Pump and packer integrated water exploration and plugging pipe pile and floating bottom plug thereof

An integrated, pump-sealing technology, applied in the fields of fluid production, sealing/packing, wellbore/well components, etc., can solve the problems of piston effect, increased unsealing load, and difficulty in unsealing, and achieve increased cross-sectional area. area, reduce liquid pressure, and facilitate the effect of unsealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

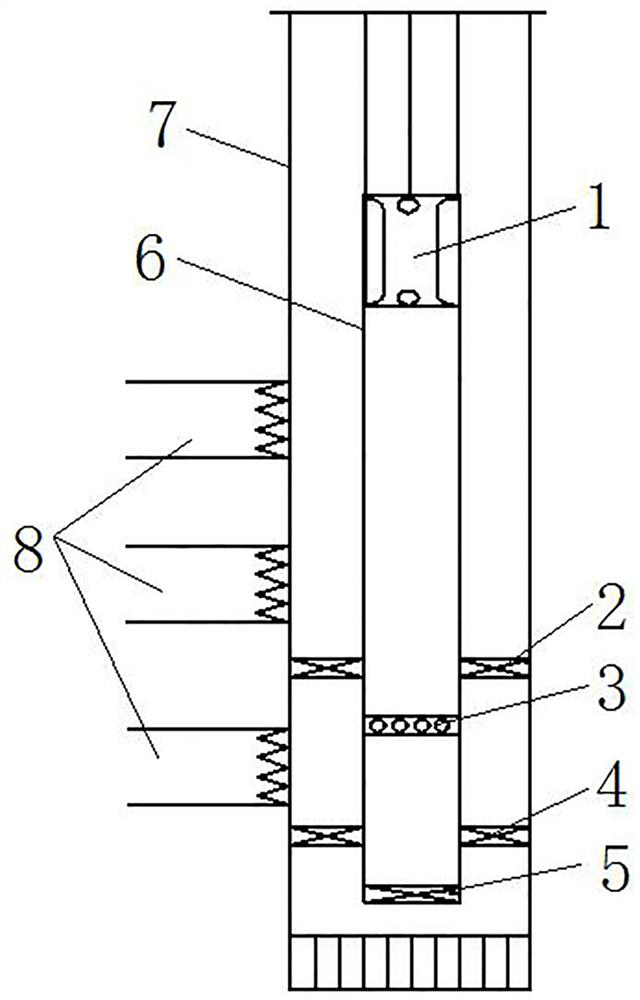

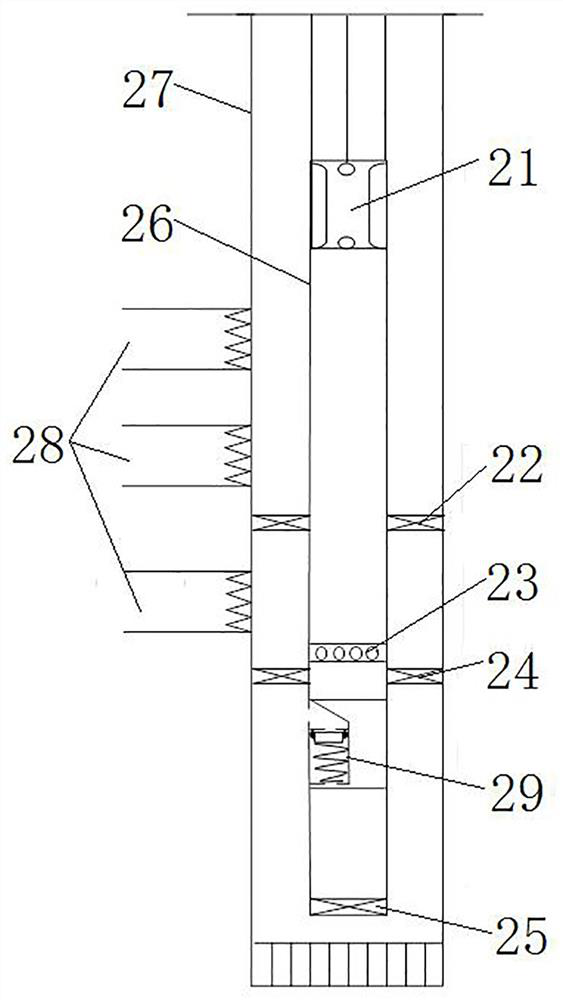

[0063] like figure 2 As shown, the pump-seal integrated water pipe string includes an oil pipe 26, and the oil pipe 26 includes pipe string sections connected in series in sequence. The upper part of the oil pipe 26 is connected with the oil well pump 21, and the upper end of the oil well pump 21 is connected with a sucker rod, which drives Oil well pump 21 carries out oil pumping operation. The oil pipe 26 is connected with an upper packer 22 and a lower packer 24 below the oil pump 21, and the upper packer 22 and the lower packer 24 are arranged at intervals in the vertical direction to separate each oil layer 28 .

[0064] In this embodiment, the upper packer 22 is a Y111 packer, and the lower packer 24 is a Y211 packer, wherein both the Y111 packer and the Y211 packer are mature products in the prior art, and here No longer.

[0065] Wherein, the oil pipe 26 is connected with a screen pipe 23, the screen pipe 23 is located between the upper packer 22 and the lower pack...

specific Embodiment 2

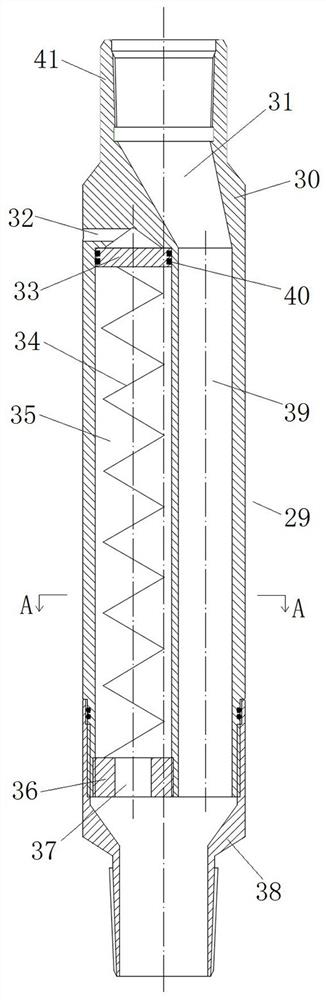

[0082] The difference from the specific embodiment 1 is that in embodiment 1, the elastic member is a compression spring 34, and the compression spring 34 is located below the piston 33 to apply an upward elastic force to the piston 33. In this embodiment, the elastic member is a pull spring 34. The spring, the extension spring is above the piston to apply upward elastic force to the piston.

specific Embodiment 3

[0084] The difference with the specific embodiment 1 is that in embodiment 1, the bottom of the piston chamber 35 is detachably connected with a retaining ring 36, and the retaining ring 36 is used to stop the lower end of the compression spring 34. In this embodiment, the retaining ring can be fixed by screws. The lower part of the piston chamber is disassembled and connected. For example, the lower part of the piston chamber is provided with a stepped structure, the stepped surface of the stepped structure is provided with a threaded hole, and the retaining ring is provided with a perforation. The screw is fixed on the lower part of the piston cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com