Thin diaphragm battery and preparing method thereof

A thin-film battery and battery technology, which is applied in the manufacture of secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of poor bending performance of aluminum foil, easy breakage of pole ears, and difficulty in ultra-thin batteries. The method is simple, the conductivity is enhanced, and the effect of preventing liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

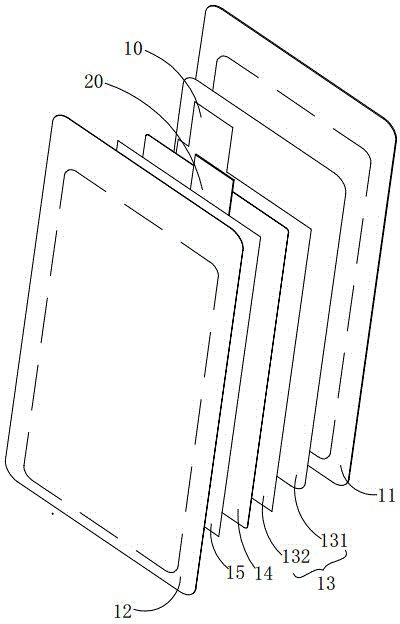

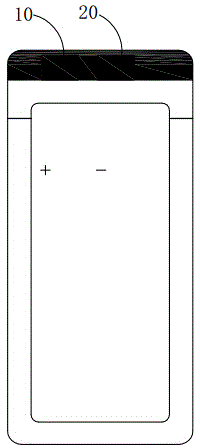

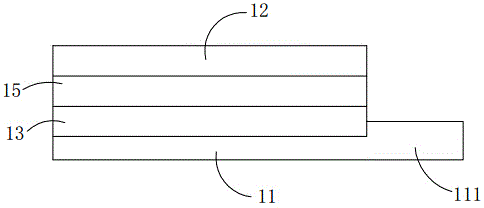

[0040] The thin film battery of the present invention and its preparation method will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0041] Such as Figure 1 to Figure 3 As shown, in a preferred embodiment, the thin film battery of the present invention only includes one cell. The cell includes a positive electrode sheet 13 , a separator 14 and a negative electrode sheet 15 . Among them, the positive electrode sheet 13, the separator 14 and the negative electrode sheet 15 are all in the shape of a rectangular sheet. After the three are stacked in sequence, they are packaged from the outside with the first outer packaging film 11 and the second outer packaging film 12, leaving only a small opening, and then passing through the The opening is filled with electrolyte and then vacuum-packed. The first outer packaging film 11 is disposed on the side of the positive electrode sheet 13 of the electric core, and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com