Injection moulding process and apparatus for plastic diaphragm of press filter

A technology of injection molding and filter press, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high product finish, long production cycle, and low efficiency, and reduce production costs and equipment investment , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

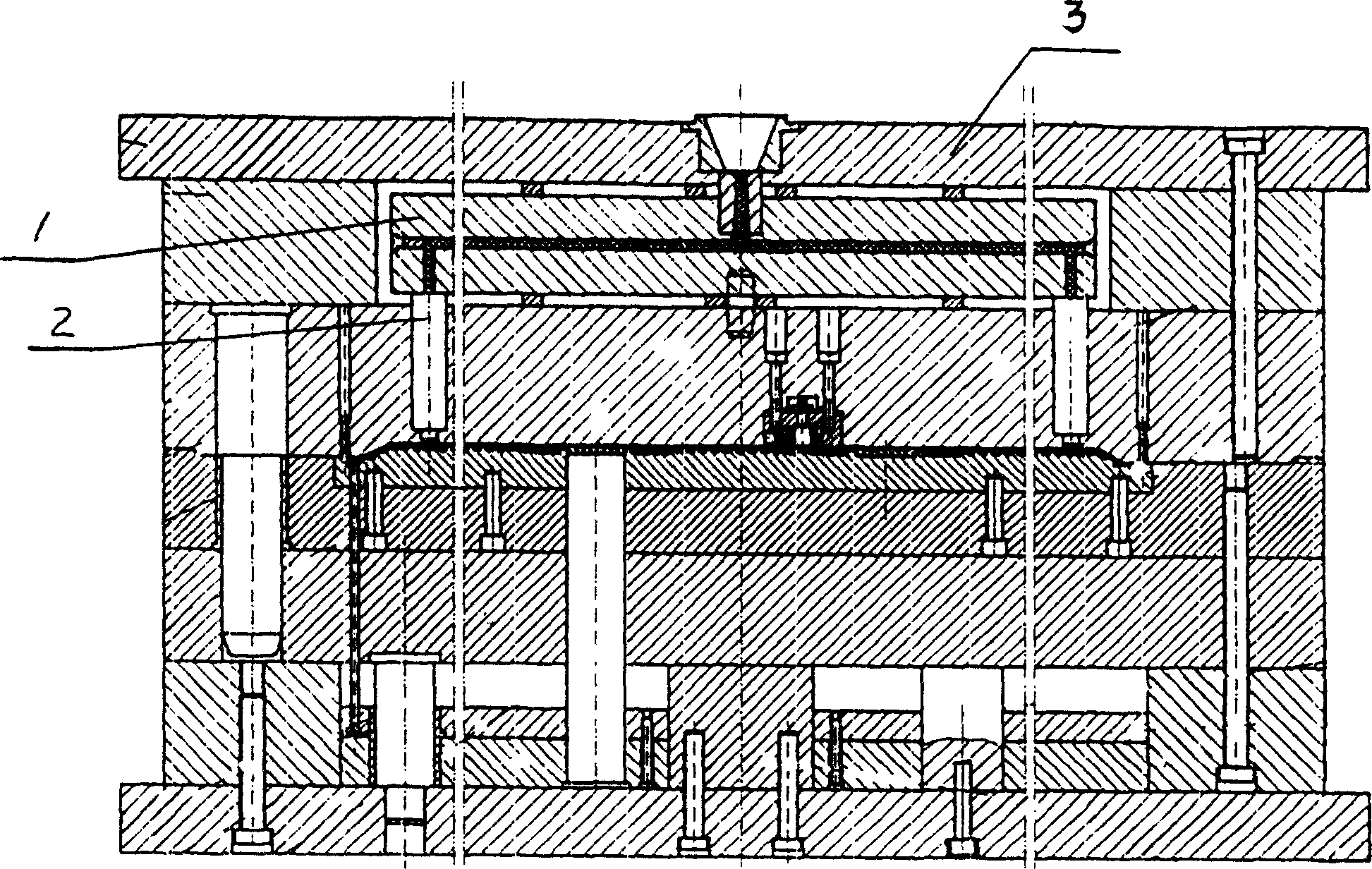

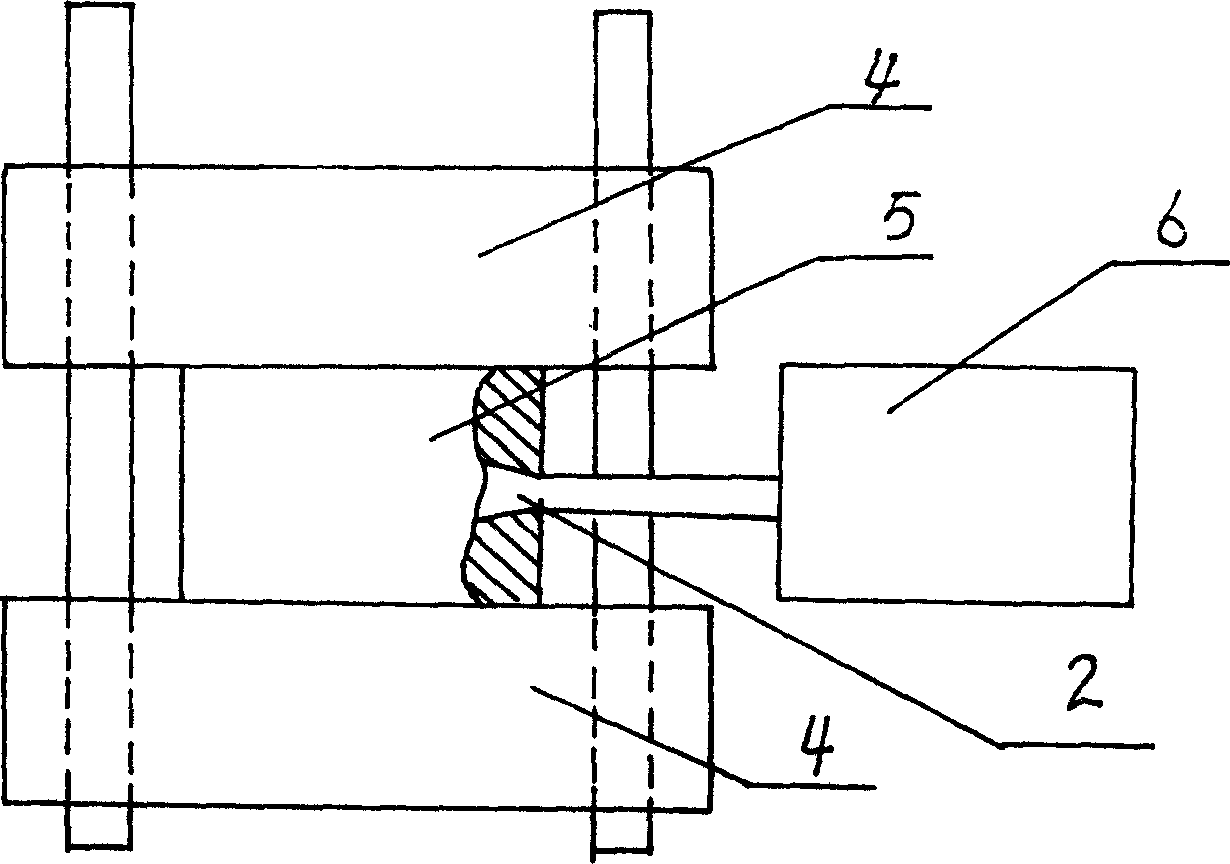

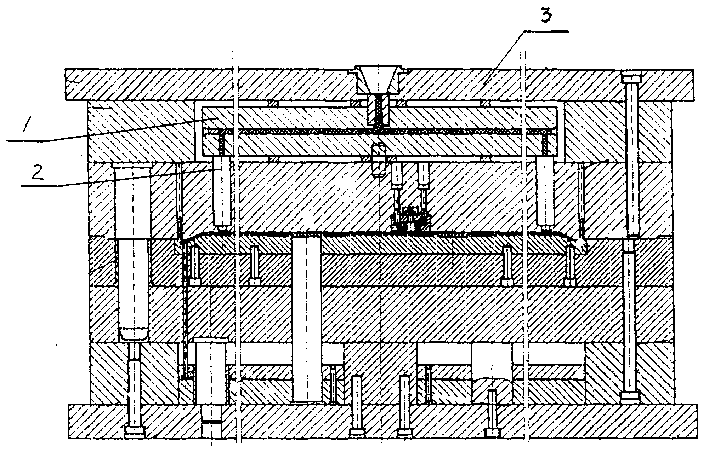

[0014] Embodiment 1: with reference to attached figure 1 . Plastic diaphragm injection molding device for filter press, plastic diaphragm is injection molded by hot runner forming mold, and the hot runner mold is composed of mold and hot runner 1 located in the mould. The making of mold 3 is prior art, and the structure of hot runner can be various; Heat source can be electric heating (as heating wire heating), also can be fluid heating (as steam, water, oil etc. heating) etc.; Heating The way of heating can be external heating, internal heating, or self-heating; but no matter what kind of heating structure, what kind of heating source, what kind of heating method, the temperature can be set at any time according to the needs, and the temperature can be automatically controlled . The setting, detection and automatic control of the temperature are all existing technologies, and will not be described here. The hot runner forming mold is composed of a mold and a hot runner 1, ...

Embodiment 2

[0015] Embodiment 2: On the basis of Embodiment 1, the hot runner 3 is made of conductive heating material (the hot runner material itself has the function of self-heating after electrification, such as heating ceramics, etc.) and the temperature is adjustable.

Embodiment 3

[0016] Example 3: Injection molding process of filter press plastic diaphragm, after the plastic raw material is heated and plasticized by the injection part of the injection molding machine, it is injected into the hot runner in the hot runner forming mold, and then enters the cavity of the plastic diaphragm mold through the heating nozzle for molding and cooling After setting the mold, the mold can be taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com