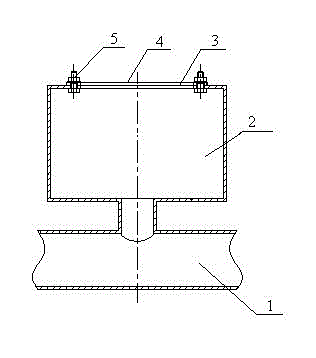

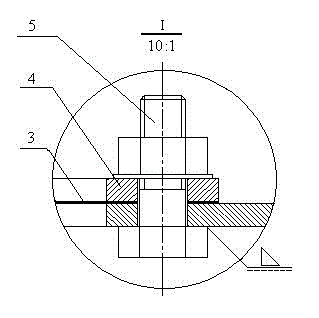

Single-cavity multi-resonant-frequency lateral-support resonant muffler

A technology of resonant frequency and resonator, applied in the direction of intake muffler, etc., can solve the problems of difficult layout of muffler cabin and narrow muffler frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The main pipe of the muffler is installed on the main pipe of the engine intake. When the sound wave from the engine cylinder propagates in the main pipe and reaches the intersection of the resonator inlet and the main pipe, due to the sudden change of the acoustic impedance, part of the sound energy is reflected back and part of the sound energy is transmitted. In the small hole and the resonator, due to the loss of sound resistance, sound quality and sound volume of the resonator, part of the energy is consumed, and only part of the sound energy continues to propagate along the pipe, so as to achieve the purpose of noise reduction. Especially when the frequency of the sound wave is close to or equal to the natural frequency of the resonator, resonance will be excited, and the resonator absorbs and consumes a large amount of sound energy. At this time, the noise reduction effect is the most significant. Since the wall of the resonator is a diaphragm with a small thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com