Patents

Literature

67 results about "Thin diaphragm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

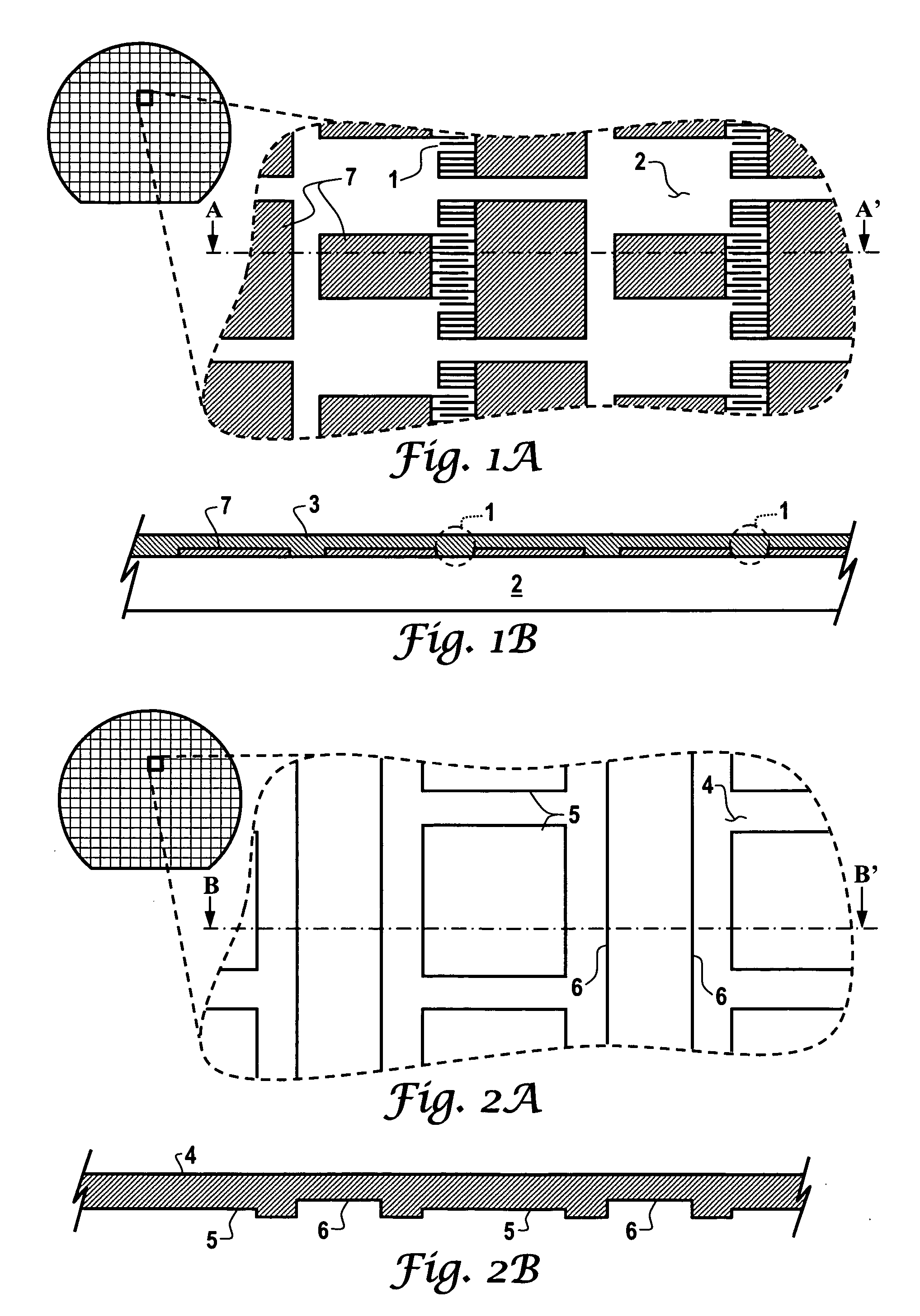

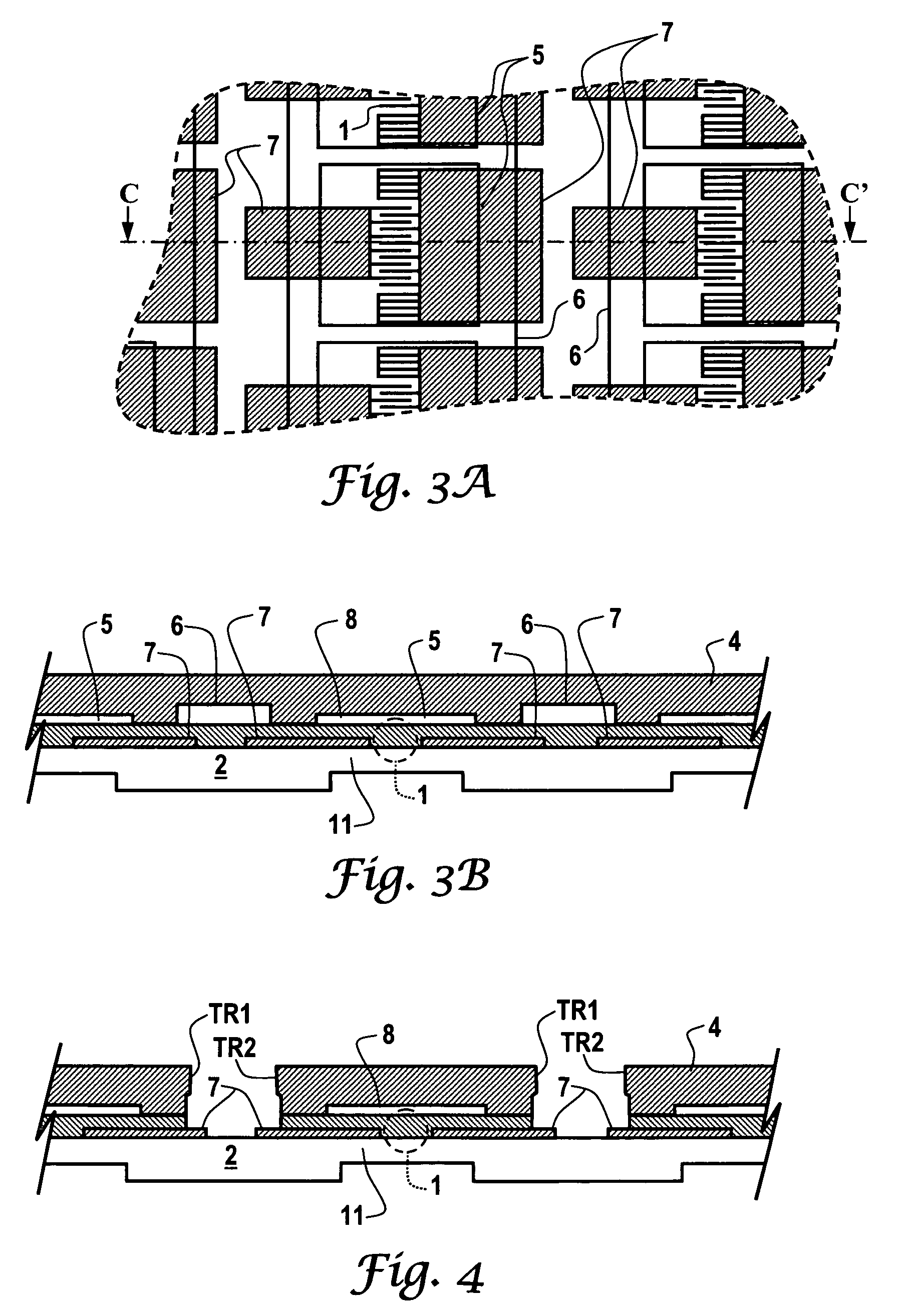

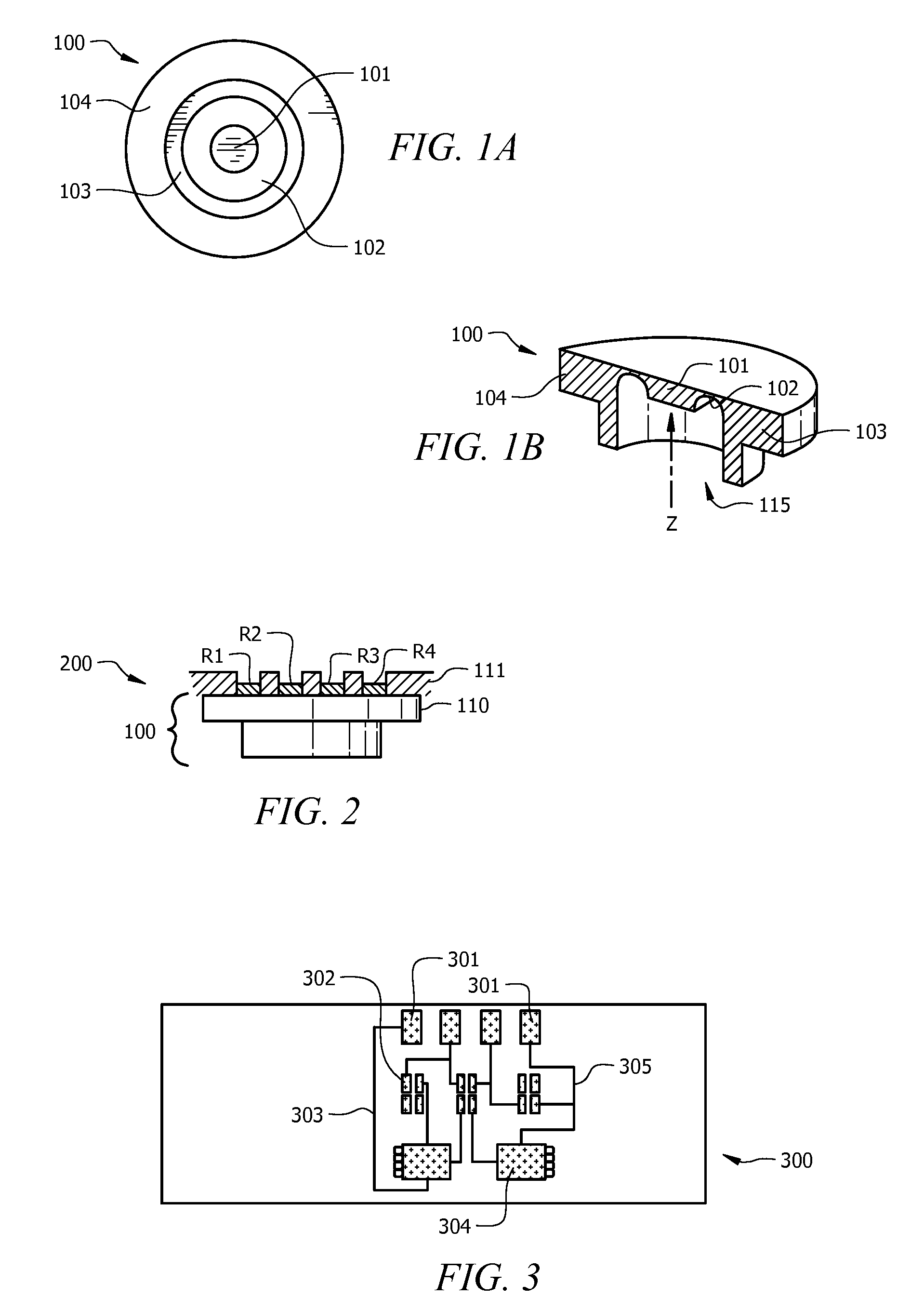

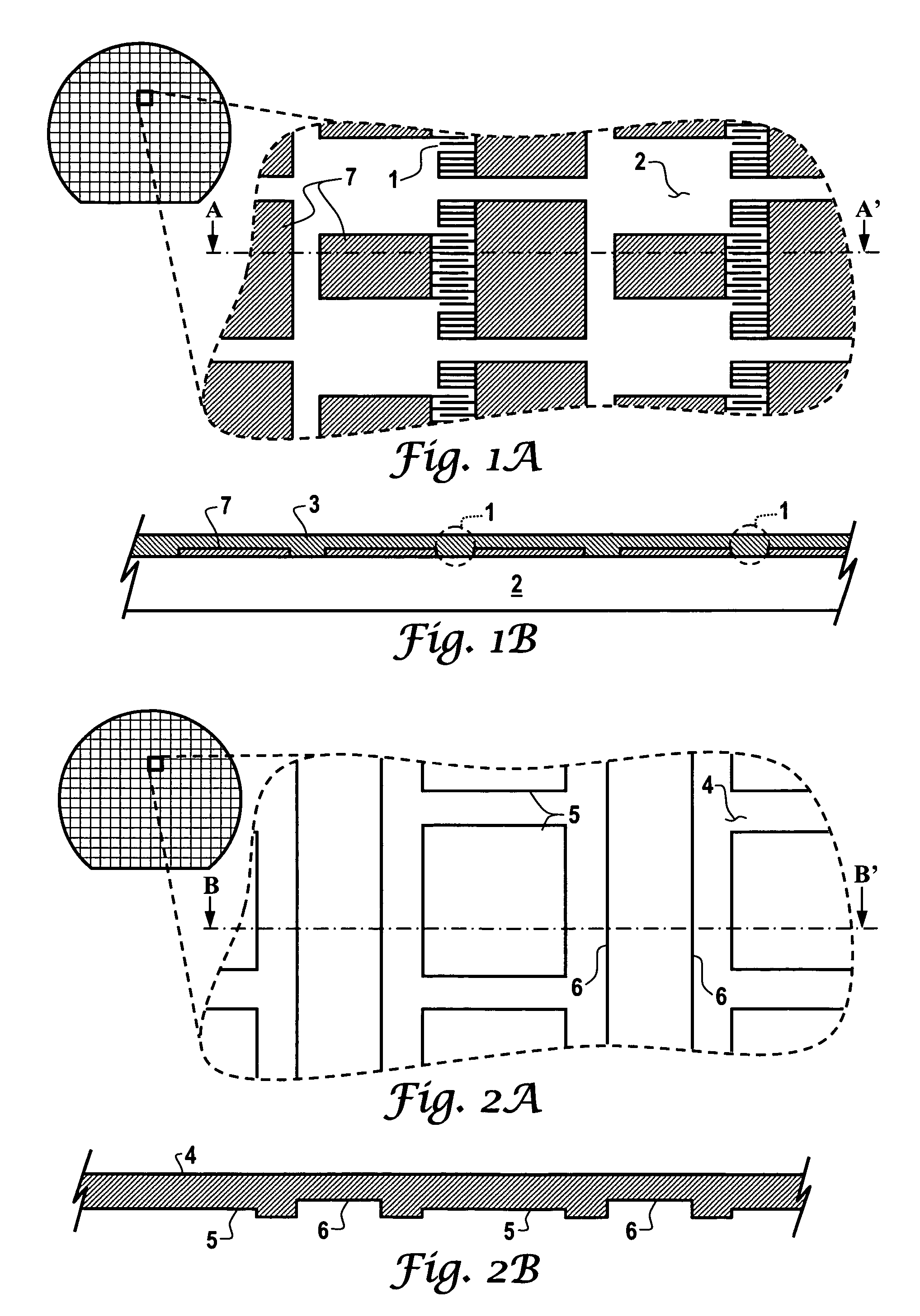

Apparatus and method for making a low capacitance artificial nanopore

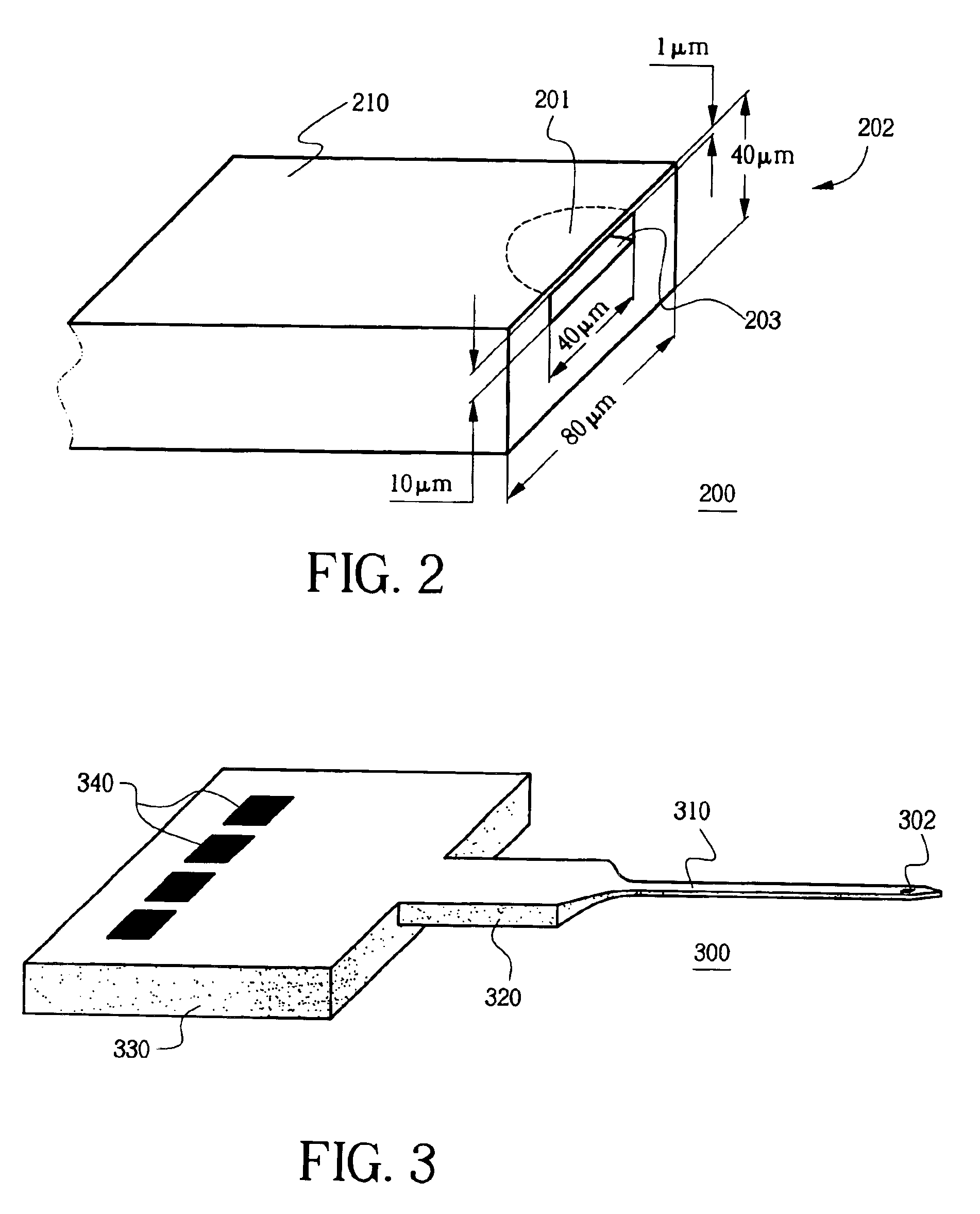

An apparatus and method for making a nanopore chip exhibiting low capacitance. The apparatus provides a thin diaphragm on a rigid semiconductor frame suitable for nanopore fabrication, the diaphragm having associated thicker insulator regions to reduce capacitance. Also disclosed is a method of making the apparatus.

Owner:AGILENT TECH INC

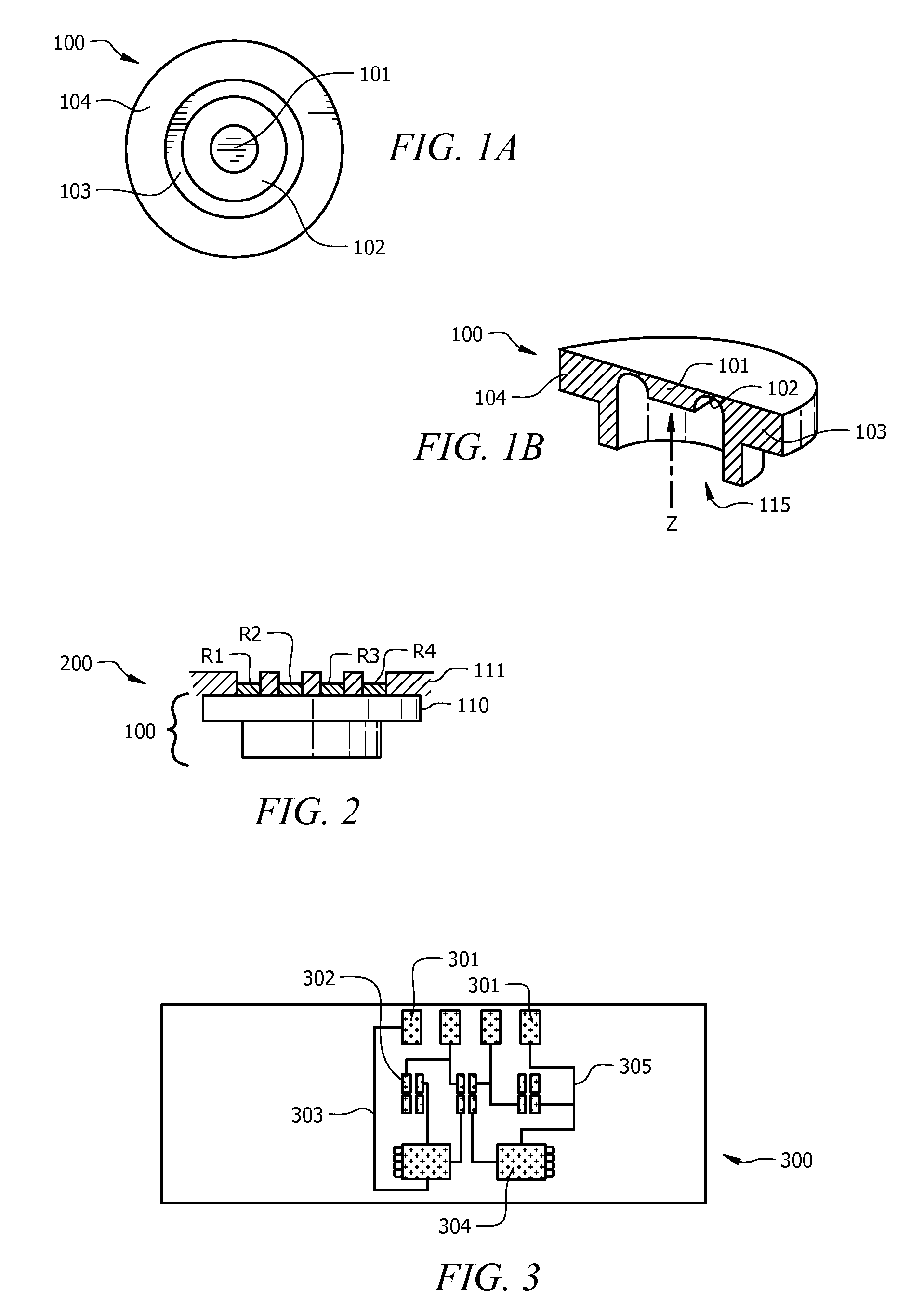

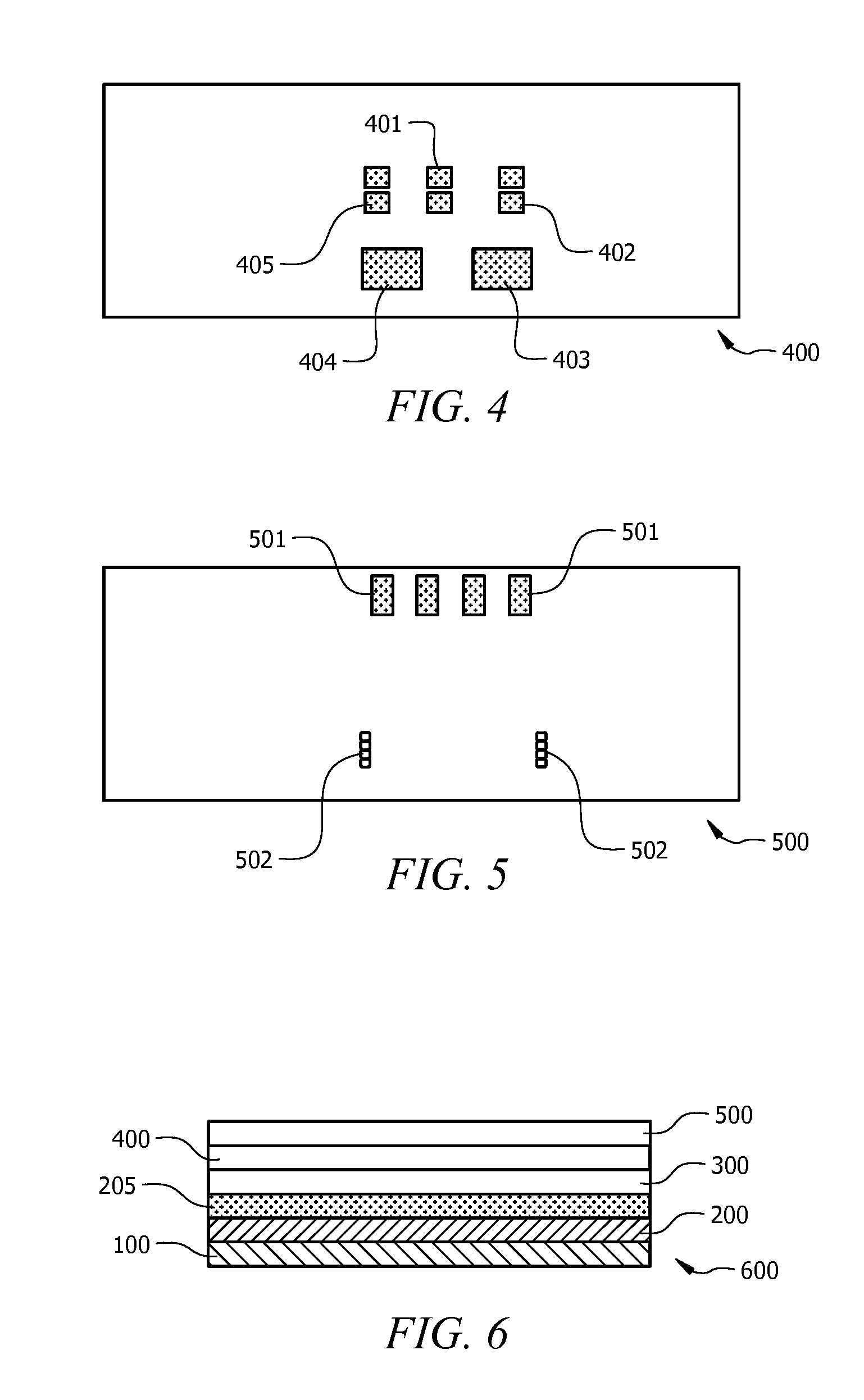

Media isolated pressure transducer having boss comprising single metal diaphragm

ActiveUS20100180688A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorTransducer

A pressure sensor for sensing a pressure of a fluid includes a monolithic metal including substrate having a substantially planar top side, wherein the metallic comprising substrate includes s a relatively thick boss near a center of the substrate and a thinned sensing portion that is elastically deformable and pressure-sensitive positioned radially outward from the boss. At least one dielectric layer is on the top side of the substrate. A plurality of piezoresistors are on the dielectric layer, wherein the piezoresistors are positioned over the thinned diaphragm portion. At least one overglaze layer is over the conductor layer that provides apertures for electrically contacting the plurality of piezoresistors. A sensing system includes a housing including at least a first port for coupling to a fluid for measurement of a pressure of the fluid and at least one sensor in the housing including a pressure sensor according to an embodiment of the invention.

Owner:HONEYWELL INT INC

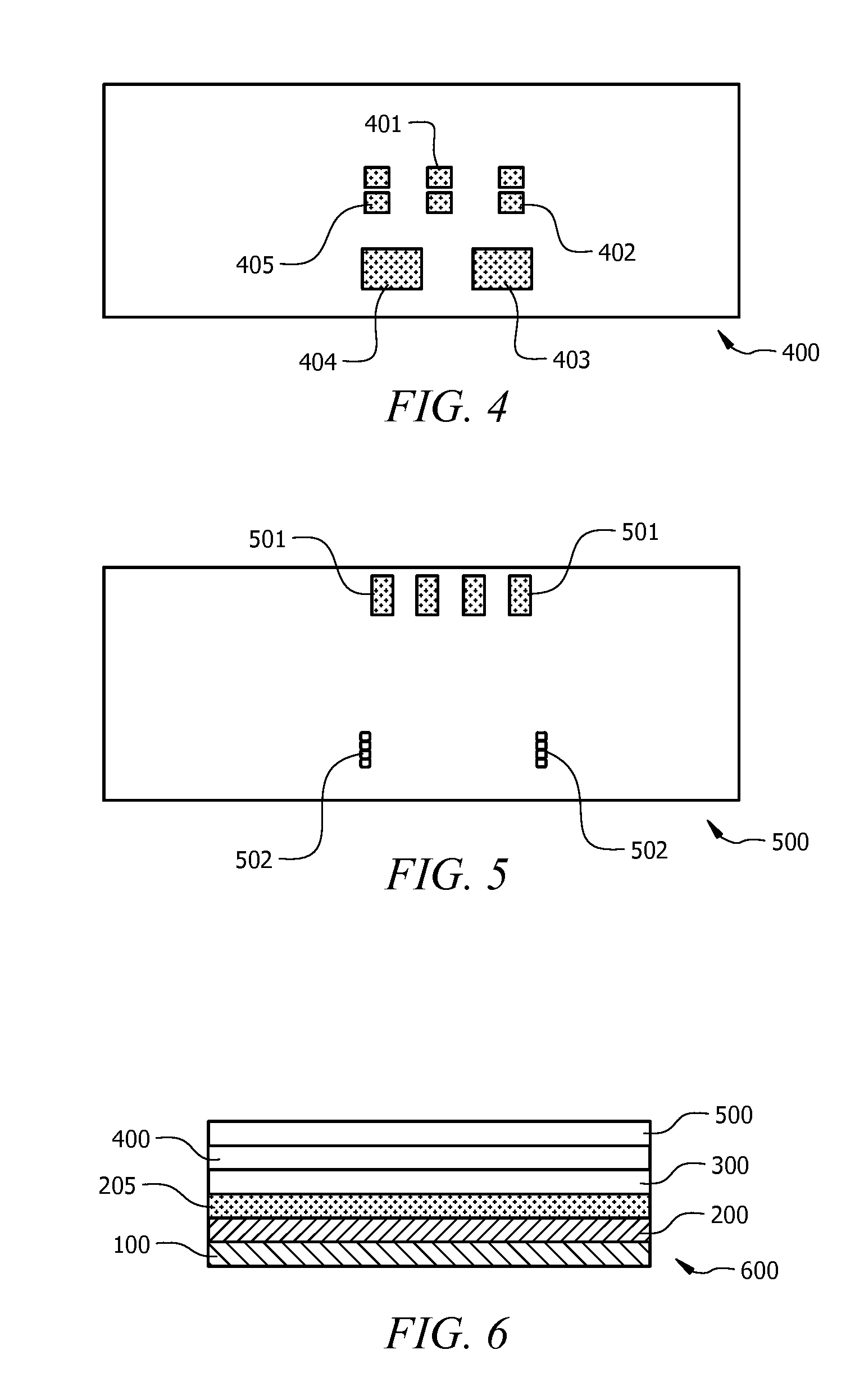

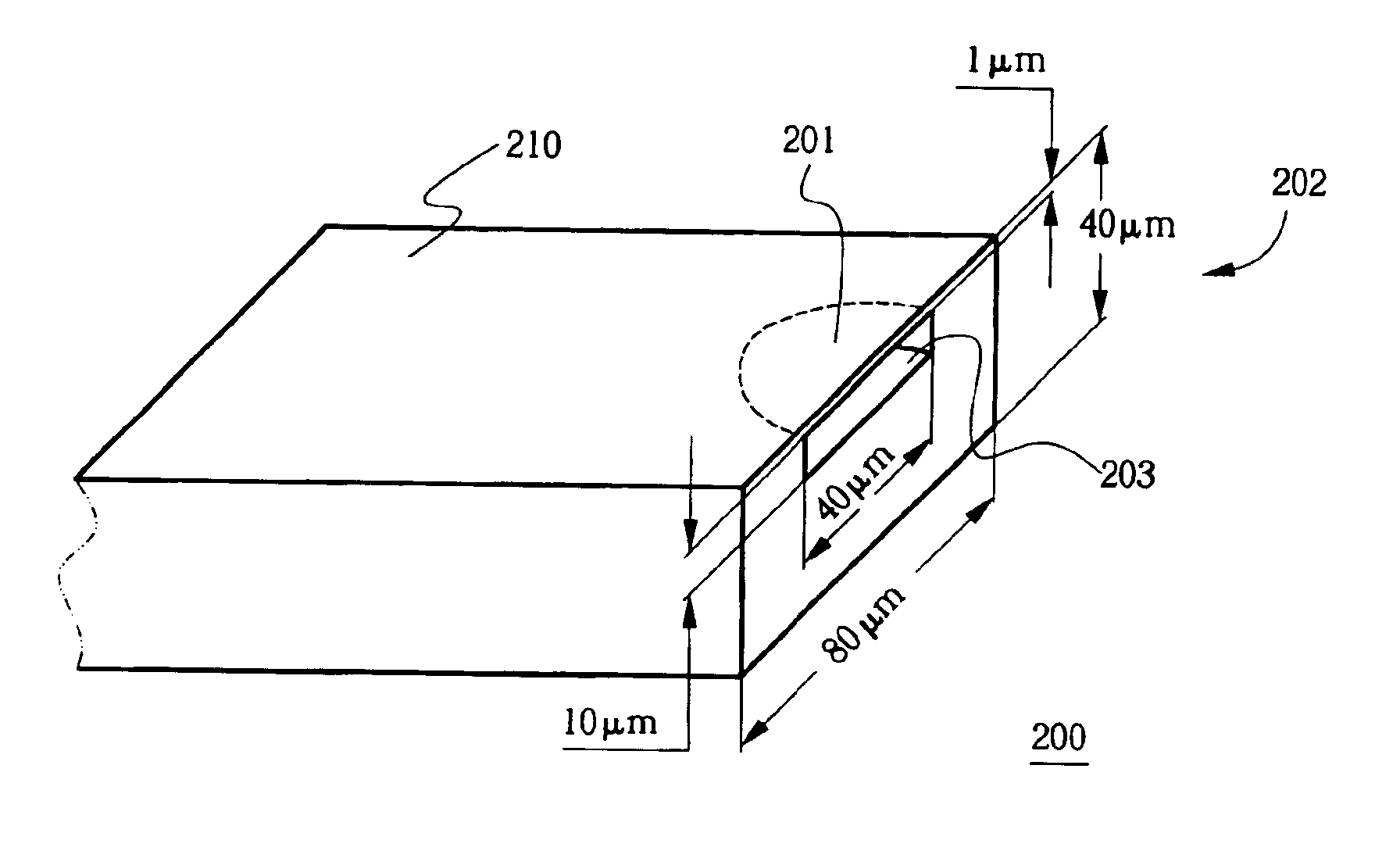

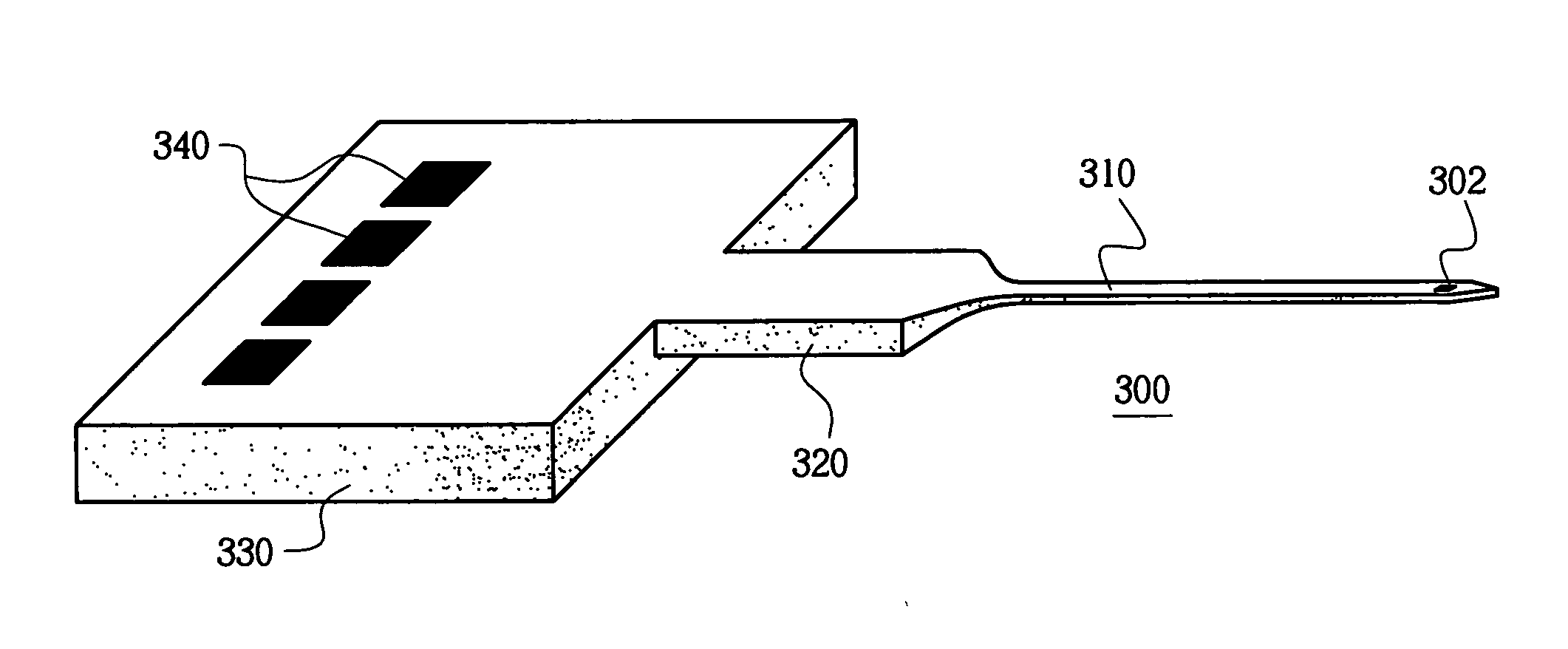

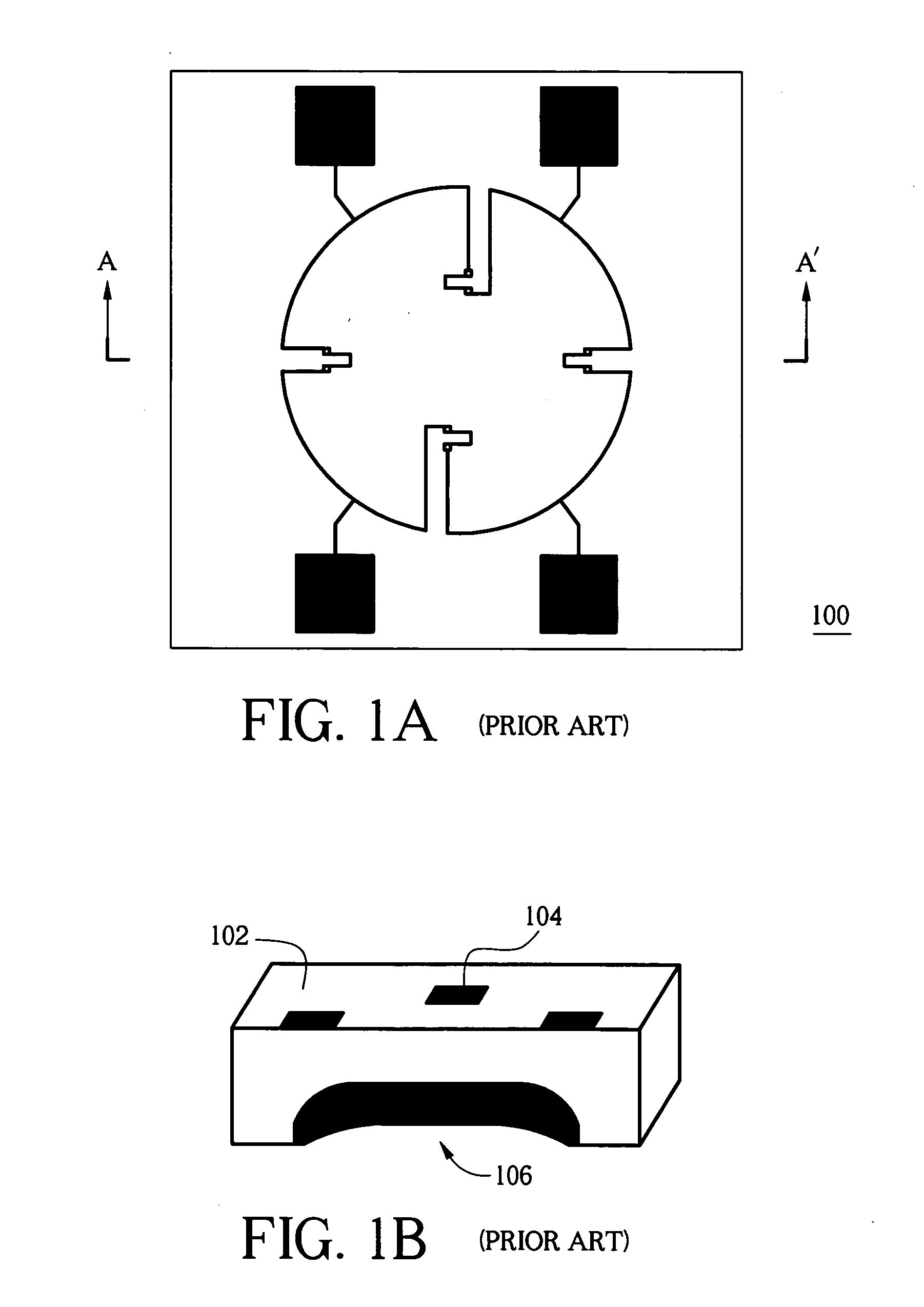

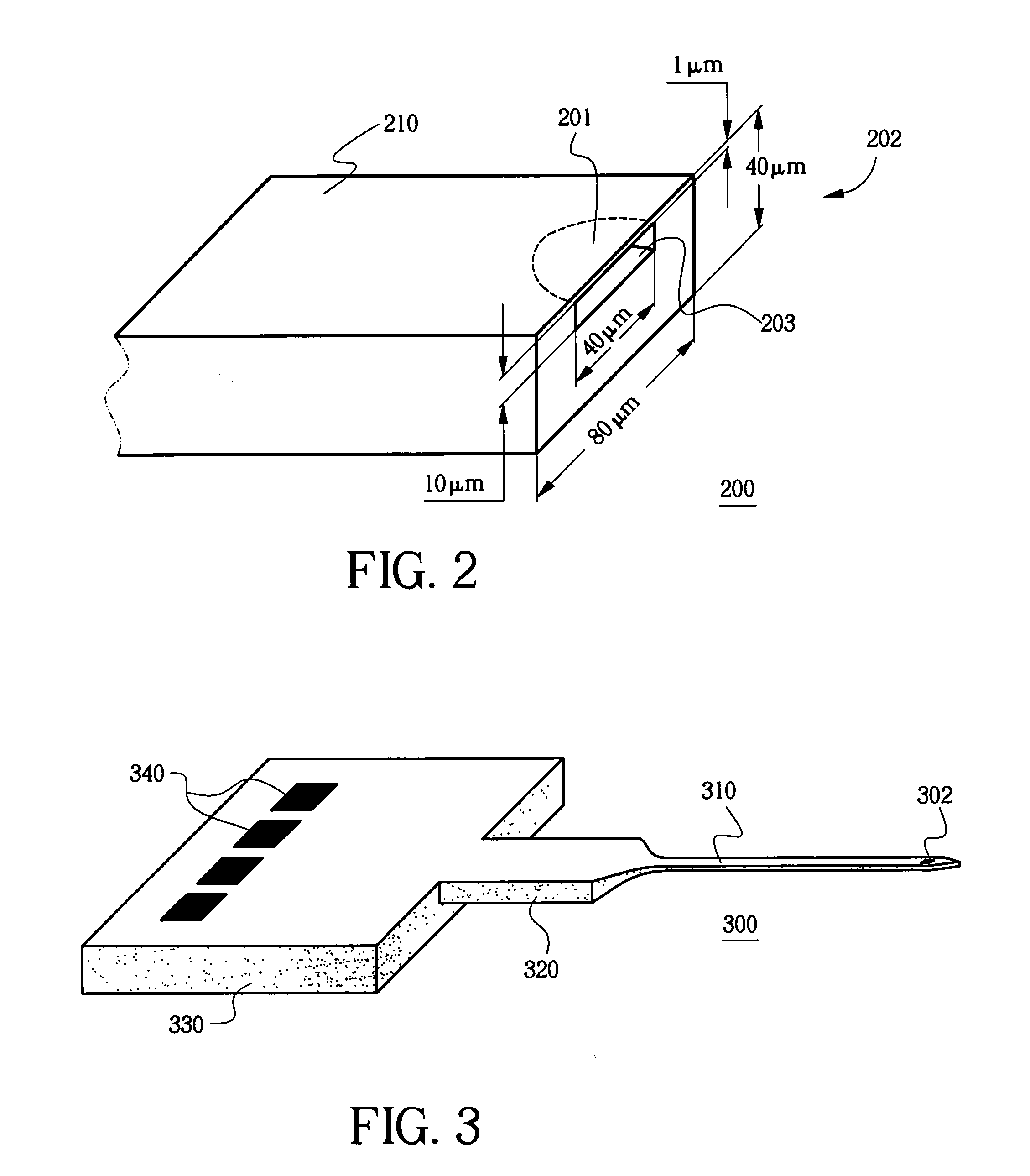

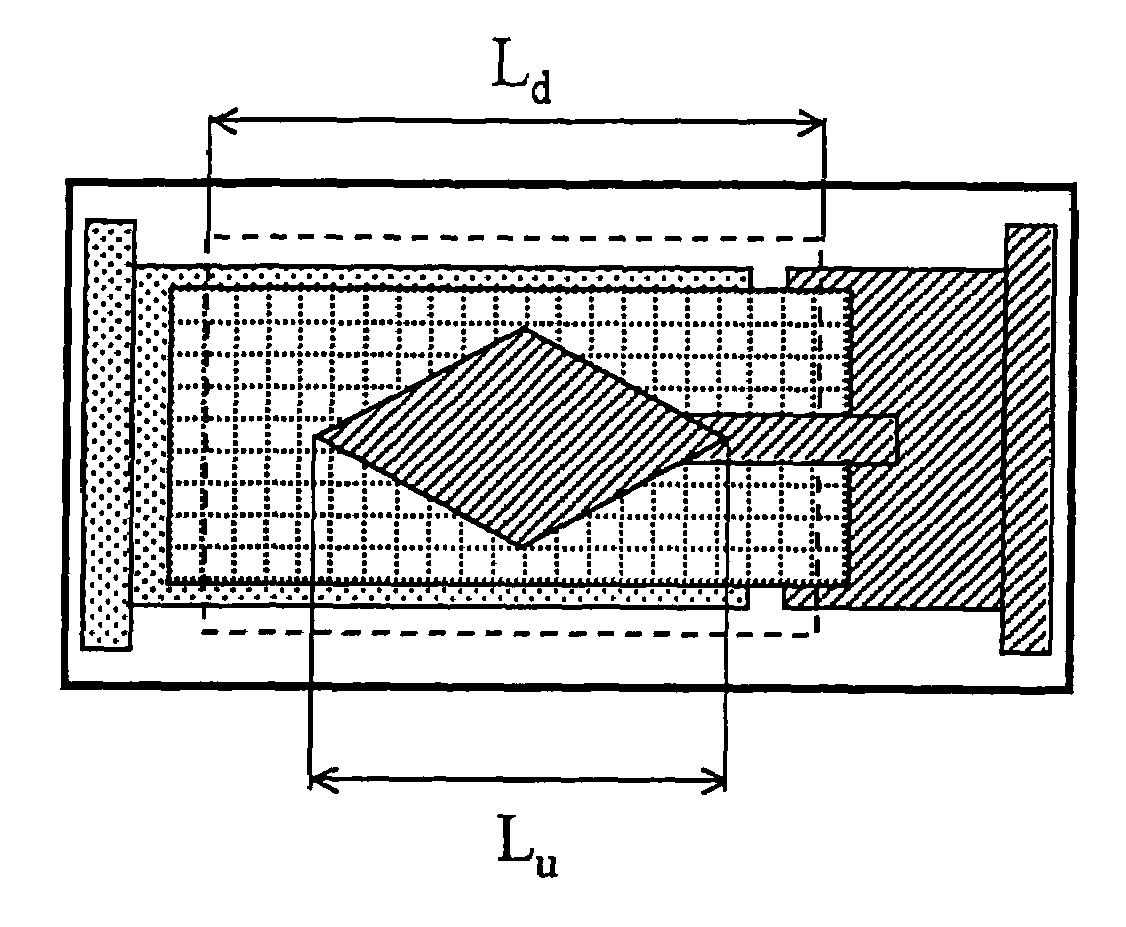

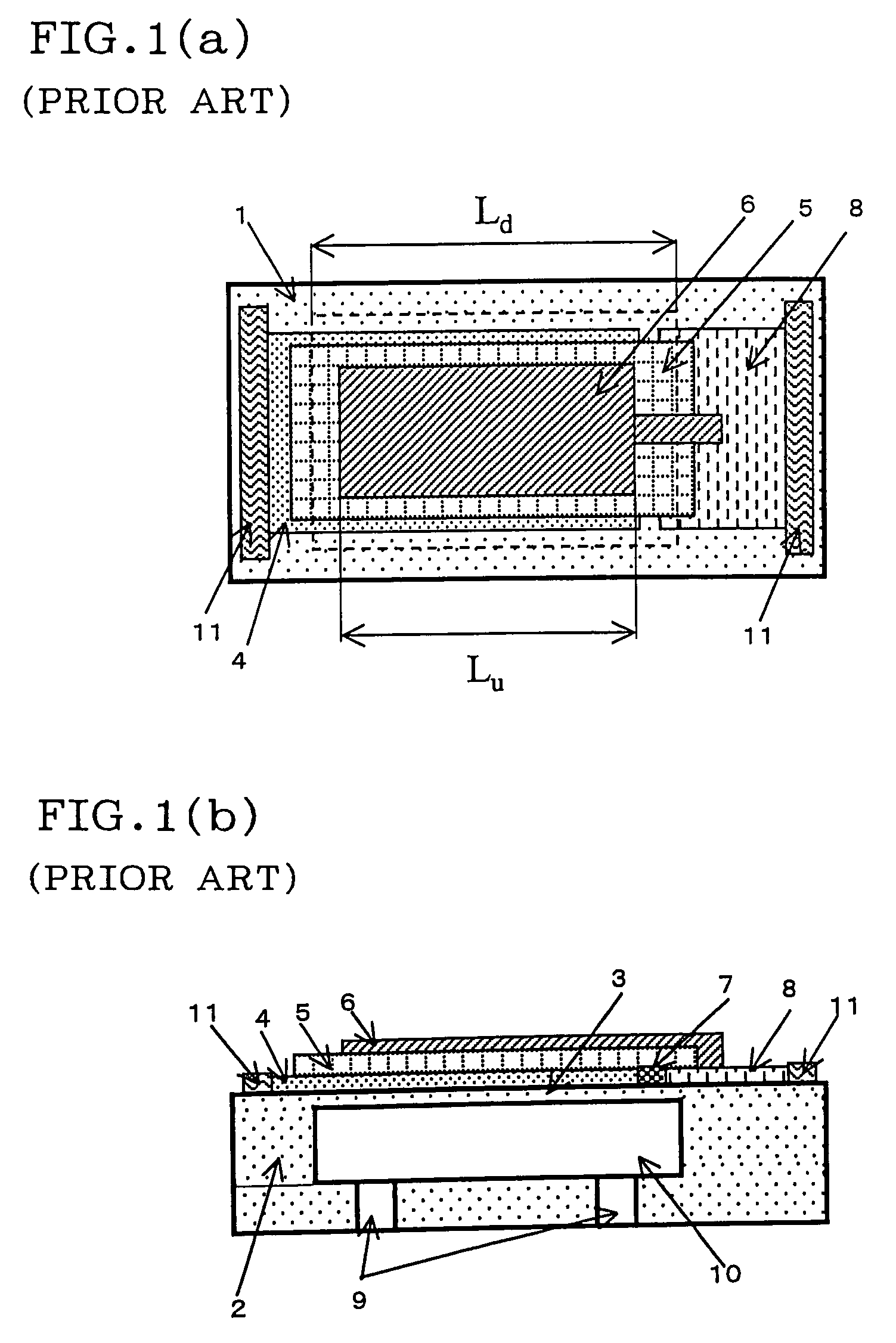

Ultra-miniature pressure sensors and probes

InactiveUS6959608B2Improve accuracyHigh bandwidthFluid pressure measurement by electric/magnetic elementsMiniaturizationEngineering

A new and versatile ultra-miniature pressure sensor comprises a very thin diaphragm of approximately one micron or less, e.g., 0.2 microns. In some embodiments, the diaphragm has a radius of 20 microns and the pressure sensor can detect signals at or near 0.1 Atm with 1% accuracy. The diaphragm is formed by epitaxial growth of silicon or by bonding and etching. A plurality of high sensitivity piezoresistive strain gauges measure strain of the diaphragm. Less than 0.1 microns thick, the piezoresistive strain gauges are embedded in the diaphragm by ion implantation or formed thereon by epitaxial growth. The ability to form ultra-thin piezoresistive layers on very thin diaphragms enables the miniaturization of the pressure sensor as well as any device that employs it.

Owner:TEH BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIVERSTIY

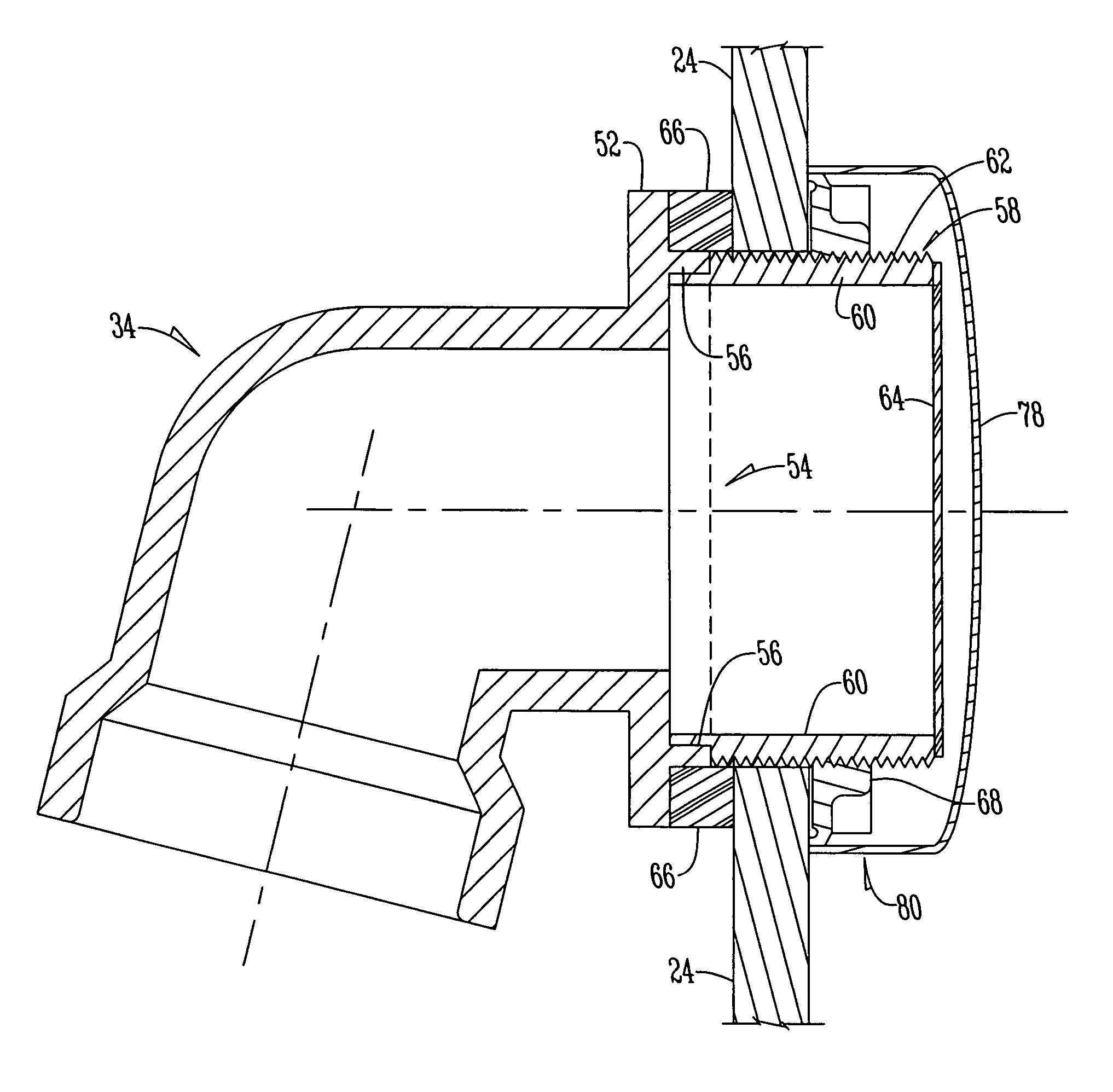

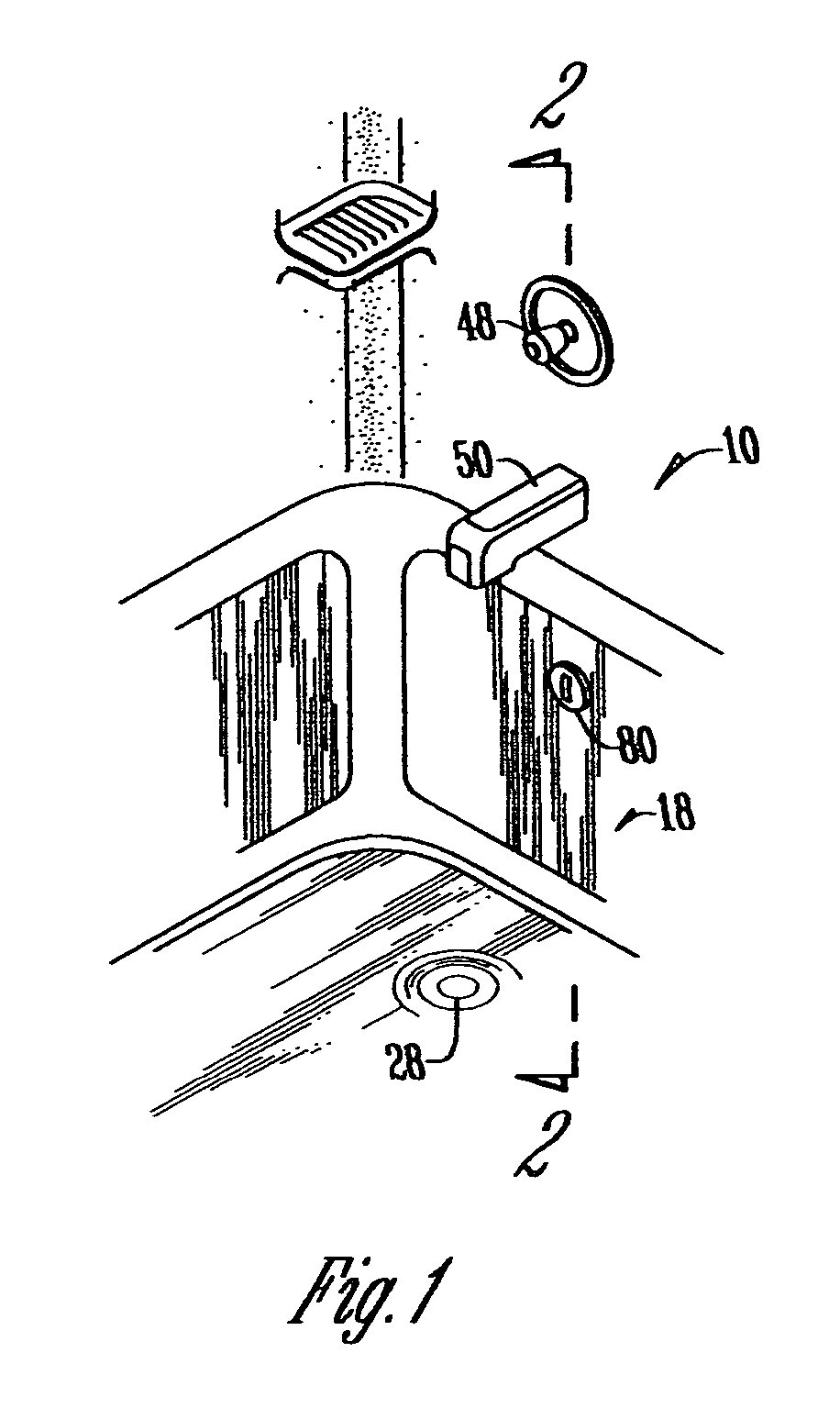

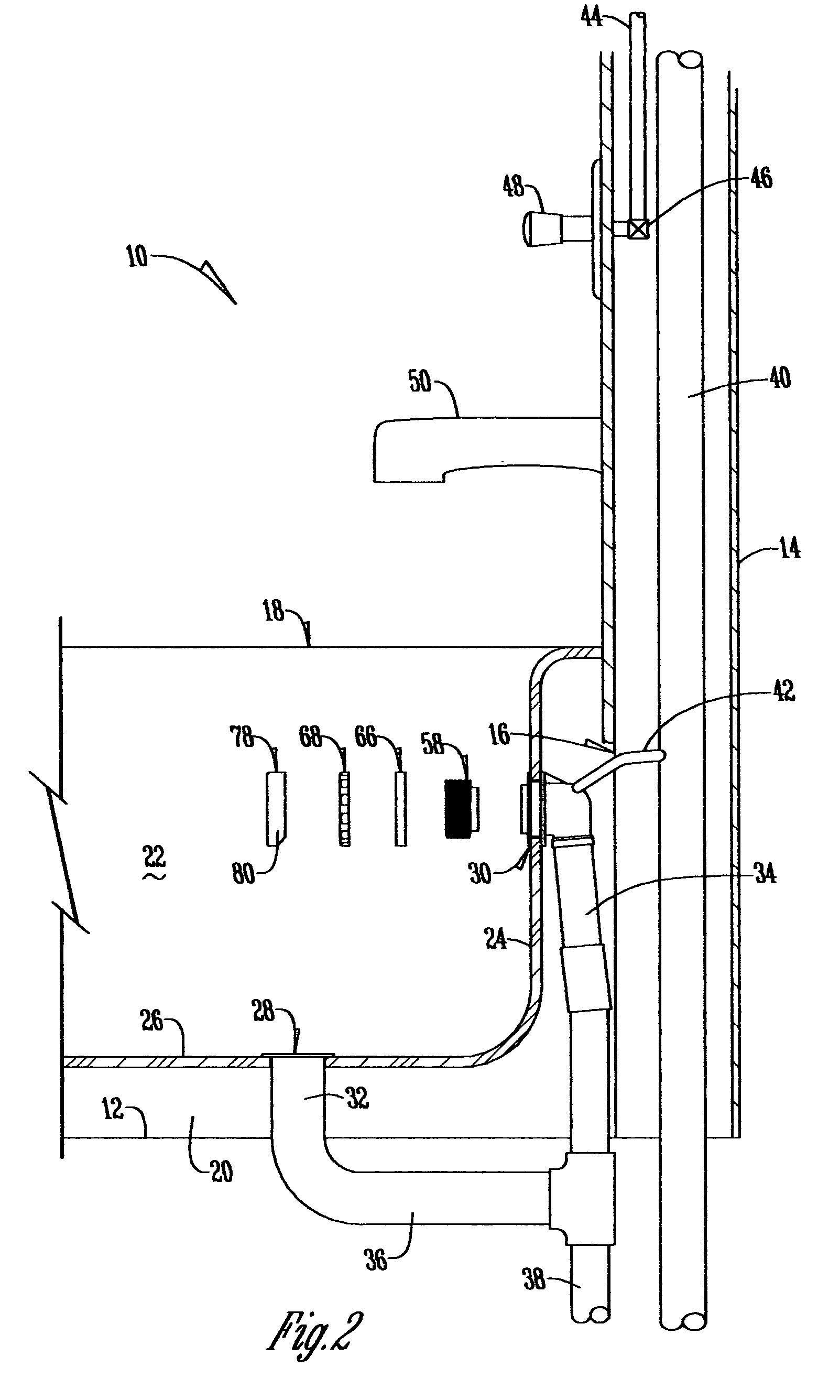

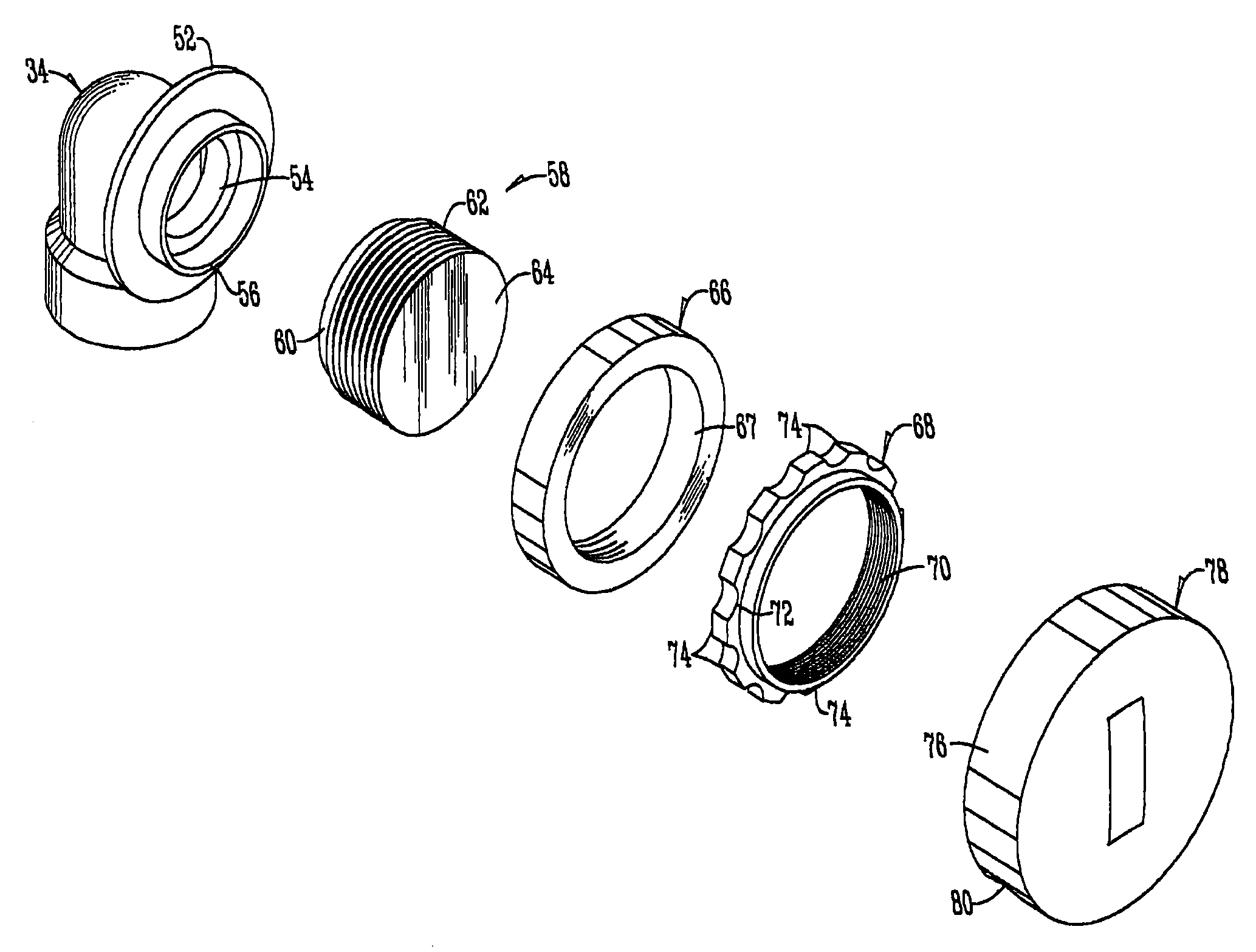

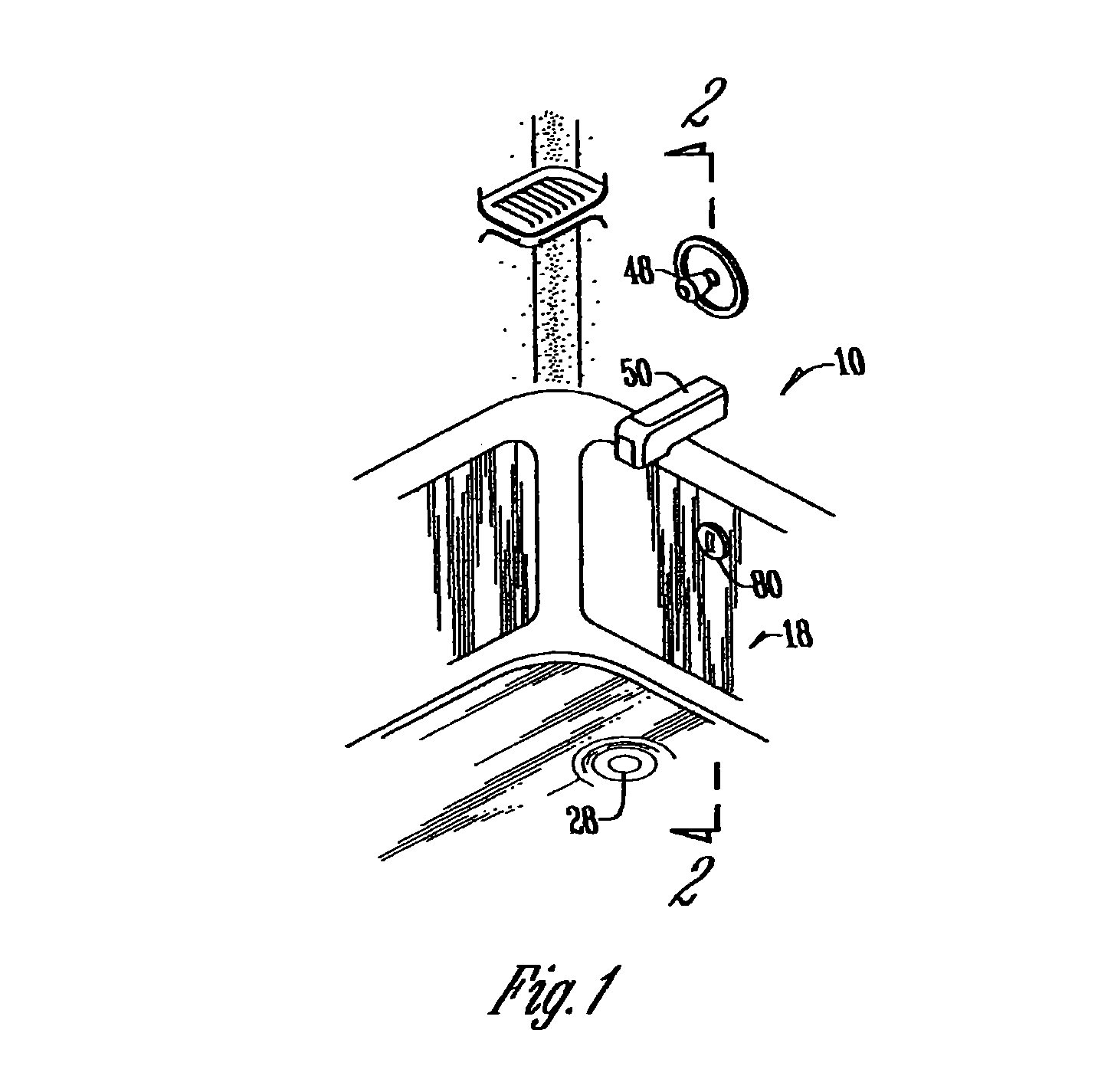

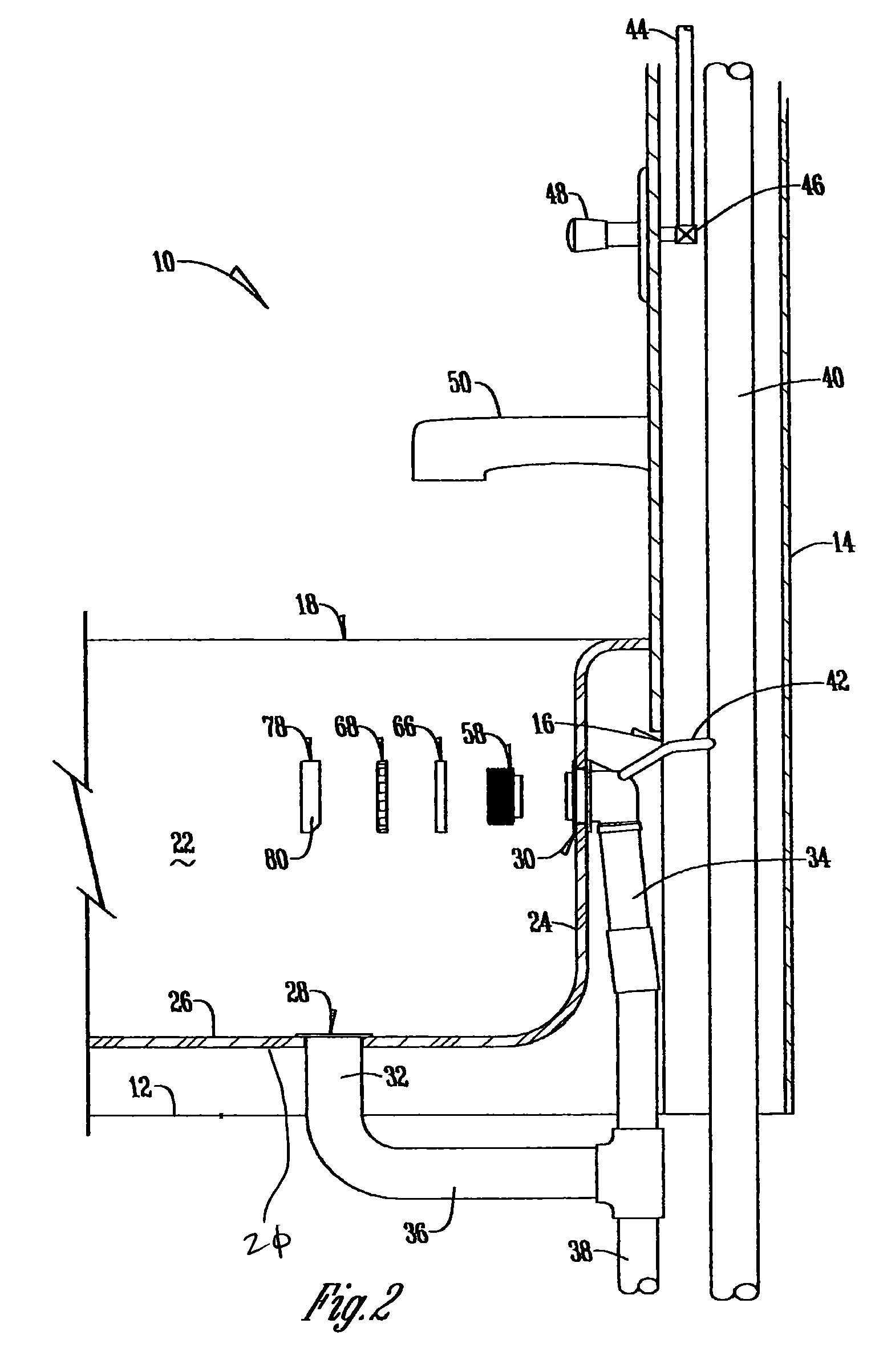

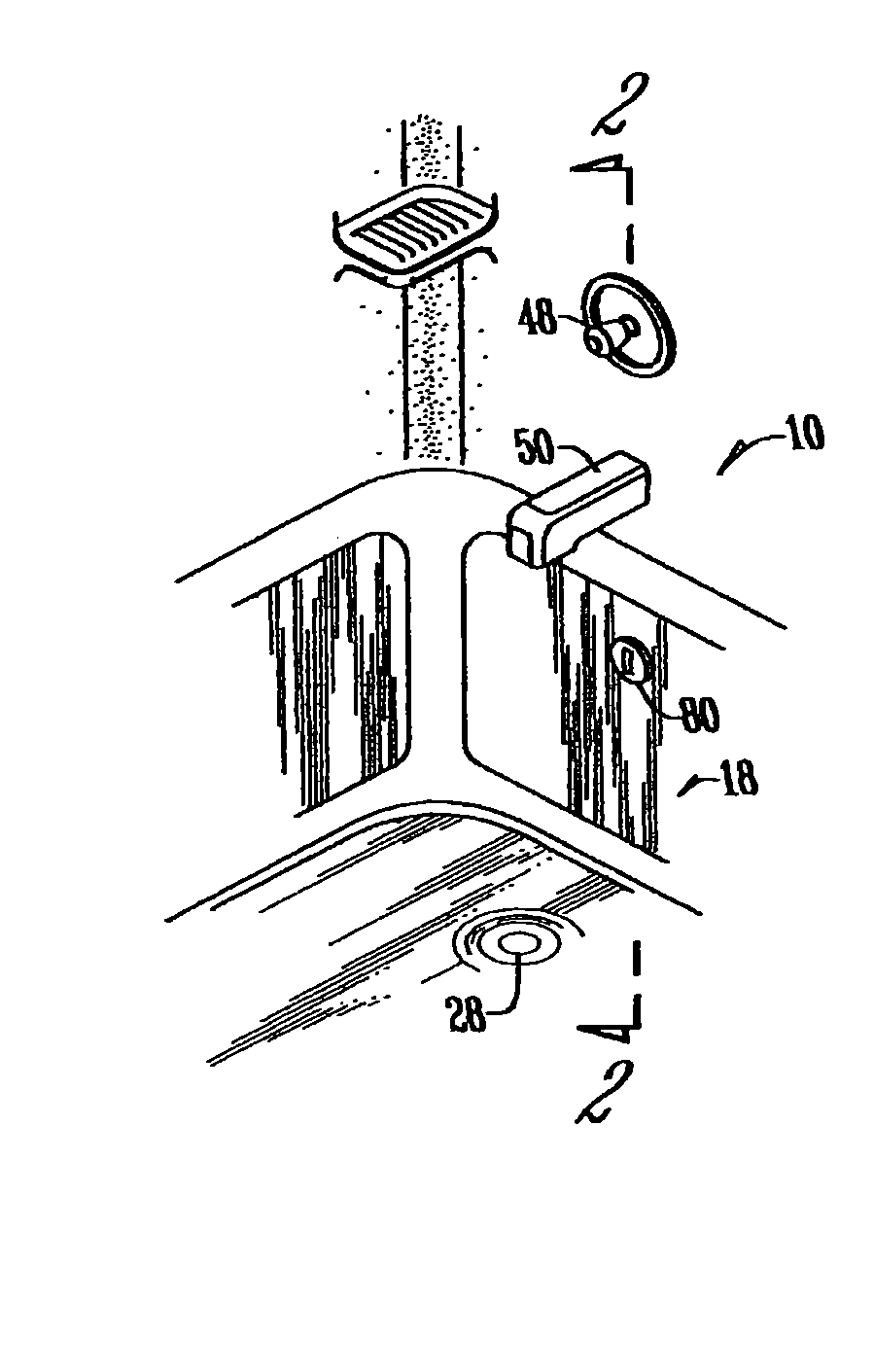

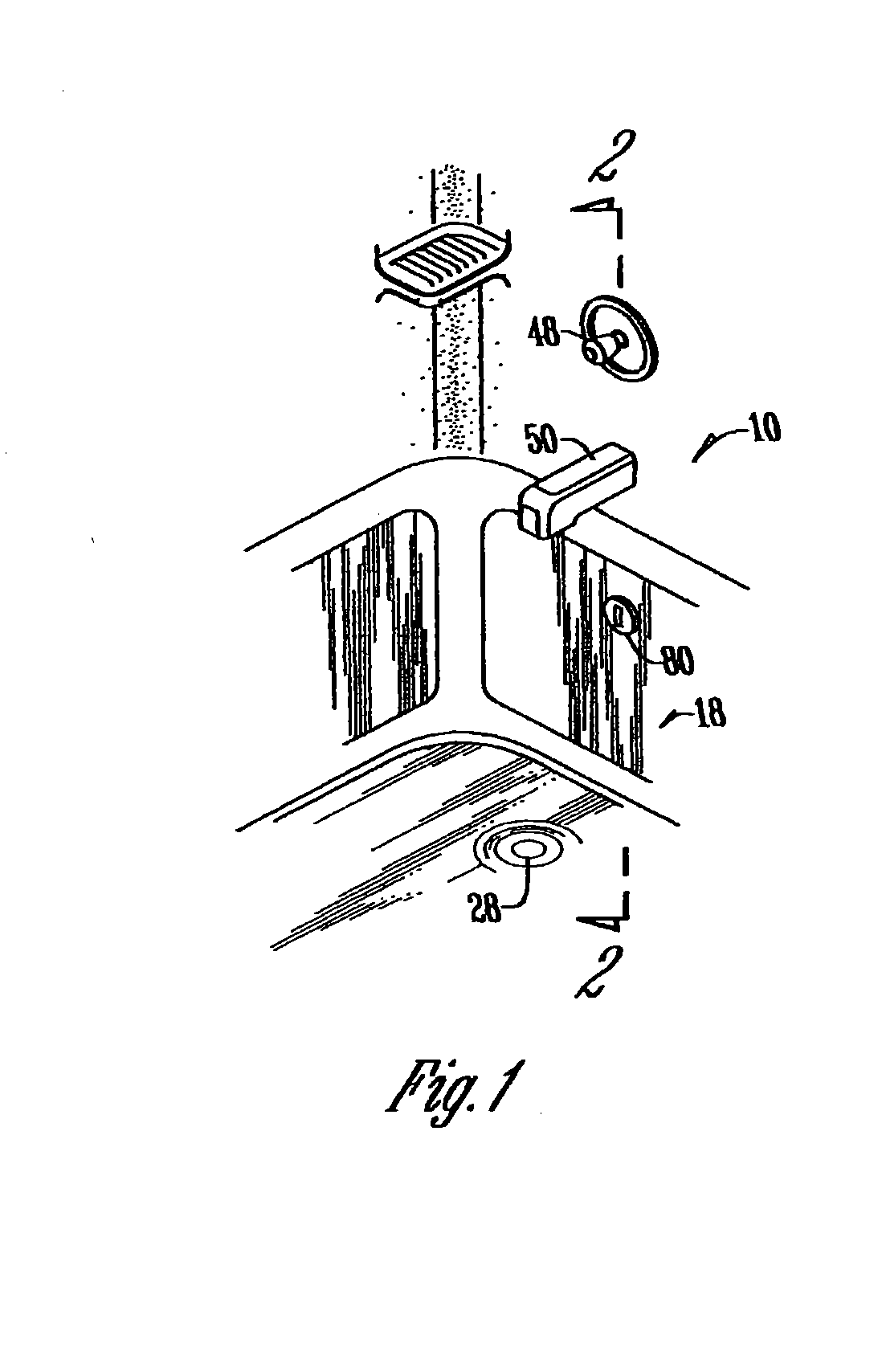

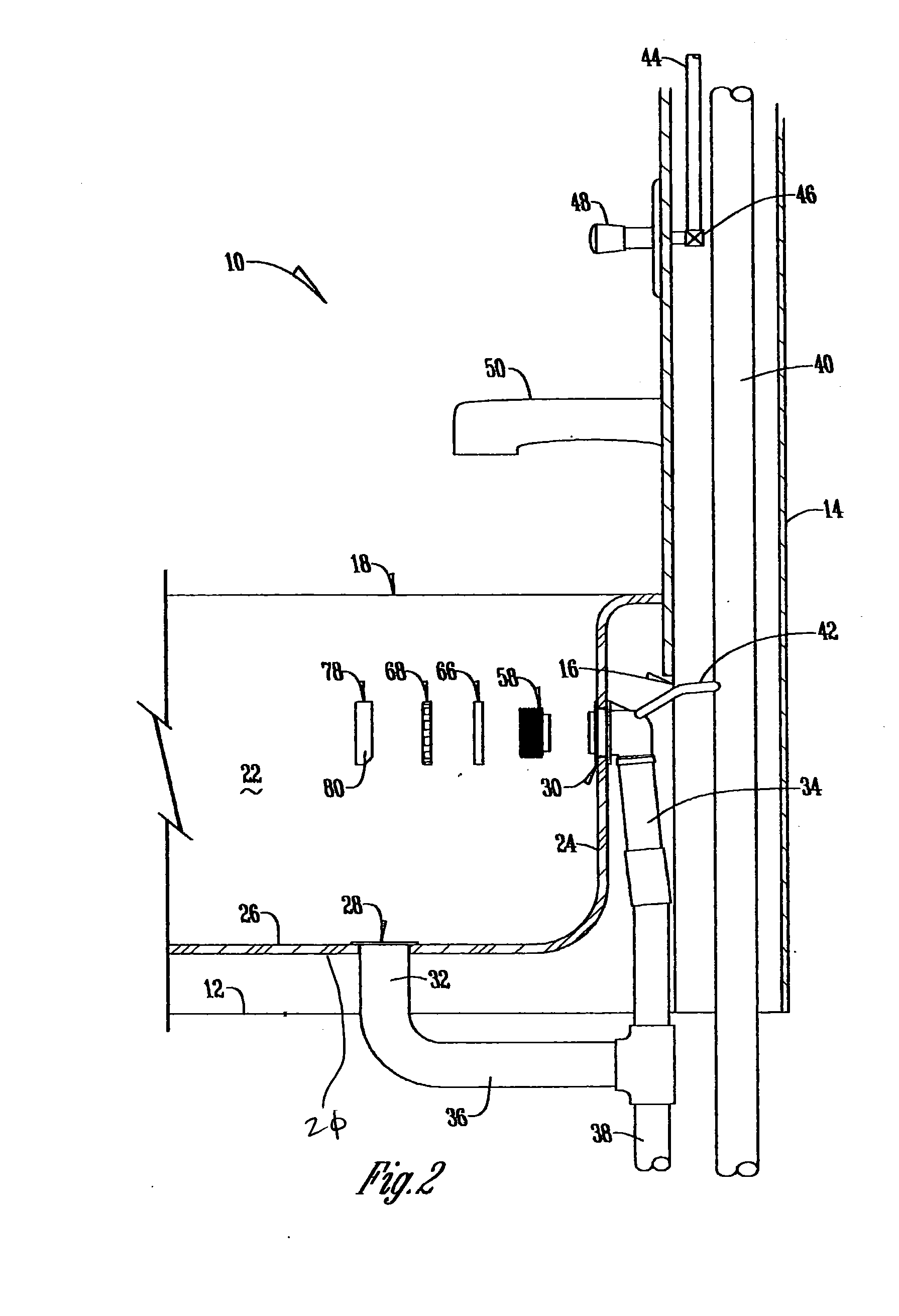

Overflow assembly for bathtubs and the like

An overflow system in the bathtub has an overflow port and has a drain pipe in connection with the overflow port. A threaded flange has a stub shoulder on one end which is fitted into a circular sleeve on the overflow port. The threaded flange has exterior threads on its outer surface and a thin diaphragm secured to the end thereof opposite to the stub shoulder. A large sealing washer embraces the outside of the circular flange on the overflow port and extends partially over the threads of the threaded flange. A large internally threaded nut is threadably mounted on the outer end of the threaded flange and compresses the sealing washer against a vertical flange on the port to seal the connection between the threaded flange and the port. A decorative cap is frictionally snapped into engagement with protrusions on the outer surface of the nut. The cap can be removed when needed to permit the plumber to gain access to the diaphragm to cut it open for fluid flow after the system has been tested for leaks, or put in place after the cut takes place.

Owner:WCM IND INC

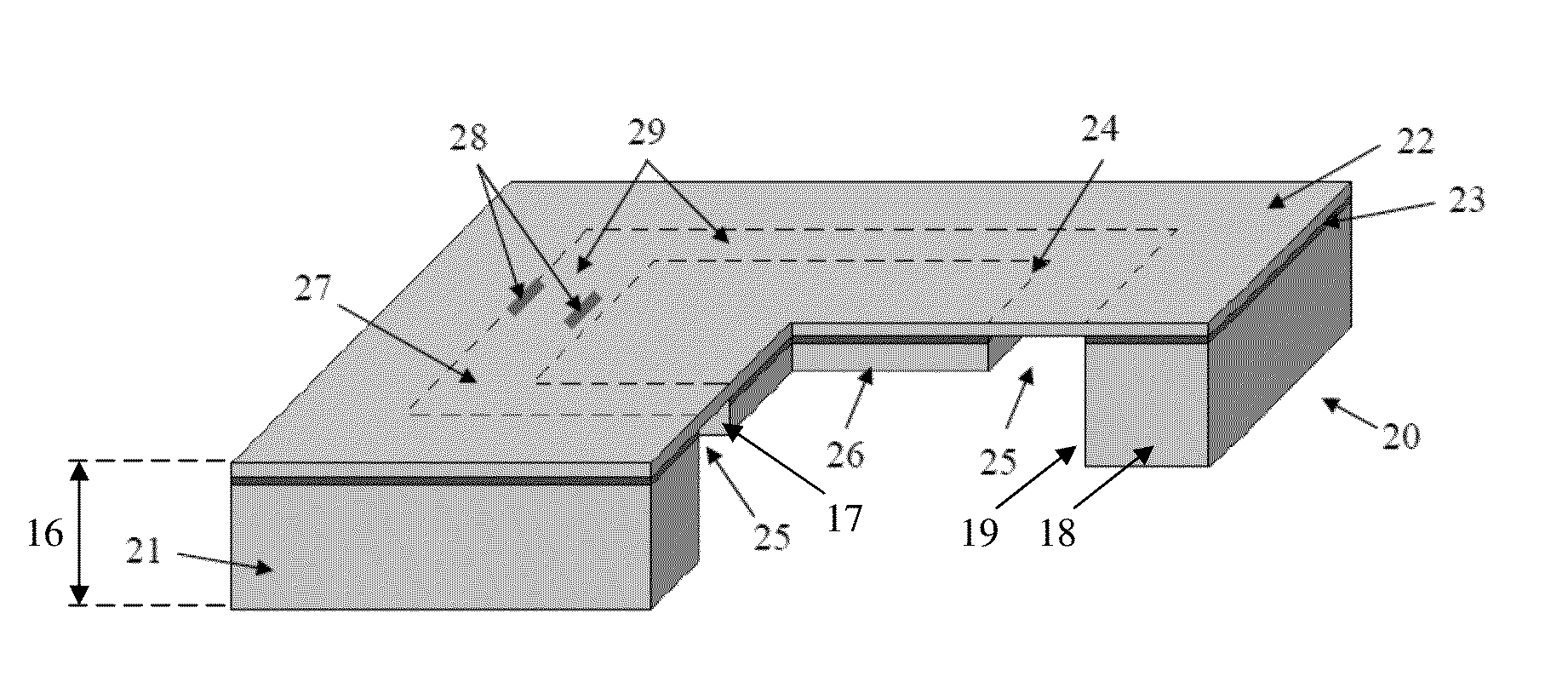

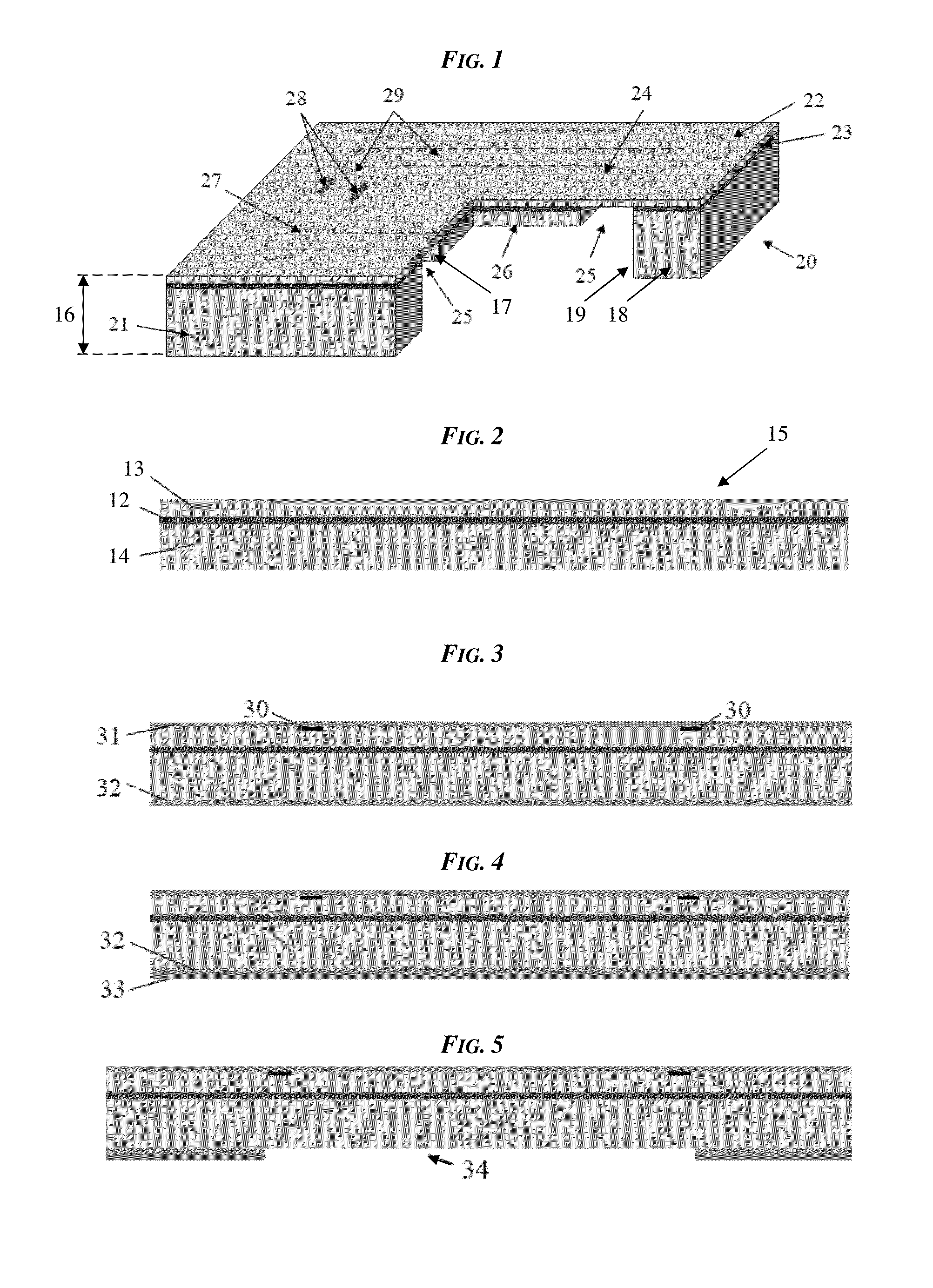

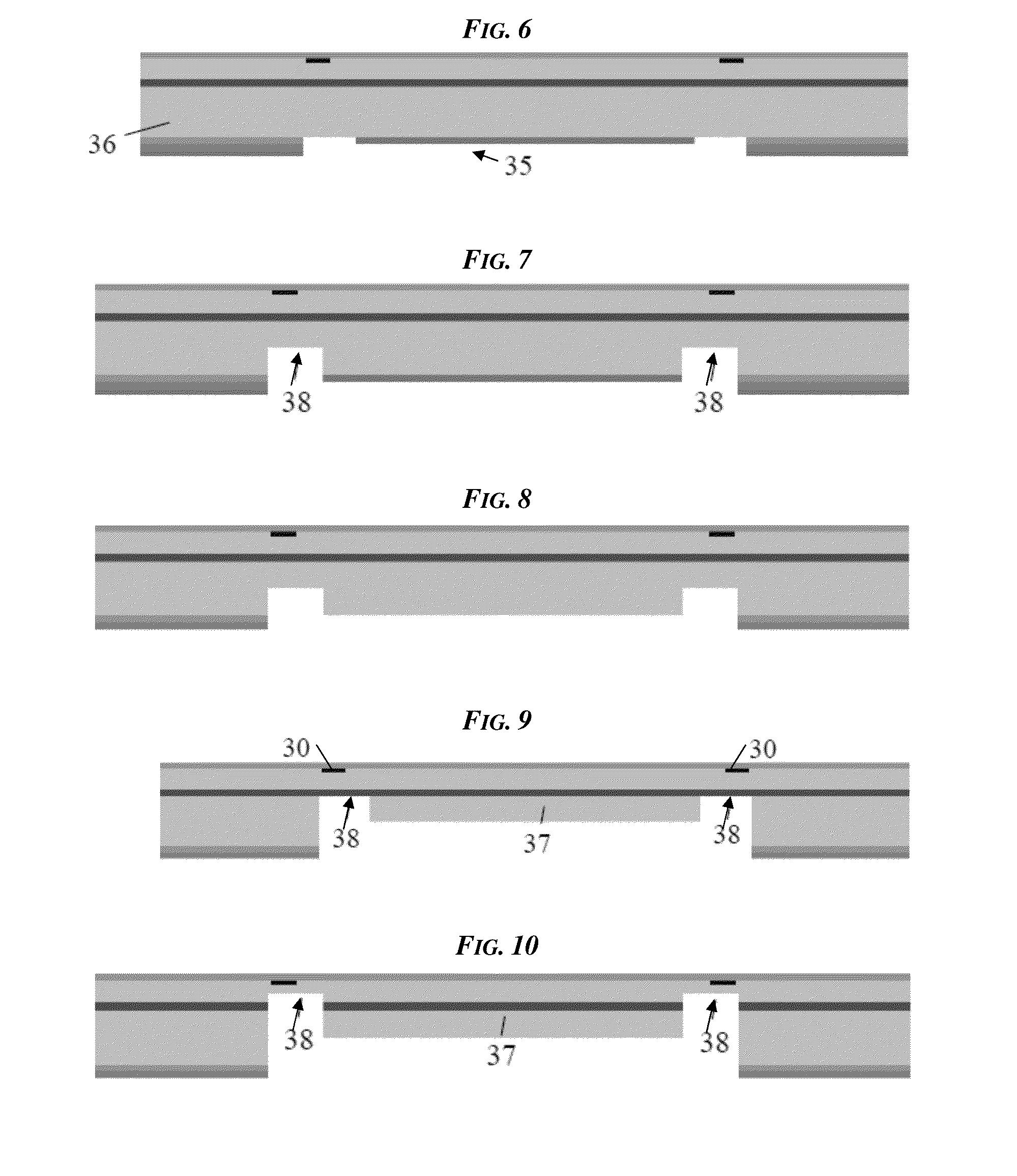

Apparatus and method for making a low capacitance artificial nanopore

InactiveUS20050102721A1Fixed microstructural devicesVolume/mass flow measurementCapacitanceEngineering

An apparatus and method for making a nanopore chip exhibiting low capacitance. The apparatus provides a thin diaphragm on a rigid semiconductor frame suitable for nanopore fabrication, the diaphragm having associated thicker insulator regions to reduce capacitance. Also disclosed is a method of making the apparatus.

Owner:AGILENT TECH INC

Ultraminiature pressure sensors and probes

InactiveUS20050103114A1Improve accuracyHigh bandwidthFluid pressure measurement by electric/magnetic elementsMiniaturizationEngineering

A new and versatile ultra-miniature pressure sensor comprises a very thin diaphragm of approximately one micron or less, e.g., 0.2 microns. In some embodiments, the diaphragm has a radius of 20 microns and the pressure sensor can detect signals at or near 0.1 Atm with 1% accuracy. The diaphragm is formed by epitaxial growth of silicon or by bonding and etching. A plurality of high sensitivity piezoresistive strain gauges measure strain of the diaphragm. Less than 0.1 microns thick, the piezoresistive strain gauges are embedded in the diaphragm by ion implantation or formed thereon by epitaxial growth. The ability to form ultra-thin piezoresistive layers on very thin diaphragms enables the miniaturization of the pressure sensor as well as any device that employs it.

Owner:TEH BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIVERSTIY

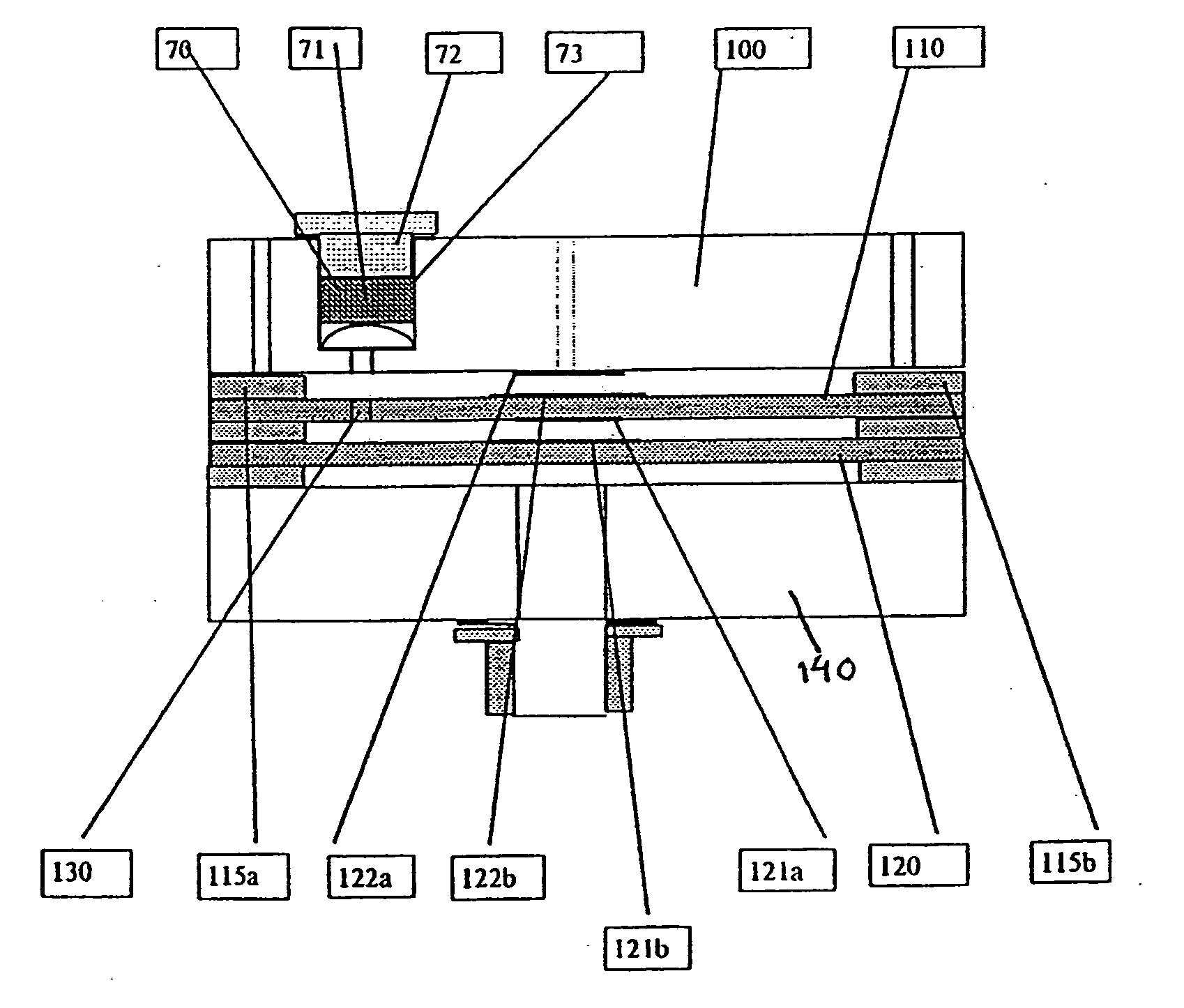

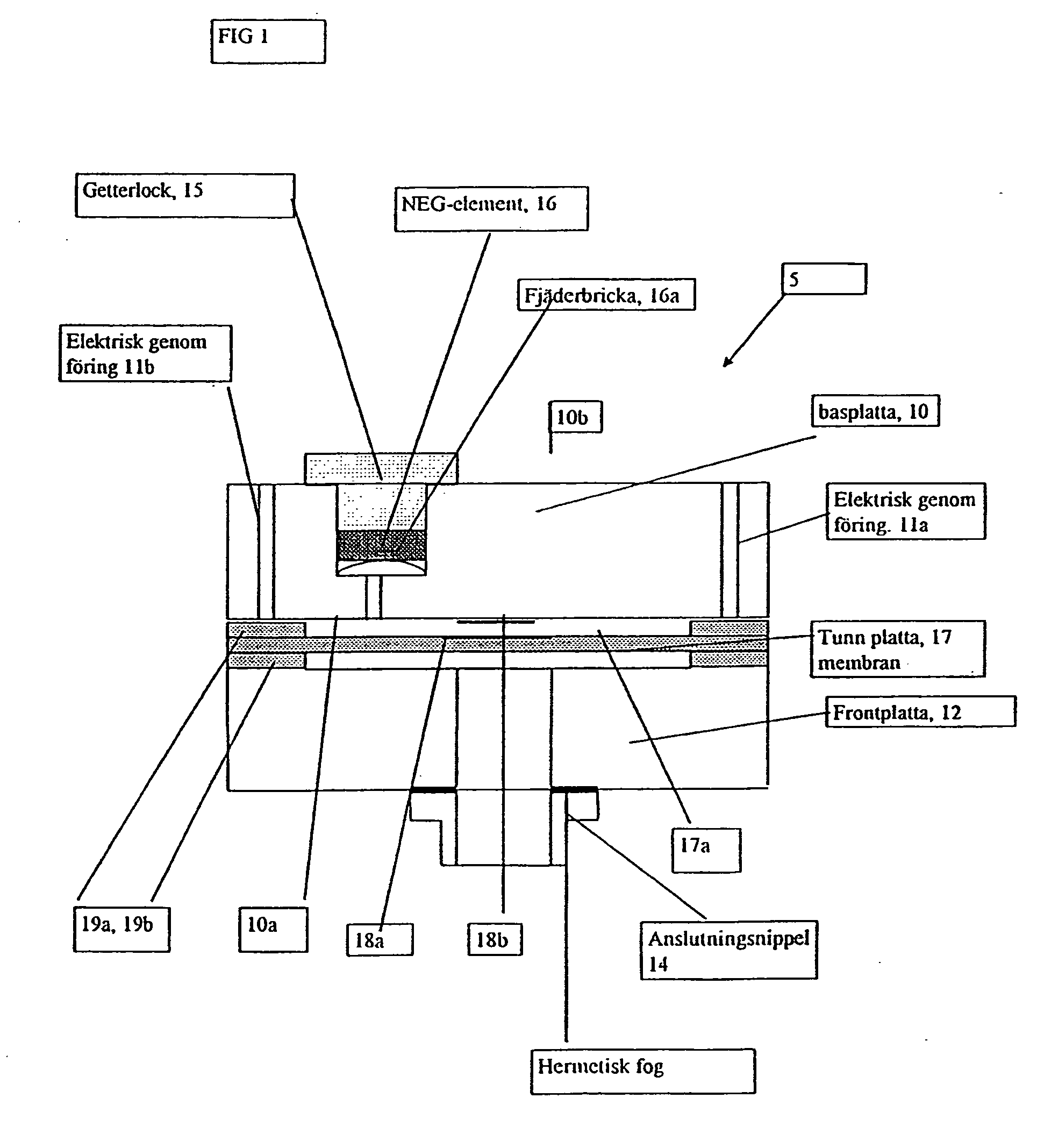

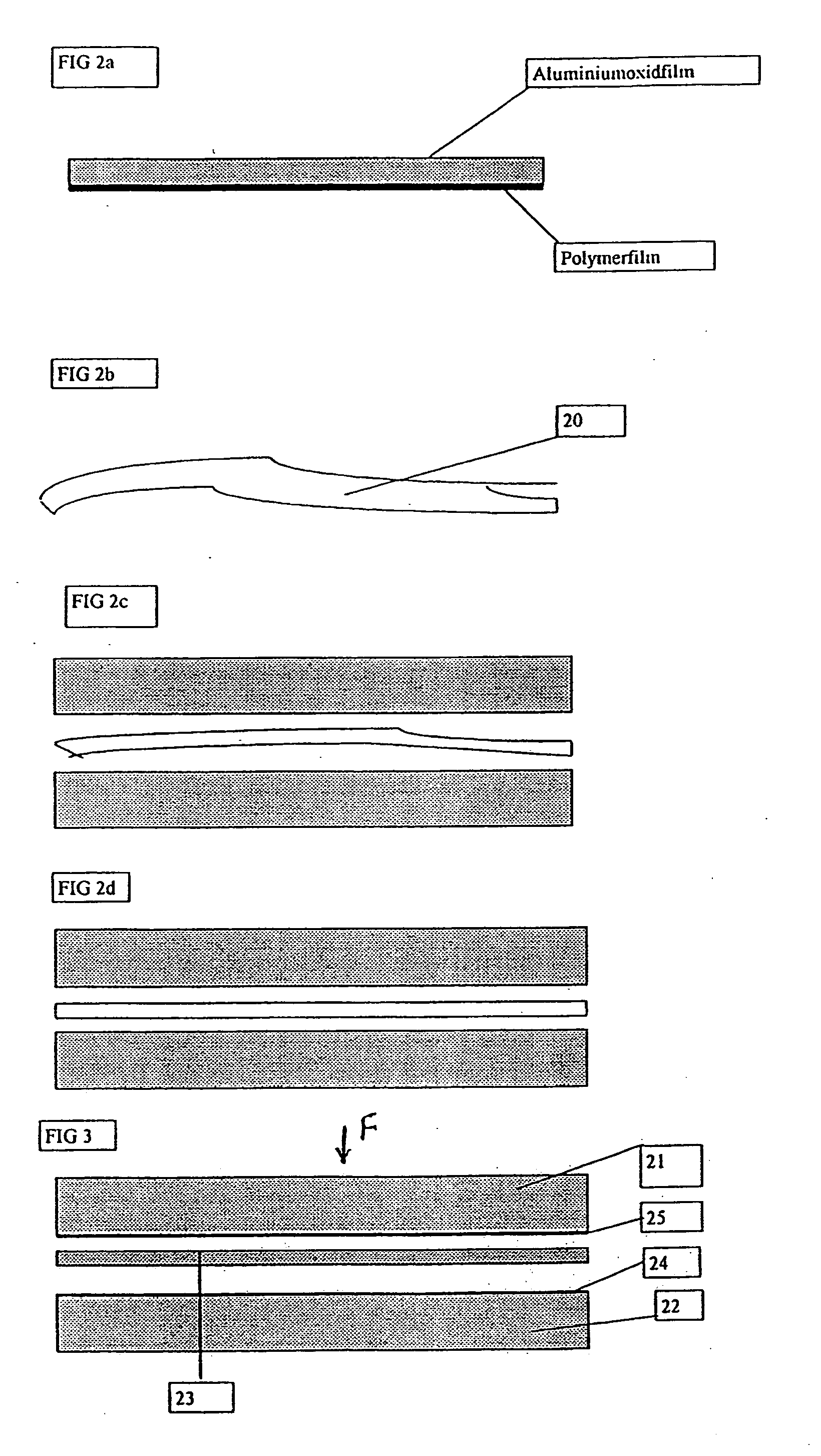

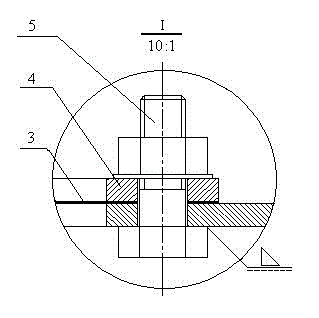

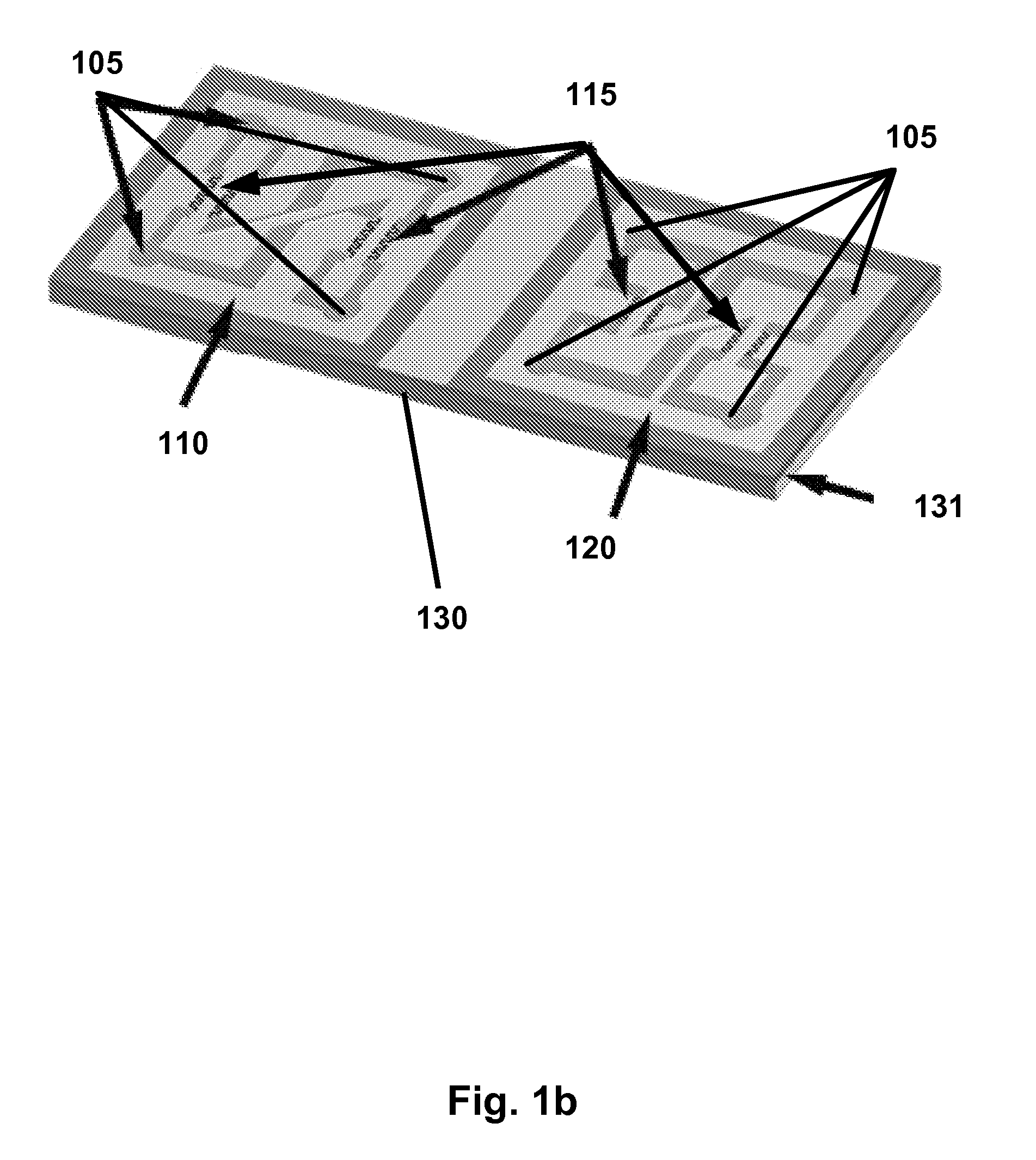

Pressure sensor for detecting small pressure differences and low pressures

InactiveUS20060000289A1High sensitivity and stabilityLarge pressure variationPressure difference measurement between multiple valvesFluid pressure measurement using capacitance variationCapacitive pressure sensorMetallurgy

A capacitive pressure sensor of substantially ceramic material comprises a thick base plate (100), a front plate (140) having the same thickness as the base plate and a movable diaphragm (120) located between the front plate and the base plate. Capacitor electrodes (121b, 121a) are provided at the surface of the diaphragm facing the base plate and form a measurement capacitor. The diaphragm (120) is extremely thin and is produced by sintering a ceramic material such aluminium oxide. Owing to a pressing process used during the sintering a strong, very thin diaphragm is obtained having no mechanical stresses and fracture indications. It can be produced to have a very small thickness in order to provide pressure sensors having a high sensitivity, which can also for high-vacuum applications tolerate to be subjected to the atmospheric pressure. A shielding plate (110) can be inserted between the base plate (100) compensating the measurement capacitor. The shielding plate (110) can also be extremely thin, having a thickness down to a thickness corresponding to the thickness of a diaphragm (120).

Owner:MKS INSTR INC

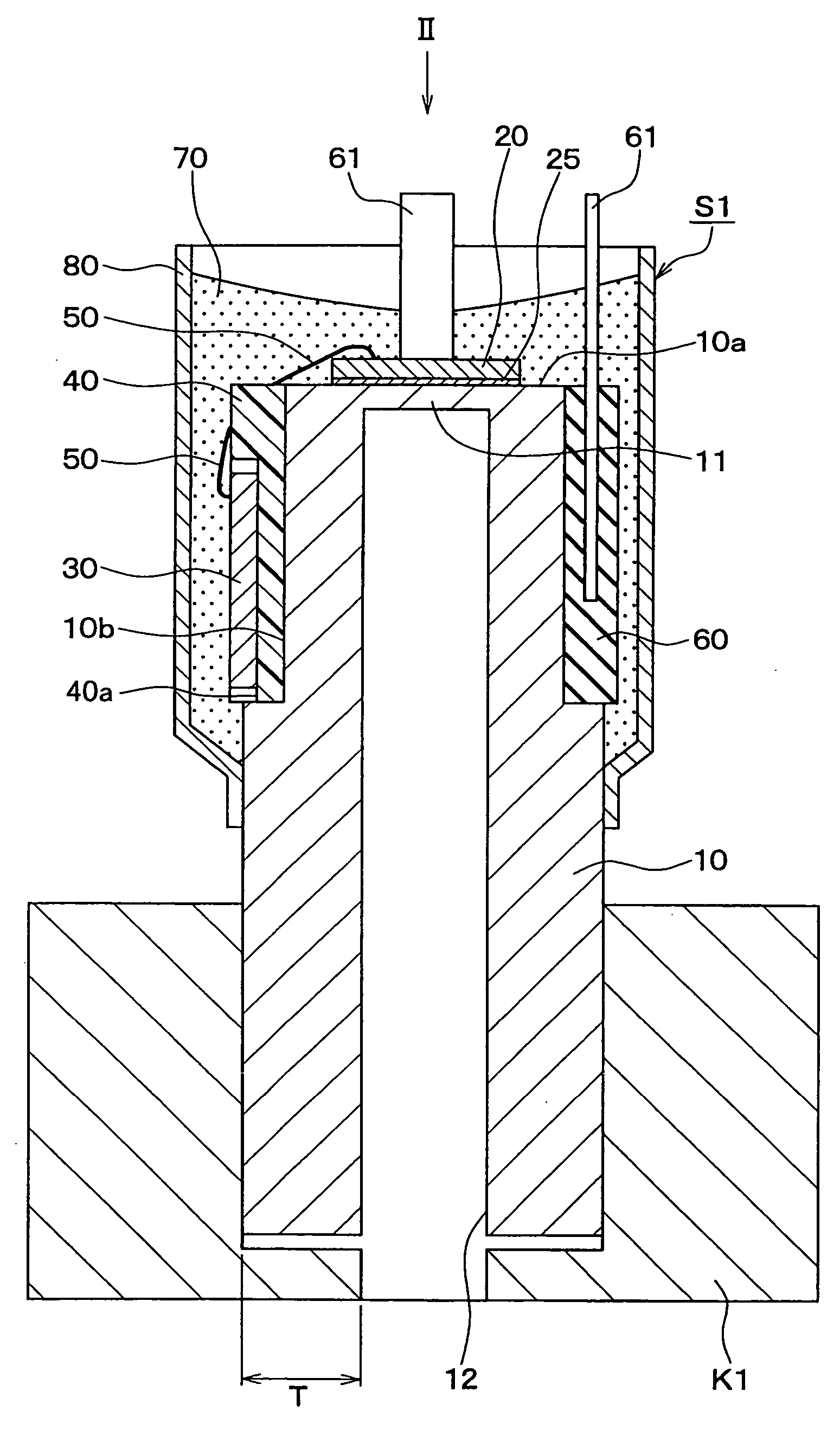

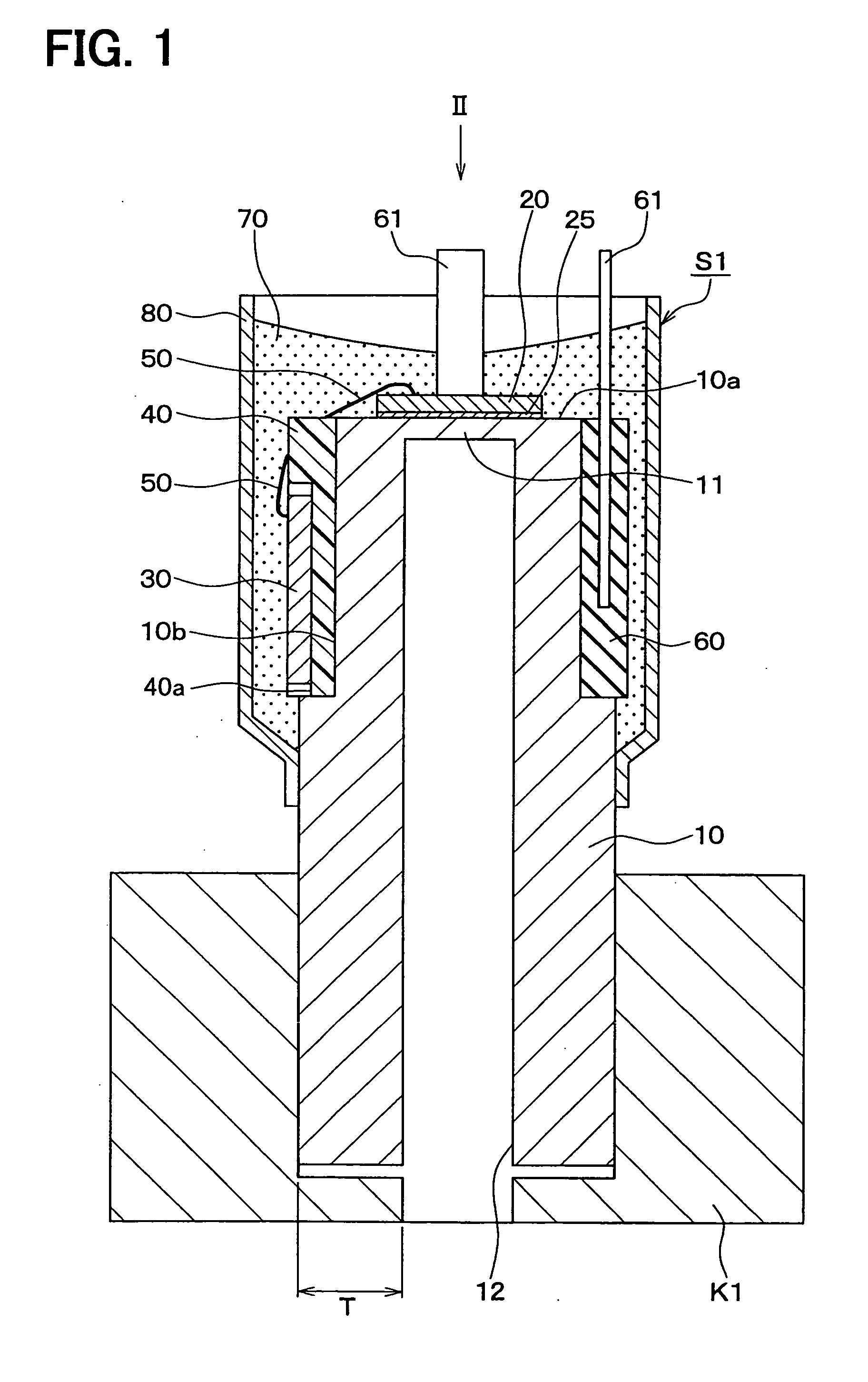

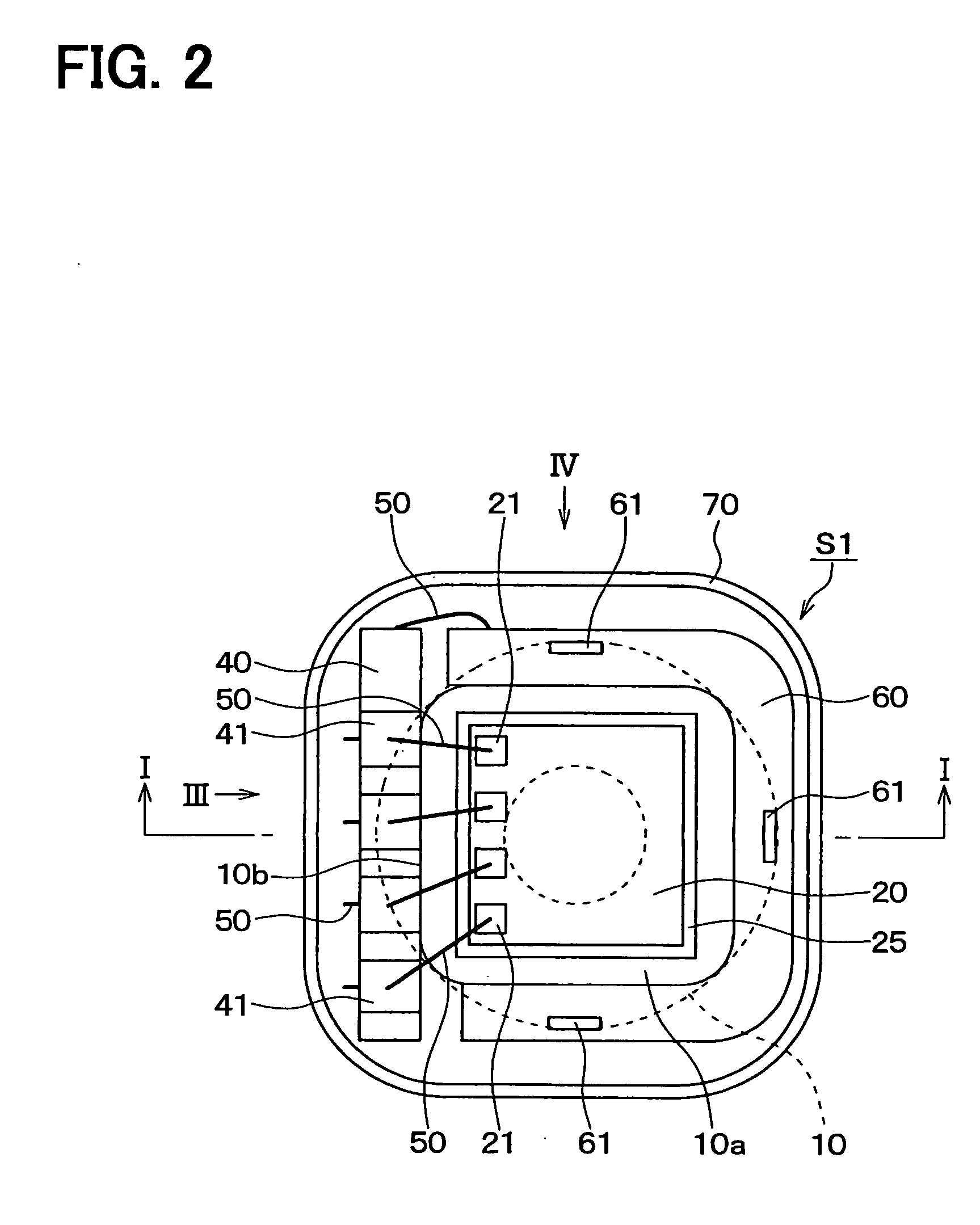

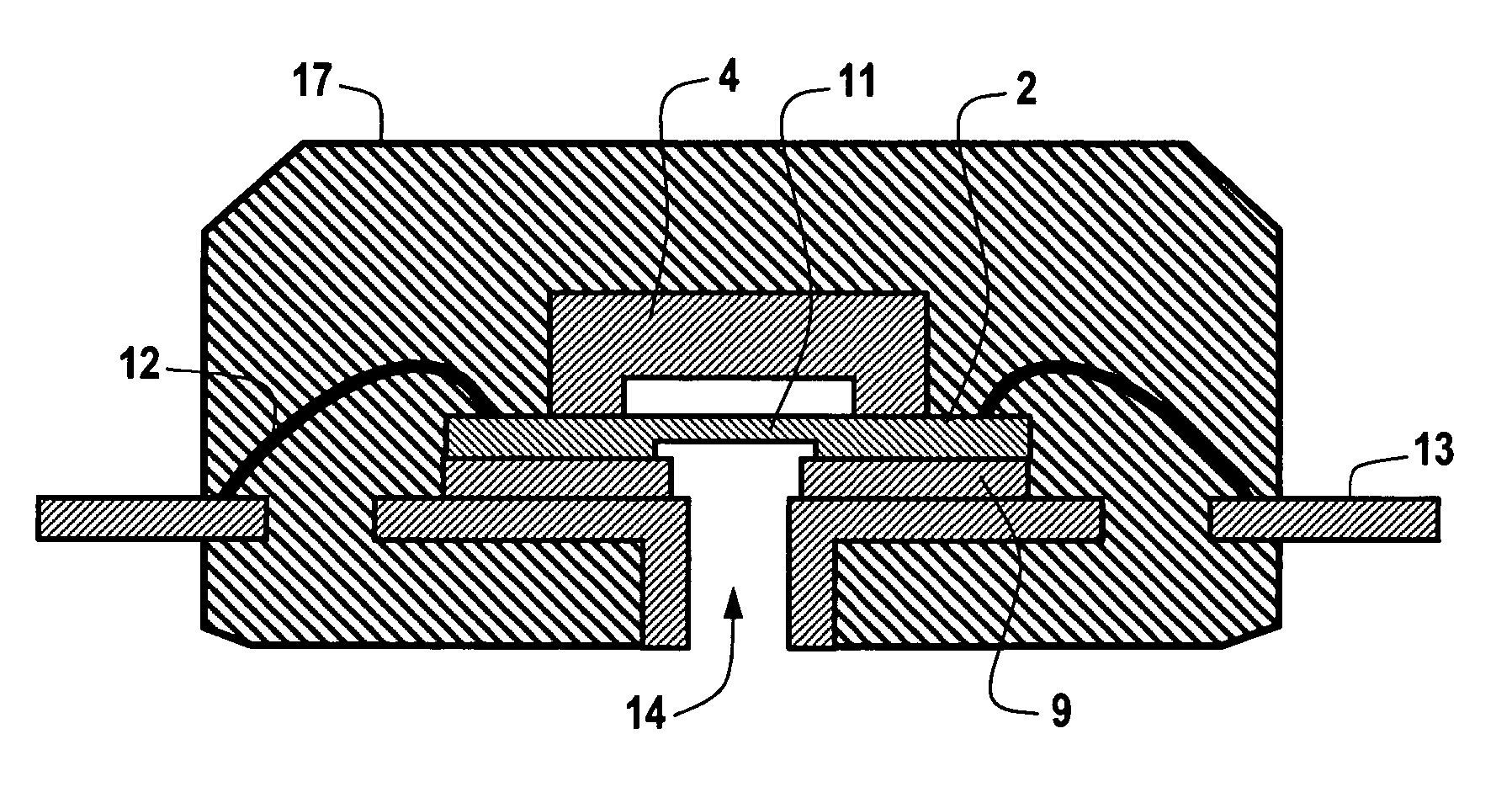

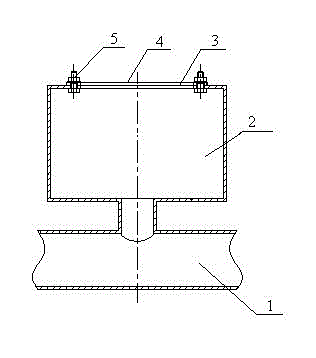

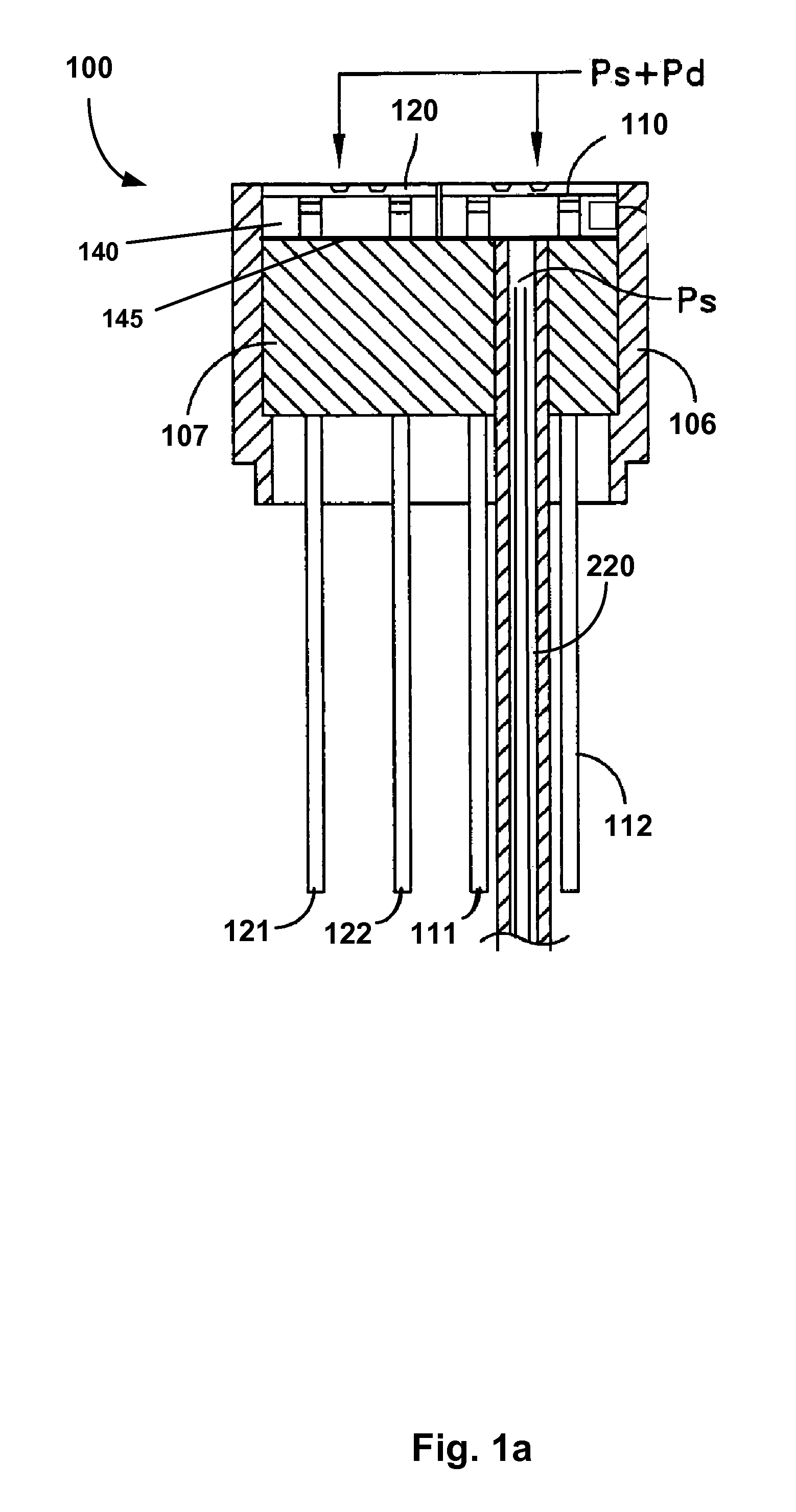

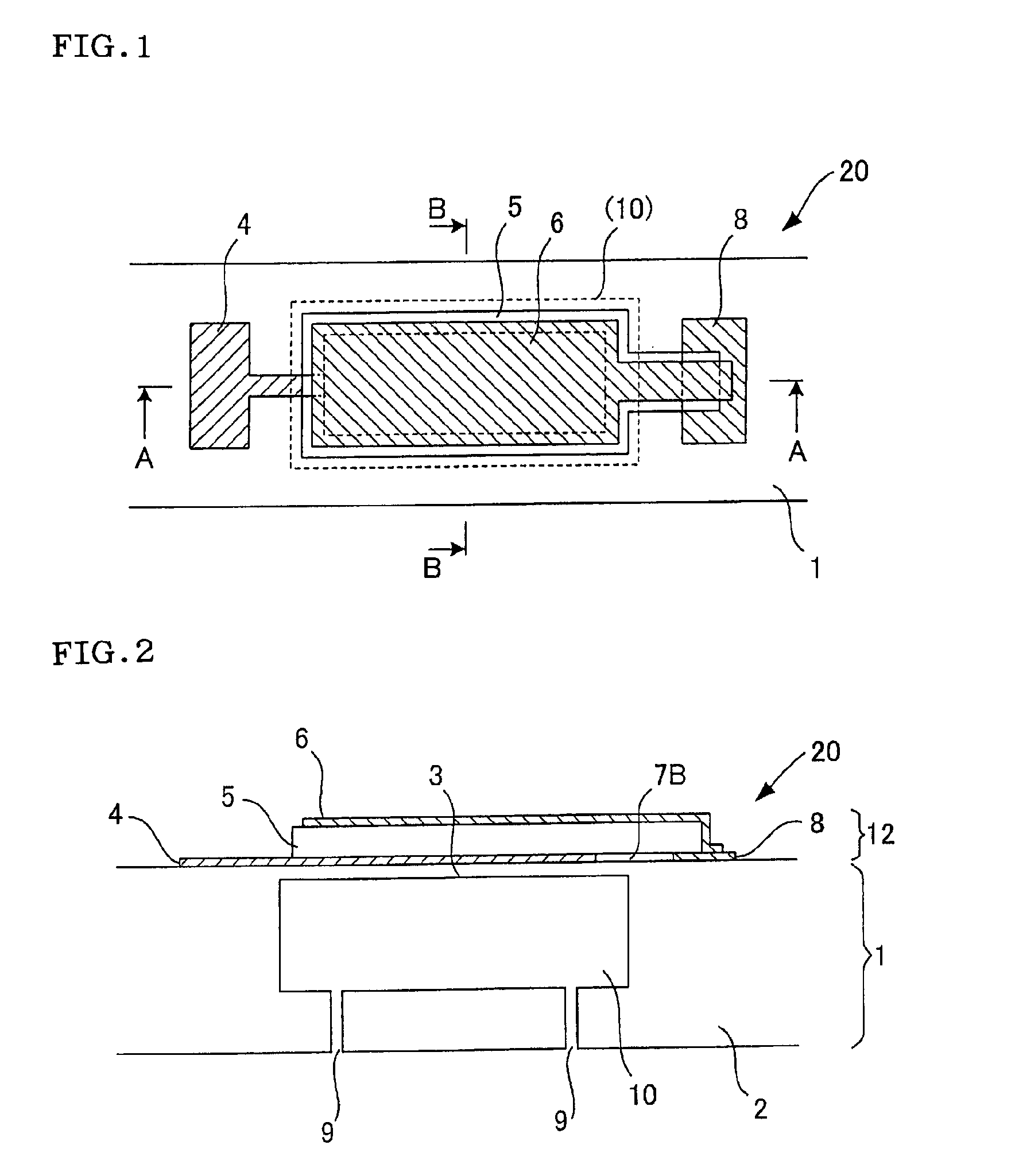

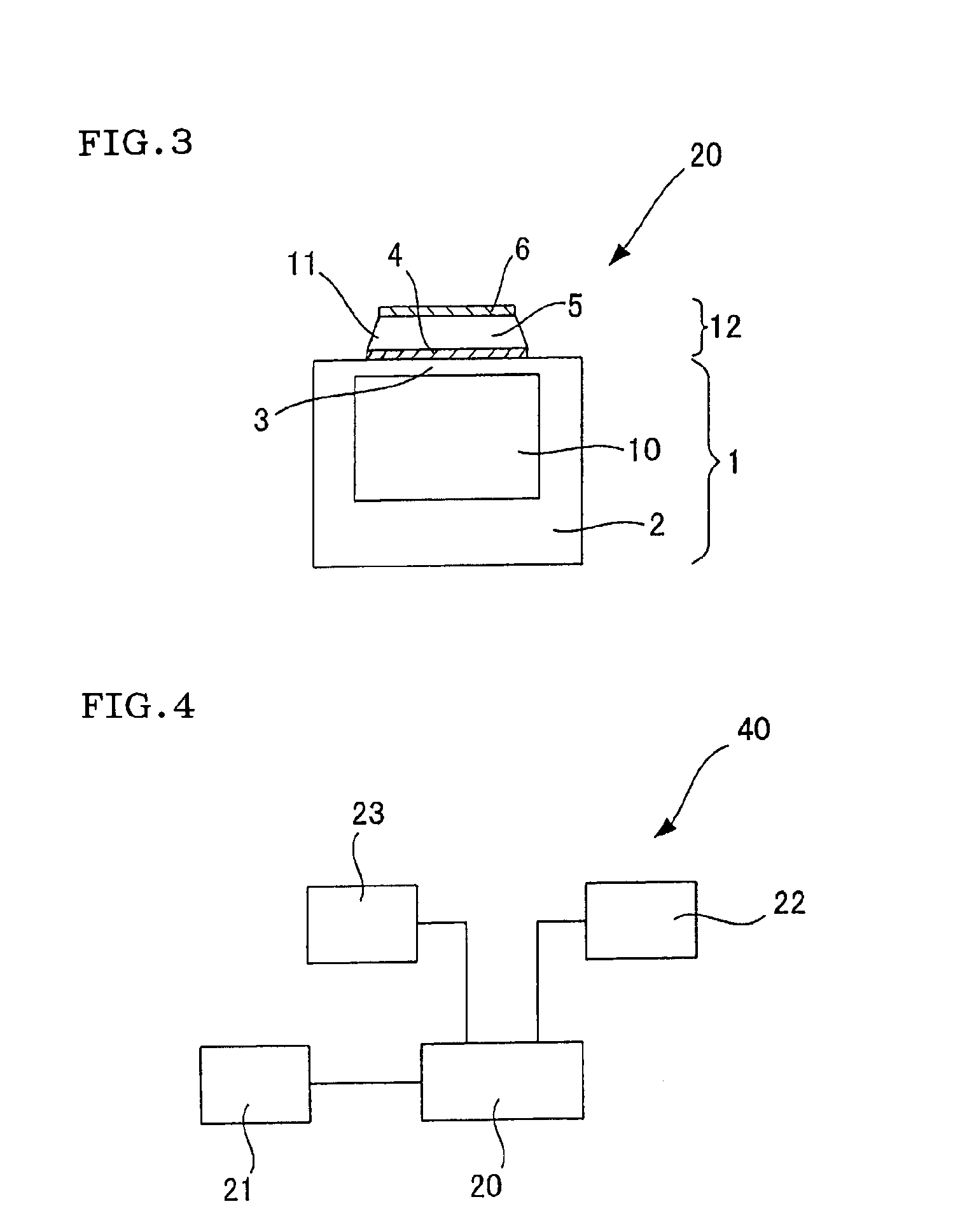

Pressure sensor having sensor chip and signal processing circuit mounted on a common stem

InactiveUS20050103111A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesSignal processing circuitsEngineering

A pressure sensor for detecting a pressure such as a brake oil pressure in an automobile is composed of a cylindrical stem, a sensor chip and a circuit board for processing an electrical signal from the sensor chip. The cylindrical stem includes a thin diaphragm formed at an axial end and an opening formed at the other axial end. The sensor chip is mounted on the diaphragm, and the circuit board is mounted on a flat side surface formed on the outer periphery of the cylindrical stem so that the circuit board is positioned perpendicularly to the sensor chip, thereby reducing a size of the pressure sensor in the radial direction of the stem. The pressure to be detected is introduced into the cylindrical stem from its opening, and the pressure is detected by the sensor chip mounted on the diaphragm.

Owner:DENSO CORP

Vacuum sealed surface acoustic wave pressure sensor

InactiveUS20060086188A1Simple structureLow costFluid pressure measurement by electric/magnetic elementsSolid-state devicesEngineeringSurface acoustic wave sensor

A vacuum sealed SAW pressure sensor is disclosed herein, which includes a sensing element configured as a SAW device (e.g., SAW resonator or SAW delay line) supported by a thin diaphragm. The substrate material can be implemented as a quartz wafer (i.e., a “base” wafer). The SAW device can be configured on one side of the wafer and the diaphragm etched on the opposite side. A quartz micromachined pressure sensor can thus be realized, which operates based on a variation of the surface wave velocity of a SAW device situated on the thin diaphragm. The SAW sensor is generally sealed in a vacuum and diaphragm sustains the sensor, thereby implementing a sensor on a wafer scale while allowing for a cost reduction per chip.

Owner:HONEYWELL INT INC

Media isolated pressure transducer having boss comprising single metal diaphragm

InactiveUS8024978B2Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectricityElectrical conductor

A pressure sensor for sensing a pressure of a fluid includes a monolithic metal including substrate having a substantially planar top side, wherein the metallic comprising substrate includes s a relatively thick boss near a center of the substrate and a thinned sensing portion that is elastically deformable and pressure-sensitive positioned radially outward from the boss. At least one dielectric layer is on the top side of the substrate. A plurality of piezoresistors are on the dielectric layer, wherein the piezoresistors are positioned over the thinned diaphragm portion. At least one overglaze layer is over the conductor layer that provides apertures for electrically contacting the plurality of piezoresistors. A sensing system includes a housing including at least a first port for coupling to a fluid for measurement of a pressure of the fluid and at least one sensor in the housing including a pressure sensor according to an embodiment of the invention.

Owner:HONEYWELL INT INC

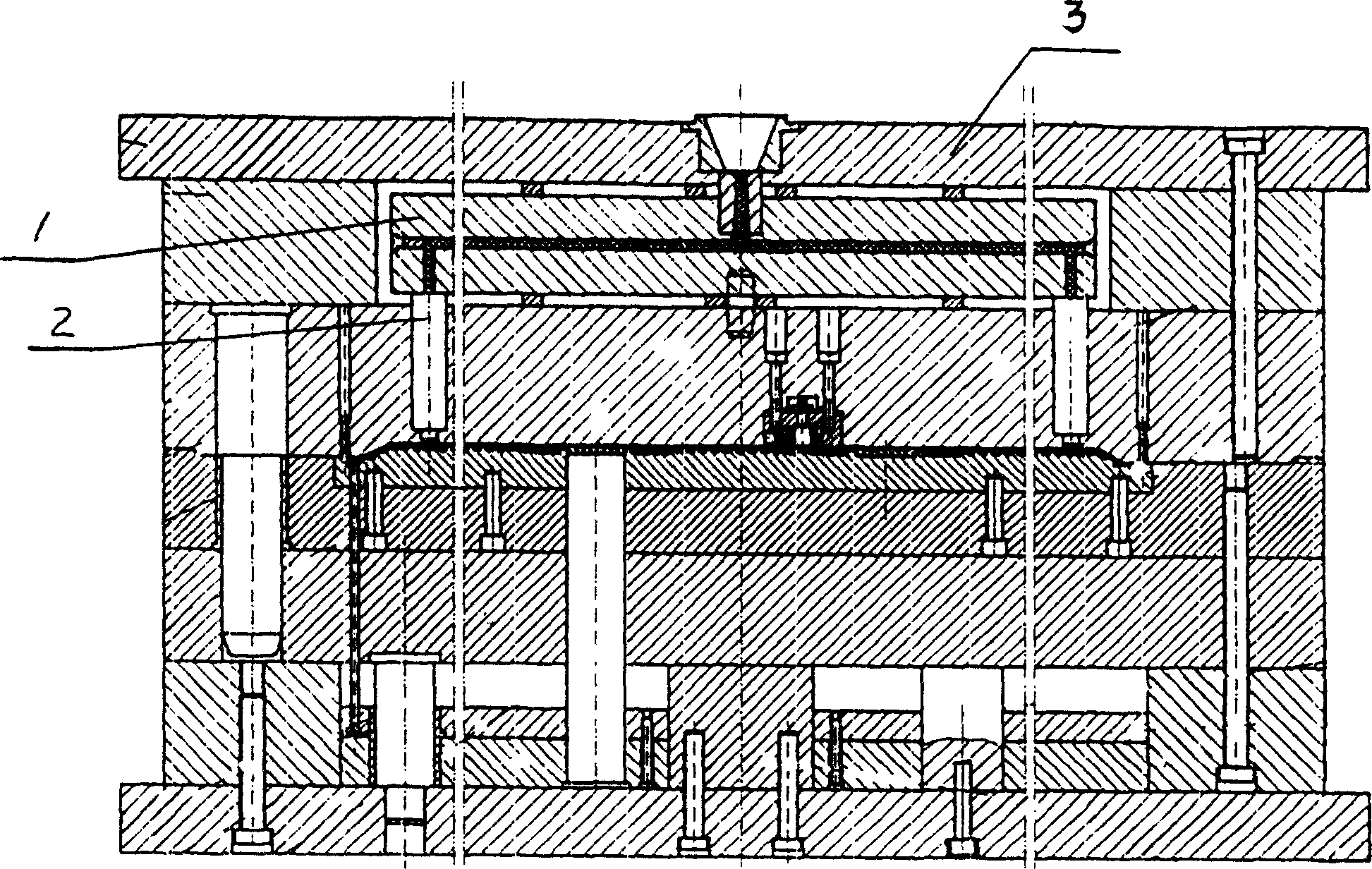

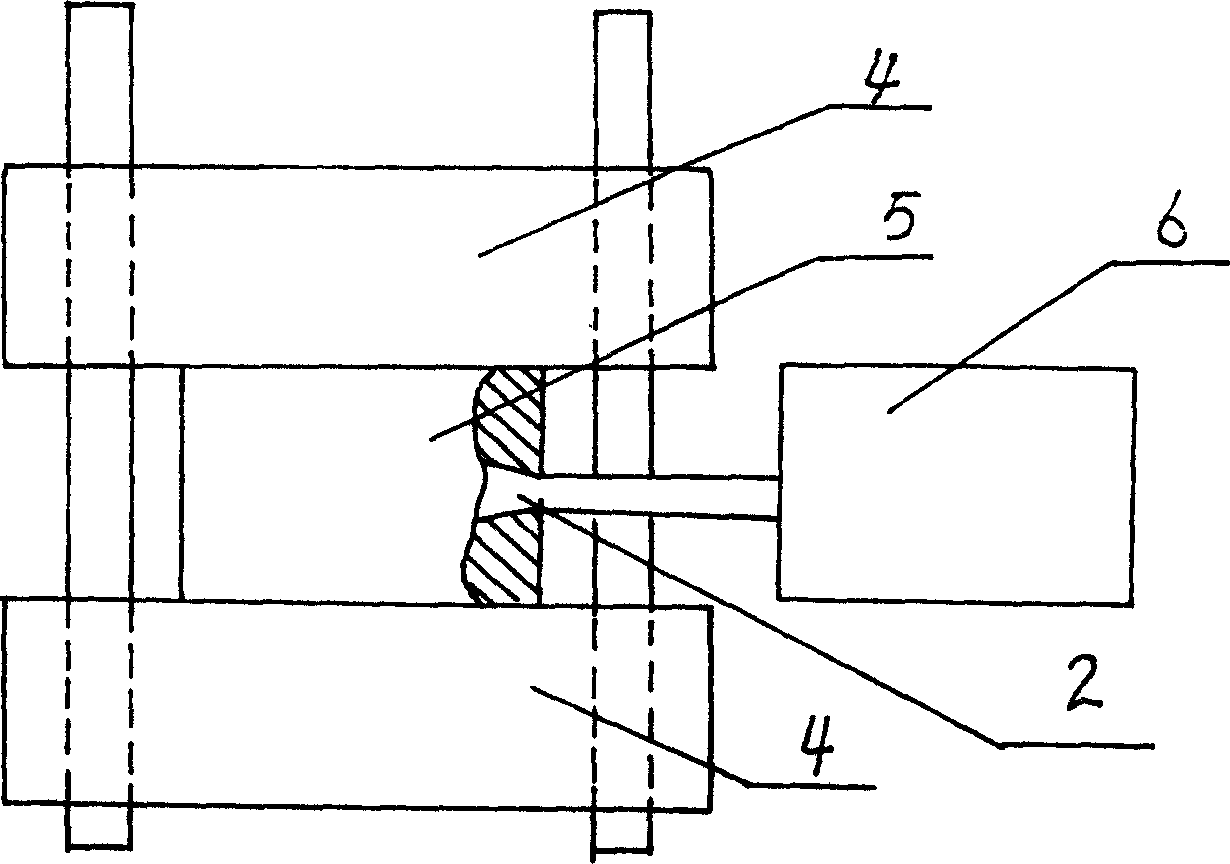

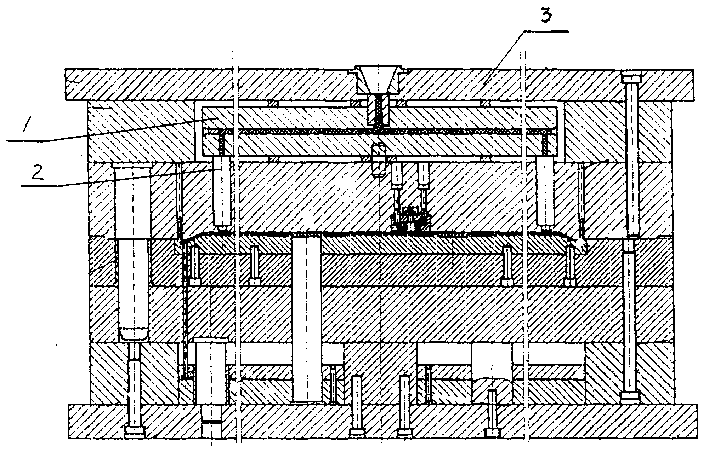

Injection moulding process and apparatus for plastic diaphragm of press filter

InactiveCN1436651ASolve the problem that cannot be injection moldedResolution cycleFiltration separationHot runnerPlastic materials

The present invention relates to plastic diaphragm forming process and equipment. During the process, plastic material is first heated and plasticized in injection molding machine and then injected into the hot flow channel of the plastic diaphragm forming mold and sprayed via the heating nozzle into mold cavity, and the plastic diaphragm is finally taken out after cooling, setting and mold opening. The structure of hot injection flow channel ensures the plasticized material to fill the different parts of the mold cavity and this makes it possible to make thin diaphragm with very large area. The combined design of hot flow channel forming mold and the injection part makes the present invention is superior to available technology, especially being suitable for producing thin-wall plastic diaphragm.

Owner:朱兴源

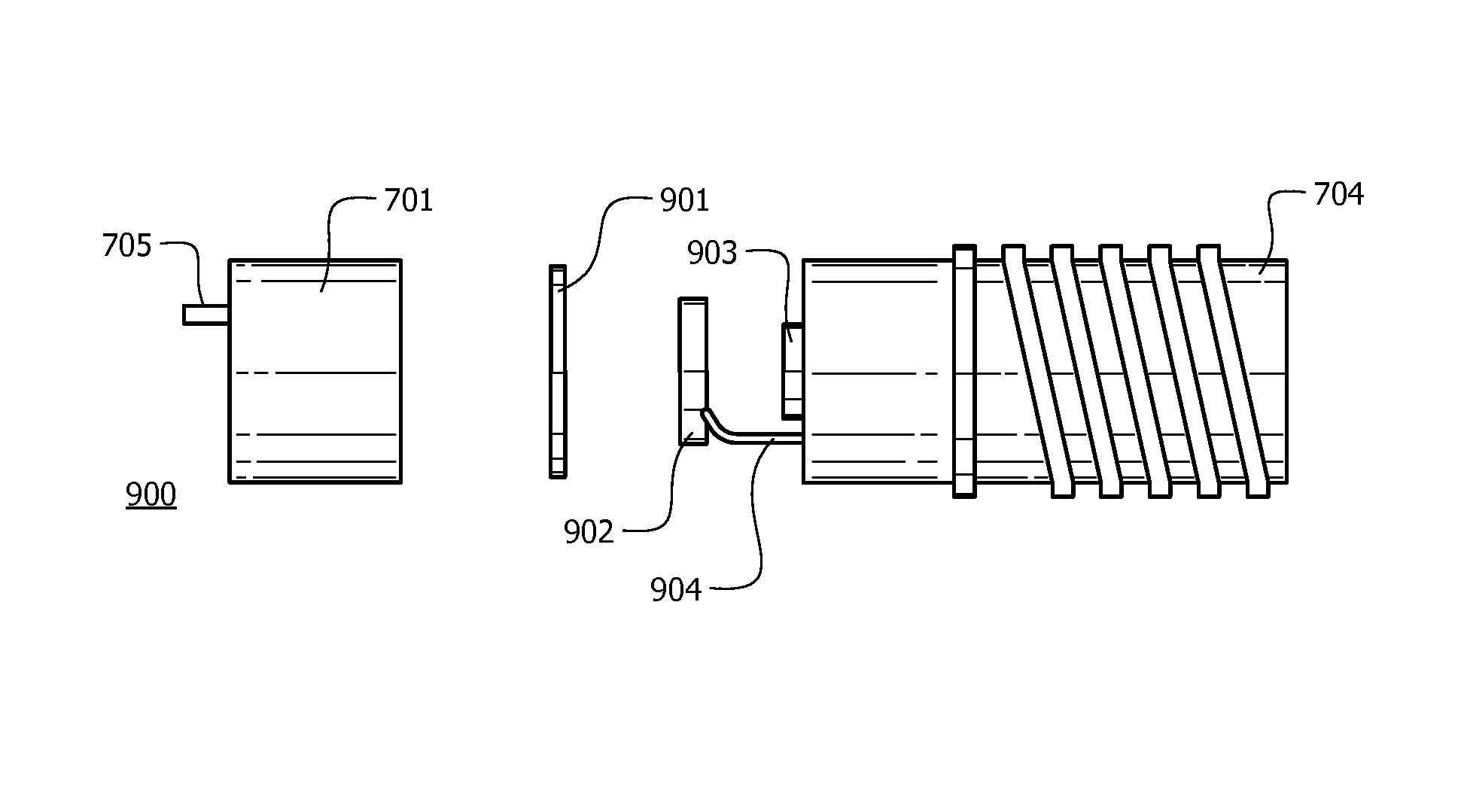

Low pressure sensors and flow sensors

InactiveUS20150192487A1Fluid pressure measurement using ohmic-resistance variationDecorative surface effectsEtchingEngineering

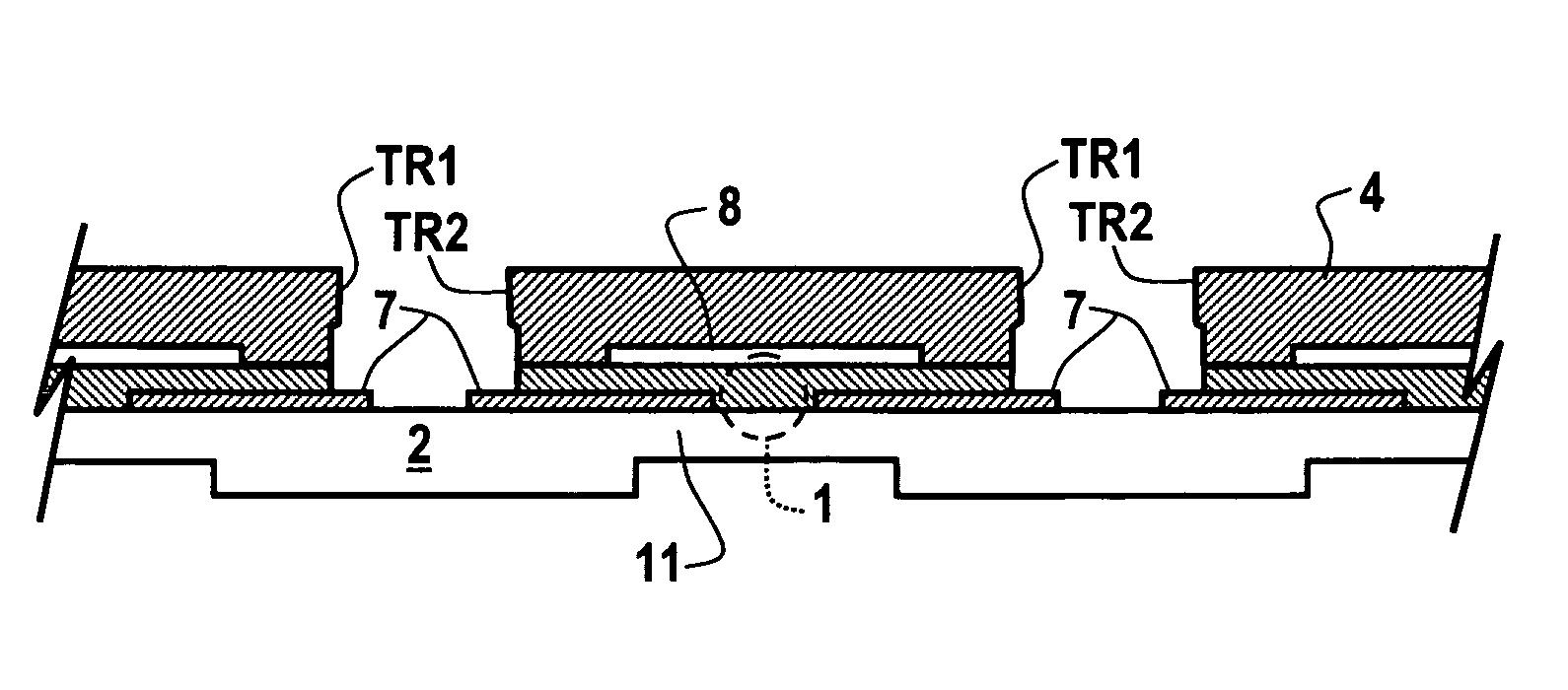

Low pressure sensors and flow sensors are provided. In some embodiments, a pressure sensor can include a sensor die that includes a substrate and a cavity that is formed in a bottom side of the substrate and that defines an elastic element including a thin diaphragm area and a rigid island. A maximum thickness of the rigid island can be substantially smaller than a thickness of the substrate and can be greater than a thickness of the thin diaphragm area. Side walls of the rigid island can be substantially parallel to one another and can be substantially perpendicular to top and bottom surfaces of the wafer and substantially perpendicular to top and bottom surfaces of the die. The side walls of the at least one rigid island can be formed by wet etching the cavity into the die. The wafer can have an impurity diffused in one or more portions thereof prior to the wet etching such that the one or more portions are doped.

Owner:AMPHENOL THERMOMETRICS

Overflow assembly for bathtubs and the like

An overflow system in the bathtub has an overflow port and has a drain pipe in connection with the overflow port. A threaded flange has a stub shoulder on one end which is fitted into a circular sleeve on the overflow port. The threaded flange has exterior threads on its outer surface and a thin diaphragm secured to the end thereof opposite to the stub shoulder. A large sealing washer embraces the outside of the circular flange on the overflow port and extends partially over the threads of the threaded flange. A large internally threaded nut is threadably mounted on the outer end of the threaded flange and compresses the sealing washer against a vertical flange on the port to seal the connection between the threaded flange and the port. A decorative cap is frictionally snapped into engagement with protrusions on the outer surface of the nut. The cap can be removed when needed to permit the plumber to gain access to the diaphragm to cut it open for fluid flow after the system has been tested for leaks, or put in place after the cut takes place.

Owner:WCM IND INC

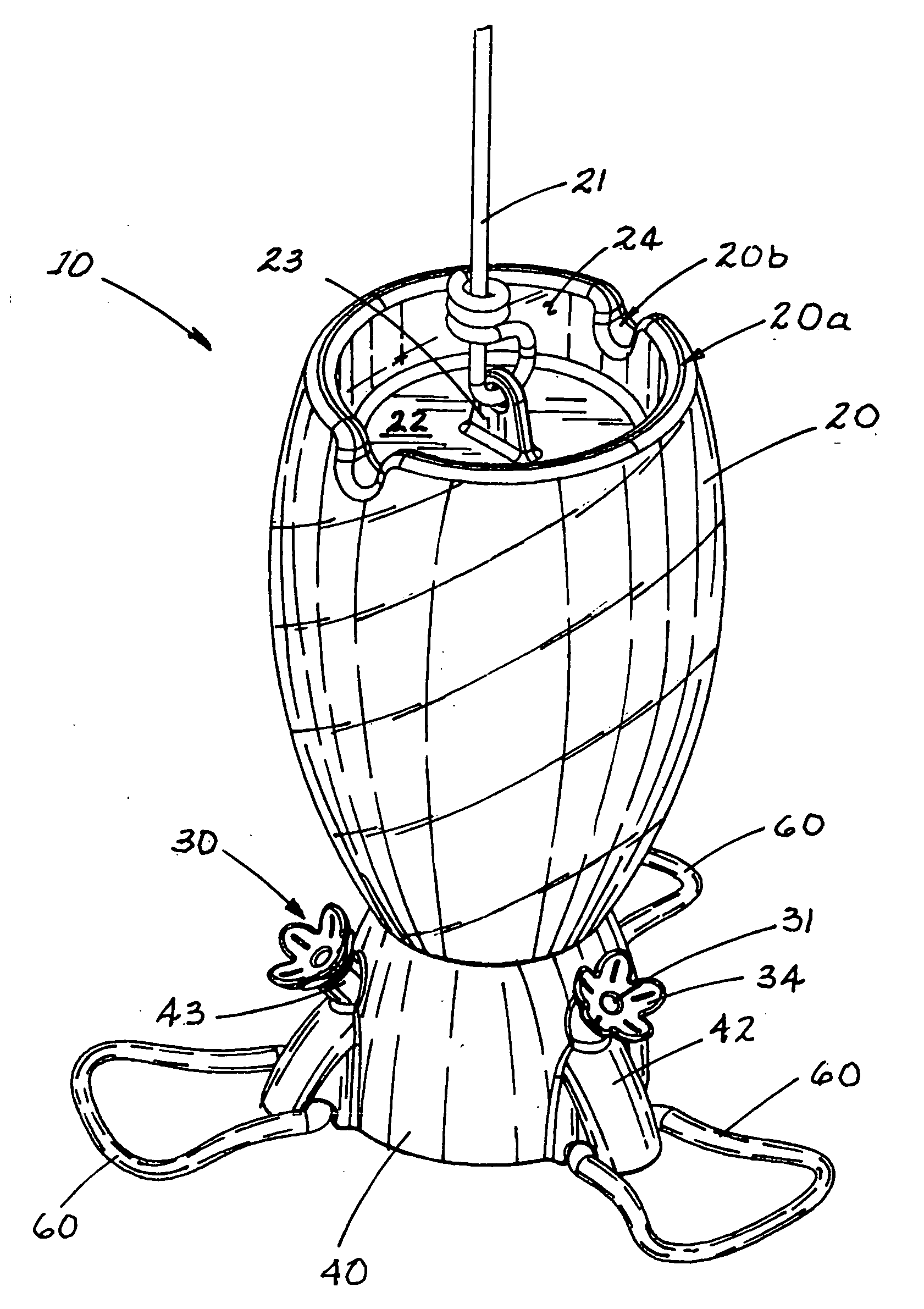

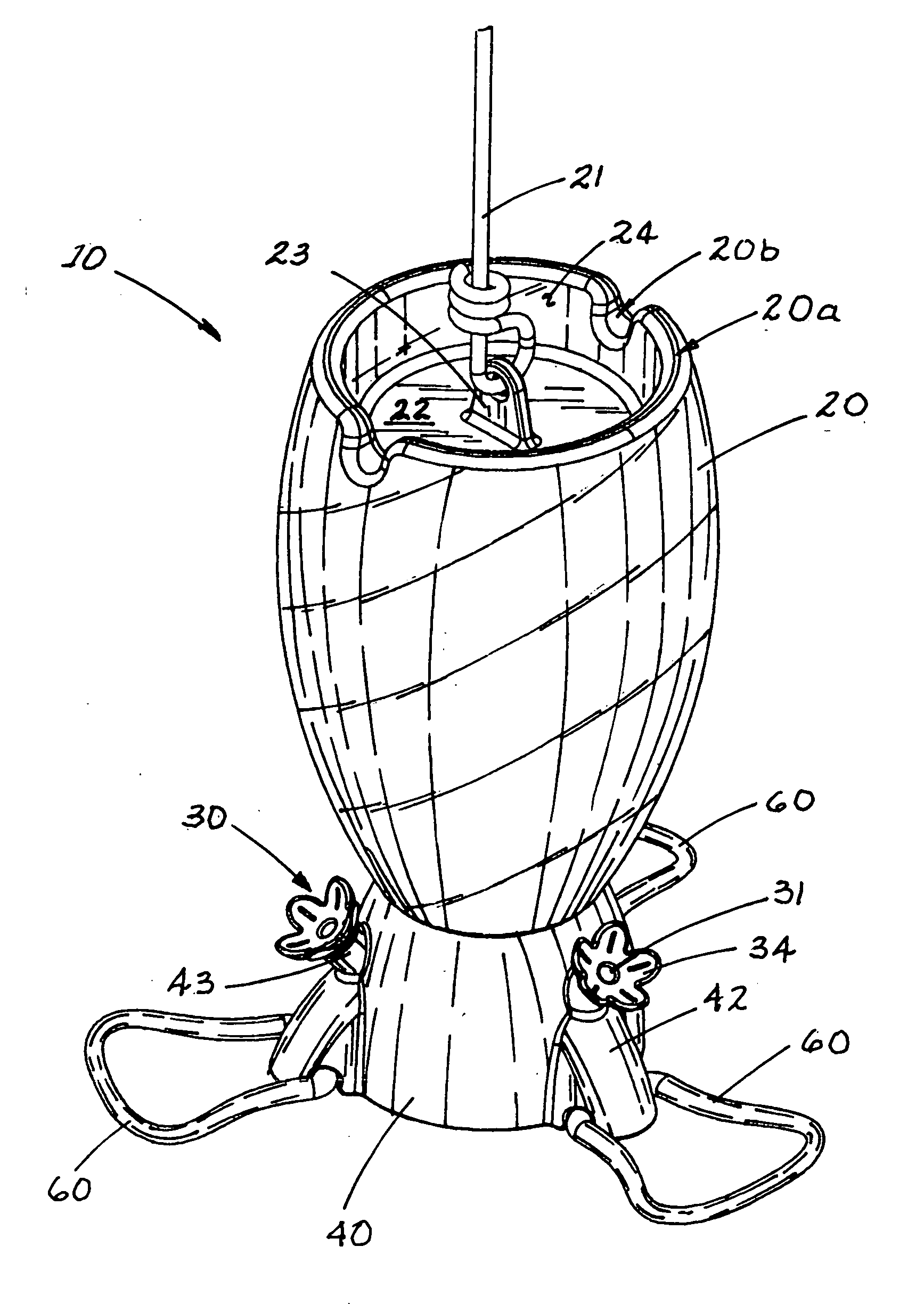

Disposable hummingbird feeder

InactiveUS20100192866A1Remove cleanEliminating solution preparation taskAnimal watering devicesAvicultureEngineeringFeeding tube

The hummingbird feeder of this invention has an initial storage and shipping configuration and a final feeding configuration. In a first embodiment, a transparent fluid reservoir contains a feeding solution that is dispensed through a punctured thin diaphragm into a cap cavity of a bottom cap threaded on the reservoir. In a second embodiment a removable sealer cap initially keeps the feeding solution in the reservoir. In a third embodiment, the feeding solution is dispensed by removing a “peel-away” diaphragm from the reservoir. Each feeding assembly has a red feeding guide and a feeding tube with an aperture for the hummingbird to access the feeding solution. Perches supported by the bottom cap are provided for the hummingbirds to rest. The feeding solution is made aseptic and bacteria free to help keep it from spoiling. The top of the fluid reservoir has a moat filled with an insect inhibiting material to protect against insects and ants reaching the feeding solution. A label can be placed on the reservoir to provide logo, legal information, directions for use, essential safety warnings and red coloring to attract hummingbirds.

Owner:MCMULLEN JOSEPH E

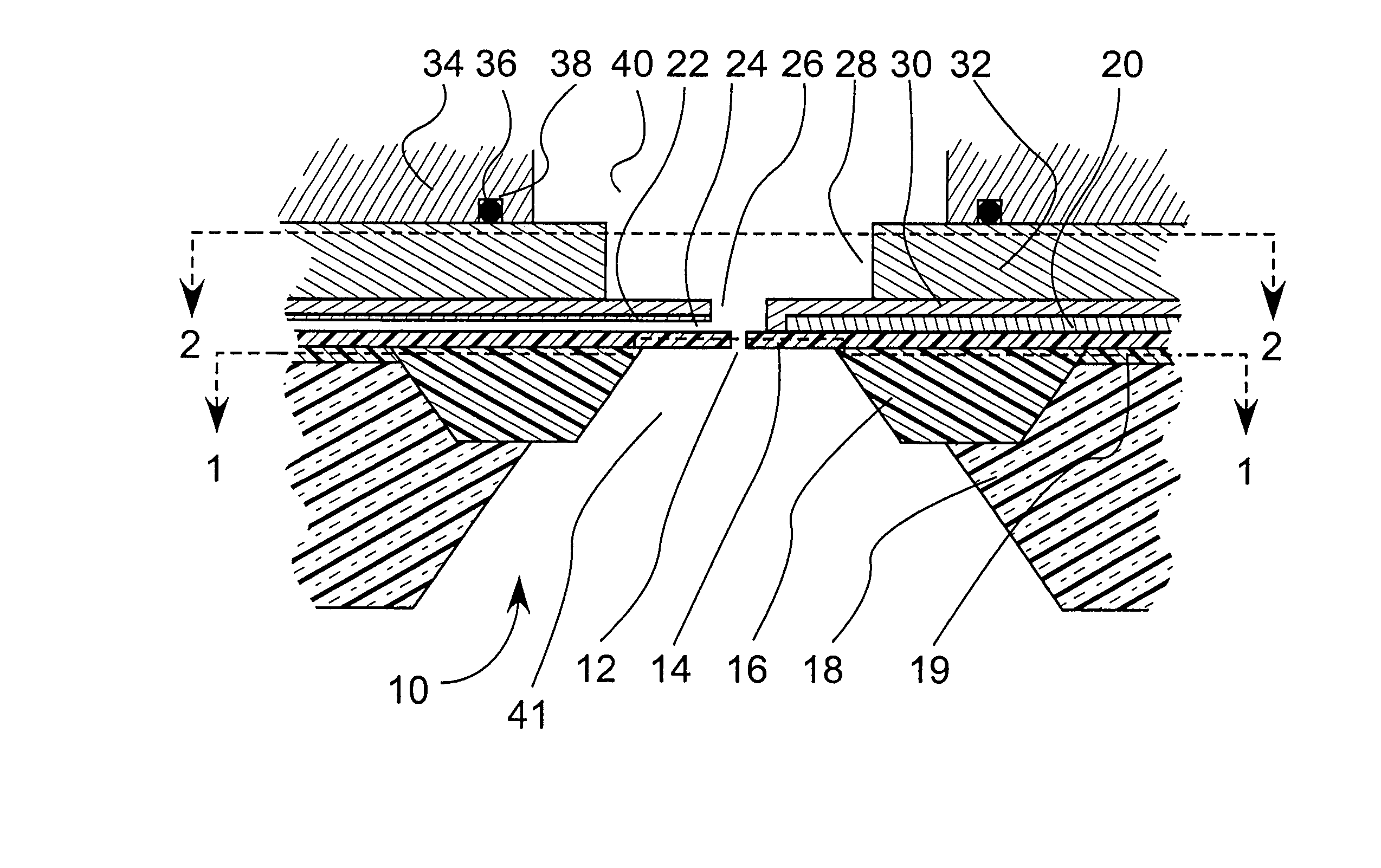

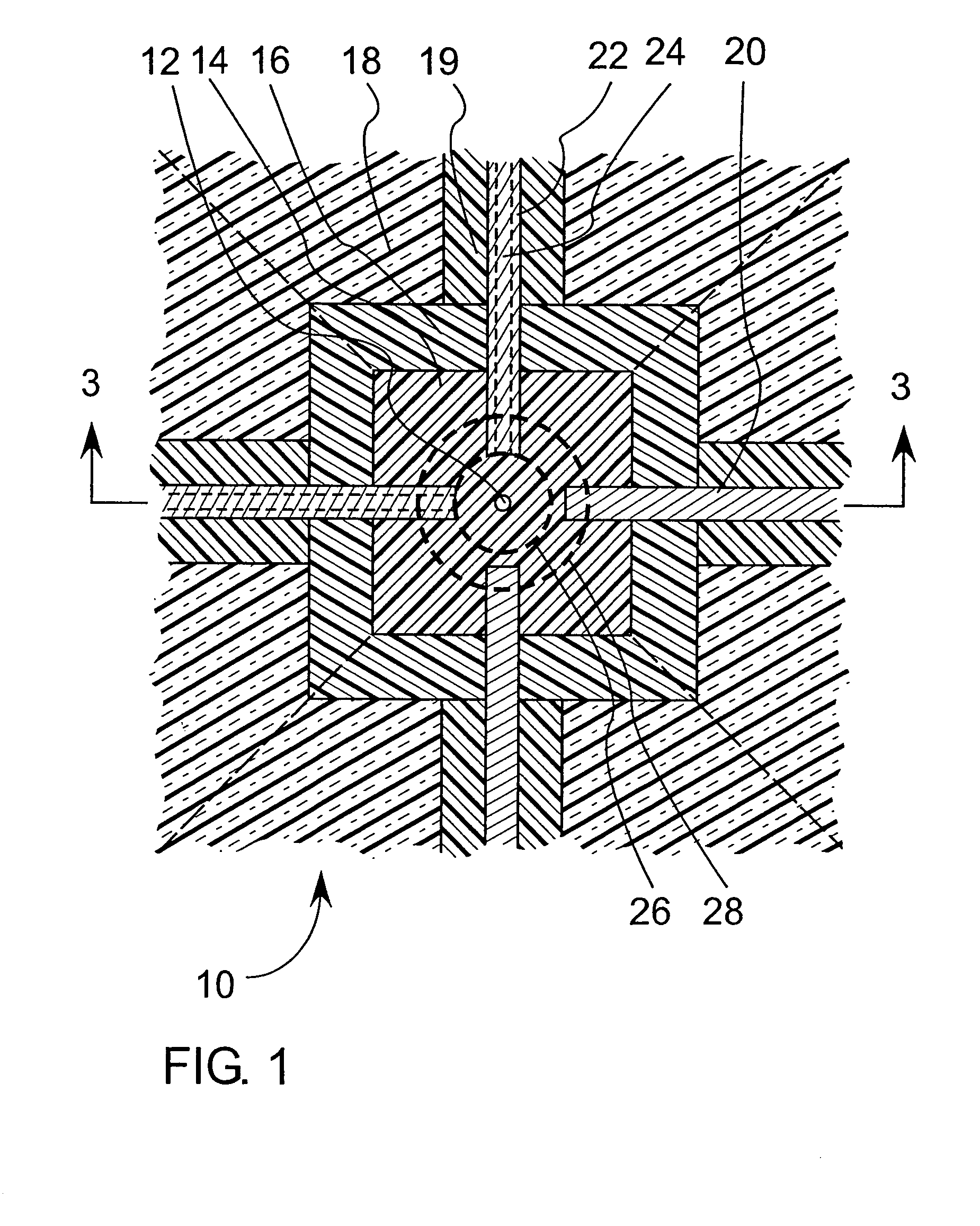

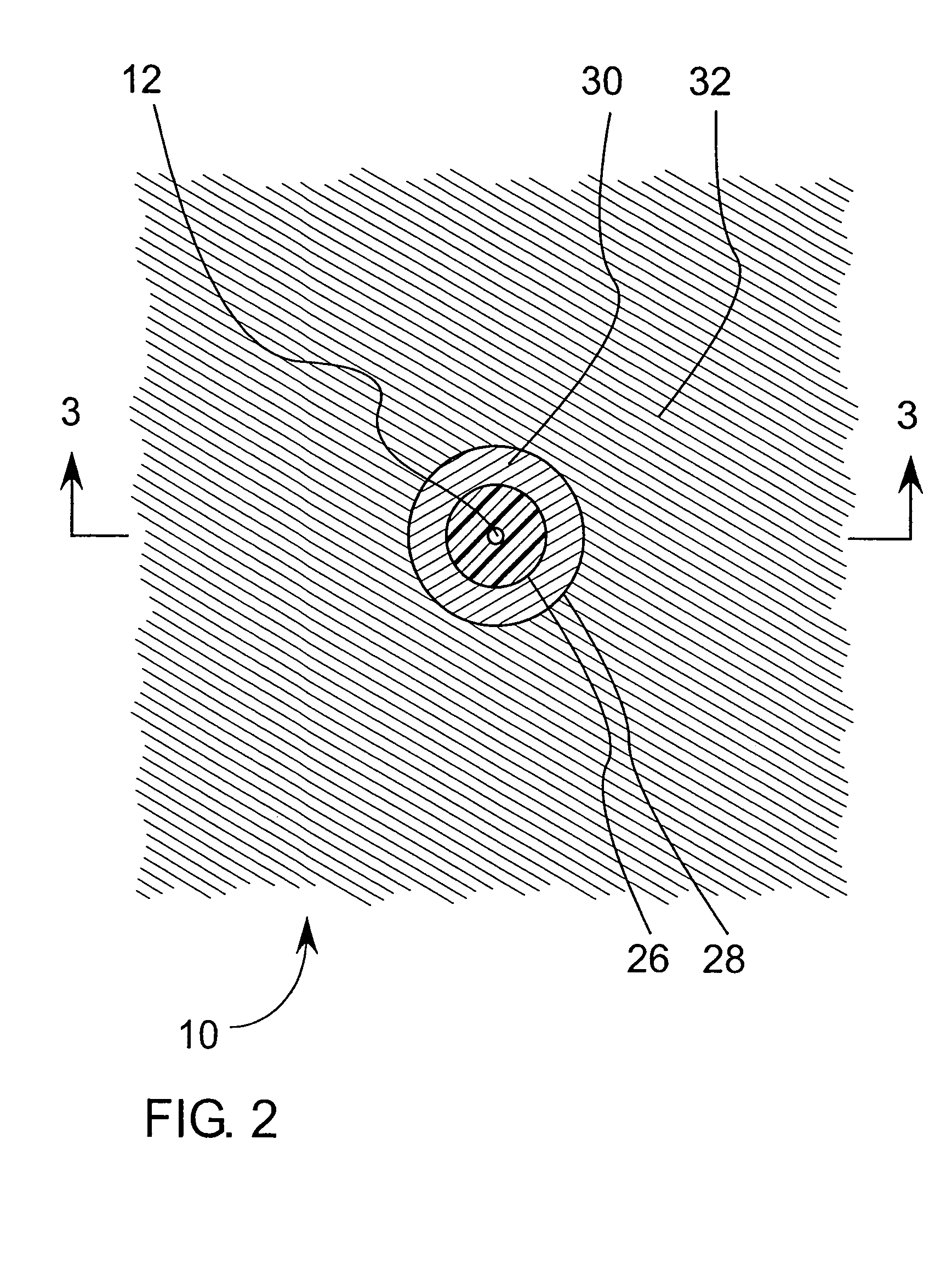

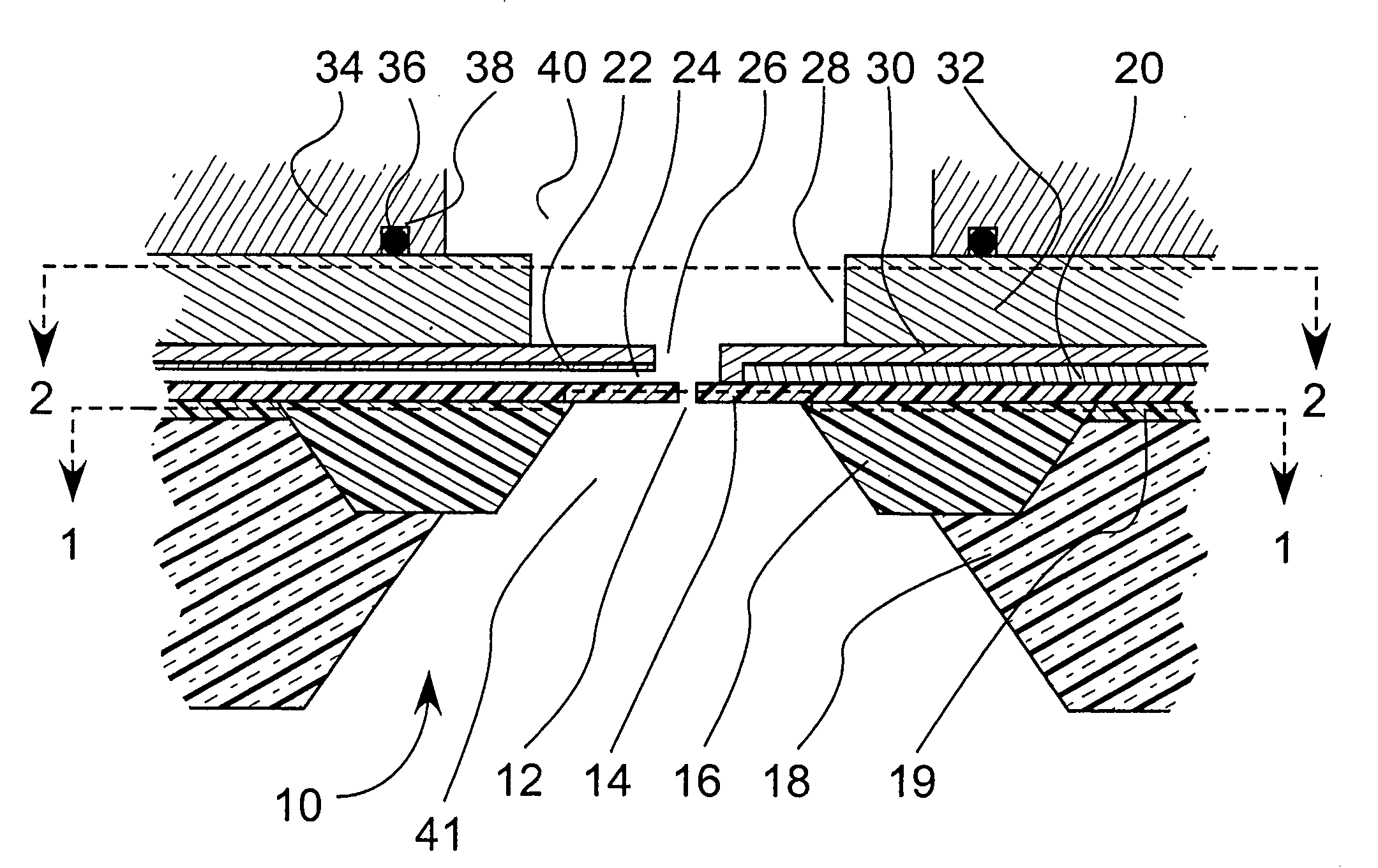

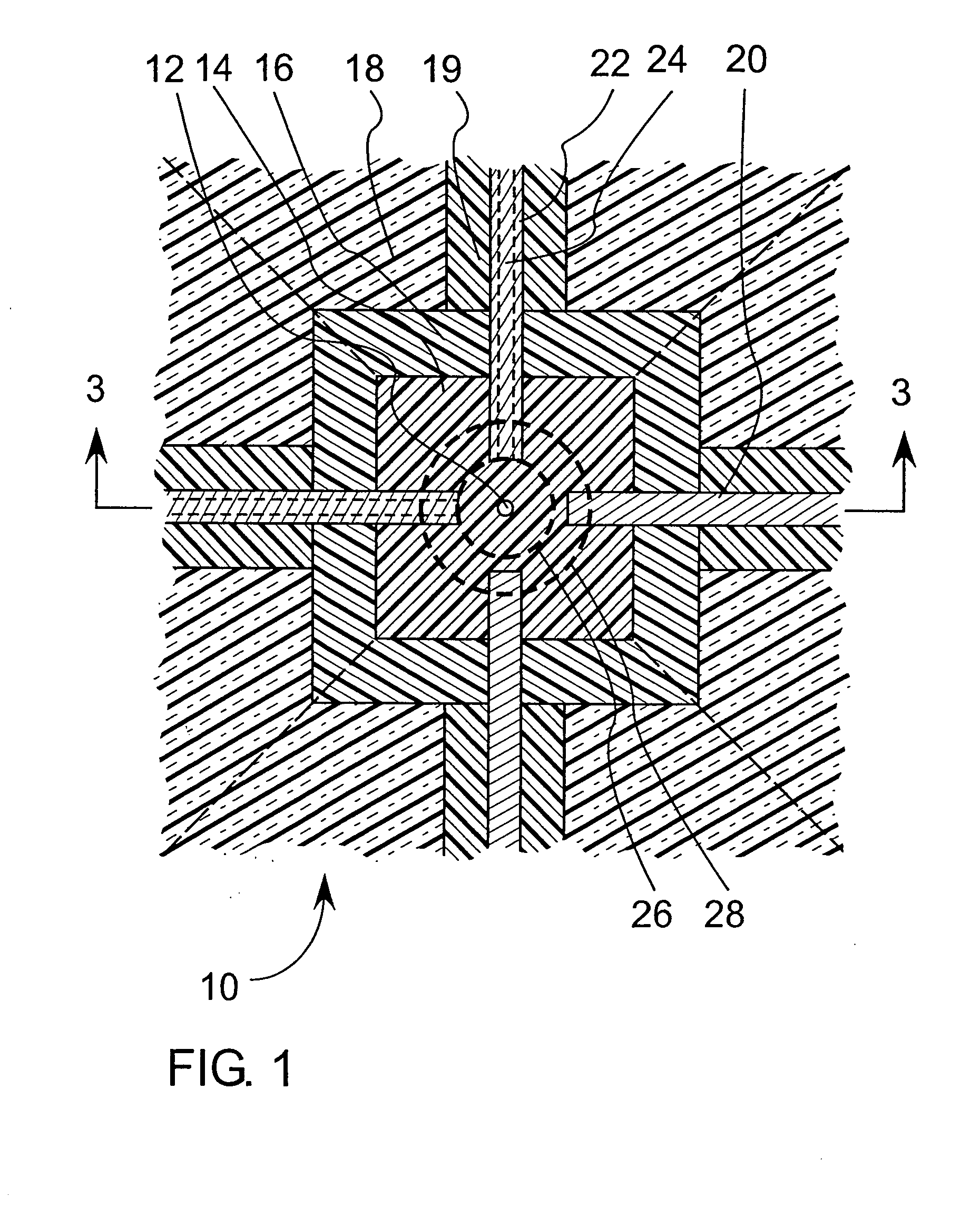

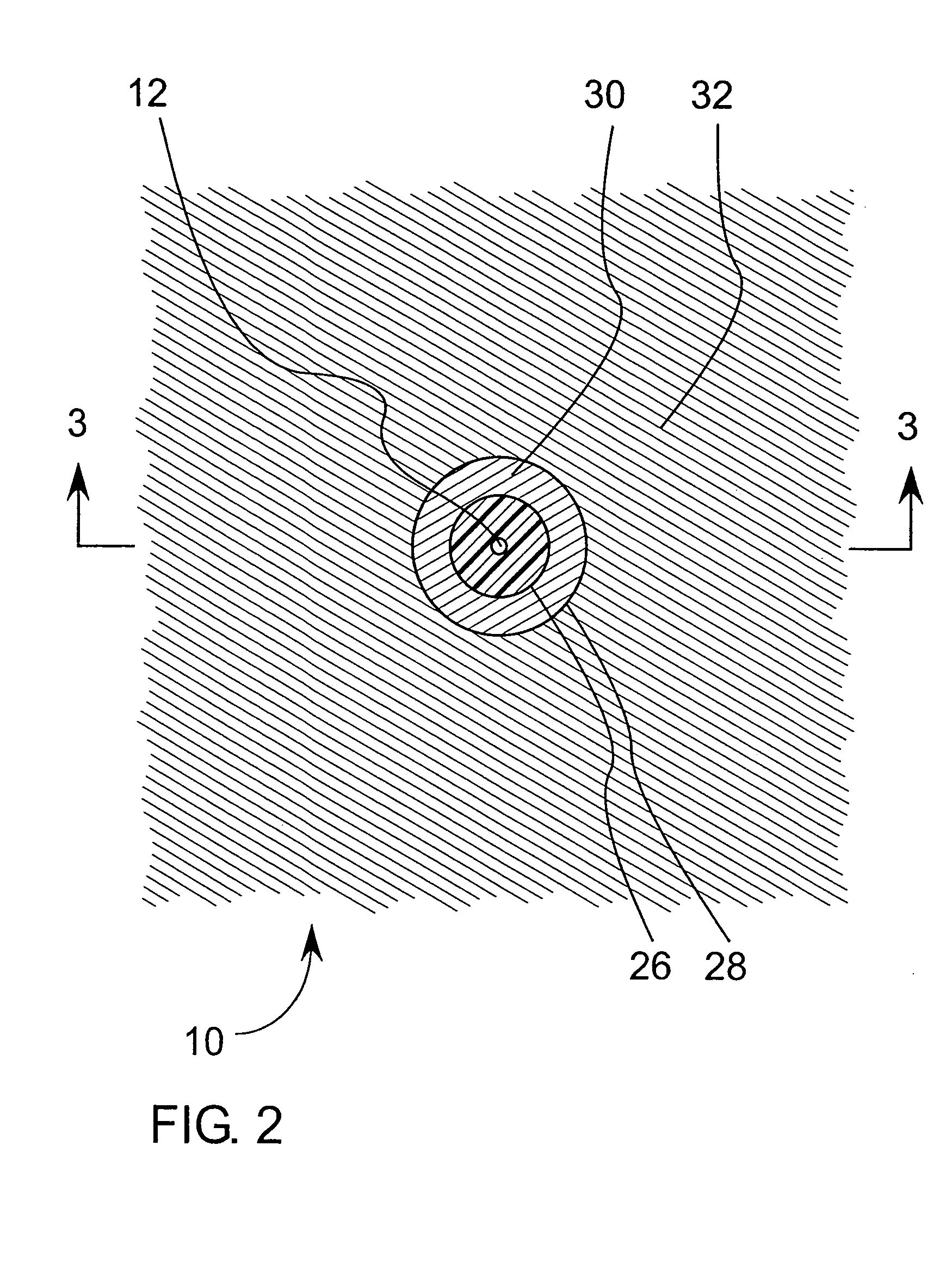

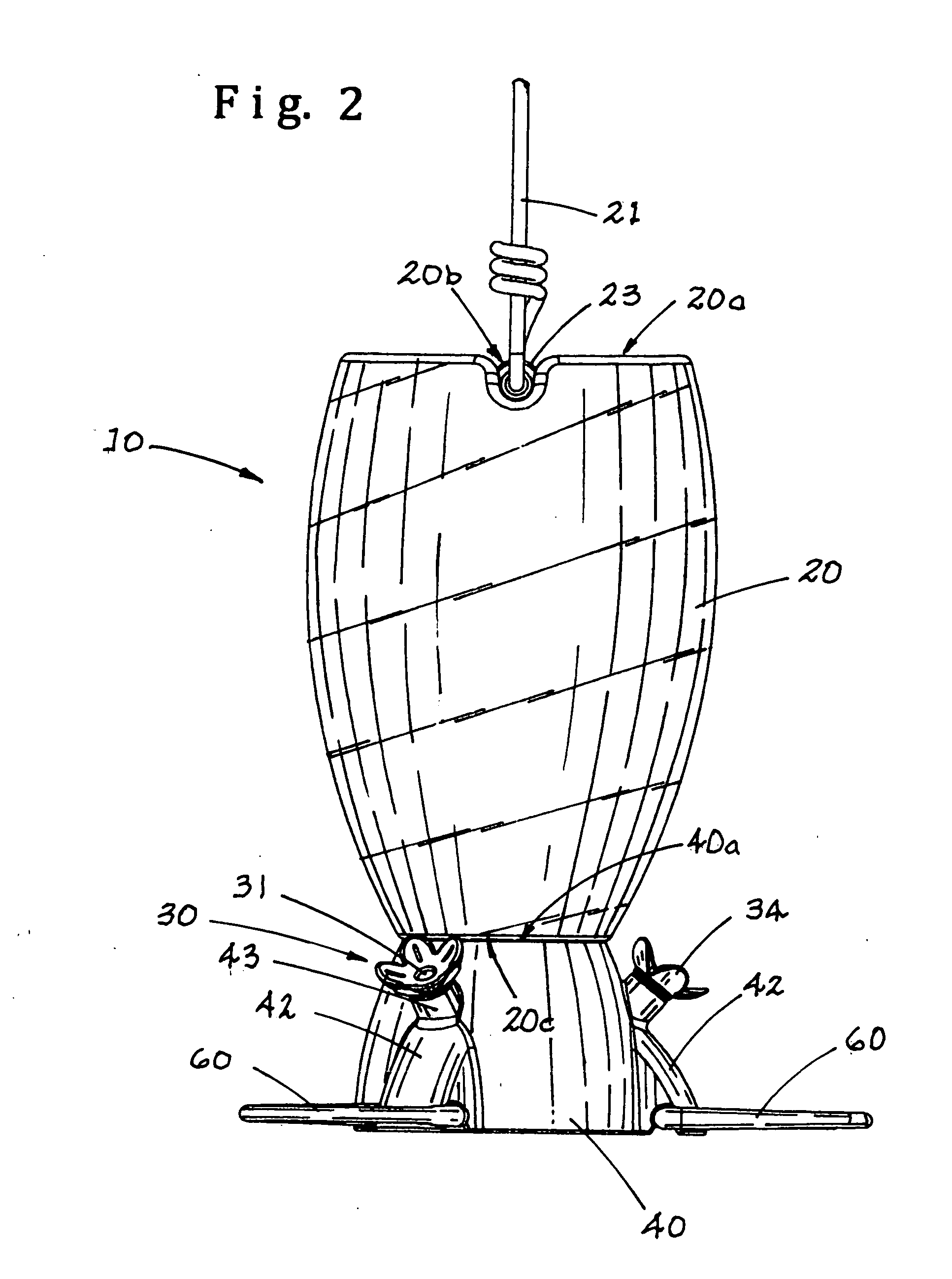

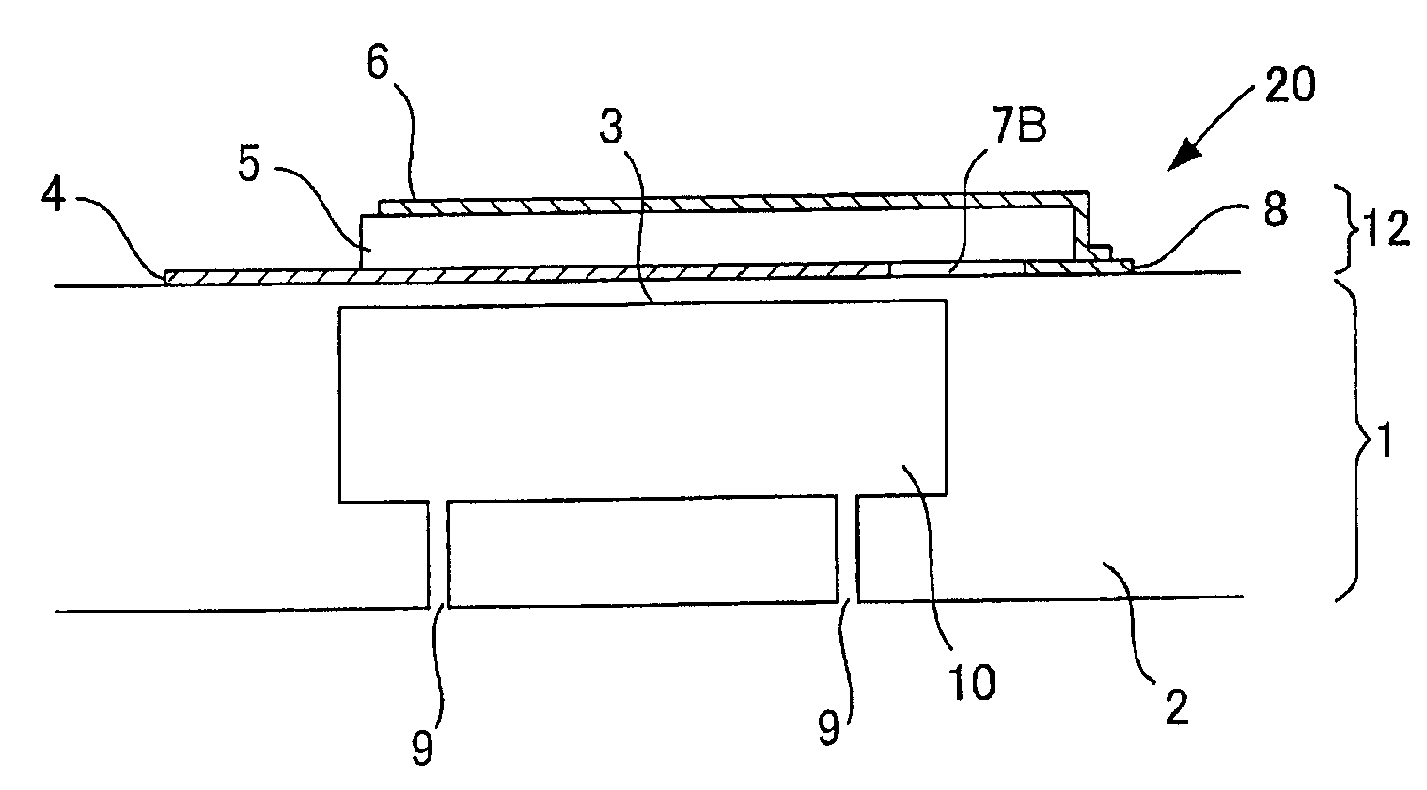

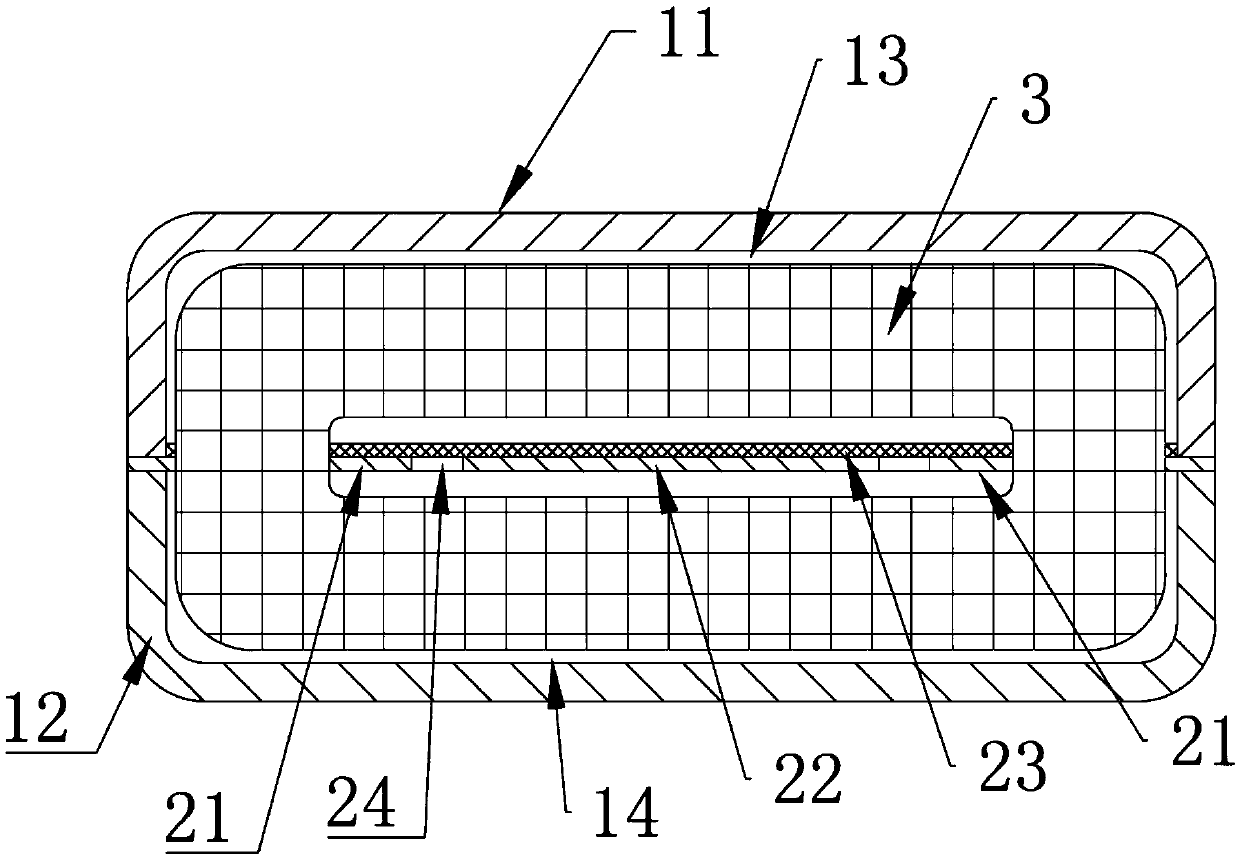

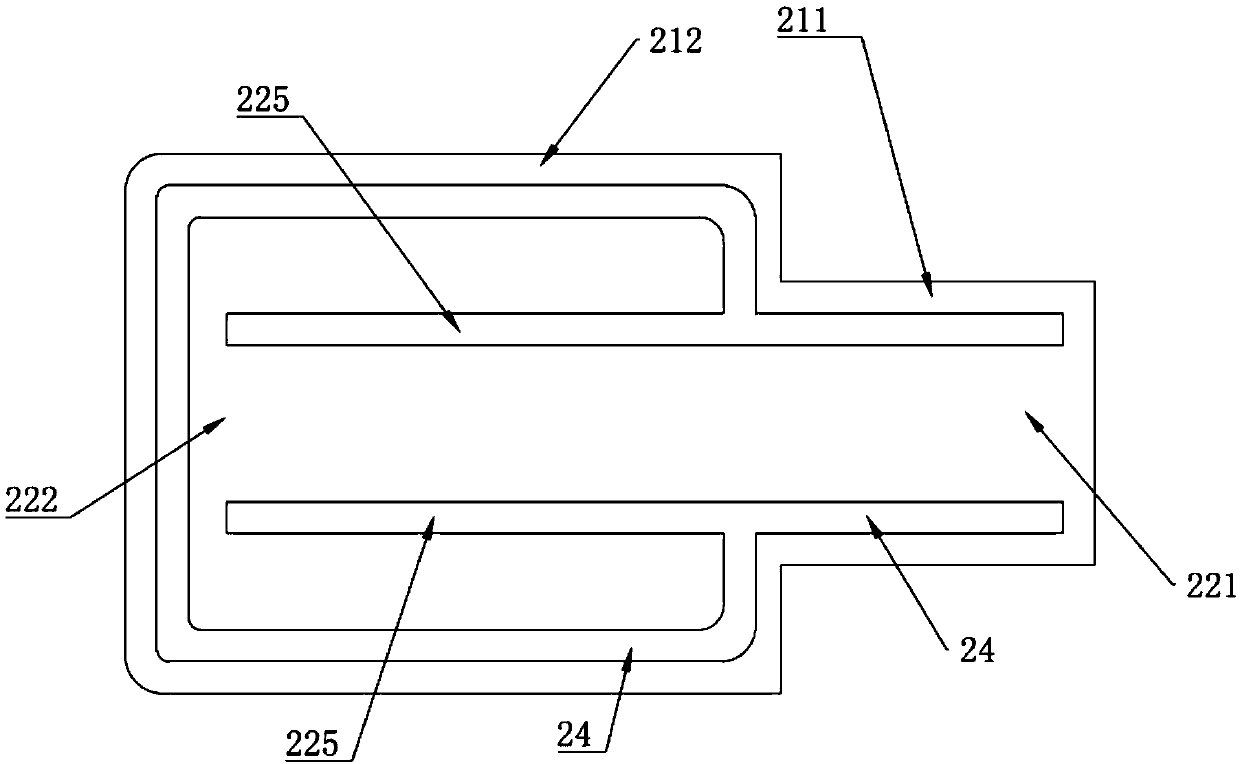

Piezoelectric/electrostrictive film-type device

InactiveUS7126255B2High sensitivity and resolutionSharp changePiezoelectric/electrostriction/magnetostriction machinesFlow propertiesAuxiliary electrodeCeramic substrate

A piezoelectric / electrostrictive film-type device is provided which includes a ceramic substrate having a thin diaphragm portion and a peripheral thick portion, a lower electrode, an auxiliary electrode, a piezoelectric / electrostrictive film, and an upper electrode. The lower electrode, the auxiliary electrode, the piezoelectric / electrostrictive film, and the upper electrode are layered in that order on the ceramic substrate. The upper electrode has a length of 30 to 70% relative to the length of the thin diaphragm portion, and preferably has a width of 70% or more relative to the width of the thin diaphragm portion.

Owner:NGK INSULATORS LTD

Overflow Assembly for Bathtubs and the Like

An overflow system in the bathtub has an overflow port and has a drain pipe in connection with the overflow port. A threaded flange has a stub shoulder on one end which is fitted into a circular sleeve on the overflow port. The threaded flange has exterior threads on its outer surface and a thin diaphragm secured to the end thereof opposite to the stub shoulder. A large sealing washer embraces the outside of the circular flange on the overflow port and extends partially over the threads of the threaded flange. A large internally threaded nut is threadably mounted on the outer end of the threaded flange and compresses the sealing washer against a vertical flange on the port to seal the connection between the threaded flange and the port. A decorative cap is frictionally snapped into engagement with protrusions on the outer surface of the nut. The cap can be removed when needed to permit the plumber to gain access to the diaphragm to cut it open for fluid flow after the system has been tested for leaks, or put in place after the cut takes place.

Owner:WCM IND INC

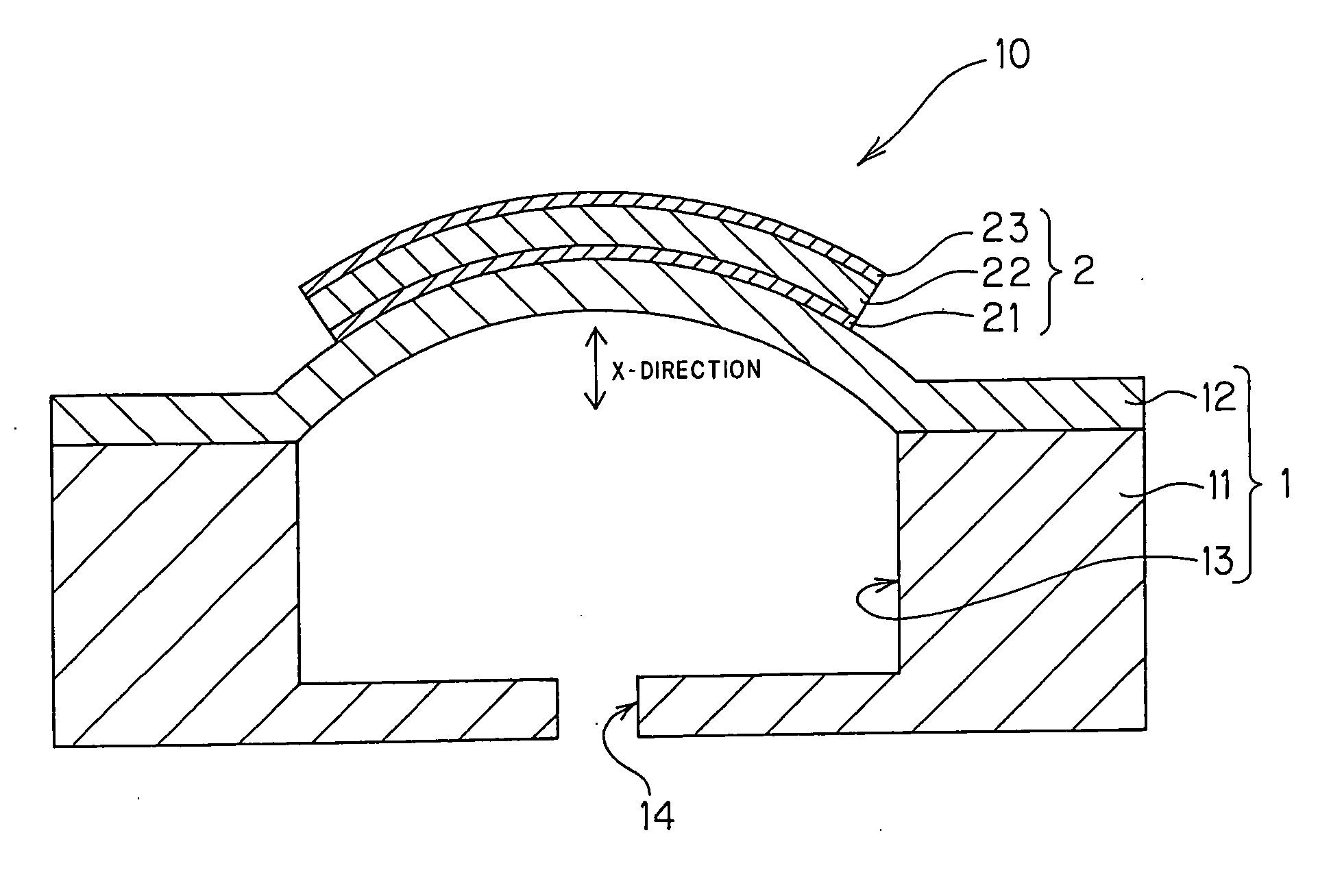

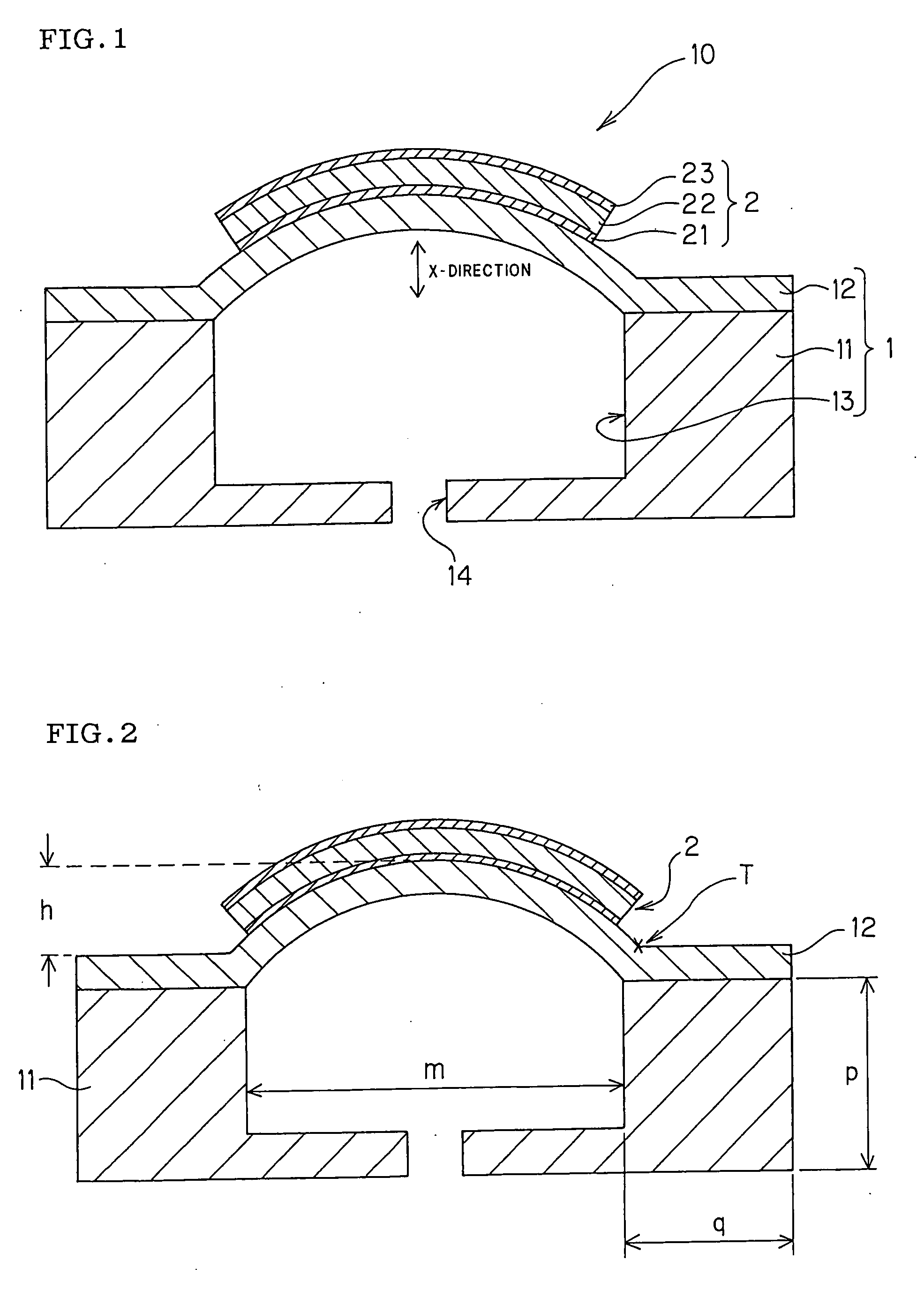

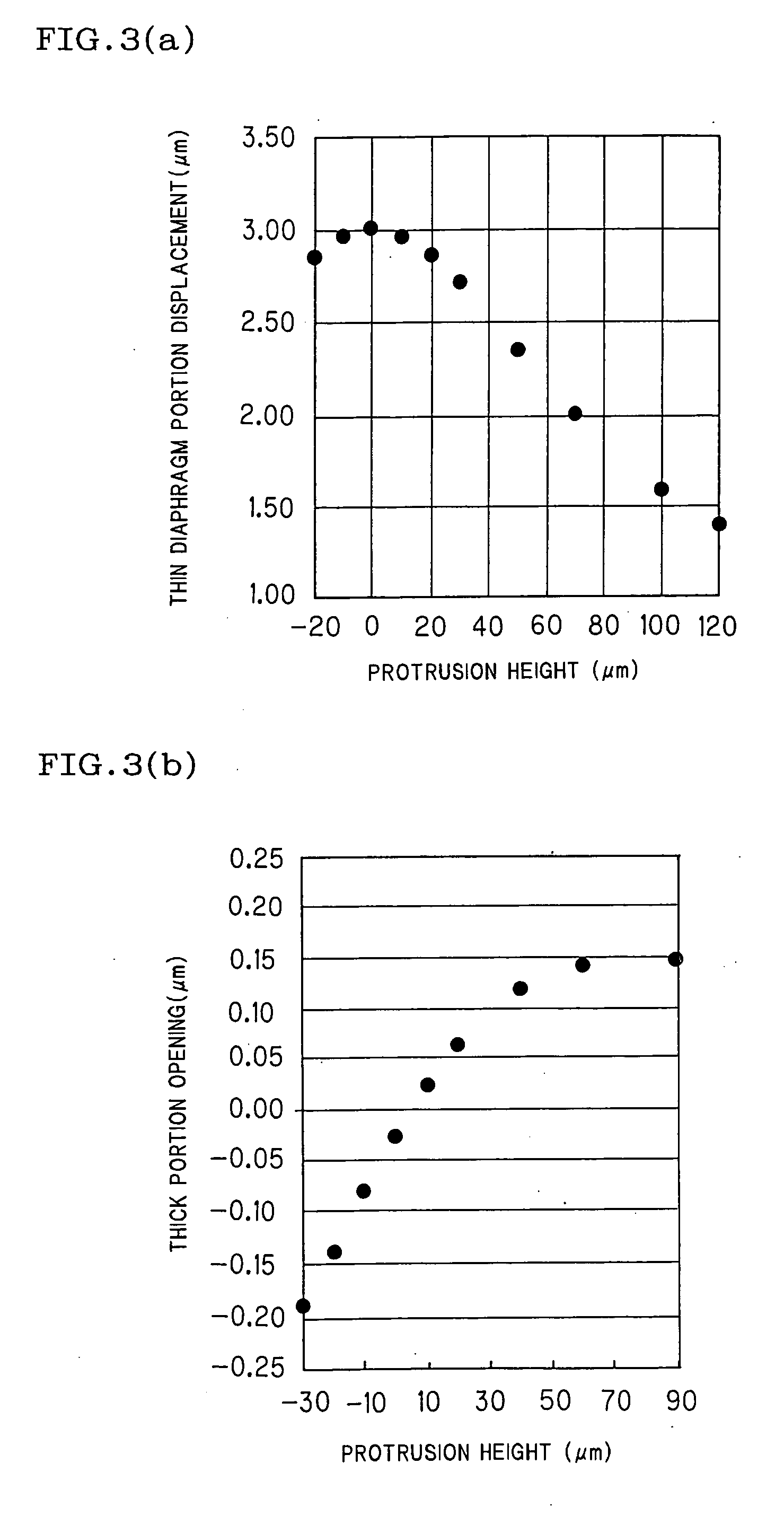

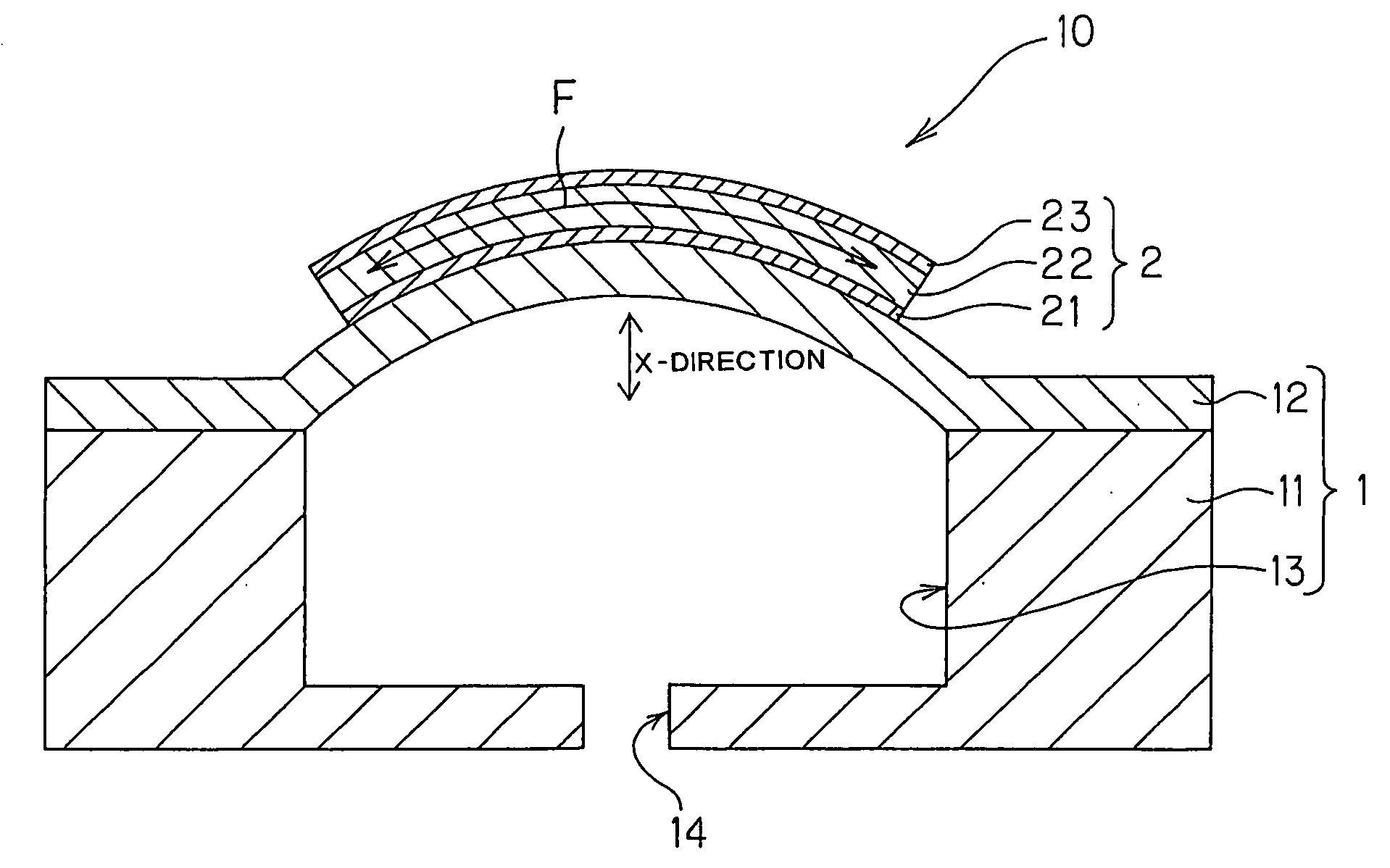

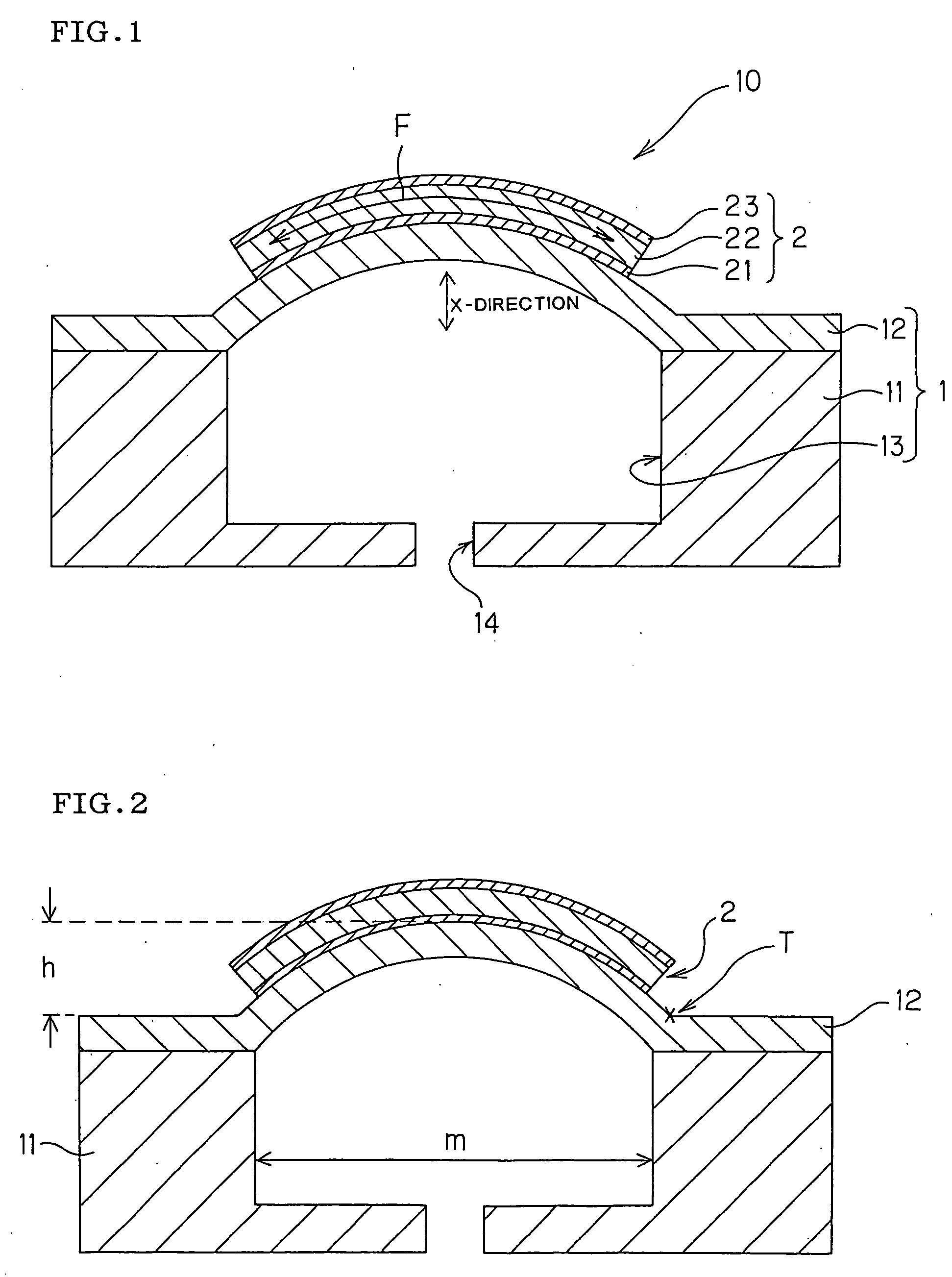

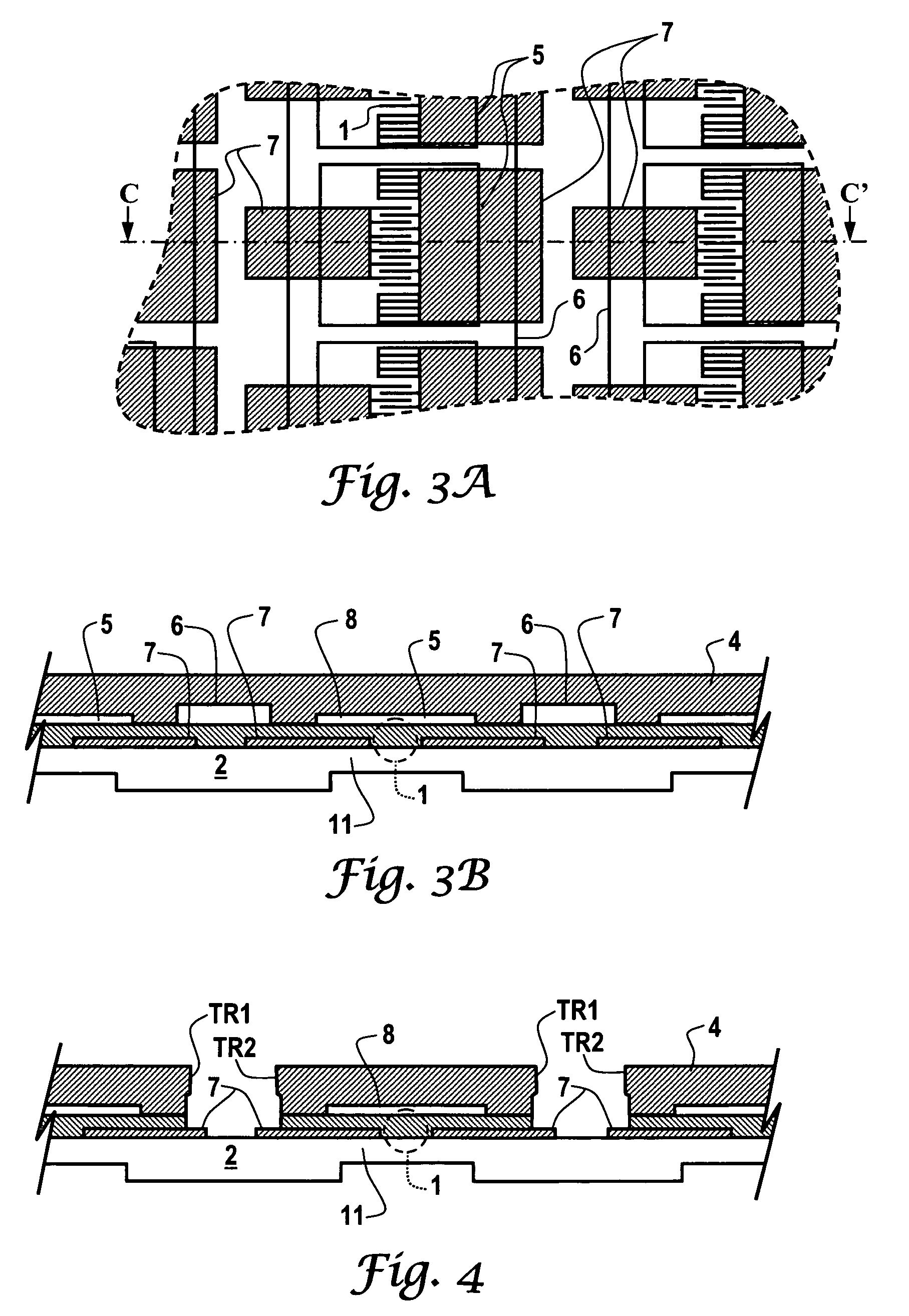

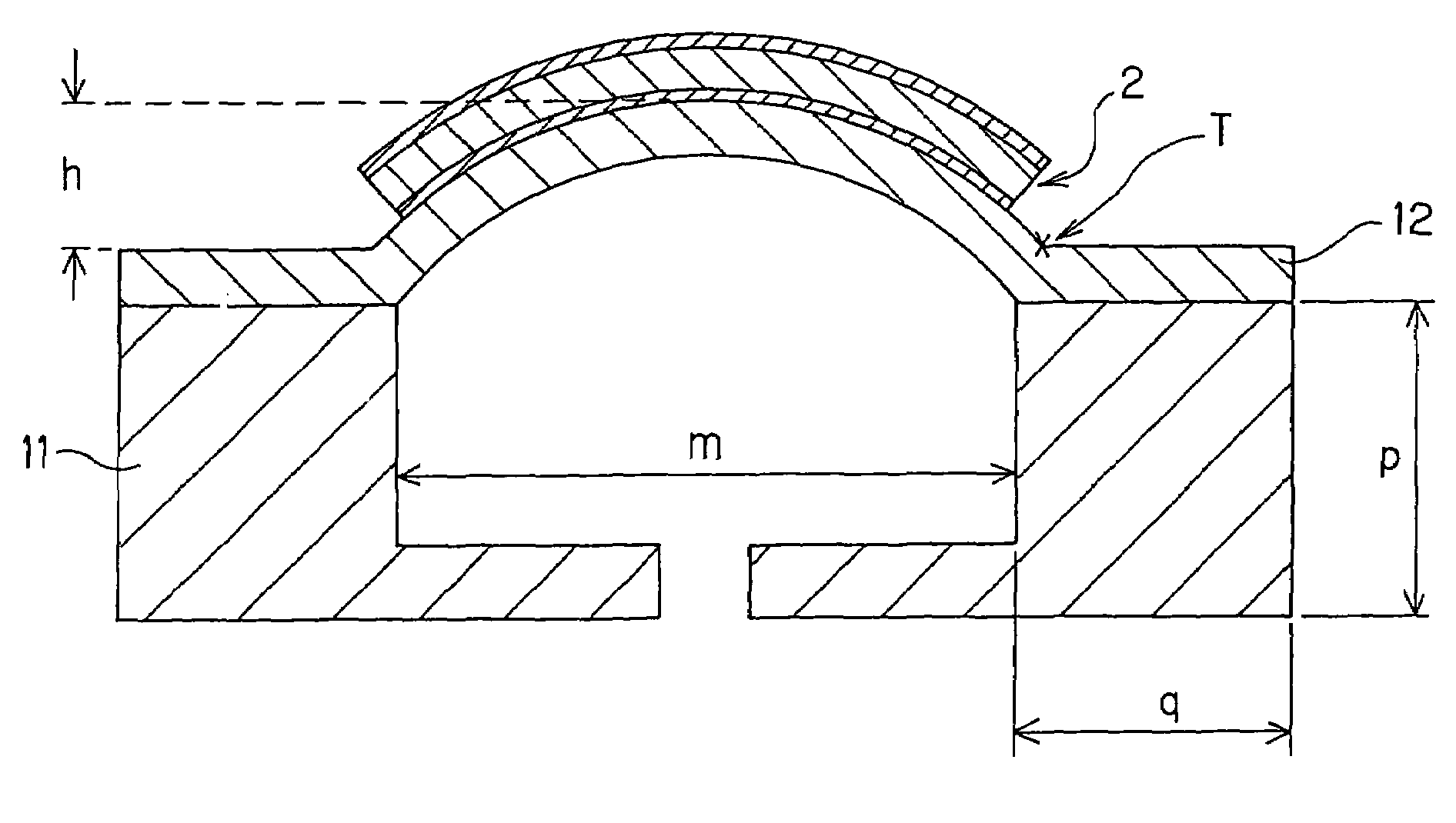

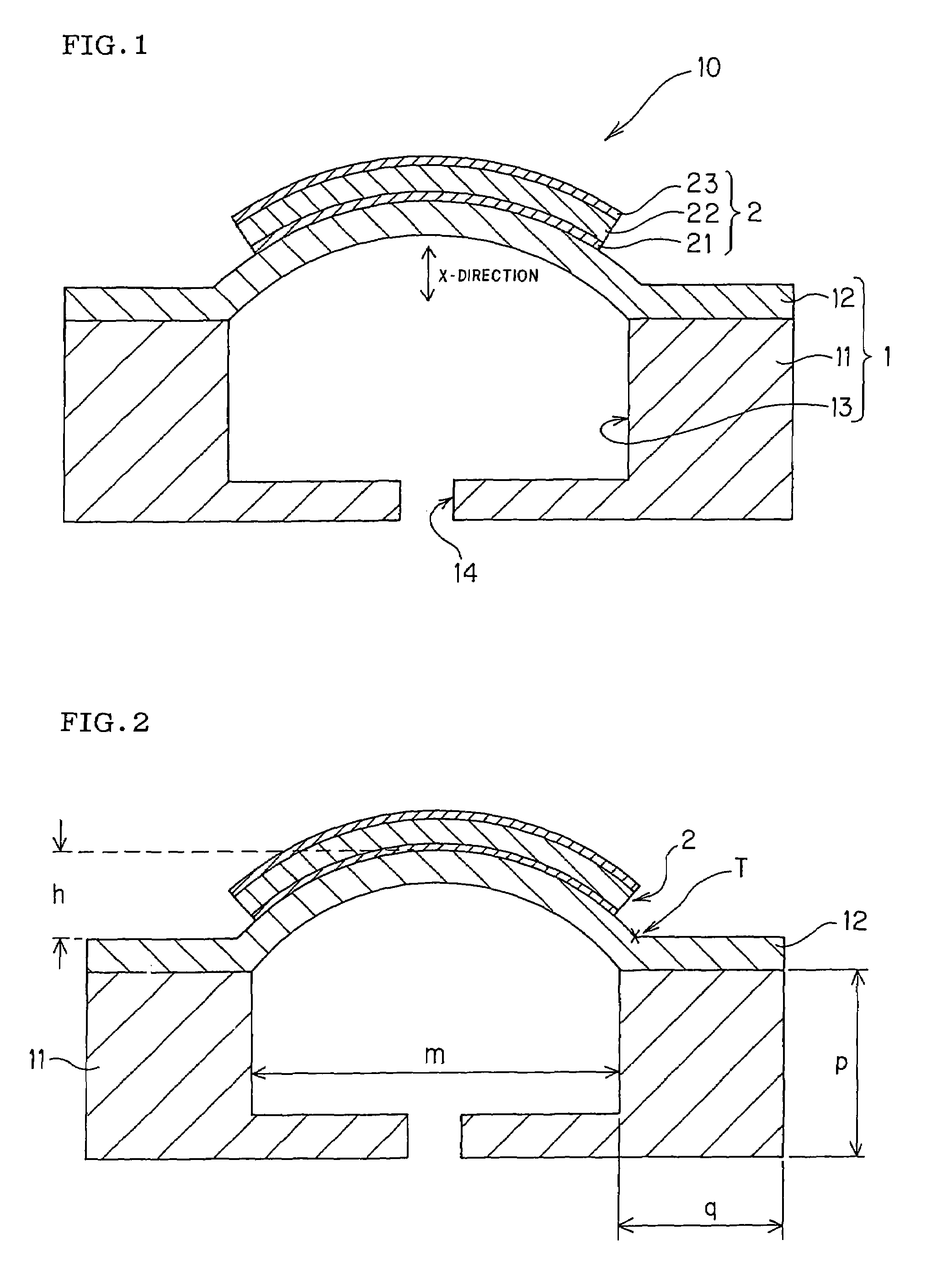

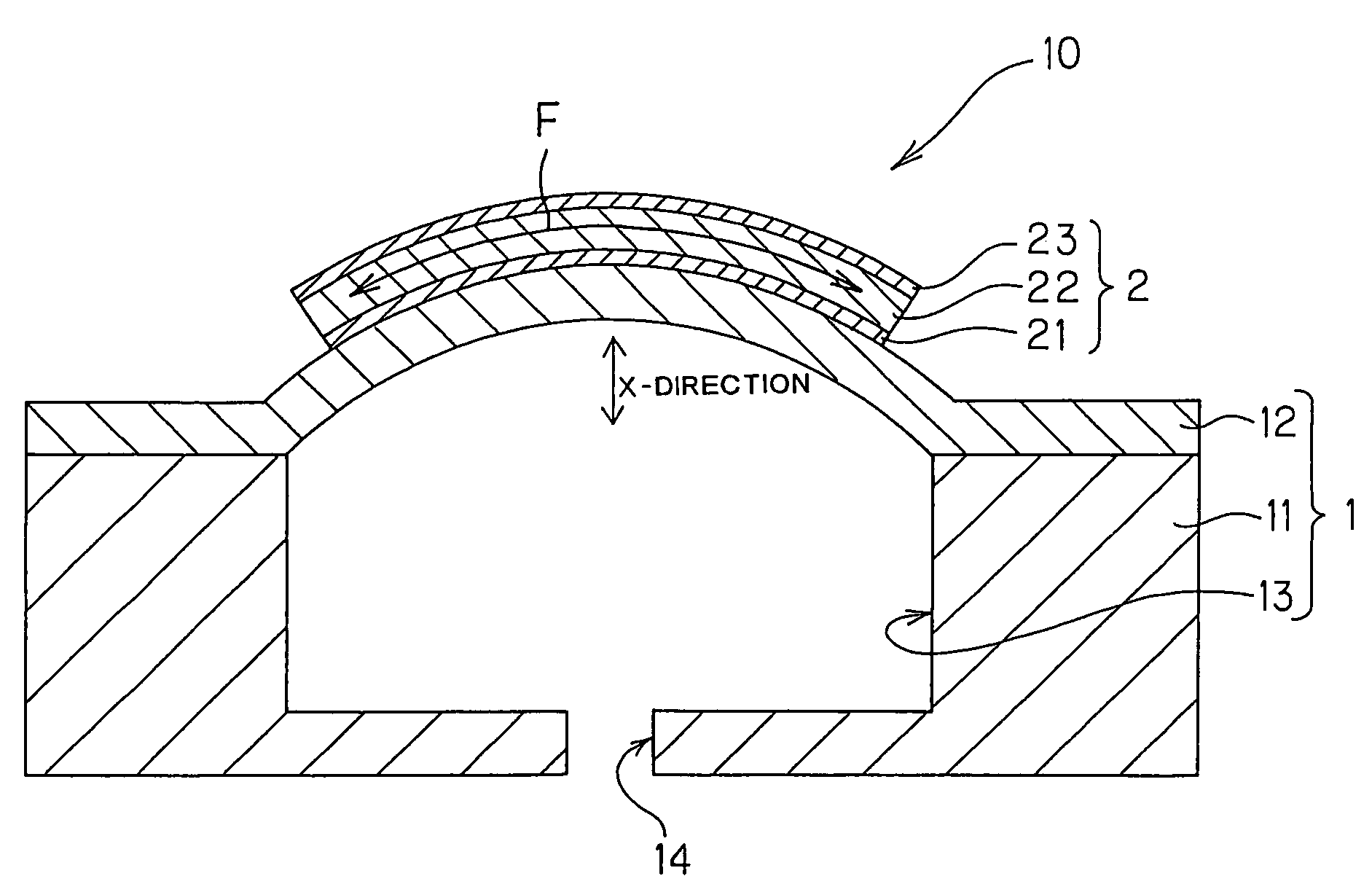

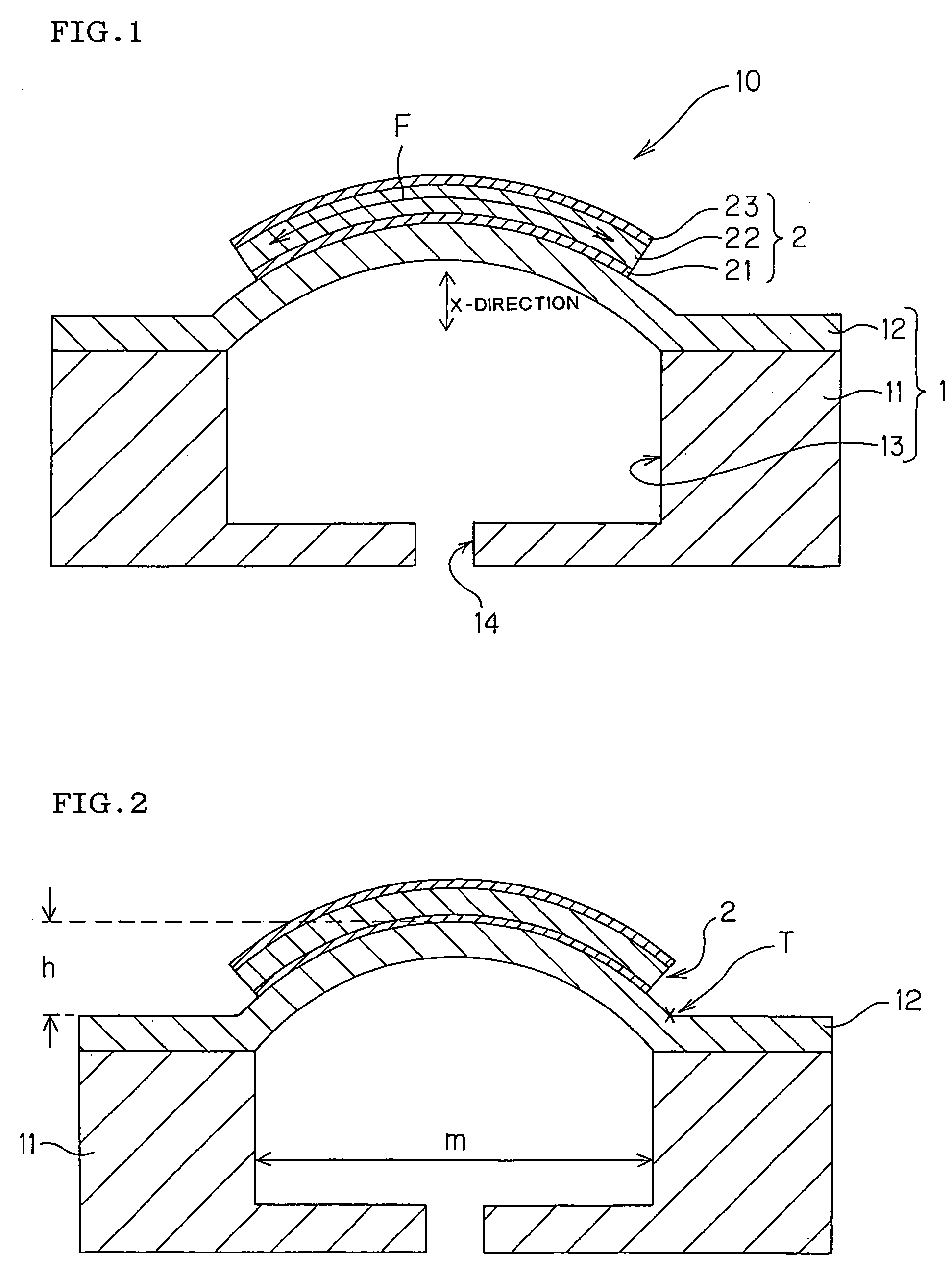

Piezoelectric/electrostrictive device

InactiveUS20060108896A1Prevents damp of vibration of thinImprove responsePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallurgyCeramic substrate

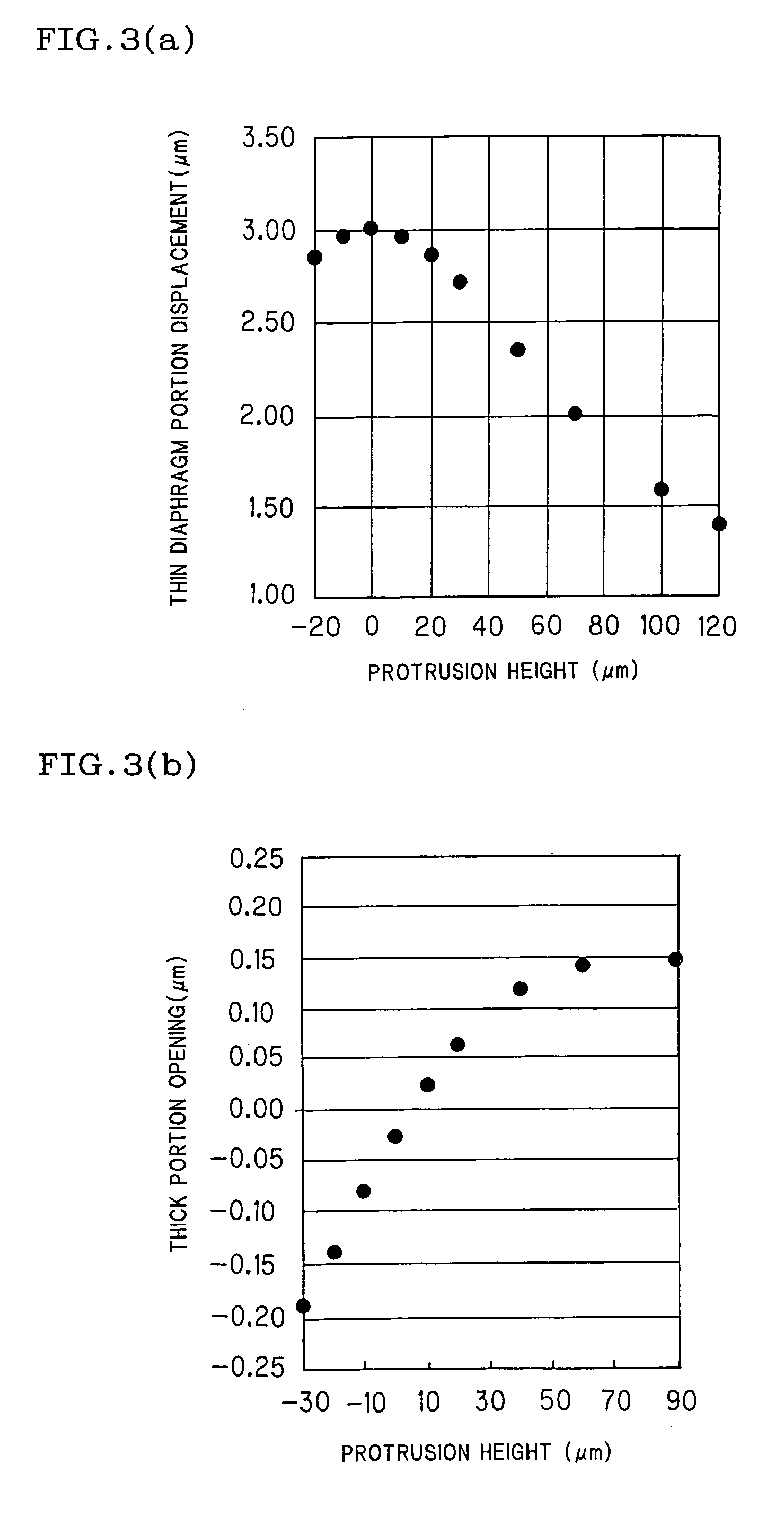

A piezoelectric / electrostrictive device includes: a ceramic substrate having a thick portion and a thin diaphragm portion; and a piezoelectric / electrostrictive element having a layered structure including a lower electrode, a piezoelectric / electrostrictive film, and an upper electrode, and the thin diaphragm portion of the ceramic substrate is constituted to vibrate in conjunction with the driving of the piezoelectric / electrostrictive element. Furthermore, shape and dimension relations defined in the following (A) to (C) are satisfied: (A) a shape of the thin diaphragm portion 12 is an outward protruding arch shape, and an outward protrusion height of the arch shape is in a range of 5 to 50 μm; (B) a mounting width of the thin diaphragm portion is in a range of 600 to 2000 μm; and (C) a ratio (height / width) of the height to the width of the thick portion is in a range of 0.25 to 3.

Owner:NGK INSULATORS LTD

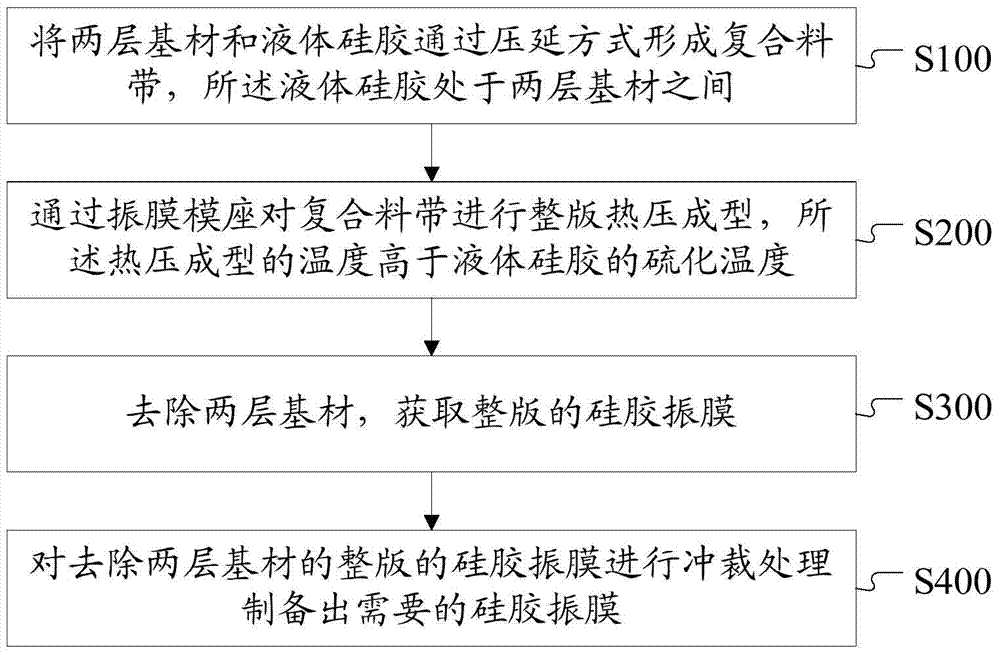

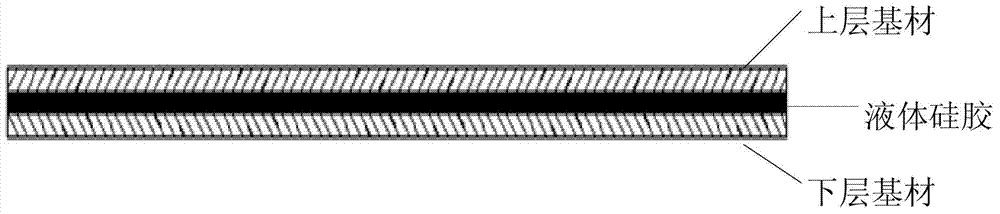

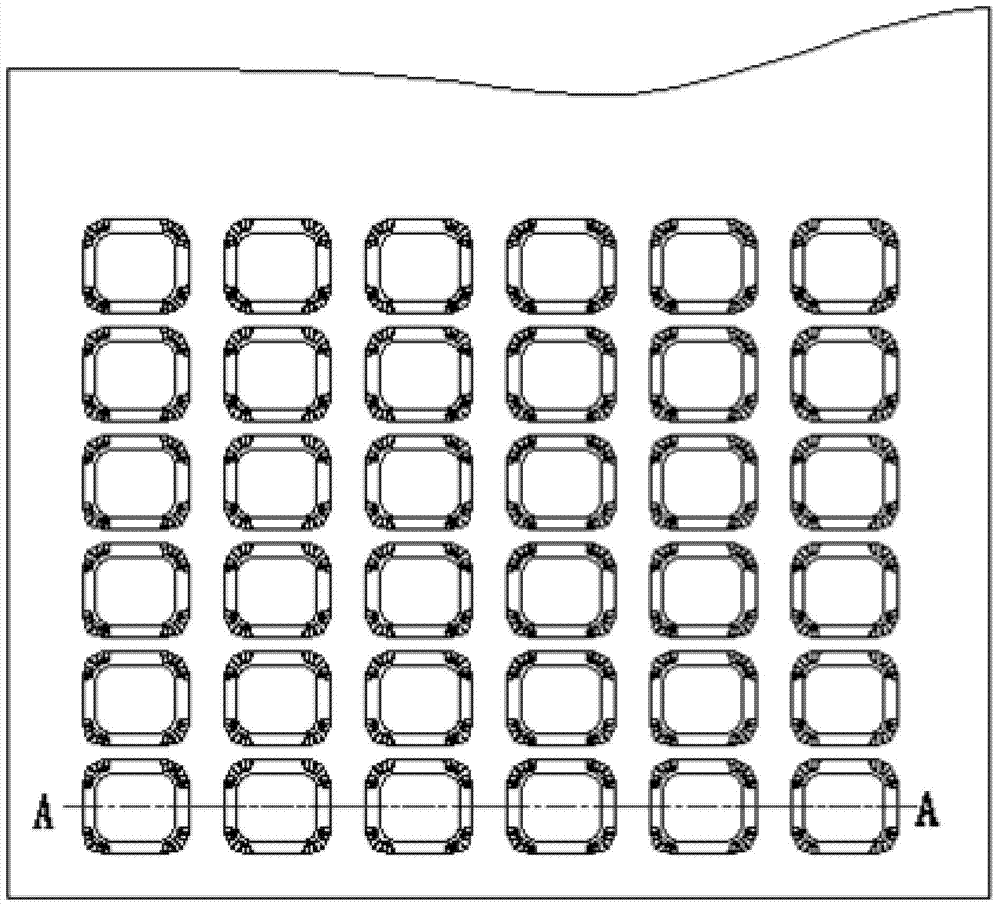

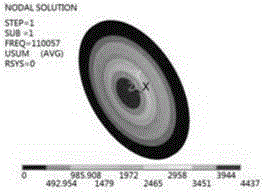

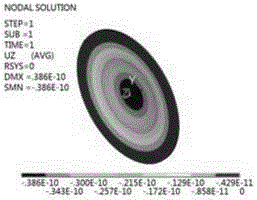

Method for preparing silica gel diaphragm and silica gel diaphragm

ActiveCN104853303ARich styleSimple forming methodPolymeric diaphragmsDomestic articlesPolymer scienceSilica gel

The invention discloses a method for preparing a silica gel diaphragm and the silica gel diaphragm. The method comprises: forming a composite material tape by two layers of substrates and liquid silica gel through a calendering method, the liquid silica gel being between the two layers of substrates; performing full-plate hot press molding on the composite material tape through a diaphragm die holder, temperature of the hot press molding being higher than vulcanizing temperature of the liquid silica gel; removing the two layers of substrates, to obtain a full-plate silica gel diaphragm; and performing blanking on the full-plate silica gel diaphragm from which the two layers of substrates are removed, so as to prepare a required silica gel diaphragm. Compared with a conventional scheme, the technical scheme is advantaged by simple forming method, low cost, diverse diaphragm forms, and thin diaphragm thickness.

Owner:GOERTEK INC

Diaphragm coupling type extrinsic fiber fabry-perot sensor probe

ActiveCN105222883AHigh detection sensitivitySimple preparation processTesting dielectric strengthSubsonic/sonic/ultrasonic wave measurementFiberExperimental research

The invention discloses a diaphragm coupling type extrinsic fiber fabry-perot sensor probe, which comprises a support sleeve, an optical fiber stub installation part, an optical fiber stub arranged in the support sleeve via the optical fiber stub installation part, and an optical fiber arranged in the optical fiber installation hole of the optical fiber stub. A first reflection film is coated onto the front end of the optical fiber stub. The first reflection film at the front end of the optical fiber stub is positioned inside the support sleeve. The front end of the support sleeve is fixedly provided with a second reflection film. The second reflection film and the first reflection film are the same in reflectivity. The second reflection film and the optical fiber stub with the first reflection film together form a fabry-perot cavity. According to the technical scheme of the invention, a fabry-perot sensor is higher in response frequency while being provided with a thinner diaphragm. Therefore, the detection sensitivity of the partial discharge sensor is improved. At the same time, the probe is simple in manufacturing process. During the experiment and investigation process, the trial production of the sensor can be easily conducted.

Owner:STATE GRID CORP OF CHINA +3

Piezoelectric/electrostrictive device

InactiveUS20060108897A1Improve responseHigh-precision (high-resolutionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesThick wallMaterials science

A piezoelectric / electrostrictive device includes: a ceramic substrate having a frame-like thick portion, a thin diaphragm portion, and a cavity formed by the thick portion and the thin diaphragm portion to communicate with the outside; and a piezoelectric / electrostrictive element having a layered structure including a lower electrode, a piezoelectric / electrostrictive film, and an upper electrode. Furthermore, the thin diaphragm portion is provided with an outward protruding arch shape, and in the piezoelectric / electrostrictive element, there remains a tensile stress parallel to a fixed surface of the element to the thin diaphragm portion. The piezoelectric / electrostrictive device is superior in response, and in the device high-precision (high-resolution, high-sensitivity) detection is possible, while effectively preventing decay of vibration of a thin diaphragm portion and maintaining displacement (amplitude) to be high.

Owner:NGK INSULATORS LTD

Vacuum sealed surface acoustic wave pressure sensor

InactiveUS7198981B2Simple structureLow costFluid pressure measurement by electric/magnetic elementsSolid-state devicesSurface acoustic wave sensorEngineering

A vacuum sealed SAW pressure sensor is disclosed herein, which includes a sensing element configured as a SAW device (e.g., SAW resonator or SAW delay line) supported by a thin diaphragm. The substrate material can be implemented as a quartz wafer (i.e., a “base” wafer). The SAW device can be configured on one side of the wafer and the diaphragm etched on the opposite side. A quartz micromachined pressure sensor can thus be realized, which operates based on a variation of the surface wave velocity of a SAW device situated on the thin diaphragm. The SAW sensor is generally sealed in a vacuum and diaphragm sustains the sensor, thereby implementing a sensor on a wafer scale while allowing for a cost reduction per chip.

Owner:HONEYWELL INT INC

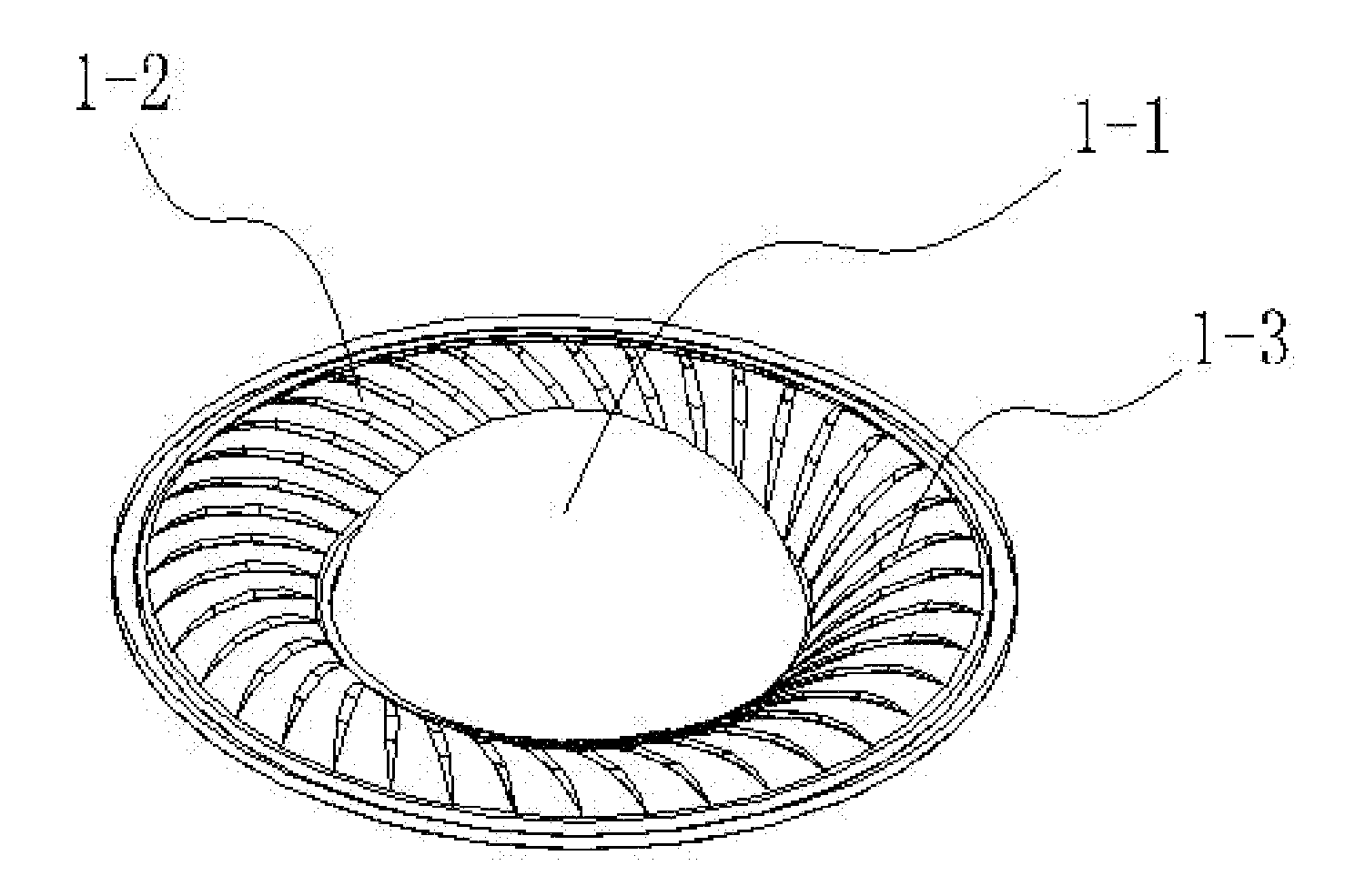

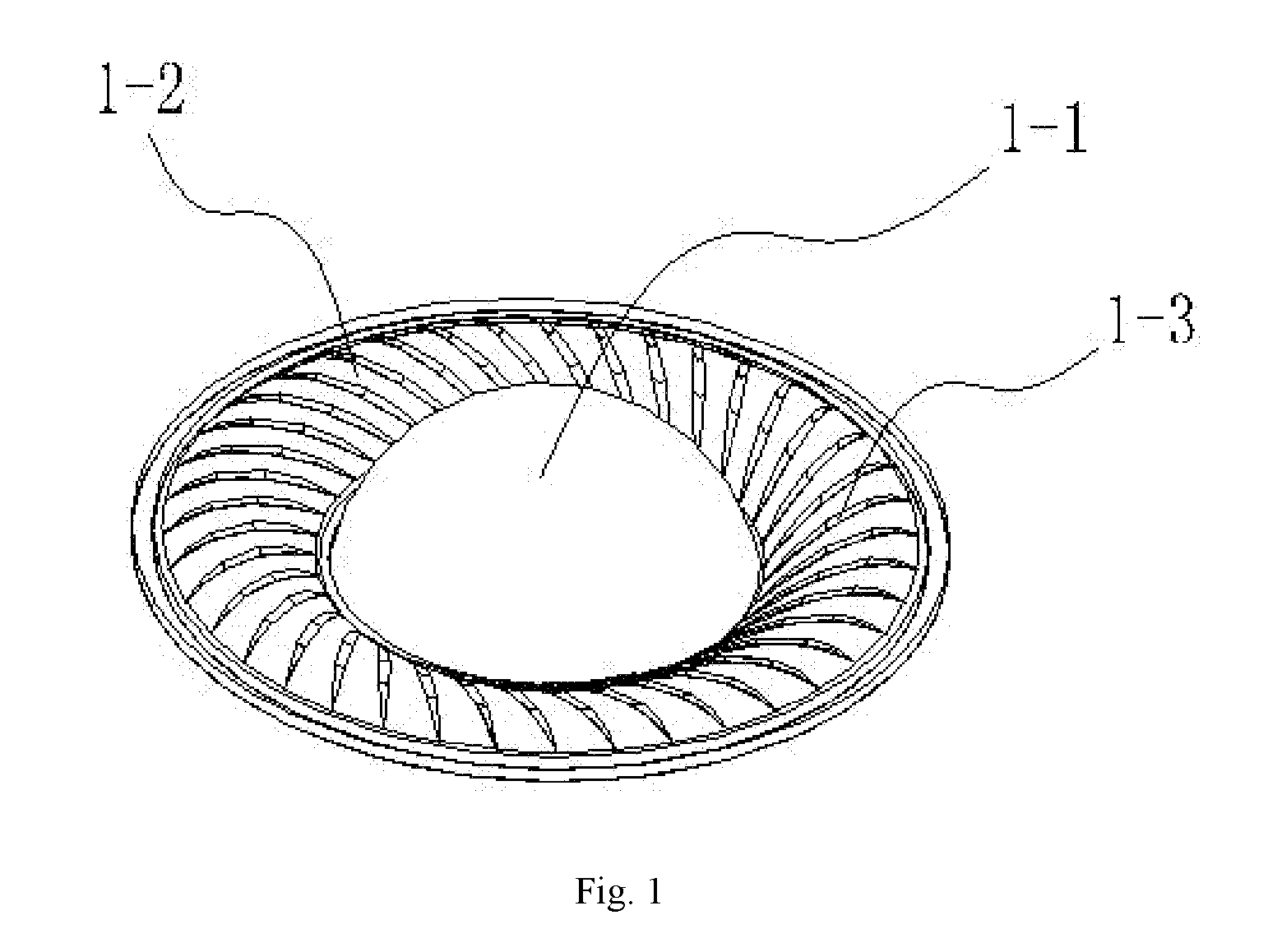

Speaker Diaphragms and Speakers with the Same

The utility model relates to a type of speaker diaphragm and speakers with the same, the diaphragm is formed of the first polyester film layer, a polyurethane film layer and the second polyester film layer which are laminated sequentially and adhered together. Another technical solution is: a speaker diaphragm, the diaphragm is formed of the first polyester film layer and the second polyester film layer which are laminated and adhered by using the adhesive. In addition to using the speaker diaphragm, the speaker further comprises sequentially assembled voice coil, washer, magnet, U-shaped iron cup, holder, PCB board and sound mixing paper. The speaker diaphragm of the utility model is made of the composite material, which solved the defects that the thin diaphragm of the traditional speaker diaphragm is soft and the damping of the existing polyester thin film material is small Moreover, the surface of the diaphragm is added with stiffeners such that the diaphragm vibration is more balanced after installation, thus obtaining a wider frequency response and more exquisite subjective auditory sense.

Owner:INNOVATION SOUND TECH

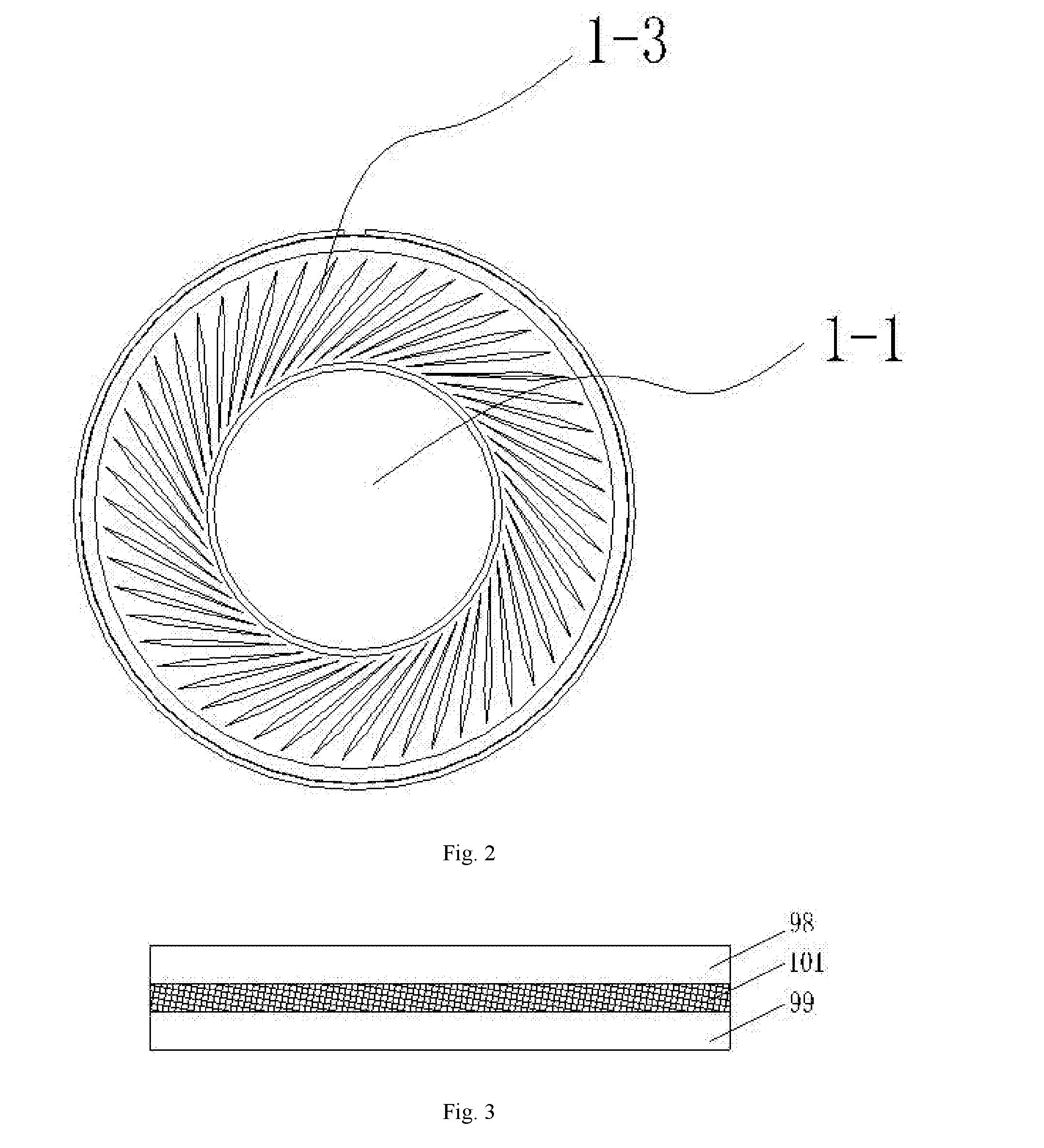

Single-cavity multi-resonant-frequency lateral-support resonant muffler

A single-cavity multi-resonant-frequency lateral-support resonant muffler belongs to the field of the control of automobile noise and mainly consists of a main pipe, a resonator, a diaphragm, a pressing plate and a connecting screw assembly. According to characteristics of an air inlet noise source and the distribution situation of an engine cabin, a resonator cavity can be designed into a cylindrical shape and a hexagonal shape. When the resonator cavity is a cylindrical cavity, the cylindrical bottom surface is completely or partially covered by the thin diaphragm, and two resonant frequencies can be obtained by optimizing the size and the thickness of the diaphragm; and when the resonator cavity is a hexagonal cavity, at most five surfaces of the resonator are substituted by the thin diaphragm, and more than one and less than five resonant frequencies can be obtained. The single-cavity multi-resonant-frequency lateral-support resonant muffler has characteristics that through the method by utilizing the thin diaphragm to substitute the rigid wall of the traditional resonator, two or more resonant frequencies can be obtained, so that multiple frequency band noise in an air inlet system of the engine can be eliminated, and the defects that the traditional single-cavity resonant muffler only can eliminate one frequency band noise can be overcome.

Owner:CHONGQING UNIV

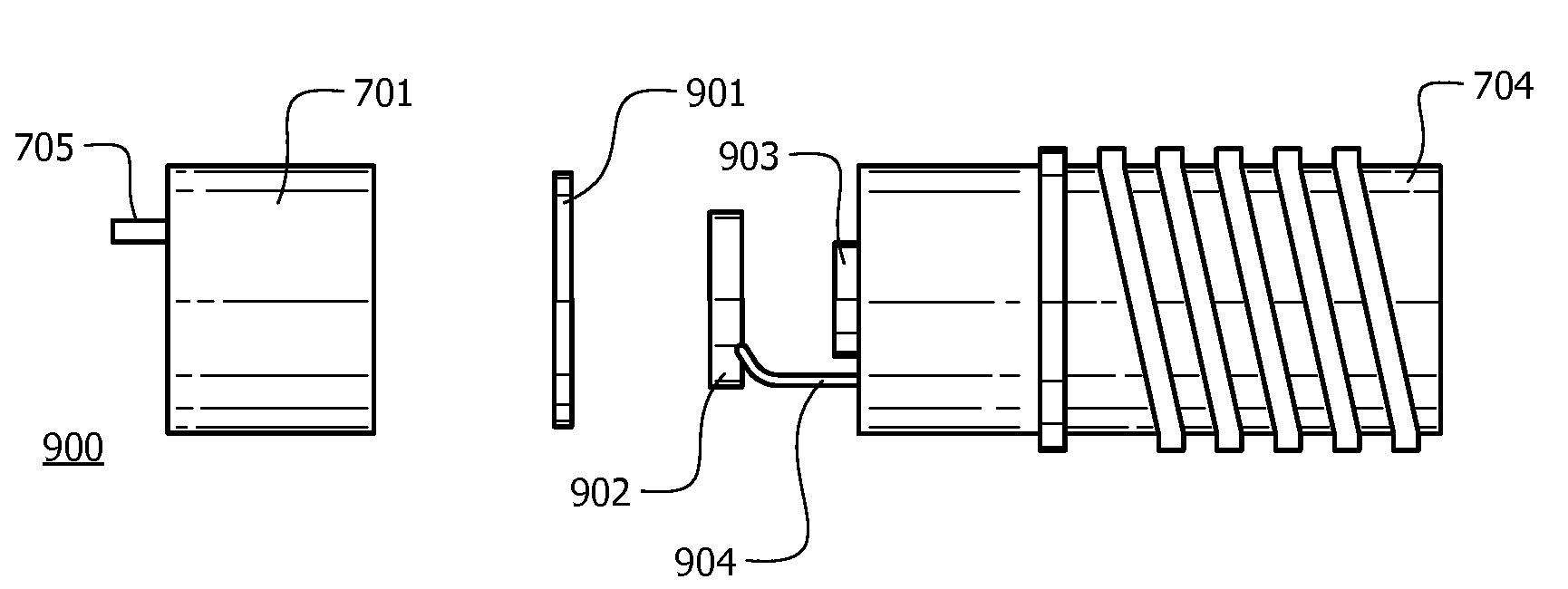

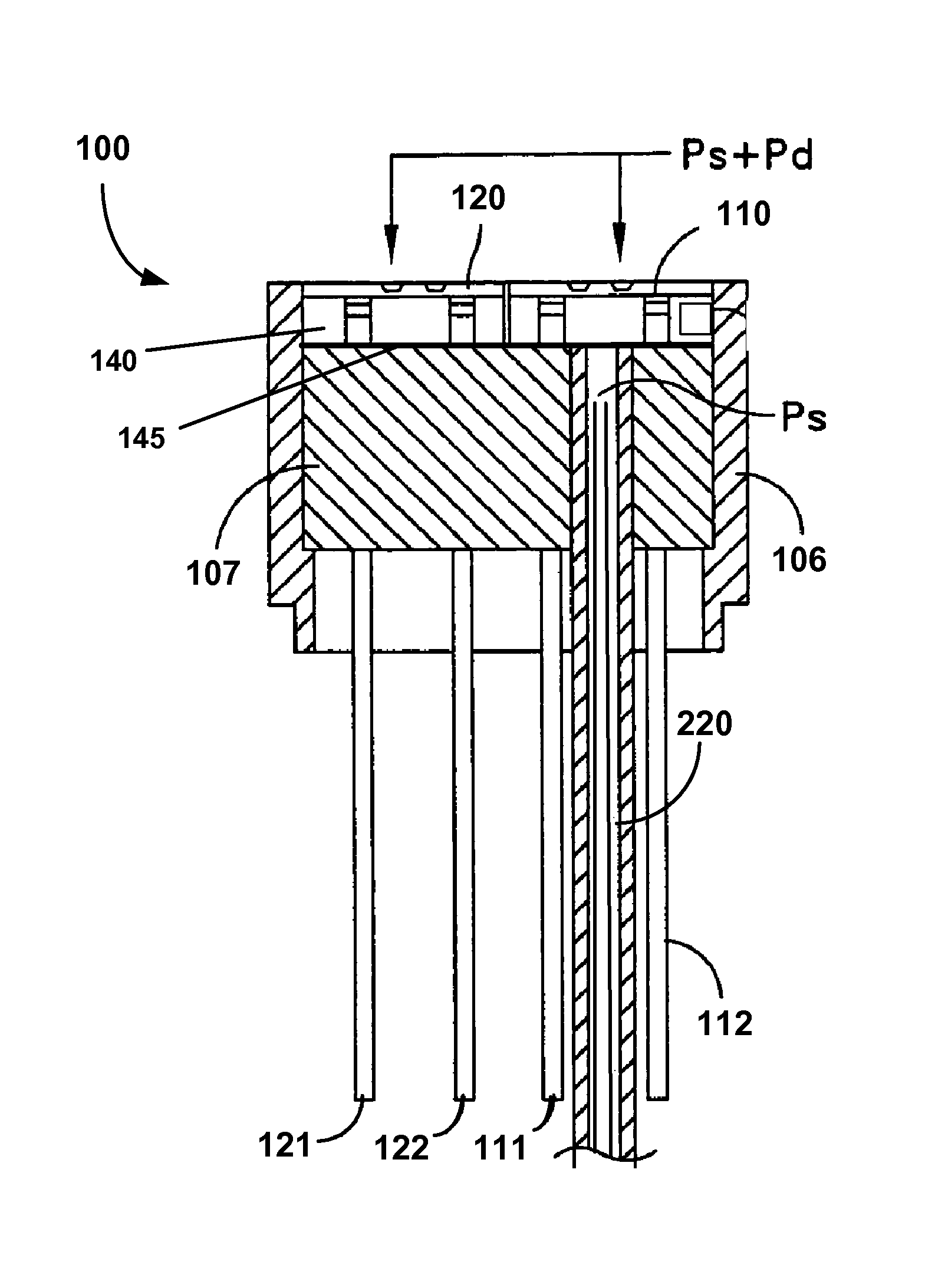

Enhanced static-dynamic pressure transducer suitable for use in gas turbines and other compressor applications

ActiveUS8074521B2Fluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsTransducerPiezoresistive pressure sensors

A filter assembly for use with a static-dynamic piezoresistive pressure transducer that measures low amplitude, dynamic pressure perturbations superimposed on top of a high static pressure through the implementation of a low-pass mechanical filter assembly is disclosed. The filter assembly may comprise a dual lumen reference tube and a removable filter subassembly further comprising a porous metal filter and narrow diameter tube. The transducer, which may be capable of operating at ultra-high temperatures and in harsh environments, may comprise of a static piezoresistive pressure sensor, which measures the large pressures on the order of 200 psi and greater, and an ultrasensitive, dynamic piezoresistive pressure sensor which may capture small, high frequency pressure oscillations on the order of a few psi or less. The filter assembly may transmit static pressure to the back of the dynamic pressure sensor to cancel out the static pressure present at the front of the sensor while keeping dynamic pressure from reaching the back of the sensor. In this manner, the filter assembly enables the transducer to accurately read dynamic pressure in the presence of high static pressure without rupturing the thin diaphragm of the dynamic pressure sensor.

Owner:KULITE SEMICON PRODS

Piezoelectric/electrostrictive device

InactiveUS7221075B2Improve responsePreventing damp of vibration of thinPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesImage resolutionMaterials science

A piezoelectric / electrostrictive device includes: a ceramic substrate having a thick portion and a thin diaphragm portion; and a piezoelectric / electrostrictive element having a layered structure including a lower electrode, a piezoelectric / electrostrictive film, and an upper electrode, and the thin diaphragm portion of the ceramic substrate is constituted to vibrate in conjunction with the driving of the piezoelectric / electrostrictive element. Furthermore, shape and dimension relations defined in the following (A) to (C) are satisfied: (A) a shape of the thin diaphragm portion 12 is an outward protruding arch shape, and an outward protrusion height of the arch shape is in a range of 5 to 50 μm; (B) a mounting width of the thin diaphragm portion is in a range of 600 to 2000 μm; and (C) a ratio (height / width) of the height to the width of the thick portion is in a range of 0.25 to 3. According to the piezoelectric / electrostrictive device, vibration of a thin diaphragm portion is effectively prevented from being damped, and the device maintains displacement (amplitude) to be high and is superior in response and highprecision (highresolution, high-sensitivity) detection is possible.

Owner:NGK INSULATORS LTD

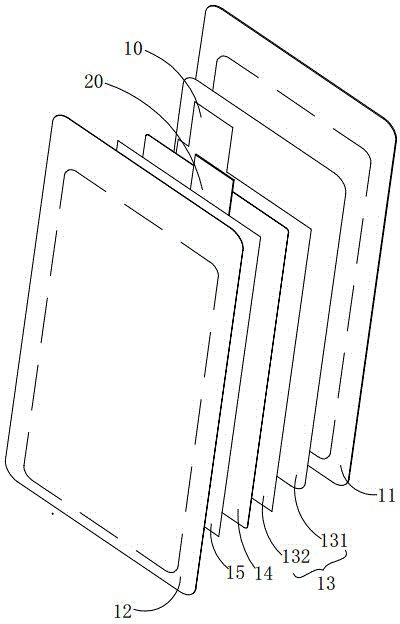

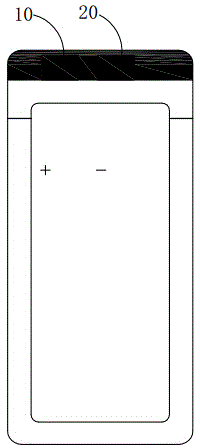

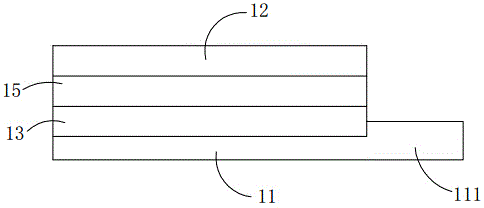

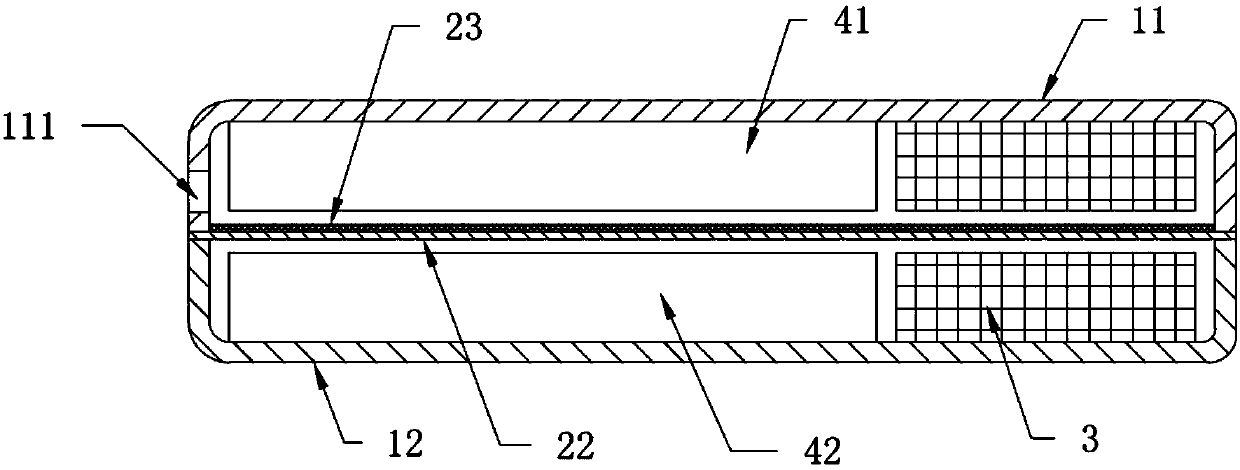

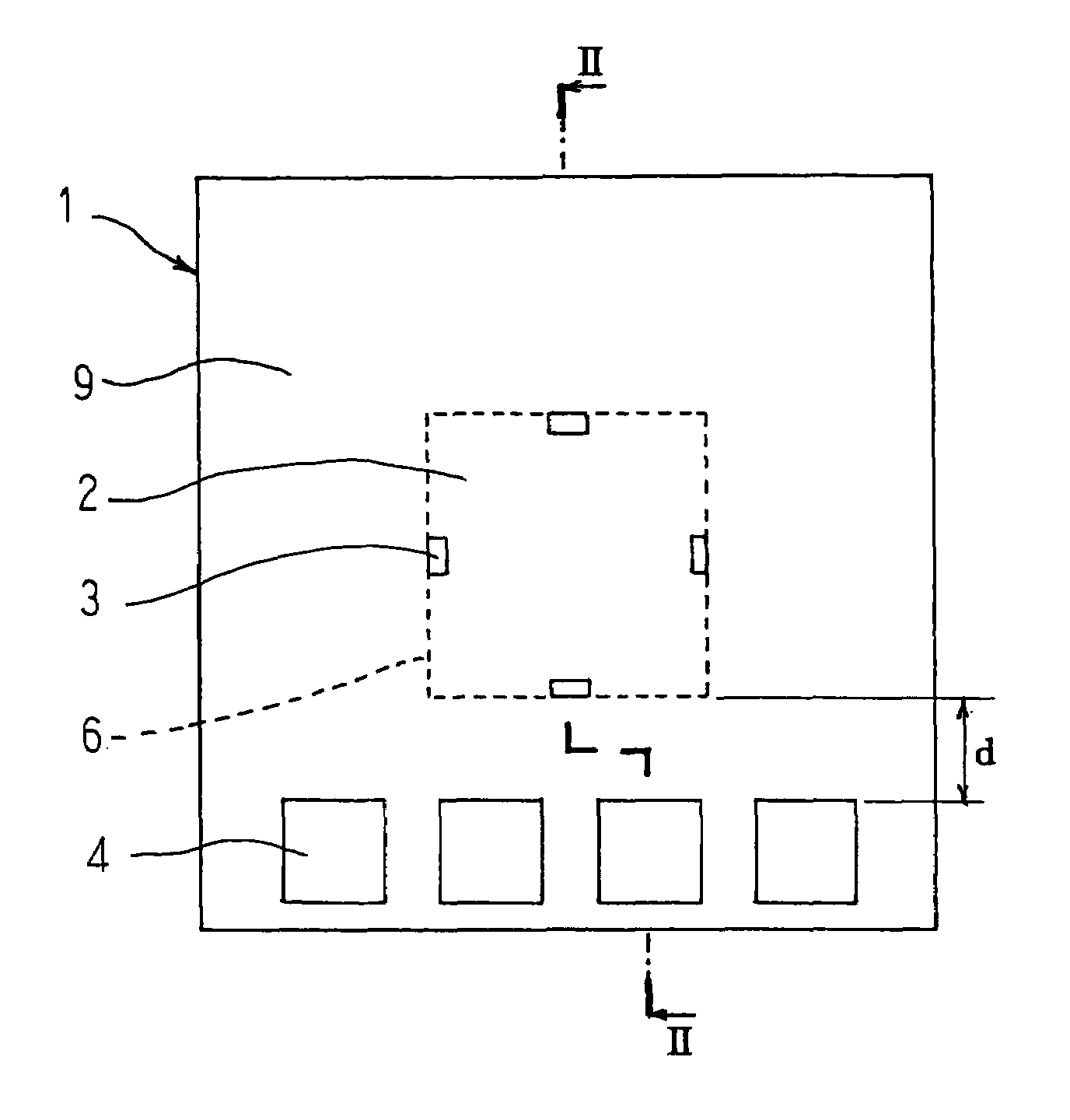

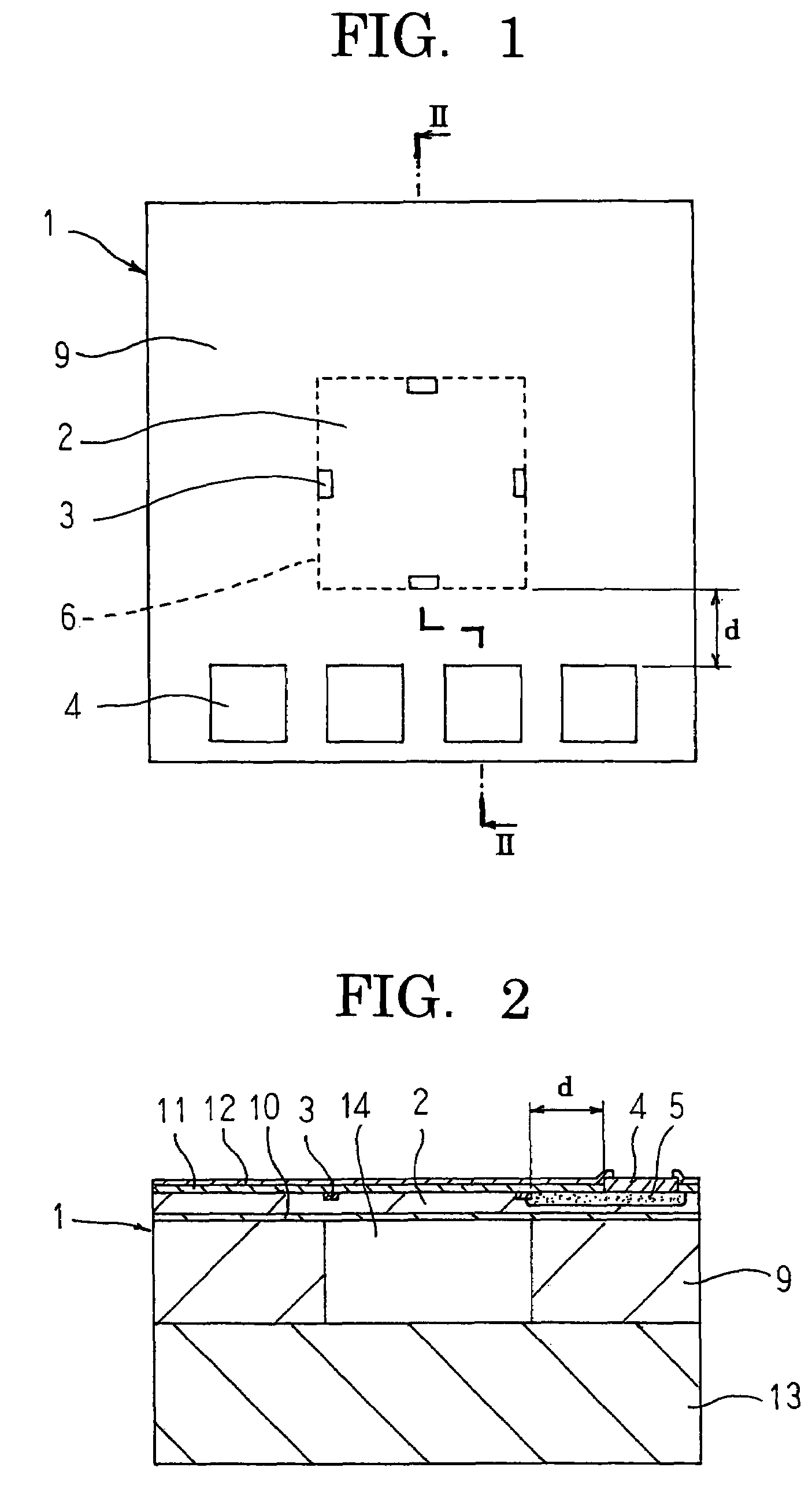

Thin diaphragm battery and preparing method thereof

ActiveCN104377361AImprove conductivityReduce thicknessFinal product manufactureSmall-sized cells cases/jacketsSealantElectrode material

The invention relates to a thin diaphragm battery. The battery comprises a positive electrode plate, a diaphragm and a negative electrode plate which are successively laminated. The positive electrode tab is led out from one end of the positive electrode plate. The negative electrode tab is led out from one end of the negative electrode plate. The positive electrode tab and the negative electrode tab are arranged on the same side of a battery body. The thin diaphragm battery also comprises a first outer packaging diaphragm arranged on the positive electrode plate side and a second outer packaging diaphragm arranged on the negative electrode plate side. The first and second outer packaging diaphragms are sealed peripherally for packaging the positive electrode plate, the diaphragm, the negative electrode plate and electrolyte of the battery. The positive electrode plate comprises a current collector layer and a positive electrode material layer with which the current collector layer is coated. On one side of the first outer package diaphragm, close to the positive electrode tab, extends outwards to form an extension sheet. One surface of the extension sheet, facing to the positive electrode tab, is coated with sealant. The positive electrode tab and the negative electrode tab are fixedly stuck on the extension sheet of the first outer packaging diaphragm. The thickness of the battery is 0.1-5.5mm. The thin diaphragm battery disclosed by the invention has the characteristics of being thin, good in conductivity, good in tightness, and the like and the electrode tabs are not easy to break.

Owner:EVE ENERGY CO LTD

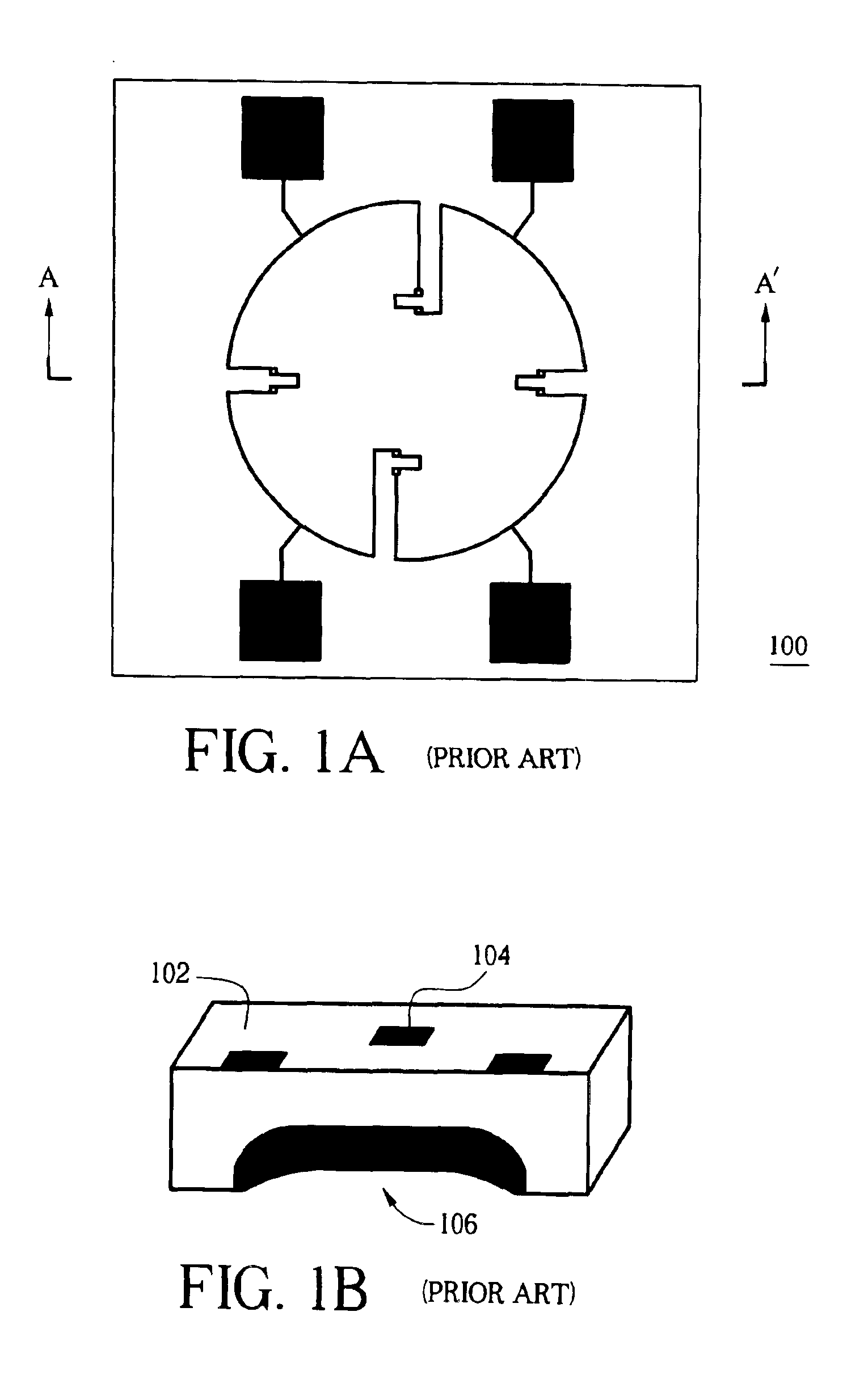

Piezoelectric/electrostrictive membrane type sensor

InactiveUS20090095072A1High sensitivityAccurate measurement of concentrationPiezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesAlkaline earth metalMetal

Disclosed is a piezoelectric / electrostrictive membrane type sensor 20 provided with a ceramic base body 1 and a piezoelectric / electrostrictive element 12. The ceramic base body is provided with a thin diaphragm portion 3, a thick portion 2 and a cavity 10 formed by the portions. The piezoelectric / electrostrictive element is arranged on the ceramic base body 1 and includes a piezoelectric / electrostrictive body 5, and an upper electrode 6 and a lower electrode 4 sandwiching the piezoelectric / electrostrictive body 5. In the piezoelectric / electrostrictive membrane type sensor 20, the piezoelectric / electrostrictive body 5 contains an alkaline metal or an alkaline earth metal, and the upper electrode 6 and the lower electrode 4 contain gold or platinum. When there is a change in the atmosphere at a place where the sensor is used, the sensor copes with such change and at least prevents continuation of low-quality measurement.

Owner:NGK INSULATORS LTD

A thin receiver

InactiveCN109104663AHigh frequency responseImprove the sound effectEarpiece/earphone attachmentsPlane diaphragmsEngineeringSound production

The invention provides a thin-type receiver, comprising a housing, a diaphragm module and a coil. A diaphragm assembly includes a frame, Diaphragm and seal film, since a mounting area is formed between a part of the side wall of the frame and an inner wall surface of the housing, the coil seal is secured to the mounting area and the seal is sleeved outside the frame, and the sealing film is spreadto seal all first gaps between the frame and the diaphragm, thereby dividing the mounting cavity of the housing into two chambers that are side-by-side and do not communicate with each other, boundedby the diaphragm assembly. When the coil is energized and the electromagnetic field generated by the coil interacts with the fixed magnetic field of the permanent magnet in the receiver, the whole diaphragm vibrates, so that when a thin diaphragm is formed on the diaphragm module by snare on line, the diaphragm covered with the sealing diaphragm participates in the sound production, the effectivearea of the diaphragm vibration is maximized, and the frequency response of the receiver is improved.

Owner:SUZHOU YICHUAN TECH CO LTD

Semiconductor strain sensor

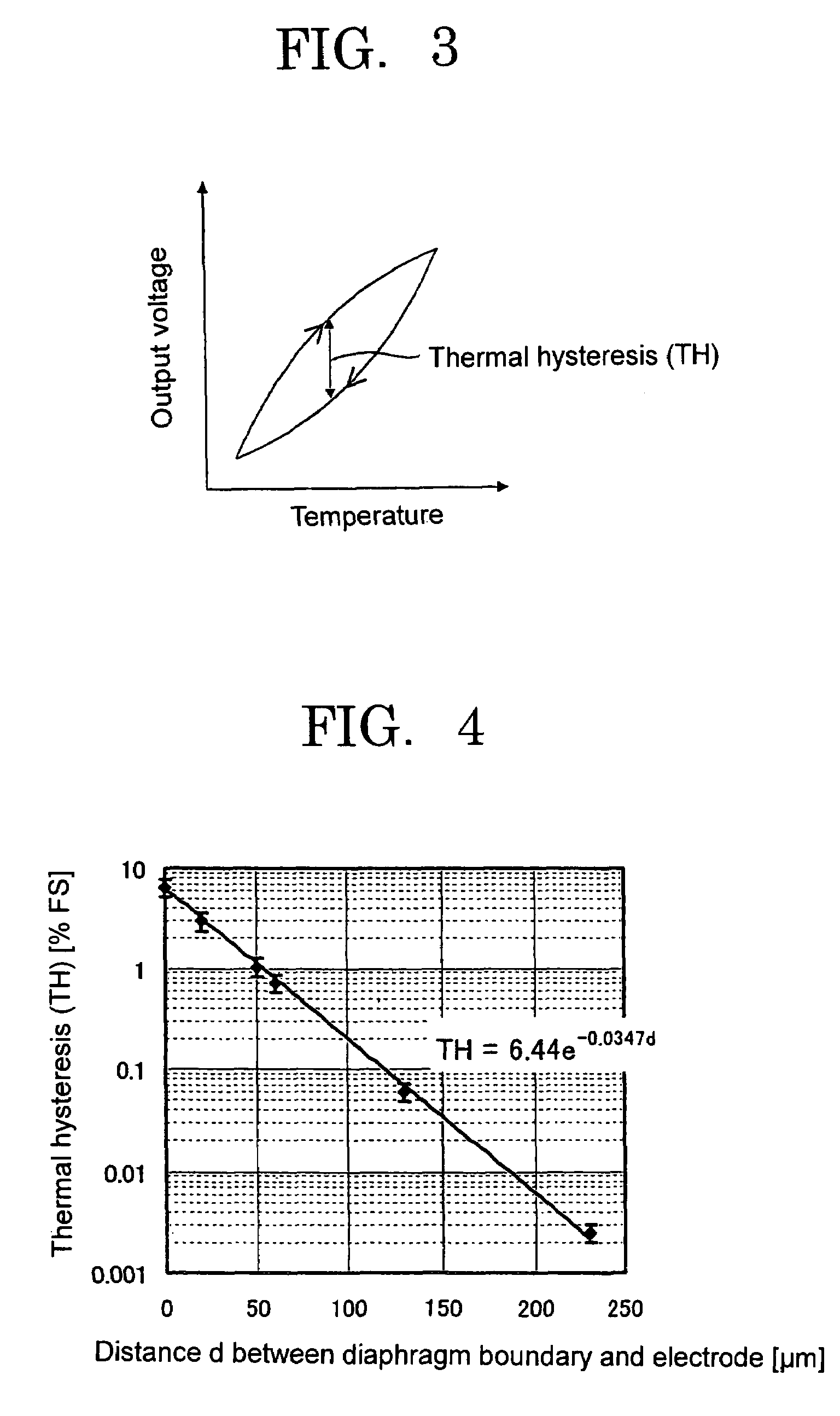

ActiveUS7562582B2Improve temperature stabilitySuppressing thermal hysteresis of output voltageFluid pressure measurement by electric/magnetic elementsForce measurementSoi substrateEngineering

An SOI substrate includes a thin diaphragm portion that is formed by removing a portion of the substrate from a rear surface side, and a thick outer frame portion that surrounds the diaphragm portion. A piezoresistive element that outputs an electrical signal in response to pressure is formed on the diaphragm portion, and an electrode that extracts the electrical signal from the piezoresistive element is formed on the outer frame portion. The electrode is disposed at a position on the outer frame portion that is separated by greater than or equal to 100 μm from a boundary line between the diaphragm portion and the outer frame portion.

Owner:MITSUBISHI ELECTRIC CORP

Piezoelectric/electrostrictive device

InactiveUS7183694B2Improve responseHigh-precision (high-resolutionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesImage resolutionCeramic substrate

A piezoelectric / electrostrictive device includes: a ceramic substrate having a frame-like thick portion, a thin diaphragm portion, and a cavity formed by the thick portion and the thin diaphragm portion to communicate with the outside; and a piezoelectric / electrostrictive element having a layered structure including a lower electrode, a piezoelectric / electrostrictive film, and an upper electrode. Furthermore, the thin diaphragm portion is provided with an outward protruding arch shape, and in the piezoelectric / electrostrictive element, there remains a tensile stress parallel to a fixed surface of the element to the thin diaphragm portion. The piezoelectric / electrostrictive device is superior in response, and in the device high-precision (high-resolution, high-sensitivity) detection is possible, while effectively preventing decay of vibration of a thin diaphragm portion and maintaining displacement (amplitude) to be high.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com