Patents

Literature

69results about How to "Reduce cavity volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

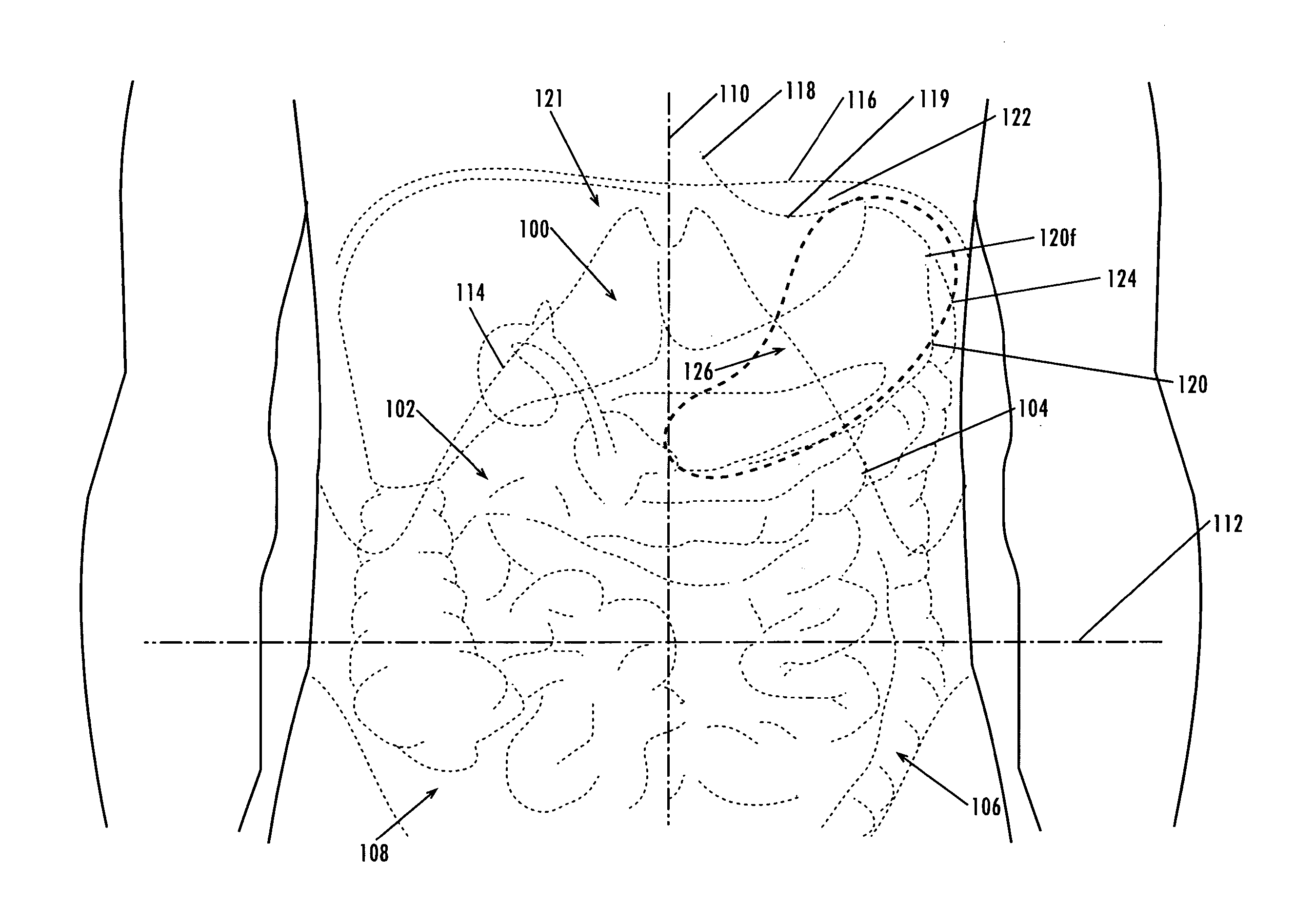

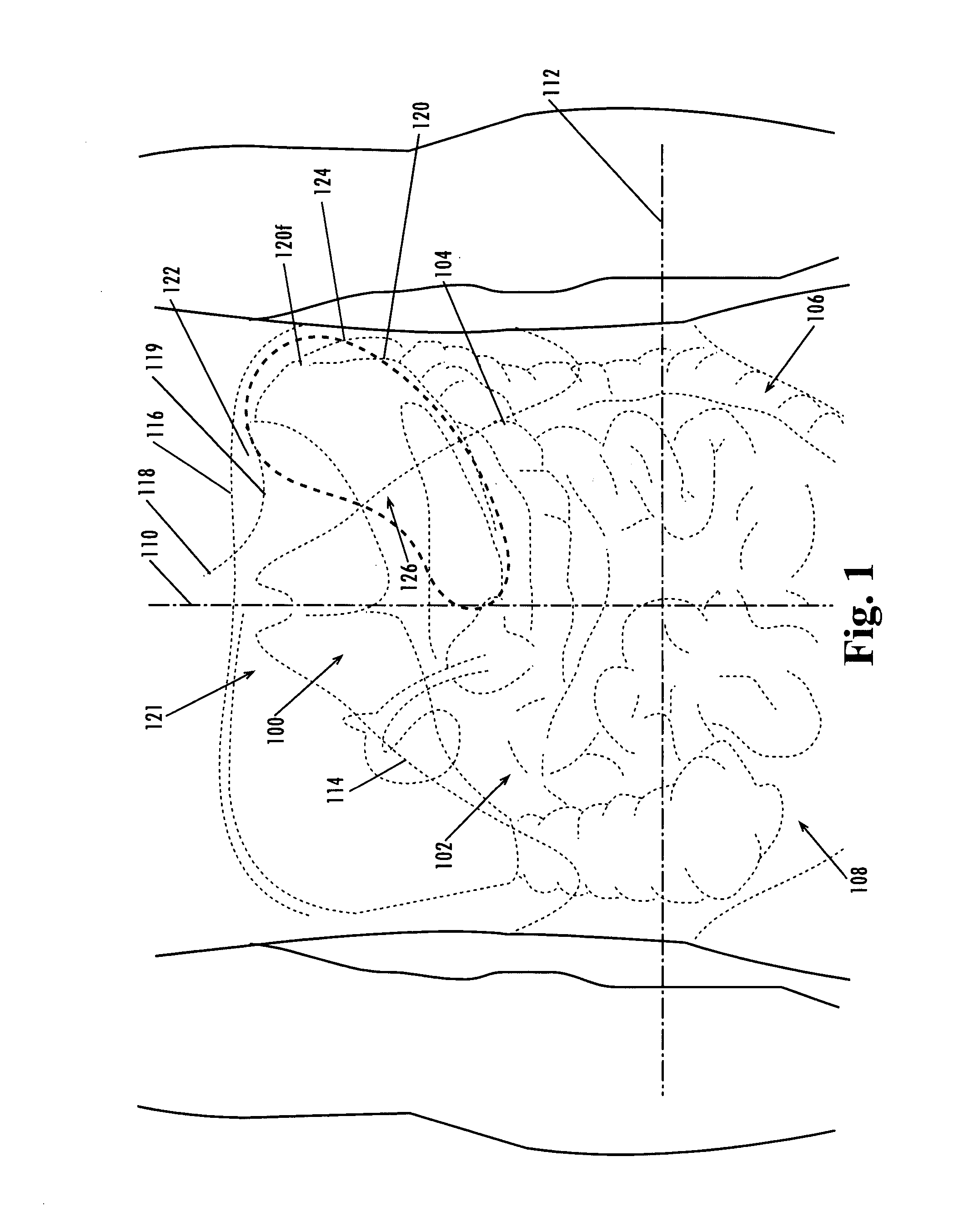

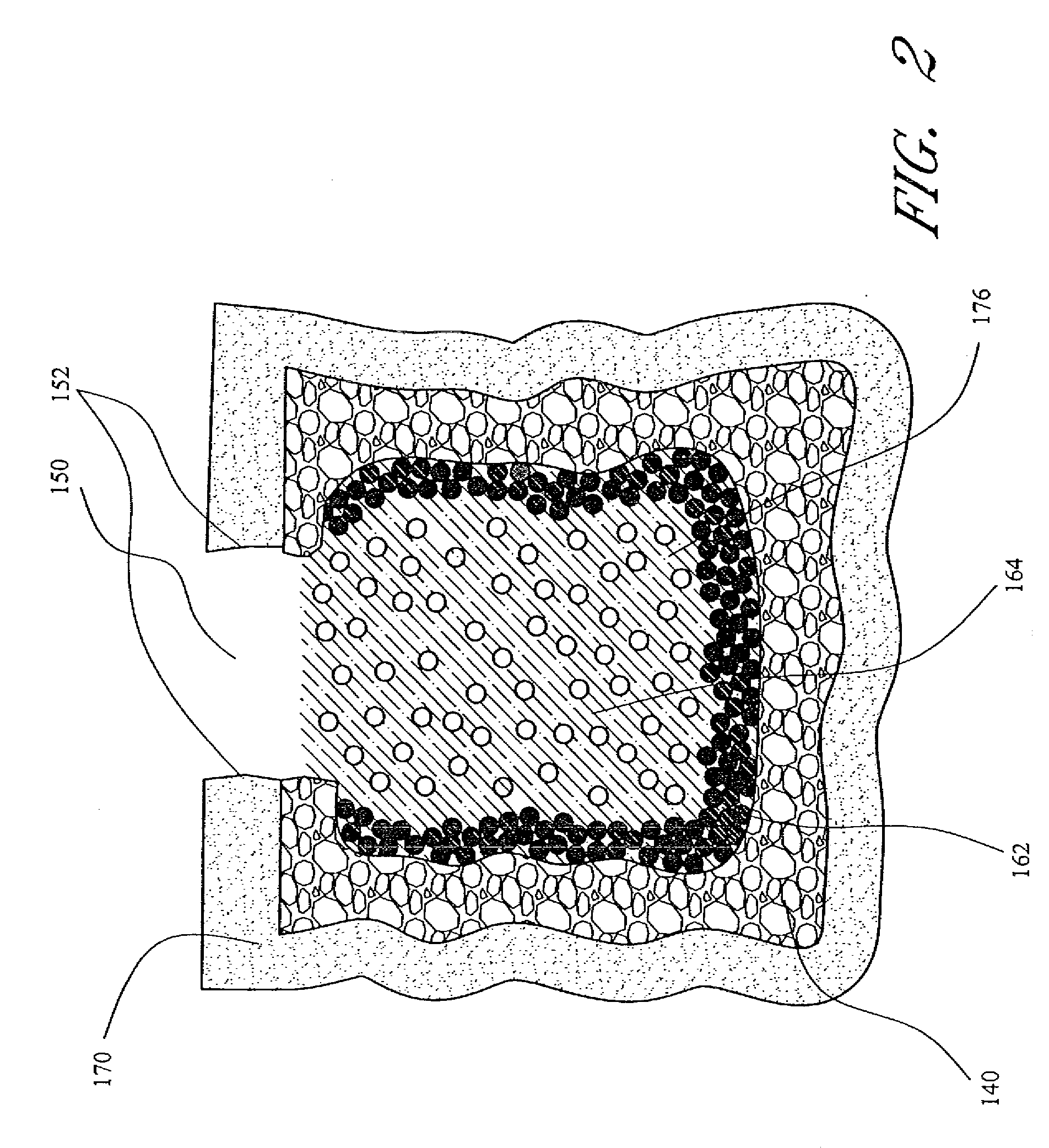

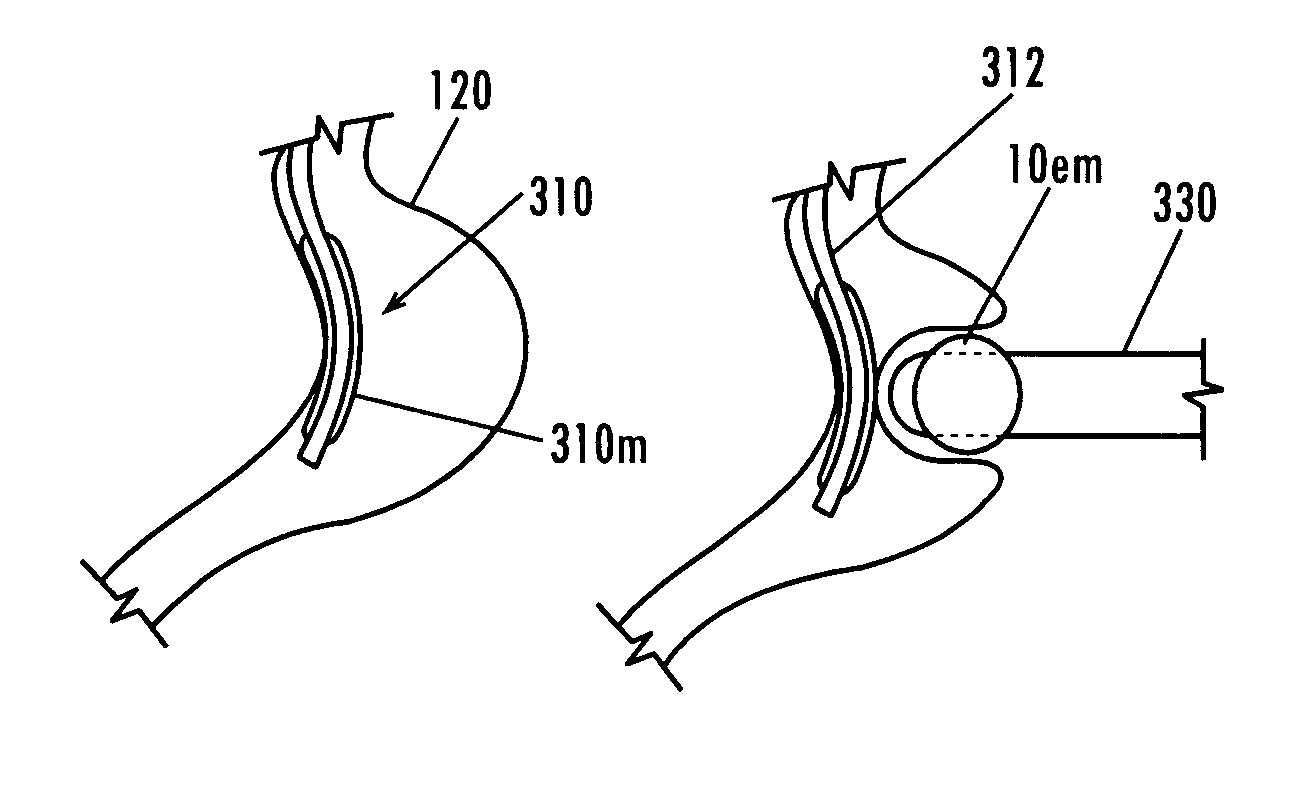

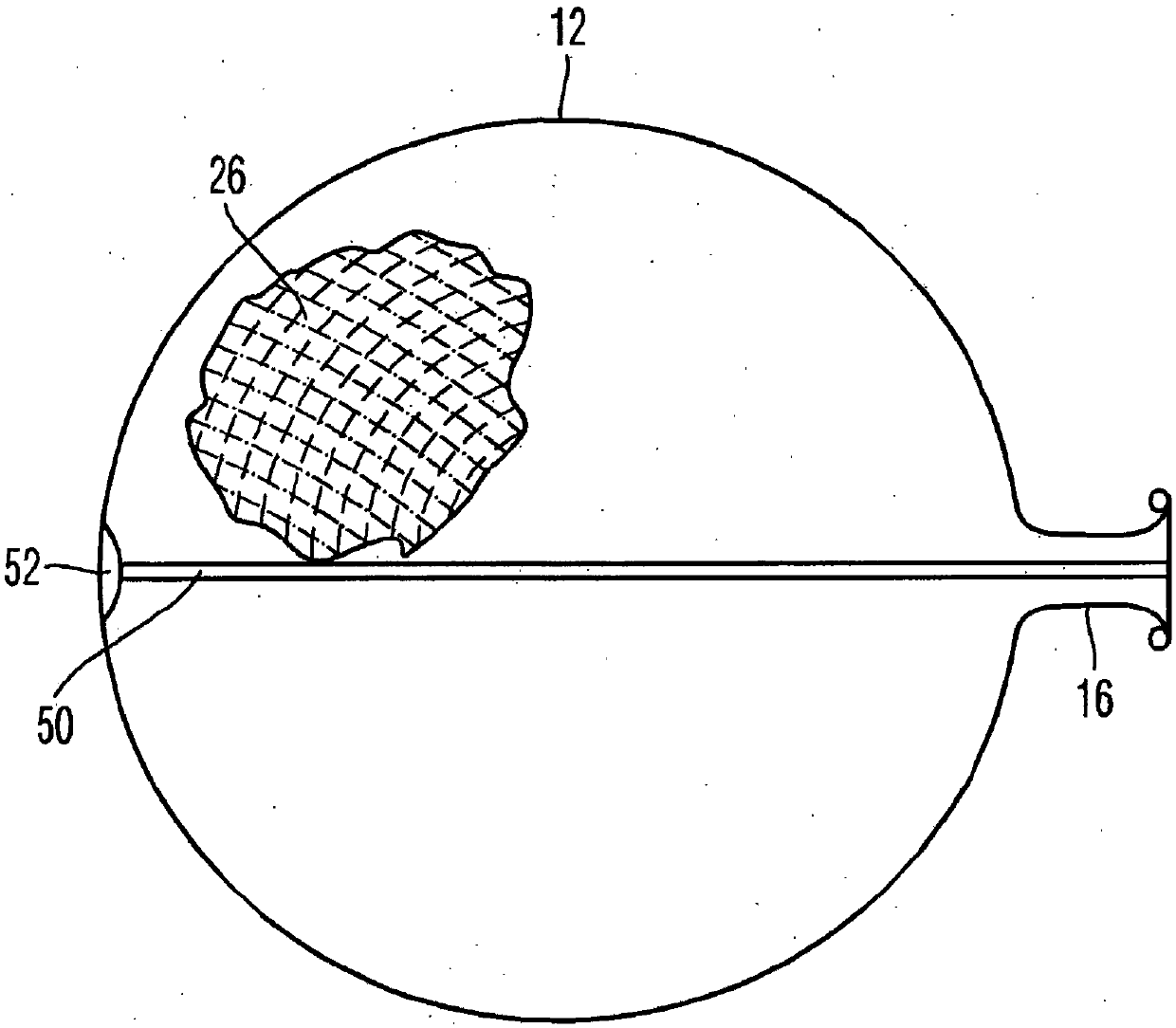

Devices and methods for treatment of obesity

ActiveUS20080051823A1Reduce cavity volumeDecrease total lumenDiagnosticsDilatorsPERITONEOSCOPEObesity

Devices, methods for treatment of obesity, as well as instruments and tools used in placing, adjusting and maintaining devices for treatment of obesity. Various embodiments of devices that are implanted extra-gastrically are provided. Various embodiments of devices that are implanted intra-gastrically are provided. Methods include laparoscopic, percutaneous and / or trans-oral methods. Alternatively, devices describe can generally also be implanted by open surgical procedures.

Owner:VIBRYNT

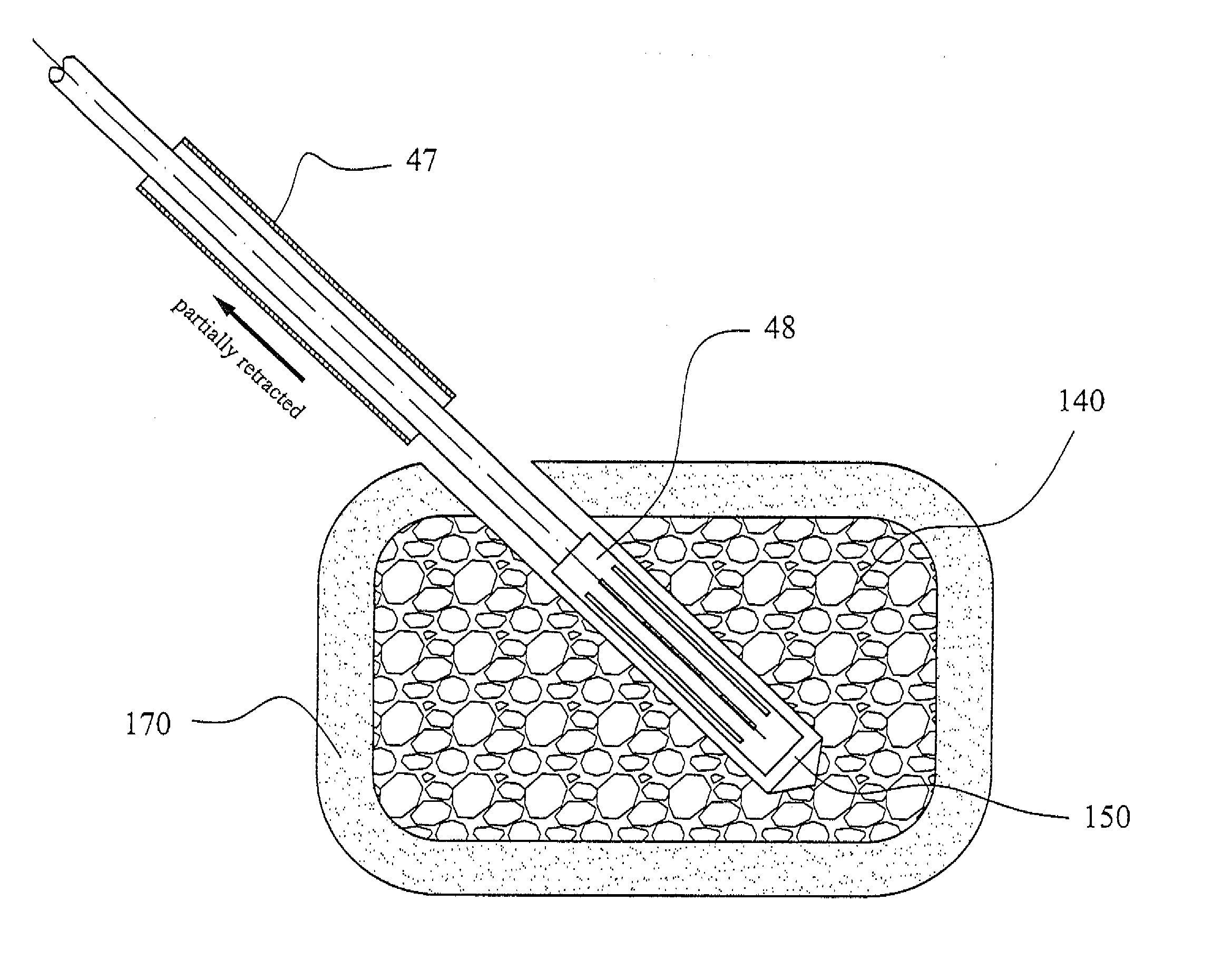

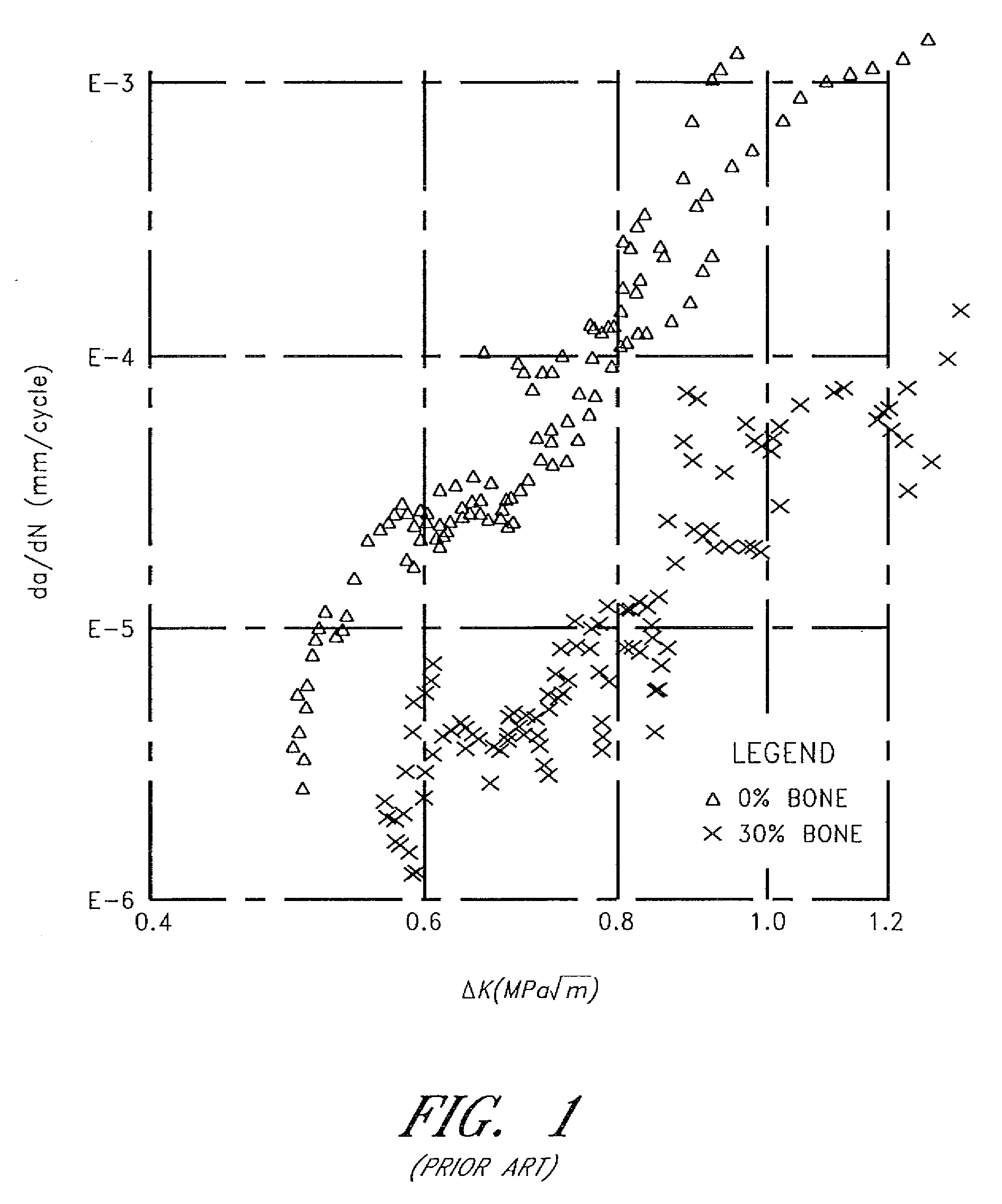

Vertebroplasty methods with optimized shear strength and crack propagation resistance

InactiveUS20080195112A1Reduce cavity volumeImpression capsSurgical adhesivesNatural boneControl manner

Owner:LIU Y KING +3

Devices and methods for treatment of obesity

Devices, methods for treatment of obesity, as well as instruments and tools used in placing, adjusting and maintaining devices for treatment of obesity. Various embodiments of devices that are implanted extra-gastrically are provided. Various embodiments of devices that are implanted intra-gastrically are provided. Methods include laparoscopic, percutaneous and / or trans-oral methods. Alternatively, devices describe can generally also be implanted by open surgical procedures.

Owner:VIBRYNT

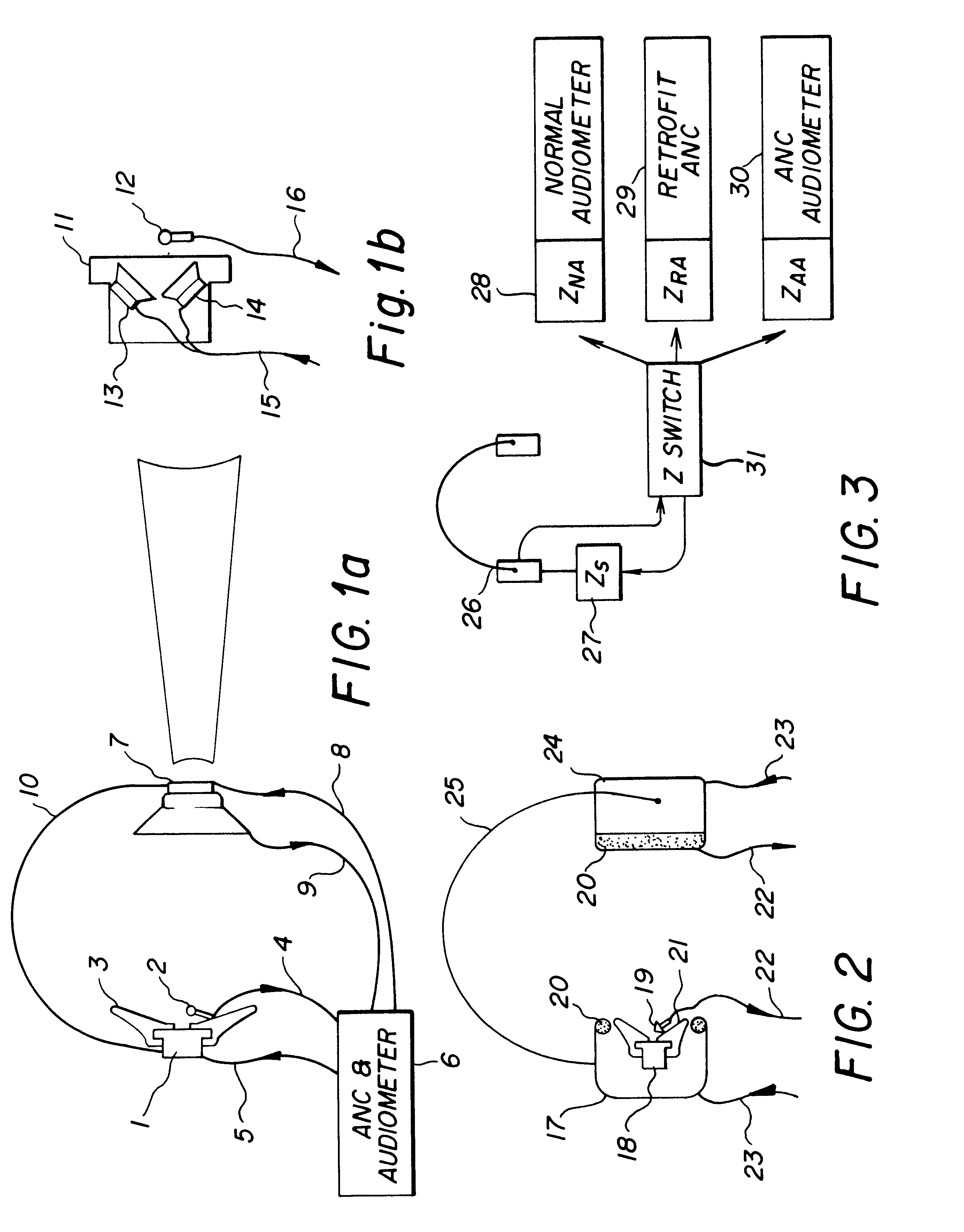

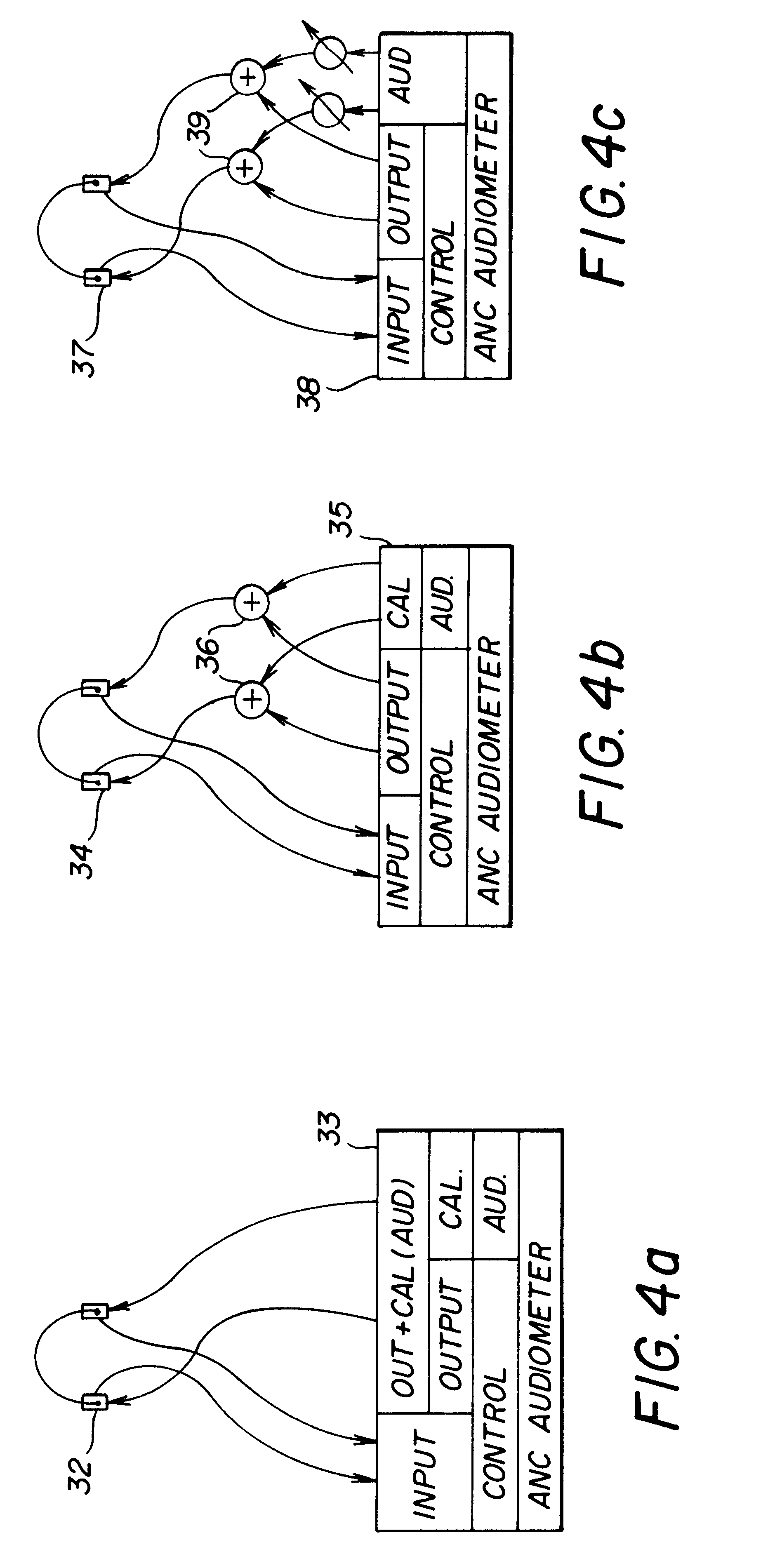

Active noise reduction audiometric headphones

InactiveUS6532296B1Reduce cavity volumeReduce the cushioning forceEar treatmentAudiometeringNoise controlAudiometry test

Active noise reduction headphones for audiometry where the earphone portion of said headphones has a cavity volume greater than 6 cc and including an acoustic-electric sensing means and an electro-acoustic transducing means which are used cooperatively and which has additional passive noise control means in the form of a circumaural seal around the ear for improving high frequency noise control performance, the headphone having a summing junction for combining the active noise reduction signal and an audiometry test signal.

Owner:GENTEX CORP

Apparatus for filling a sample volume defining device

ActiveUS20060228263A1Easily deforms permanentlyReduce cavity volumeAnalysis using chemical indicatorsDispensing apparatusPhysicsSample volume

An apparatus for filling a sample volume defining device for separating at least one small defined volume of a liquid sample from a relatively larger undefined volume of said sample, said device including a first body and a second body movable relative to each other, whereby said first body has at least one cavity in a surface thereof, said at least one cavity having said defined volume. One of said first or said second body has at least one inlet opening adapted to be placed in a drop of the liquid sample. A defined channel is provided between said first and second body, which channel has fluid connection with said at least one opening and at least beyond said at least one cavity whereby the dimensions of said channel being such that said channel and said at least one cavity is filled with said liquid sample.

Owner:BOULA MEDICAL AB

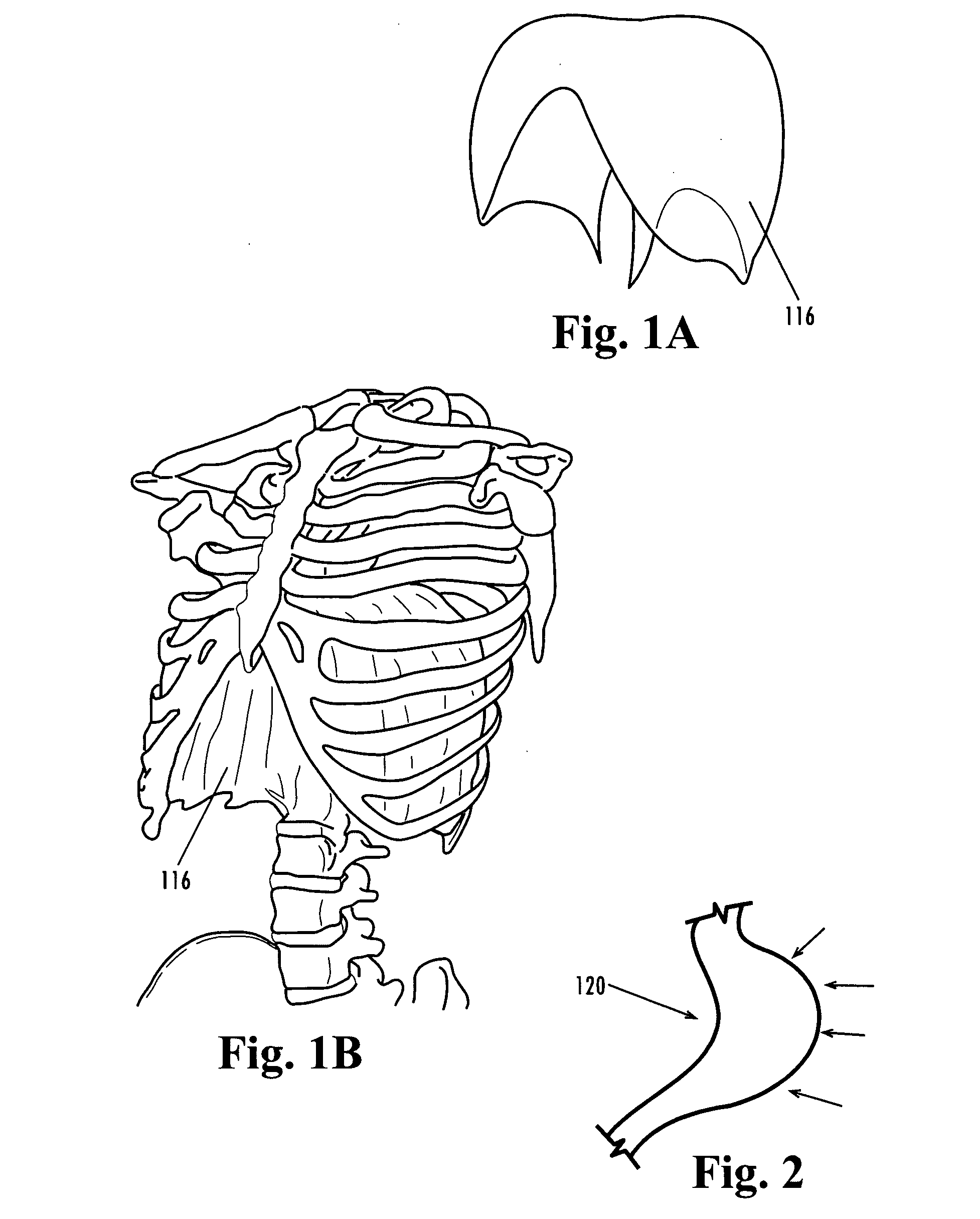

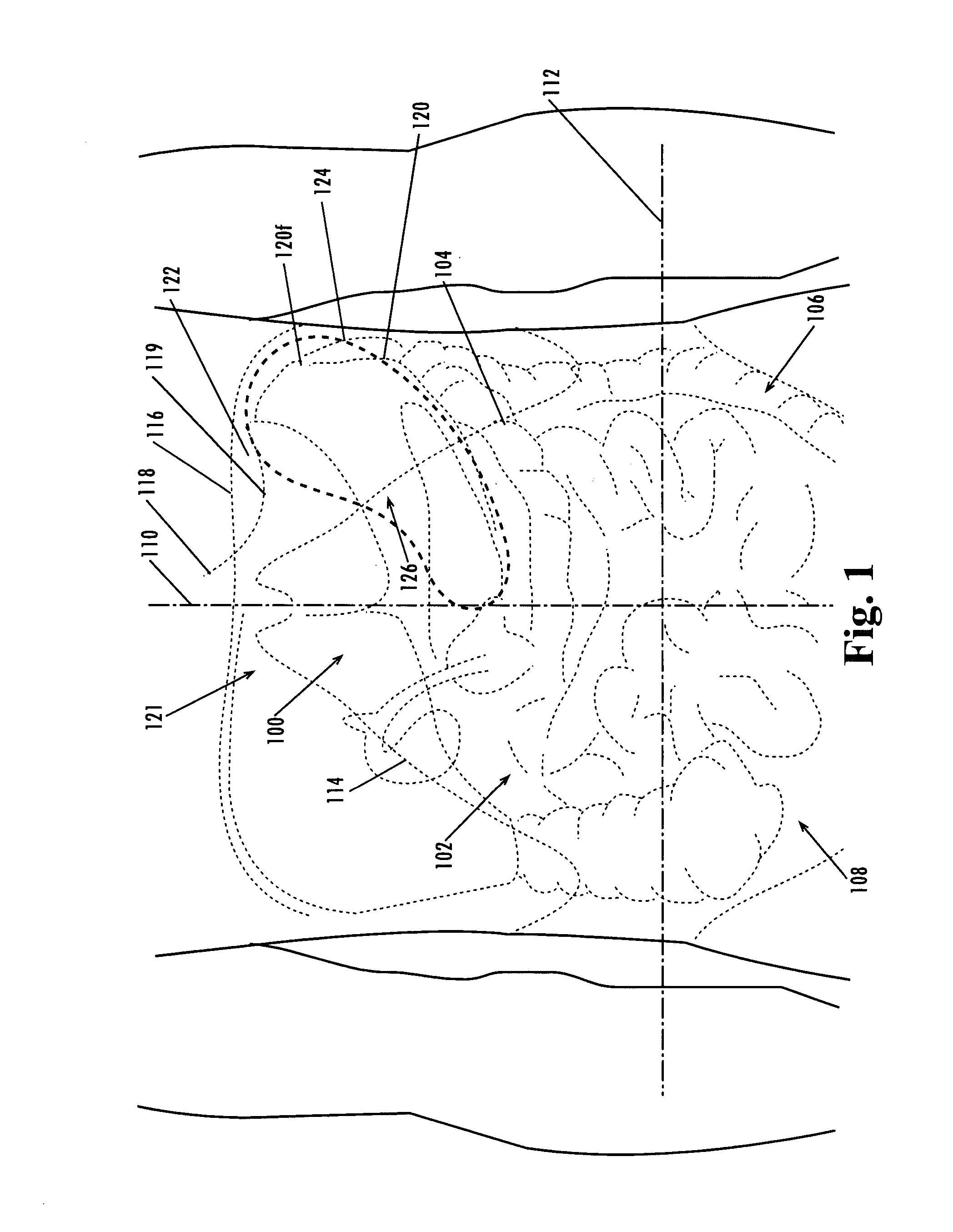

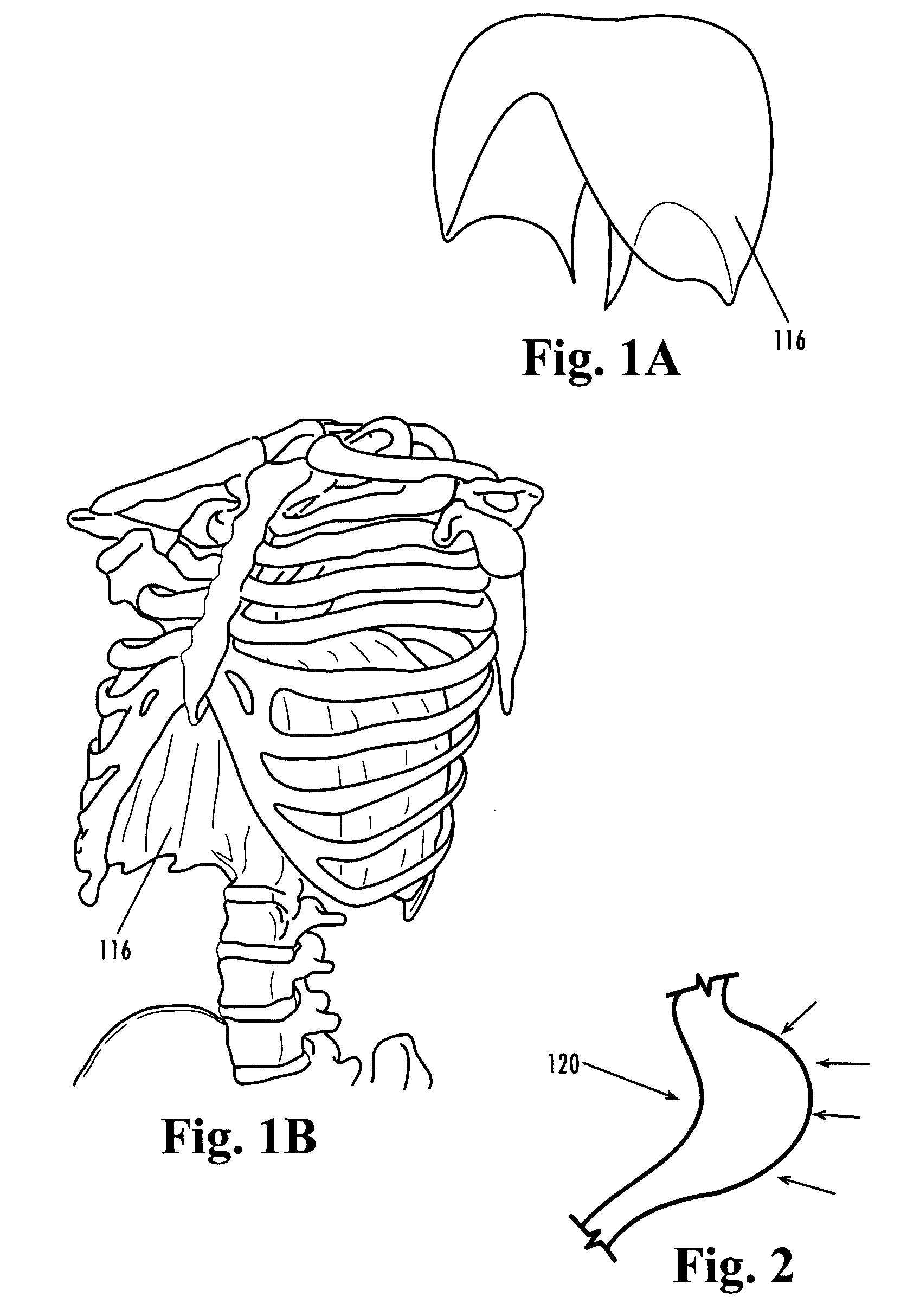

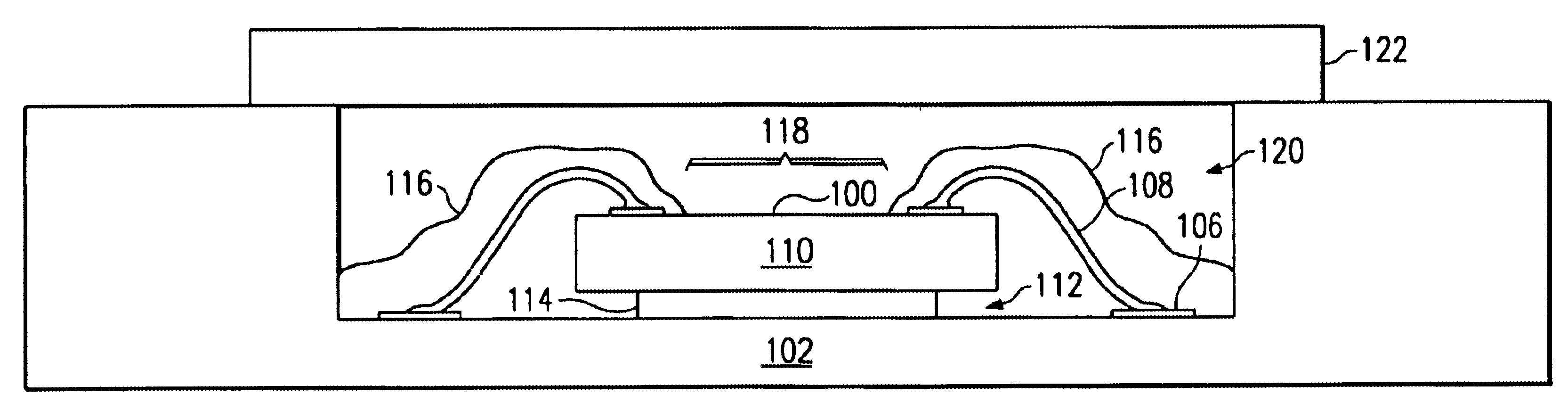

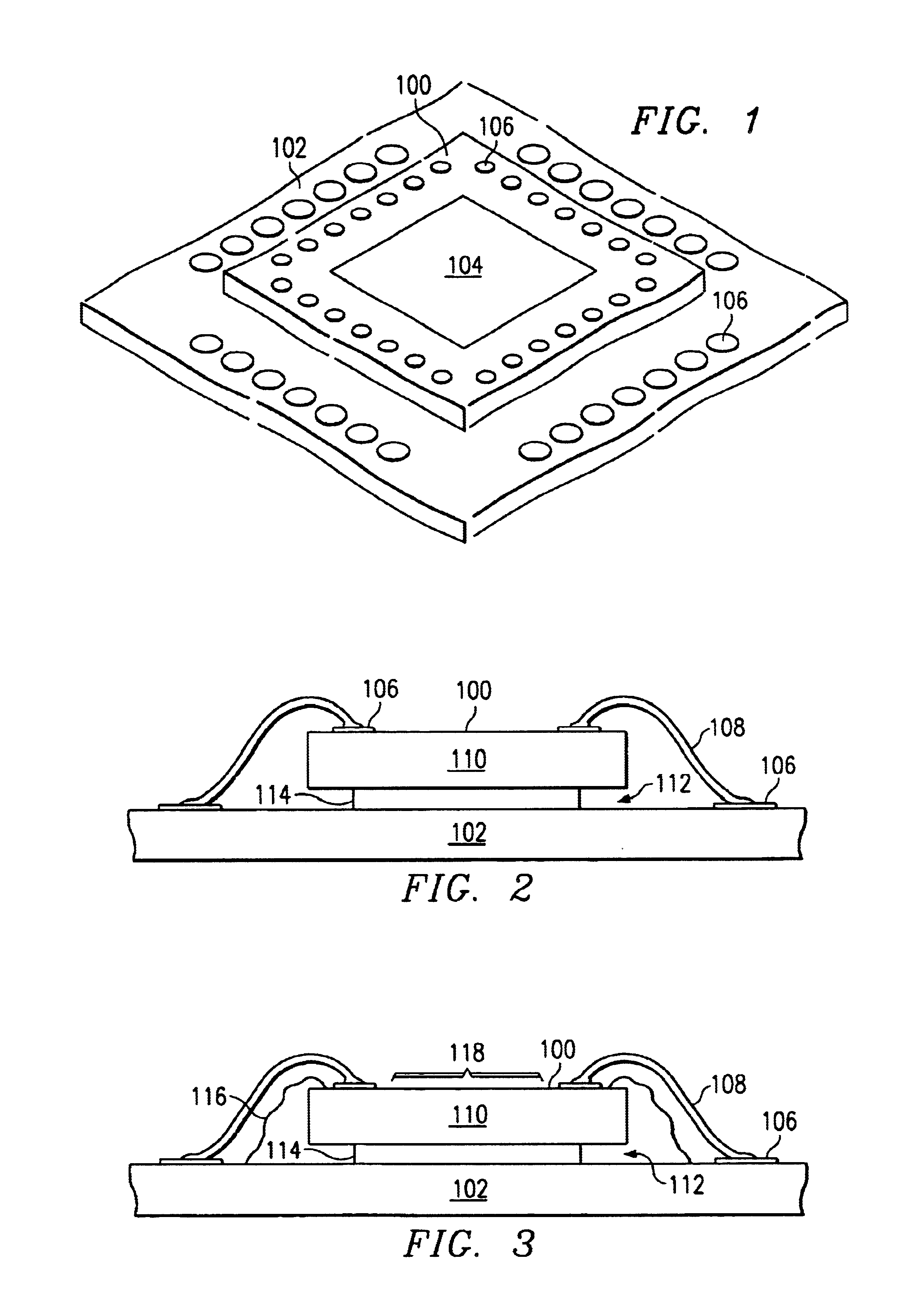

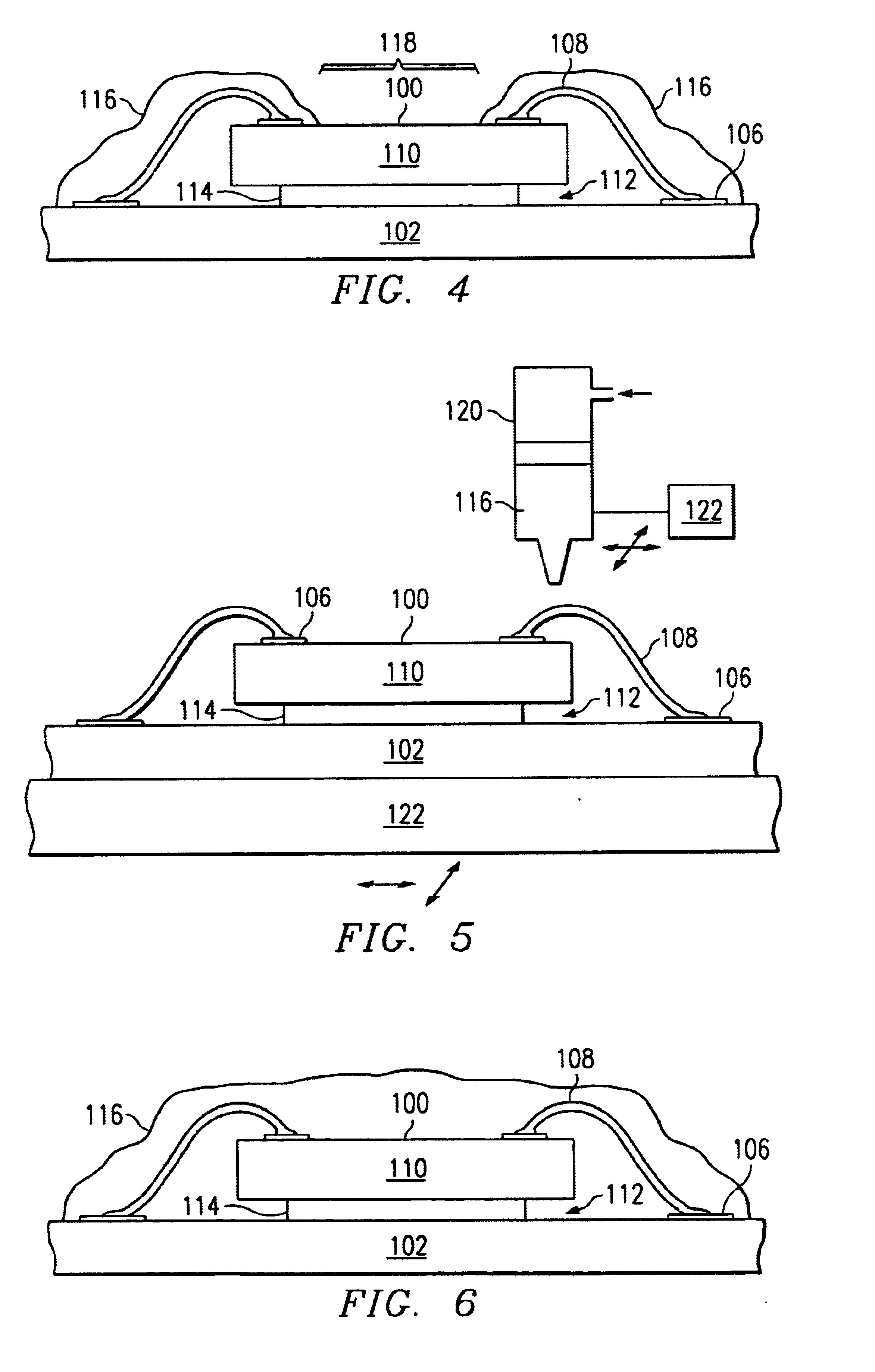

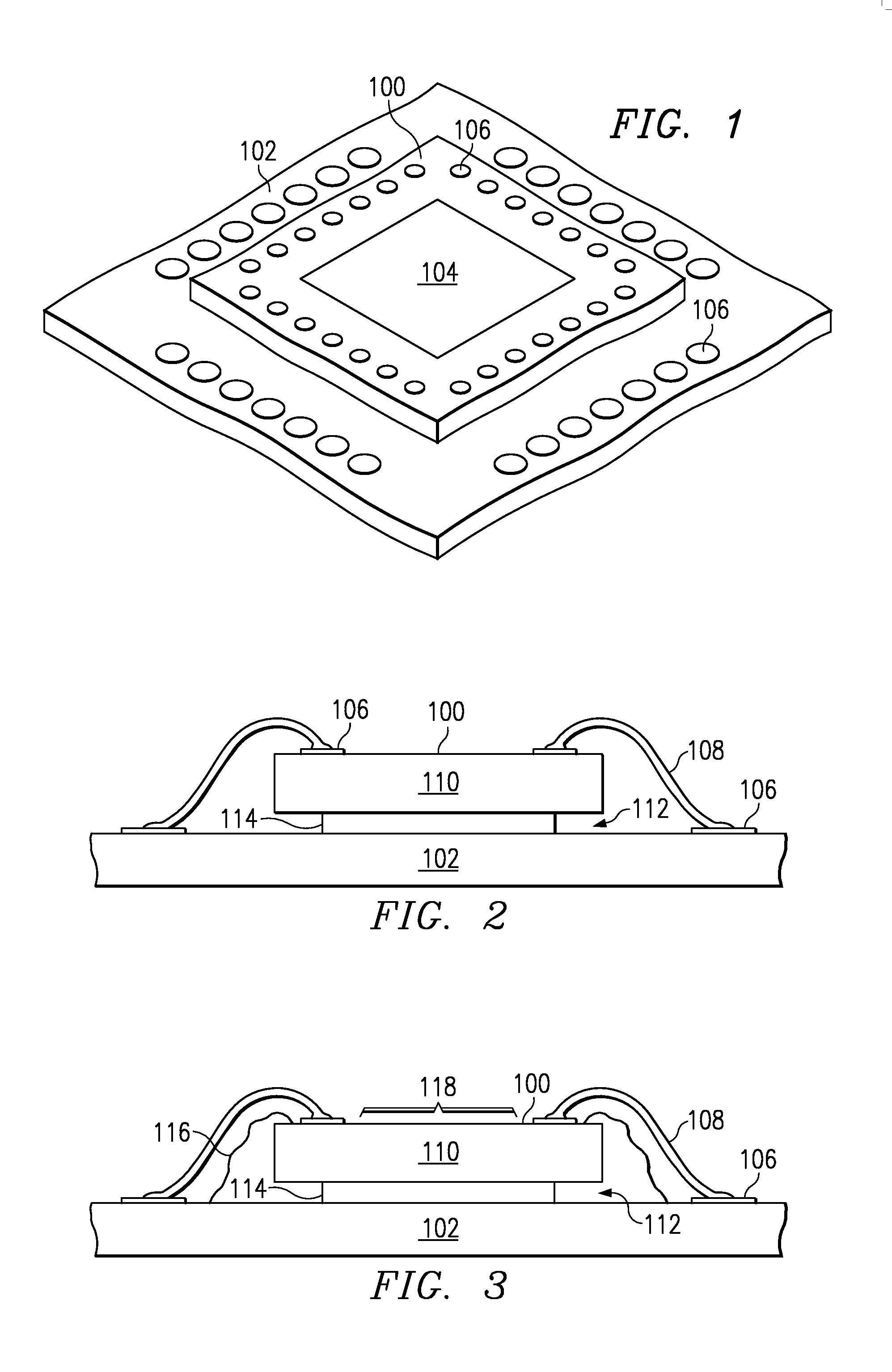

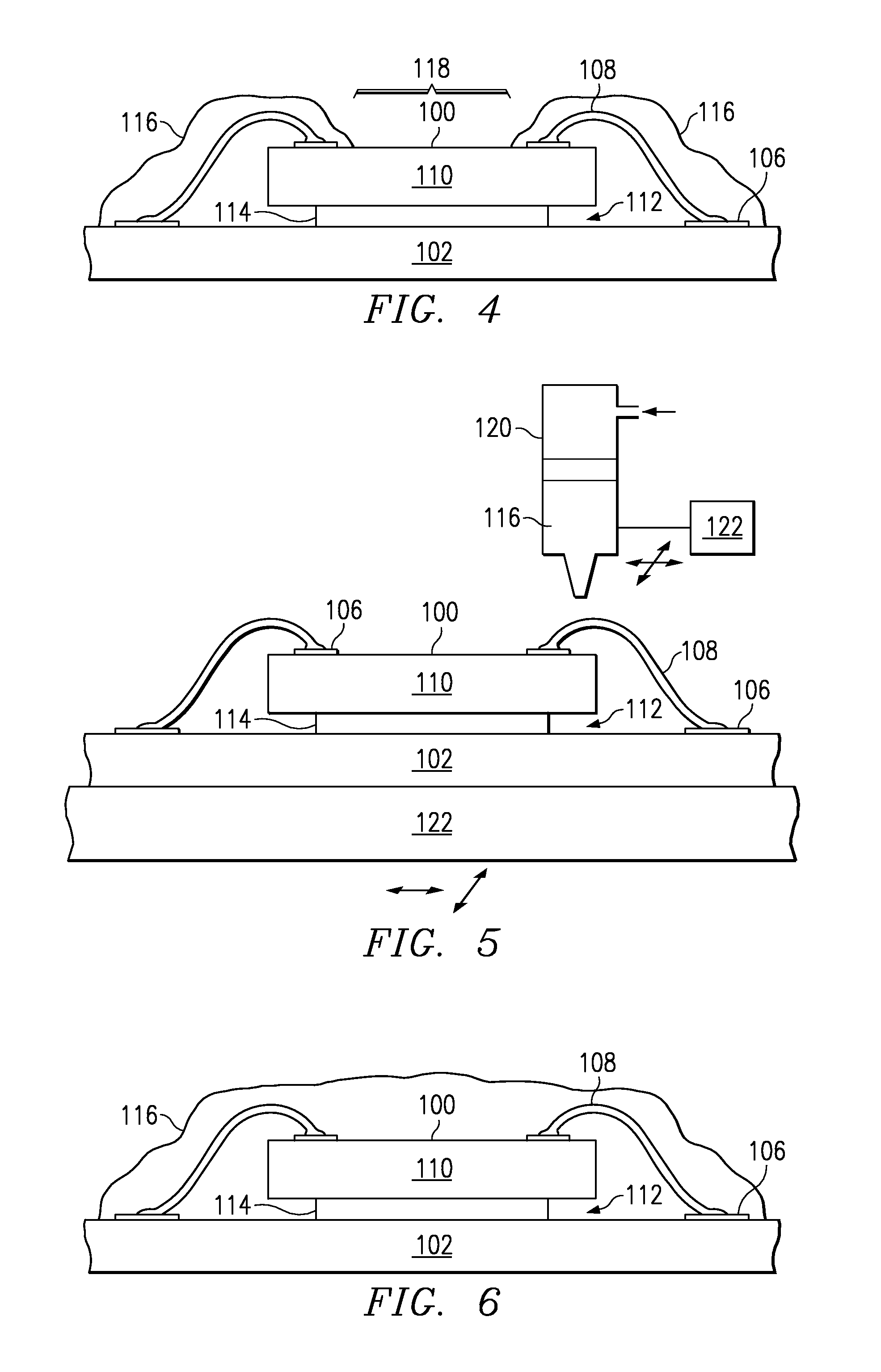

Encapsulation for particle entrapment

InactiveUS6841412B1Reduce volume of cavityReduce effectSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringElectrical connection

A packaged micromechanical device (100) having a blocking material (116) encapsulating debris-generating regions thereof. The blocking material (116) prevents the generation of debris that could interfere with the operation of the micromechanical device (100). Debris-generating regions of the device (100), including debris-creating sidewalls and any debris-harboring cavities, as well as electrical connections (108) linking the device (100) to the package substrate (102) are encapsulated by the blocking material (116). The blocking material (116) avoids contact with any debris-intolerant regions (118) of the device (100). A package lid (122), which is glass in the case of many DMD packages, seals the device (100) in a package cavity (120).

Owner:TEXAS INSTR INC

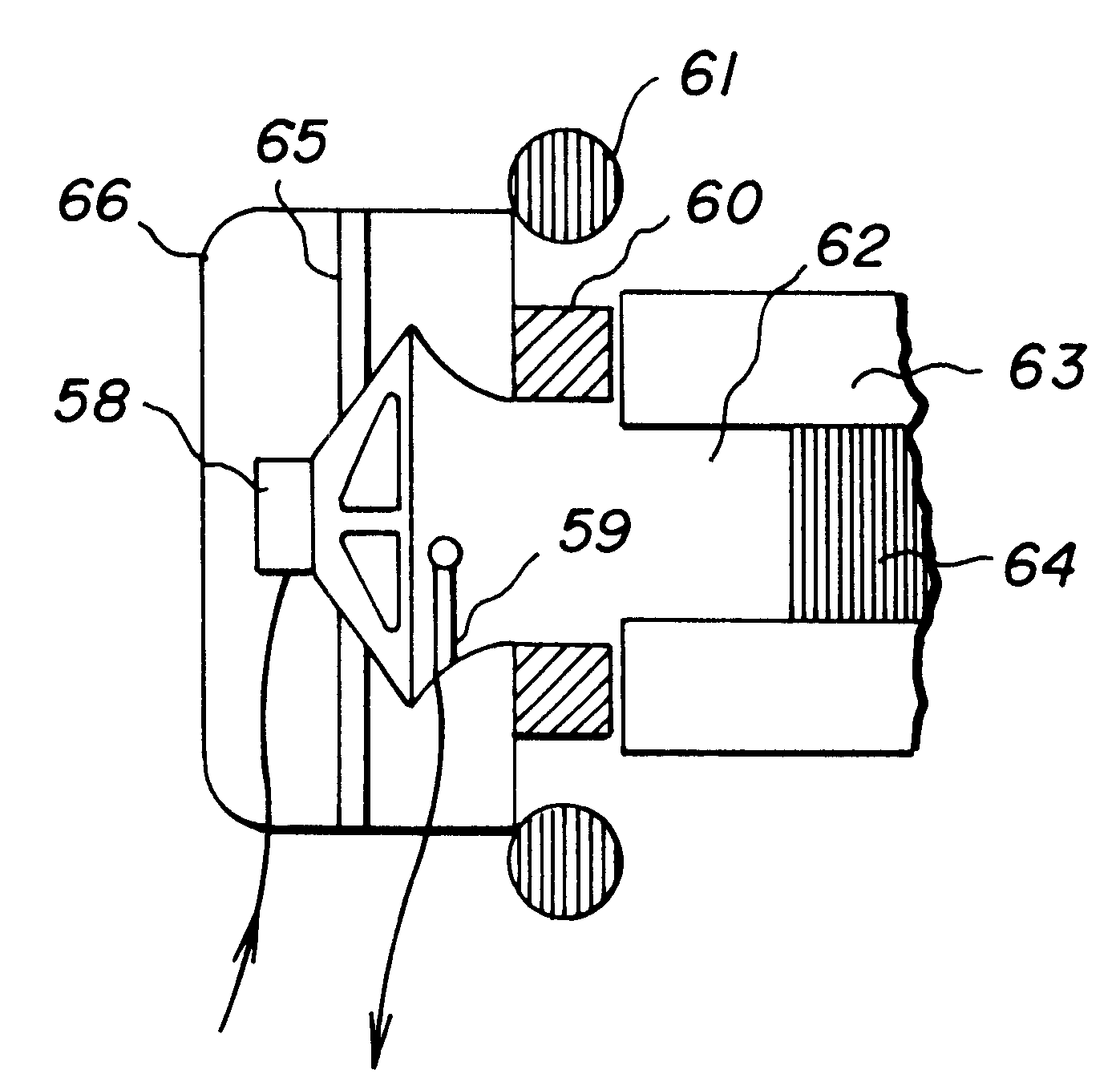

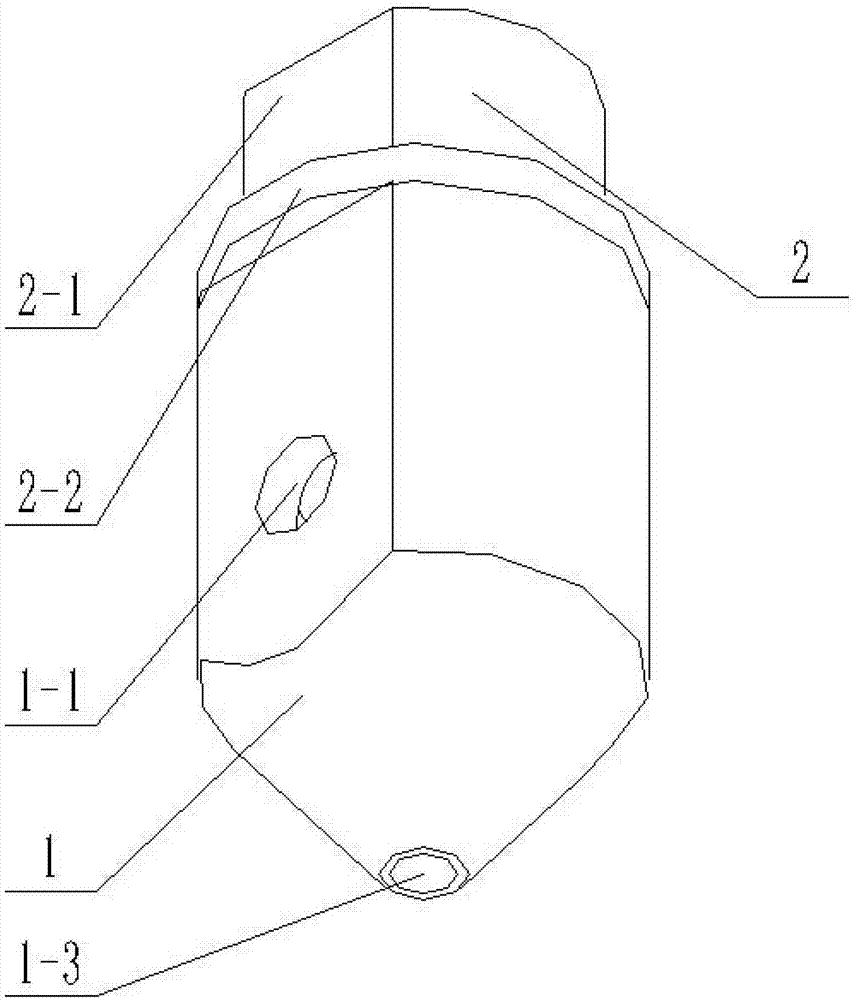

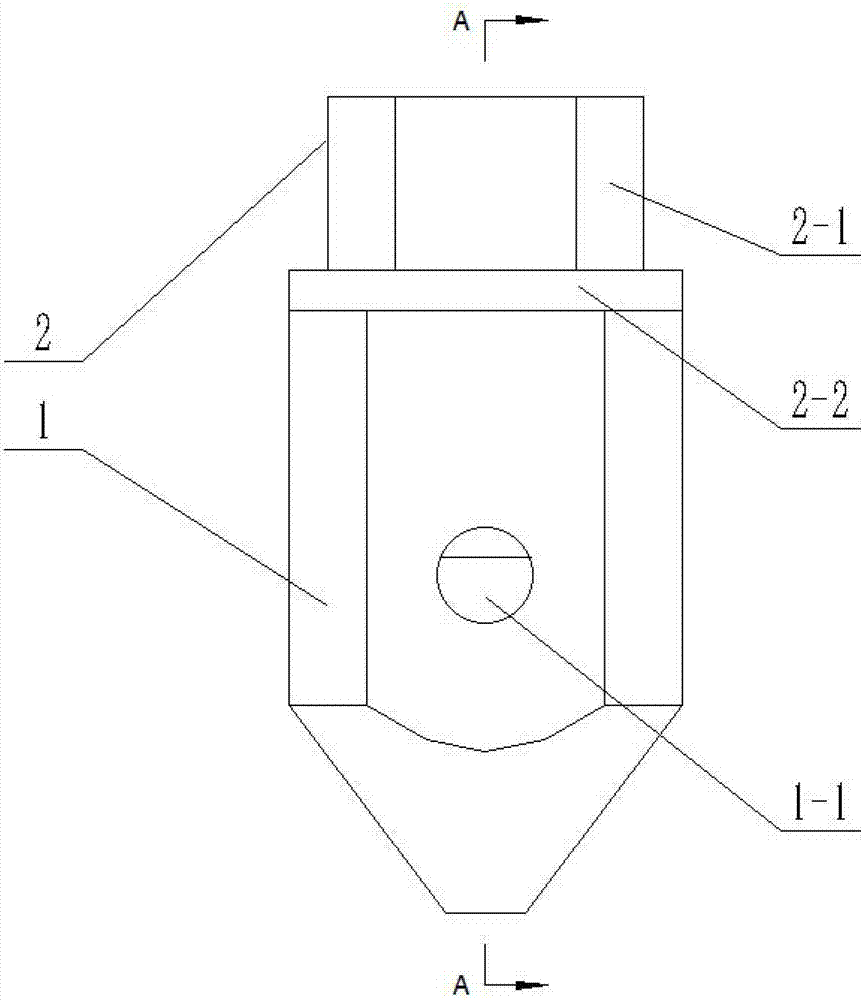

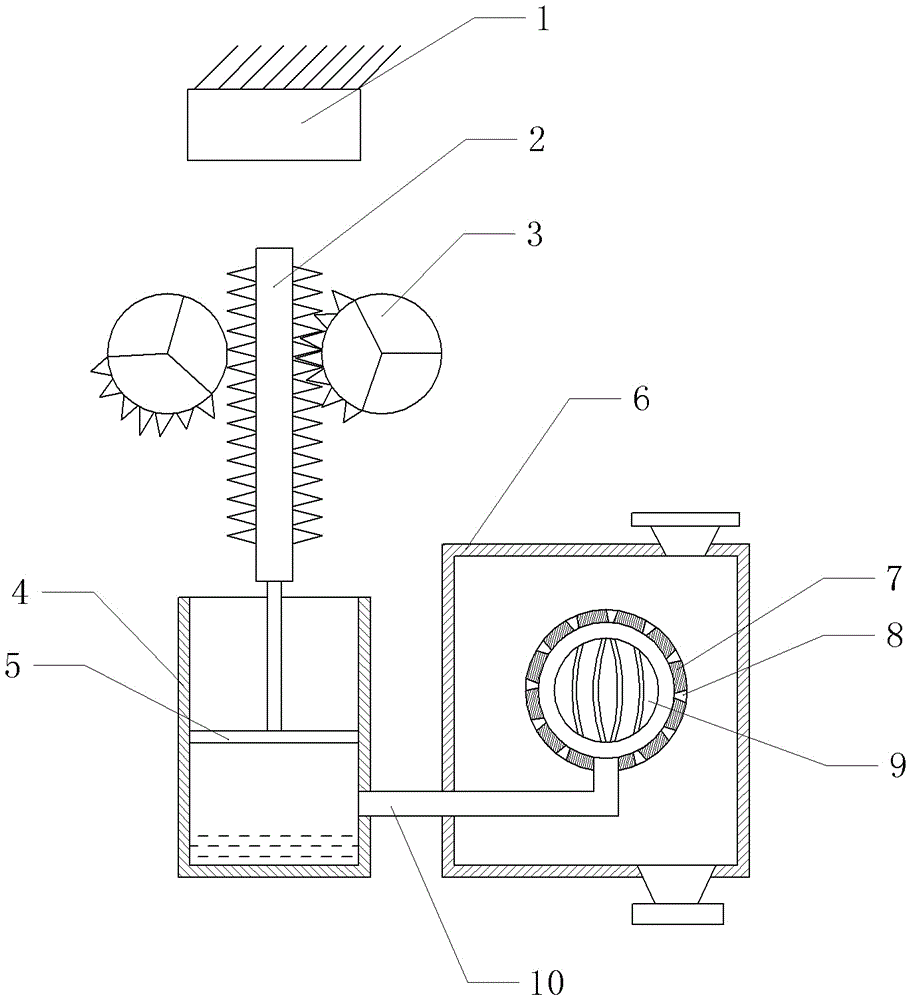

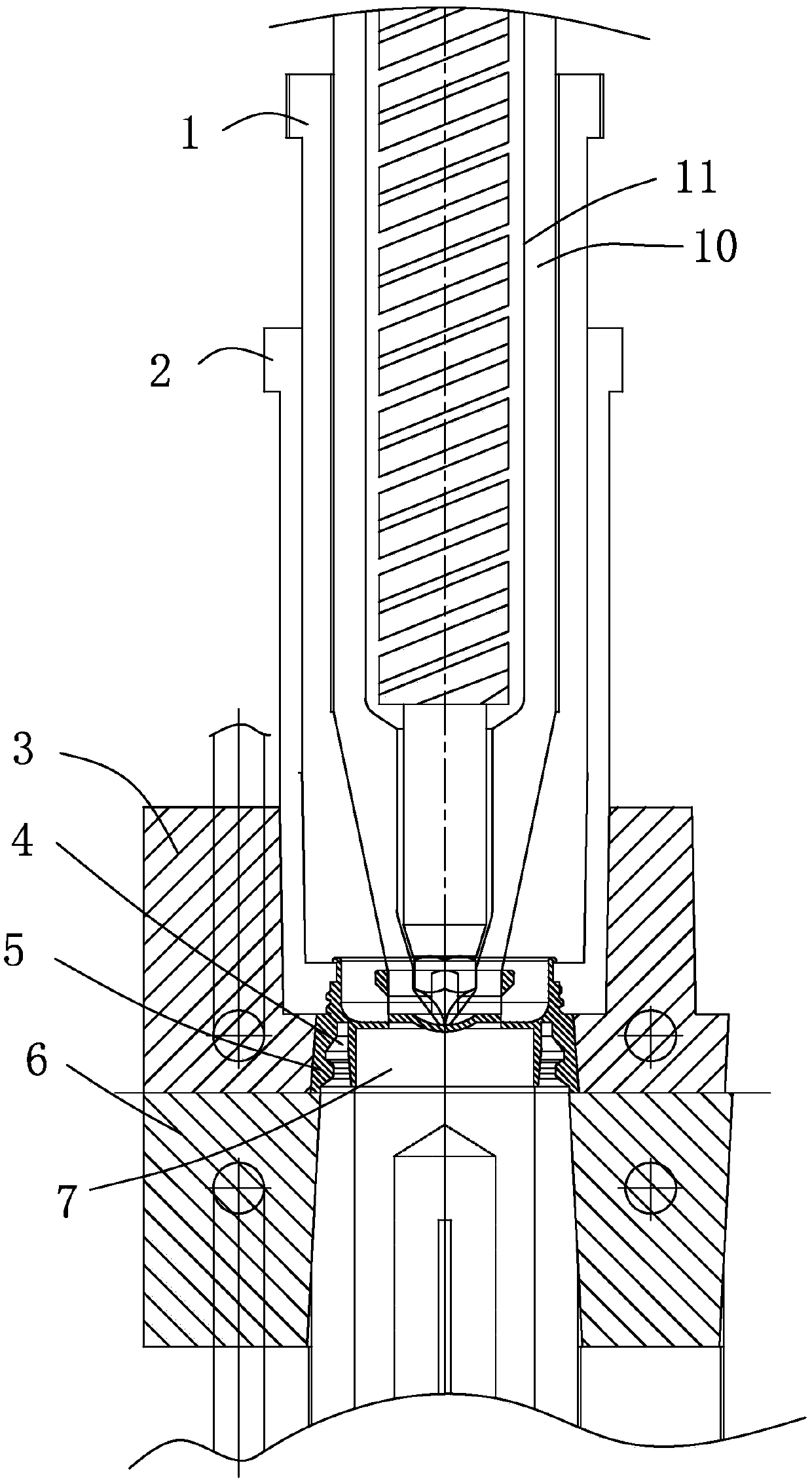

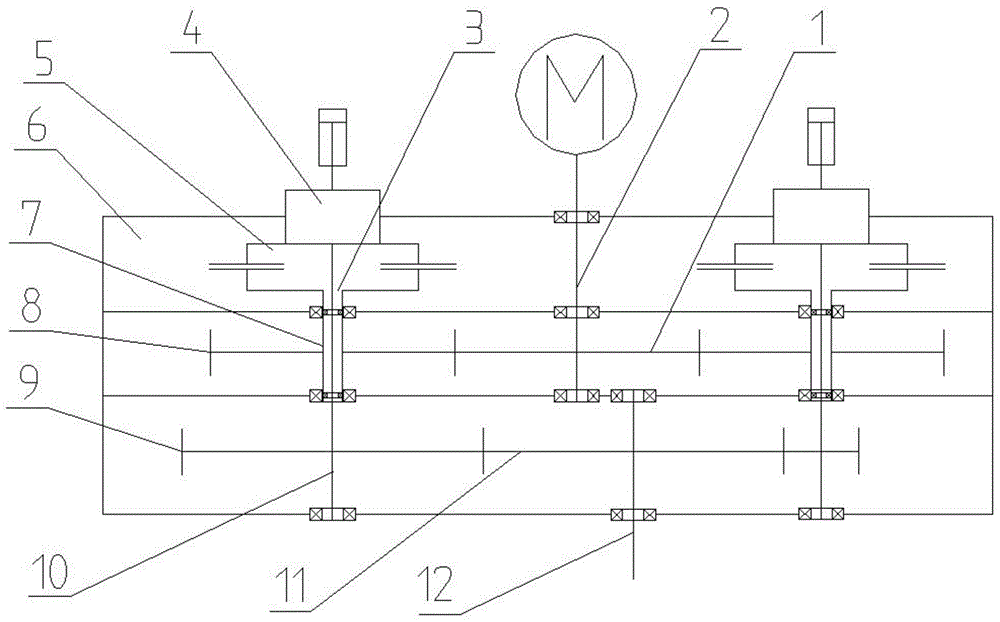

Additive manufacturing apparatus of continuous fiber reinforced composite material

ActiveCN107139459ASmall diameterSmall size3D object support structuresApplying layer meansTemperature monitoringFiber-reinforced composite

The invention discloses an additive manufacturing apparatus of a continuous fiber reinforced composite material. The apparatus has a simple nozzle structure and smaller dimension, and can improve moulding precision; a vertical distance between an outlet of an internal nozzle and an outlet of an external nozzle is adjustable, in order to control centering of the fiber composite material, and improve moulding quality. An additive manufacturing nozzle of the continuous fiber reinforced composite material is installed on a two-dimensional moving platform, a workbench is arranged below the additive manufacturing nozzle of the continuous fiber reinforced composite material, and the workbench is installed on a one-dimensional moving platform; a filament extruding mechanism, a heating device and a temperature monitoring device are installed on the additive manufacturing nozzle of the continuous fiber reinforced composite material and follows motion of the two-dimensional moving platform; the heating device is used for heating the additive manufacturing nozzle of the continuous fiber reinforced composite material; a temperature monitoring device is used for measuring the temperature of the additive manufacturing nozzle of the continuous fiber reinforced composite material; a controlling means is used for controlling the working states of the two-dimensional moving platform, the one-dimensional moving platform, the filament extruding mechanism, the heating device, and the temperature monitoring device.

Owner:陕西众德科创科技有限责任公司

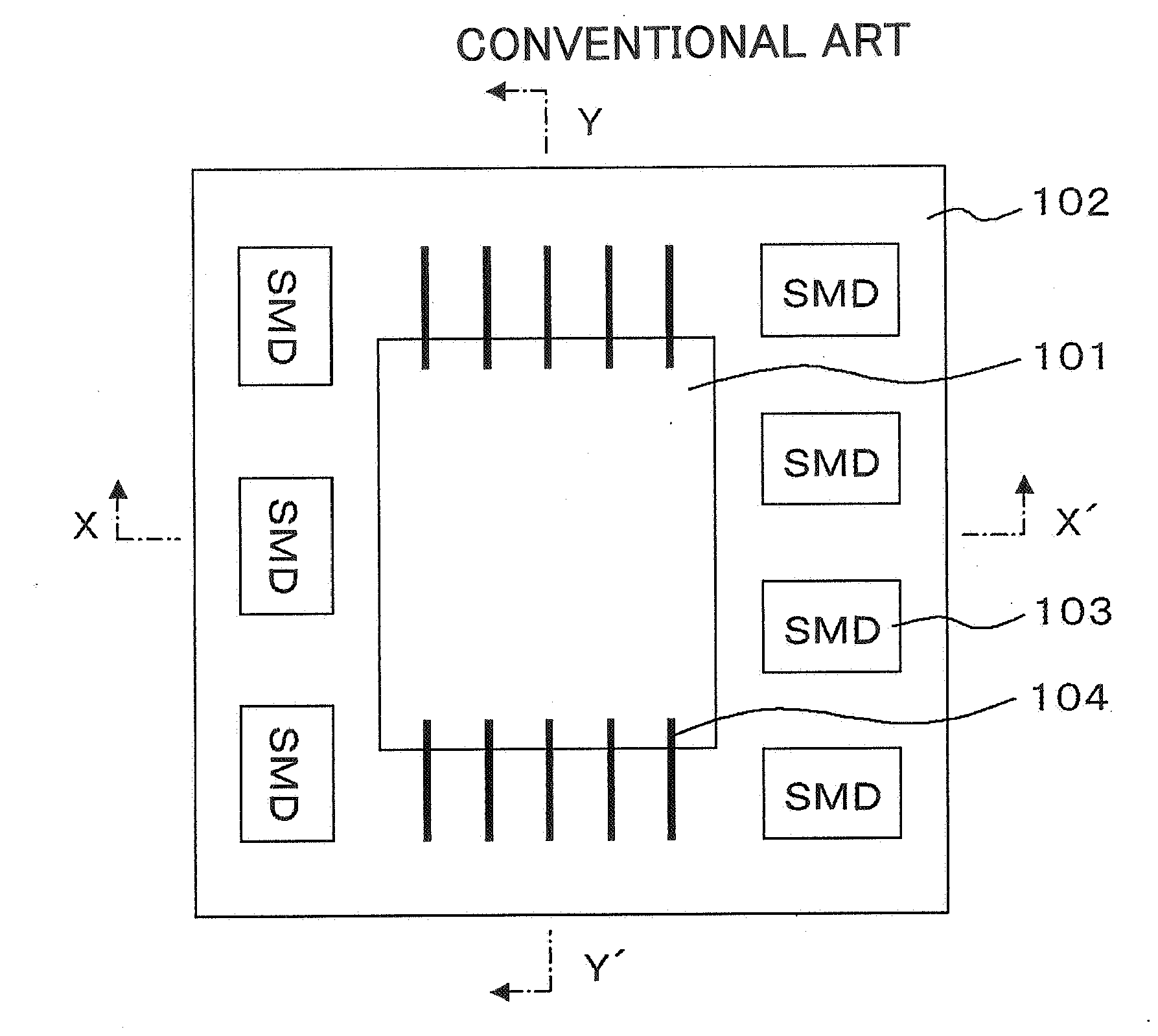

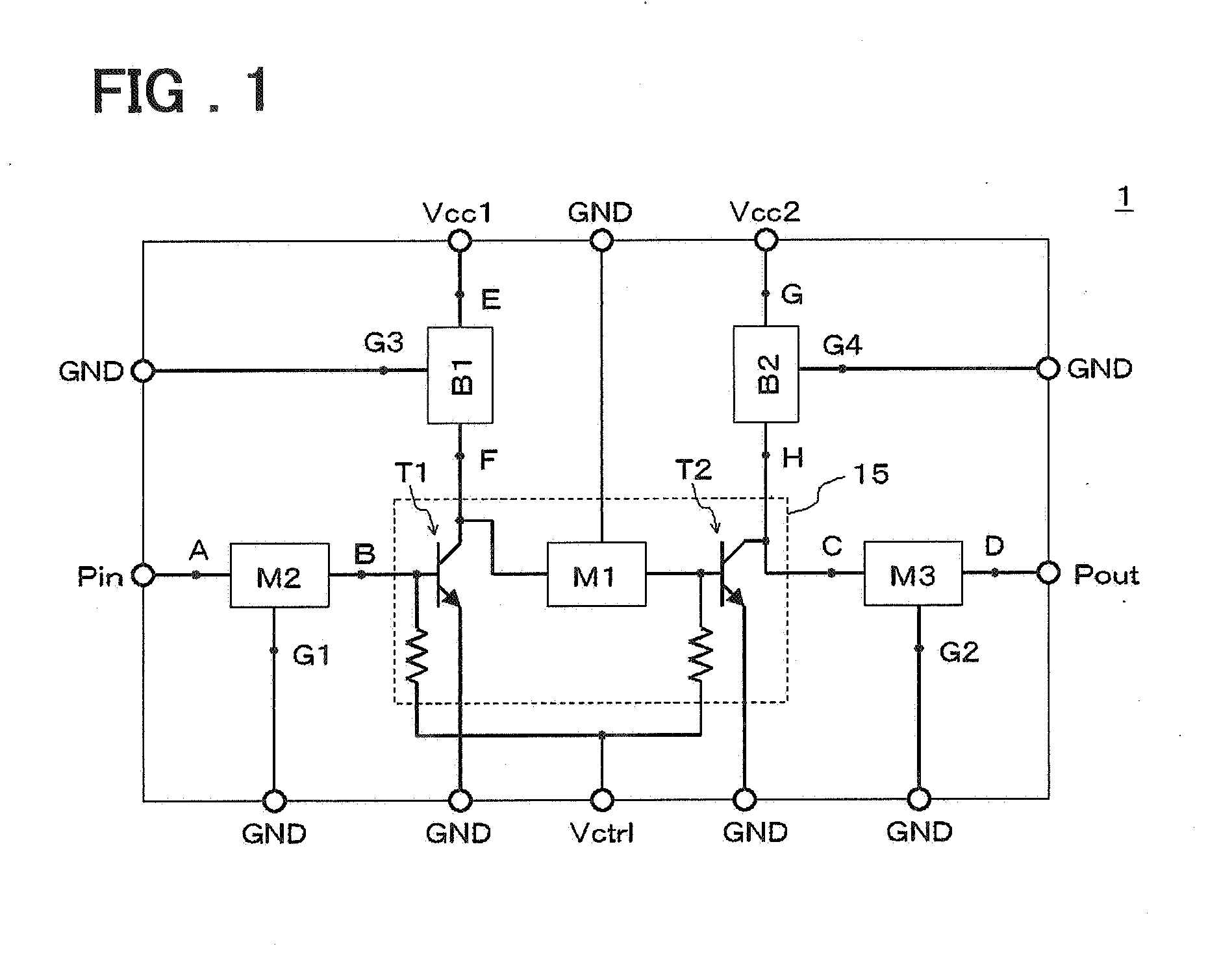

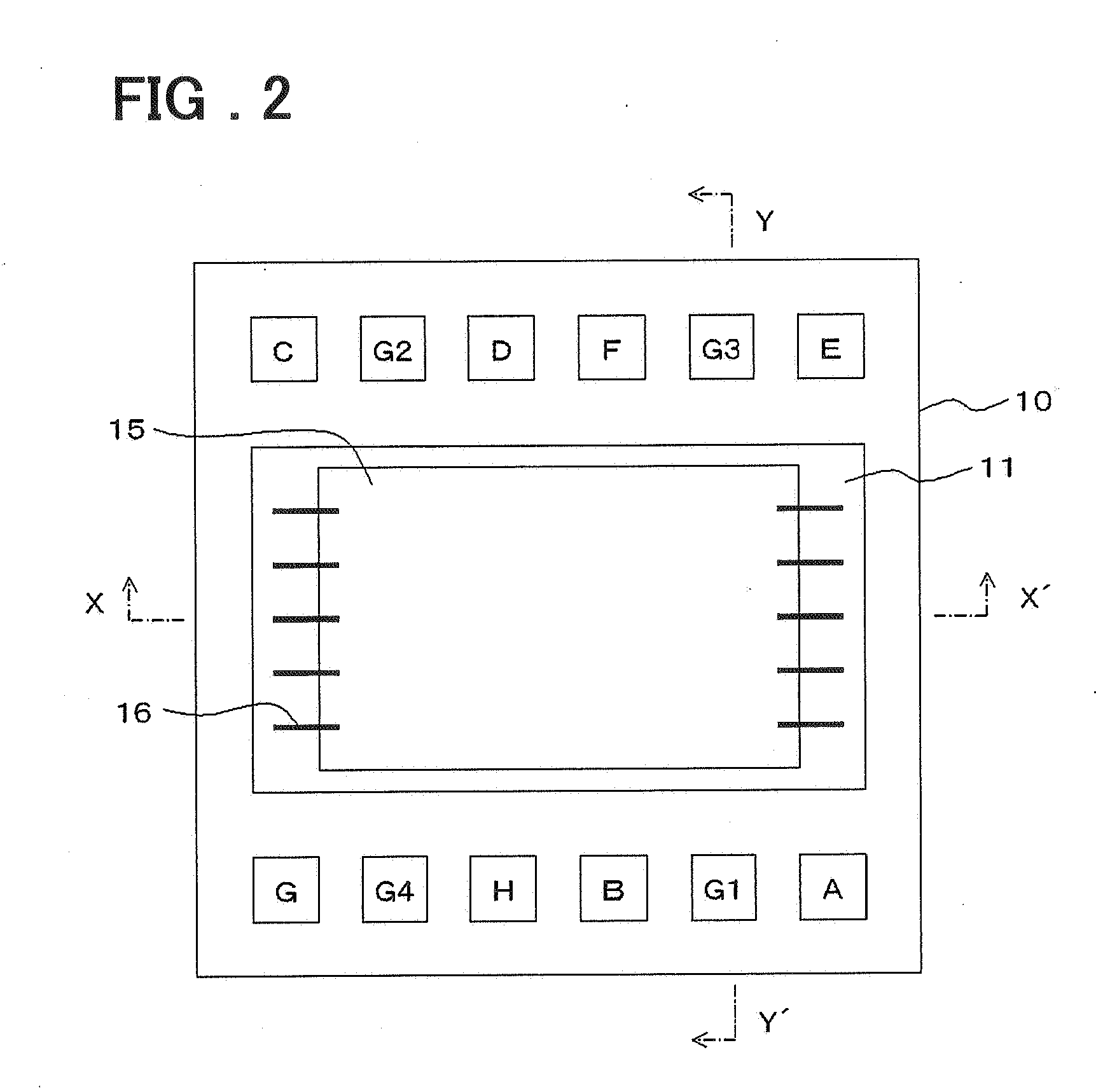

Power amplifier module

InactiveUS20080001281A1Reduce cavity volumeReduce power levelHigh frequency amplifiersSemiconductor/solid-state device detailsAudio power amplifier

A power amplifier module (IC module) of stacked layer structure is miniaturized while dissipating heat from a power amplifier chip. The module includes a first LTCC wiring board having a cavity in which a power amplifier chip is embedded, and a plurality of vias, which are electrically connected to ground, immediately underlying the power amplifier chip; and a second LTCC wiring board joined to the first LTCC wiring board and incorporating a matching circuit and a bias circuit electrically connected to the power amplifier chip. Ground pads of the matching circuit and bias circuit are all grounded by separating wiring or vias in the first LTCC wiring board and second LTCC wiring board.

Owner:NEC ELECTRONICS CORP

Feedstock scattering device for coir mattress

The invention belongs to the technical field of pretreatment of fiber materials and discloses a feedstock scattering device for a coir mattress. The feedstock scattering device comprises a scattering box and a power case, wherein a hollow scattering ball is arranged in the scattering box, a plurality of scattering holes are uniformly distributed in the sidewall of the scattering ball, the scattering ball communicates with a ventilating pipe, and the ventilating pipe penetrates through the scattering box and communicates with the power case; the power case contains water, a water surface is located below a communicating position of the ventilating pipe and the power case, a piston is arranged in the power case, and a piston rod is arranged at the upper end of the piston; a control device is arranged at the upper end of the piston rod and can drive the piston rod to slide up and down, and the piston rod can stay static during the switching of upward sliding and downward sliding. According to the feedstock scattering device for the coir mattress, the technical problem in the prior art that the feedstock scattering effect is poor during the manufacturing of the coir mattress is solved.

Owner:重庆市永川区植成家俱厂

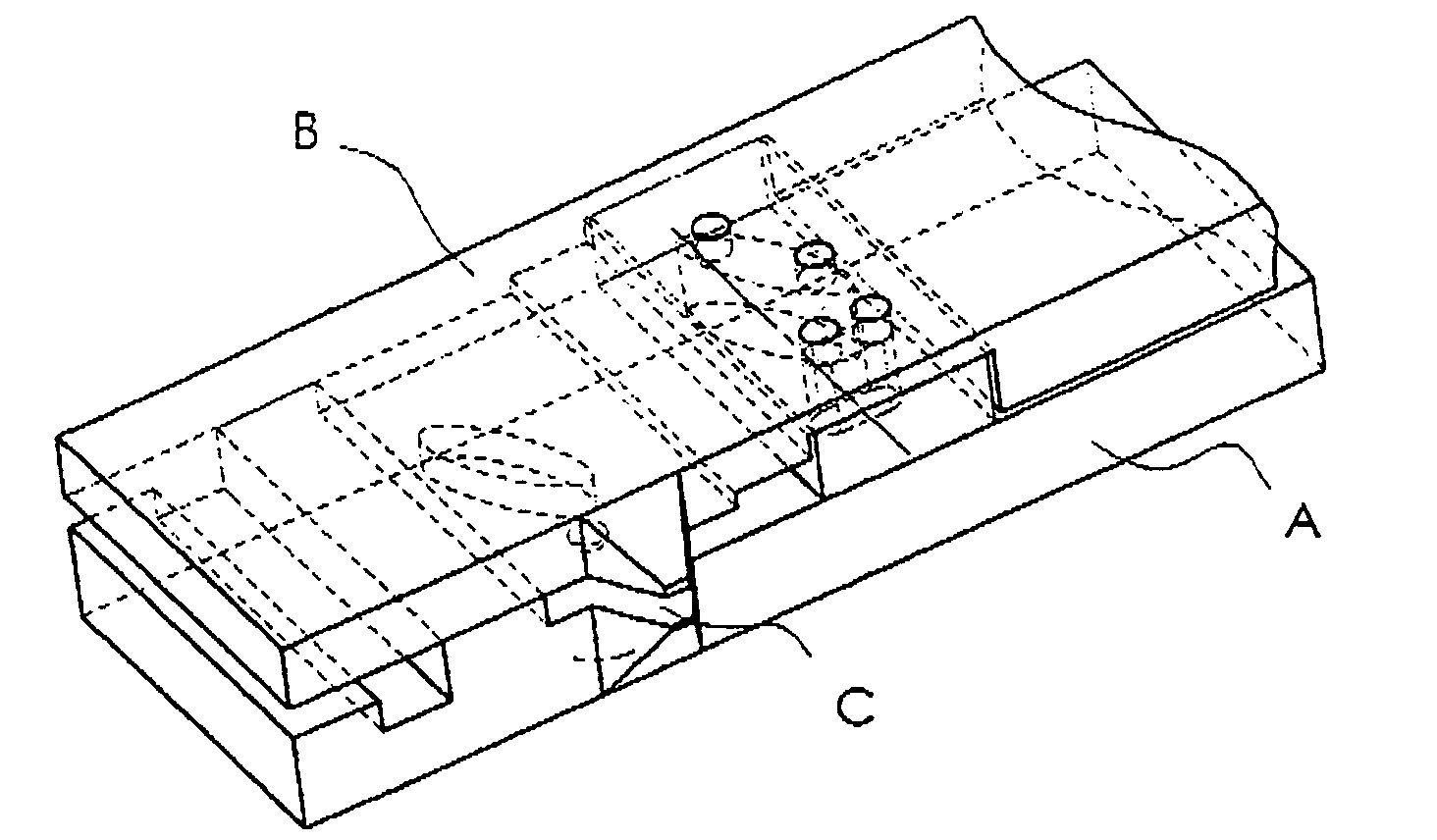

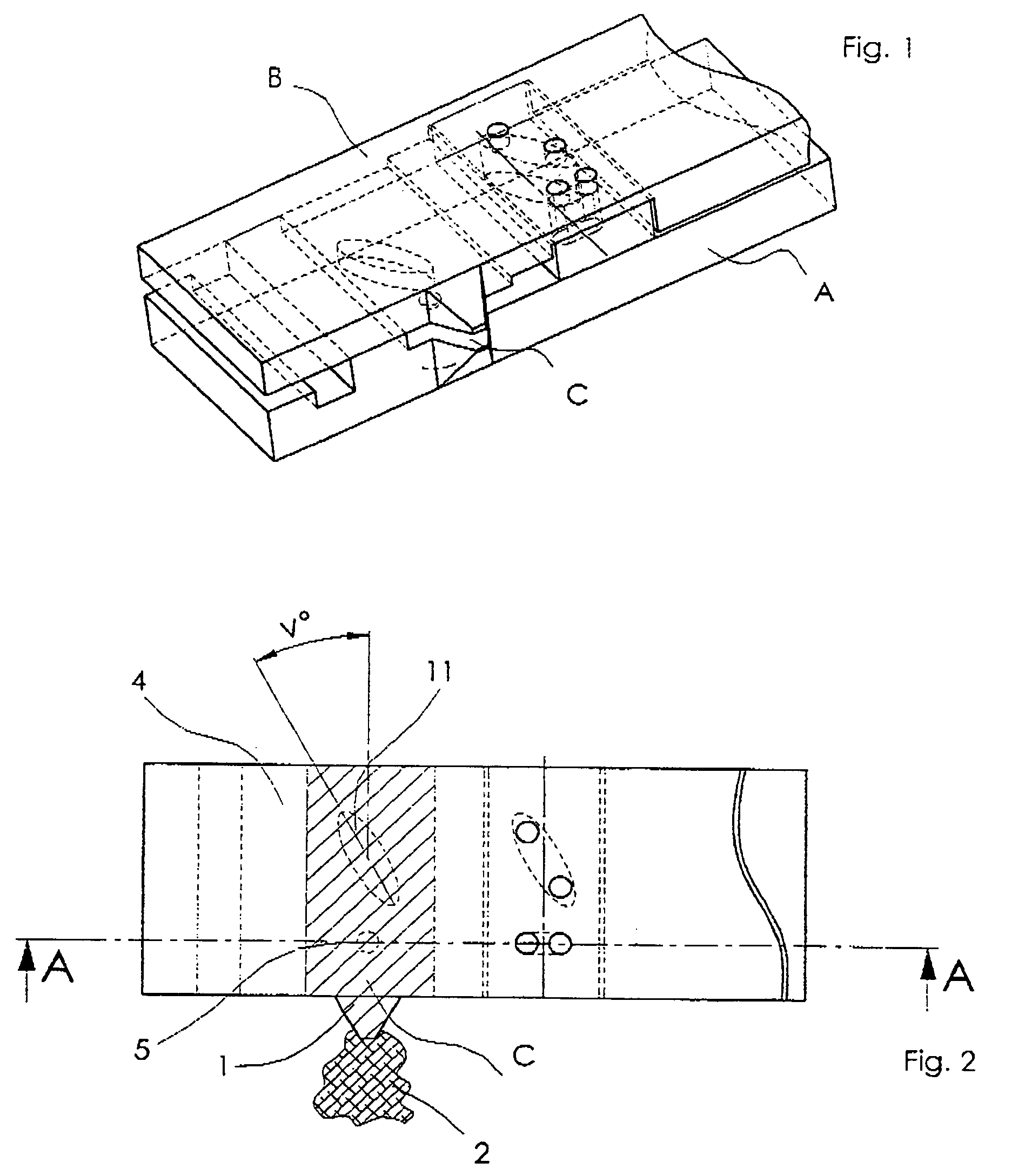

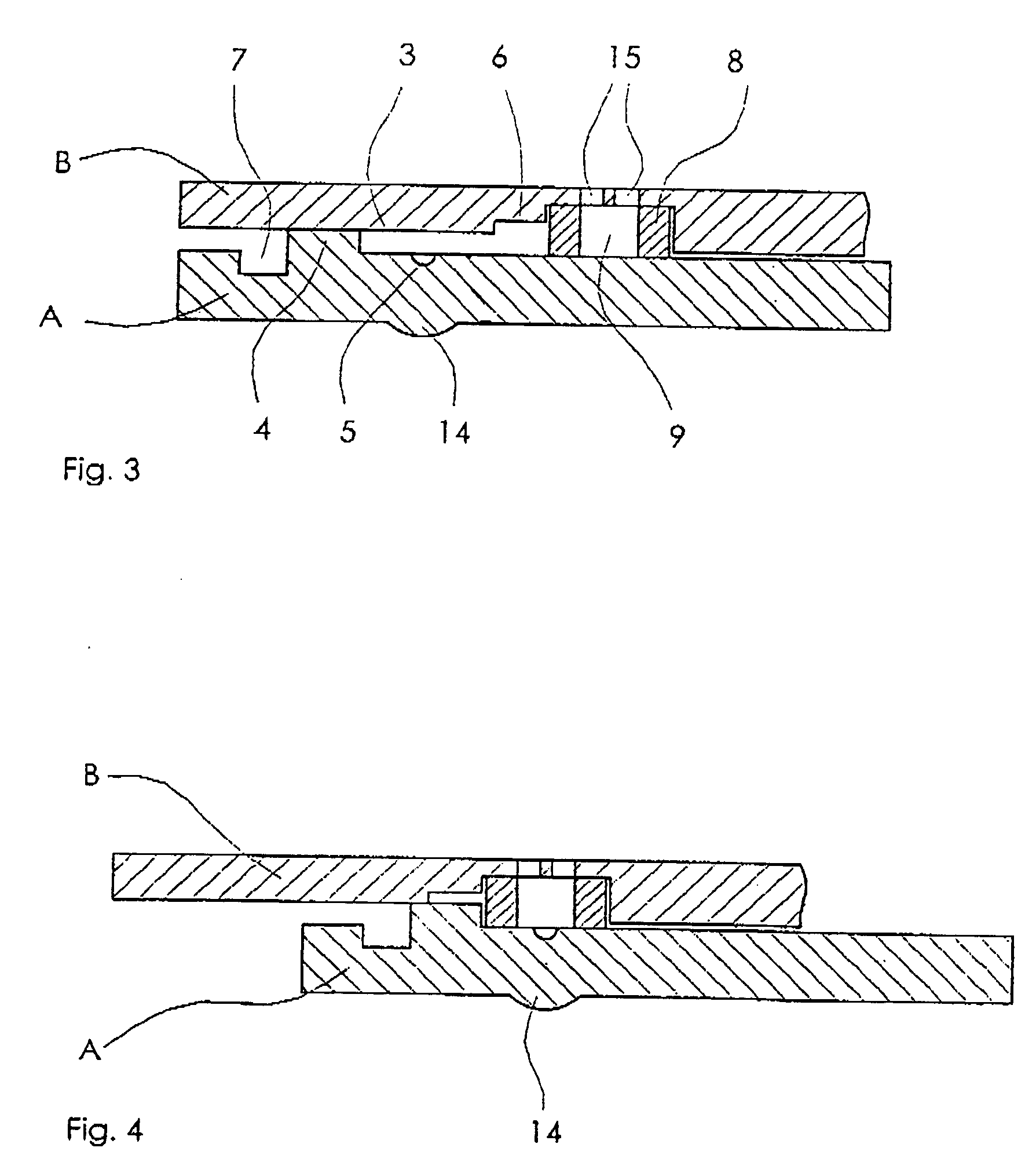

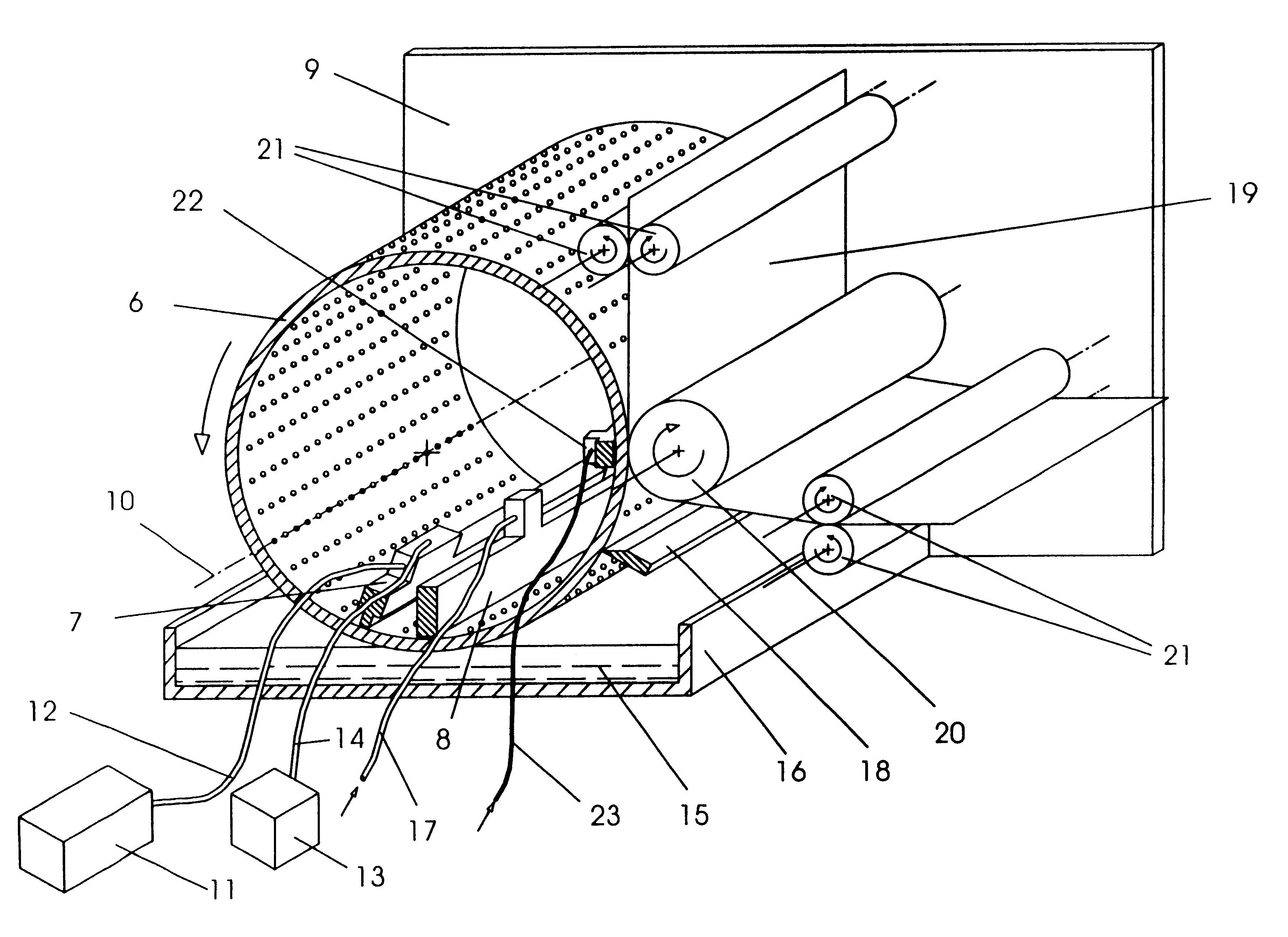

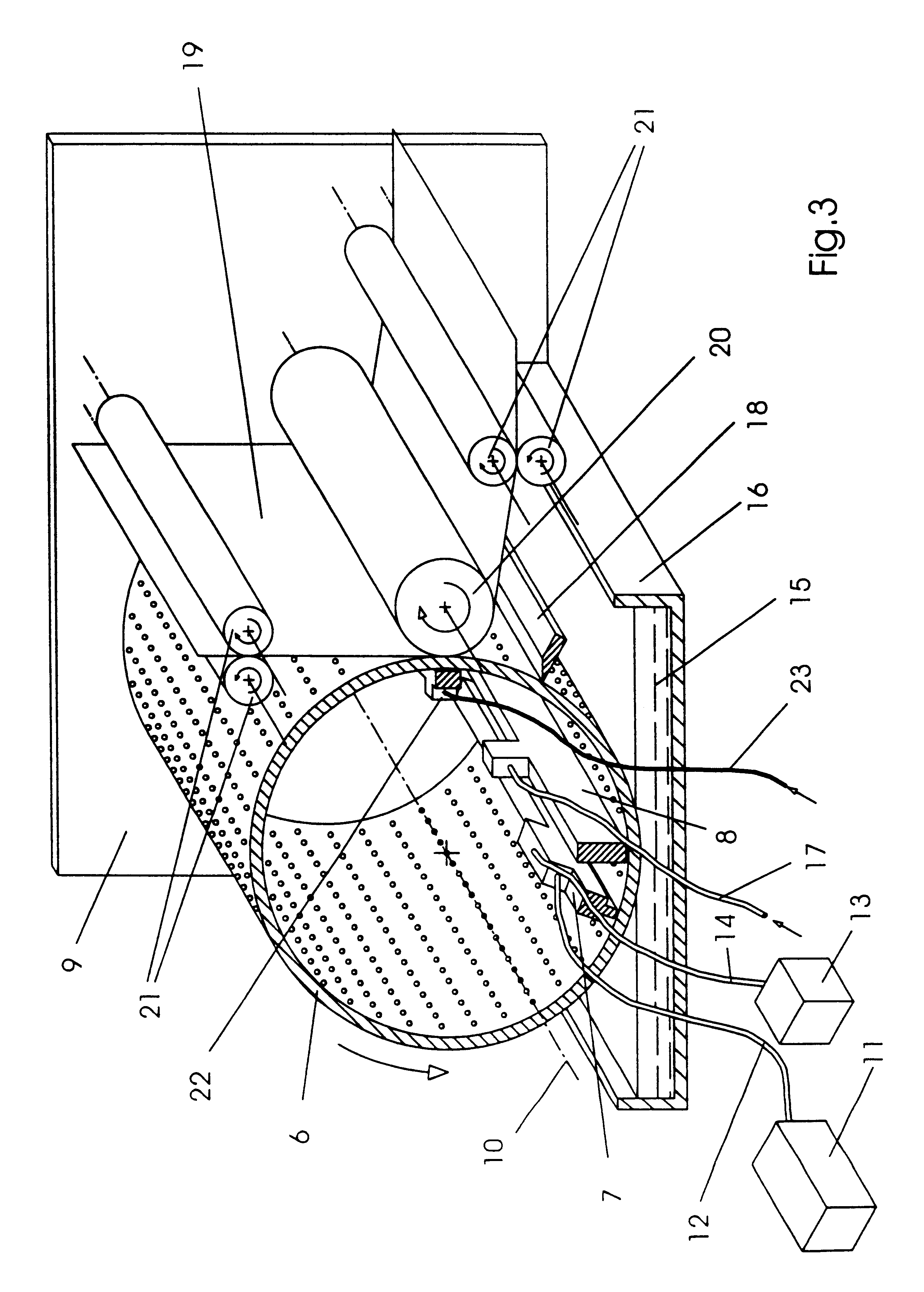

Method, device and printing form for transferring free-flowing printing ink onto a printing material

InactiveUS6651560B2Increase cavity volumeReduce cavity volumeLiquid surface applicatorsInk ribbonsEngineeringPrinting ink

A printing form for transferring free-flowing printing ink to a printing material to be printed includes a body having a surface formed with a multiplicity of openings coverable by printing ink; a multiplicity of gas-containing cavities formed in the body, the cavities, respectively, terminating in the openings, respectively, at the surface of the body; and devices assigned to the cavities, respectively, for producing a vacuum therein for sucking printing ink covering the openings of the cavities into a region adjacent to the openings of the cavities, respectively, when a vacuum is produced by devices in the cavities, respectively; an ink transferring device including the printing form; and a method of producing the printing form.

Owner:DR DIETMAR NEUHAUS

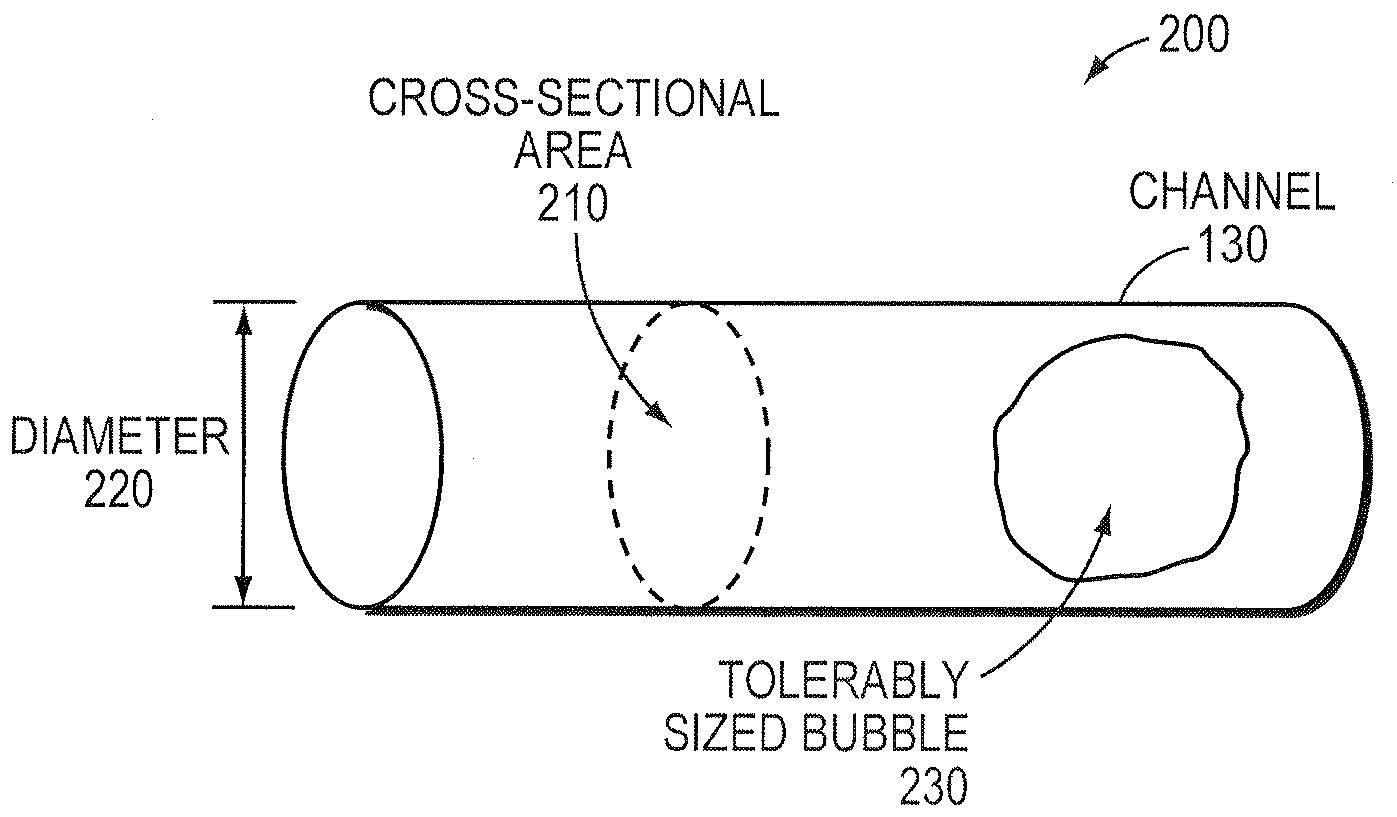

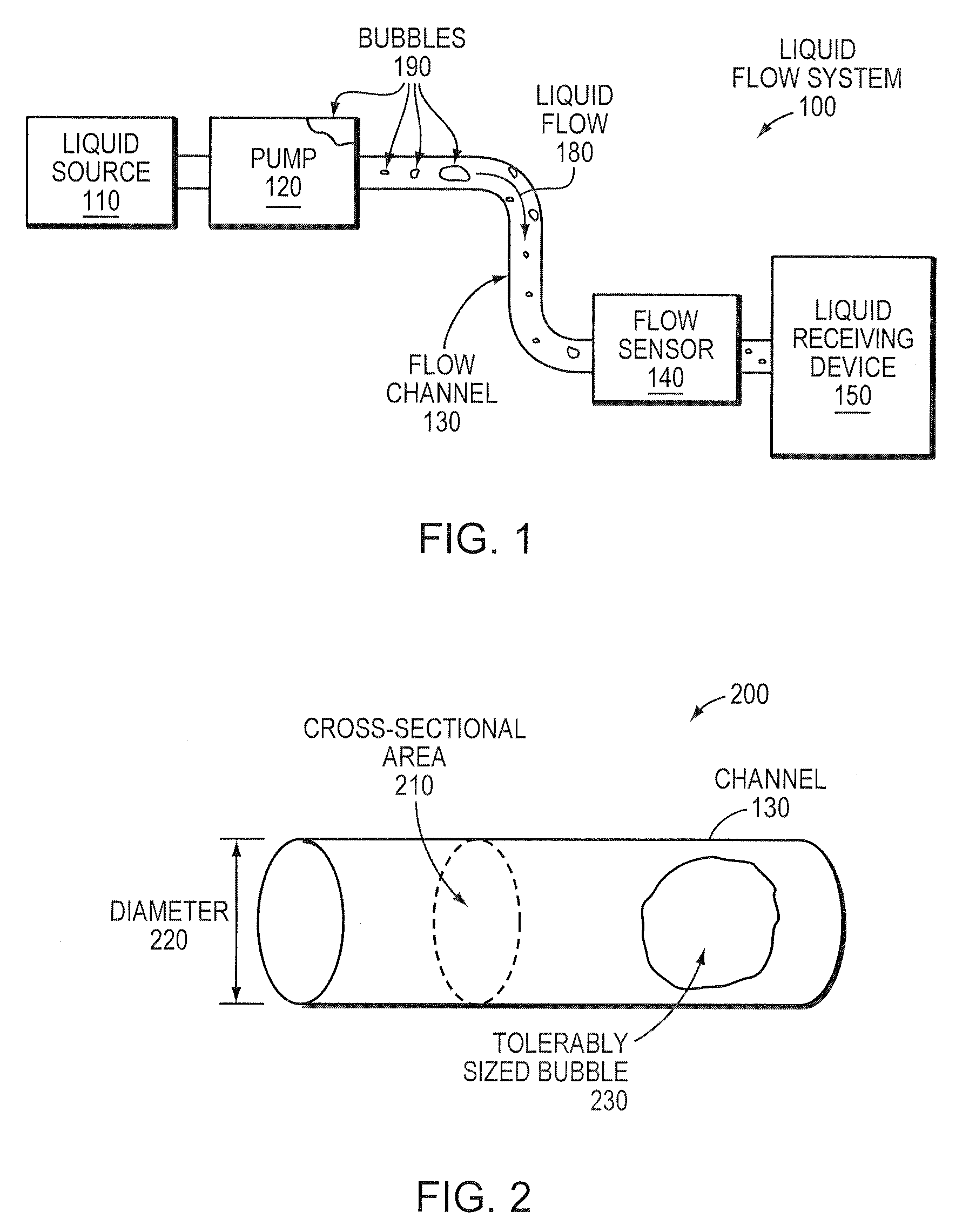

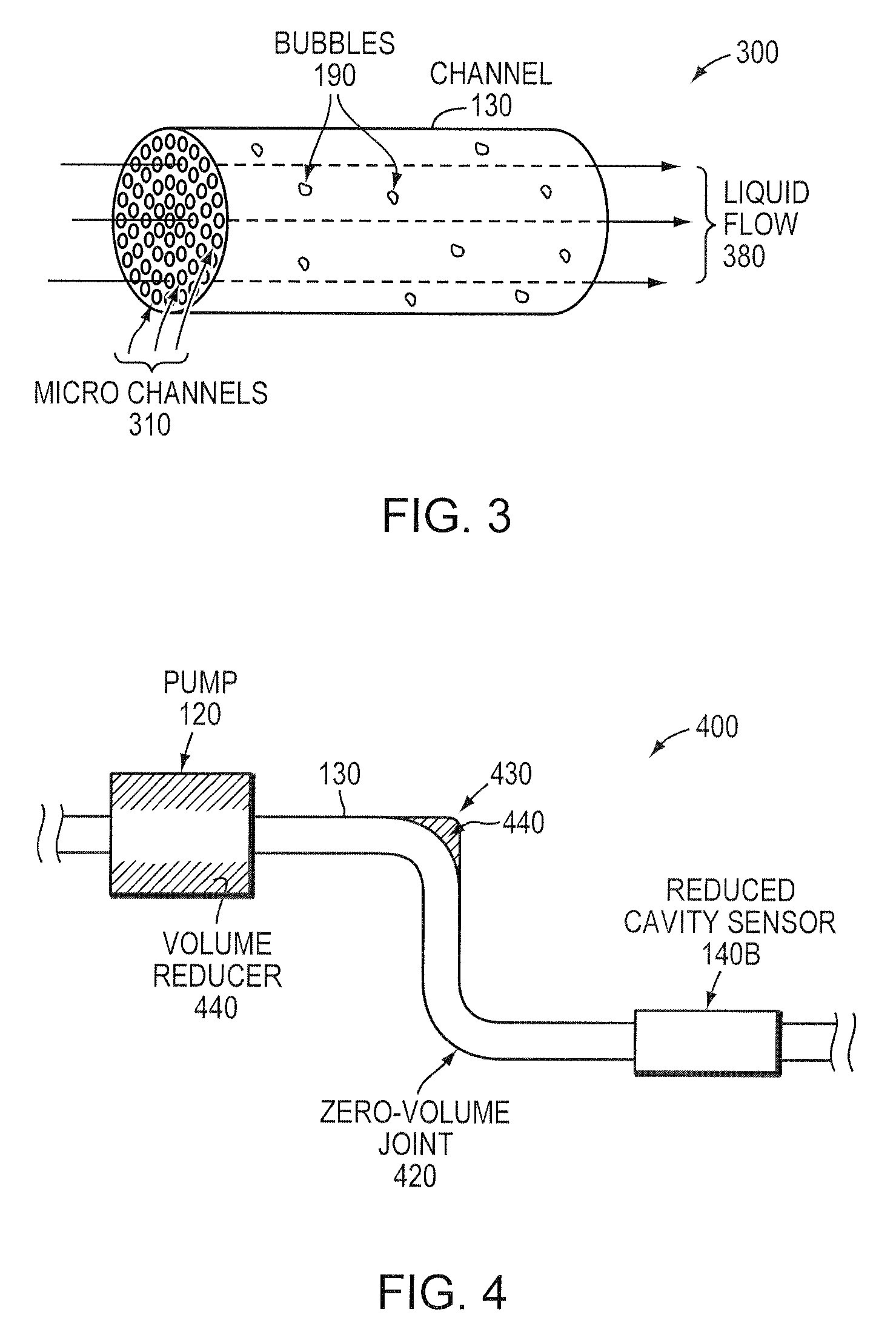

Managing gas bubbles in a liquid flow system

InactiveUS20100124676A1Reduce power fluctuationsEasy to controlReactant parameters controlLiquid degasification regulation/controlEngineeringGas bubble

A system and method for managing gas bubbles in a liquid flow system are described. In particular, according to the system and method, novel techniques reduce a volume of cavities in the liquid flow system and limit a cross-sectional area of the liquid flow system to a maximum cross-sectional area of tolerably sized bubbles. In this manner, by reducing the cavity volumes and limiting cross-sectional areas, the formation of intolerably sized bubbles and the aggregation of tolerably sized bubbles into intolerably sized bubbles are each substantially prevented. Also, bubbles may be removed from the system to reduce the quantity of bubbles that are to be managed.

Owner:MTI MICROFUEL CELLS

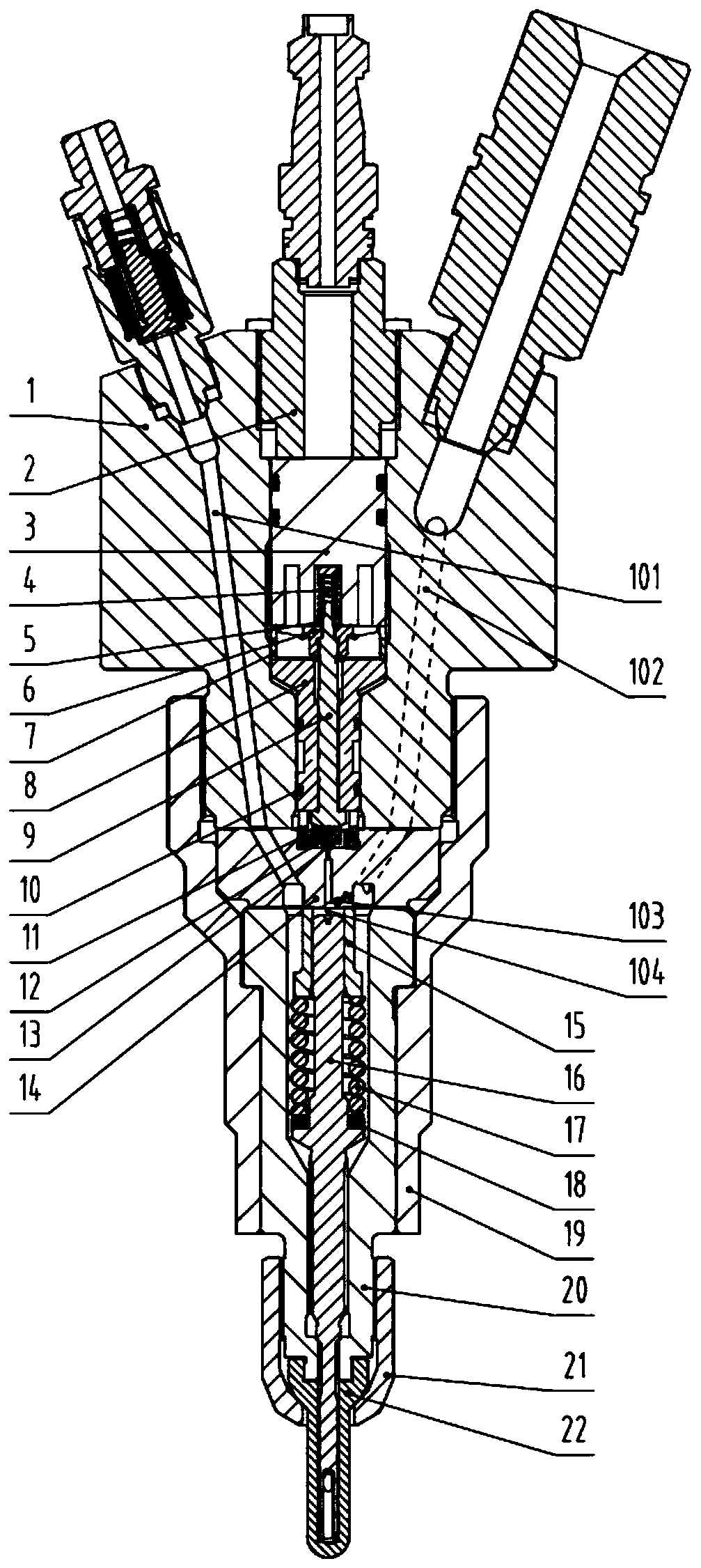

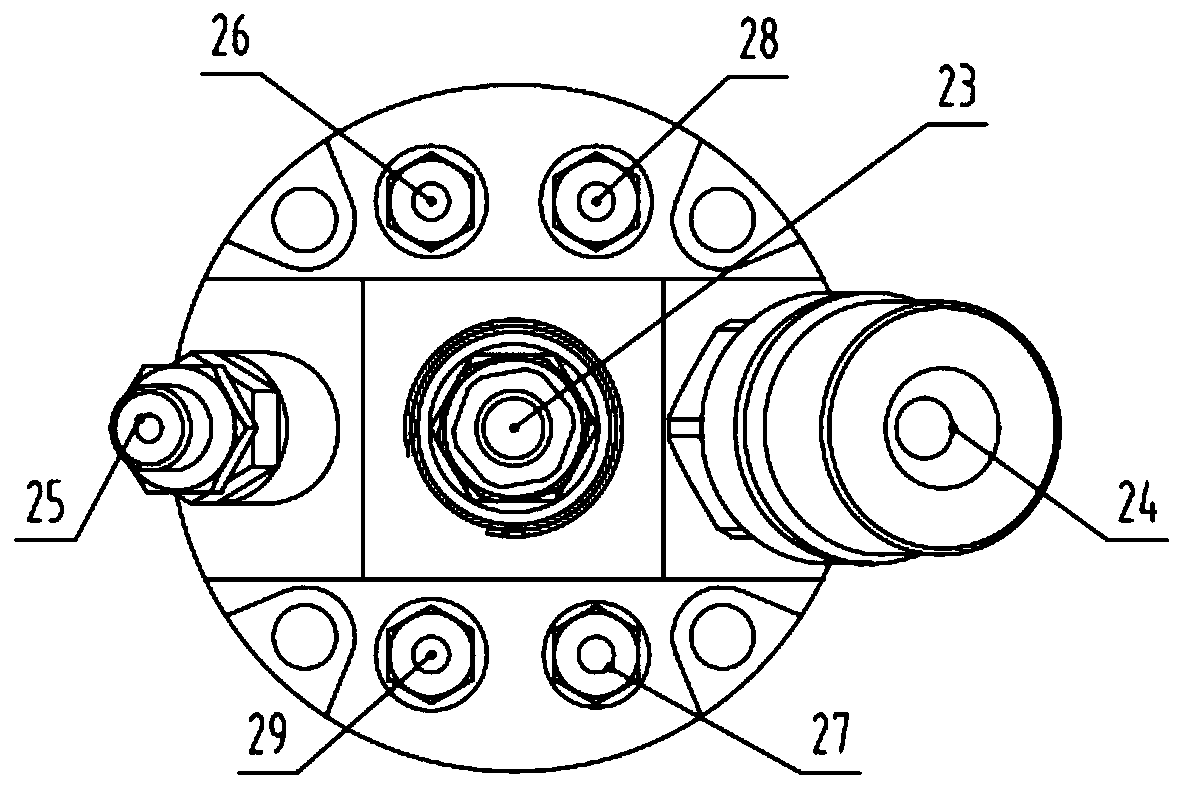

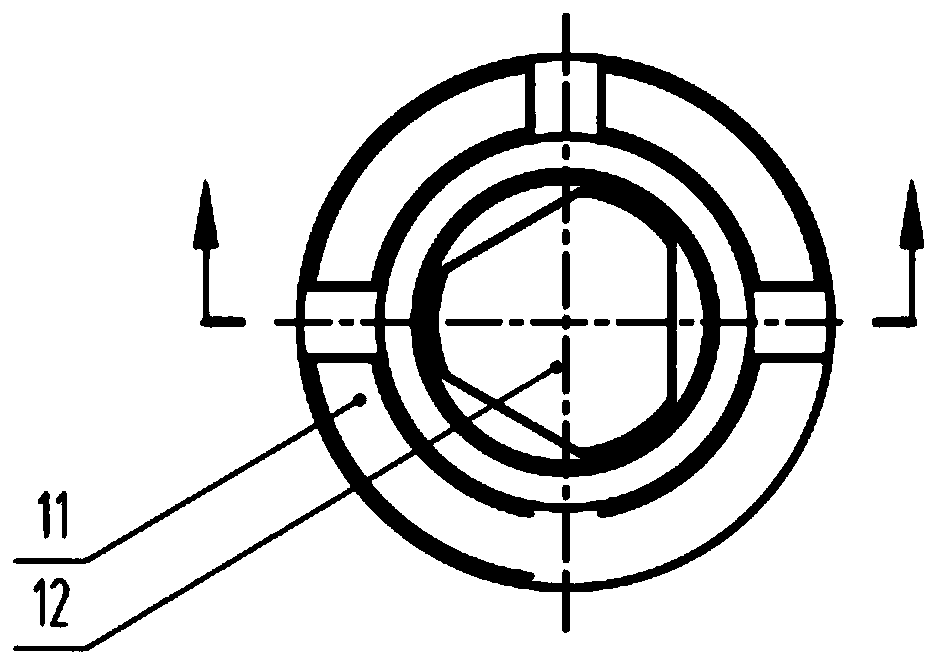

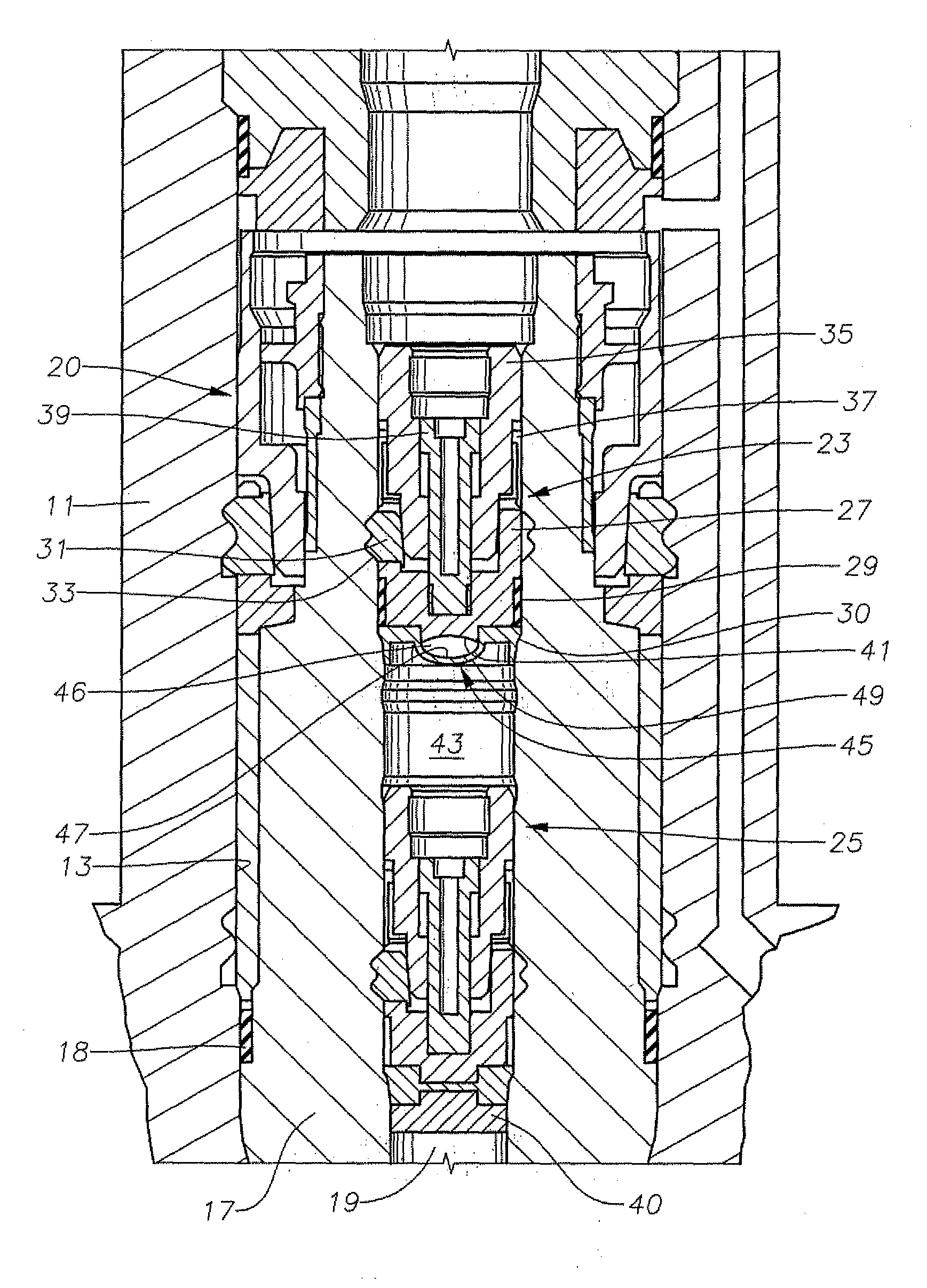

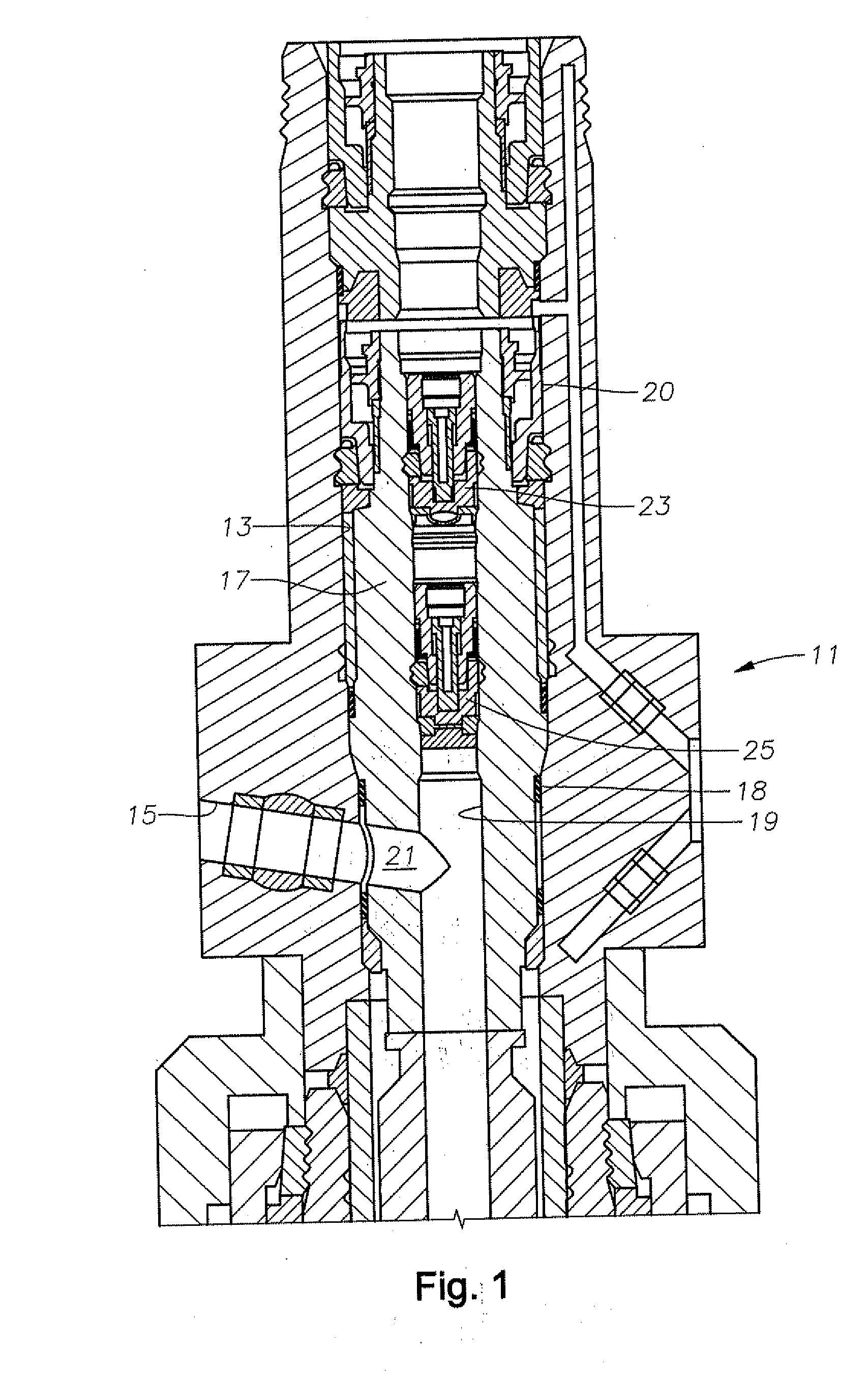

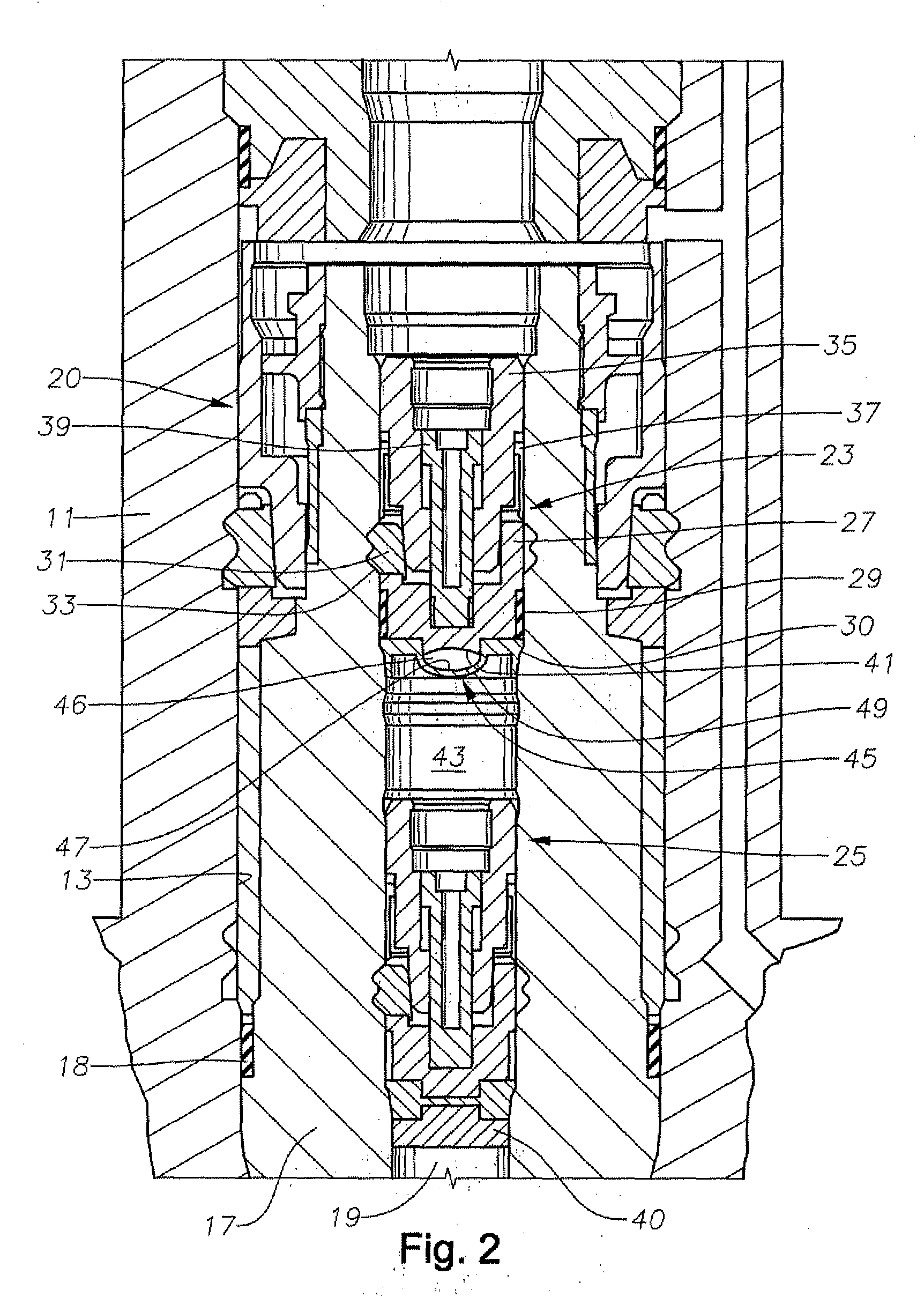

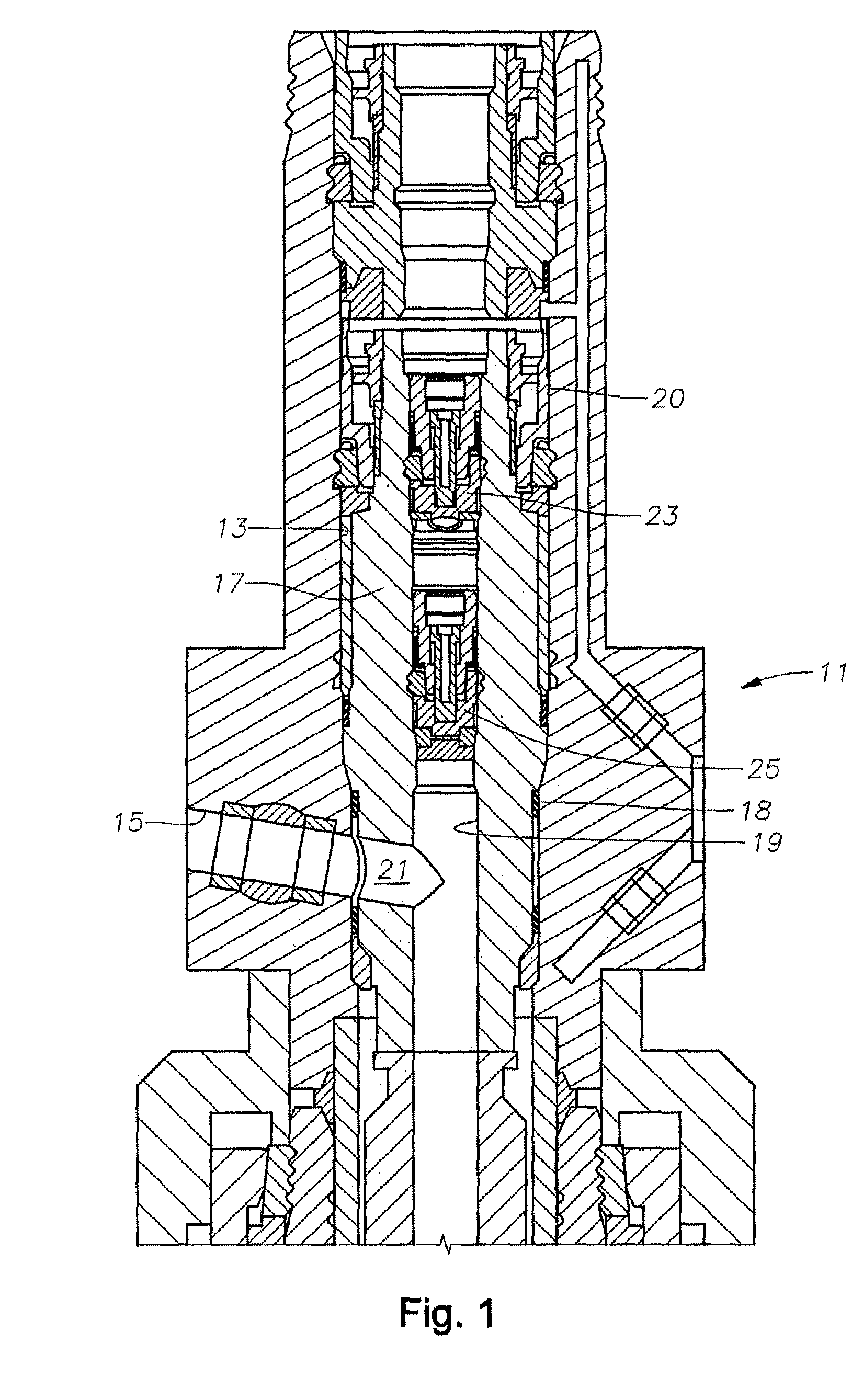

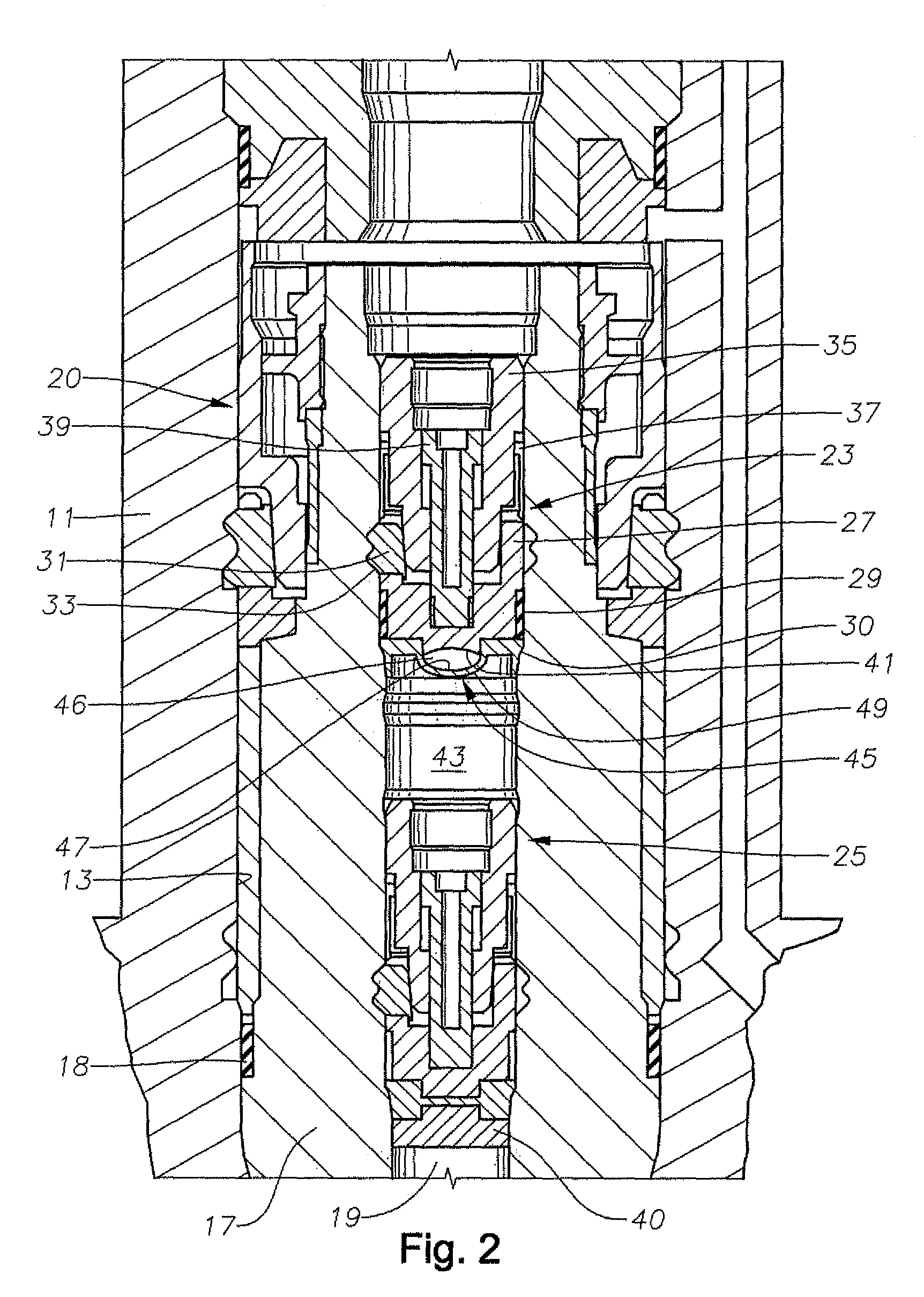

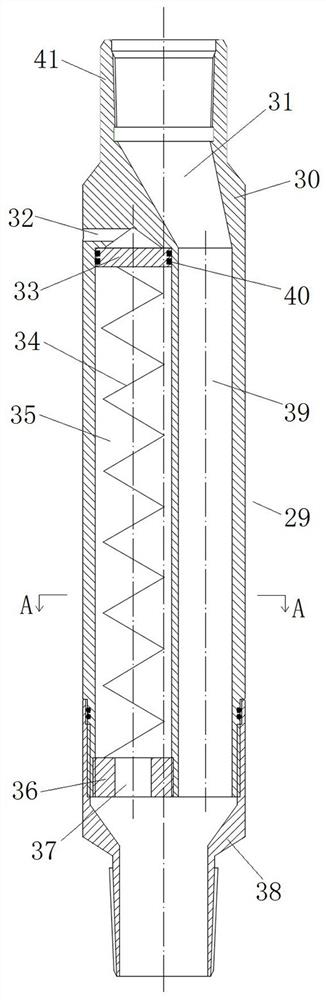

Electronically-controlled common rail heavy oil injector

ActiveCN110594061AChange the work schedule at any timeSave spaceCorrosion preventing fuel injectionMachines/enginesVena contracta diameterCommon rail

The invention relates to an electronically-controlled common rail heavy oil injector which comprises an injector body, an electro-hydraulic control member and a nozzle member. In the electro-hydrauliccontrol member, a ring groove is formed in the middle of the outer side of a guide sleeve, a transverse through hole is formed in the middle of the groove to directly communicate with a middle hole of the guide sleeve, the two sides of the ring groove are provided with seal rings, and the interior of the oil injector is divided into three chambers. A control valve core guide section is provided with three ring grooves, and the second ring groove is in communication with the transverse through hole in the middle of the guide sleeve. An electromagnetic component is in contact with cooling oil,a cooling oil circuit is isolated from a fuel oil circuit by means of dynamic sealing, static sealing and drainage manners, and corroding and thermal damage of heavy oil to electronic components can be effectively prevented; and a sinking groove is formed in the middle of the top end of an orifice plate, a ball valve seat guide sleeve can be sleeved with the sinking groove of the orifice plate tobe in clearance fit with a ball valve seat, and a certain guiding ability for axial movement of the ball valve seat is achieved.

Owner:CHONGQING HONGJIANG MACHINERY

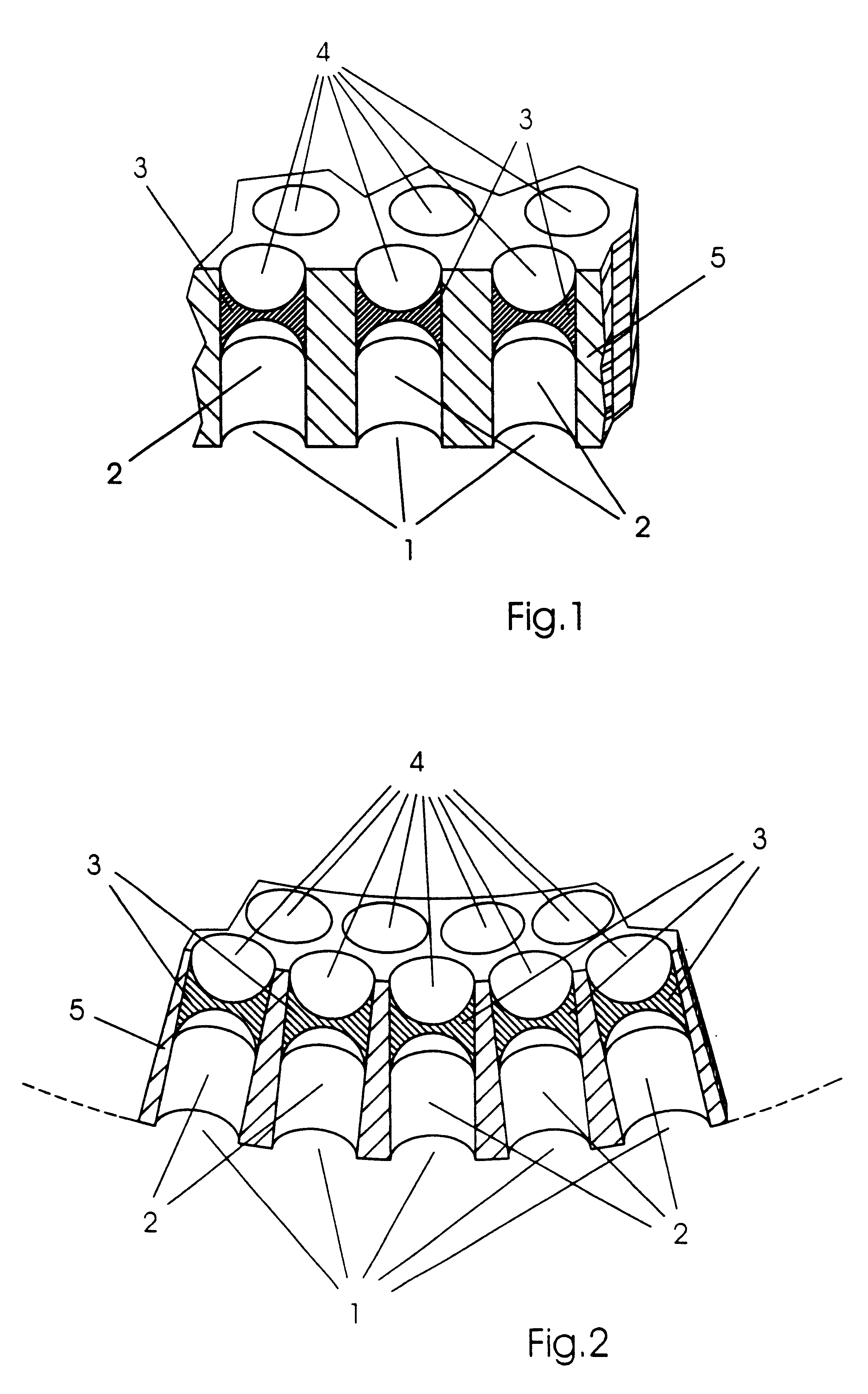

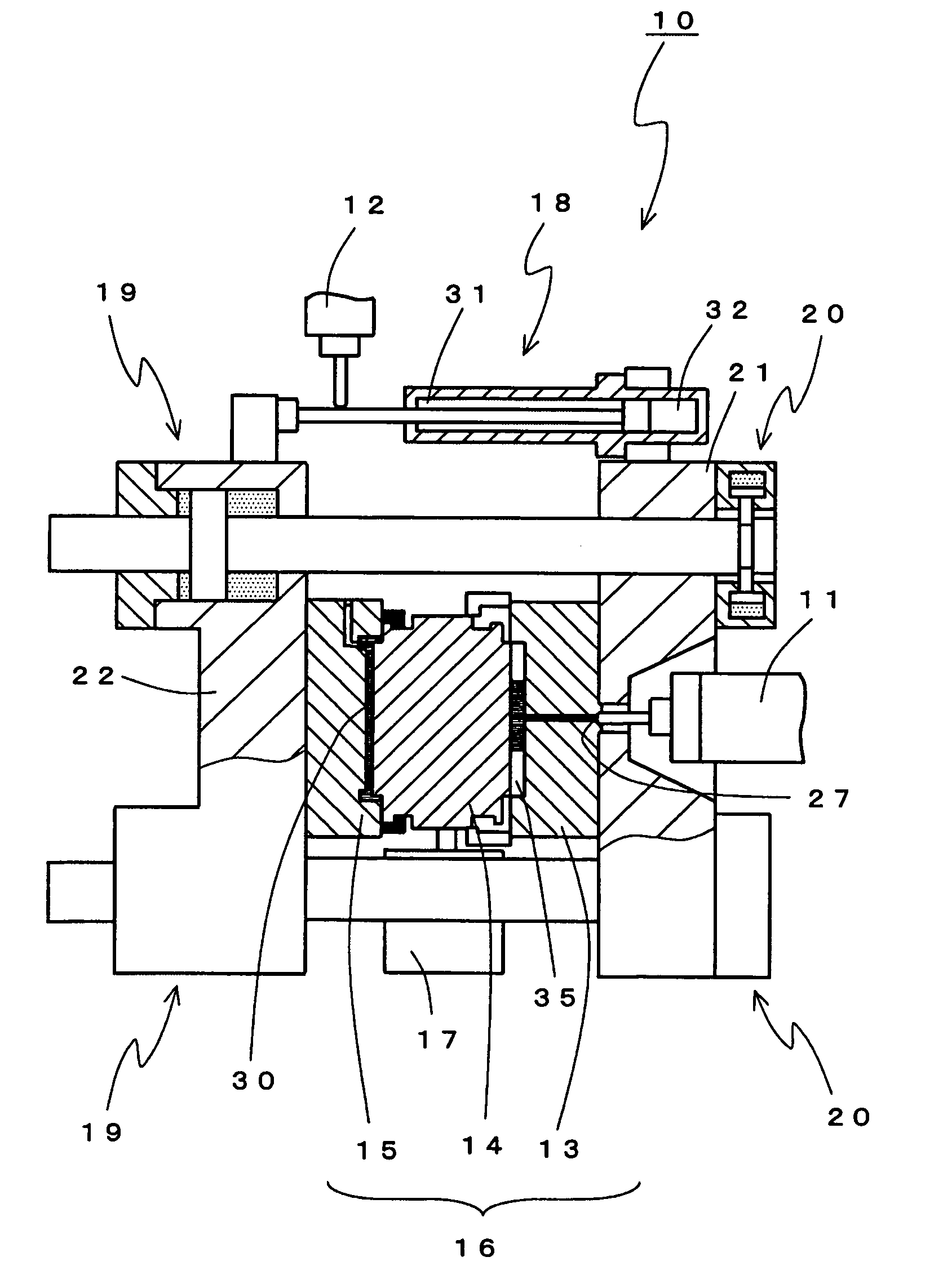

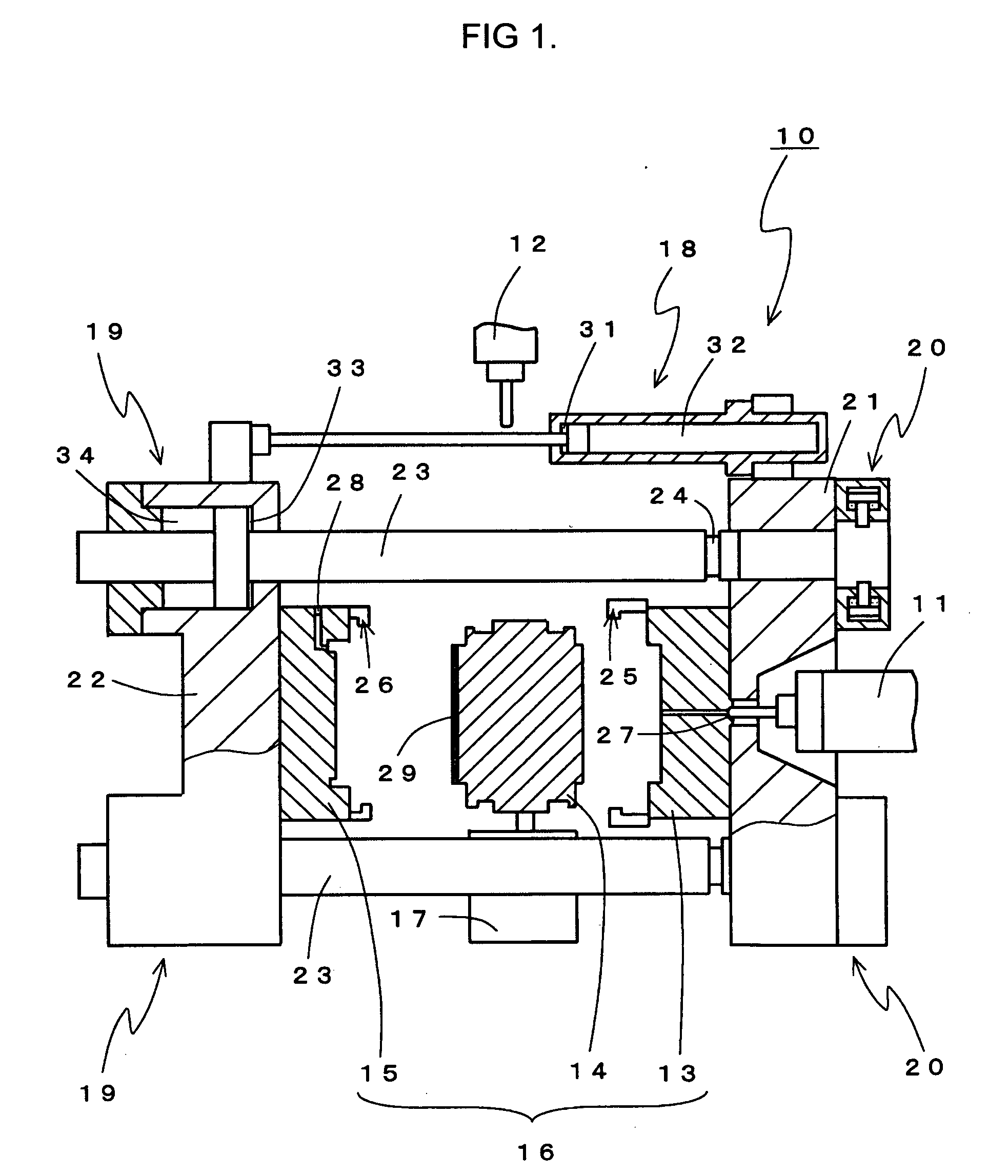

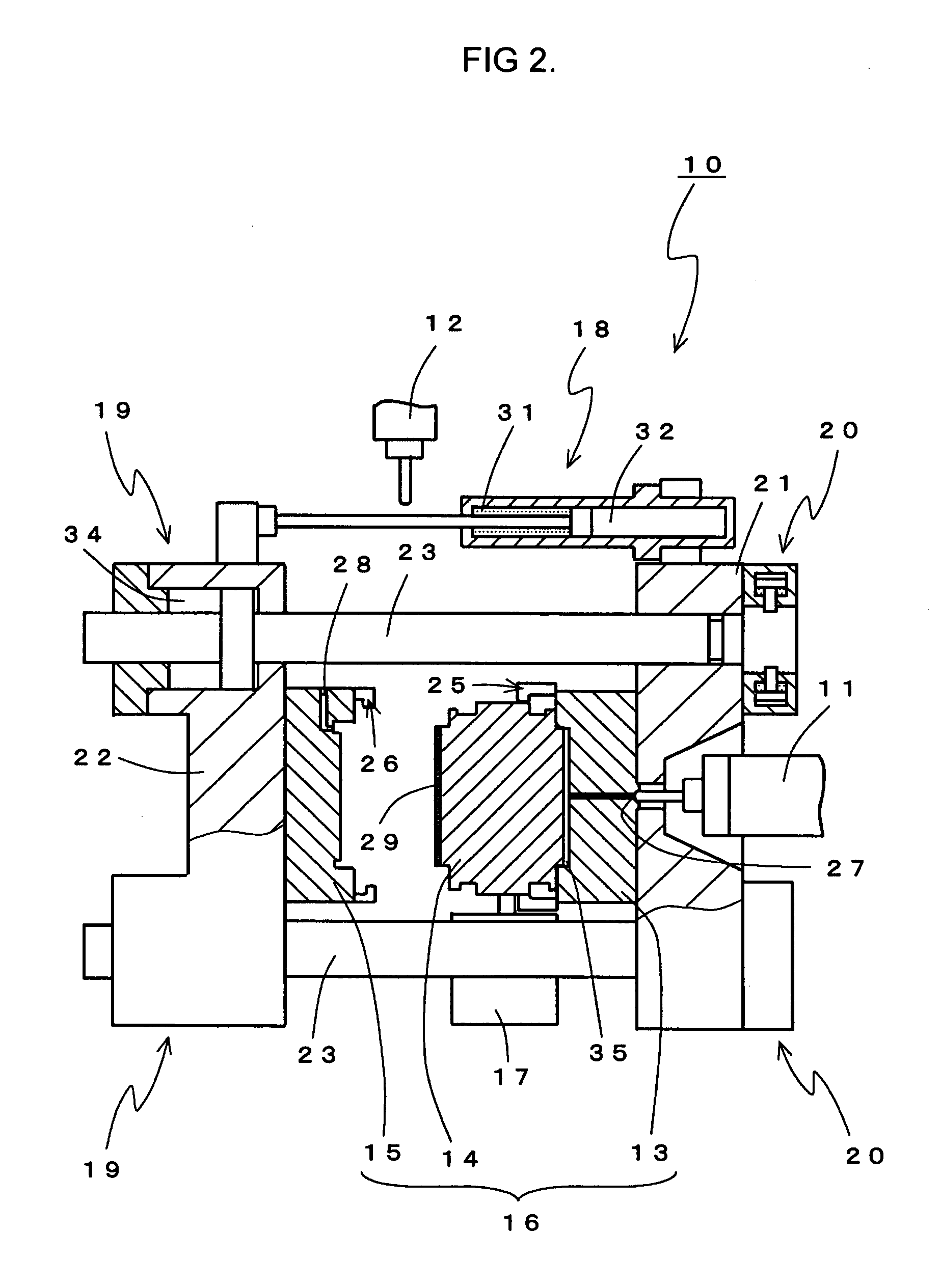

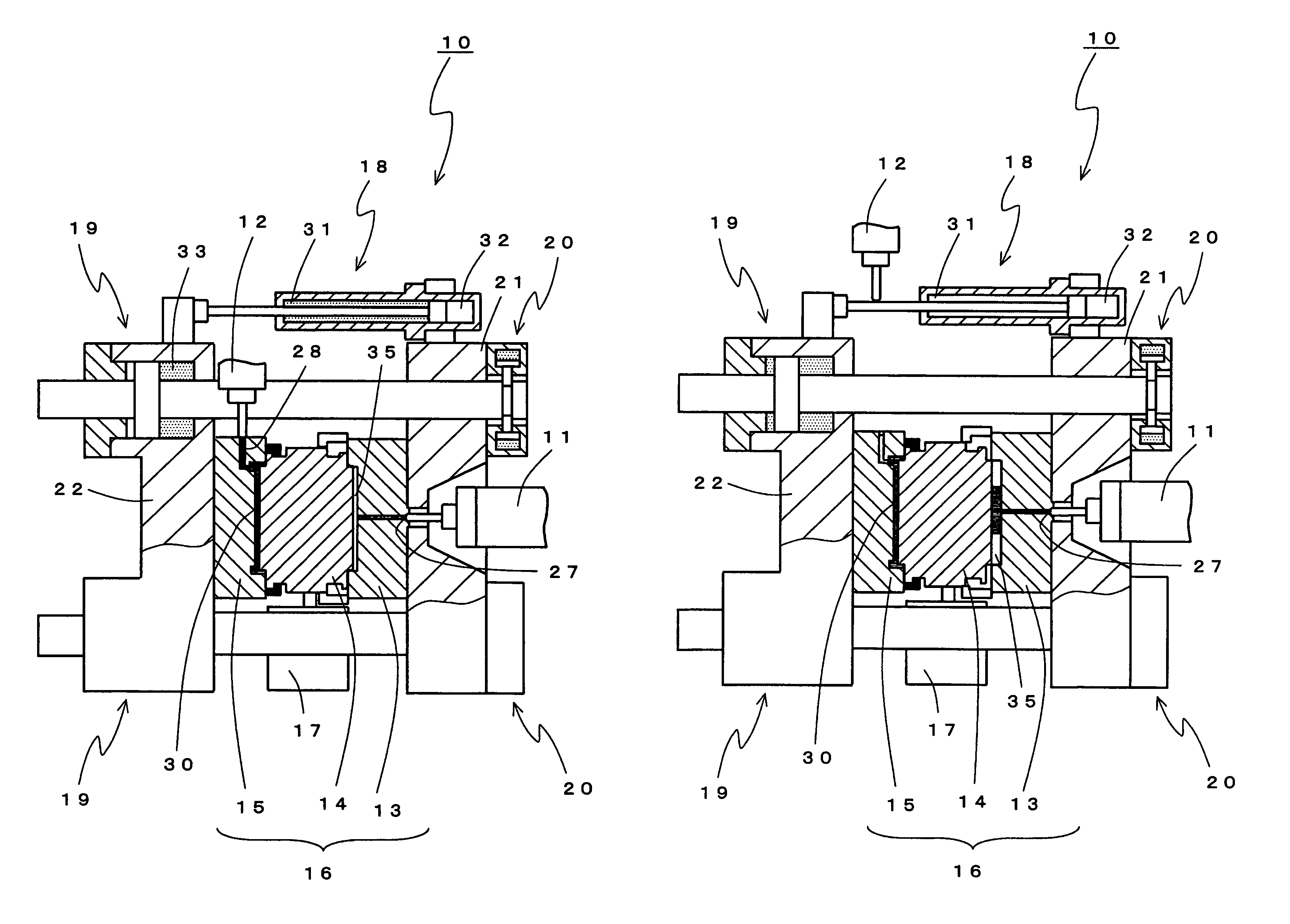

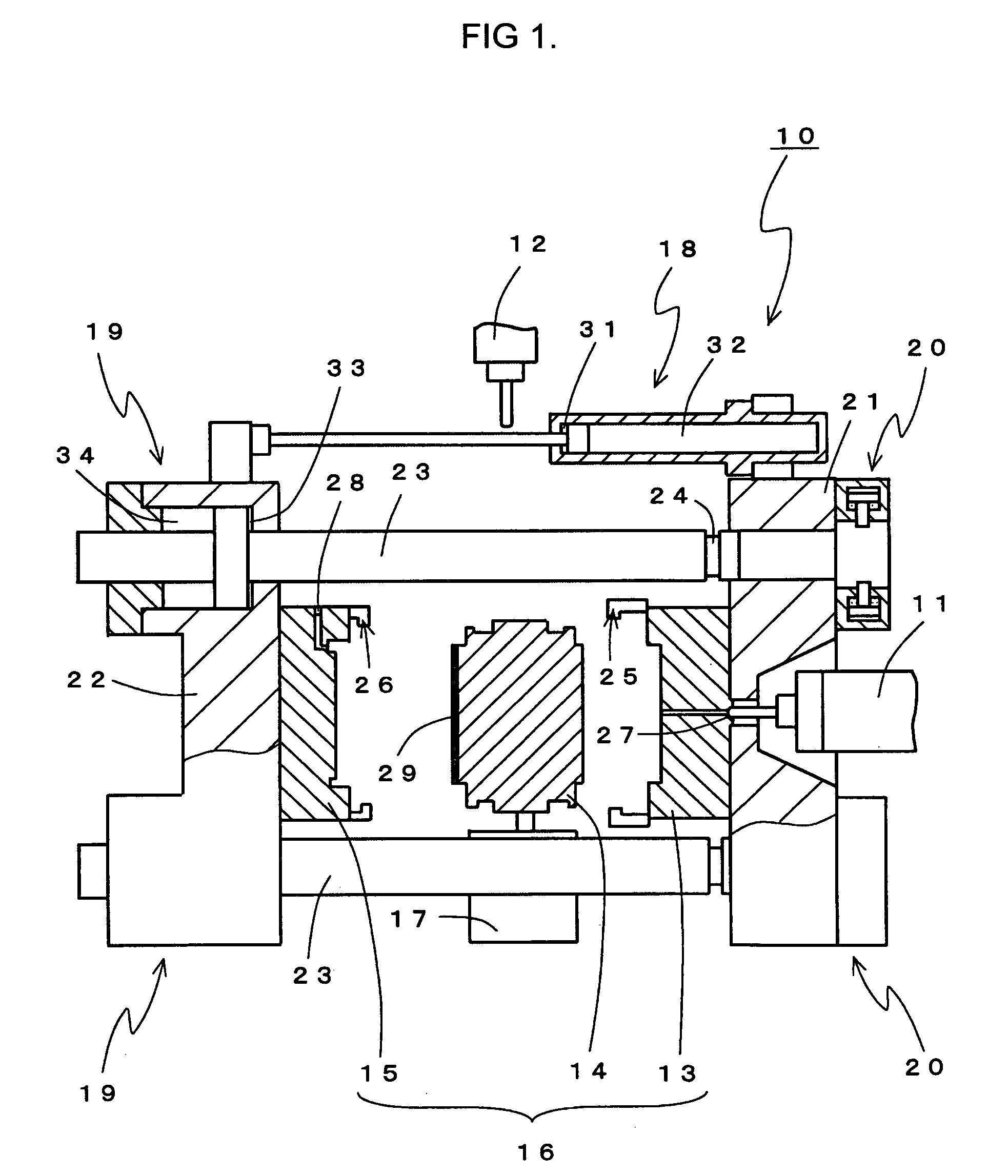

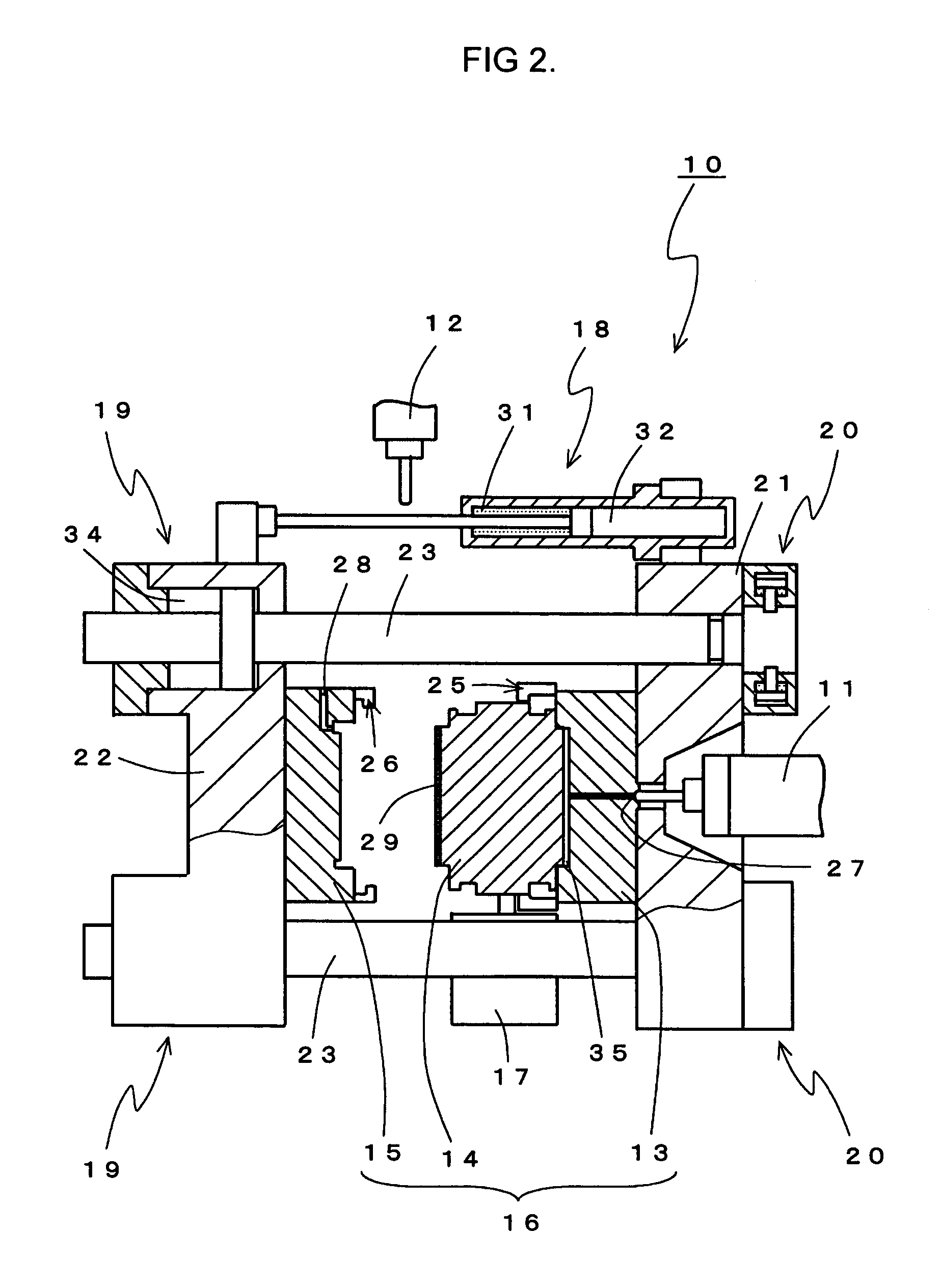

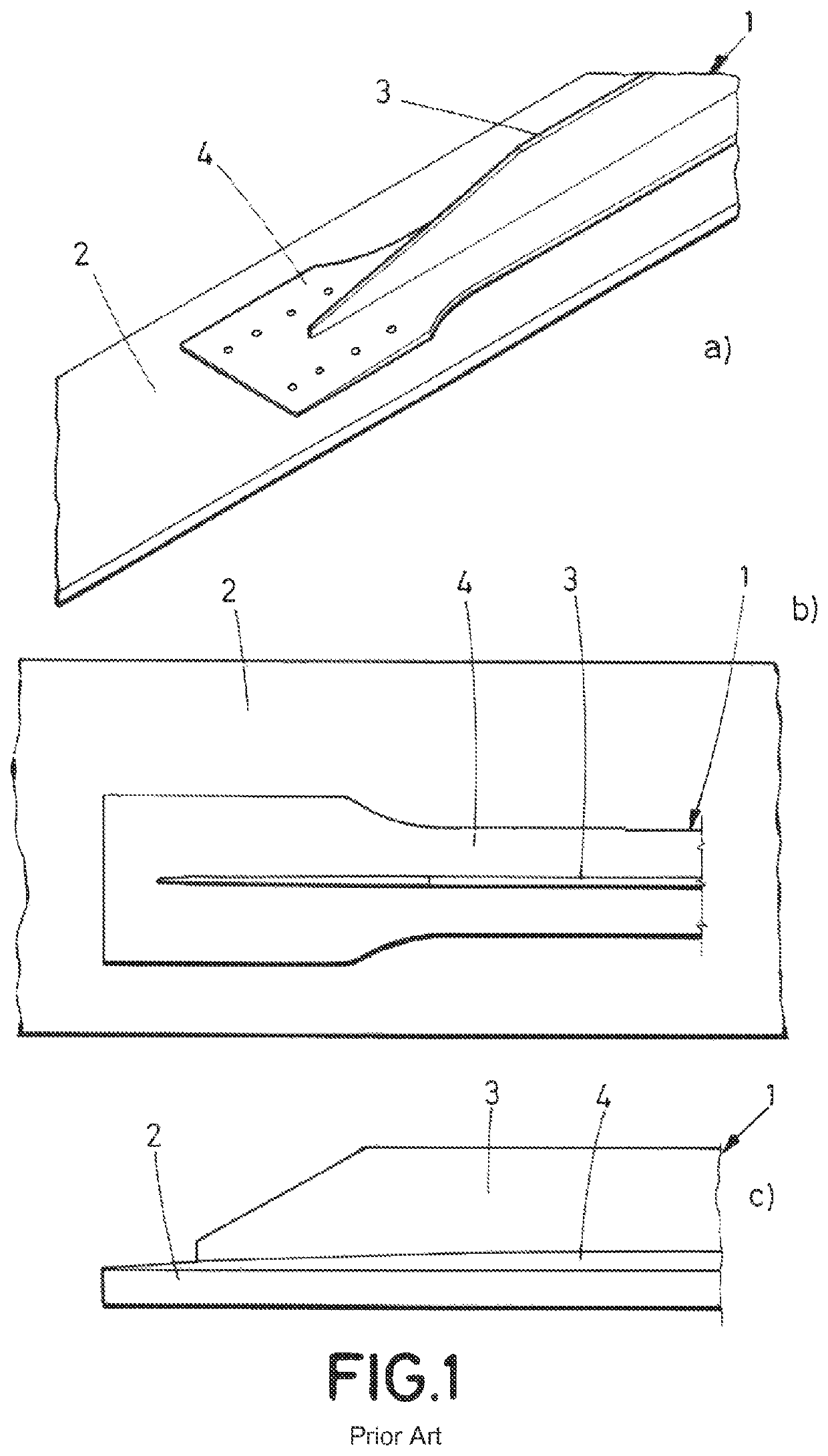

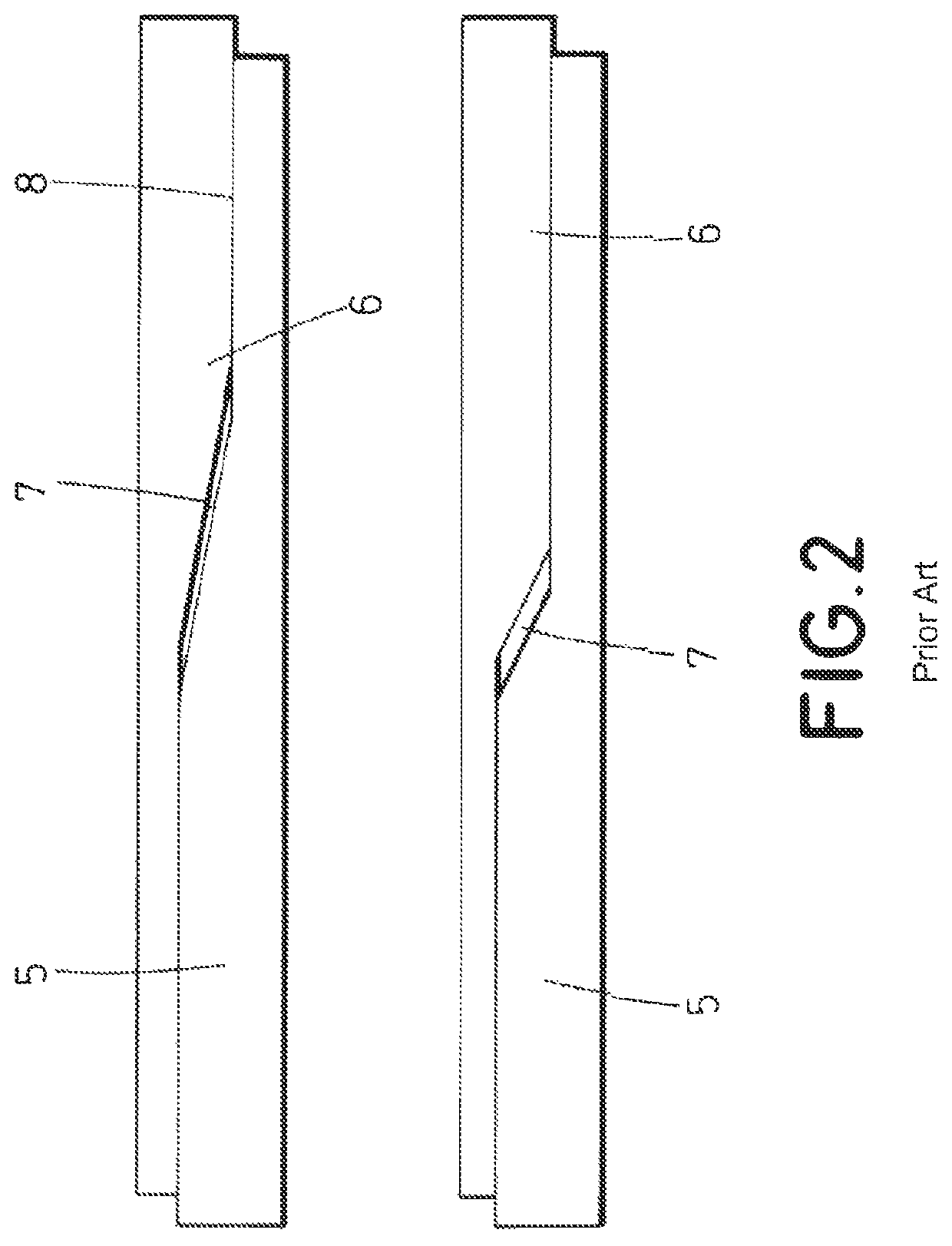

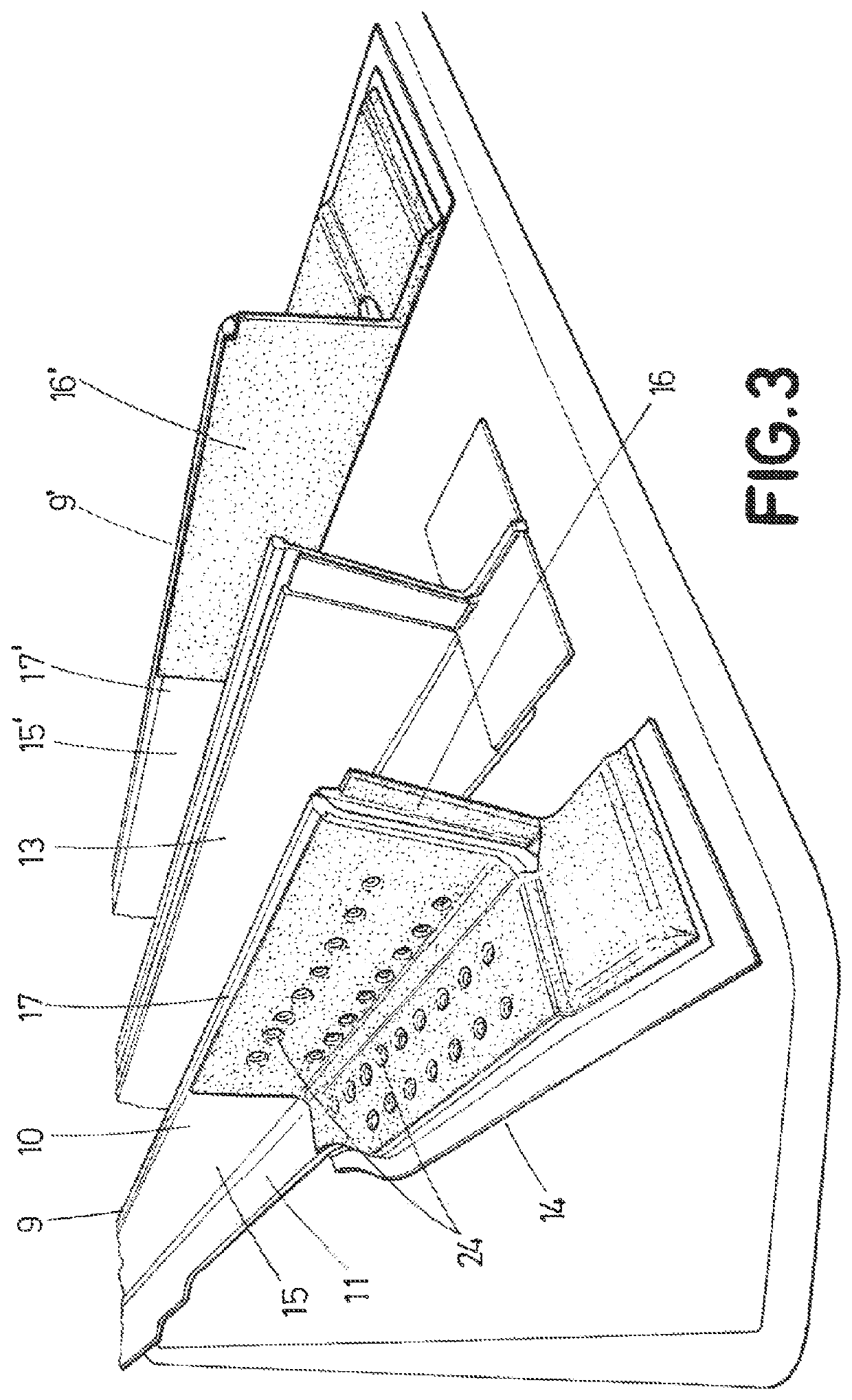

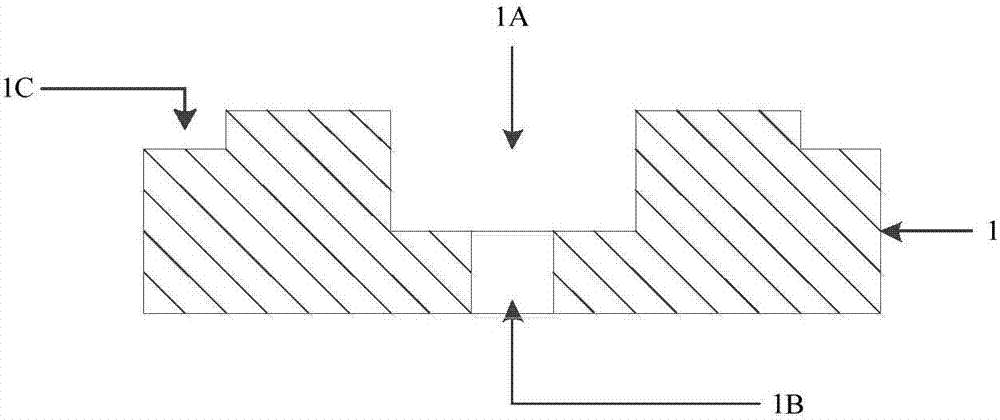

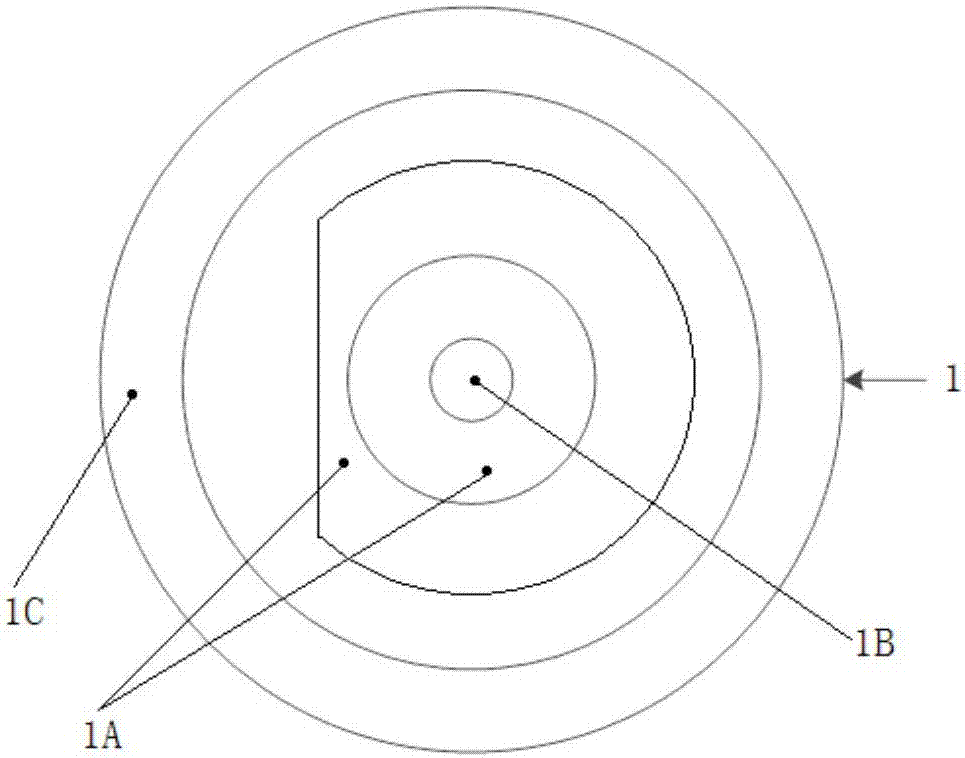

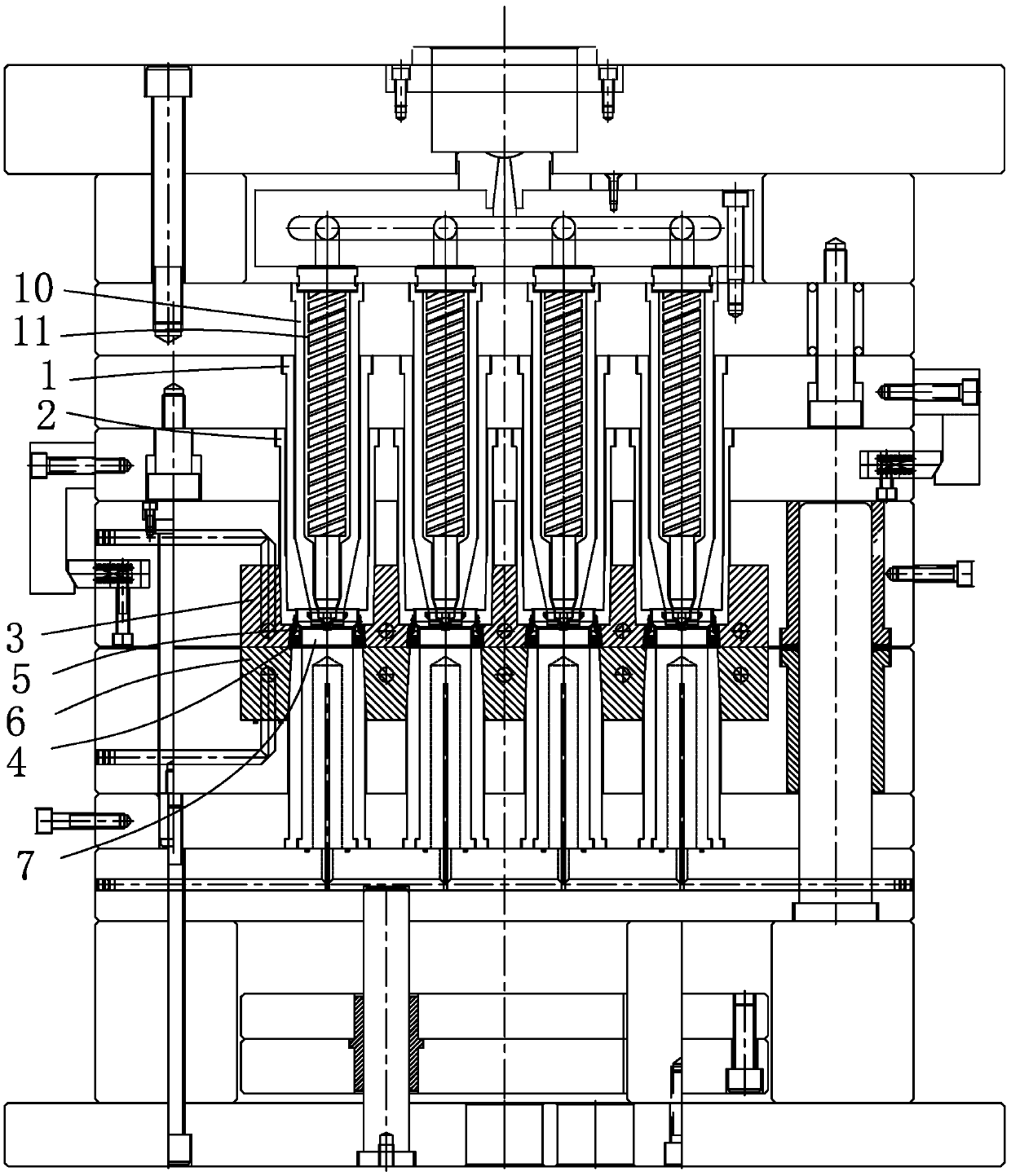

Method of molding composite molded article and mold system used for same

ActiveUS20100019411A1Effectively executeReduce volumeConfectioneryOptical articlesInjection molding machineShell molding

[Problem] To provide a method of molding a composite molded article enabling compression molding without requiring a large sized injection molding machine and a mold system used for that.[Means for Solution] A method of molding a composite molded article using a first mold member 13 to mold a primary molded article 29 by primary molding, switching a movable mold member holding the primary molded article 29 with a movable mold member 14 positioned with a second mold member 15, then using a second mold member 15 in which the primary molded article 29 is inserted to mold a secondary molded article 30 by secondary molding, wherein the primary molding and the secondary molding are executed by non-continuous different steps at points of time different from each other.

Owner:TEIJINKASEI +1

Mold system for composite molding

ActiveUS8408890B2Efficient executionReduce cavity volumeConfectioneryOptical articlesCompression moldingShell molding

[PROBLEM]To provide a method of molding a composite molded article enabling compression molding without requiring a large sized injection molding machine and a mold system used for that.[MEANS FOR SOLUTION]A method of molding a composite molded article using a first mold member 13 to mold a primary molded article 29 by primary molding, switching a movable mold member holding the primary molded article 29 with a movable mold member 14 positioned with a second mold member 15, then using a second mold member 15 in which the primary molded article 29 is inserted to mold a secondary molded article 30 by secondary molding, wherein the primary molding and the secondary molding are executed by non-continuous different steps at points of time different from each other.

Owner:TEIJINKASEI +1

Process of injection molding a foamable plastic composition

InactiveUS6245263B1Reduce volumeReduce cavity volumeLaminationLamination apparatusPlastic foamShell molding

A process of injection molding a foamable plastic composition which comprises filling completely a molten foamable plastic composition into a cavity, while reducing a volume of the cavity in the middle of injection or immediately after injection; cooling the composition to the state wherein a solidified layer in contact with a mold surface mingles with a molten inside layer; enlarging the volume of the cavity to that of the desired molded article; and after further cooling, removing the molded plastic foam article. This molded article comprises a layer having a non- or low-foamed, dense structure on the surface and a high-foamed layer at the inside, and has a light weight, good appearance and stiffness.

Owner:JNC CORP

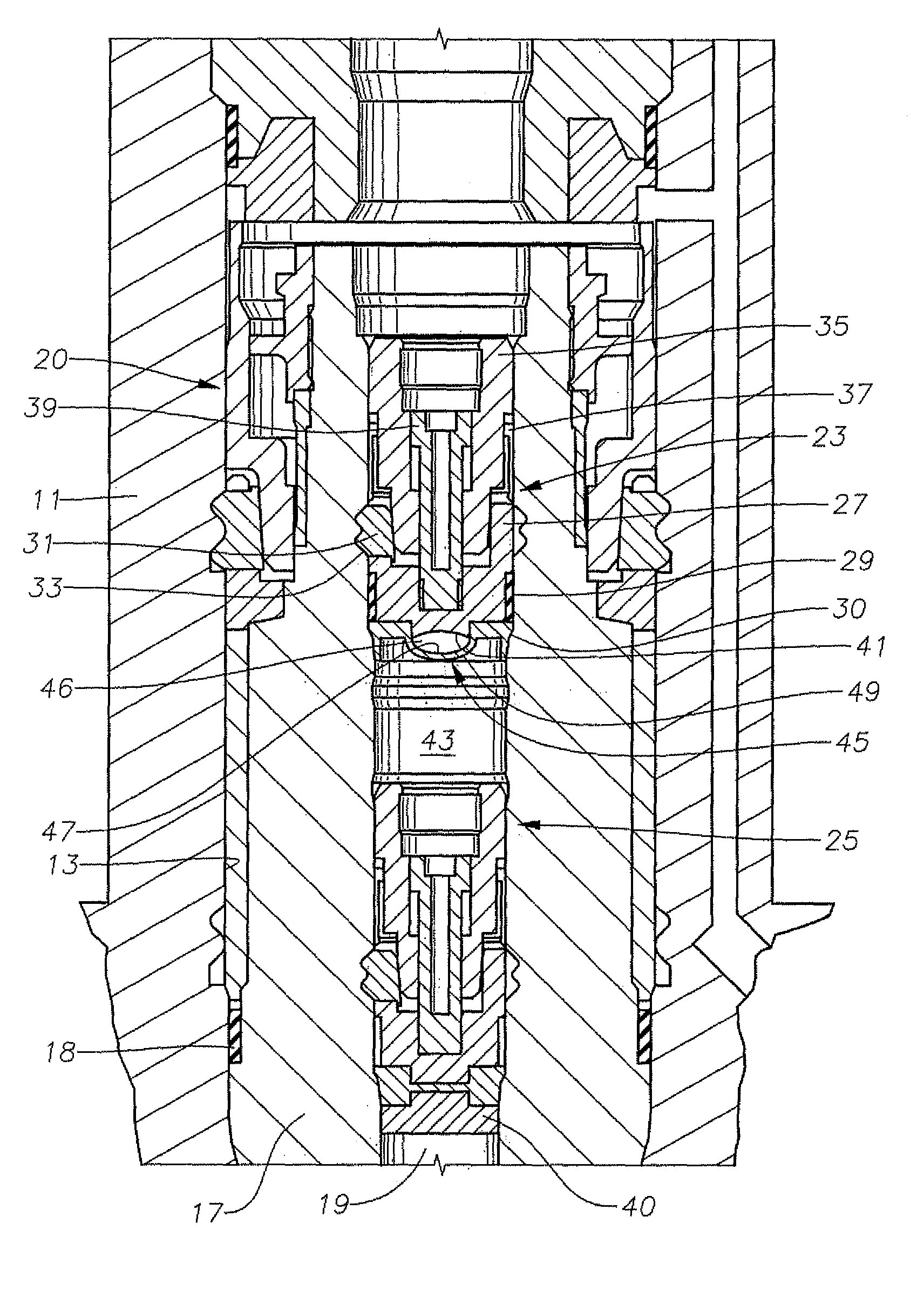

Bimetallic Diaphragm for Trapped Fluid Expansion

InactiveUS20100307764A1Relieve stressReduce cavity volumeDrilling rodsFluid removalMechanical engineering

A subsea well tubular member has an axial passage with upper and lower retrievable plugs releasably mounted in the passage, the plugs having ends facing each other. A cavity is formed on one of the ends of one of the plugs. A movable barrier is mounted sealingly over the cavity, the barrier being movable repeatedly between inner and outer positions in response to temperature changes. The inner position reduces a volume of the cavity and increases a volume of a trapped fluid space between the ends of the plugs. The outer position increases the volume of the cavity and decreases the volume of the trapped fluid space. The barrier has two metallic layers with different coefficients of expansion.

Owner:VETCO GRAY

Double-light-resistance wall and preparation method thereof

ActiveCN102591138AIncrease bonding areaImprove bindingPhotomechanical apparatusSemiconductor/solid-state device manufacturingCooking & bakingEngineering

The invention discloses a double-light-resistance wall and a preparation method of the double-light-resistance wall applied for through-silicon vias wafer level package. The preparation method mainly comprises the steps of glass cleaning, photoresist coating, exposure, development, baking and the like. In the exposure step, a double-light-resistance wall light cover is adopted, and the exposure energy is 800 to 1000mJ / cm<2>; and in the development step, 10 to 11g / L of Na2CO3 solution is adopted, and the development lasts 3 to 5 minutes. The double-light-resistance wall obtained by the method comprises a plurality of double-light-resistance wall units, wherein each double-light-resistance wall unit comprises an inner light resistance wall, an outer light resistance wall and a cutting passage, the outer light resistance wall is arranged on the periphery of the inner light resistance wall, and the cutting passage is arranged between the inner resistance wall and the outer resistance wall. The double-light-resistance wall has the advantages that the gluing area between the wall and wafers can be effectively increased, and in addition, the air bubble no-glue risk caused by glue overflowing and nonuniform glue can be reduced.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

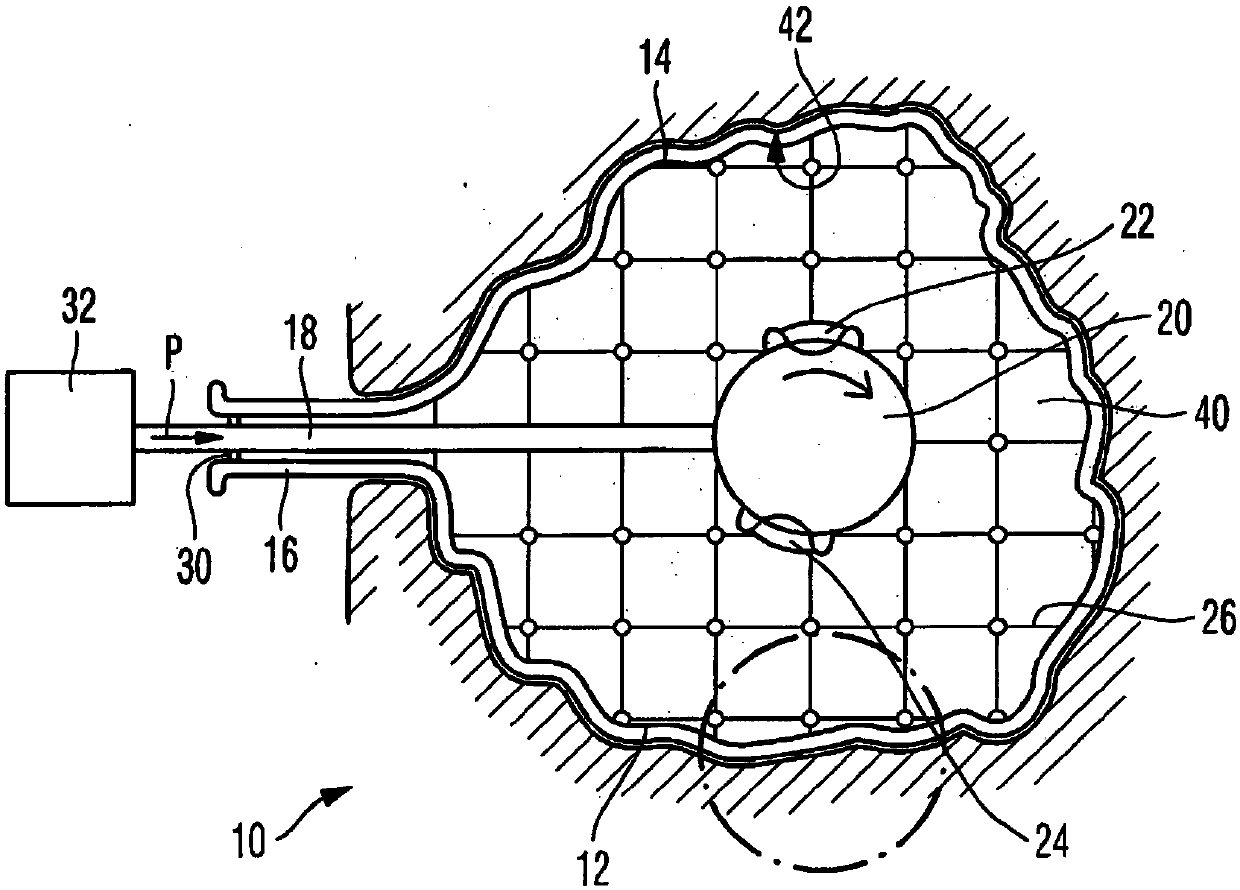

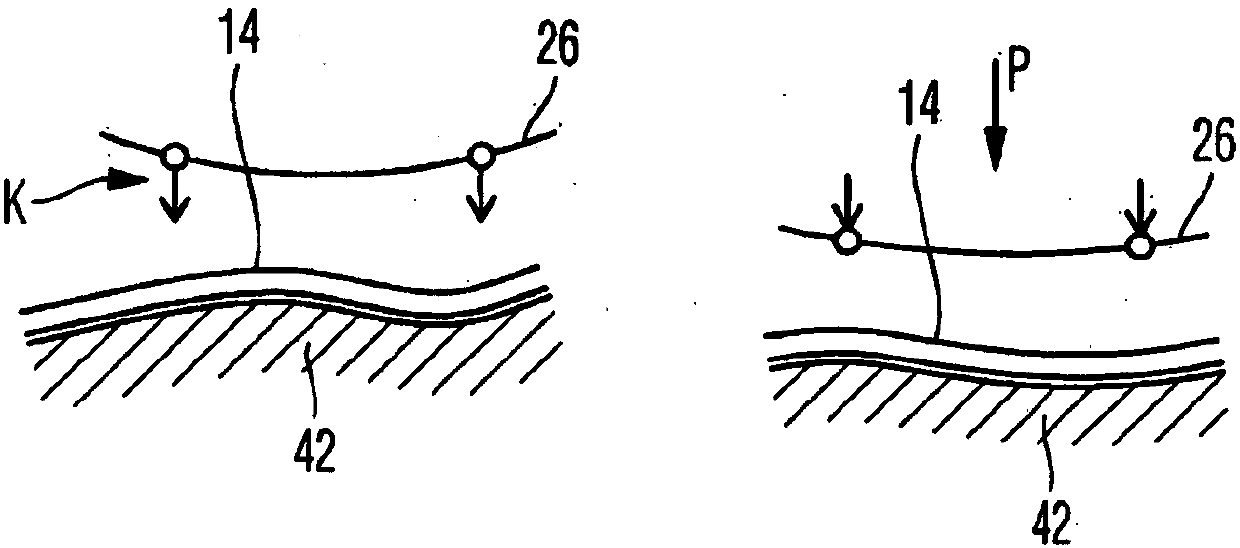

Image-recording device, balloon for operation with an image-recording device, method for operating an image-recording device, and control program for an image-recording device

The invention relates to an image-recording device (10), comprising a scanning-head guide (18) for moving the scanning head (20) across a scanning region (42) of a cavity, which scanning region (42) extends around the scanning head (20). A planar or film-like, elastically extensible material extends between the scanning head (20) and the scanning region (42), which material can be pressed againstthe scanning region (42) by the application of overpressure in the manner of a balloon (12). The scanning-head guide (18) extends through the balloon connection (16) of the balloon (12) to the scanning head (20). In particular, a control device (32) determines the shape of the cavity (40) against which the material rests from the deformation of the material while the overpressure is present.

Owner:IVOCLAR VIVADENT AG

Hybrid tool for curing pieces of composite material

ActiveUS10576723B2Repeat usageAvoid flowLamination ancillary operationsLaminationStringerMechanical engineering

A hybrid tool for curing composite structures for aircrafts, such as stringers, torsion boxes, skin panels, wing surfaces, horizontal tail or vertical stabilizers, etc. The hybrid tool comprises a metallic portion and an elastic portion arranged on a surface of the metallic portion. The elastic portion and the metallic portion are permanently joined to each other so that the metallic portion and the elastic portion together define a surface having a shape which copies at least part of a surface of a piece of composite material to be cured. The tool is capable of satisfactorily curing pieces of composite material which have a minimum thickness and / or a very aggressive change of thickness.

Owner:AIRBUS OPERATIONS SL

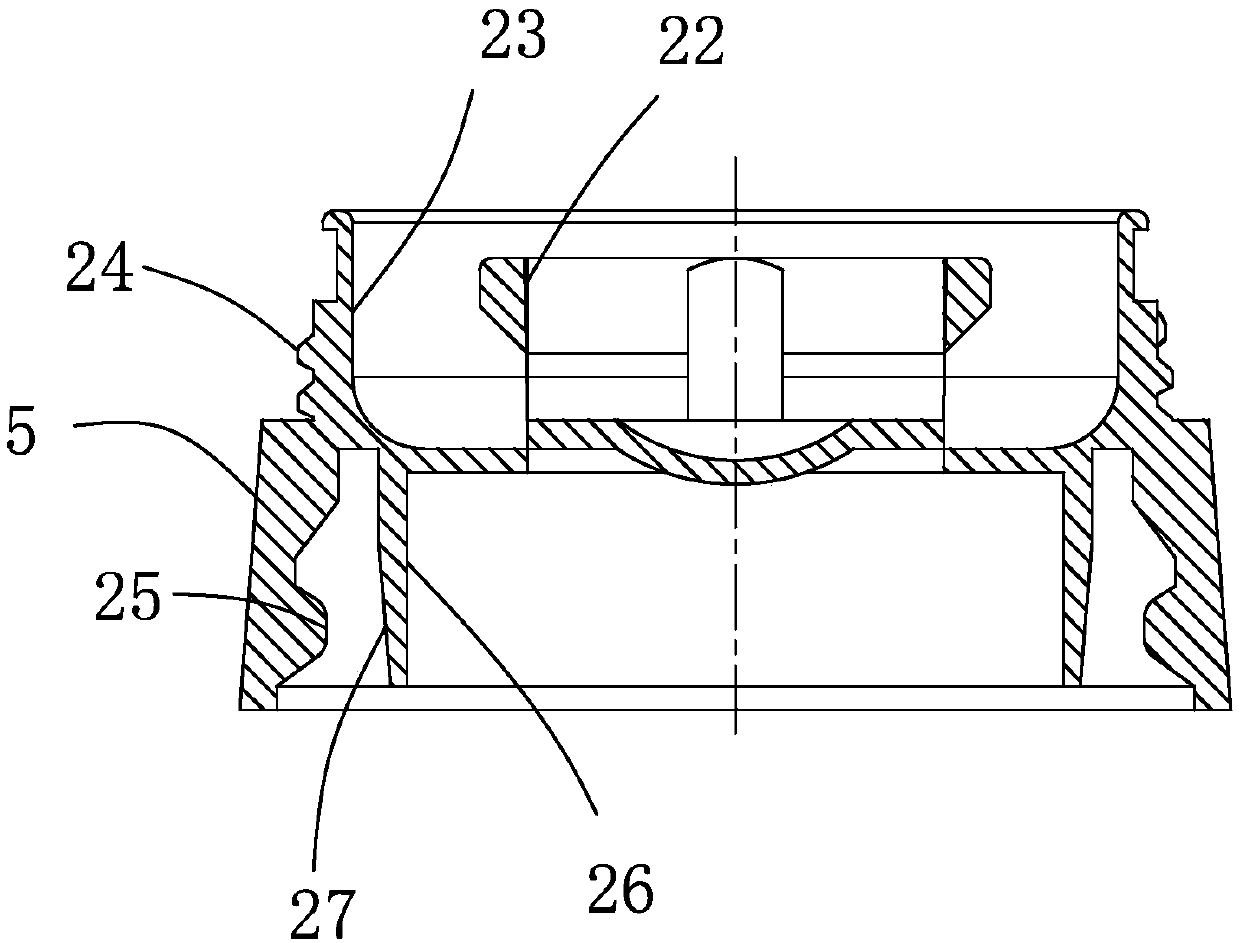

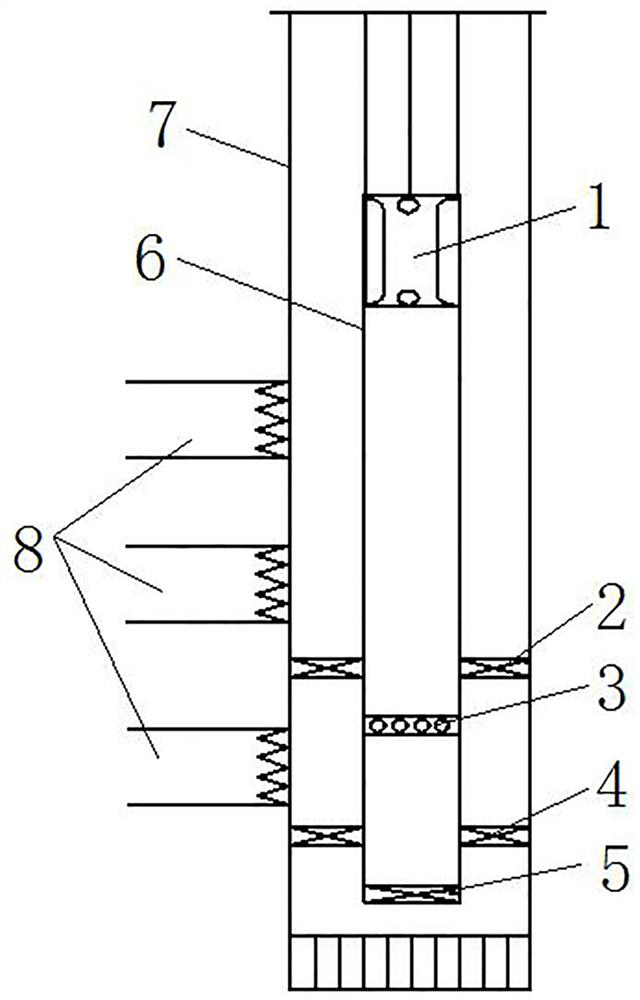

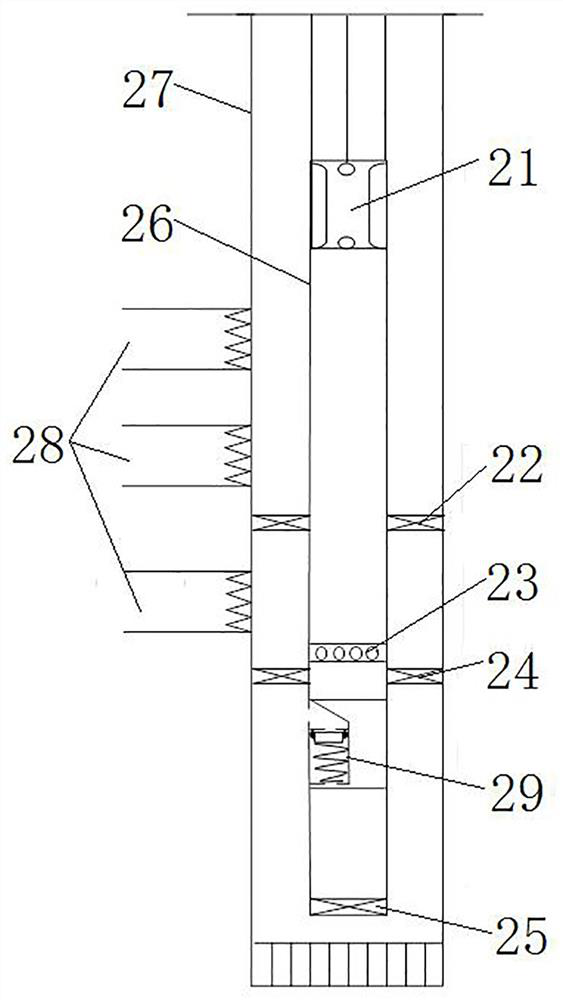

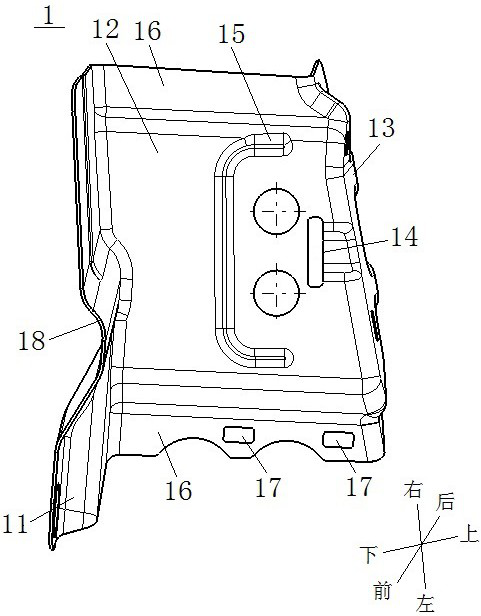

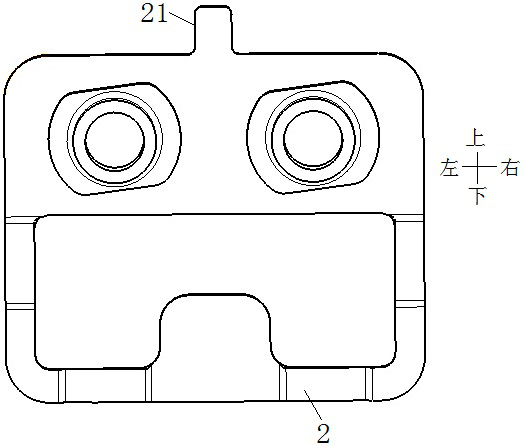

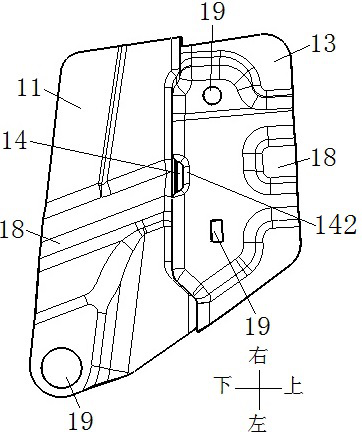

Microcircuit internal atmosphere detection test clamp

ActiveCN107389867AReduce cavity volumeReduce the amount of gasGas analyser construction detailsEngineeringAtmosphere

The invention discloses a microcircuit internal atmosphere detection test clamp and relates to the field of reliability and environment tests of electronic products. The clamp comprises a primary clamp body, a secondary clamp body and a cover body, wherein an inwards concave press cavity is formed in the central position of one end of the primary clamp body and used for accommodating the secondary clamp body, a through connecting channel is formed in the press cavity and used for accommodating a to-be-tested device, a yield part is arranged on the peripheral edge, located on the same side of an opening part of the press cavity, of the primary clamp body and used for mounting a seal ring, and the cover body covers the opening of the press cavity and the seal ring. The clamp provides a new thought for accommodating of the to-be-tested device, that is, the connecting channel with the diameter slightly larger than that of the to-be-tested device is designed, the to-be-tested device is put in the connecting channel, the sealing property of the clamp and protection of the to-be-tested device are greatly improved, besides, the matched secondary clamp body is designed, can fix the to-be-tested device and can greatly reduce vacant space in the clamp, and influence of the atmosphere of the clamp on the detection result is further reduced.

Owner:NO 24 RES INST OF CETC

Forcible release multi-parting bottle cap injection mold

The invention discloses a forcible release multi-parting bottle cap injection mold, comprising a mold cavity and a pouring system, wherein a plastic part is arranged under the pouring system; a thirdcore insert is inserted into a first hole; a fourth cavity insert is disposed in a first annular groove; a first cavity insert is disposed at an outer circumferential surface of the plastic part withan external thread; a smooth outer circumferential surface of the plastic part is provided with a second cavity insert; a first core insert is disposed at a first internal thread; a second core insertis inserted into a second hole; and a third core insert is arranged on the end face, far away from the pouring system, of the plastic part. The invention has the advantages that the cavity inserts and the core inserts have a simple structure and a small volume, which is convenient for operation, and dozens or even hundreds of mold cavities can be arranged in a mold as required, thereby greatly improving production efficiency and reducing the number of required molds, and reducing production costs and mold manufacturing costs.

Owner:ZHEJIANG BUSINESS TECH INST

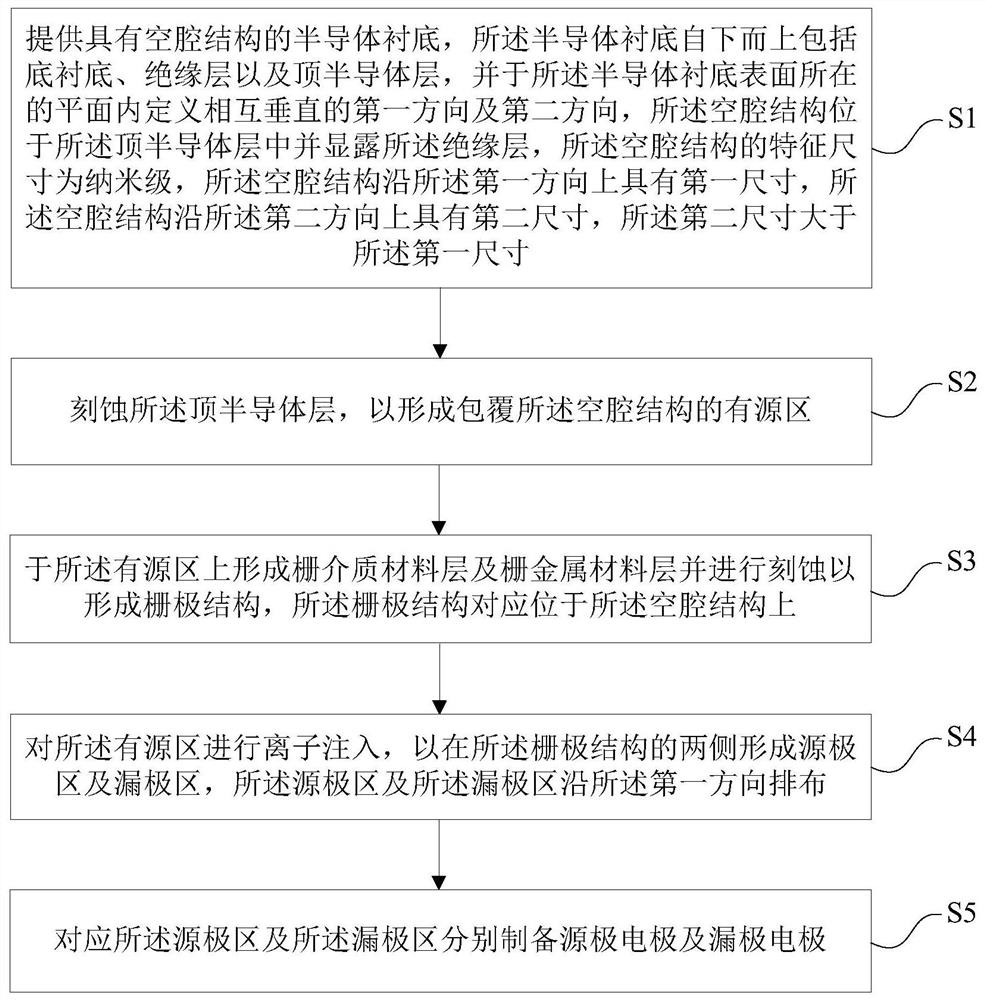

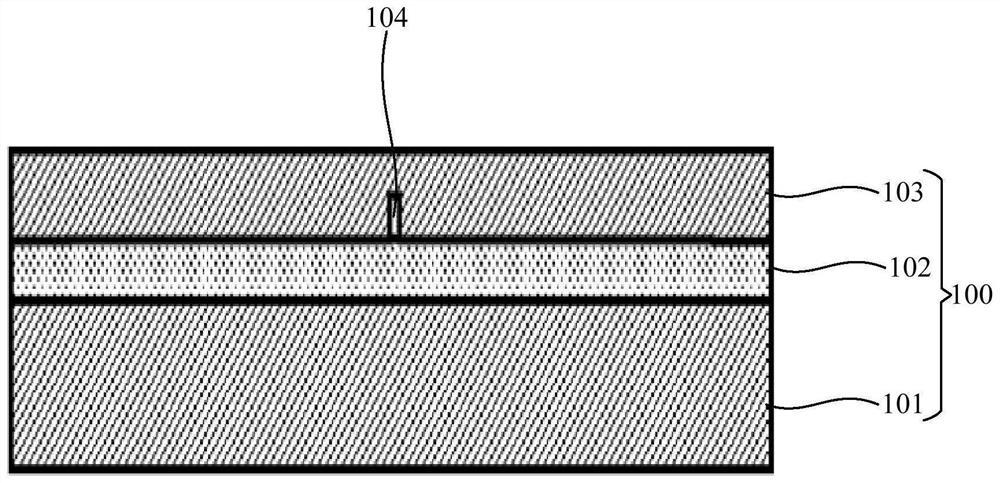

SOI device capable of improving self-heating effect and preparation method thereof

ActiveCN111986996AGuaranteed breakageReduce self-heating effectTransistorSemiconductor/solid-state device manufacturingFloating body effectEngineering

The invention provides an SOI device capable of improving a self-heating effect and a preparation method thereof. The preparation comprises the steps: providing a semiconductor substrate with a cavitystructure, enabling the cavity structure to be located in a top semiconductor layer and exposing an insulating layer, preparing an active region coating the cavity structure, and preparing a gate electrode structure, a source-drain region and a source-drain electrode. The SOI substrate with the nanoscale cavity is adopted, the cavity structure is located in the top semiconductor layer, the size of the cavity is effectively reduced, the cavity is in the nanoscale size in the channel length direction, the heat dissipation path of the device cannot be obviously blocked, and compared with a device with a large-size cavity, the self-heating effect is relieved. Theoretically, the thickness of the top semiconductor layer above the cavity can reach 2 nm, it is guaranteed that top silicon is not damaged, a channel can be completely exhausted by a gate electrode, and the floating body effect is effectively restrained. The cavity is located in the top semiconductor layer and makes contact with the insulating layer, parasitic charges in the insulating layer cannot be introduced into a parasitic channel at the bottom of the top semiconductor layer, and the total dose radiation effect is effectively restrained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Machine tool main shaft speed changing box

InactiveCN104534032AImprove rigiditySmall meshing displacementToothed gearingsGearing controlCavity sizeMachine tool

The invention relates to a machine tool main shaft speed changing box which comprises a box body, an input shaft and an output shaft. The input shaft is fixedly connected with a main input gear. The output shaft is fixedly connected with a main output gear. A speed changing group comprises a clutch, a hollow shaft and a solid shaft. The upper portion of the hollow shaft and the lower half side of the clutch are fixed. The lower portion of the hollow shaft is fixedly provided with a hollow shaft gear meshed with the main input gear. The upper portion of the solid shaft is fixedly connected with the upper half side of the clutch. The lower portion of the solid shaft is provided with a solid shaft gear meshed with the main input gear. The solid shaft is connected into the hollow shaft in a sleeved mode through a bearing, and the solid shaft and the hollow shaft are coaxial. Transmission chain rigidity is improved, the service life of the gears and a supporting bearing on a shaft is prolonged, the cavity size in the speed changing box is reduced, so that a gear box is stable, the design of an inner-outer sliding spline in the transmission main shaft speed changing box is avoided, the machining difficulty of the shaft gears is lowered, and reliability is improved.

Owner:SHANDONG YONGHUA MACHINERY

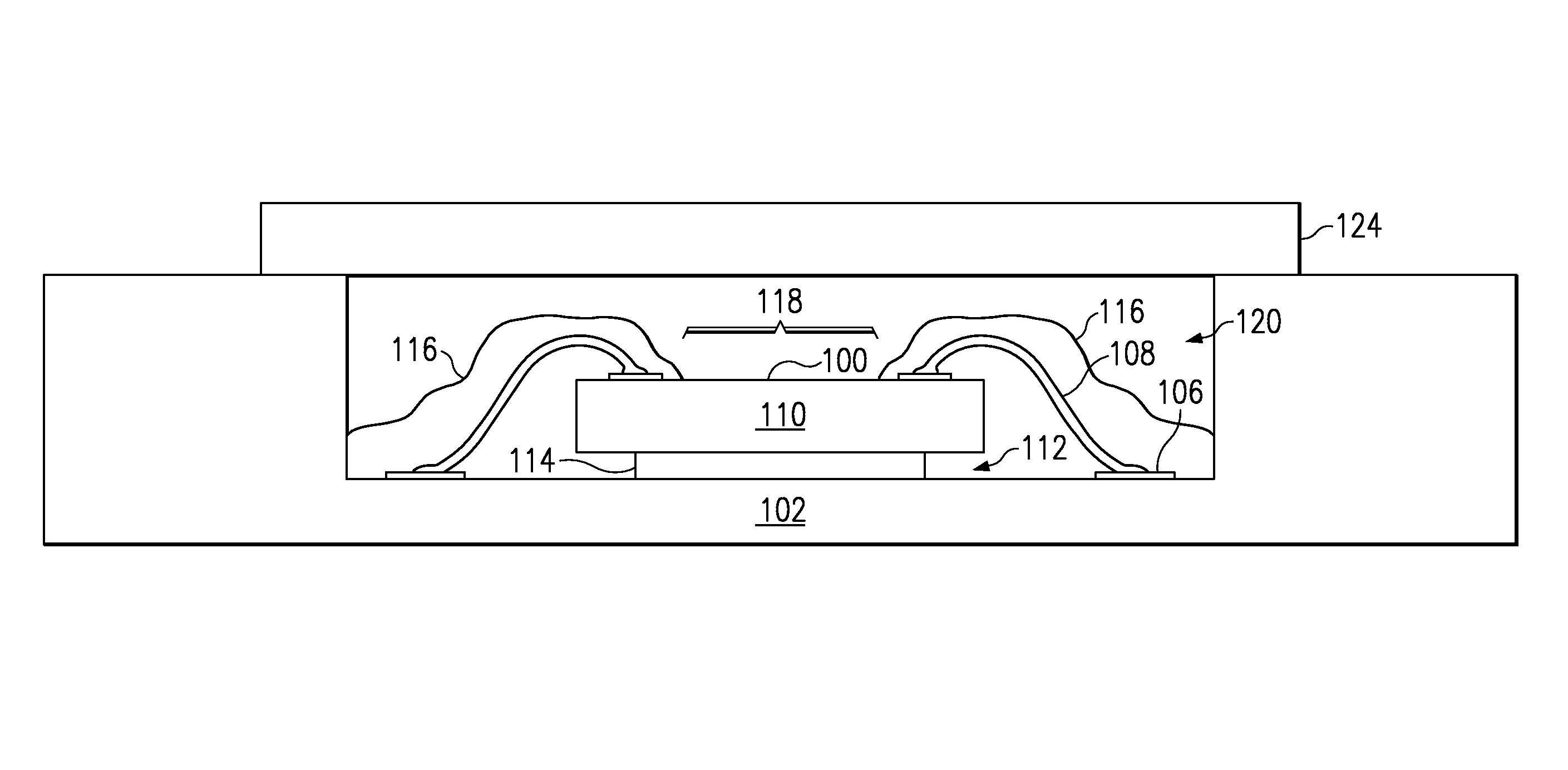

Encapsulation for particle entrapment

InactiveUS7230325B2Reduce cavity volumeEliminate the effects ofSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEntrapment

A packaged micromechanical device (100) having a blocking material (116) encapsulating debris-generating regions thereof. The blocking material (116) prevents the generation of debris that could interfere with the operation of the micromechanical device (100). Debris-generating regions of the device (100), including debris-creating sidewalls and any debris-harboring cavities, as well as electrical connections (108) linking the device (100) to the package substrate (102) are encapsulated by the blocking material (116). The blocking material (116) avoids contact with any debris-intolerant regions (118) of the device (100). A package lid (124), which is glass in the case of many DMD packages, seals the device (100) in a package cavity (120).

Owner:TEXAS INSTR INC

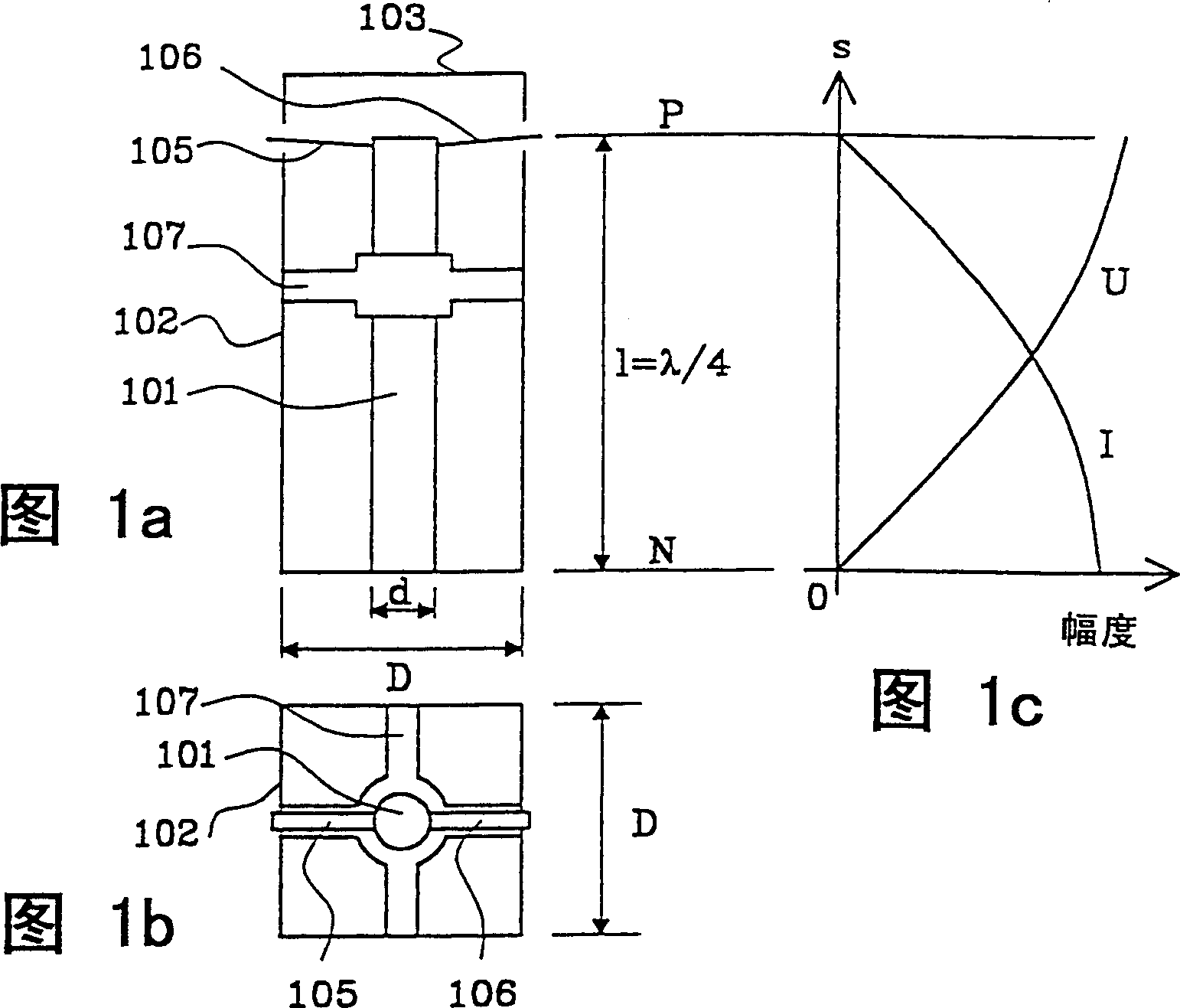

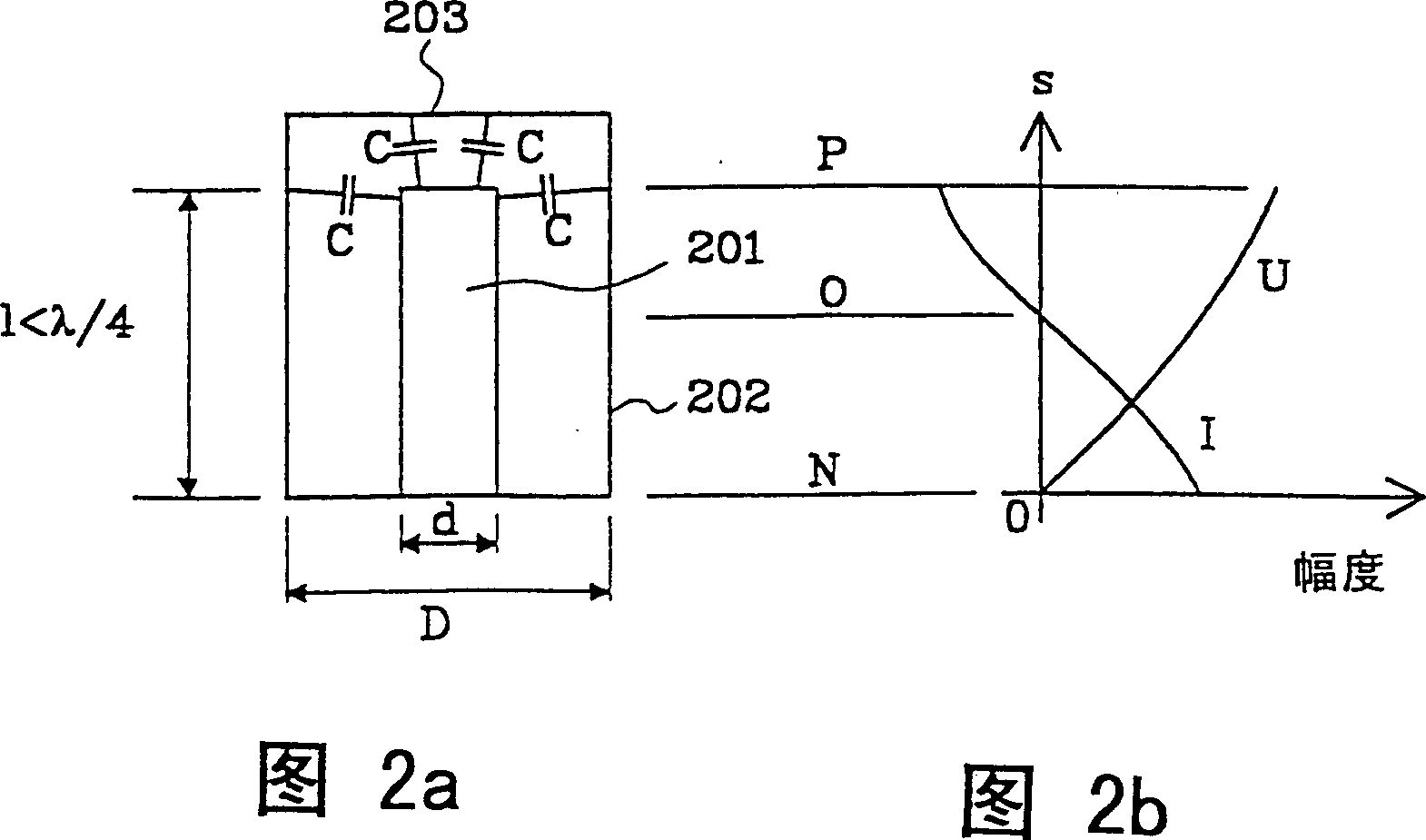

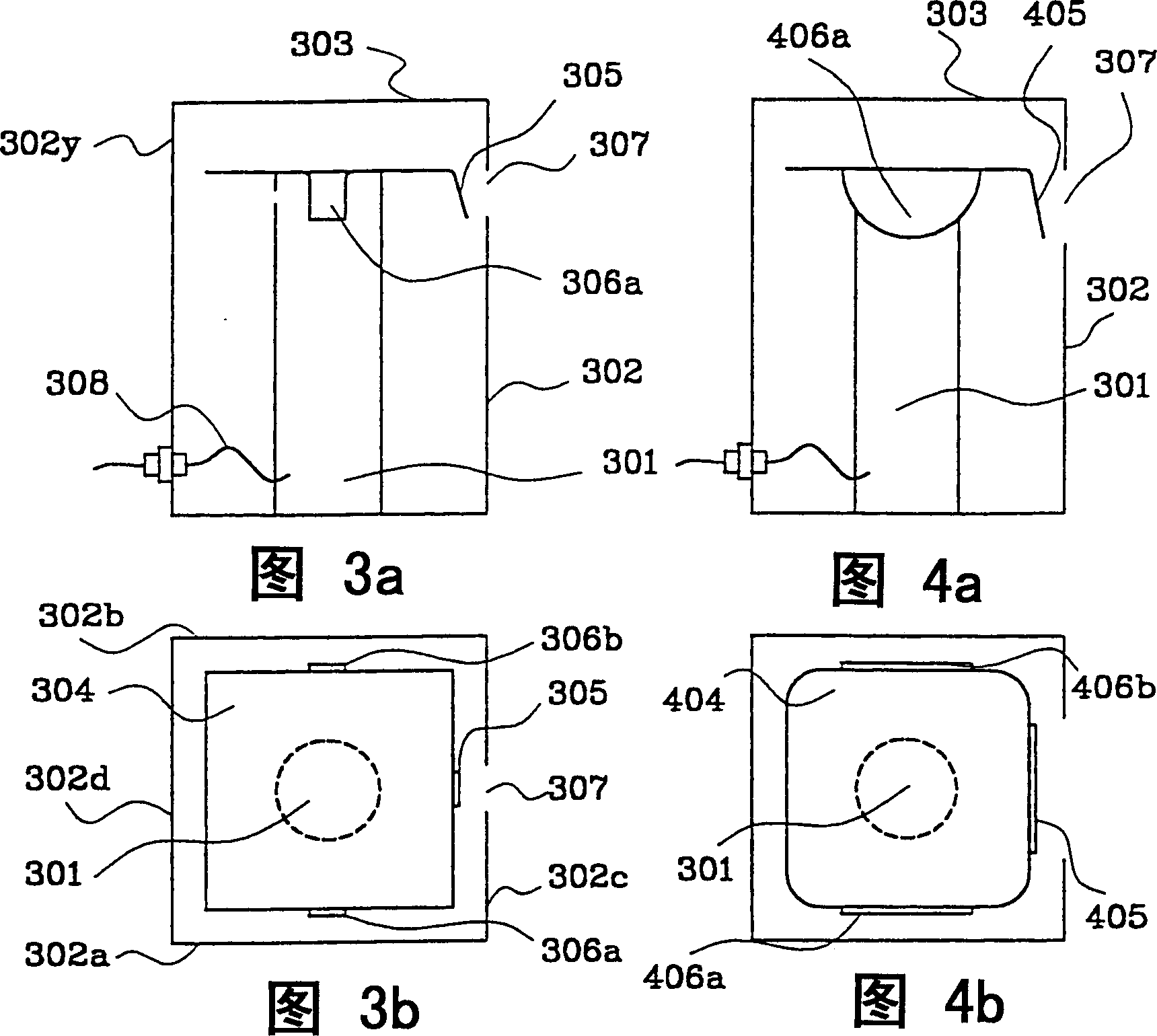

Multisurface coupled coaxial resonator

The invention relates to an air-insulated coaxial resonator, which is particularly suitable for a structural part in duplex filters. The resonator has an inner conductor (301) extended at one end, so that it forms extra capacitance with the cover (303) of the resonator and the upper part (302y) of the outer conductor. Because of the extra capacitance, a resonator of a certain frequency is shorter than a corresponding quarter-wave resonator. Because of this it is also mechanically stronger and is more stable in its properties. The extension of the inner conductor and the shortening of the construction also have a dissipation-reducing effect. The extension (304, 305, 306a, 306b) can also be used for tuning the resonator and for coupling to the adjacent circuit elements. In a construction according to the invention, a third harmonic of the basic frequency component does not occur, which is a remarkable advantage in the manufacture of filters.

Owner:INTEL CORP

Bimetallic diaphragm for trapped fluid expansion

InactiveUS8276672B2Relieve stressReduce cavity volumeDrilling rodsFluid removalEngineeringMechanical engineering

A subsea well tubular member has an axial passage with upper and lower retrievable plugs releasably mounted in the passage, the plugs having ends facing each other. A cavity is formed on one of the ends of one of the plugs. A movable barrier is mounted sealingly over the cavity, the barrier being movable repeatedly between inner and outer positions in response to temperature changes. The inner position reduces a volume of the cavity and increases a volume of a trapped fluid space between the ends of the plugs. The outer position increases the volume of the cavity and decreases the volume of the trapped fluid space. The barrier has two metallic layers with different coefficients of expansion.

Owner:VETCO GRAY

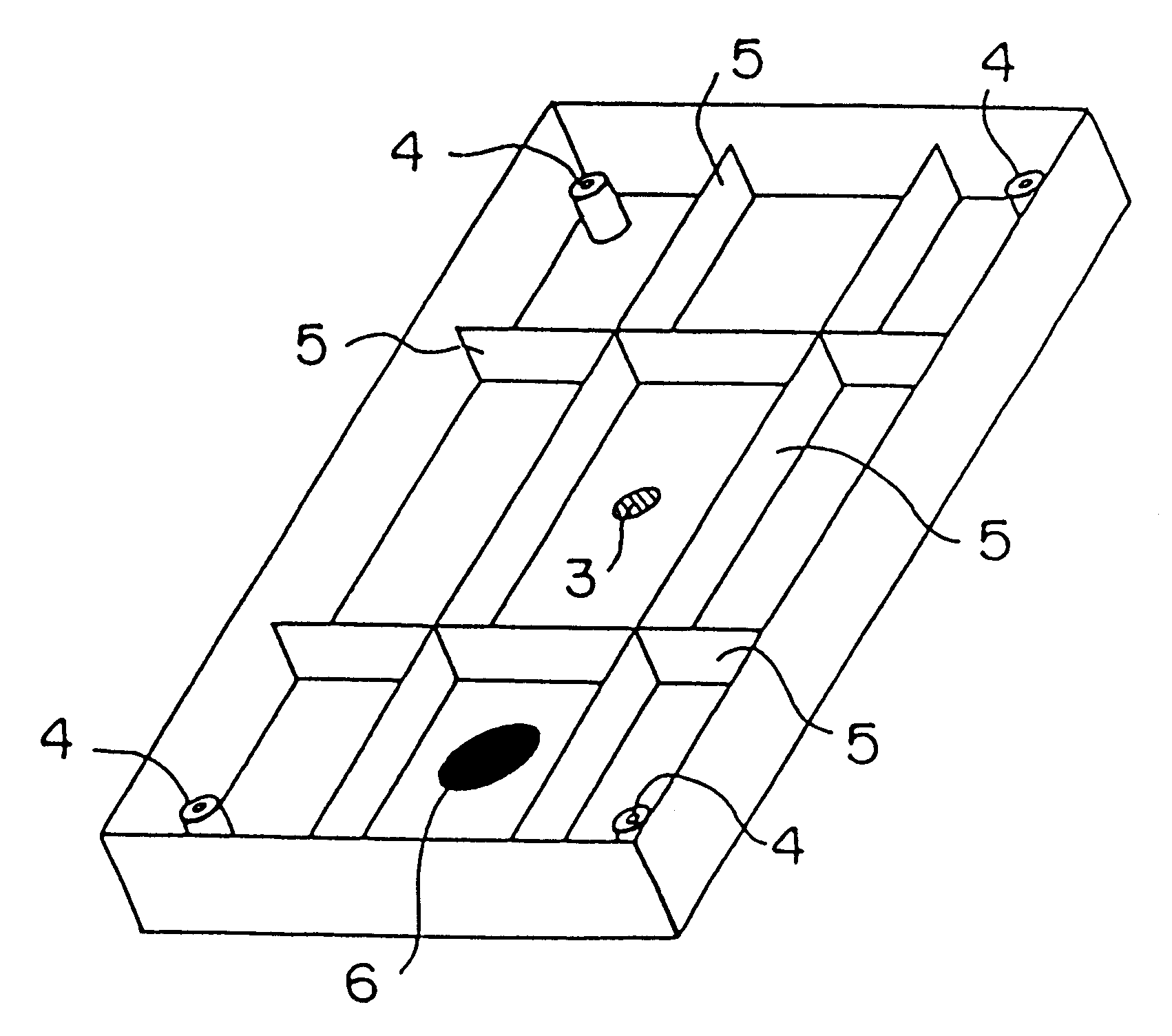

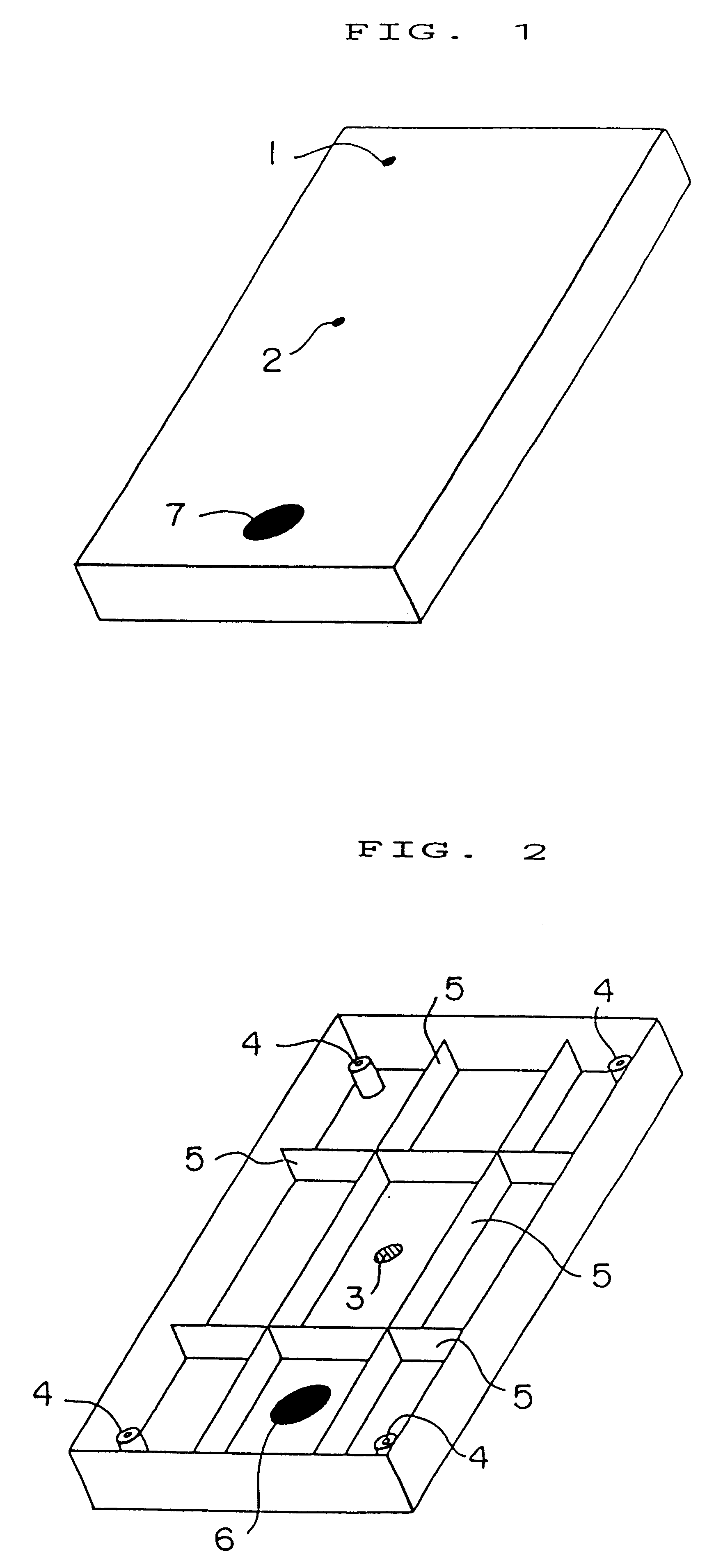

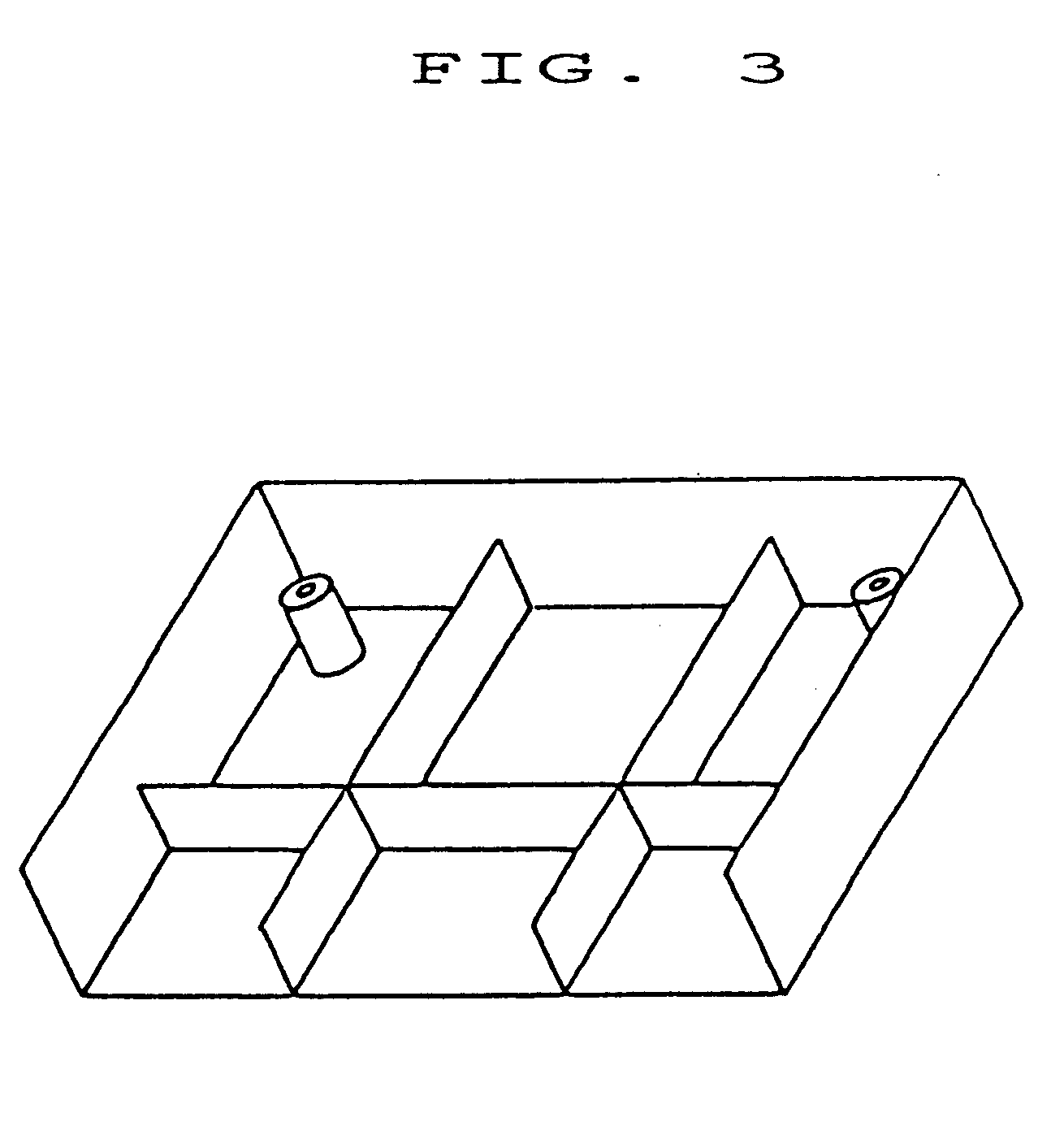

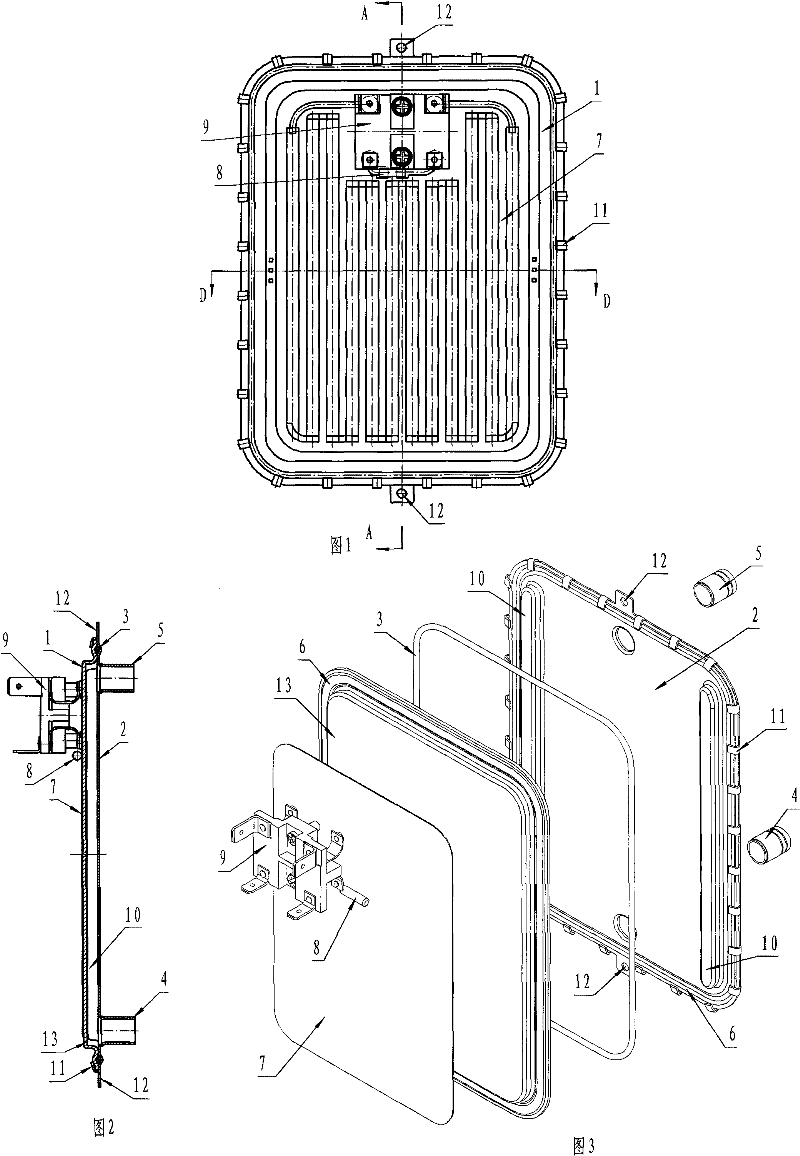

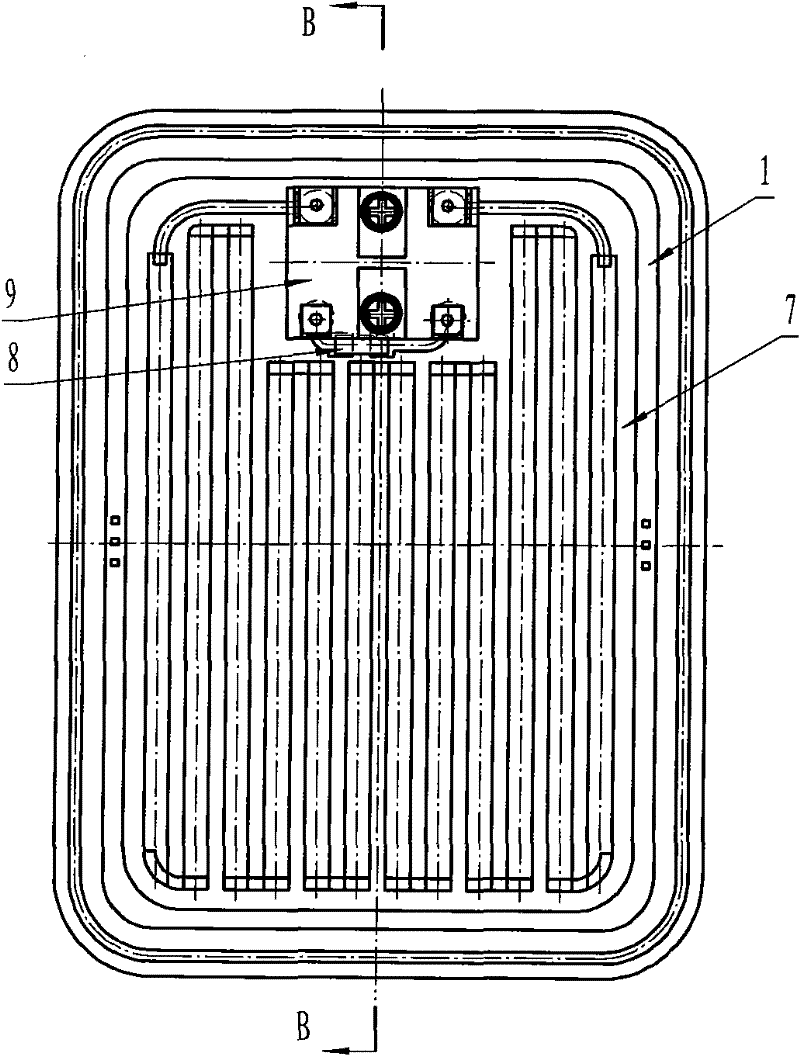

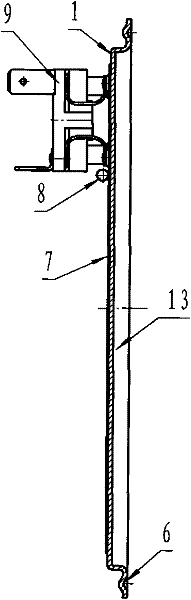

Instantaneous electric kettle heating body

InactiveCN102297518AReduce cavity volumeFast feverFluid heatersElectrical resistance and conductanceEngineering

A heating body for an instant electric kettle that uses a stainless steel substrate electric heating film to generate heat, comprising a heating plate (1), an electric heating film (7), a thermistor (8), a connector (9), and a rear plate of the heating body (2), sealing ring (3), water inlet joint (4) and water outlet joint (5), the assembly structure is shown in the figure. The electrothermal film (7) is processed on the outer surface of the heating plate (1), the water inlet joint (4) and the water outlet joint (5) are installed on the heating body rear plate (2), and the groove (6) of the heating plate (1) ) position and place the sealing ring (3), then cover the heating body rear plate (2) on the heating plate (1), bend and press the tooth-shaped mounting buckle (11) so that the heating plate (1) and the heating body The rear plate (2) is tightly assembled, and the thickness of the inner cavity of the heating body is 3-8mm after assembly. The heating body also has the characteristics of small cavity volume, small heat capacity, fast heating and small heat transfer resistance. It can provide hot water above 85°C in 3-5 seconds after being energized and heated from the cold water state.

Owner:宁波市塞纳电热电器有限公司

Pump and packer integrated water exploration and plugging pipe pile and floating bottom plug thereof

ActiveCN111997563AIncrease cavity volumeSeating benefitsFluid removalWell/borehole valve arrangementsMechanical engineeringWater pipe

The invention relates to a pump and packer integrated water exploration and plugging pipe pile and a floating bottom plug thereof. The floating bottom plug of the pump and packer integrated water exploration and plugging pipe pile comprises a cylinder body with a communication channel extending in the vertical direction, a piston cavity formed in the cylinder body and extending in the vertical direction, a piston slidably and hermetically assembled in the piston cavity, an elastic part and a flow channel, wherein the piston cavity and the communication channel are distributed at an interval inthe radial direction of the cylinder body, and the lower potion of the piston cavity communicates with the communication channel; the piston aims to adjust the volume of the portion, below a lower packer, of the cavity; the elastic part is disposed in the piston cavity and used for applying upward elastic force to the piston; and the flow channel is formed in the cylinder body and used for makingthe portion, above the piston, of the piston cavity communicate with an oil pipe annulus below the lower packer. Due to the design, lay-down setting and lifting unsealing of the pipe pile are facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

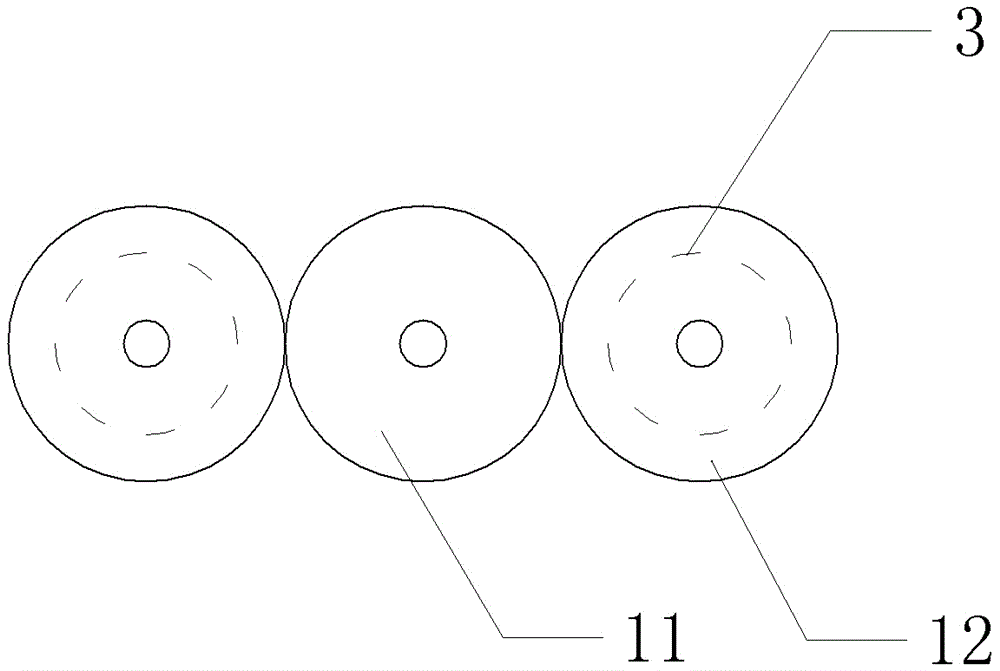

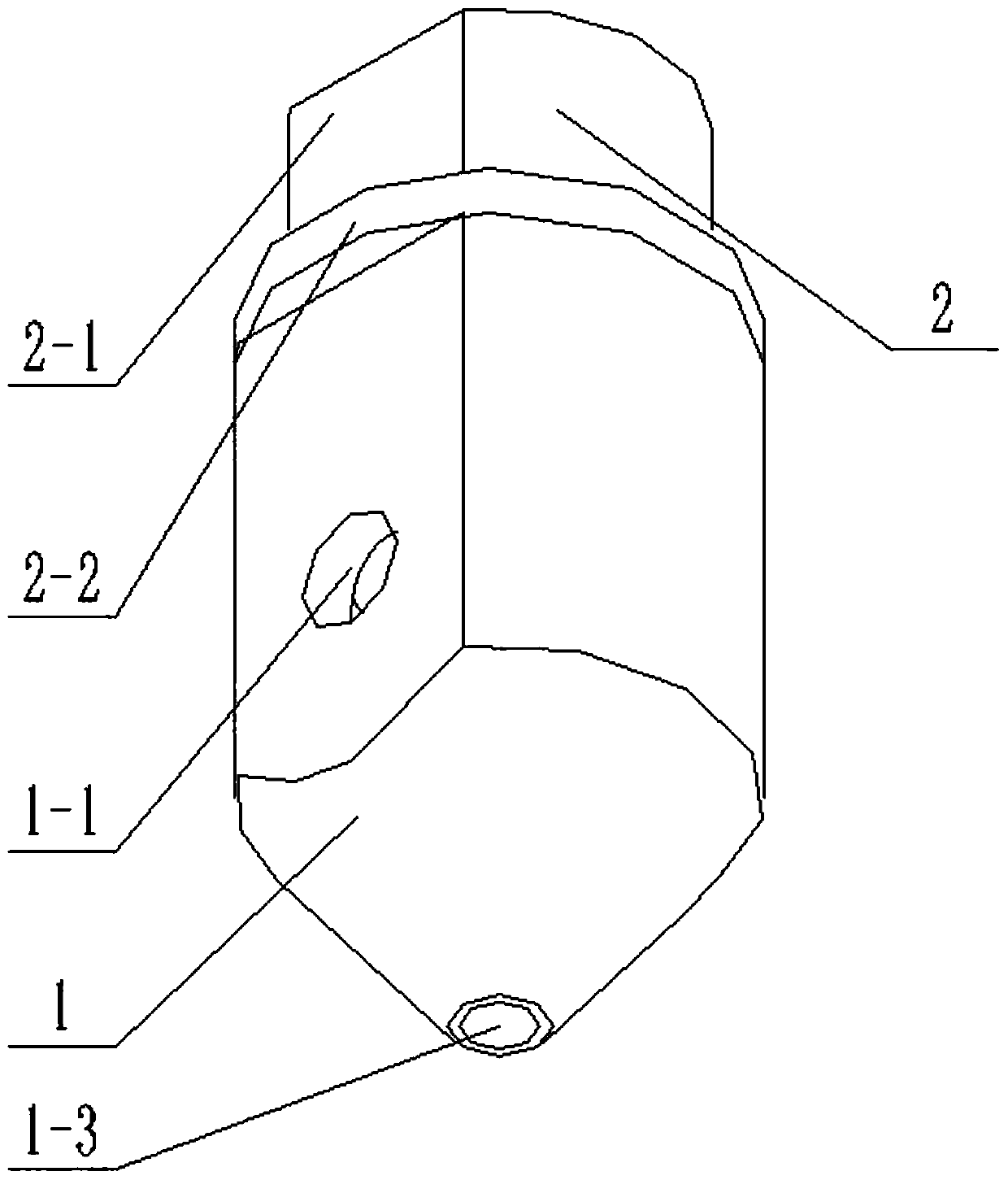

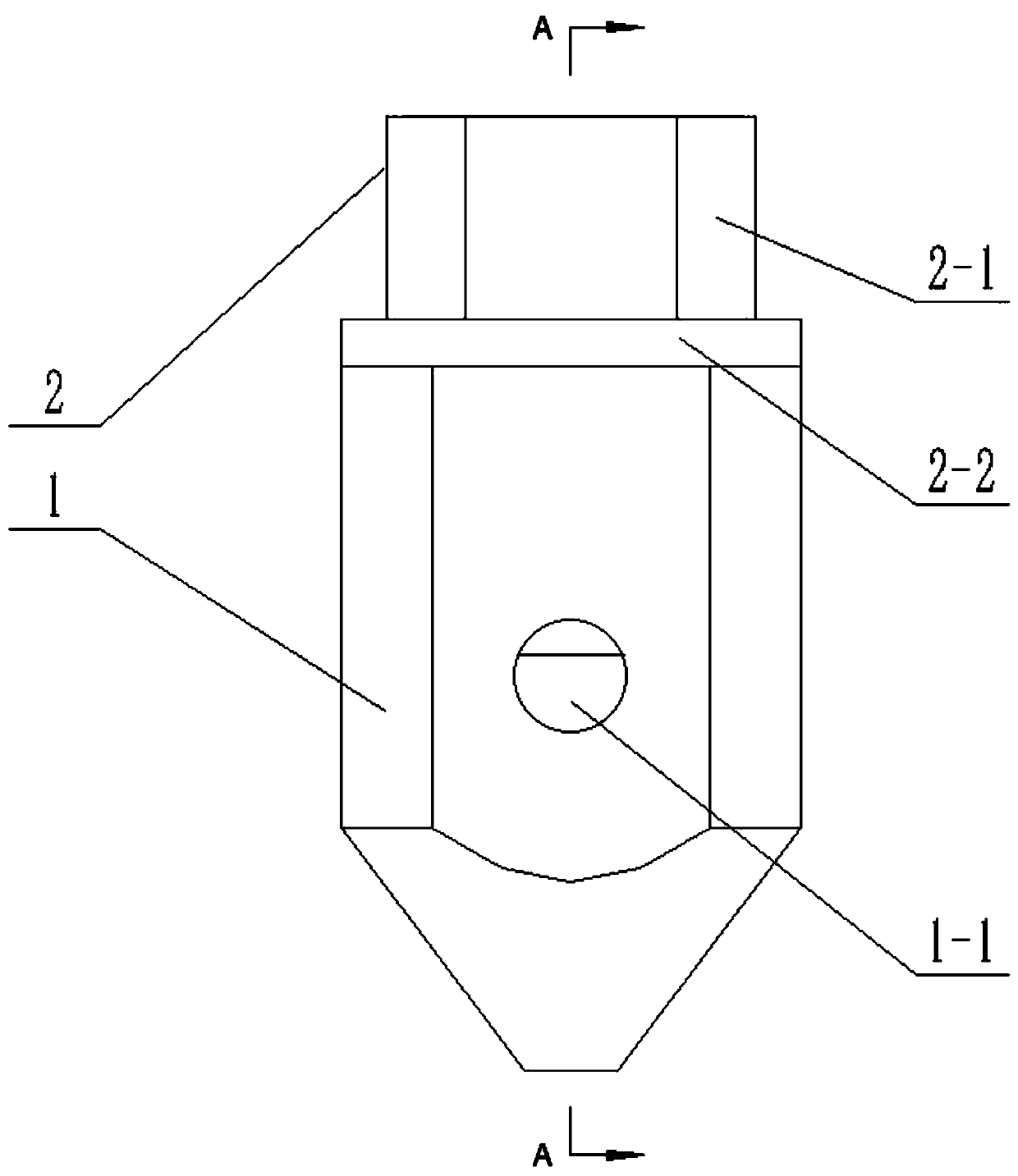

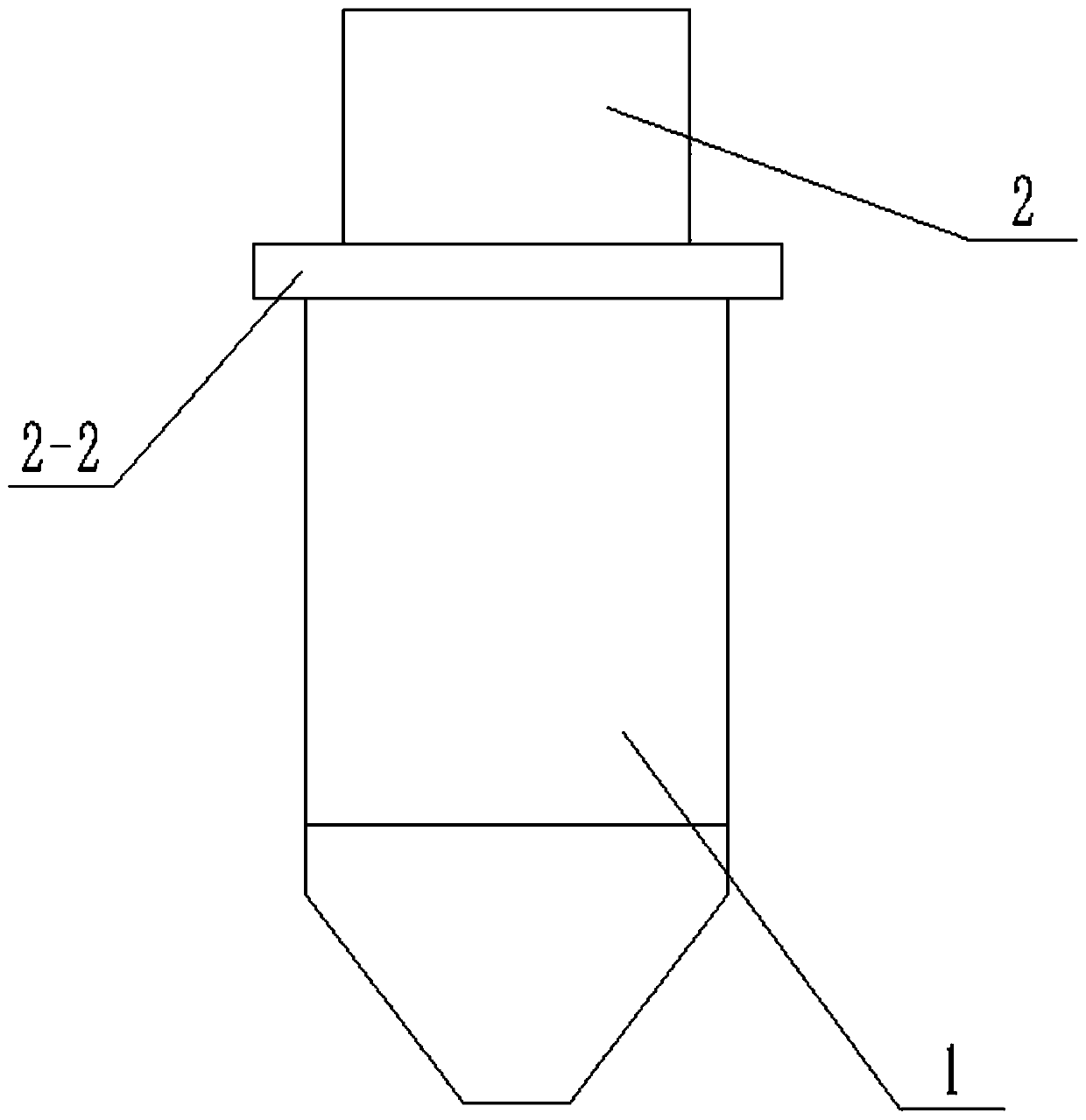

Continuous fiber reinforced composite material additive manufacturing nozzle and printer

ActiveCN107127972BSmall diameterSmall size3D object support structuresApplying layer meansYarnComputer printing

The invention belongs to the field of additive manufacturing, and particularly relates to a continuous fiber reinforced composite material additive manufacturing spray nozzle and a printing machine. The continuous fiber reinforced composite material additive manufacturing spray nozzle and the printing machine have the advantages that the continuous fiber reinforced composite material additive manufacturing spray nozzle comprises an outer spray nozzle and an inner spray nozzle, the spray nozzles are simple in structure and are small, and the forming precision can be improved; the vertical distance from an outlet of the inner spray nozzle to an outlet of the outer spray nozzle can be adjusted, accordingly, the centering properties of fiber composite materials can be controlled, and the forming quality can be improved; the inner spray nozzle is connected into the outer spray nozzle in a threaded manner, an inner cavity II is arranged inside the inner spray nozzle, fiber yarns can penetrate the inner cavity II, an inner cavity I for accommodating resin materials is arranged inside the outer spray nozzle and is coaxial with the inner cavity II, and a connecting hole which is communicated with the inner cavity I is further formed in the outer spray nozzle and is particularly formed in a side surface of the outer spray nozzle; continuous fiber reinforced composite material additive manufacturing can be implemented by the printing machine.

Owner:华明进

Vehicle door lock pin reinforcer, vehicle door assembly and vehicle

The invention discloses a vehicle door lock pin reinforcer, a vehicle door assembly and a vehicle. The vehicle door lock pin reinforcer comprises a reinforcer body with a Z-shaped cross section, wherein the reinforcer body comprises a lower transverse plate, a vertical plate and an upper transverse plate which are connected in sequence, the lower transverse plate and the upper transverse plate are in lap joint with a vehicle body, the front side of the vertical plate is fixedly connected with a lock catch nut plate; the front side of the vertical plate is provided with a limiting hole correspondingly matched with a limiting clamp on the edge of the upper end of the lock catch nut plate, and a movement allowance is reserved between the limiting clamp and the hole wall of the limiting hole. On the basis of ensuring rigidity and strength, poor attachment of the lock catch nut plate and the lock pin reinforcer can be avoided, so that the assembly quality of the lock catch nut plate is improved.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com