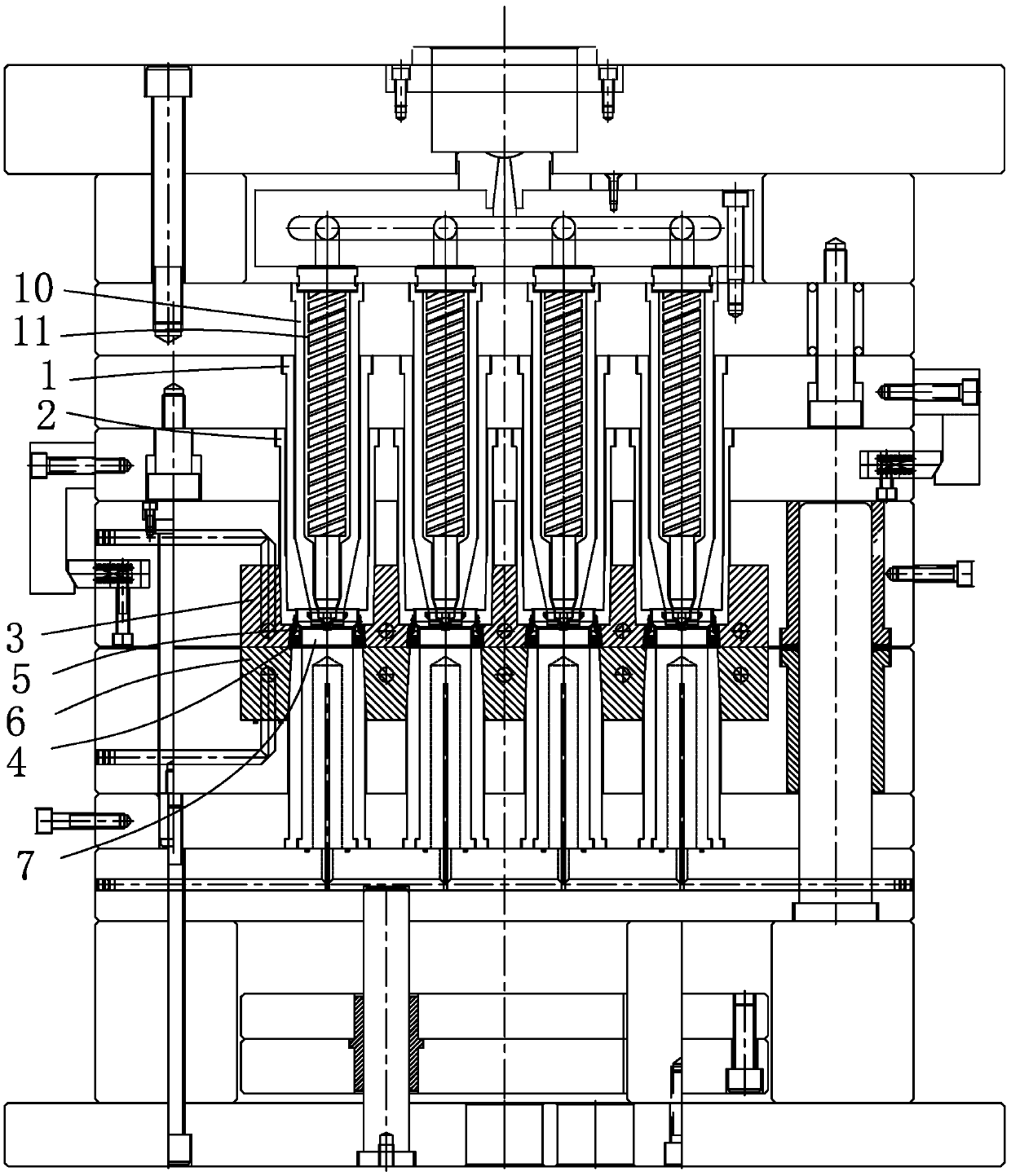

Forcible release multi-parting bottle cap injection mold

A technology for injection molds and caps, which is applied in the field of injection molds for strong release and multi-parting caps, can solve the problems of complex volume, small production quantity, troublesome operation and maintenance, etc., and achieves small volume, low maintenance cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

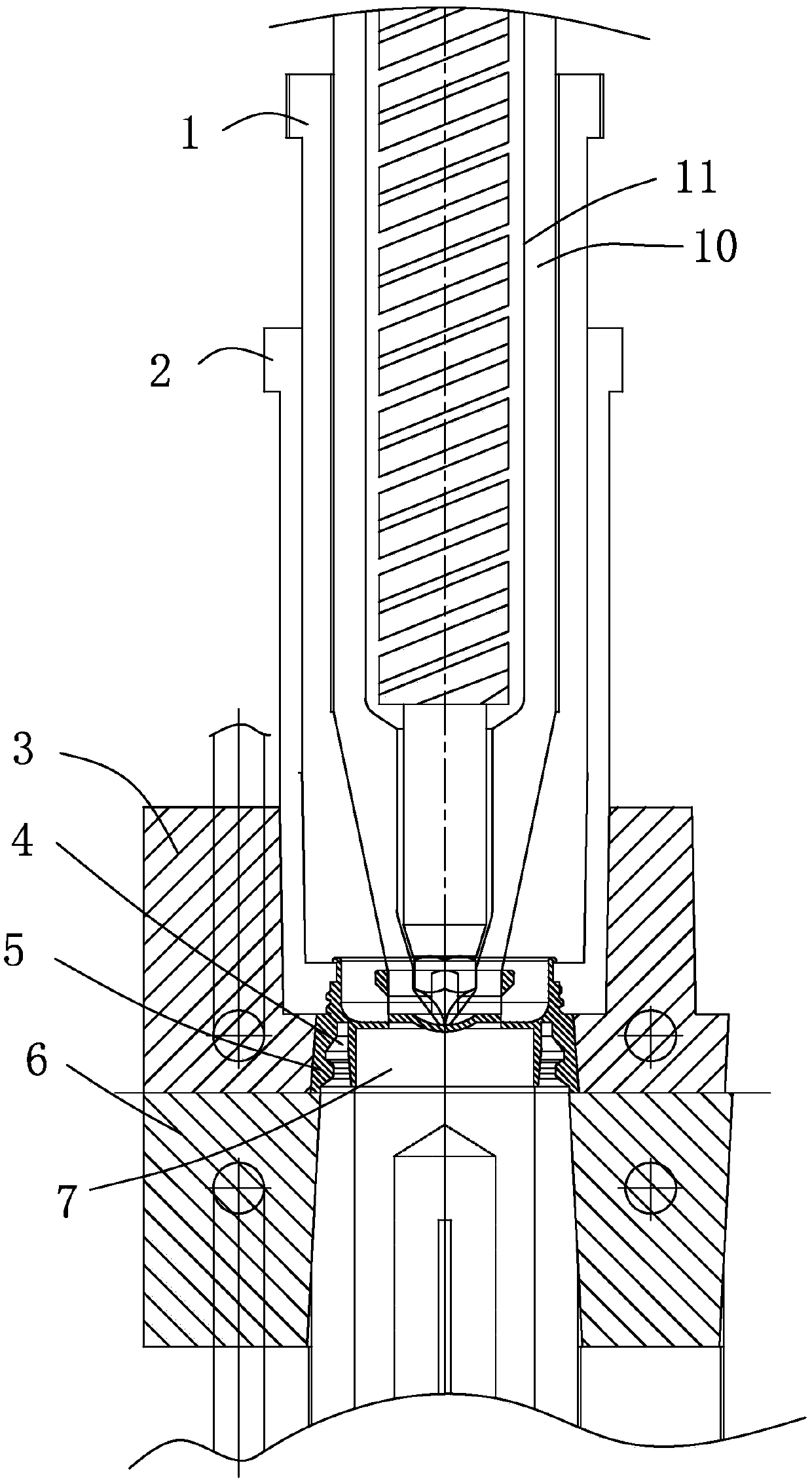

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

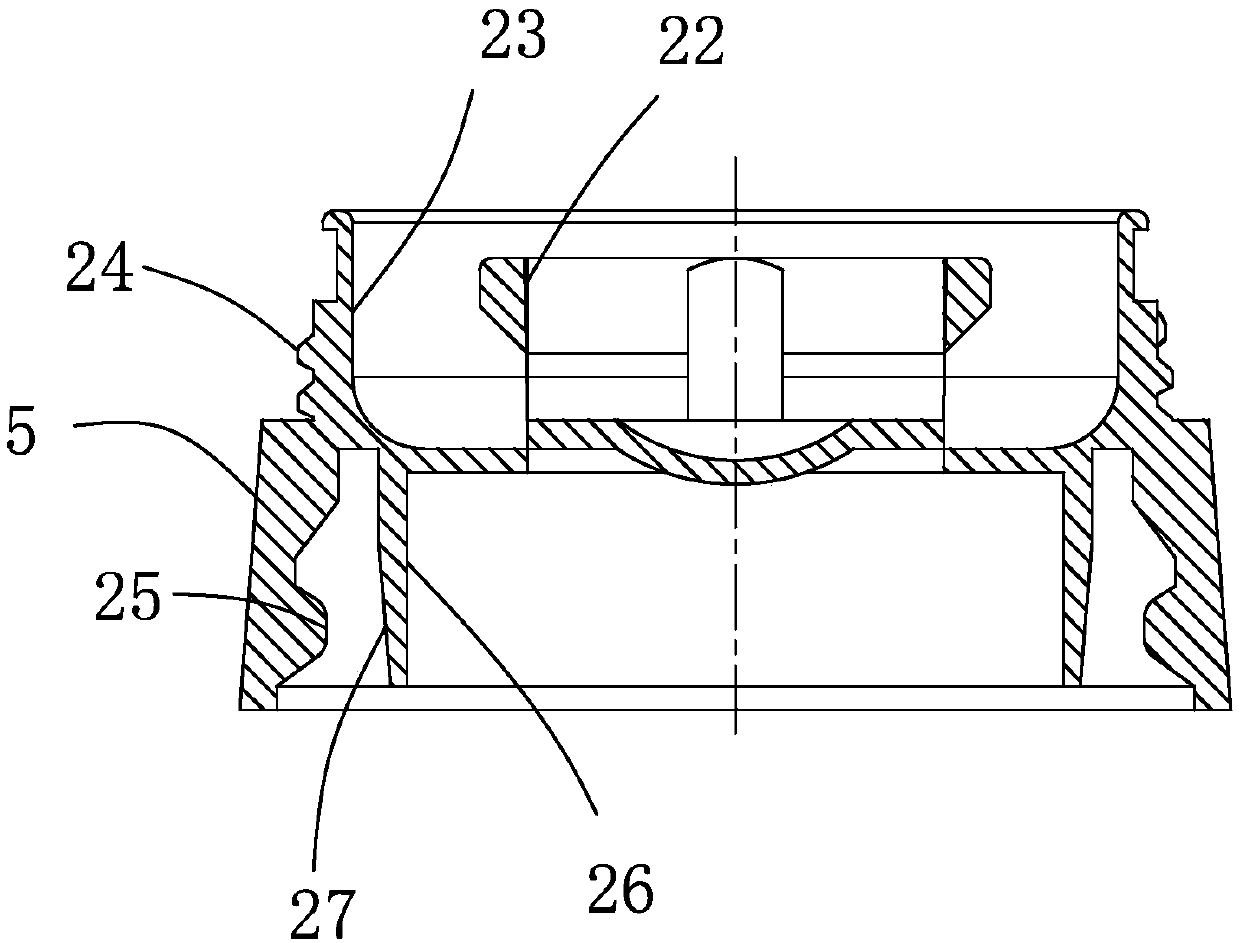

[0014] image 3 For the sectional view of the plastic part 5 to be made of this mould, make the plastic part 5 in image 3 The upper end surface is the first end surface, and the lower end surface is the second end surface. The plastic part 5 is provided with a first hole 22 in the middle of the first end surface, and the plastic part 5 is provided with a first annular groove 23 at the edge of the first end surface, and the first annular groove 23 Coaxial with the first hole 22 , a protrusion is provided at one end of the first annular groove 23 near the inner wall of the first hole 22 and near the first end surface. The plastic part 5 is provided with an annular groove on the outer peripheral surface and a side close to the first end face, and the outer peripheral surface of the plastic part 5 is corresponding to image 3 A first external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com