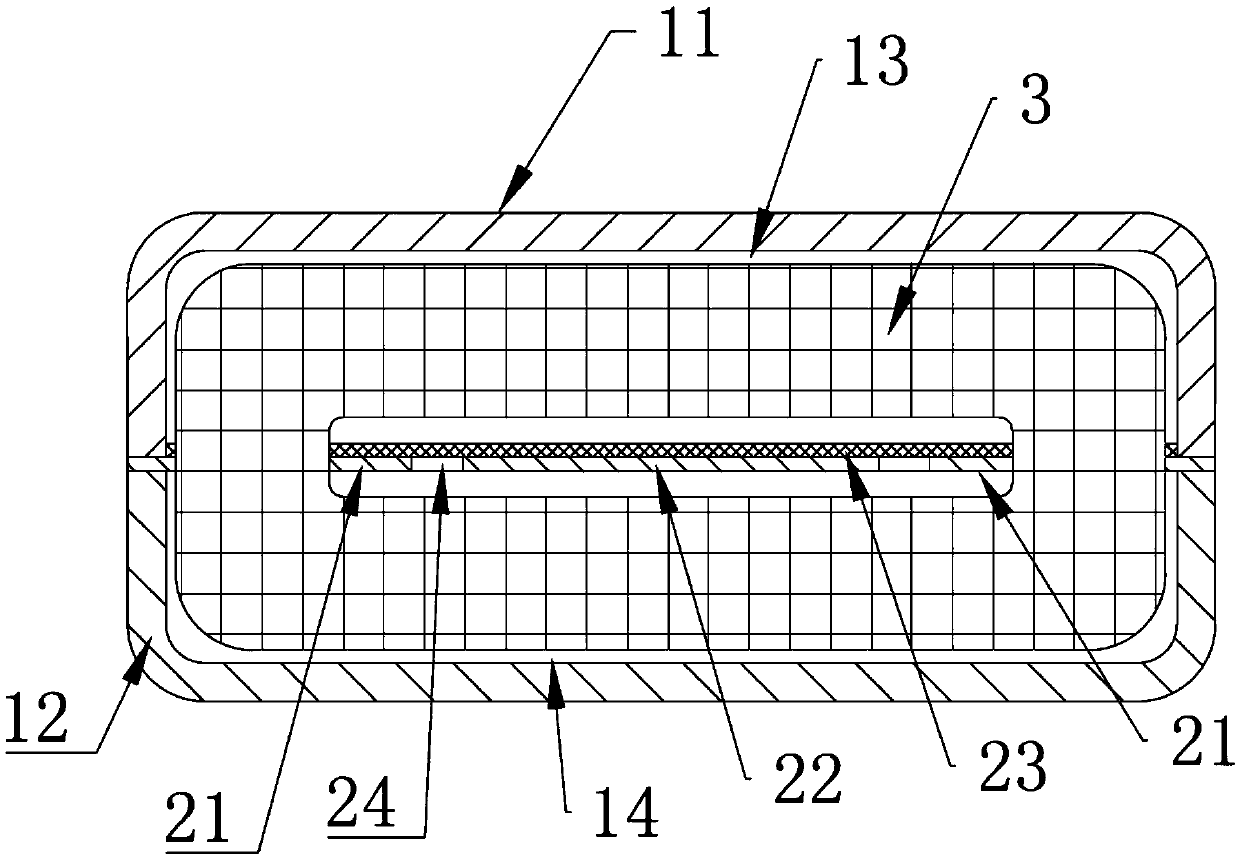

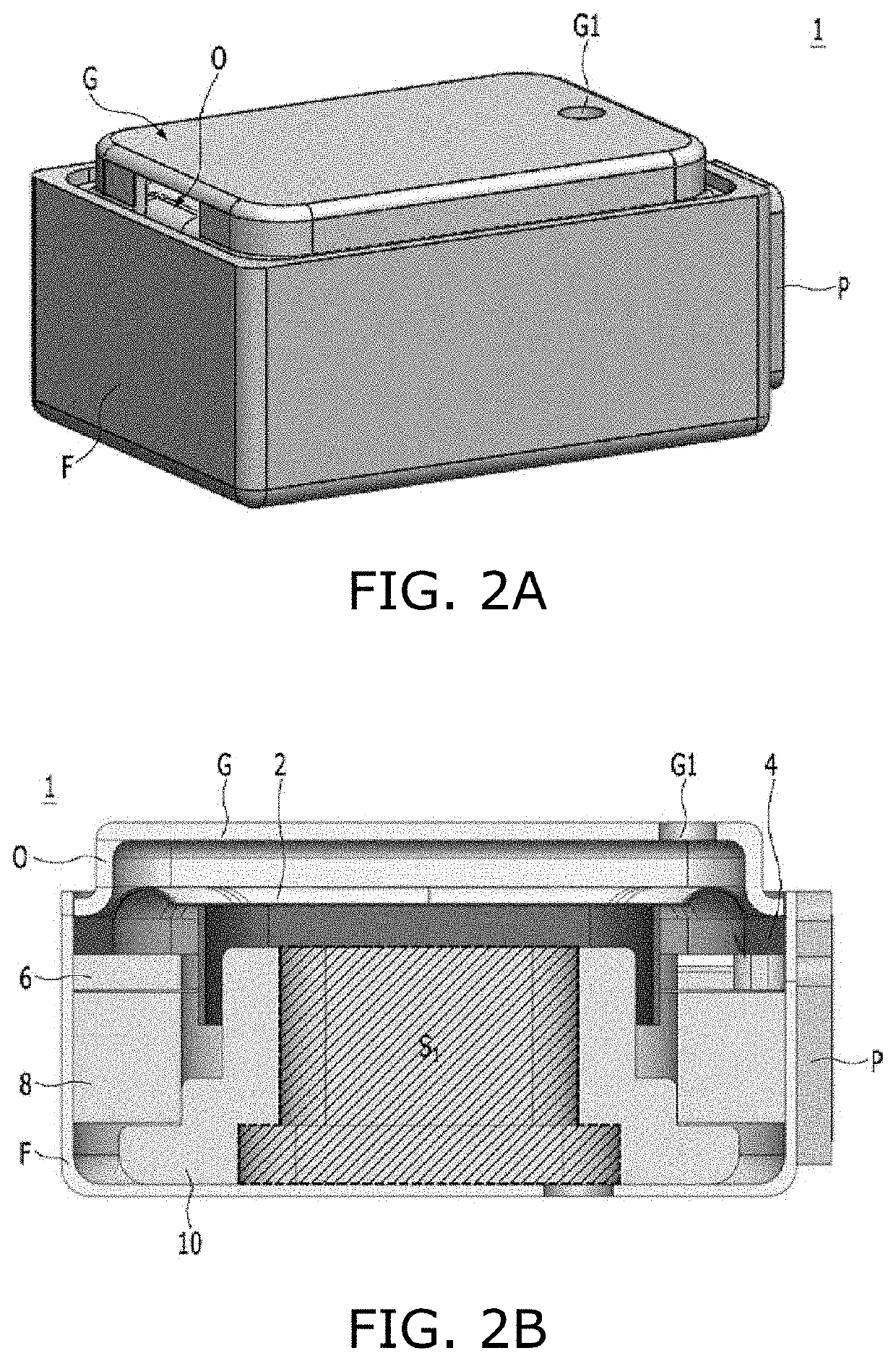

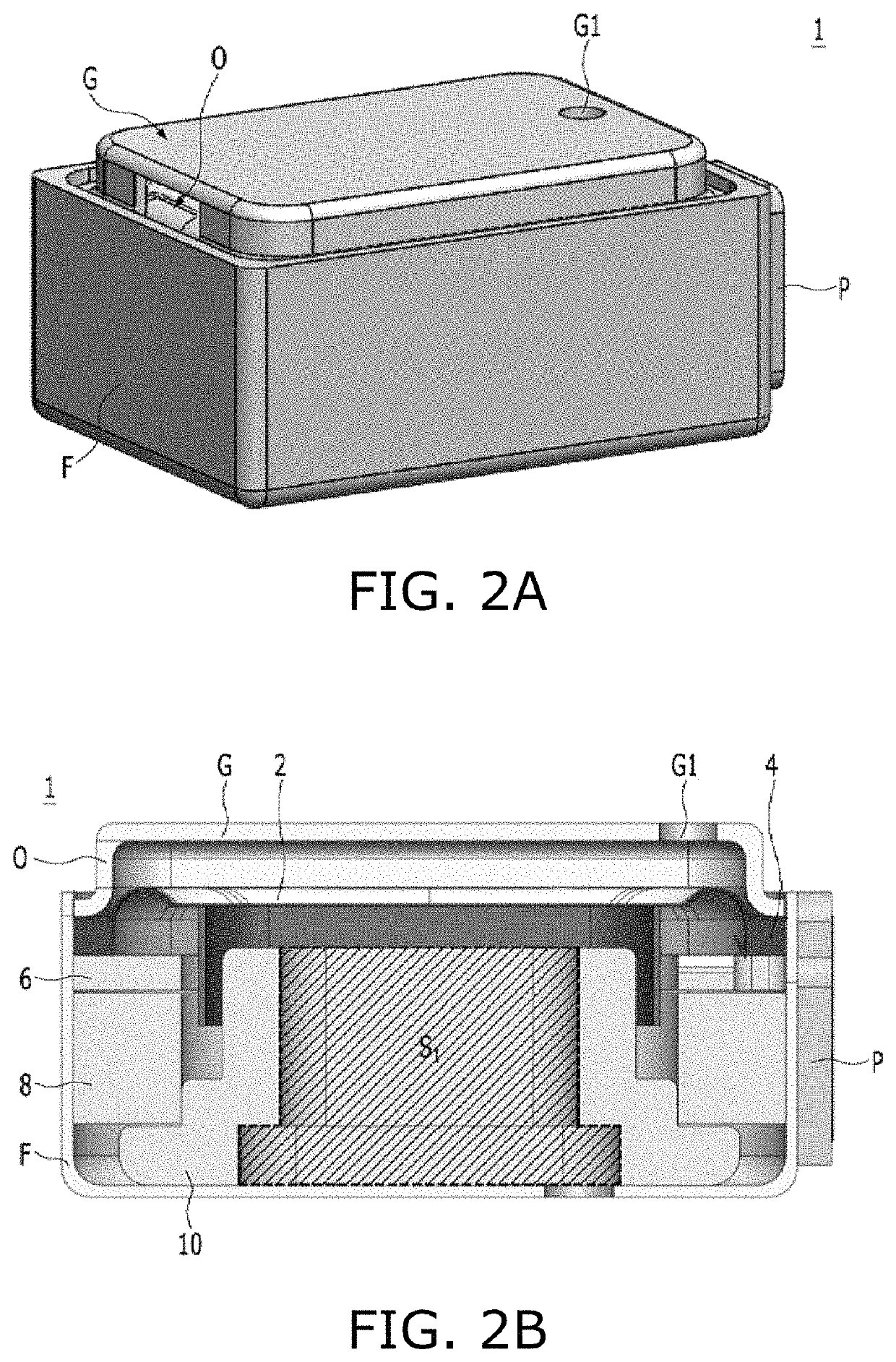

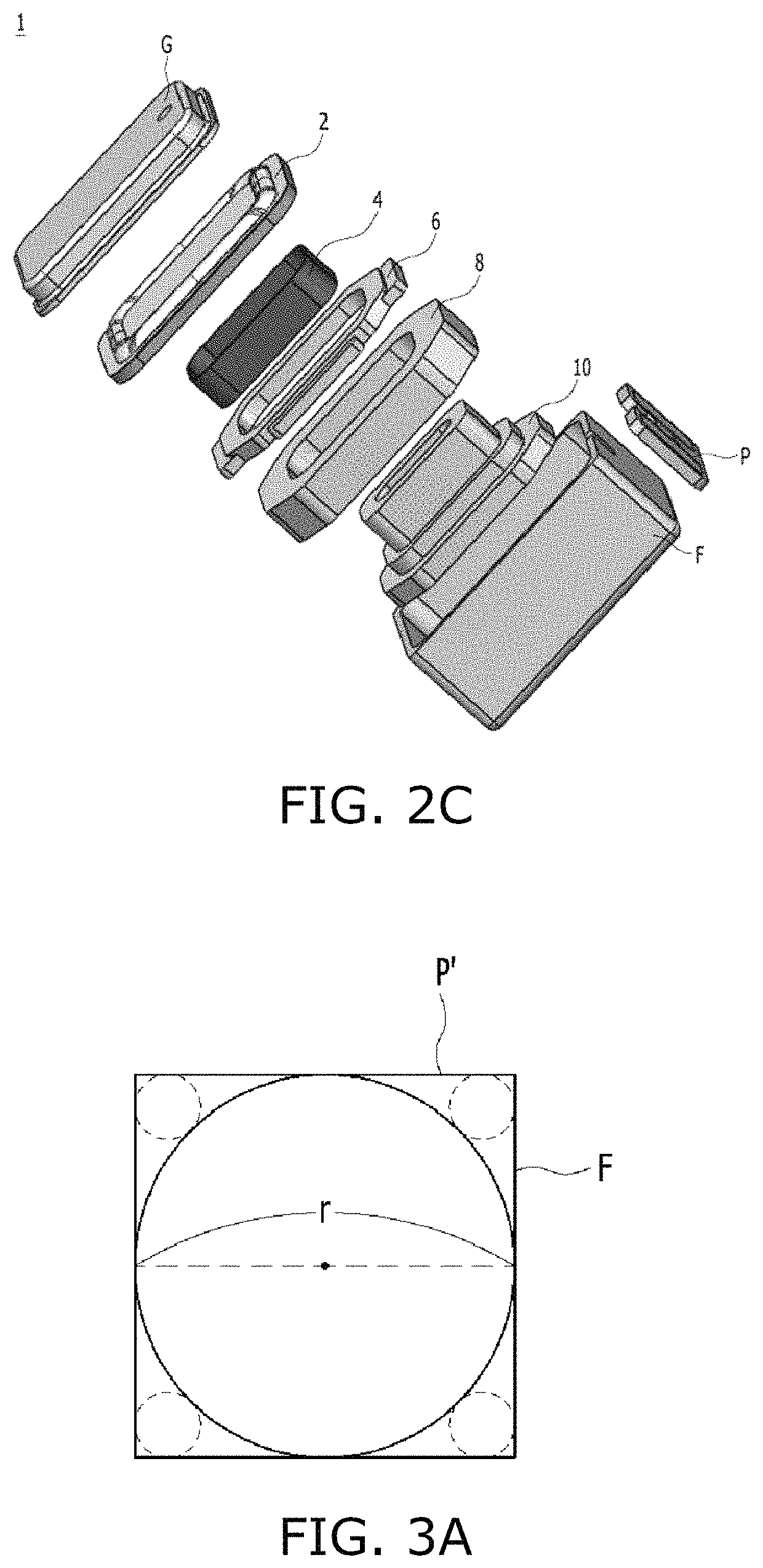

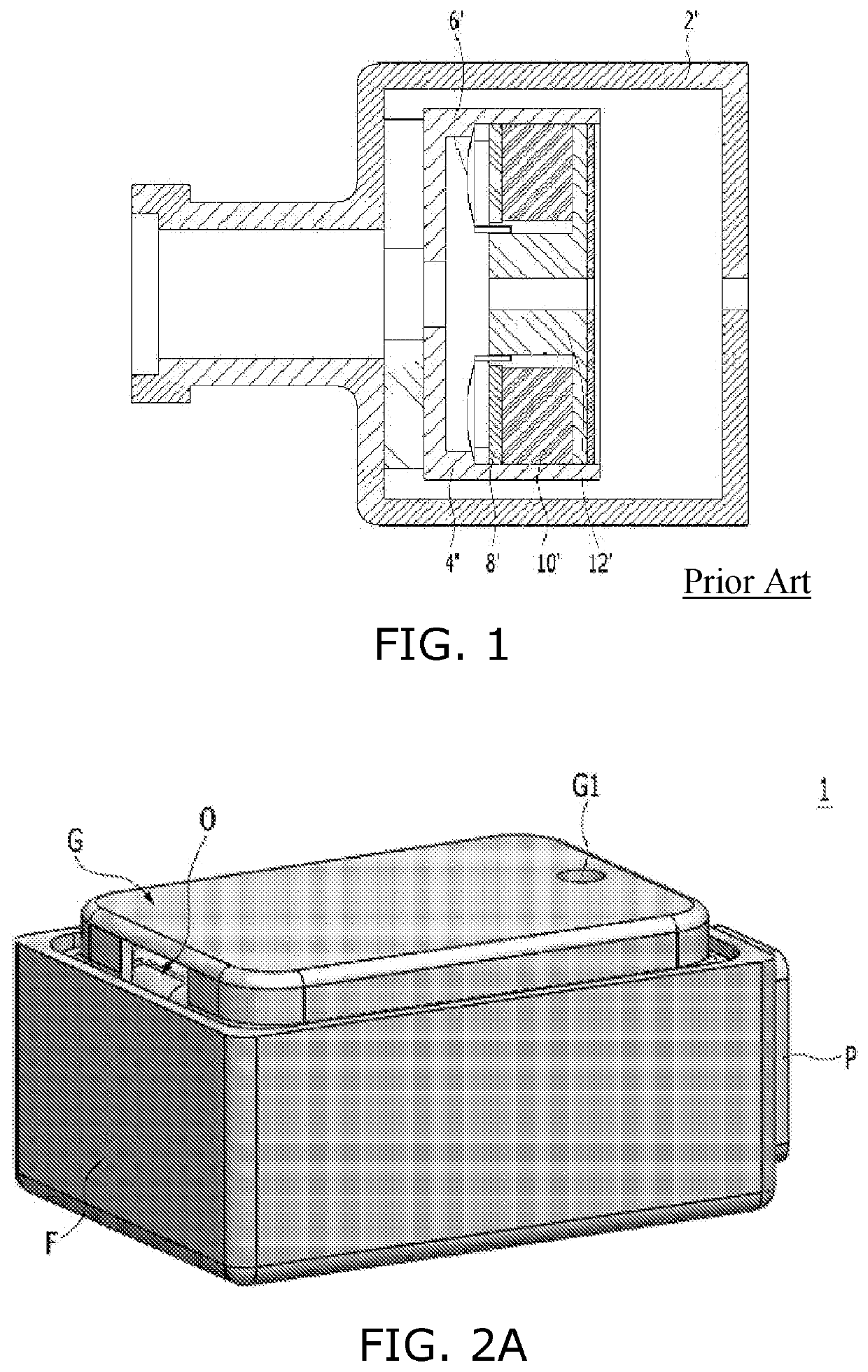

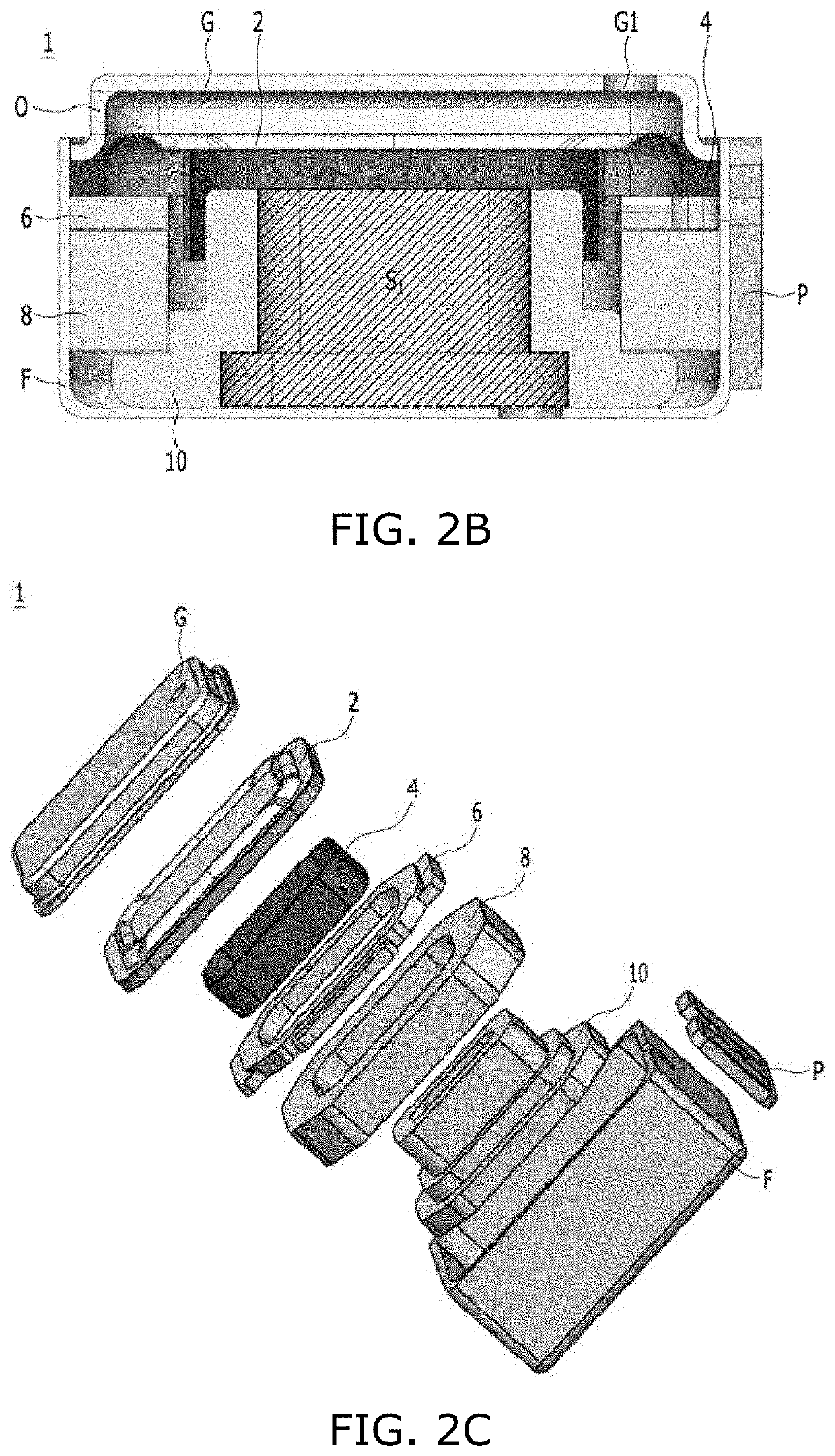

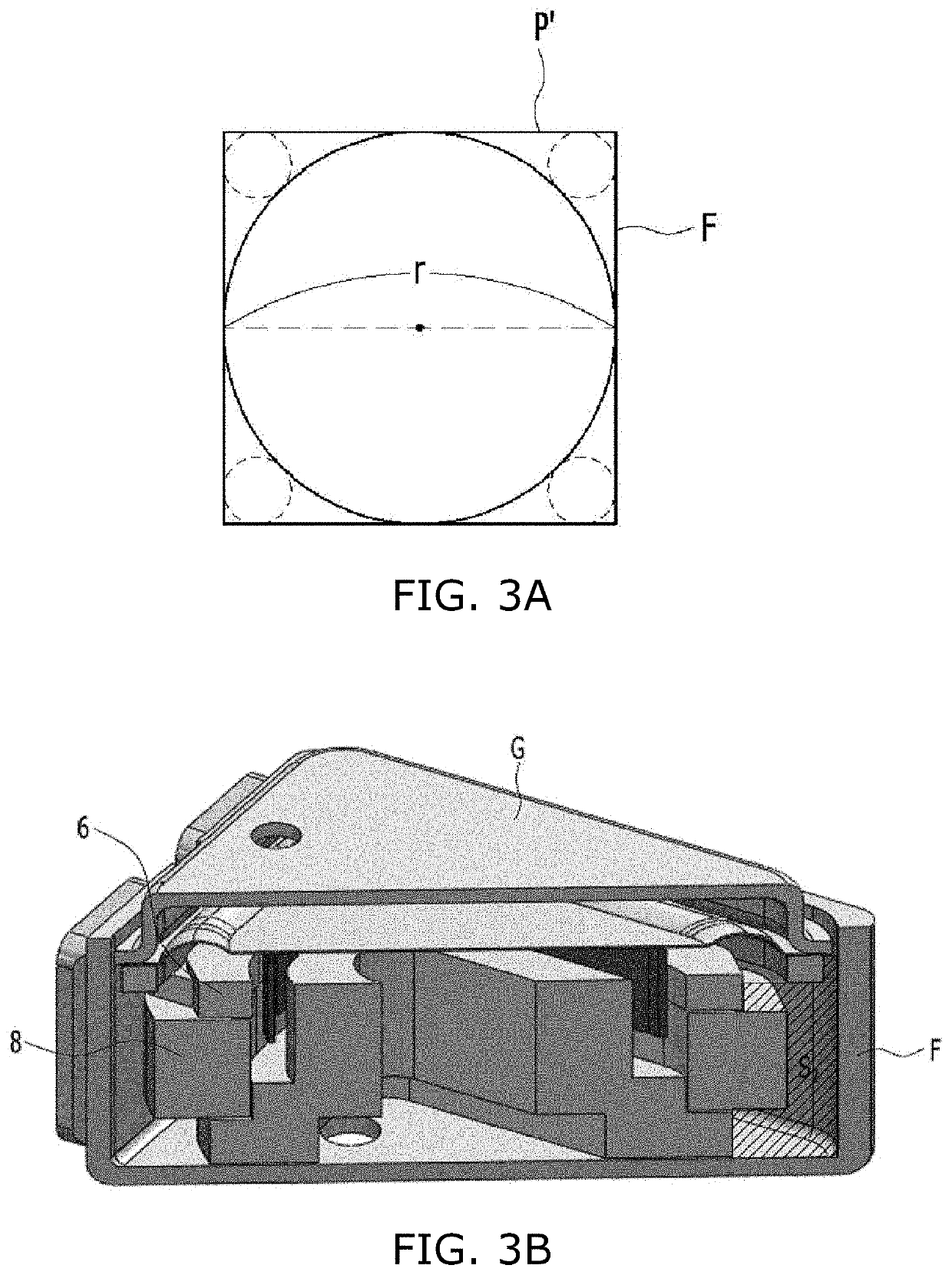

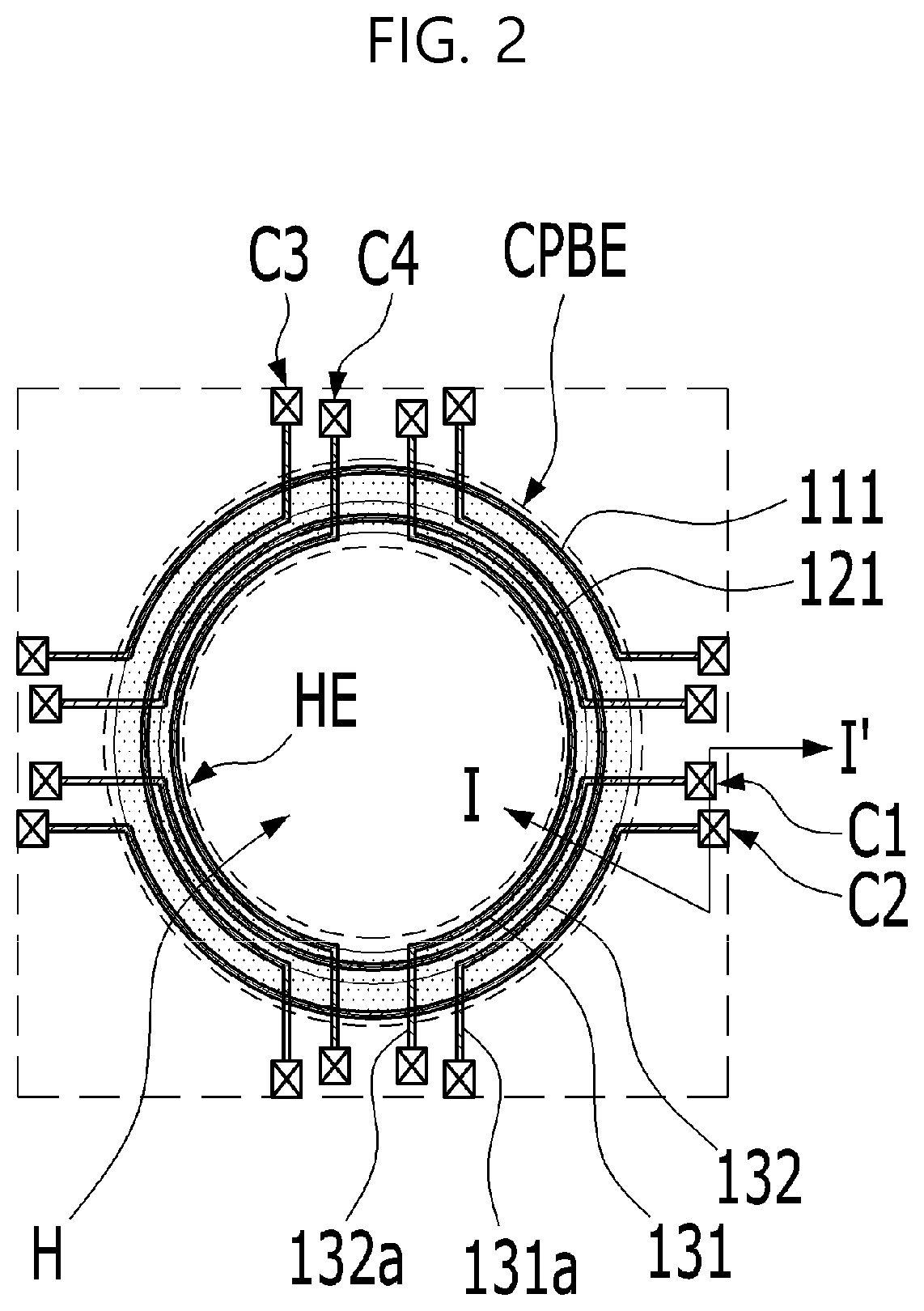

Rectangular microspeaker

ActiveUS20210044893A1Limited effective vibration areaEffective Area MaximizationSingle transducer incorporationLoudspeakersLoudspeakerMechanical engineering

A rectangular microspeaker according to the present invention transfers vibration sound through the front surface or side surface of a diaphragm. In order to maximize an effective vibration area and to expand a volume, all parts including a frame are fabricated in a rectangular shape. The present invention is applied to a P type, an F type, and a composite type. The vibration sound generated on the bottom of the diaphragm as well as the vibration sound generated on the top of the diaphragm may be discharged through the side surface. A magnetic field part may be insert-molded separately or along with the frame.

Owner:BUJEON

Night light

ActiveUS9091403B2Effective Area MaximizationSacrificing sensor isolationTumbler/rocker switchesFixed installationElectronic switchEngineering

Owner:PASS SEYMOUR

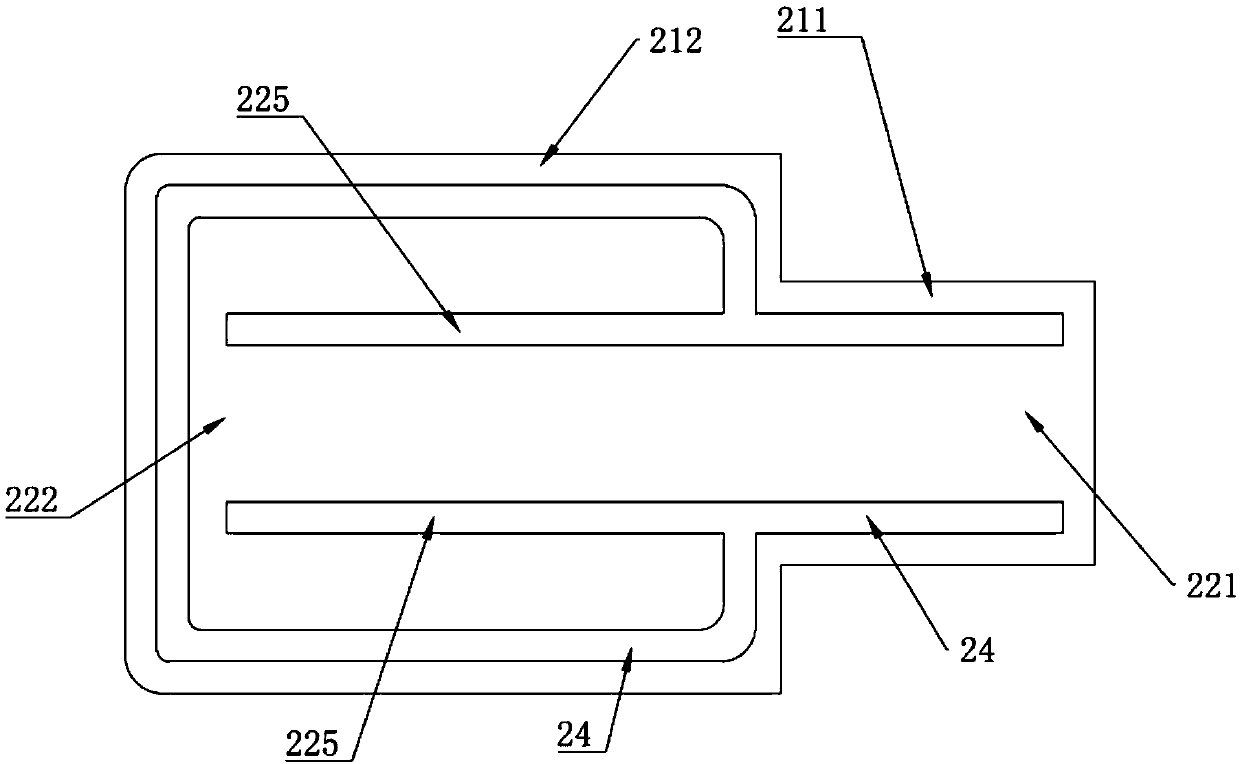

Spacers for ion-exchange device

ActiveUS20220212124A1Effective Area MaximizationImprove sealingMembranesCation exchanger materialsIon exchangeMechanical engineering

Provided are spacers, ion-exchange devices comprising spacers, and methods of preparing spacers for improved fluid distribution and sealing throughout an ion-exchange device. These spacers can include an internal cavity surrounded by a perimeter of the spacer. The perimeter can have a first opening and a second opening within the perimeter, and the first opening and the second opening can be located on opposite sides of the internal cavity. The spacers can also have a first and second plurality of channels located within the perimeter, wherein each channel of the first and second plurality of channels extends from the internal cavity towards the first opening or the second opening.

Owner:MIS IP HLDG LLC

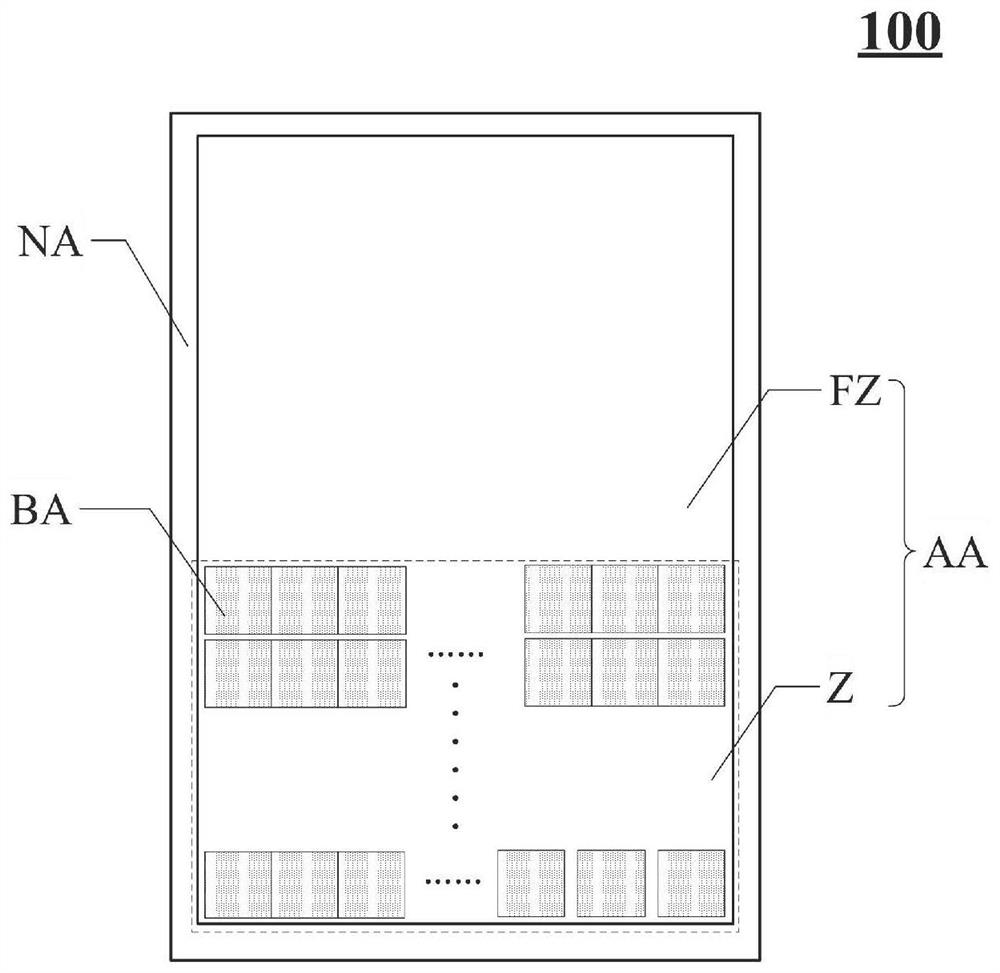

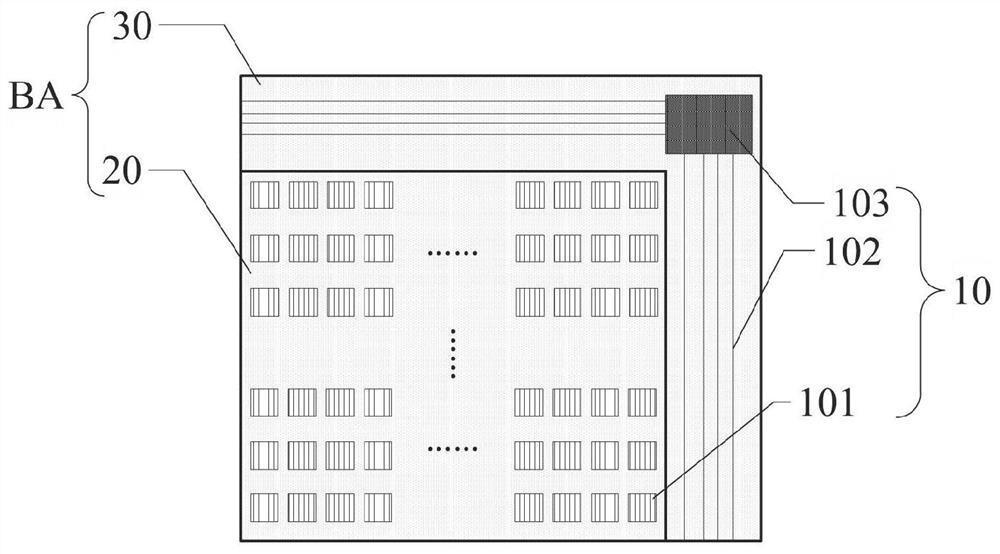

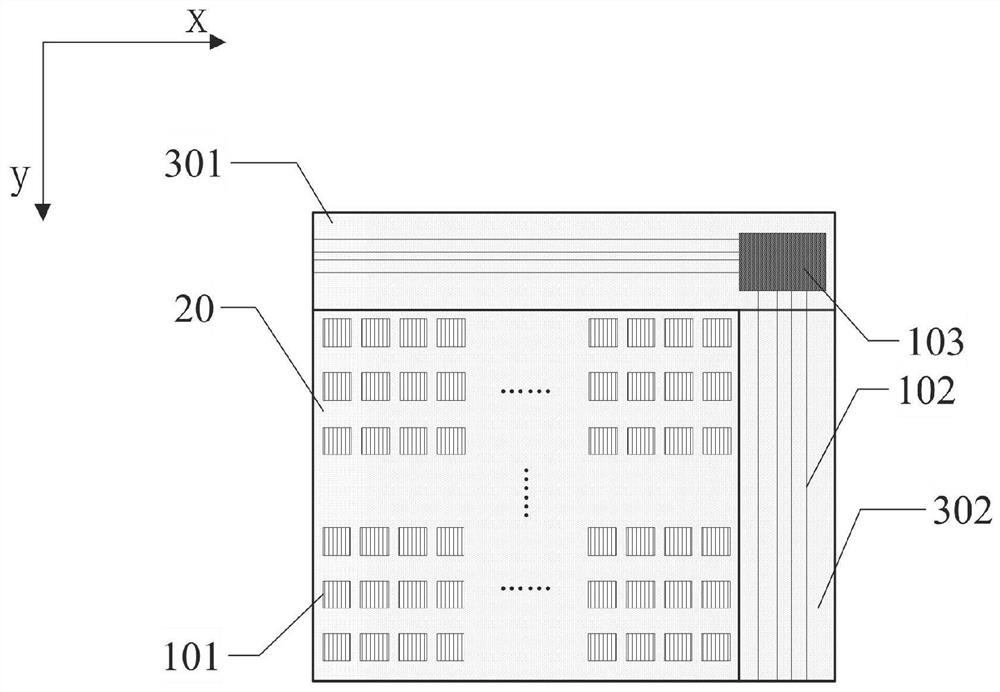

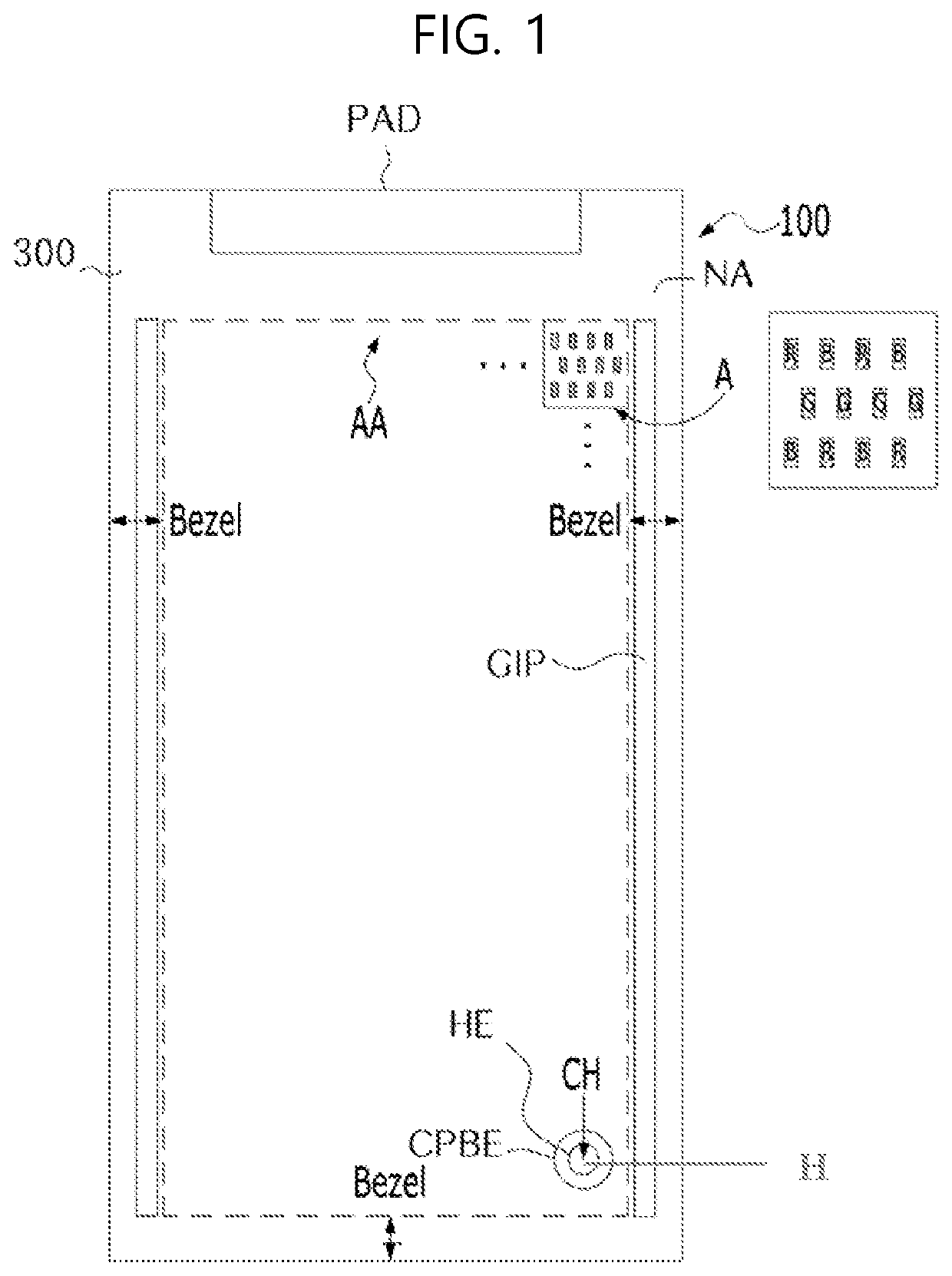

Display panel and display device

ActiveCN112768493AReduced risk of short circuitsEffective Area MaximizationSolid-state devicesCharacter and pattern recognitionDisplay deviceEngineering

The invention discloses a display panel and a display device, and relates to the technical field of display. The display panel comprises a display area and a non-display area at least partially surrounding the display area; the display area comprises a fingerprint identification area, the fingerprint identification area comprises a plurality of sub-areas arranged in an array, and each sub-area comprises at least one fingerprint identification circuit; the fingerprint identification circuit comprises at least one fingerprint identification sensor, a plurality of signal lines and a plurality of circuit elements; and each sub-area is provided with a central area and a peripheral area, at least one part of the fingerprint identification sensor is located in the central area, and the circuit elements and at least parts of the signal lines are located in the peripheral area. The signal lines in the fingerprint identification circuit are intensively arranged in the peripheral area, and the fingerprint identification sensors are intensively arranged in the central area so that the effective area of each fingerprint identification sensor can be maximized, and the light incoming amount of the fingerprint identification sensors and the fingerprint identification precision are improved; and meanwhile, the short-circuit risk of the display panel is also reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

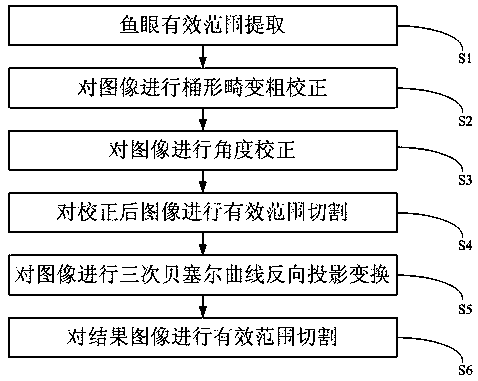

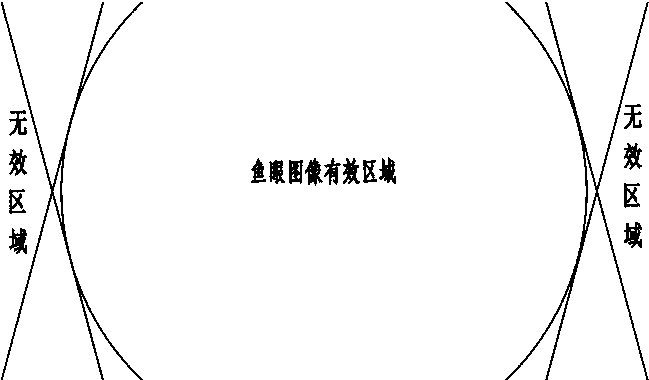

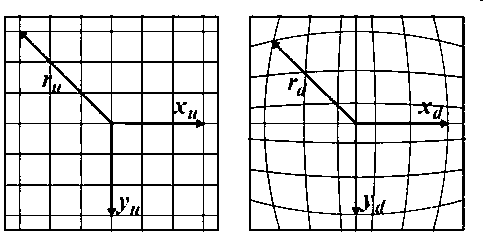

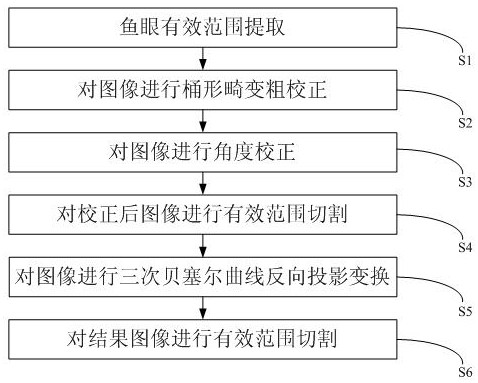

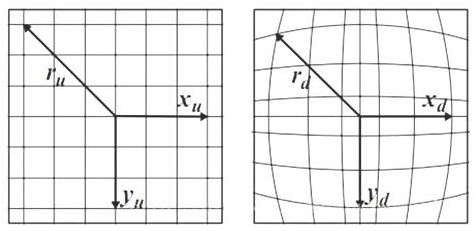

Angled side-mounted fisheye image correction method of equipment

ActiveCN108230241AMaximize the monitoring areaEffective Area MaximizationImage enhancementGeometric image transformationDistortionCorrection method

The invention discloses an angled side-mounted fisheye image correction method of equipment. The method comprises the following steps: extracting a fisheye effective range; carrying out barrel distortion rough correction on images; carrying out angle correction on the images; cutting the corrected images in an effective range; performing Bezier curves back projection transform on the images for three times; cutting a result image in the effective range. According to the angled side-mounted fisheye image correction method of the equipment disclosed by the invention, an effective area ratio of the acquired original fisheye images is maximized; moreover, the acquired fisheye images during side mounting at a certain angle are rectified at a certain angle, and a good correction effect on the fisheye images is achieved. In addition, by utilizing the method disclosed by the invention, cutting of image contents to a minimum extent can be corrected, and the maximization of the effective monitoring area can be ensured.

Owner:JINAN JOVISION TECH CO LTD

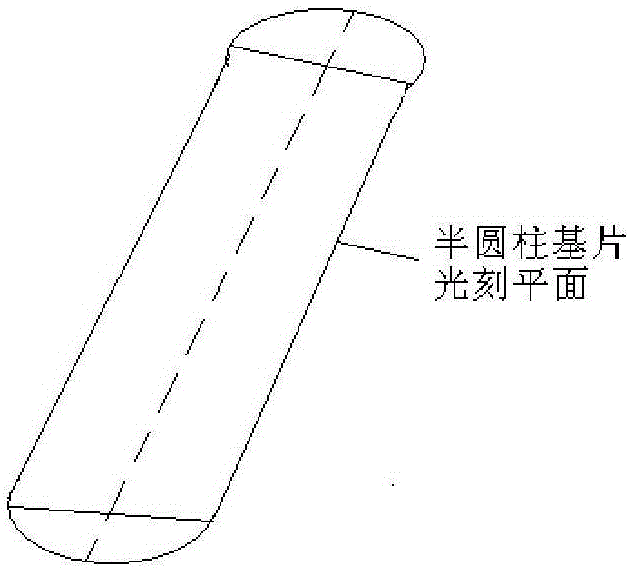

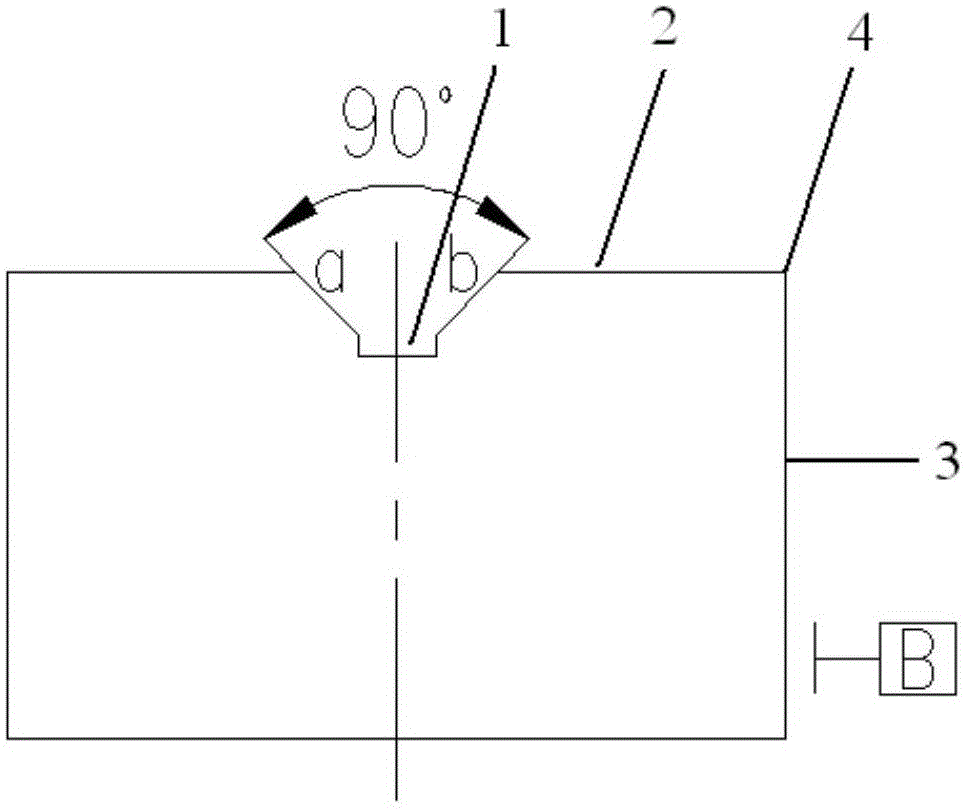

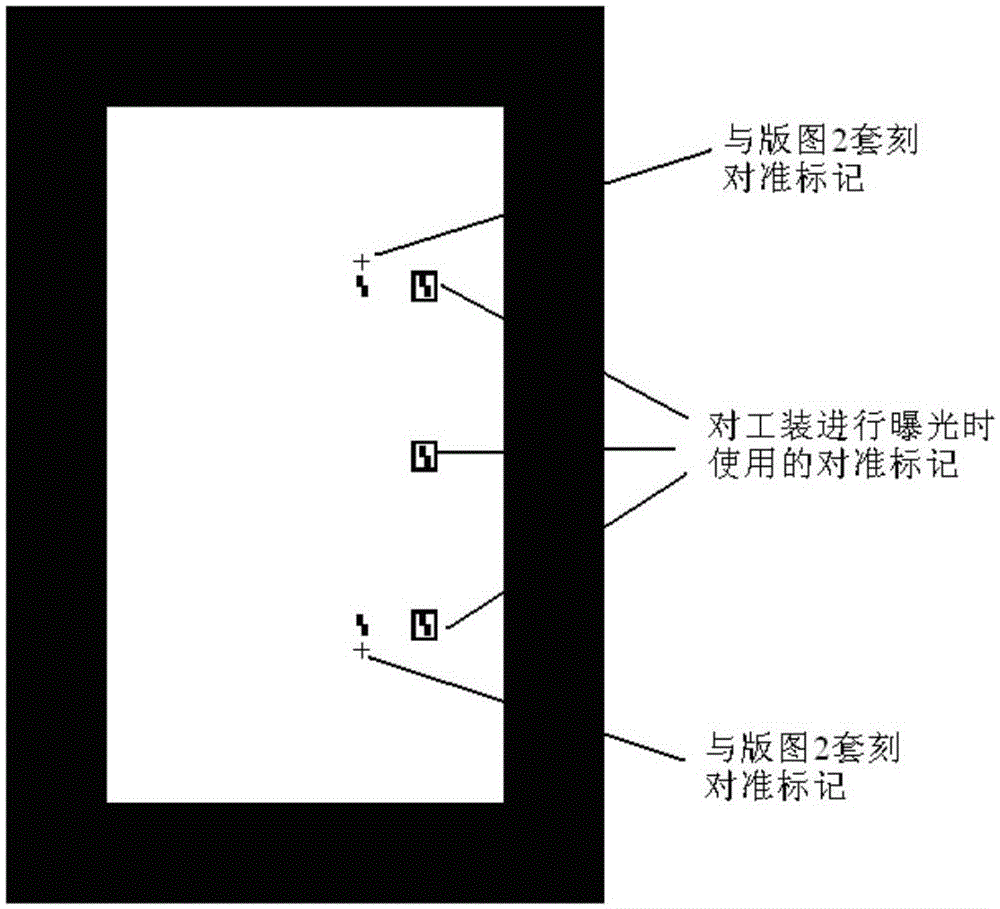

Glass substrate lithography alignment apparatus and aligning method characterized by no positioning marks

ActiveCN105047595AOvercoming vandalism and occupationMaximize the effective use areaSemiconductor/solid-state device manufacturingPhysicsLithography

The invention relates to a glass substrate lithography alignment apparatus and an aligning method characterized by no positioning marks. A special-purpose positioning tool, a first matching mask and a second matching mask are designed according to the shape of a substrate. A mark is photoetched on the positioning tool through the fist mask. By means of the mark, the positioning of the second mask is achieved. A slit is further photoetched on the glass substrate through a slit of the second mask. The precision of the slit on the glass substrate satisfies that the distance deviation between the actually photoetched slit center line and a semicircular bus is no greater than 3 mu m. Positioning accuracy is achieved. Meanwhile, no destructive marks are formed on the surface of the glass substrate. The effective usable area of the substrate is maximized.

Owner:BEIJING INST OF CONTROL ENG

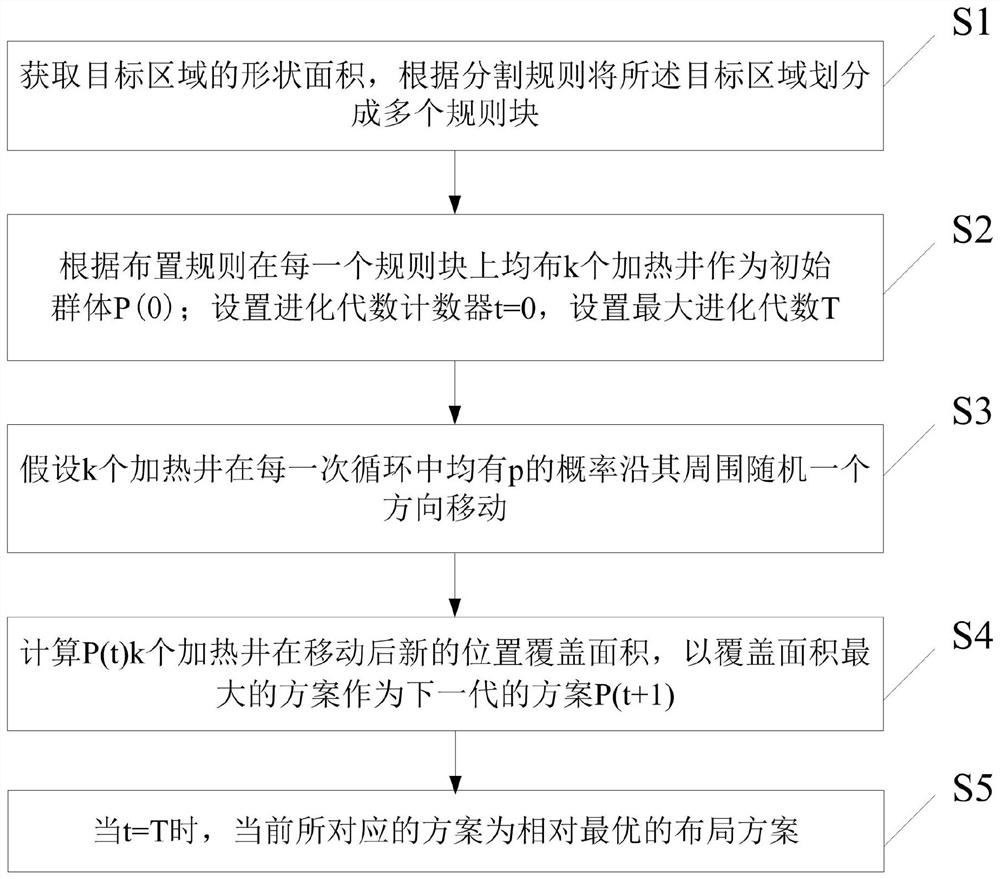

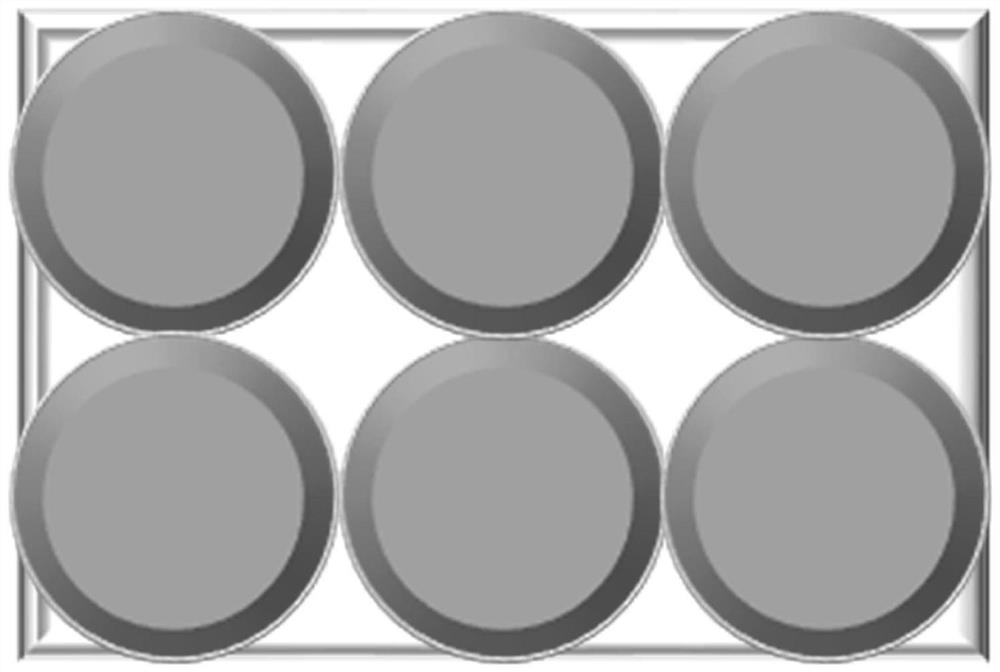

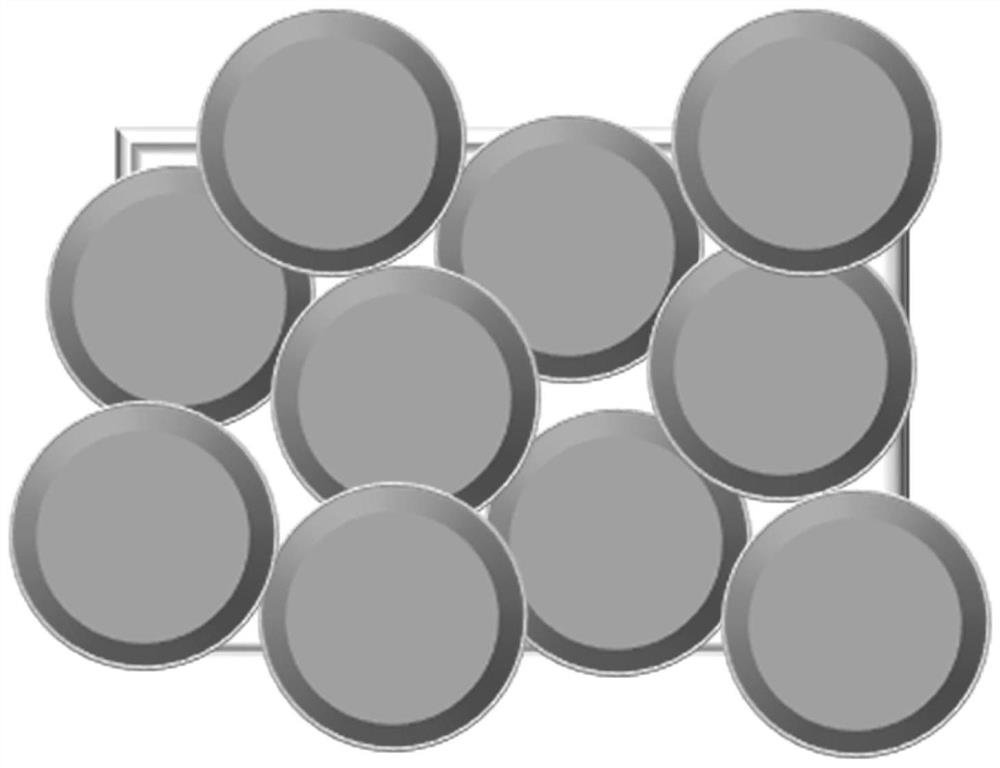

Heating well layout optimization method and device based on genetic algorithm

PendingCN113987935AEffective Area MaximizationReduce overlapDesign optimisation/simulationProbabilistic CADGreenhouseGenetics algorithms

The invention discloses a heating well layout optimization method and device based on a genetic algorithm, and the method comprises the steps of obtaining the shape and area of a target region, and dividing the target region into a plurality of regular blocks according to a segmentation rule; distributing k heating wells evenly on each regular block according to the arrangement rule as an initial group P (0); setting an evolutionary algebra counter t = 0, and setting a maximum evolutionary algebra T; assuming that k heating wells have the probability of p in each circulation and move along a random direction around the k heating wells; calculating the new position coverage area of the P (t) k heating wells after movement, and taking the scheme with the maximum coverage area as the scheme P (t+1) of the next generation; when t is equal to T, determining that the current corresponding scheme is the relatively optimal layout scheme. According to the method, the layout of the heating wells in a thermal strengthening SVE process is optimized, overlapping of the action range of the heating wells is reduced, the effective area covered by the heating wells is maximized, and therefore the purposes of reducing energy waste and controlling greenhouse gas emission are achieved.

Owner:BEIHANG UNIV

Device for manufacturing integrated thin film solar cell

InactiveCN106165121AEffective Area MaximizationMaximize power productionPhotovoltaic energy generationSemiconductor devicesElectricityPhotoelectric conversion

A device for manufacturing an integrated thin film solar cell, according to one embodiment of the present invention, is a device for manufacturing an integrated thin film solar cell in which a plurality of unit cells are electrically connected in series in a vacuum state, and the manufacturing device comprises: a photoelectric conversion unit-forming process chamber which forms a photoelectric conversion unit by emitting a photoelectric conversion material onto a substrate having a first conductive layer, which is formed from one base line inside each of a plurality of trenches formed on the substrate to areas such as a bottom surface of each of the trenches, one side surface connected to the bottom surface, and a protruding surface of the substrate connected to the one side surface; and a second conductive layer-forming process chamber which forms a second conductive layer from another base line inside each of the trenches to areas such as the bottom surface of each of the trenches, the other side surface connected to the bottom surface, and a protruding surface of the substrate connected to the other side surface, wherein the photoelectric conversion unit-forming process chamber and the second conductive layer-forming process chamber are capable of performing each of the processes in a vacuum state.

Owner:KOREA ADVANCED INST OF SCI & TECH

Rectangular microspeaker

ActiveUS11006209B2Overcome problemsControl areaSingle transducer incorporationLoudspeakersEngineeringLoudspeaker

A rectangular microspeaker according to the present invention transfers vibration sound through the front surface or side surface of a diaphragm. In order to maximize an effective vibration area and to expand a volume, all parts including a frame are fabricated in a rectangular shape. The present invention is applied to a P type, an F type, and a composite type. The vibration sound generated on the bottom of the diaphragm as well as the vibration sound generated on the top of the diaphragm may be discharged through the side surface. A magnetic field part may be insert-molded separately or along with the frame.

Owner:BUJEON

Lifter for building construction

InactiveCN102464245AImprove the utilization rate of hoistway areaLow costBuilding liftsGantry craneTractor

The invention relates to a lifter for building construction. The lifter for building construction comprises a steel structure consisting of a frame upright beam and a frame cross beam, and a mesh-cage, a guide wheel, a traction wheel and a tractor, a rescue rope, a tension rod, a tension weight, mesh-cage bottom wheels, a traction steel wire rope, a rope hitch plate, a gantry crane, a landing door device, a buffer, a guide rail, a speed limiter steel wire rope and a speed limiter tension wheel arranged in the steel structure, wherein the traction wheel and the tractor are arranged on the top or the bottom of the steel structure consisting of the frame upright beam and the frame cross beam, the guide wheel is arranged on the bottom or the top of the steel structure, and the mesh-cage is provided with four mesh-cage top wheels or mesh-cage bottom wheels. The technical problem to be solved by the invention is to provide the lifter for building construction which has the advantages of improved area utilization rate of hoistways, lowered cost of building facilities, and convenience for installation and debugging.

Owner:HAIAN LIANKE AUTOMOBILE PARTS

Hybrid acoustic apparatus including rectangular microspeaker

ActiveUS11102587B2Overcome problemsControl areaLoudspeaker screensLoudspeaker transducer fixingEngineeringLoudspeaker

Disclosed herein is a hybrid acoustic apparatus. The hybrid acoustic apparatus includes: a rectangular microspeaker used as a first acoustic device; and a second acoustic device integrated with the microspeaker. The microspeaker includes a plate configured to constitute a part of a magnetic field part, a magnet configured to be disposed beneath the plate, a diaphragm configured to be disposed on the plate, and a frame configured to accommodate the diaphragm, the plate, and the magnet. A path of vibration sound generated by the diaphragm is formed to be perpendicular to a direction in which the diaphragm vibrates so that the vibration sound is discharged through a side surface of the diaphragm.

Owner:BUJEON

A shaft top layer arrangement structure of a machine room-less elevator

ActiveCN104310158BImprove stabilityReduce security risksElevatorsBuilding liftsMachineControl theory

Owner:GIANT KONE ELEVATOR CO LTD

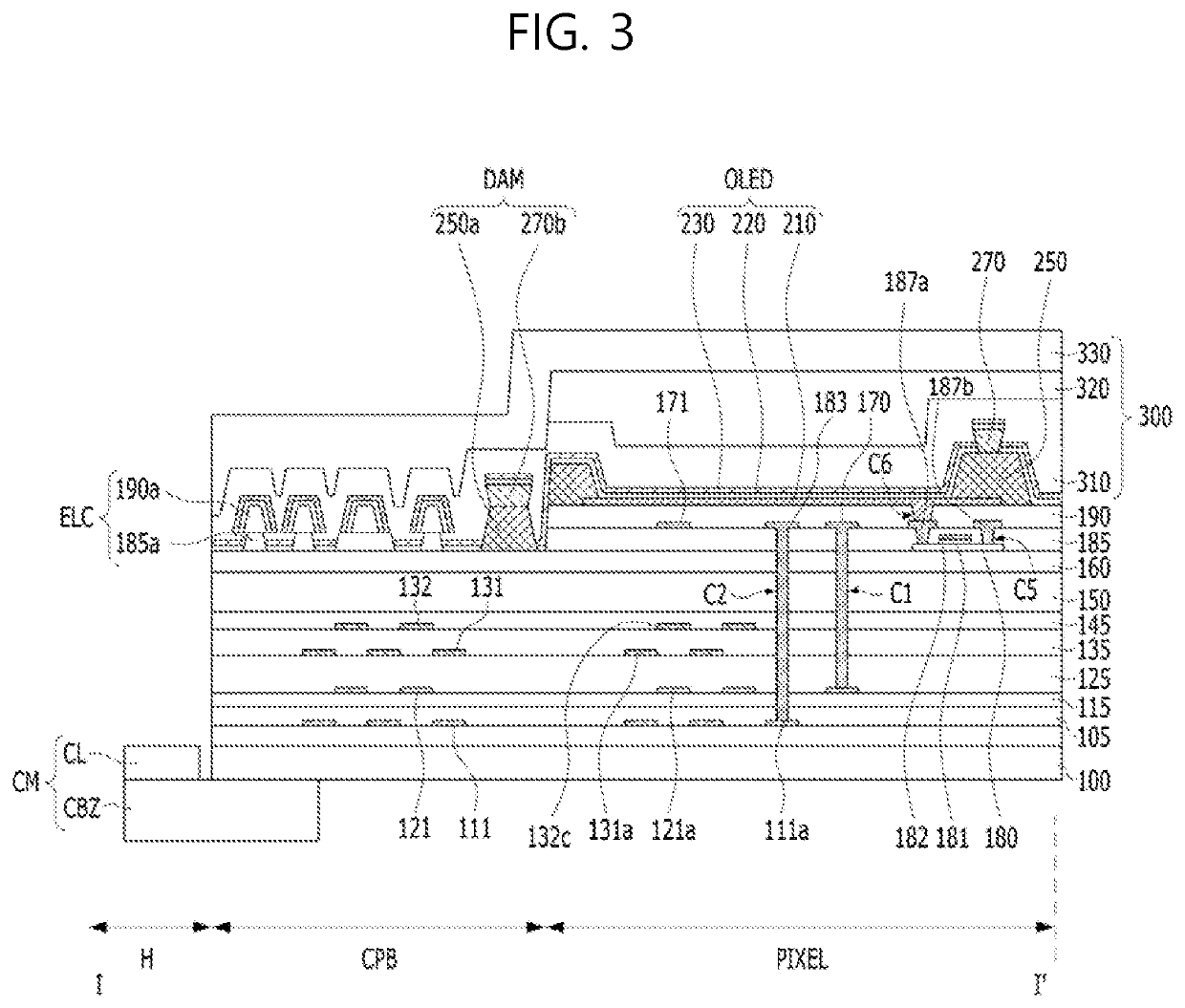

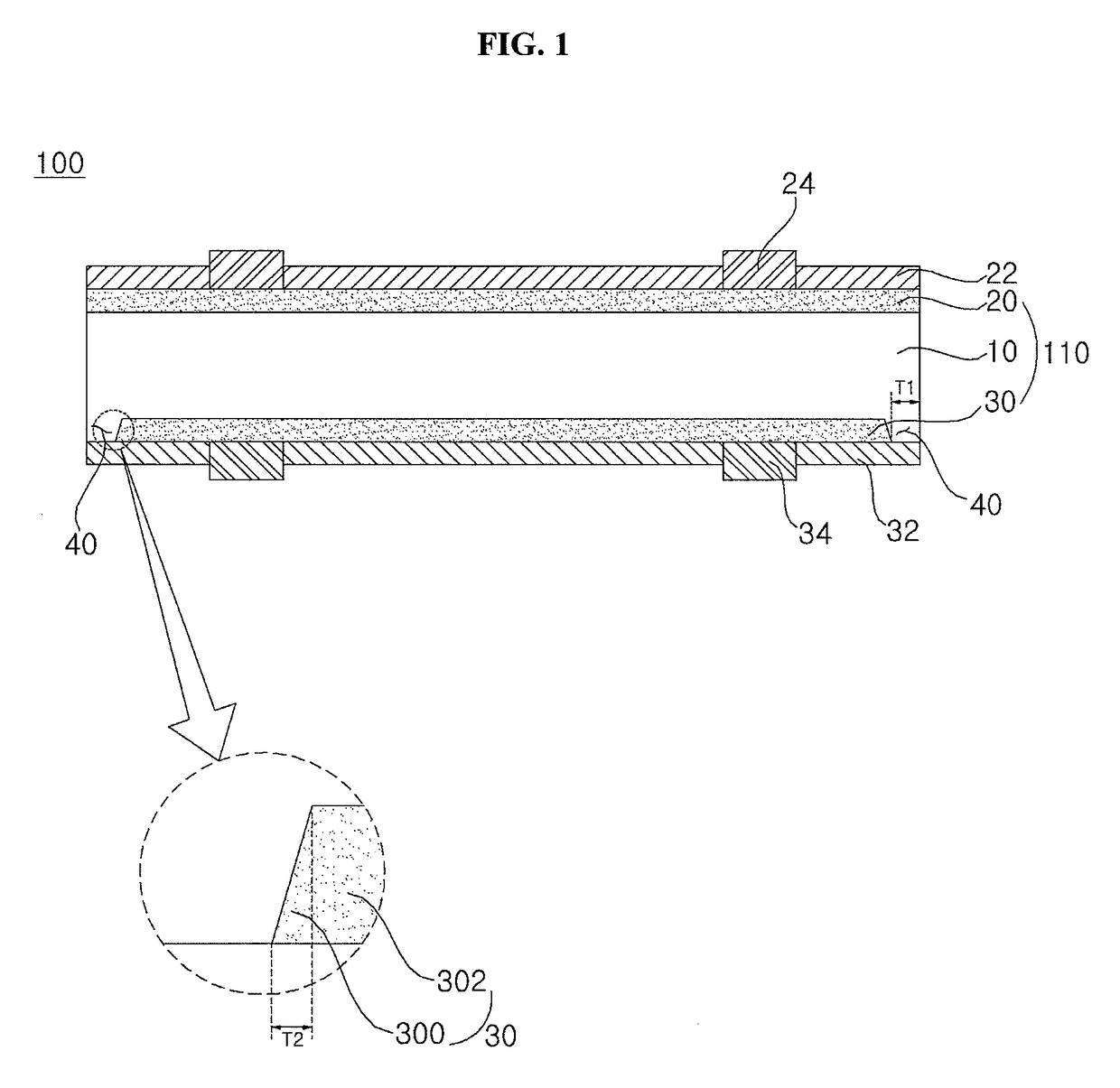

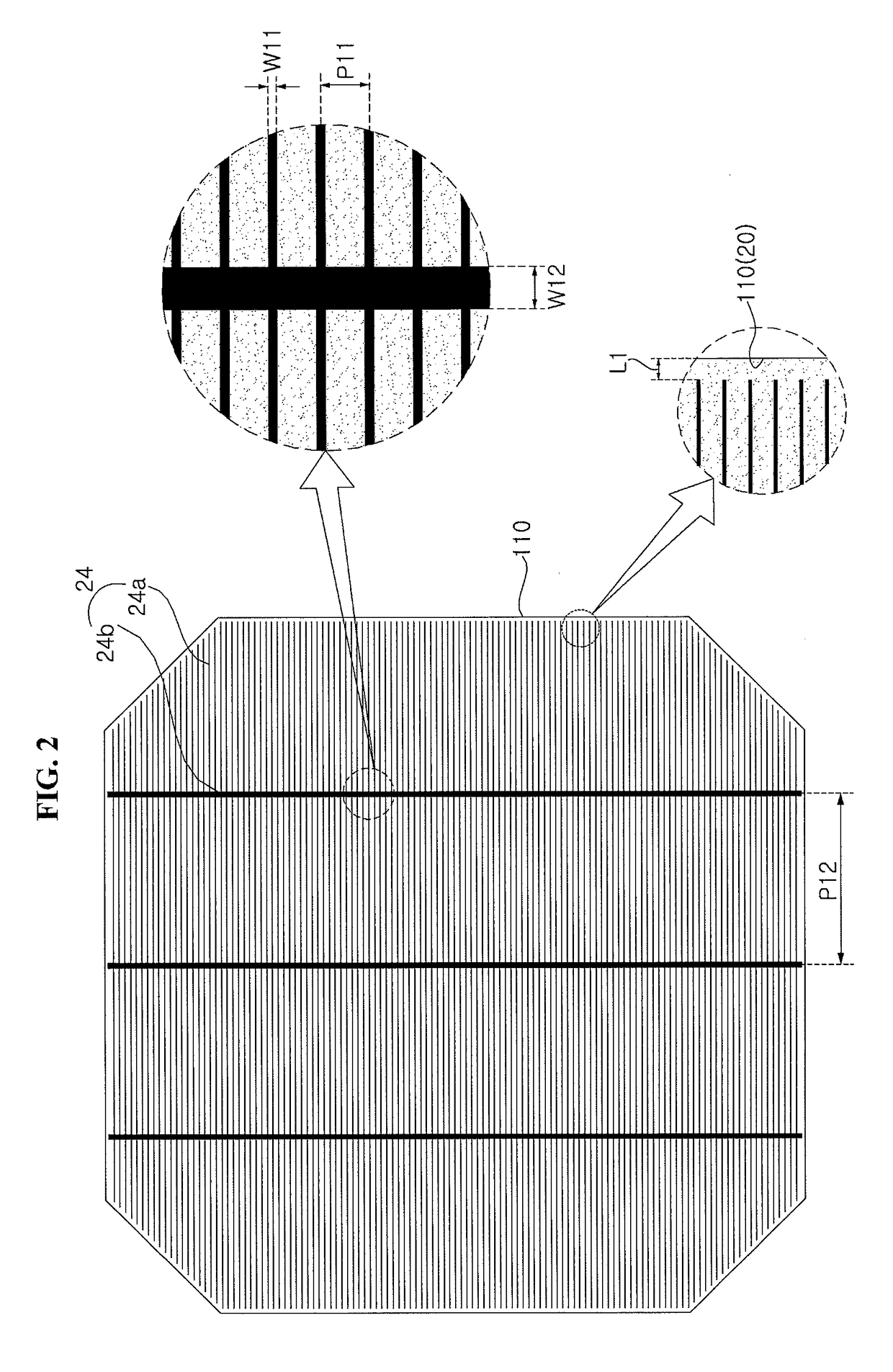

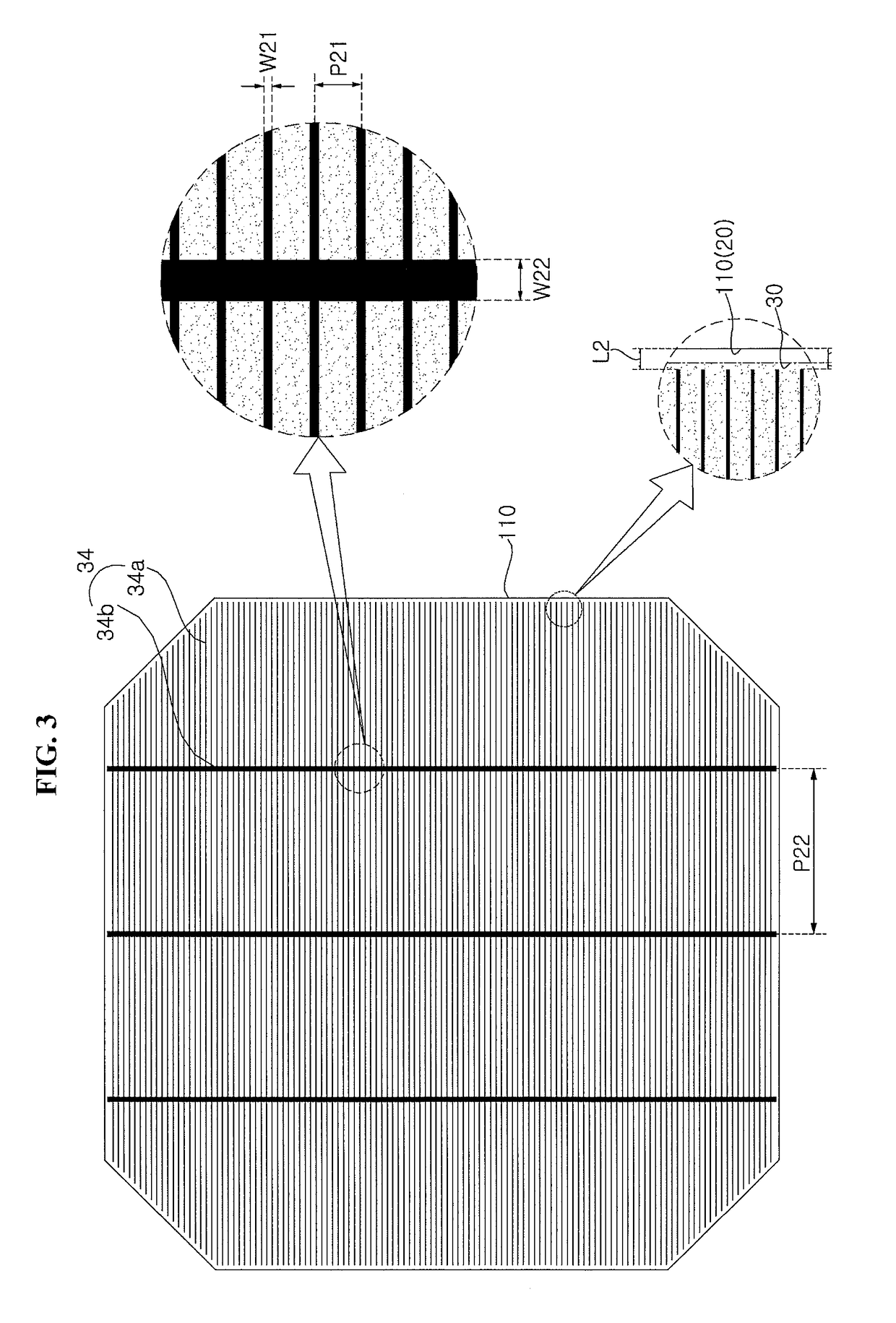

Display device

PendingUS20220208937A1Effective Area MaximizationIncrease the effective areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMaterials science

Discussed is a display device provided with a large effective area by minimizing a margin area around a camera hole in a structure in which the camera hole is formed in a display area. A bypass line module, which is formed in the same process as the process of forming a first thin-film transistor, and a light-emitting device disconnection module, which is formed in the same process as the process of forming a second thin-film transistor, are disposed around the camera hole so as to overlap each other.

Owner:LG DISPLAY CO LTD

Solar cell and method for manufacturing the same

ActiveUS10141467B2Improved reliability and productivityImprove efficiencyPhotovoltaic energy generationRenewable energy productsSolar cellSemiconductor

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

Spacers for ion-exchange device

ActiveUS11311820B2Effective Area MaximizationImprove sealingMembranesCation exchanger materialsIon exchangeEngineering

Provided are spacers, ion-exchange devices comprising spacers, and methods of preparing spacers for improved fluid distribution and sealing throughout an ion-exchange device. These spacers can include an internal cavity surrounded by a perimeter of the spacer. The perimeter can have a first opening and a second opening within the perimeter, and the first opening and the second opening can be located on opposite sides of the internal cavity. The spacers can also have a first and second plurality of channels located within the perimeter, wherein each channel of the first and second plurality of channels extends from the internal cavity towards the first opening or the second opening.

Owner:MIS IP HLDG LLC

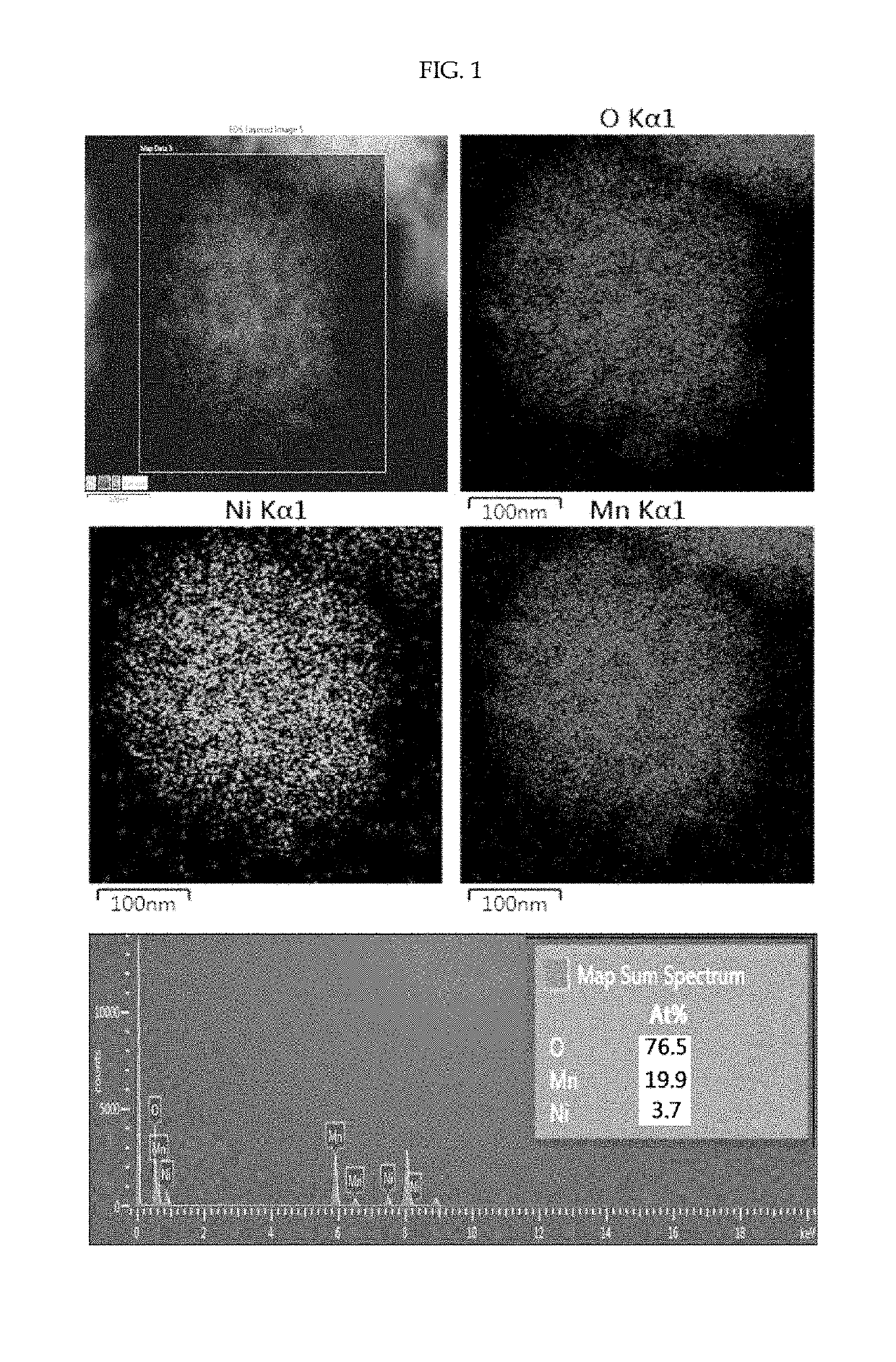

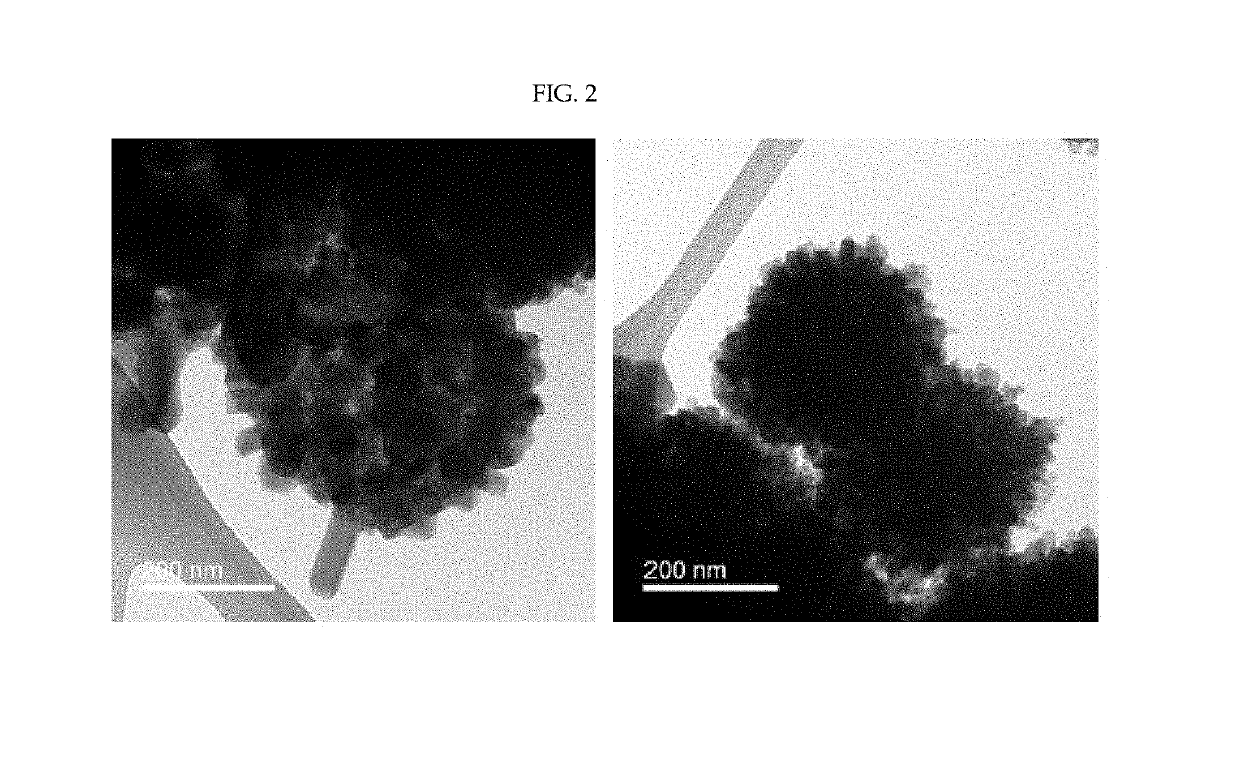

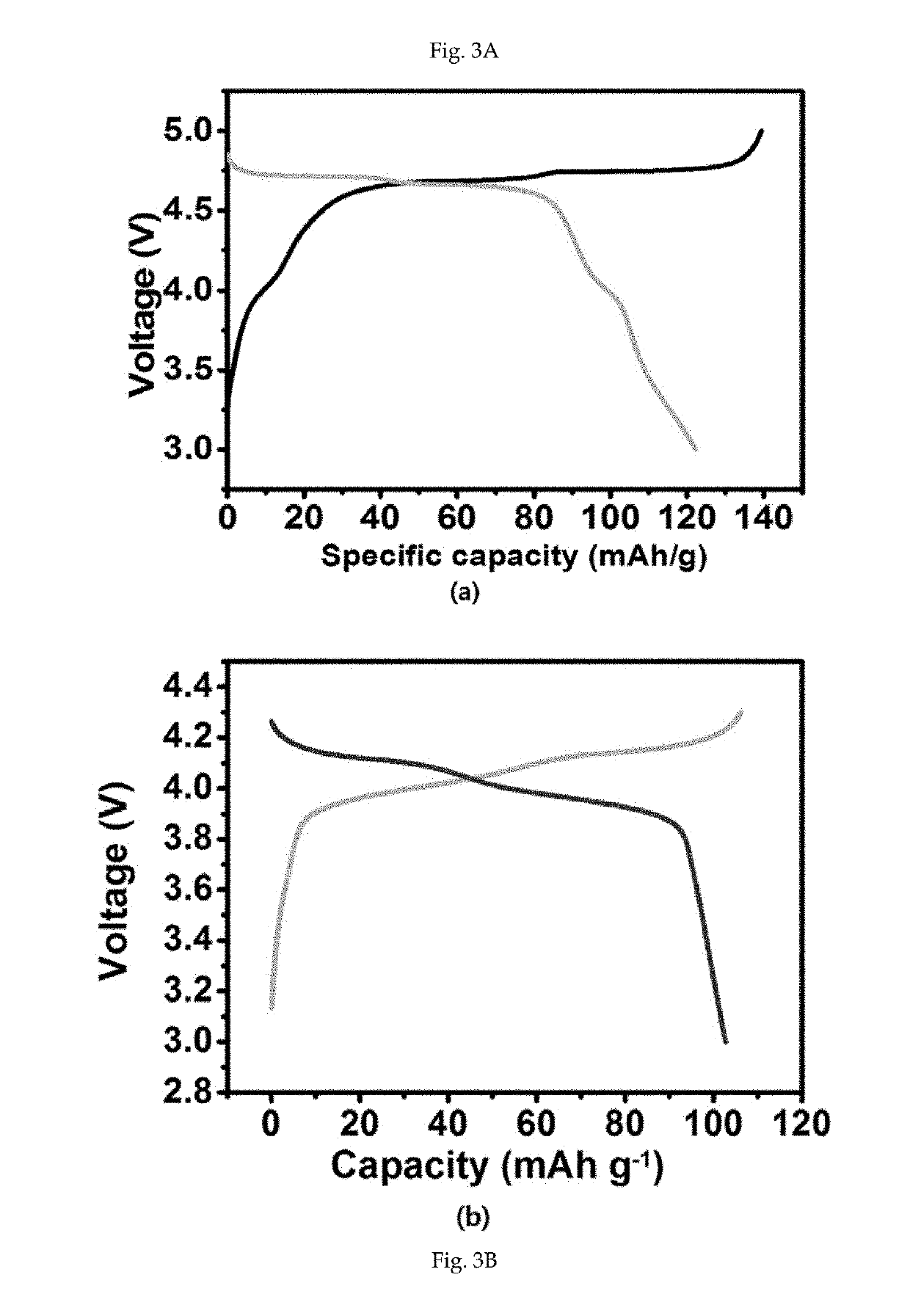

Cathode active material for lithium secondary battery, manufacturing method thereof, and lithium secondary battery including the same

InactiveUS20190140273A1Easy to manufactureSimple processPositive electrodesCobalt compoundsNanoparticleSolvent

A manufacturing method of a cathode active material for lithium secondary battery, including: preparing a first solution by mixing a metal oxide and a solvent; preparing a metal-mixed solution by adding an acidic solution to the first solution and then applying ultrasonic waves to the mixture; centrifuging the metal-mixed solution; preparing a second solution by mixing a supernatant of the centrifuged metal-mixed solution, a reductant, and a solvent and then applying ultrasonic waves to the mixture; obtaining powder by filtering and then drying the second solution; forming mesoporous spherical nanoparticles by mixing the powder, a metal, a lithium precursor, and a solvent, applying ultrasonic waves to the mixture and then drying the mixture; and performing a heat treatment to the spherical nanoparticles, and a cathode active material for a lithium secondary battery obtained by the manufacturing method. The cathode active material for lithium secondary battery is mesoporous spherical nanoparticles.

Owner:KOREA BASIC SCI INST

A Fisheye Image Correction Method for Equipment with Angled Side Mounting

ActiveCN108230241BEffective Area MaximizationMaximize the effective area ratioImage enhancementGeometric image transformationRadiologyImage correction

The invention discloses a method for correcting a fisheye image with an angled side-mounted device, which includes the following steps: extracting the effective range of the fisheye; performing rough correction of barrel distortion on the image; performing angle correction on the image; and performing effective correction on the corrected image. Range cutting; perform cubic Bezier curve back-projection transformation on the image; perform effective range cutting on the resulting image. The present invention can not only maximize the effective area ratio of the original fisheye image obtained, but can also correct the fisheye image obtained when the side belt is mounted at a certain angle, and have a good correction result for the fisheye image. In addition, , the correction method mentioned in the present invention can be used to crop the image content to a minimum, ensuring that the effective monitoring area is maximized.

Owner:JINAN JOVISION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com