Vehicle door lock pin reinforcer, vehicle door assembly and vehicle

A reinforcement and door technology, which is applied in door lock pin reinforcement, door assembly and vehicle fields, can solve the problem of warping of lock nut plate installation surface and lock pin reinforcement installation surface, lock nut plate and lock pin reinforcement Problems such as poor matching of parts and the influence of the installation position of the lock pin nut buckle, etc., to achieve the effect of improving assembly quality, improving product qualification rate, and solving unqualified problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

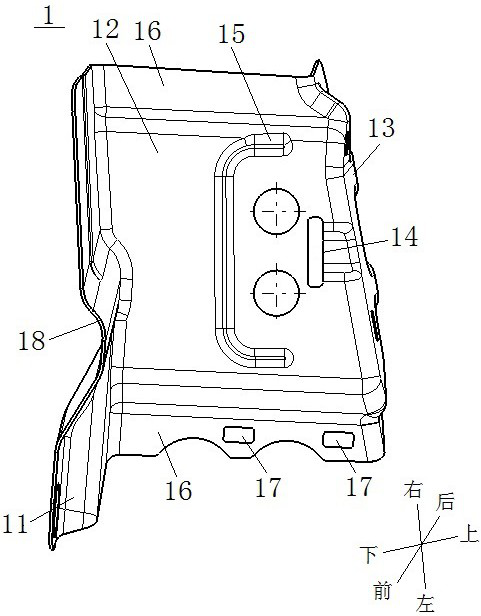

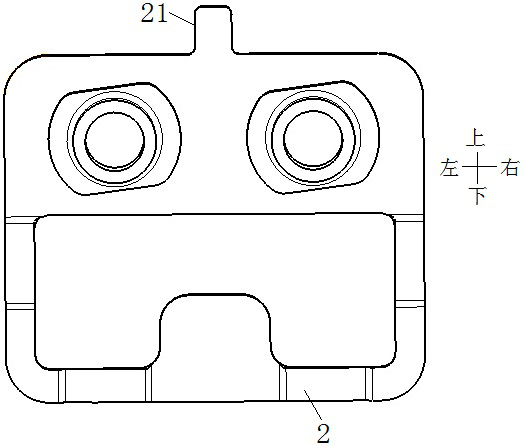

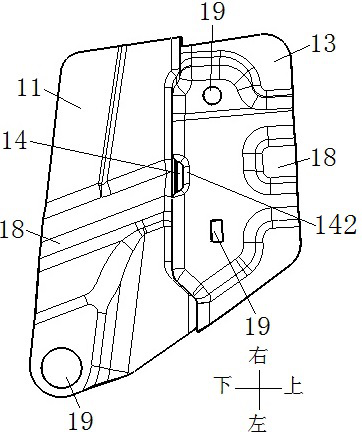

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] see Figure 1 to Figure 6 , the door lock pin reinforcement shown includes a reinforcement body 1 with a Z-shaped cross section. The horizontal plate 11 and the upper horizontal plate 13 are overlapped with the vehicle body 3, and the front side of the vertical plate 12 is fixedly connected with the lock nut plate 2, and the front side of the vertical plate 12 is provided with a limit stop with the upper edge of the lock nut plate 2 The card 21 corresponds to the matching limiting hole 14 , and there is a movement margin between the limiting card 21 and the wall of the limiting hole 14 . see Figure 7 with Figure 8 The front side of the riser 12 and the area corresponding to the lock nut plate 2 are provided with a groove 141 that is recessed toward the rear, and the opening of the groove 141 is integrally formed with a cover plate 142, and the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com