Patents

Literature

199results about How to "Easy to unpack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

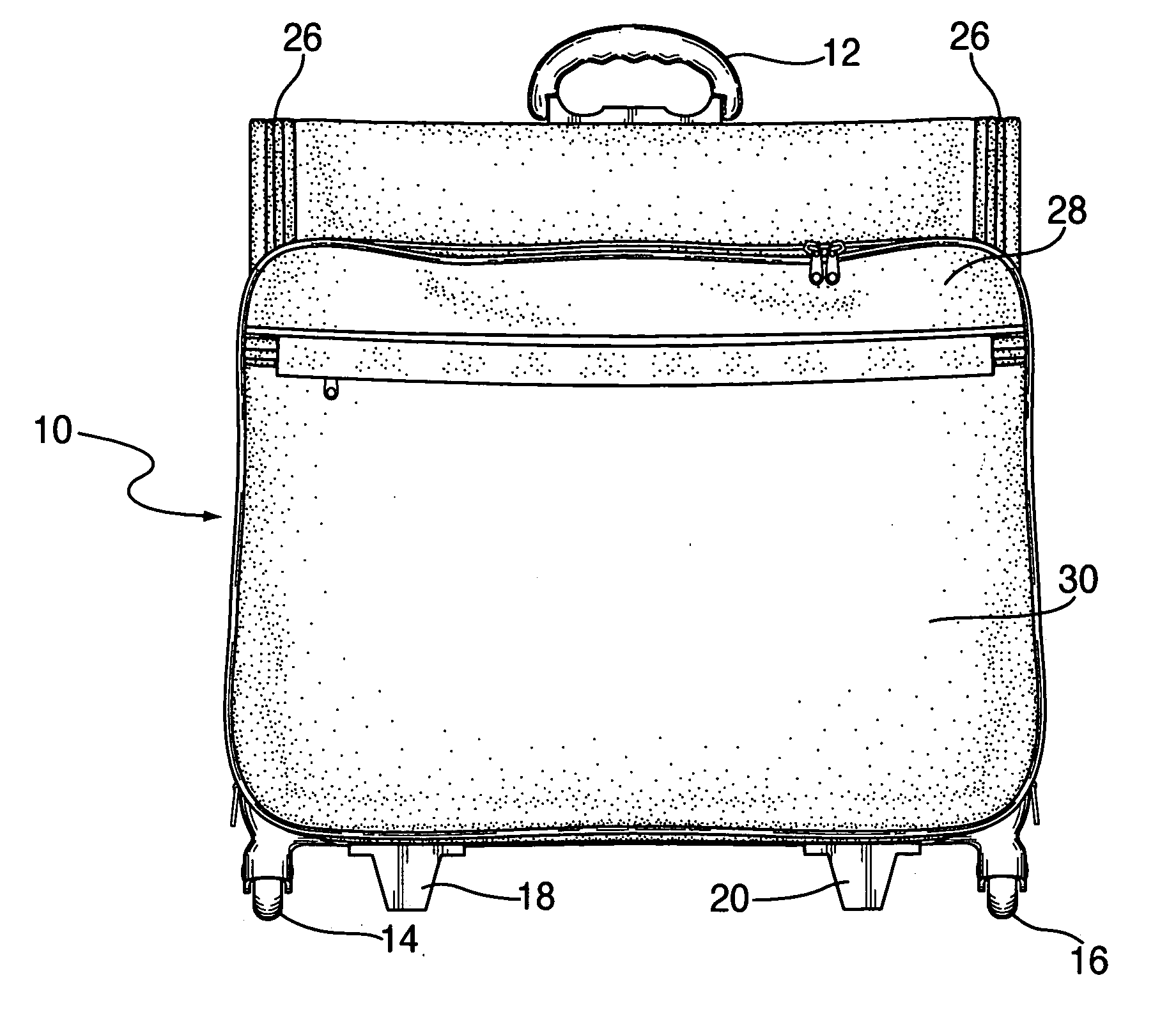

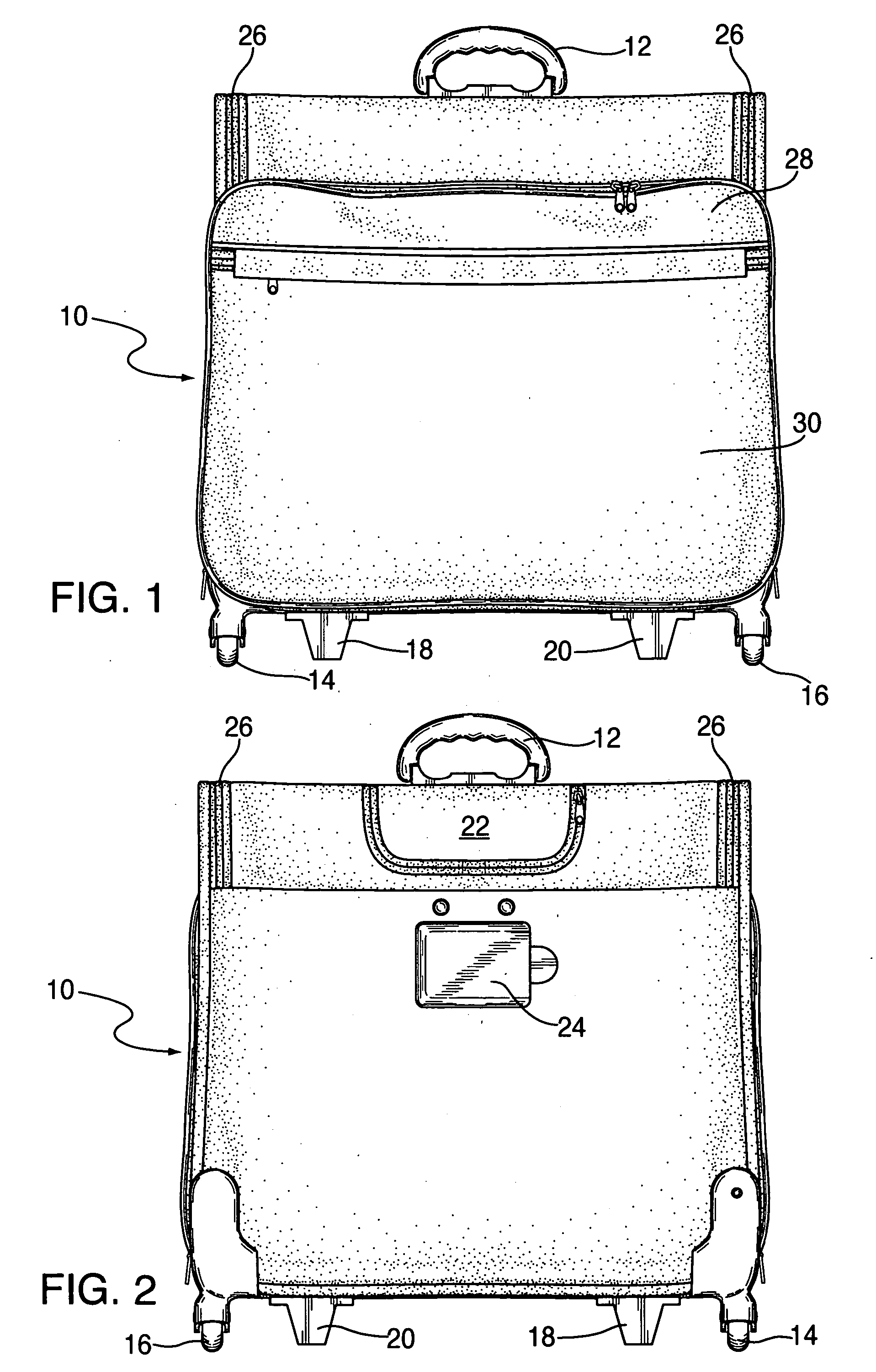

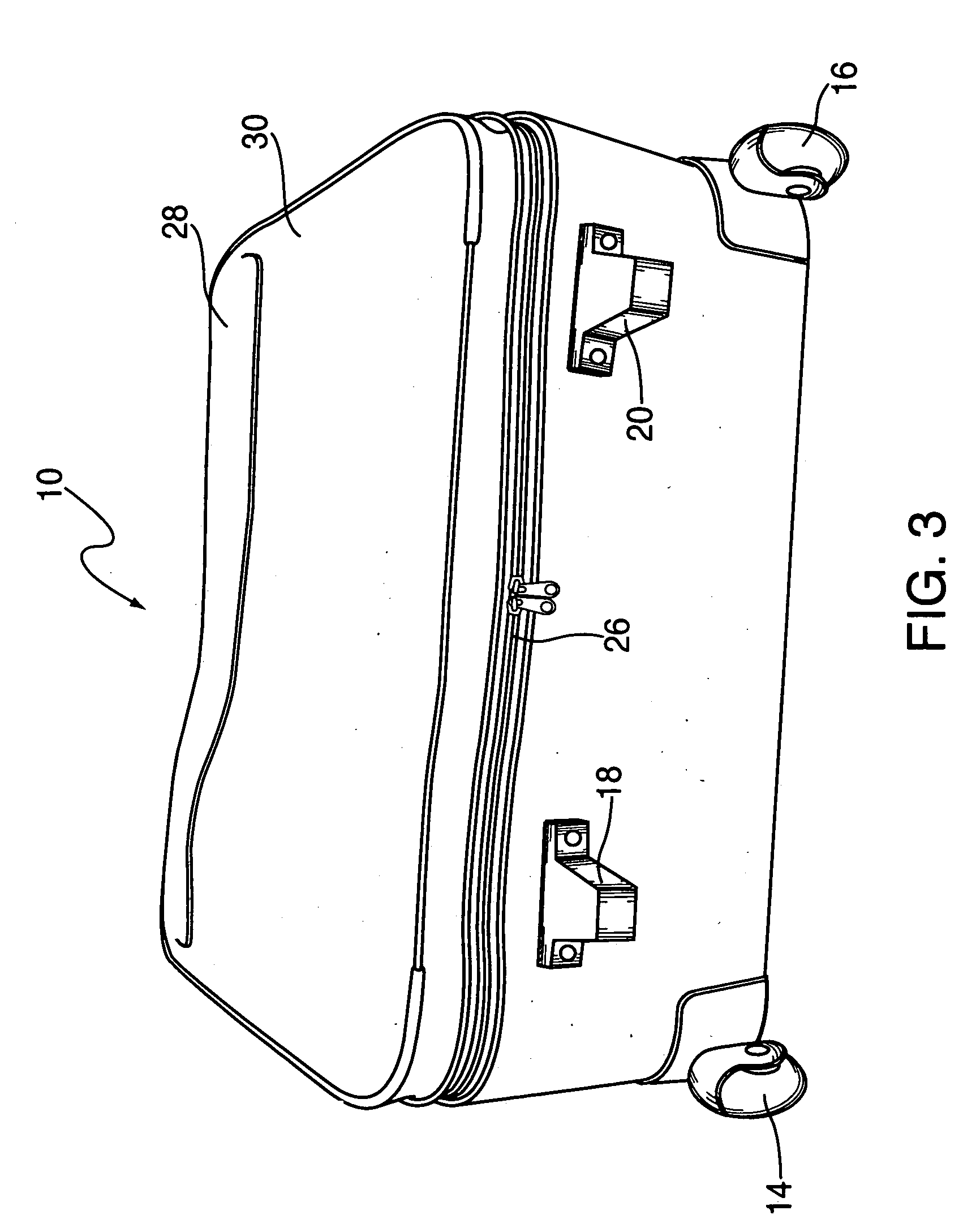

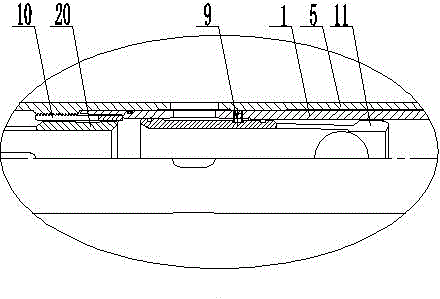

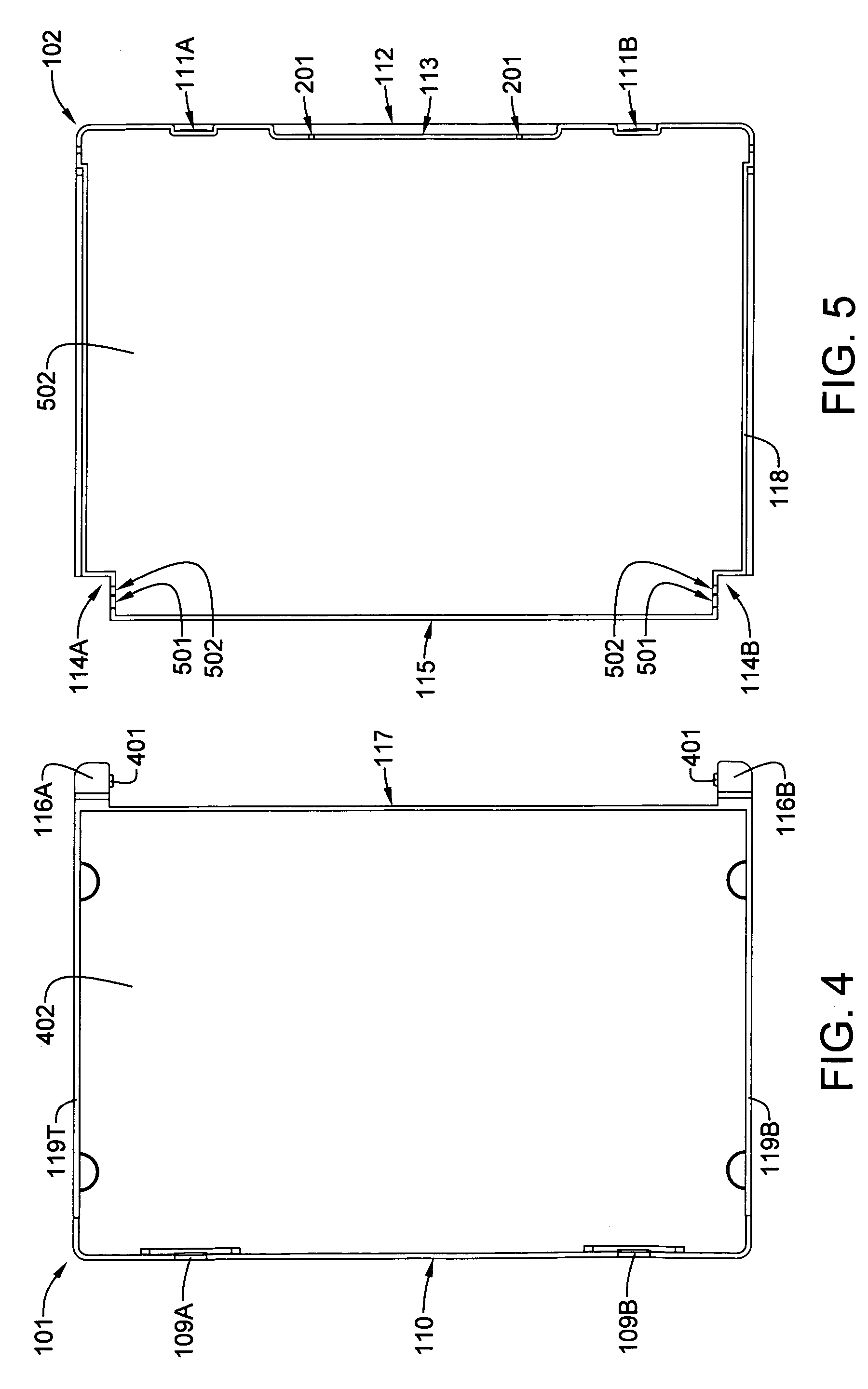

Luggage bag having a removable garment bag

InactiveUS7140479B2Easy to put together and take apartEasy to unpackGarmentsHandbagsCouplingEngineering

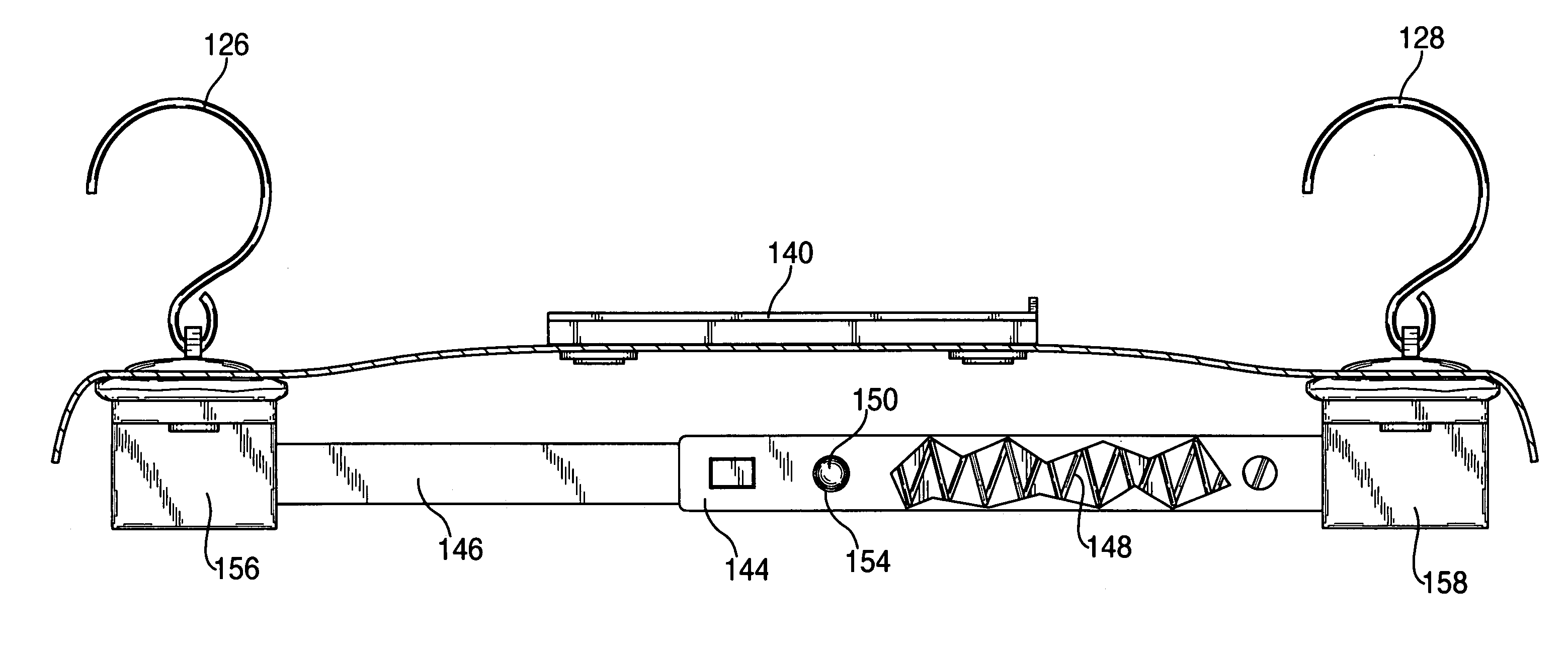

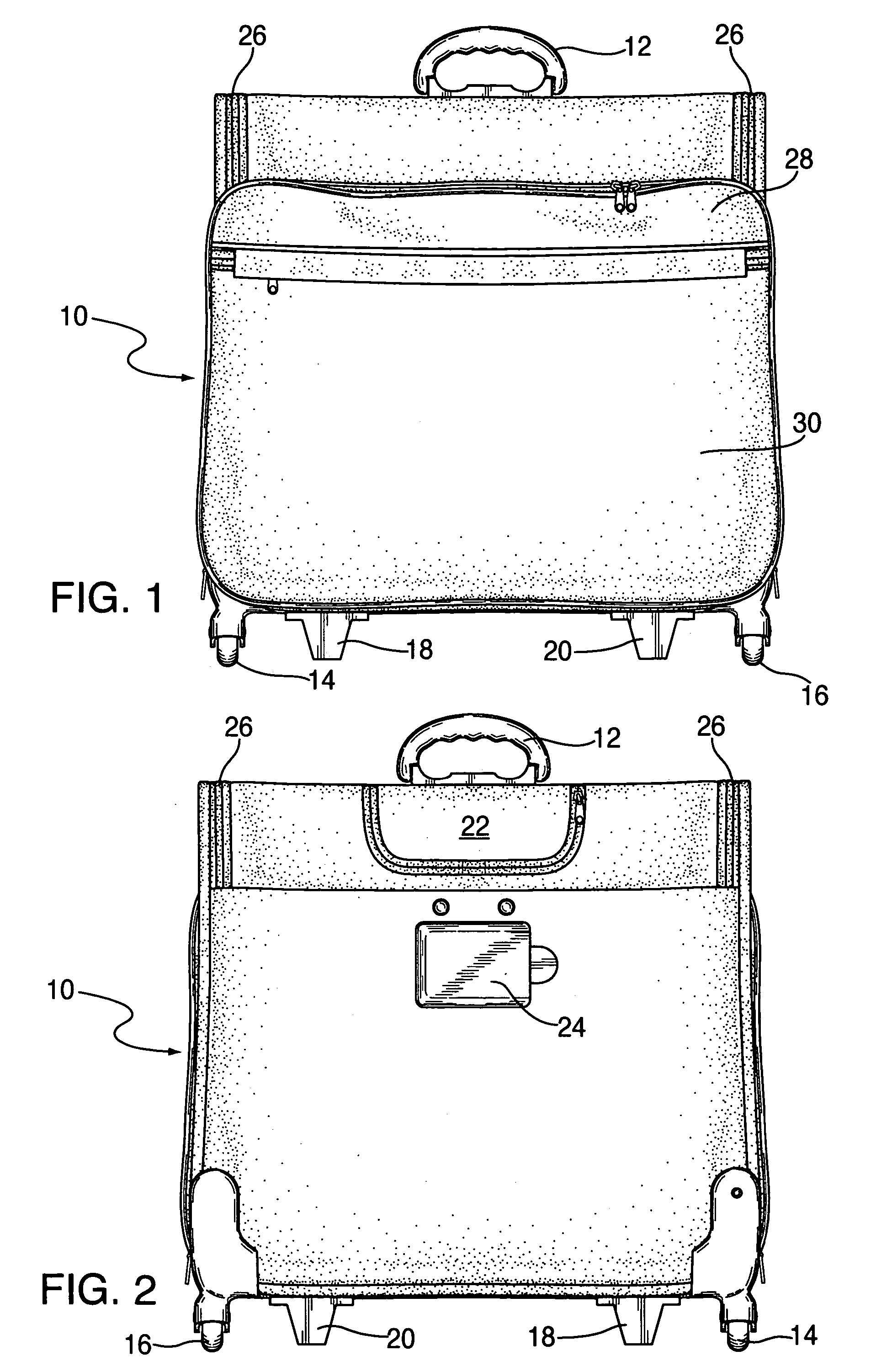

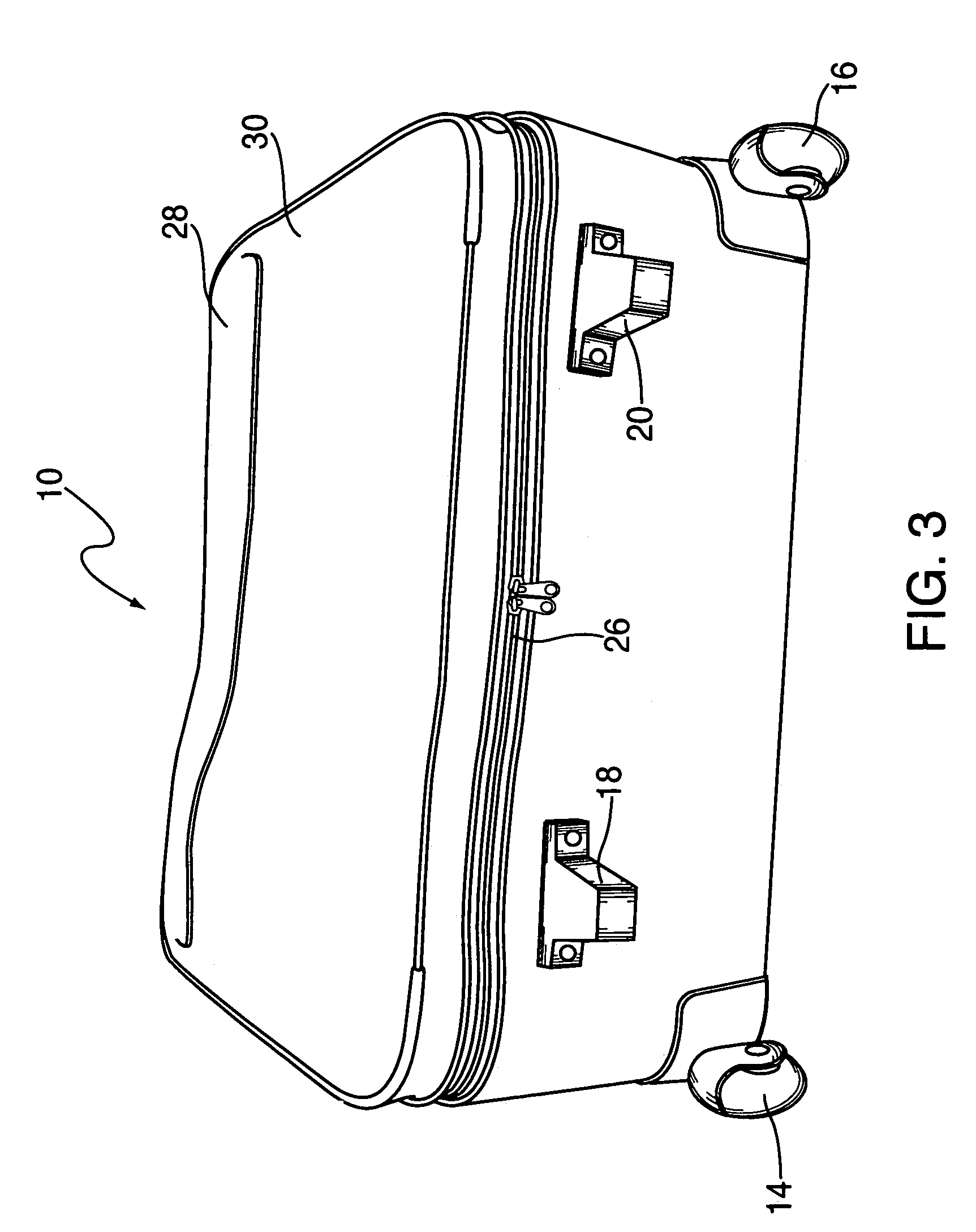

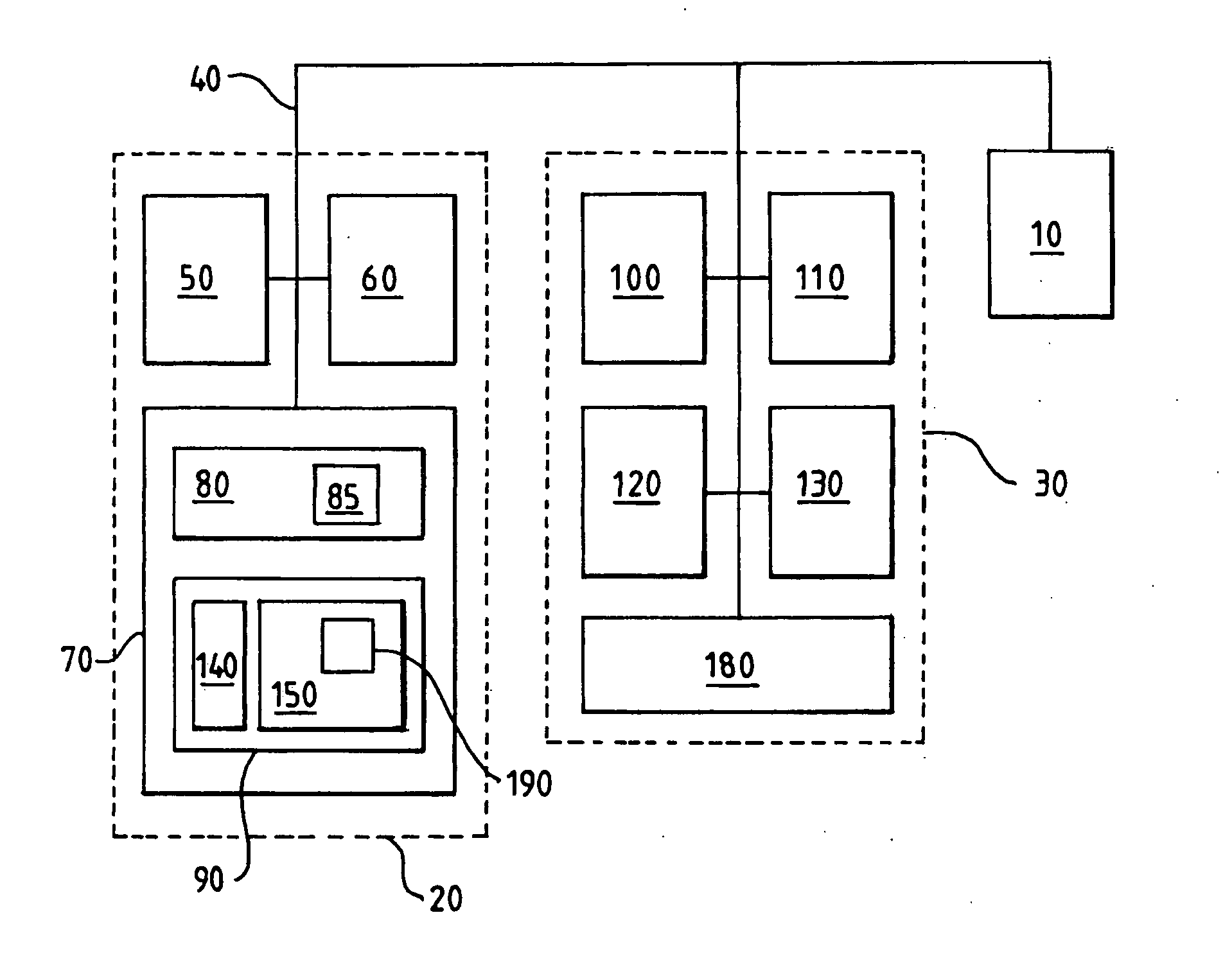

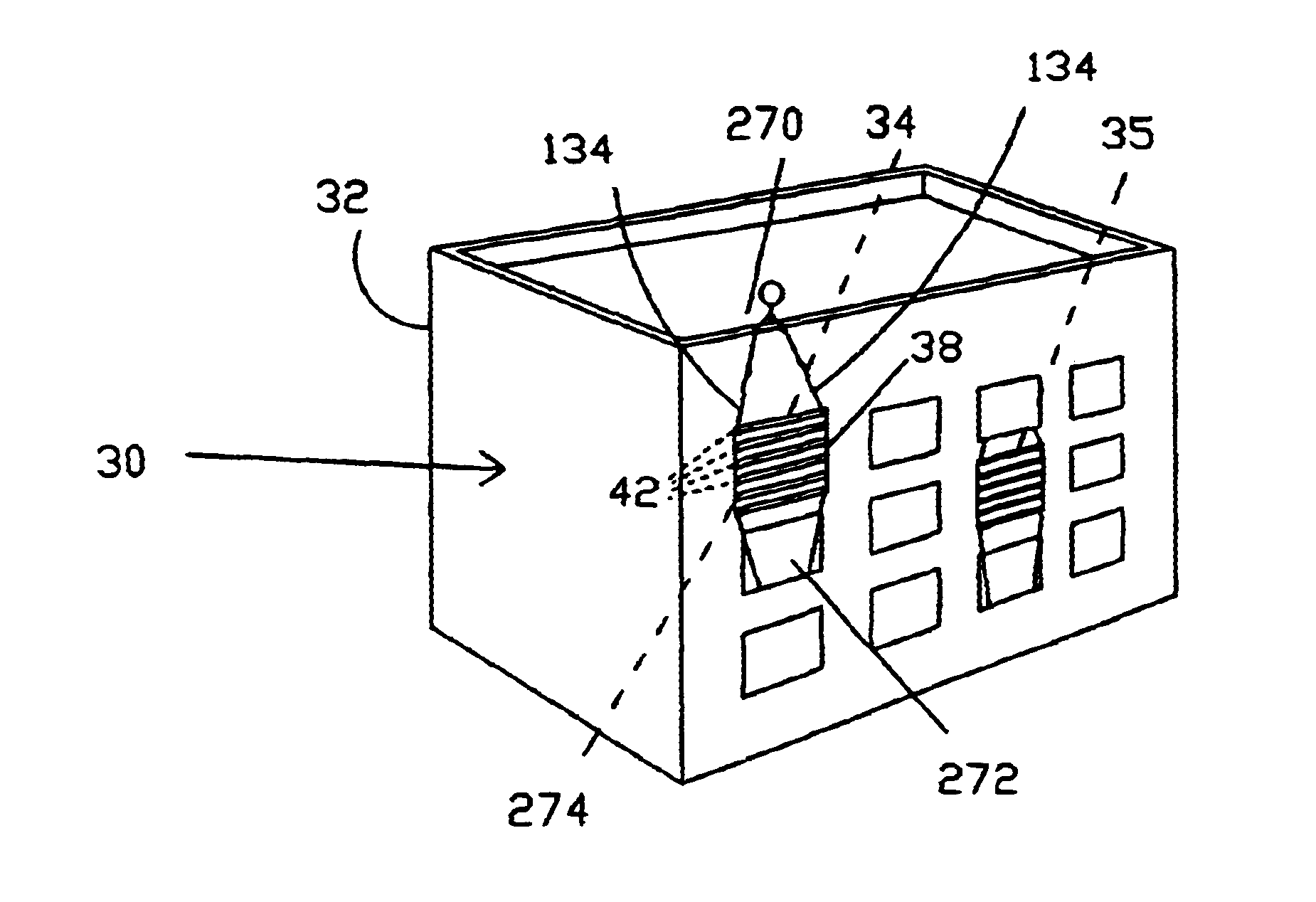

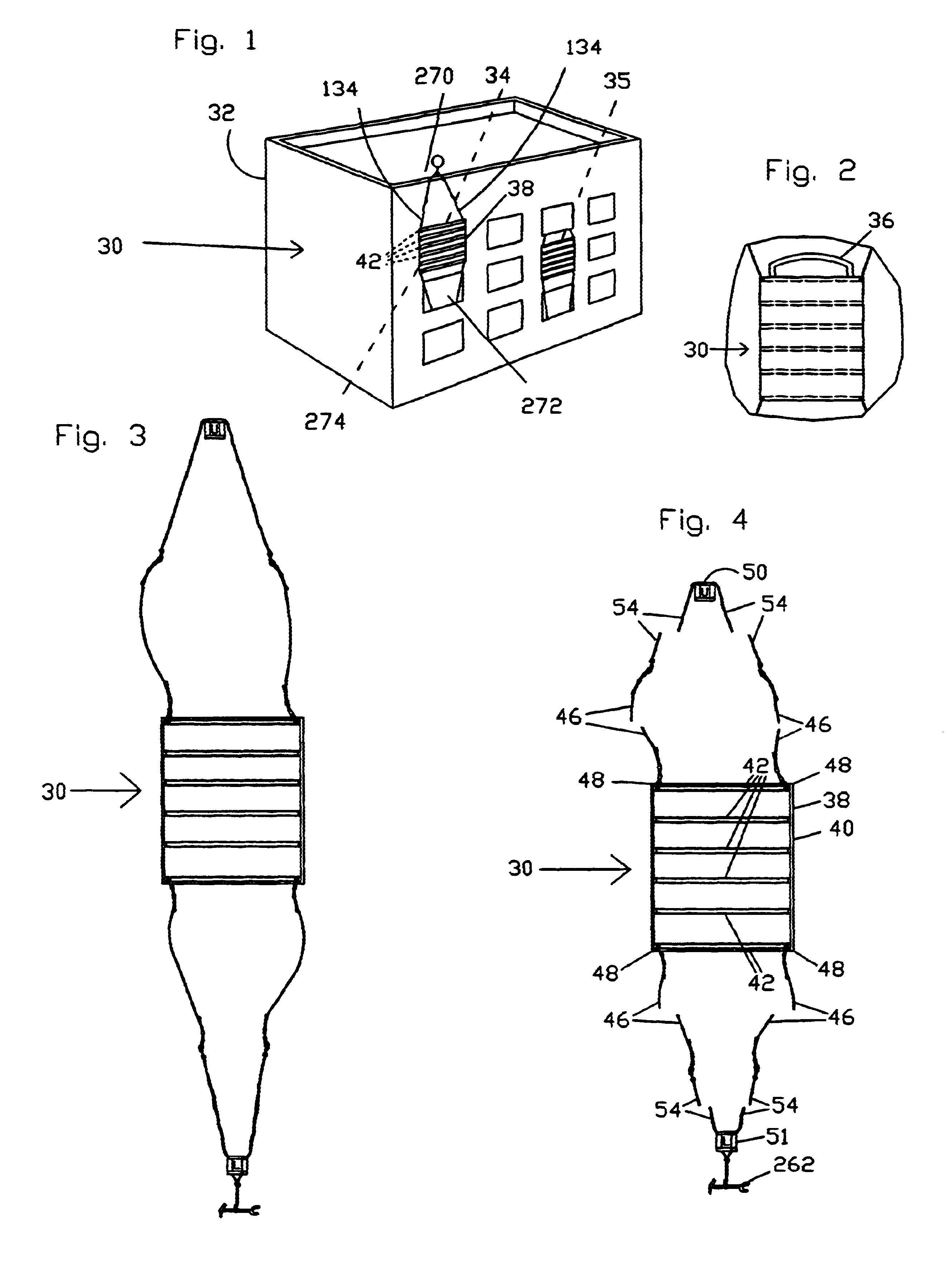

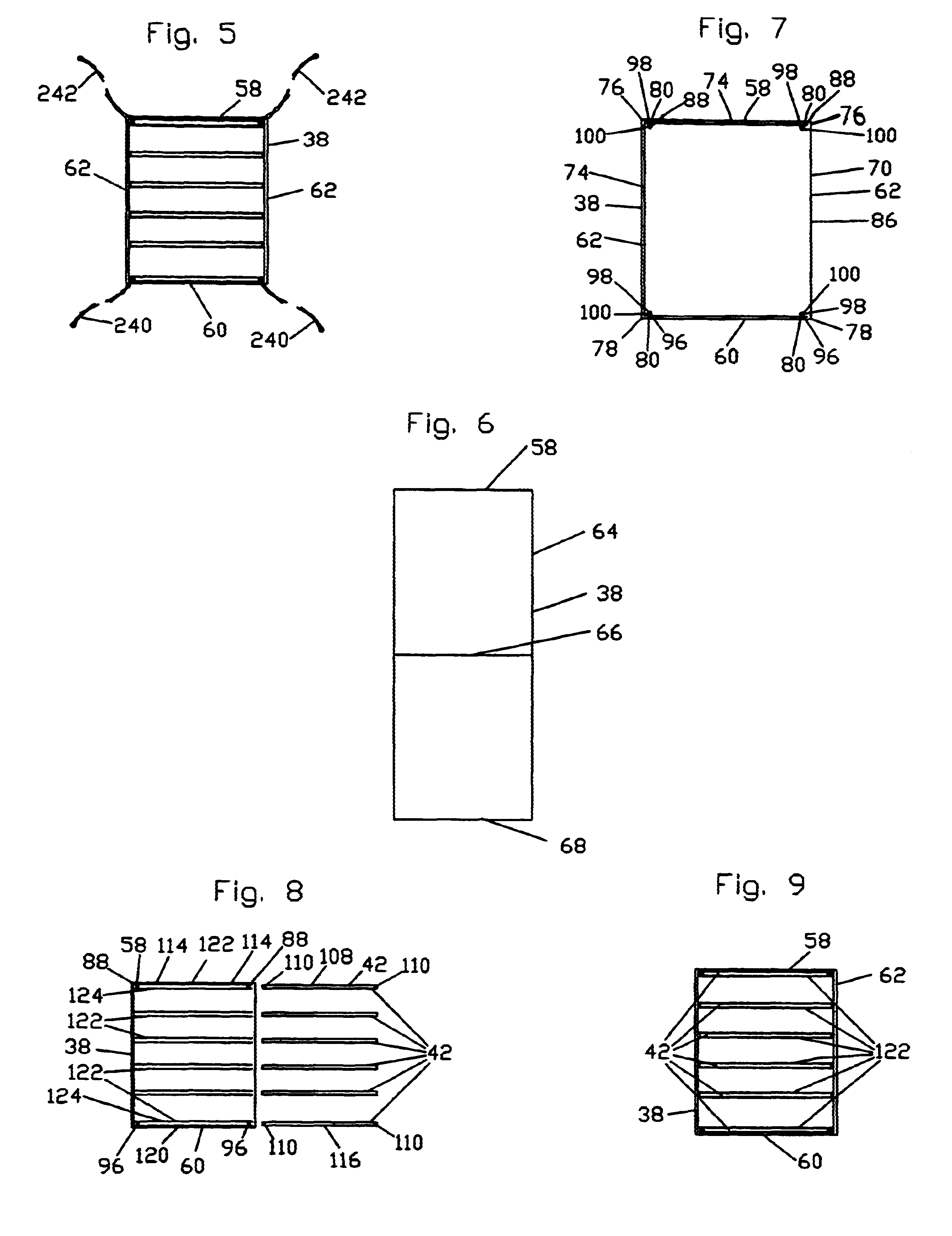

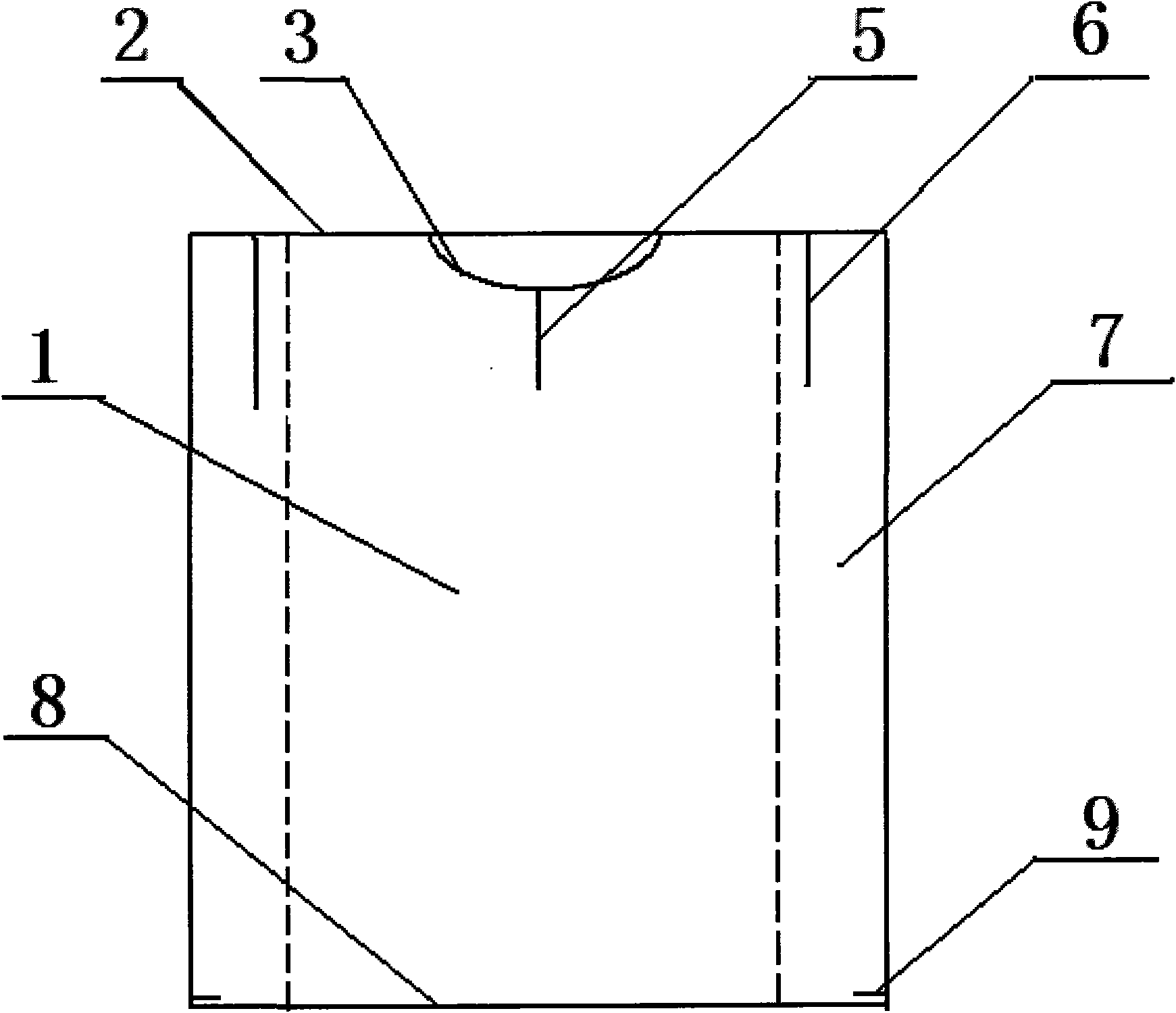

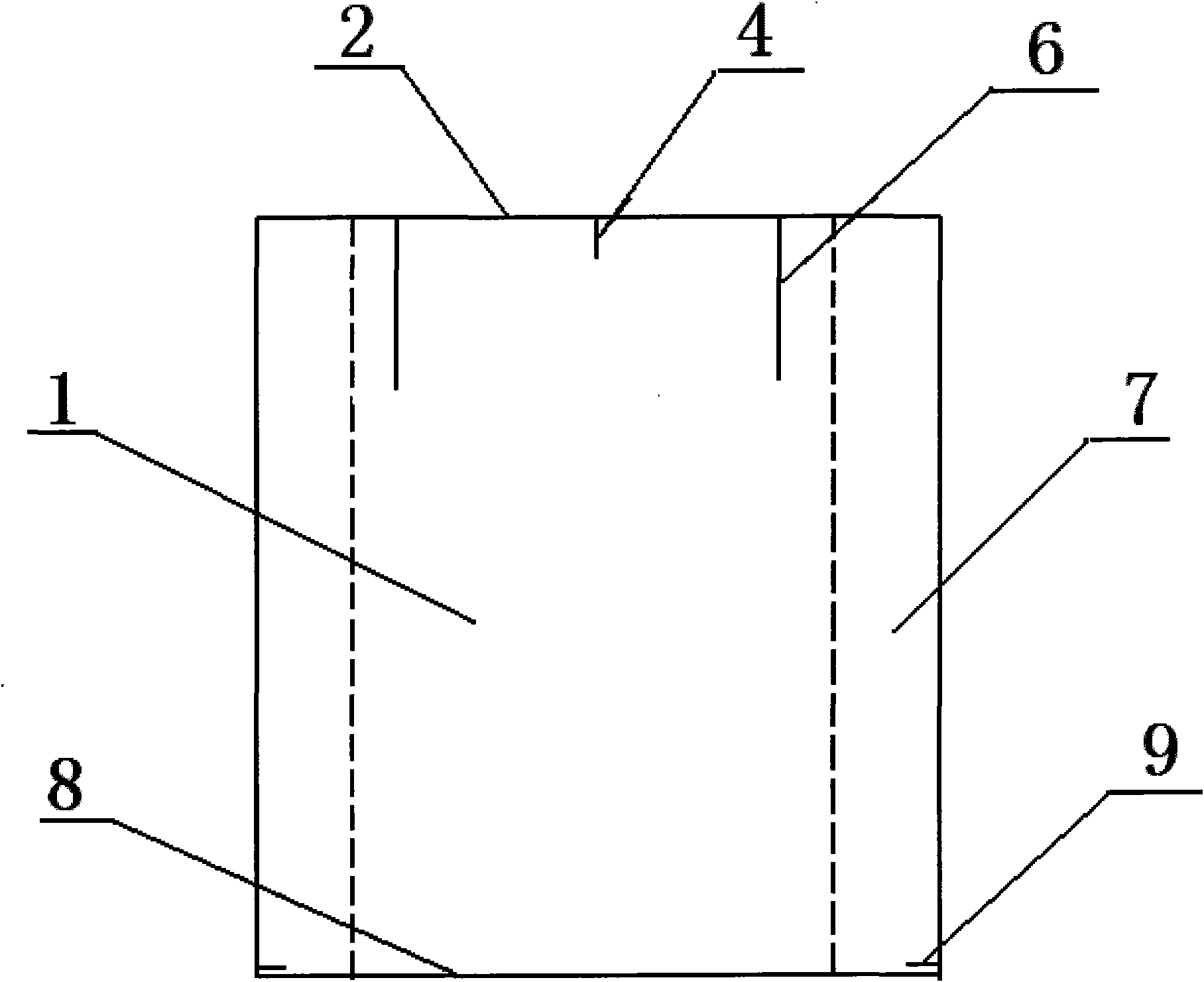

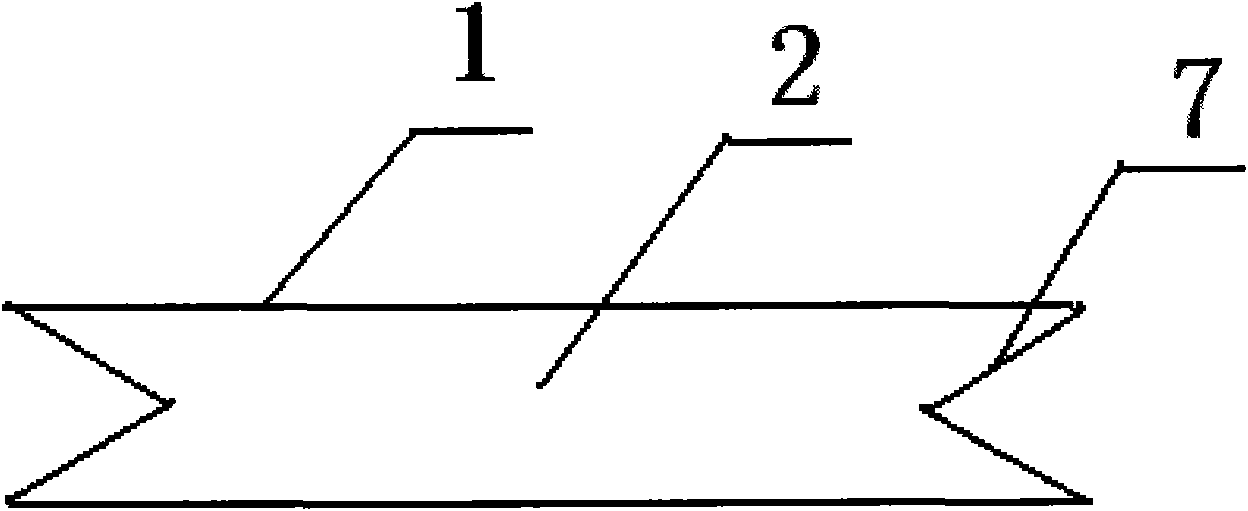

A combination garment bag and luggage bag includes a relatively rigid outer luggage bag and a relatively flexible inner garment bag. According to one aspect of the invention, the garment bag is secured to the interior of the luggage bag with the aid of a releasable coupling mechanism. According to another aspect of the invention, the interior of the garment bag is provided with a spring expandable hanger bar. The hanger bar expands when the garment bag is removed from the luggage bag. This allows easier access to the contents of the garment bag.

Owner:INGENIOUS DESIGNS

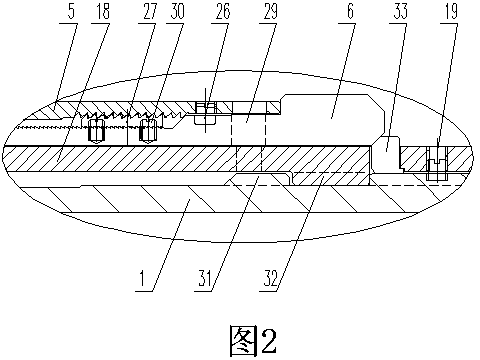

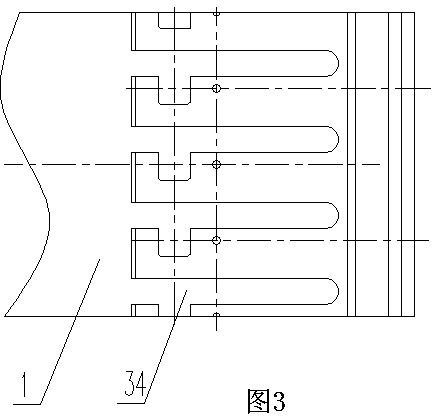

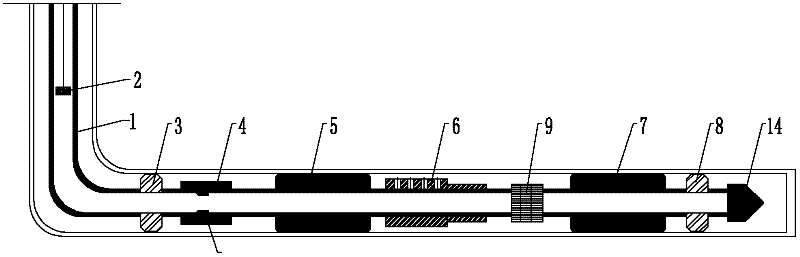

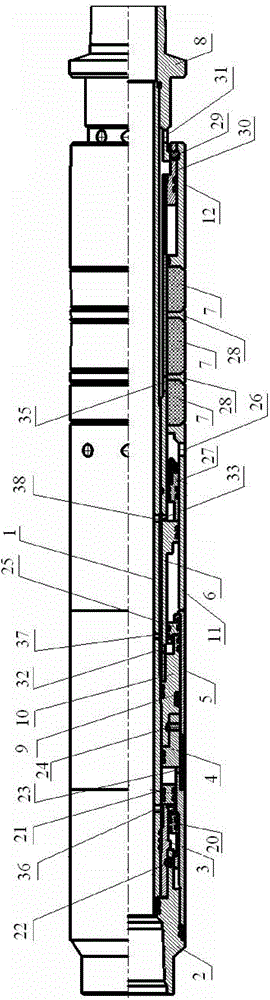

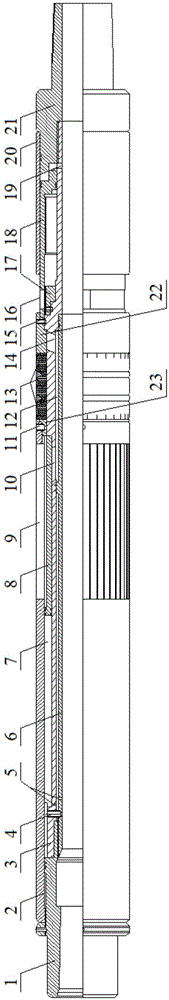

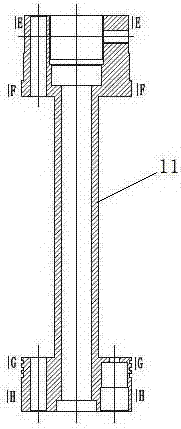

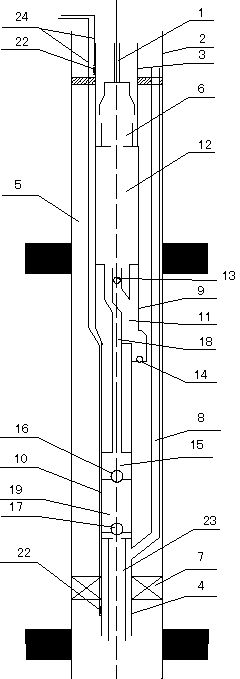

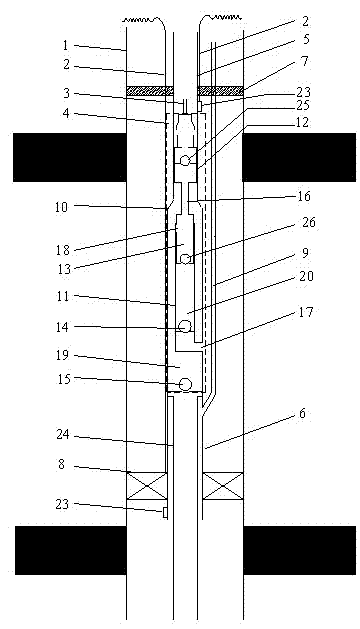

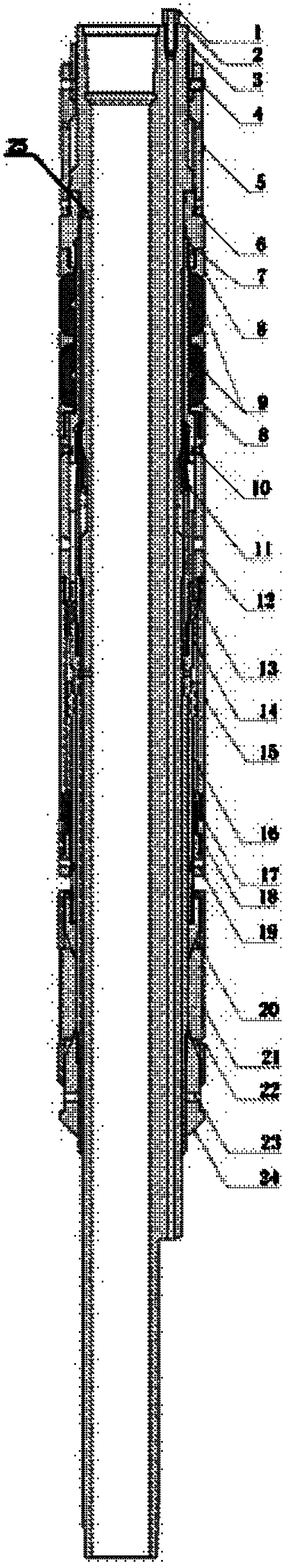

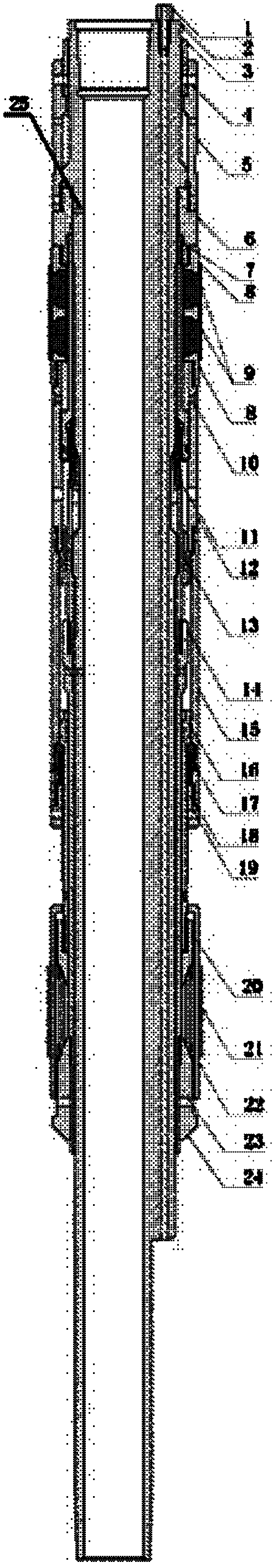

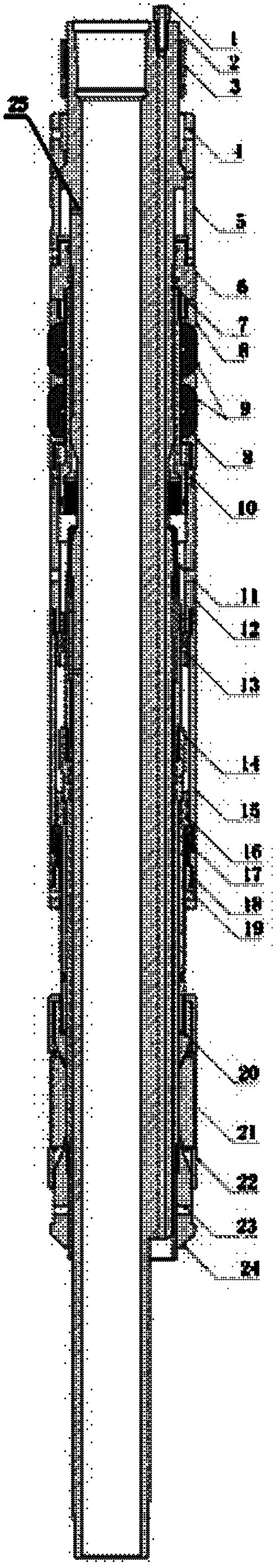

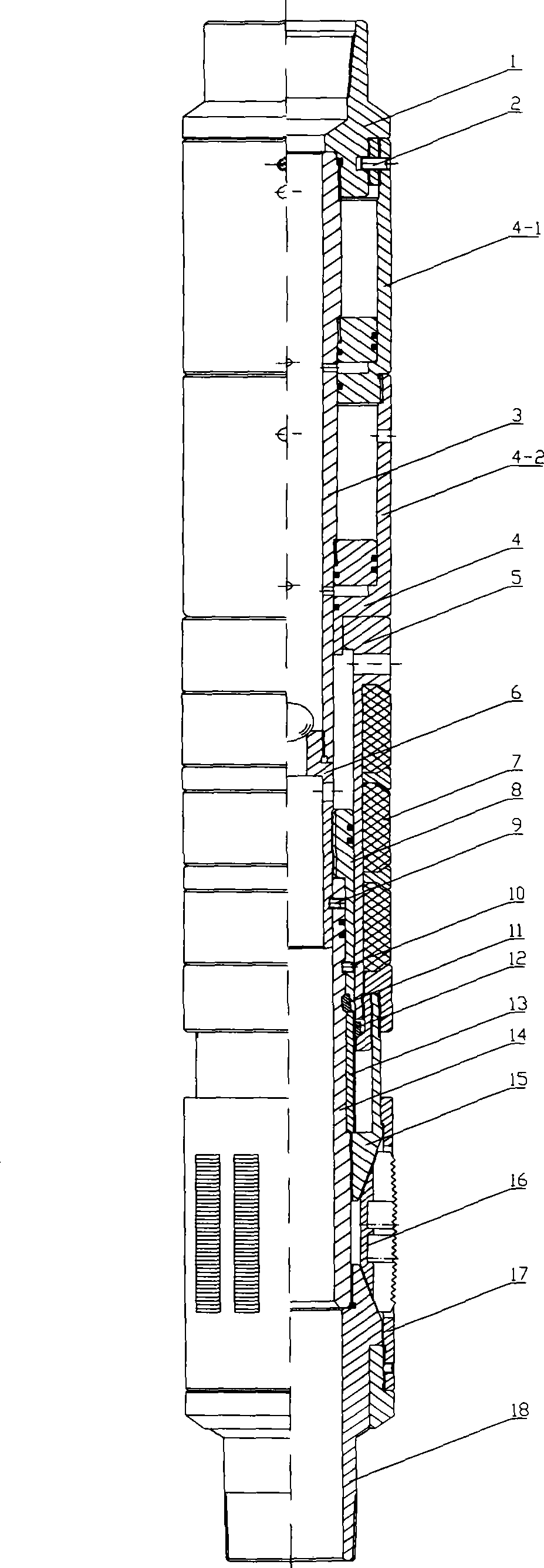

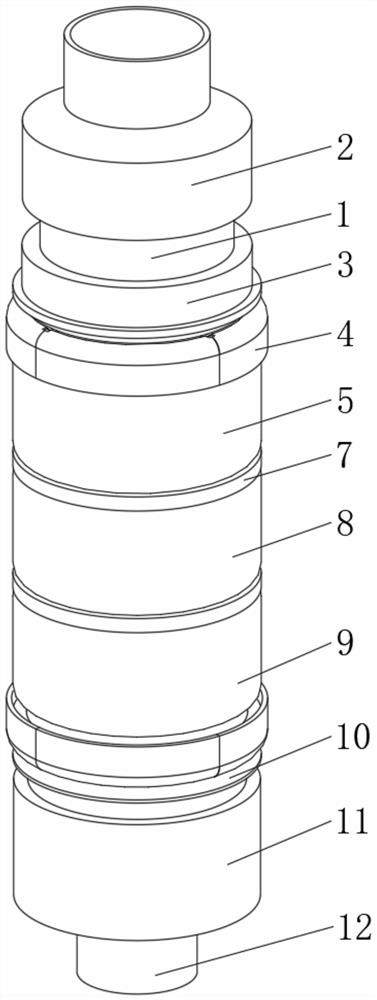

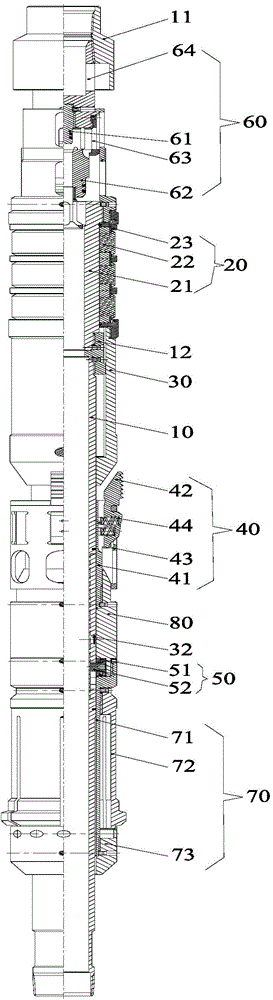

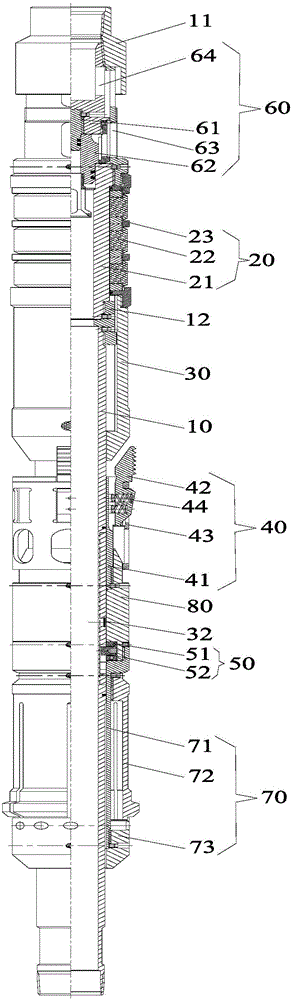

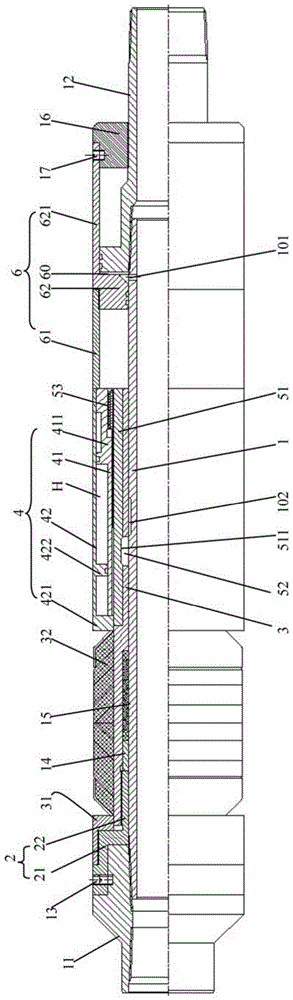

Anchor packer with hydraulic setting function and rotation unsetting function

ActiveCN104863540AGood sealing performanceLong-lasting and effective settingSealing/packingPistonEngineering

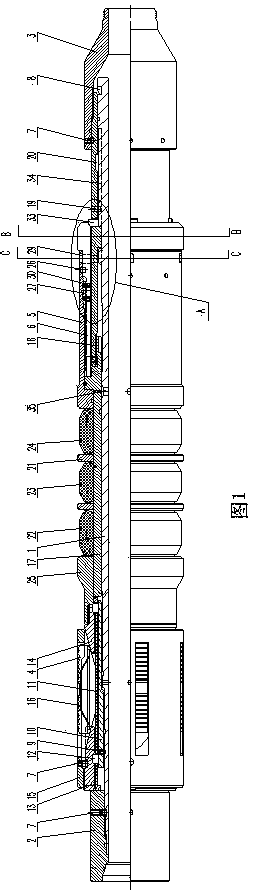

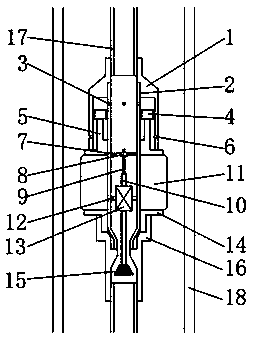

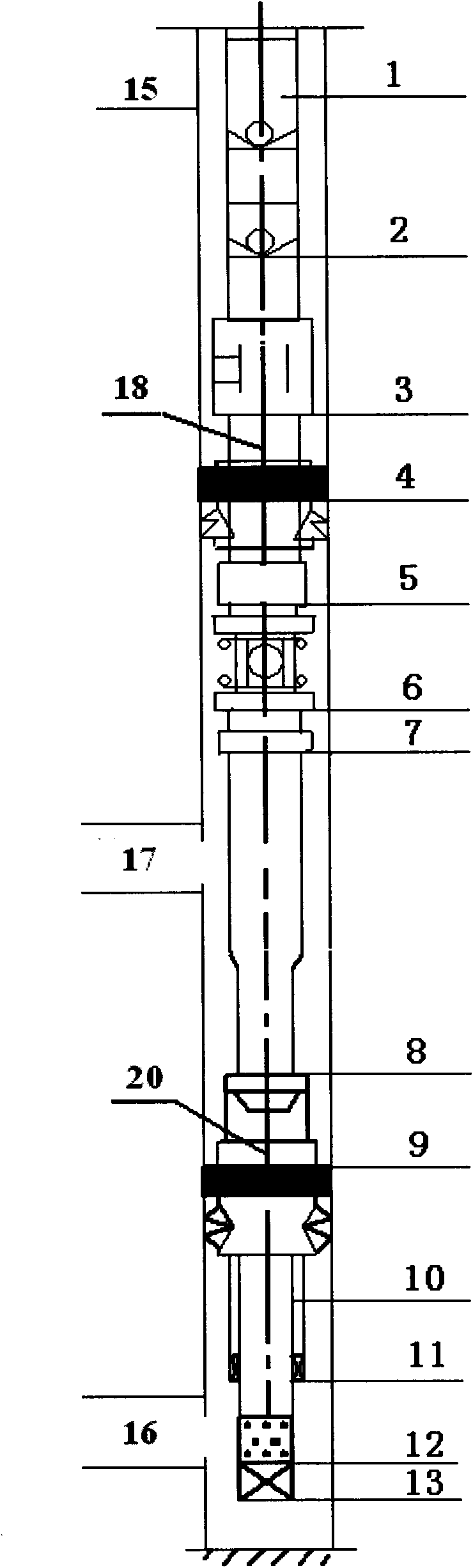

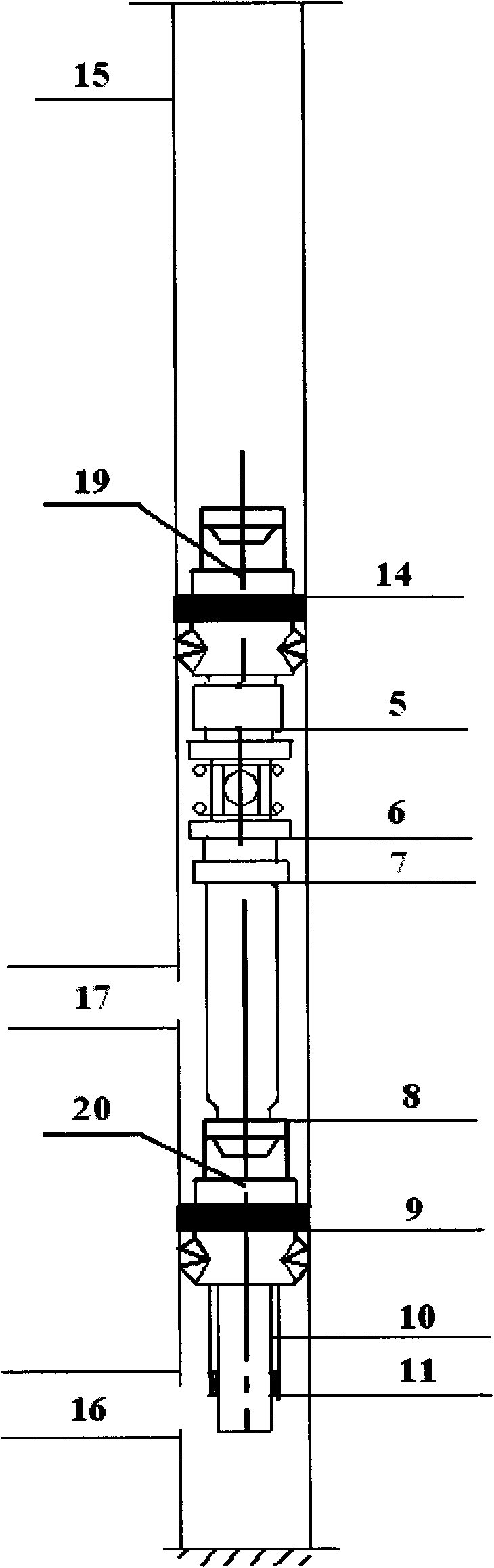

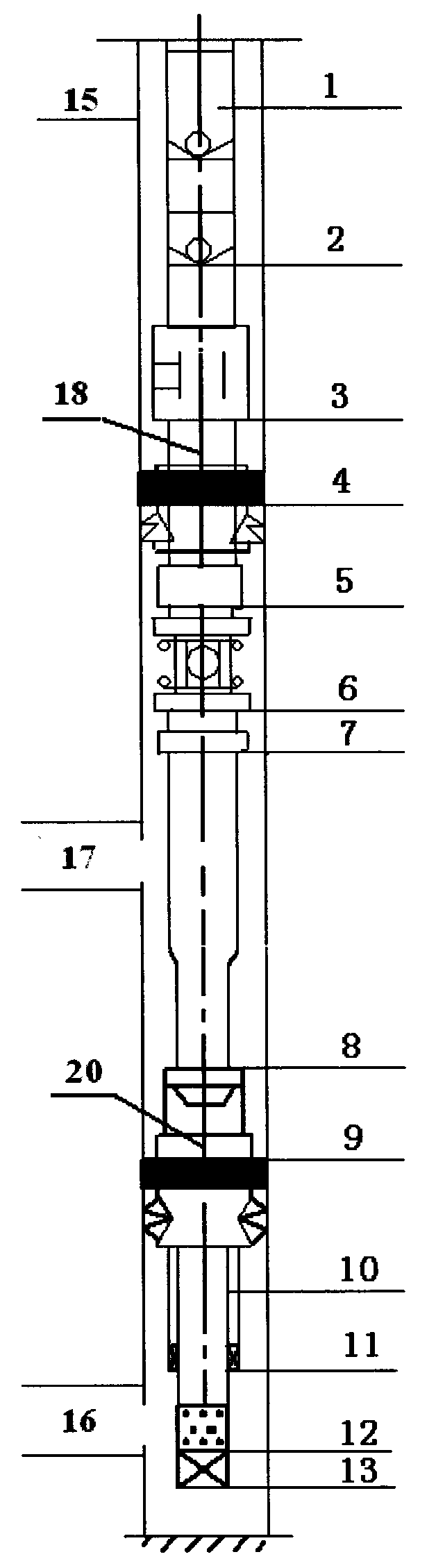

The invention relates to an anchor packer with a hydraulic setting function and a rotation unsetting function, and belongs to the field of borehole operation tools for oil gas wells. The anchor packer comprises a center pipe, an upper connector, a lower connector, a pair of slips, a piston sleeve and a release sleeve. The upper connector is arranged at one end of the center pipe, and a C-shaped ring is arranged at the other end of the center pipe. An inner sleeve is arranged on the portion, located on one side of the connector, of the center pipe. An upper slips cone and a lower slips cone are clamped to the inner sleeve through a cone release shaft and key blocks A. The slips are assembled between the upper slips cone and the lower slips cone. The anchor packer is compact in structure, setting and anchoring are achieved, and the unsetting mechanism is exquisite in design; setting is safe, it can be avoided that setting is conducted in advance, and step-by-step unsetting can be easily completed when multiple packers are used at the same time; and the problem that multi-stage unsetting is difficult in the prior art is solved. The anchor packer can bear the pressure from the position above the anchor packer and the pressure below the anchor packer, and is particularly suitable for water (gas) injection, interlayer isolation, split injection and split explosion, multilayer testing and stimulation measure operation in plumb shafts and slightly-deviated wells.

Owner:荆州市赛瑞能源技术有限公司

Luggage bag having a removable garment bag

ActiveUS20050045500A1Easy accessEasy to put together and take apartGarmentsHandbagsCouplingEngineering

A combination garment bag and luggage bag includes a relatively rigid outer luggage bag and a relatively flexible inner garment bag. According to one aspect of the invention, the garment bag is secured to the interior of the luggage bag with the aid of a releasable coupling mechanism. According to another aspect of the invention, the interior of the garment bag is provided with a spring expandable hanger bar. The hanger bar expands when the garment bag is removed from the luggage bag. This allows easier access to the contents of the garment bag.

Owner:INGENIOUS DESIGNS

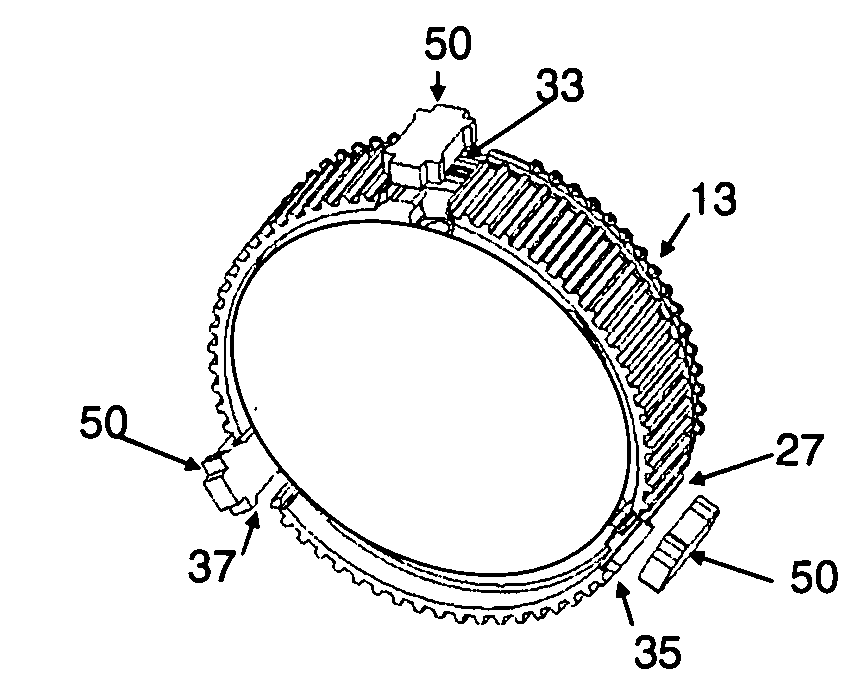

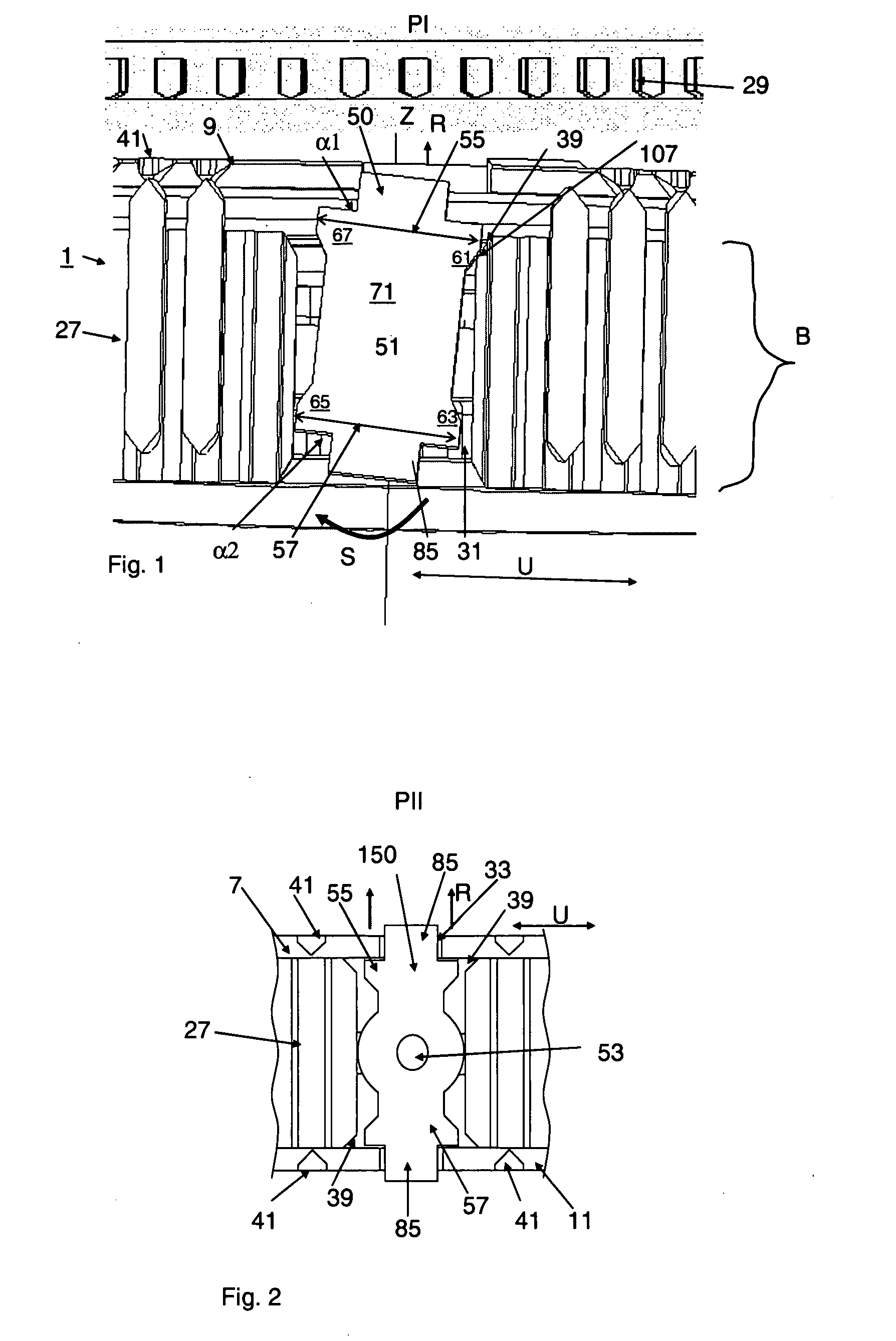

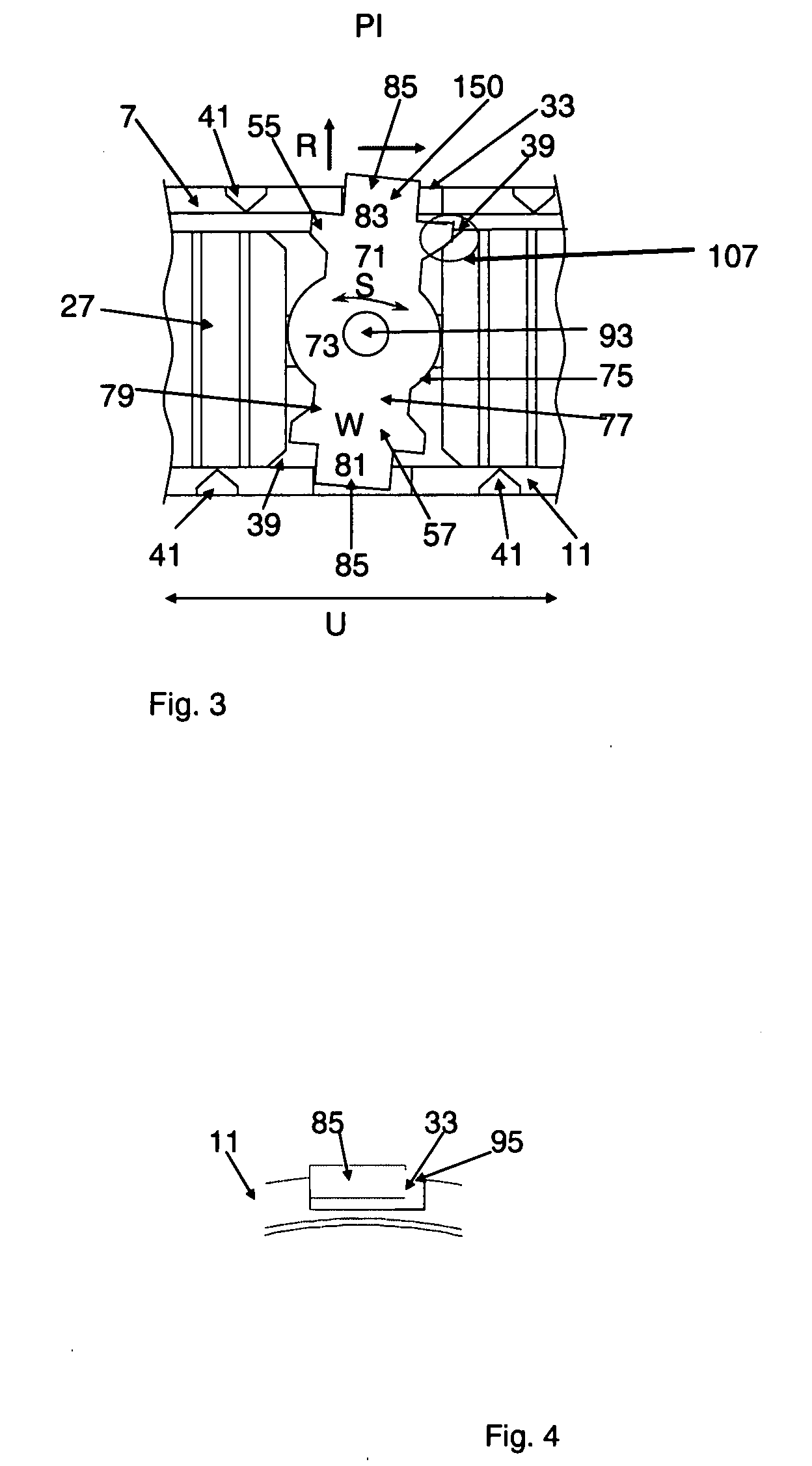

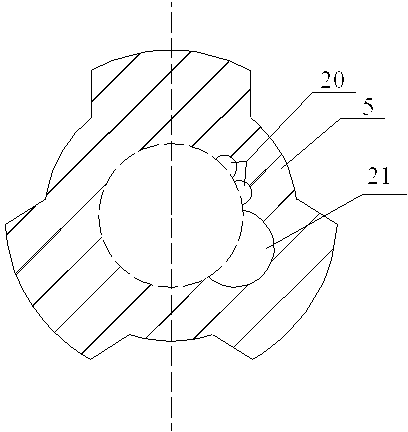

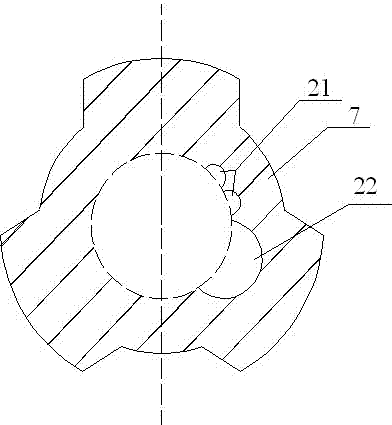

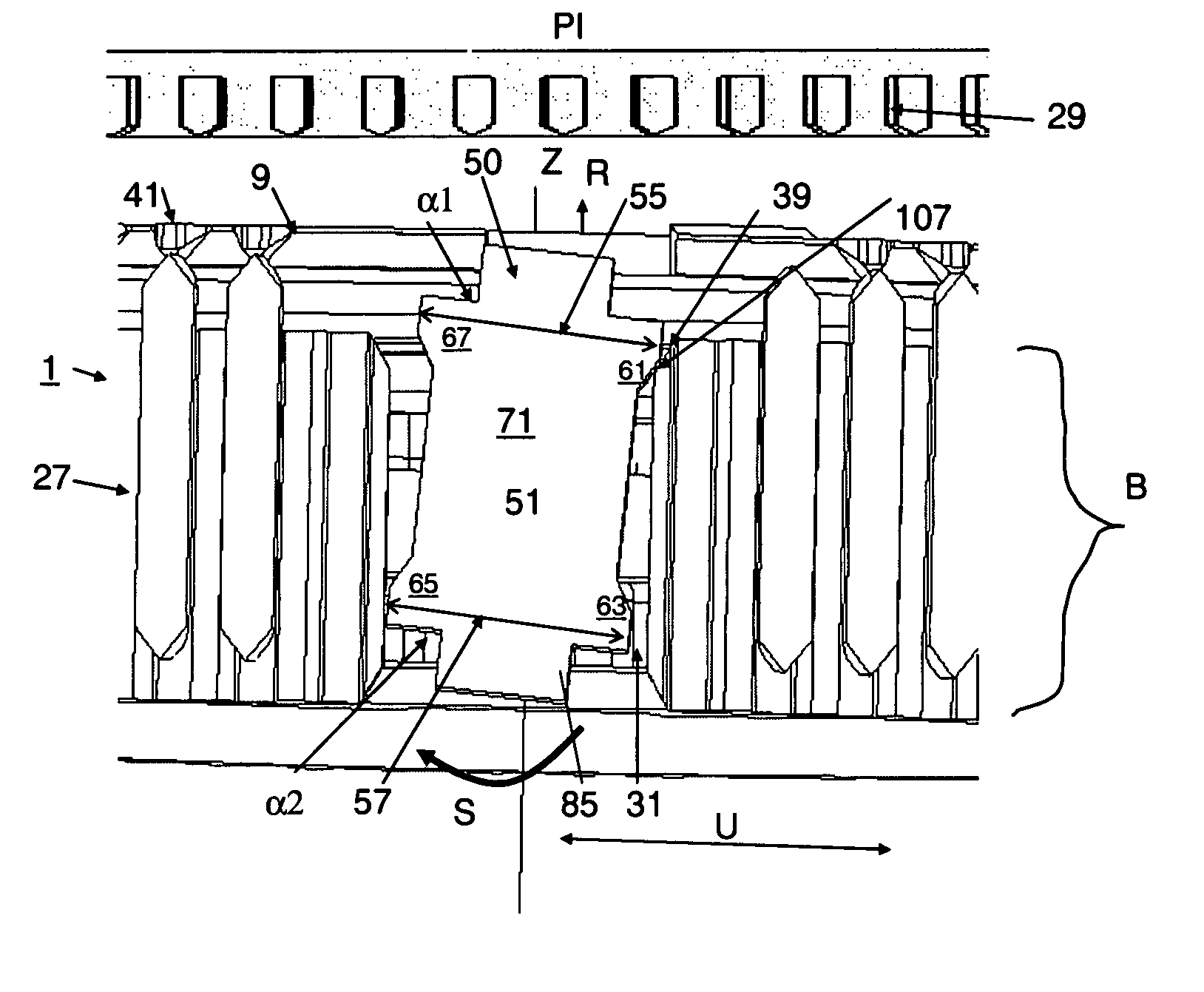

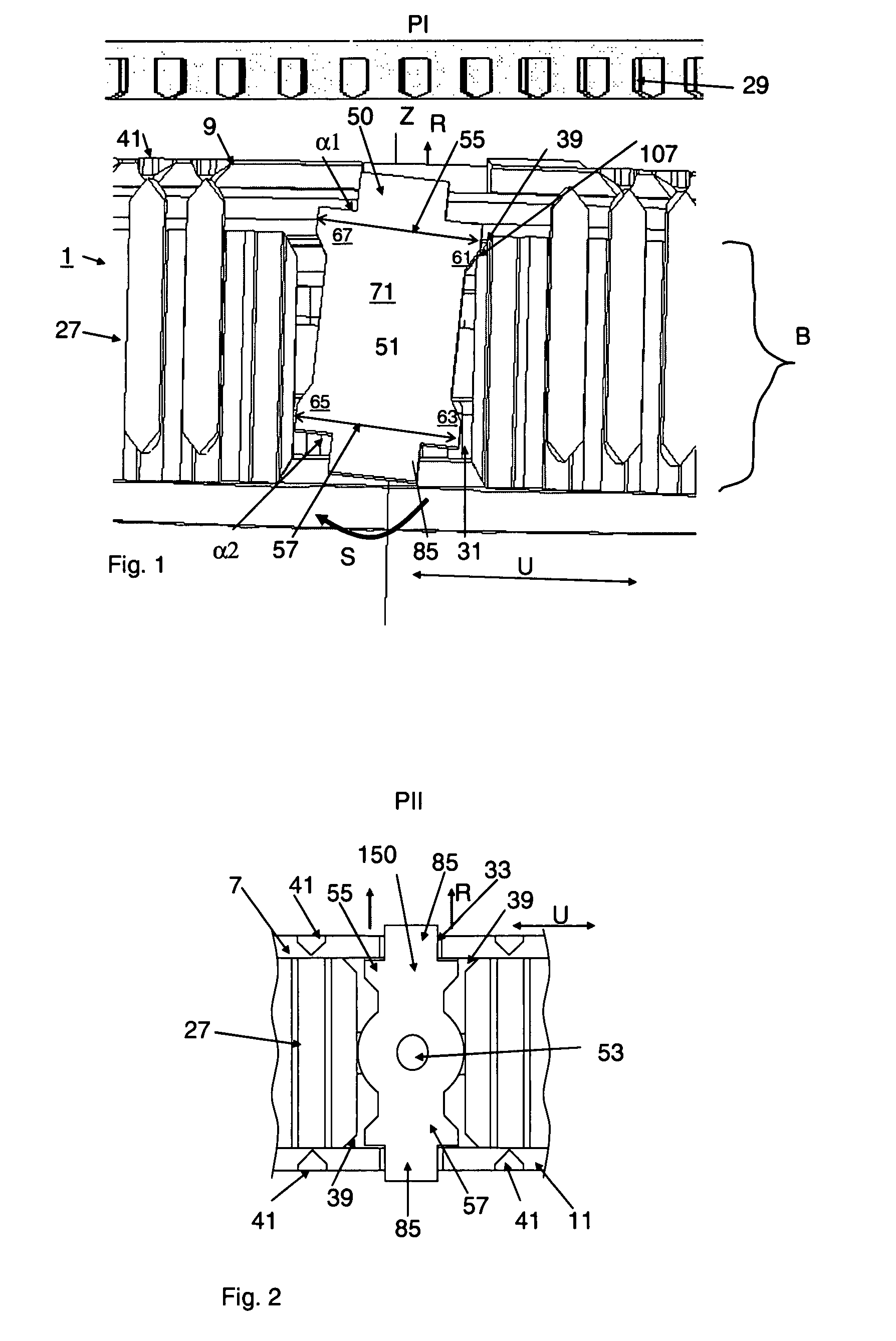

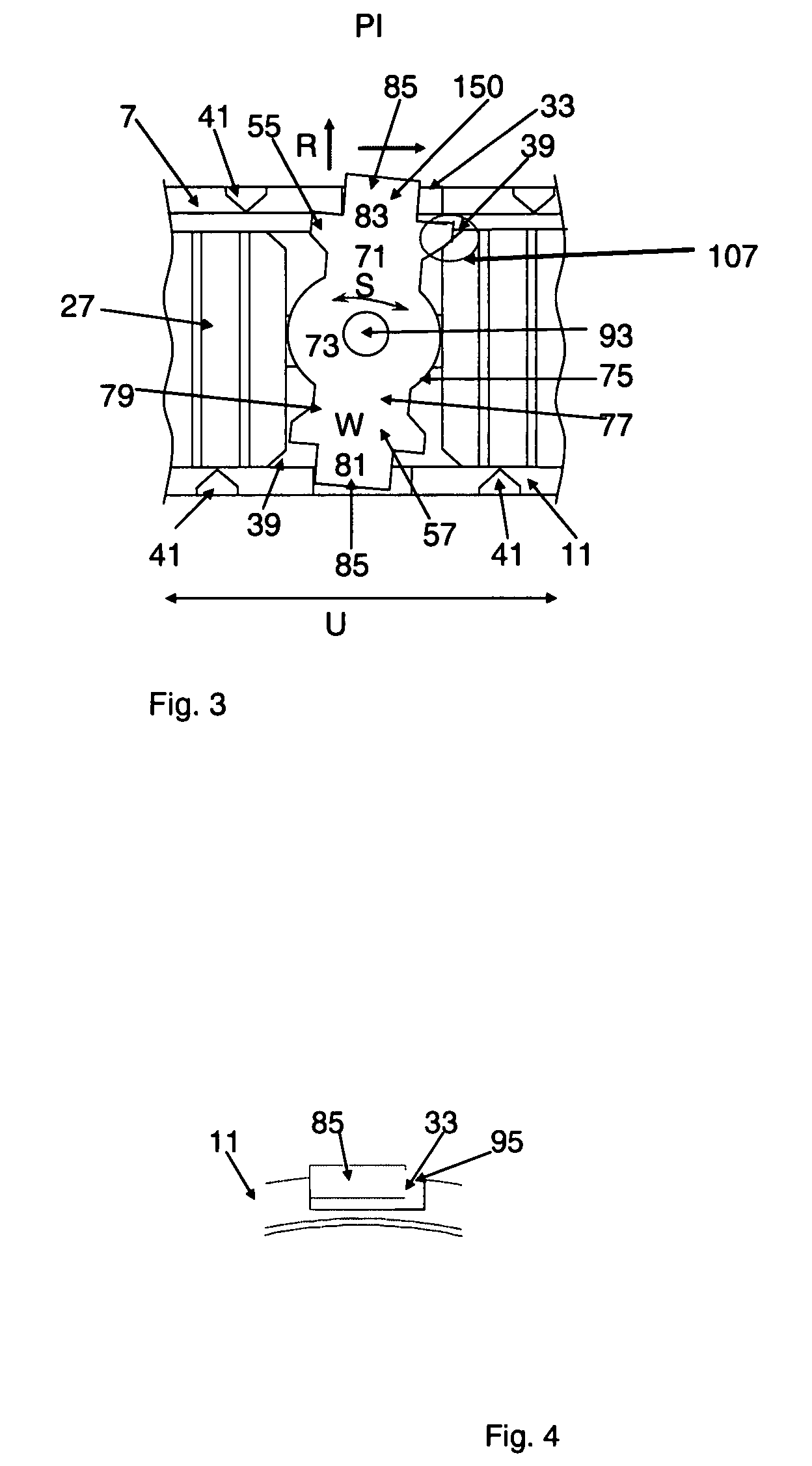

Transmission synchronizing system, in particular, in the form of a servo synchronizing system

InactiveUS20080066568A1Favor ease of productionLower requirementToothed gearingsFriction clutchesEngineeringSynchronization system

The invention relates to a synchronization piece which, as part of a servo synchronization system comprising a sliding sleeve, a clutch body, a synchronizer ring and an idler gear, can synchronize a transmission having toothed wheel gears. The invention furthermore relates to an entire synchronizing system having a synchronization piece according to the invention. A full-servo synchronization system is also presented.

Owner:HOFER PDC

Data processing system

InactiveUS20060125787A1Easy to unpackCathode-ray tube indicatorsDetails for portable computersData processing systemSimulation

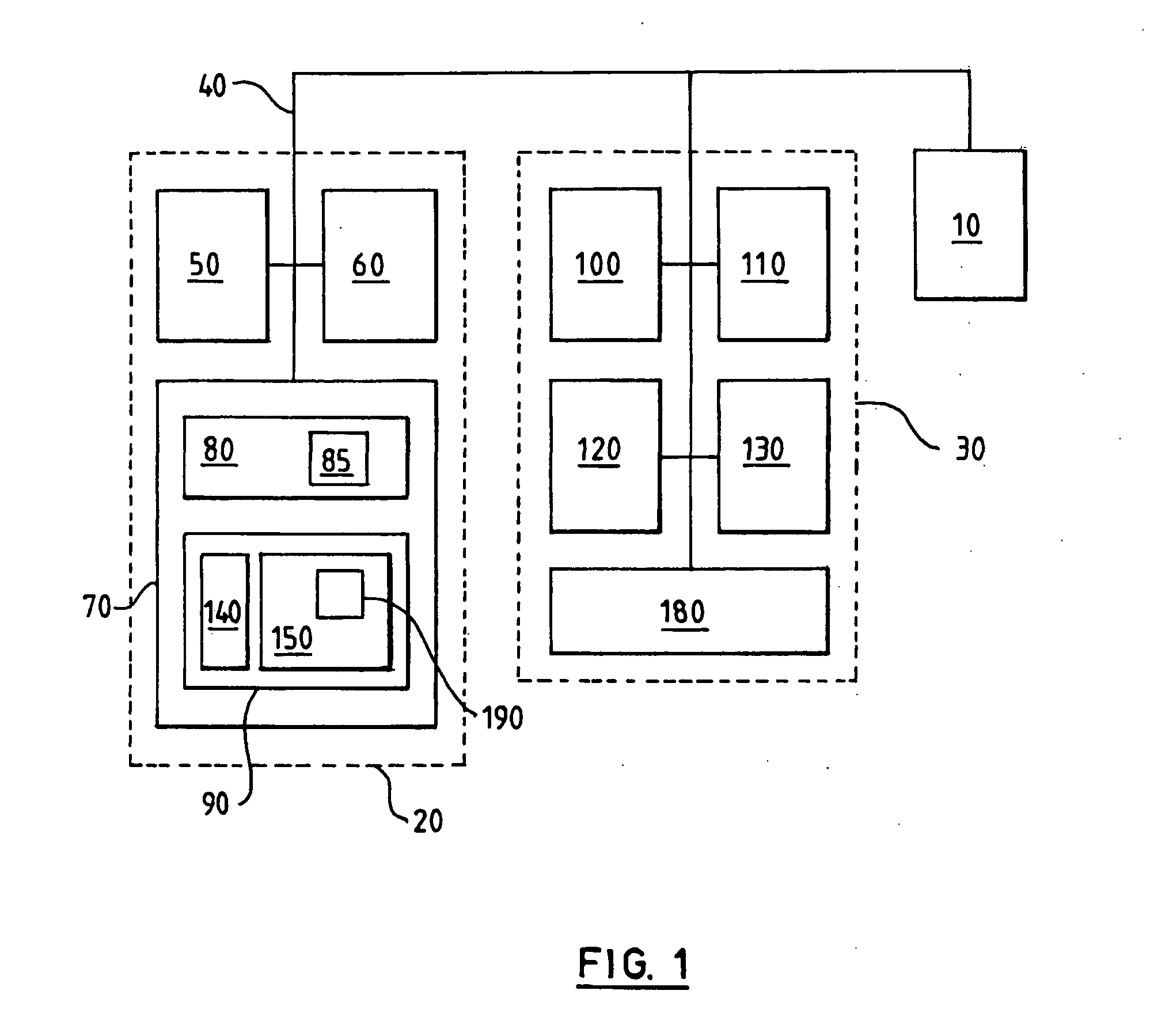

A data processing system including: a display screen; a keyboard; a sensor subsystem for generating a sensed output indicative of the position of the display screen relative to the keyboard; a memory for storing one or more outputs from the sensor subsystem; a comparator for generating feedback indicative of the difference between the output from the sensor subsystem and an output stored in the memory; and, communication means for communicating the feedback to a user of the data processing system.

Owner:BATTELLE MEMORIAL INST +1

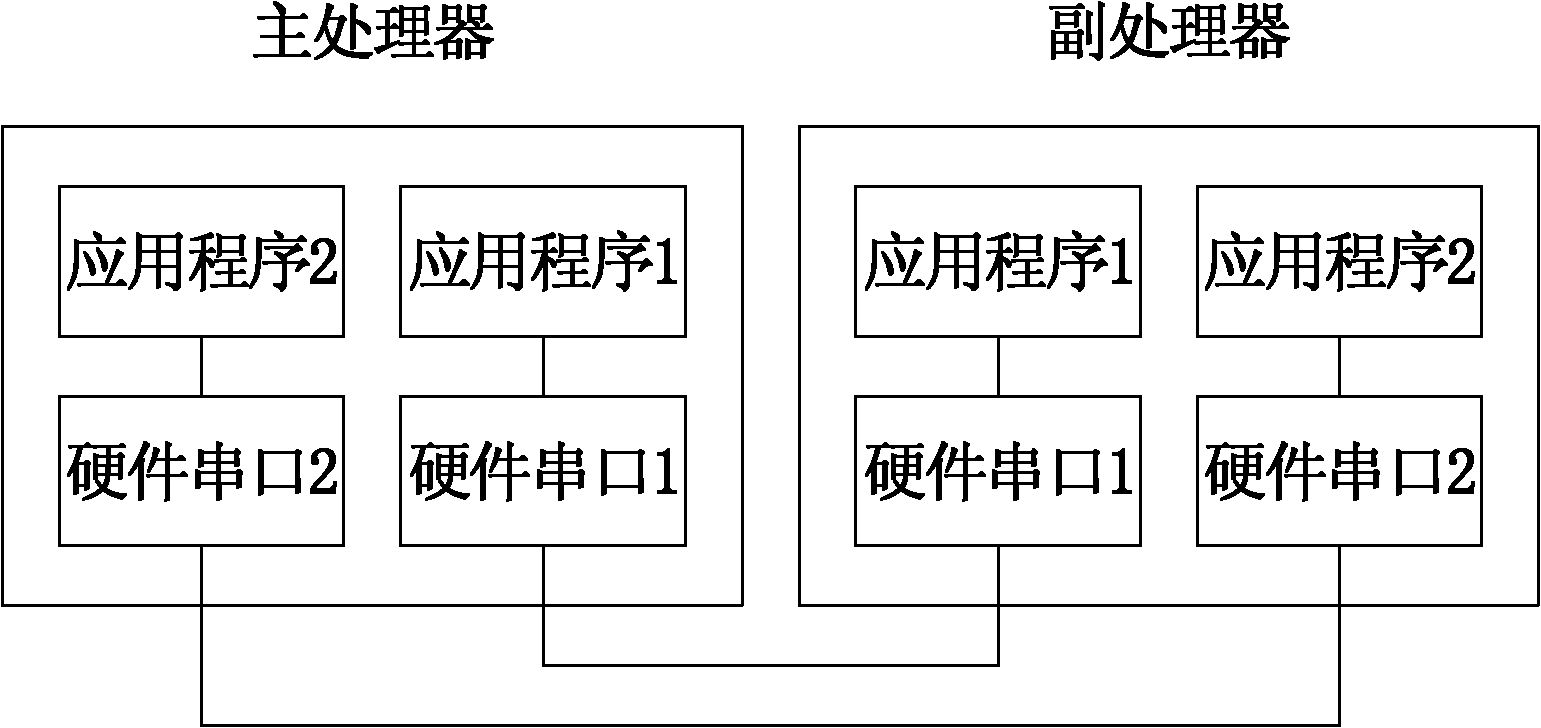

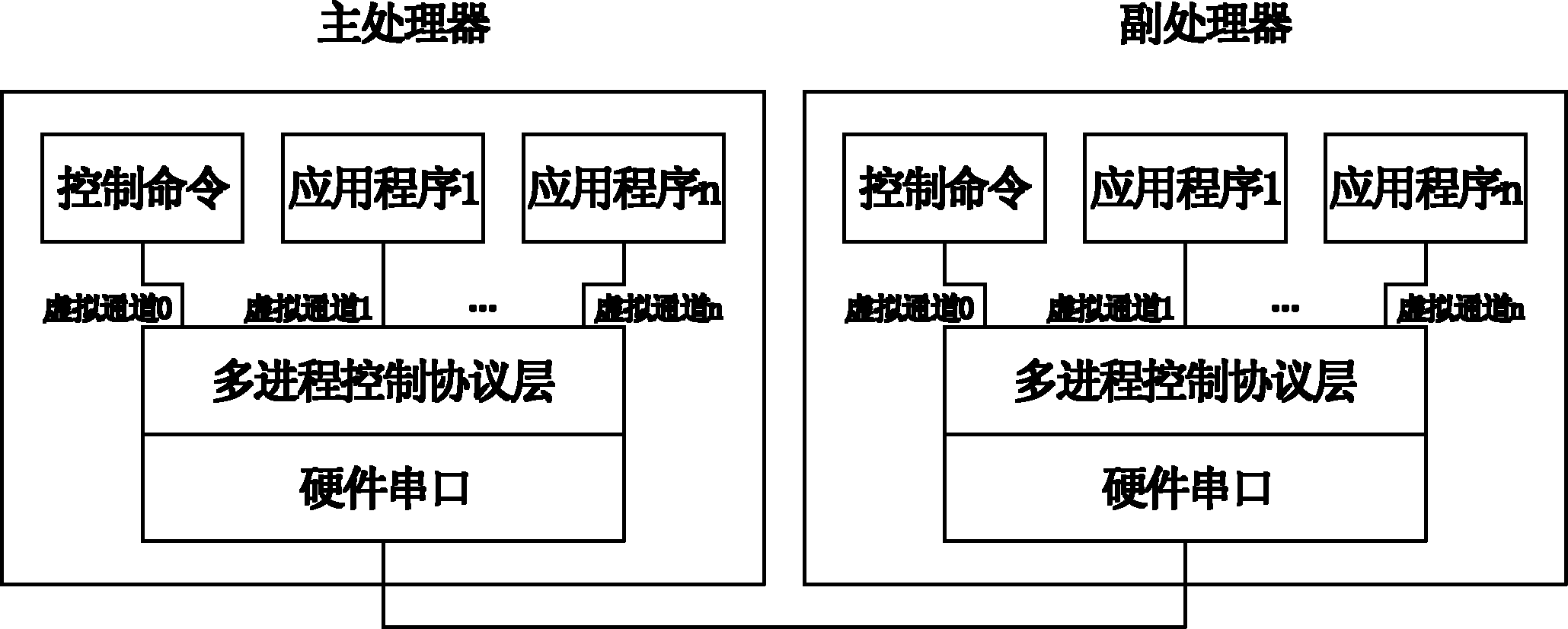

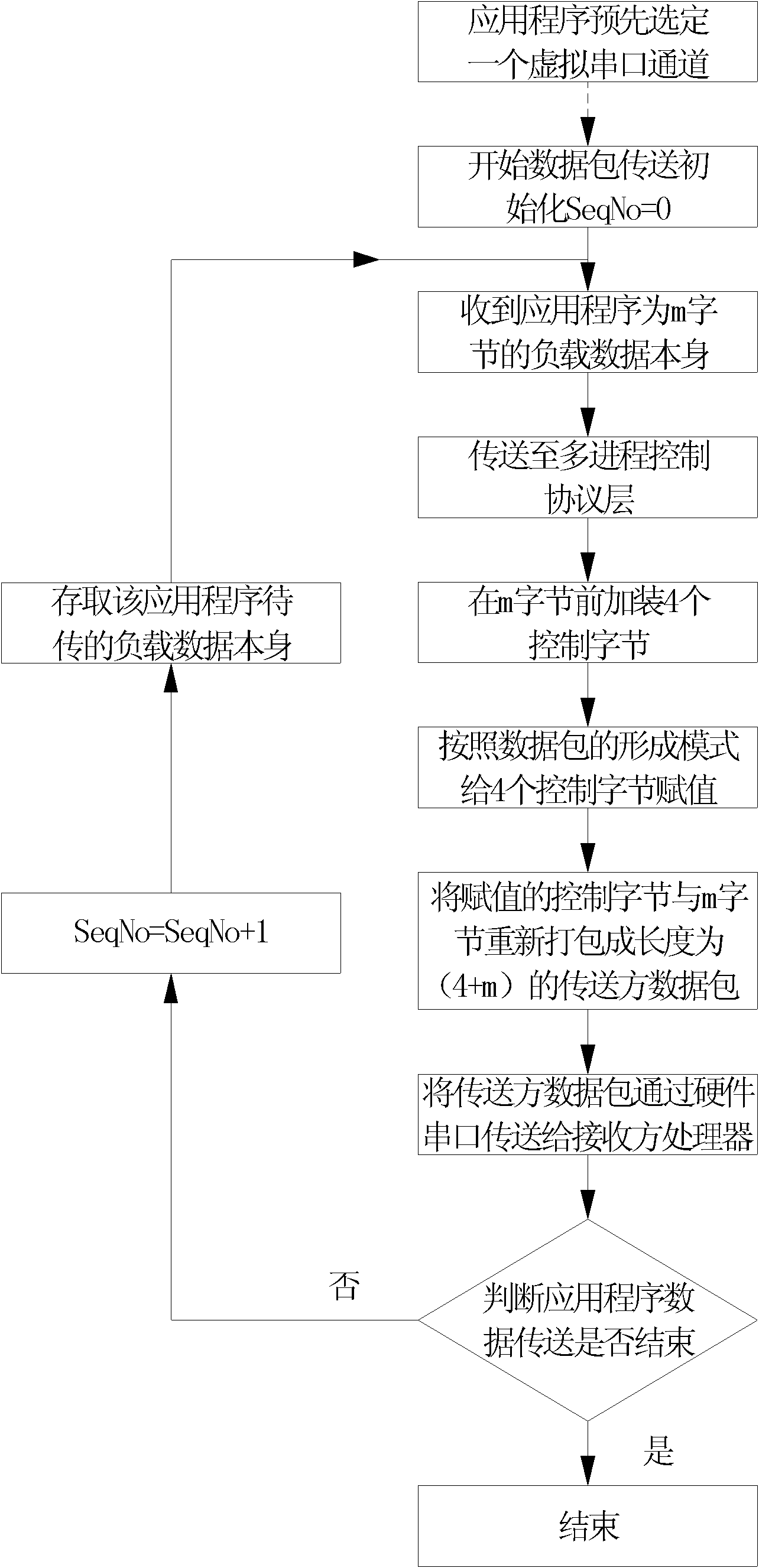

Communication method for implementing multi-process control through single hardware serial port

The invention discloses a communication method for implementing multi-process control through a single hardware serial port, which comprises the steps that: as much as 16 virtual serial port channels are provided on the single hardware serial port, a transmitting party transmits an application data packet to a receiving party on a multi-process control protocol layer according to the generation mode of the data packet, the receiving party unpacks and analyzes the data packet on the peer-to-peer multi-process control protocol layer. The method has the advantages that: multi-process control is offered to application by utilizing one essential hardware serial port, thereby saving the pin of hardware chip which increasingly becomes valuable in product design and being favorable for chip minimization; only 4 bytes are used as the control bytes for the data packet, which greatly improves the transmission speed and efficiency of data on the hardware serial port; and the data packet adopts the simple and effective generation mode which only takes up quite less memory and calculation resource, so the communication method is particularly suitable for high-speed data transmission and portable electronic products.

Owner:INTEBYTE ZHENJIANG

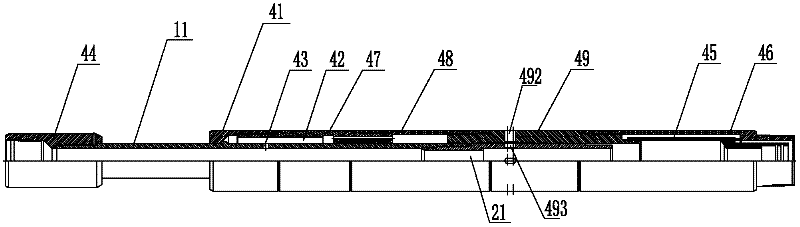

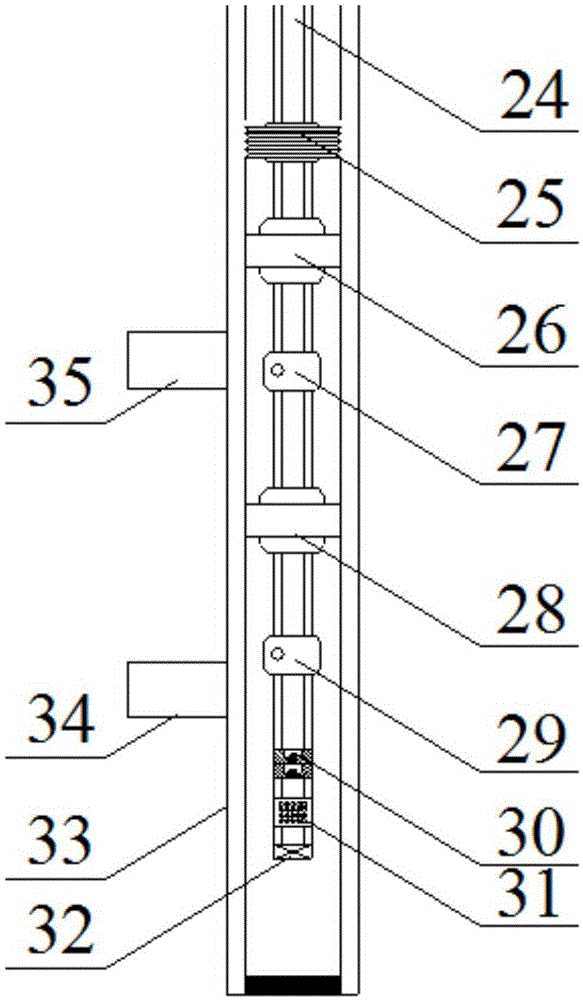

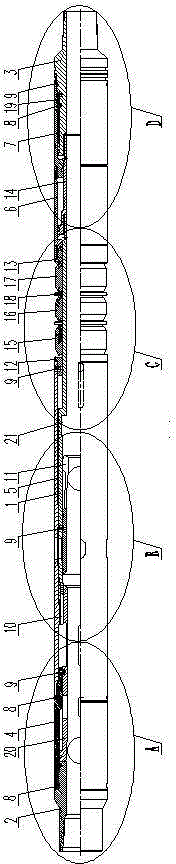

Water searching pipe column of open-hole horizontal well

The invention discloses a water searching pipe column of an open-hole horizontal well, comprising an oil pipe, wherein a suction device is arranged in the oil pipe; the water searching pipe column is characterized in that: the oil pipe extends along the axis of a shaft of the horizontal well; the lower end of the oil pipe is connected with a horizontal well centering device, a hydraulic setting tool, a long rubber cylinder water searching upper packer, a flow distributing device, a lower packet and a lower centering device which are sequentially connected from top to bottom. The long rubber cylinder water searching upper packer disclosed by the invention employs hydraulic setting and lifting unsetting; the water searching and plugging pipe column of the open-hole horizontal well can realize water searching and plugging of the open-hole horizontal well, and search water step by step on a horizontal section, and is reliable in setting and simple in unsetting.

Owner:PETROCHINA CO LTD

Portable fire curtain system

InactiveUS6658801B2Light weightEasy to useShutters/ movable grillesTents/canopiesEngineeringHigh intensity

A portable fire curtain system to provide a cloak to cover a vented opening. When deployed it will alleviate the incoming wind, which is fueling the fire. The fire curtain is made of one sheet of a fire resistant or fire proof material that is folded and sewn together. Encapsulated within the fire curtain are 6 bars of high-tempered aluminum running laterally. Each corner of the fire curtain has holes that are drilled through the top and bottom bars. Four 5 foot cable leaders with loops, (one to each corner) will be secured to these holes. Two 40 foot ropes with snaps on all ends will be connected to these cable leaders to be used in the deployment. The ropes are packed in two rope deployment bags in order to prevent the ropes from tangling.

Owner:KILDUFF PATRICK +1

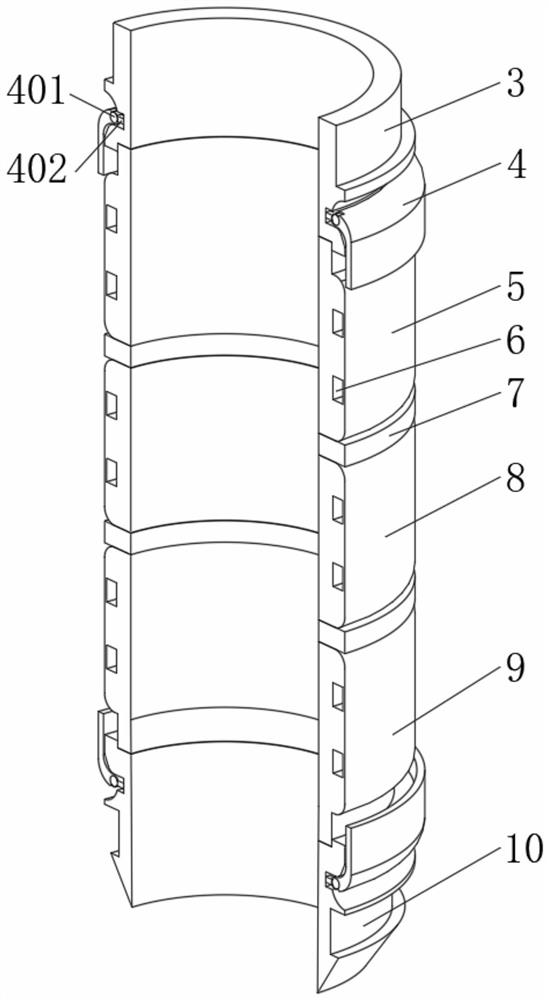

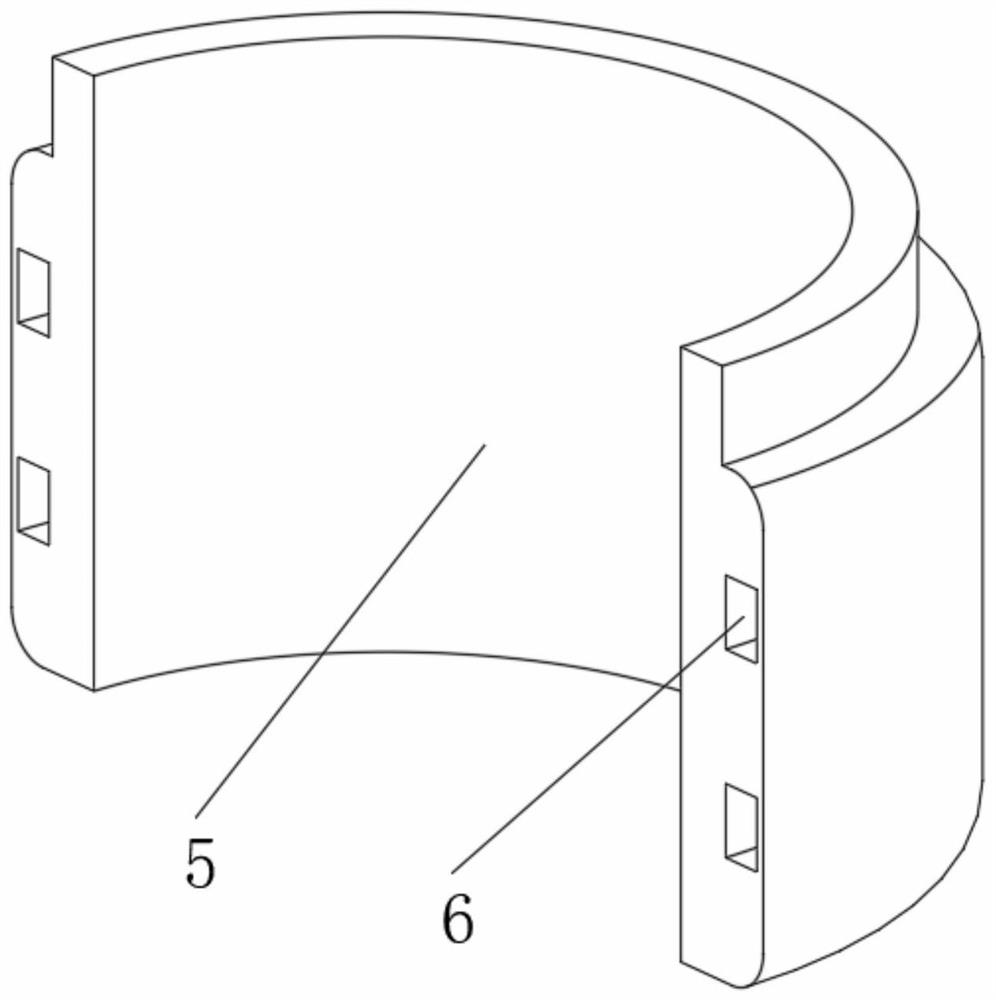

Environment-friendly well-washable step-by-step deblocking water injection packer

The invention discloses an environment-friendly well-washable step-by-step deblocking water injection packer which comprises a central pipe, an upper joint, an upper core pipe, an upper outer sleeve, a locking sleeve, an outer core pipe, a rubber barrel and a lower joint, wherein the upper joint sleeves the central pipe; the upper core pipe is arranged in an inner cavity between the upper joint and the central pipe; the upper end of the upper core pipe is connected with the central pipe; the upper outer sleeve sleeves the upper core pipe; the upper end of the upper outer sleeve is connected with the upper joint; the locking sleeve sleeves the lower end of the upper outer sleeve; a clamping spring is arranged in an inner cavity between the locking sleeve and the central pipe and is arranged on a clamping spring seat; the outer core pipe sleeves the central pipe; the upper end of the outer core pipe is connected with the clamping spring seat; the rubber barrel is arranged between the locking sleeve and the lower joint. The environment-friendly well-washable step-by-step deblocking water injection packer has the benefits that the rubber barrel of the packer can be prevented from being locked, so that the safety and the reliability of deblocking of the packer are greatly improved. An anti-locking mechanism of the environment-friendly well-washable step-by-step deblocking water injection packer has the characteristics of being simple in operation, novel in structure, safe and environmentally friendly.

Owner:中油智科(吉林)技术装备有限公司

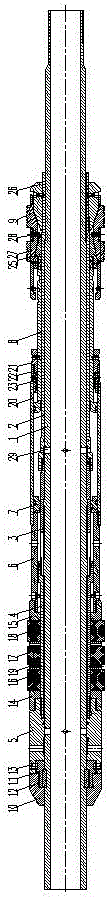

Recyclable type hydraulic packer

ActiveCN105781483AThe setting method is simpleEasy to unpackSealing/packingHigh pressureMechanical engineering

The invention relates to a recyclable type hydraulic packer and belongs to the field of oil and gas well operation downhole tools. The packer comprises an inner center pipe, an outer center pipe, a releasing claw, a bushing, a balanced connector, an oil drainage sleeve, an upper piston, a lower piston and a slip. The inner center pipe is sleeved with the outer center pipe. The releasing claw is arranged on one side of the outer center pipe. The bushing is arranged on one side of the releasing claw. A shear ring is installed on one side of the bushing through the balanced connector and a guide ring. The recyclable type hydraulic packer can bear the two-way pressure from the upper portion and the lower portion of the packer; 52 MPa high pressure can be borne by a sealing mechanism; when the slip enters a well and is unblocked and taken out, the slip is pressed through a spring and only stretches out when the cone acting force is applied to the slip under the action of the hydraulic force, and thus the advanced setting risks of a conventional packer can be effectively avoided; the packer is designed by adopting an integrated inner center pipe and can be directly connected with an oil pipe, the number of transfer buckle parts is decreased, the structure can be made more compact, the drift diameter is increased, and meanwhile the buckle disengagement risk of transfer buckles is avoided, so that the cost is reduced.

Owner:荆州市赛瑞能源技术有限公司

Well-flushing step-by-step unsetting packer

The invention discloses a well-flushing step-by-step unsetting packer, which comprises an upper joint, a well flushing cylinder tube, a rubber tube shaft, a rubber tube, a center pipe, a locking device, a main piston, a connecting sleeve and a lower joint. The well-flushing step-by-step unsetting packer has the advantages that (1) an inlet of a well-flushing passage is of a structure with a plurality of slender seams, so that the flow-passing area of the passage is sufficiently large, large-particle solid phase impurities can be prevented from entering the well-flushing step-by-step unsetting packer to block an inner passage, and the smoothness of a tool inner cavity well-flushing passage is ensured; (2) the well-flushing passage of the packer adopts a streamline design, so that machine impurities and solid phase particles can easily flow out, and passage blockage due to accumulation cannot easily occur; and (3) a step-by-step unsetting mechanism is arranged inside the packer, so that during the multi-stage use, an upper-stage packer is firstly unset; then, a lower-stage packer is unset; the unsetting force is not accumulated during the unsetting; and the packer is enabled to be easily unset.

Owner:PETROCHINA CO LTD

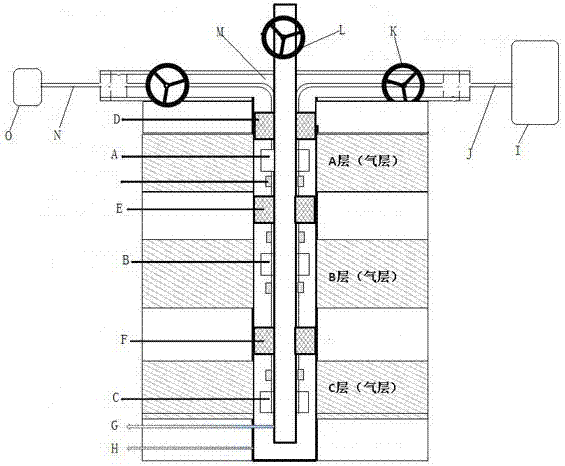

Intelligent control device and control method of layer mining, control and testing of gas well

ActiveCN107227945AEfficient power supplyEasy to controlSurveyConstructionsHierarchical testProcess engineering

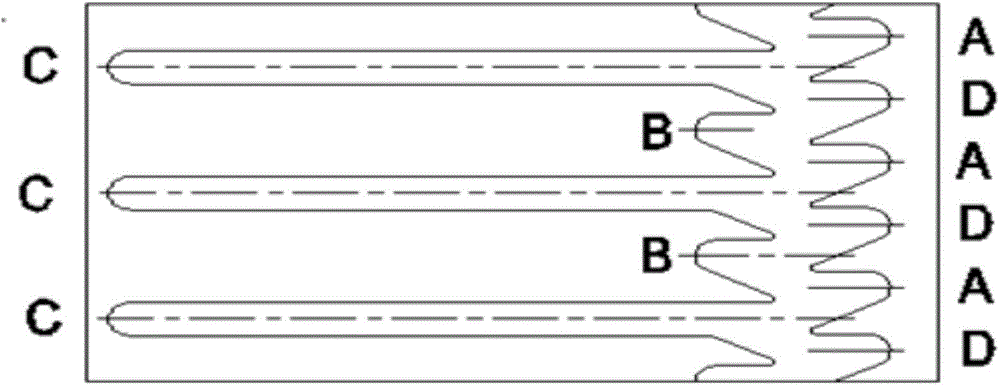

The invention discloses a control method layer mining, control and testing of gas well. The method comprises the following steps: setting three production gas layers of a natural gas well as a gas layer A, a gas layer B and a gas layer C, mounting a direct reading intelligent gas well underground layering zonal pressure measuring device on each layer, packing the three production gas layers through a gas control underground packer, and ensuring that a ground intelligent control box gives an instruction to enable the direct reading intelligent gas well underground layering zonal pressure measuring devices of the gas layers A and C to be closed, open a communicating hole of the direct reading intelligent gas well underground layering zonal pressure measuring device of the gas layer B when the gas layer A is required to be closed, the gas layer B is required to perform production and the gas layer C is required to be closed, so as to enable natural gas of the gas layer B to be output to the ground through an oil pipe and to realize layer control; ensuring that a ground metering station can timely measure the gas output of a layer, so as to realize layer gas production; ensuring that the direct reading intelligent gas well underground layering zonal pressure measuring devices can record the production pressure difference and underground temperature at the same time, so as to realize layer testing. The gas layer A, the gas layer B and the gas layer C can be subjected to simultaneously gas production and testing.

Owner:DONGYING XINJI PETROLEUM TECH

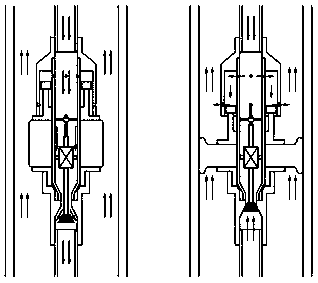

Layered pressure control combined drainage-production device for double coal-beds prone to dust and sand spraying

ActiveCN103061724AAchieve the effect of layered pressure control combined drainageLow failure rateFluid removalFailure rateCoal dust

The invention relates to a layered pressure control combined drainage-production device for double coal-beds prone to dust and sand spraying. Two drainage pumps are generally combined and used for simultaneous mining of two coal-beds. In case of the coal-beds prone to dust and sand spraying, coal dust and sand enter a suction inlet of the upper drainage pump easily, failure rate of the drainage pump is increased, and workover cycle is shortened. The layered pressure control combined drainage-production device for double coal-beds prone to dust and sand spraying comprises a drainage pump, an oil tube and a sucker rod. The oil tube comprises an upper oil tube and a lower oil tube. A centralizer is disposed on the outer wall of the upper oil tube. The device is characterized in that the drainage pump is a pump for separated zone operation, and a packer and an auxiliary communicating tube are disposed on the lower oil tube. By the use of the pump for separated zone operation, combined mining of the double coal-beds is achieved, the device is more applicable to double coal-beds prone to dust and sand spraying, the failure rate of the pump for separated zone operation is decreased and pump maintenance cycle is prolonged.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

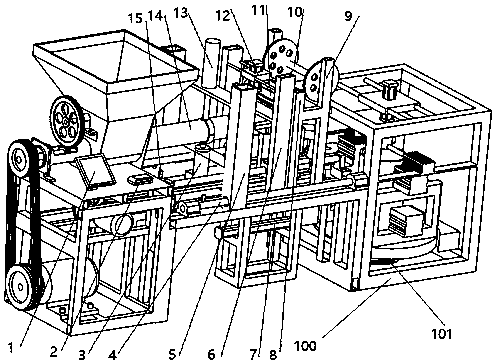

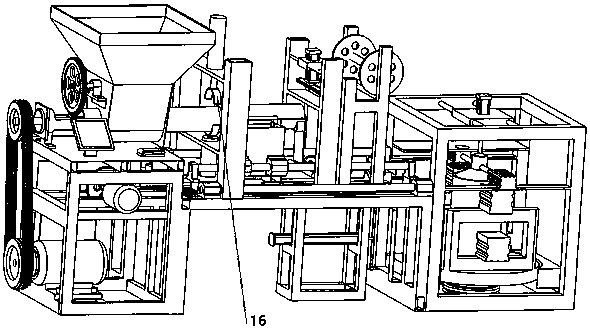

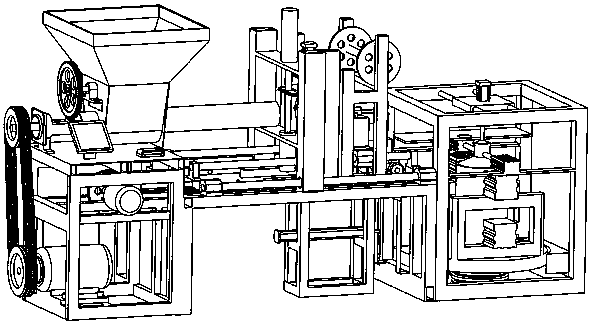

Novel full-automatic edible mushroom bagging machine

InactiveCN107821011AFully automatedRich demandCultivating equipmentsMushroom cultivationEdible mushroomEngineering

The invention provides a novel full-automatic edible mushroom bagging machine which comprises a touch screen, an emergency stop switch, a bagging frame, a cutting frame, an ejection cylinder, a conveying roller frame, a mushroom bag frame, a plurality of sensors, an opening sealing frame, a conveying roller, an elastic suction ring, a rotary cover, a rotary cover locating plate, a guide sleeve, abagging mechanism, an opening sealing mechanism, a filling mechanism, mushroom bags and mushroom packages. The touch screen is provided with a control panel, and can independently control the openingsealing device to be started and stopped, and also can control the whole equipment to be started and stopped; the equipment is provided with the sensors for detecting the operation condition of the whole equipment, and corresponding parameters can be all displayed on the touch screen; by the conveying roller, the bagging frame and the cutting frame, automatic bagging of mushroom bags is realized;by the opening sealing mechanism, rotary cover sealing operation for mushroom packages is realized, and the rotary cover sealing has the advantages of convenience, quickness, difficulty in damage to the mushroom bags, convenience in unsealing and the like. The novel full-automatic edible mushroom bagging machine disclosed by the invention can meet requirements for edible mushroom bagging automation and quickness, and is high in safety, reasonable in structure and convenient for popularization and application.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

Double-coal-bed layered pressure control device combining coal discharging and coal mining

ActiveCN103089204AAchieve the effect of layered pressure control combined drainageImplement stratified extractionFluid removalDesorptionInterference problem

The invention relates to a double-coal-bed layered pressure control device combining coal discharging and coal mining. A coal-bed gas well often meets two coal beds, and often an upper coal bed generates gases first, a lower coal bed begins to generate gases with the descending of the floating liquid level, and the guarantee that two coal beds desorb and generate gases simultaneously is difficult. The double-coal-bed layered pressure control device combining coal discharging and coal mining comprises a pumping and mining pump, an oil pipe and an oil pumping rod, wherein the oil pipe comprises an upper oil pipe and a lower oil pipe, and a centering device is arranged on the outer wall of the upper oil pipe. The double-coal-bed layered pressure control device combining coal discharging and coal mining is characterized in that the pumping and mining pump is a combined pump, the lower oil pump is provided with a packer and an auxiliary communicating tube, and the auxiliary communicating tube is arranged at the upper portion of the parker. The double-coal-bed layered pressure control device combining coal discharging and coal mining has the advantages that interbed interference problem generated in the process of discharging and mining of the double coal beds is solved, desorption and gas-generating simultaneously are guarantee, and double-coal-bed layered pressure control device combining coal discharging and coal mining is suitable for combined mining of the coal-bed gas well in double-coal-bed areas.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Film with characteristic of easy tearing in longitudinal direction, and preparation method thereof

ActiveCN107629281ASave powerGood lateral toughnessLow-density polyethyleneLinear low-density polyethylene

The invention discloses a film with a characteristic of easy tearing in a longitudinal direction, wherein the film comprises, by mass, 40-50% of low density polyethylene, 20-30% of linear low-densitypolyethylene, 5-10% of polyethylene wax, 10-20% of an ethylene-vinyl acetate copolymer, and 5-10% of polybutene. According to the present invention, the film is easy to tear in a longitudinal direction, wherein the force for tearing is small; and the film has good transverse toughness, such that the package is conveniently unpacked while the shelf life of the content cannot be affected.

Owner:苏州沃贝得无尘材料有限公司

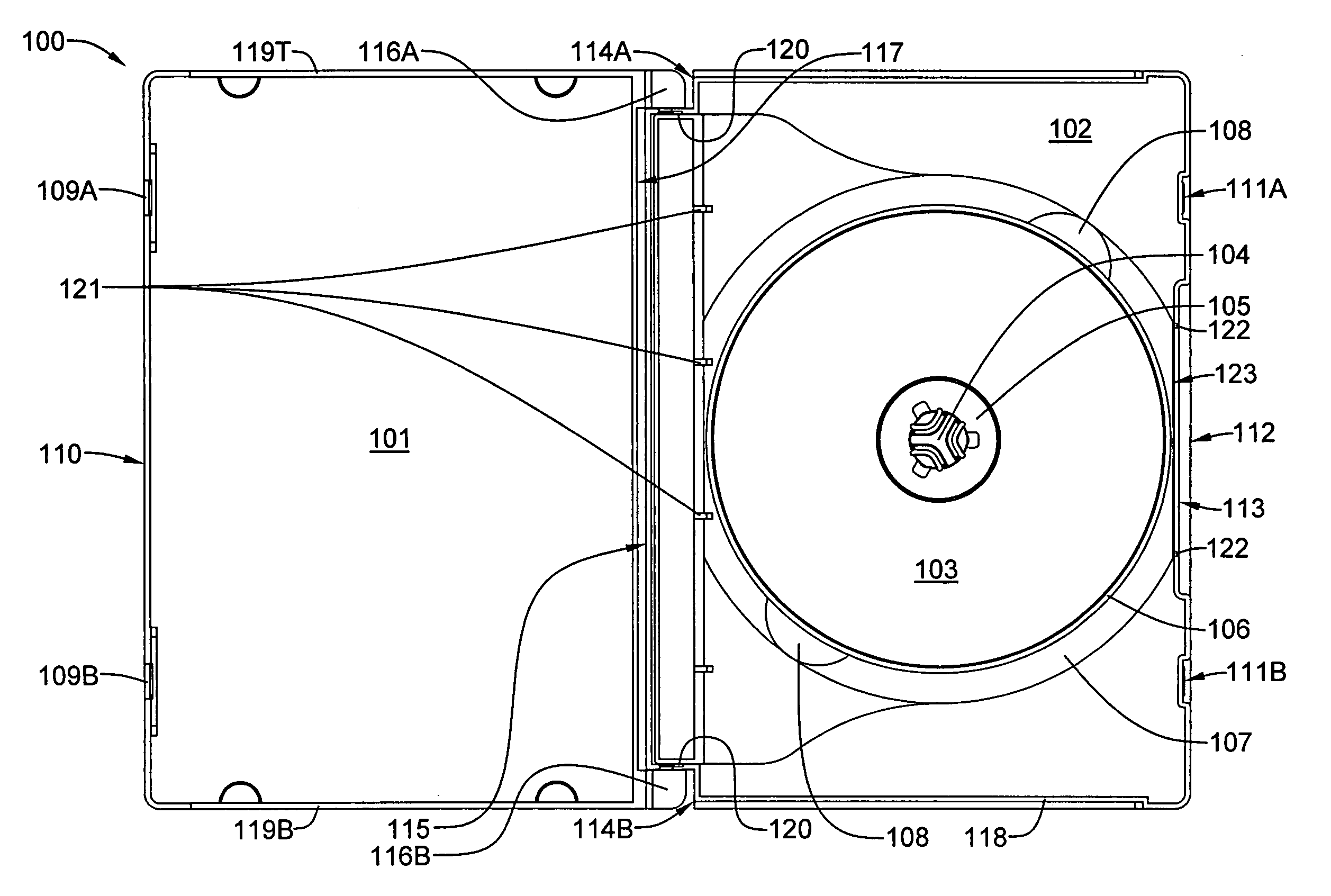

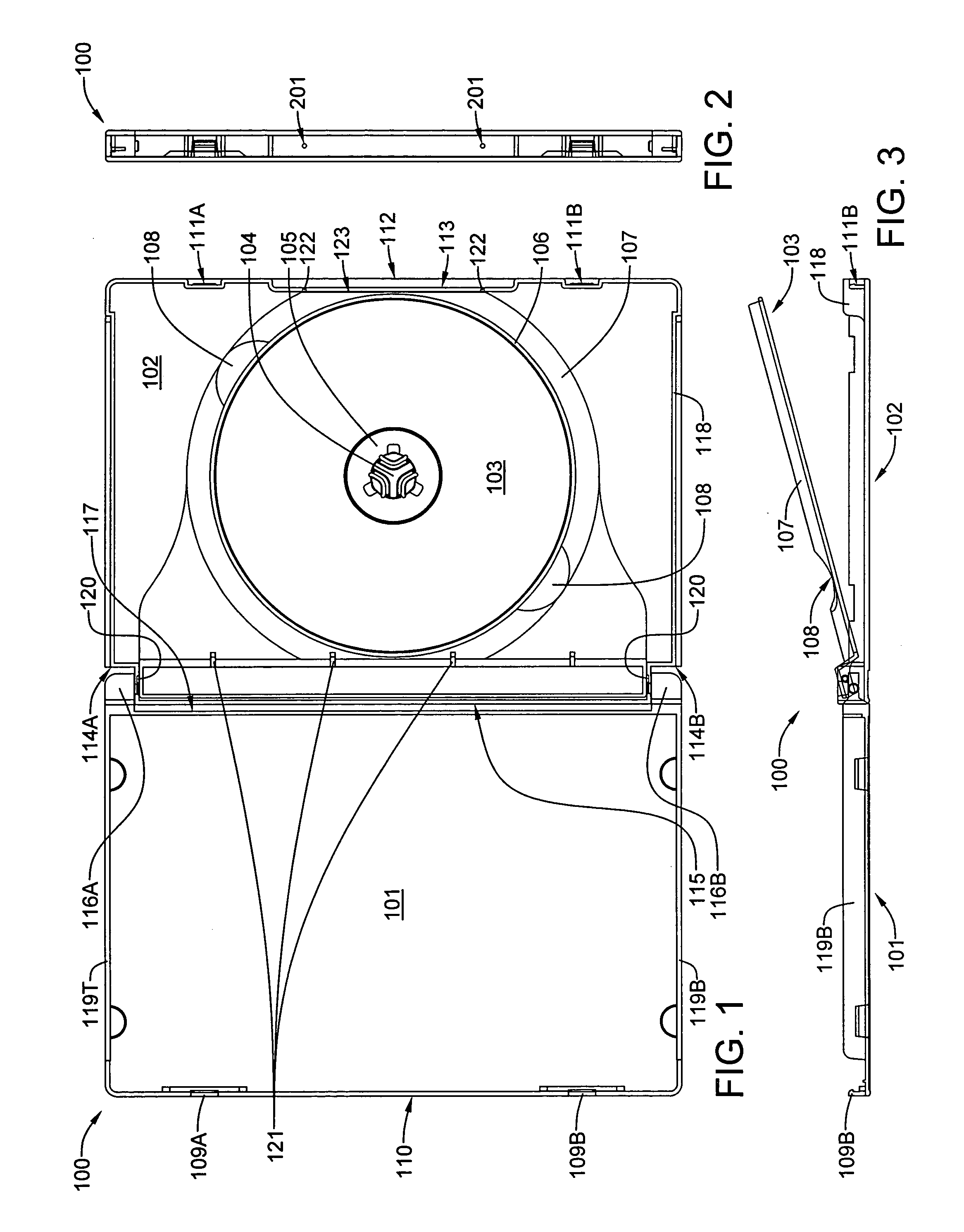

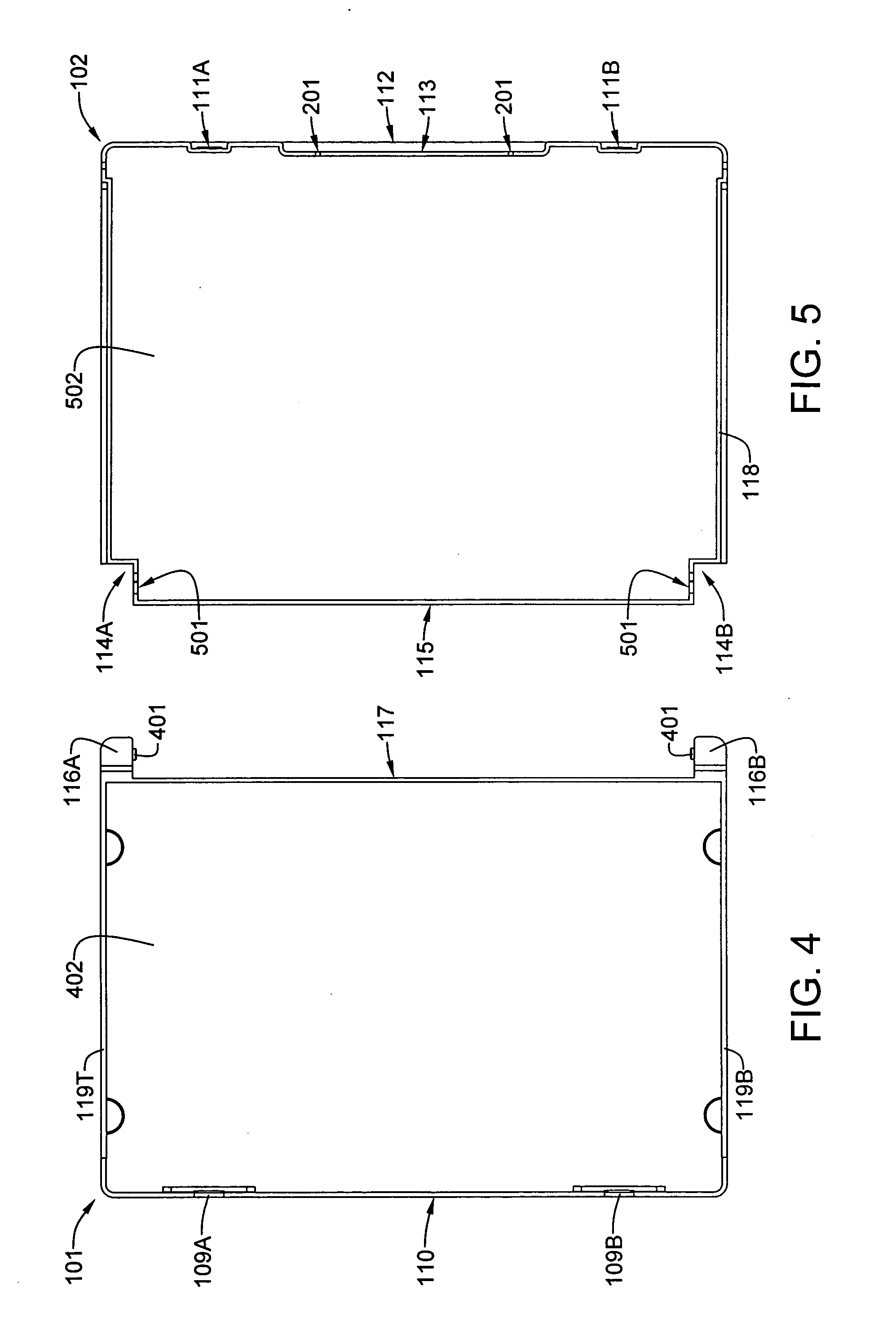

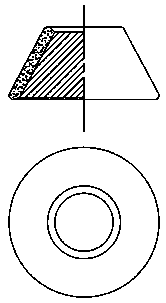

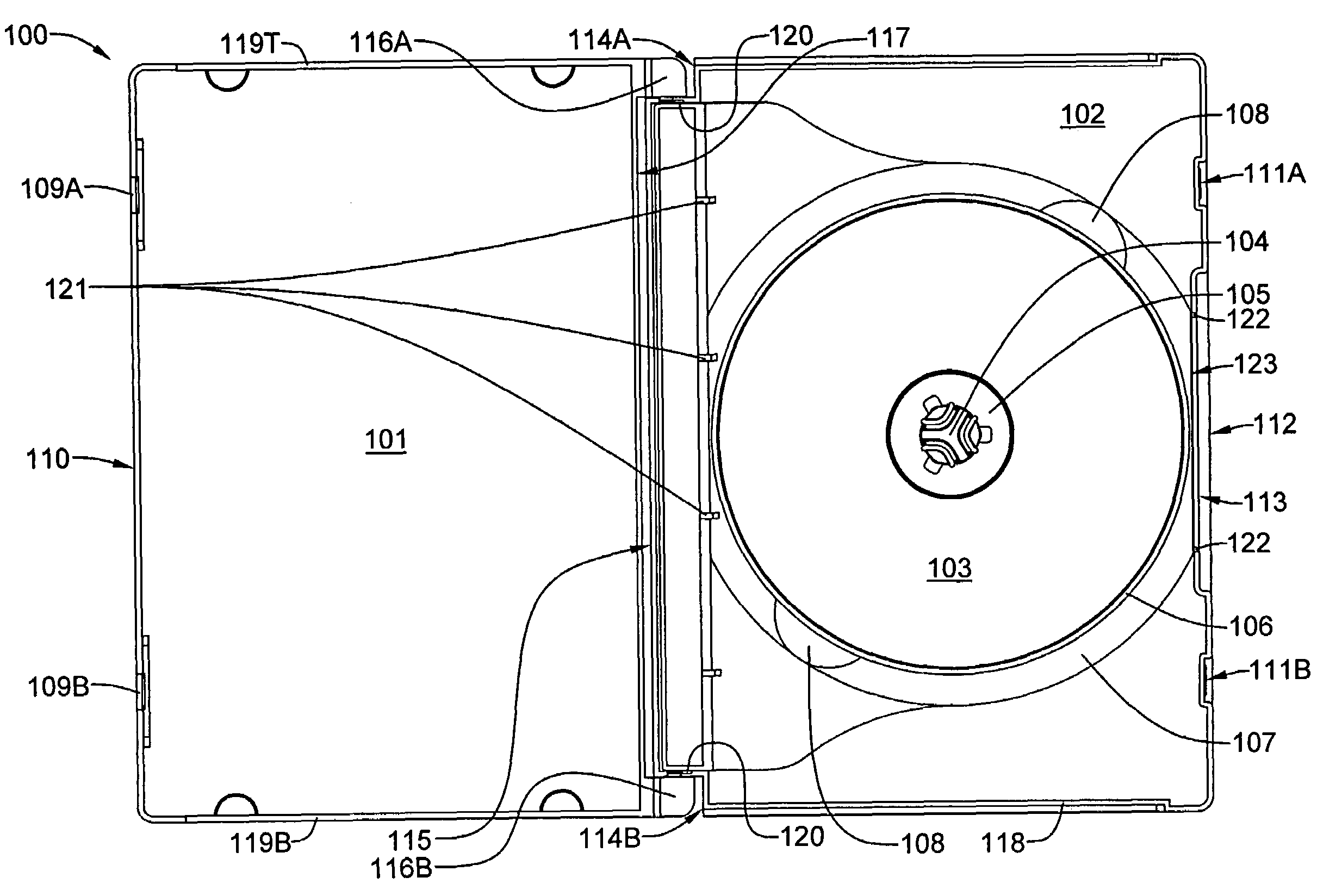

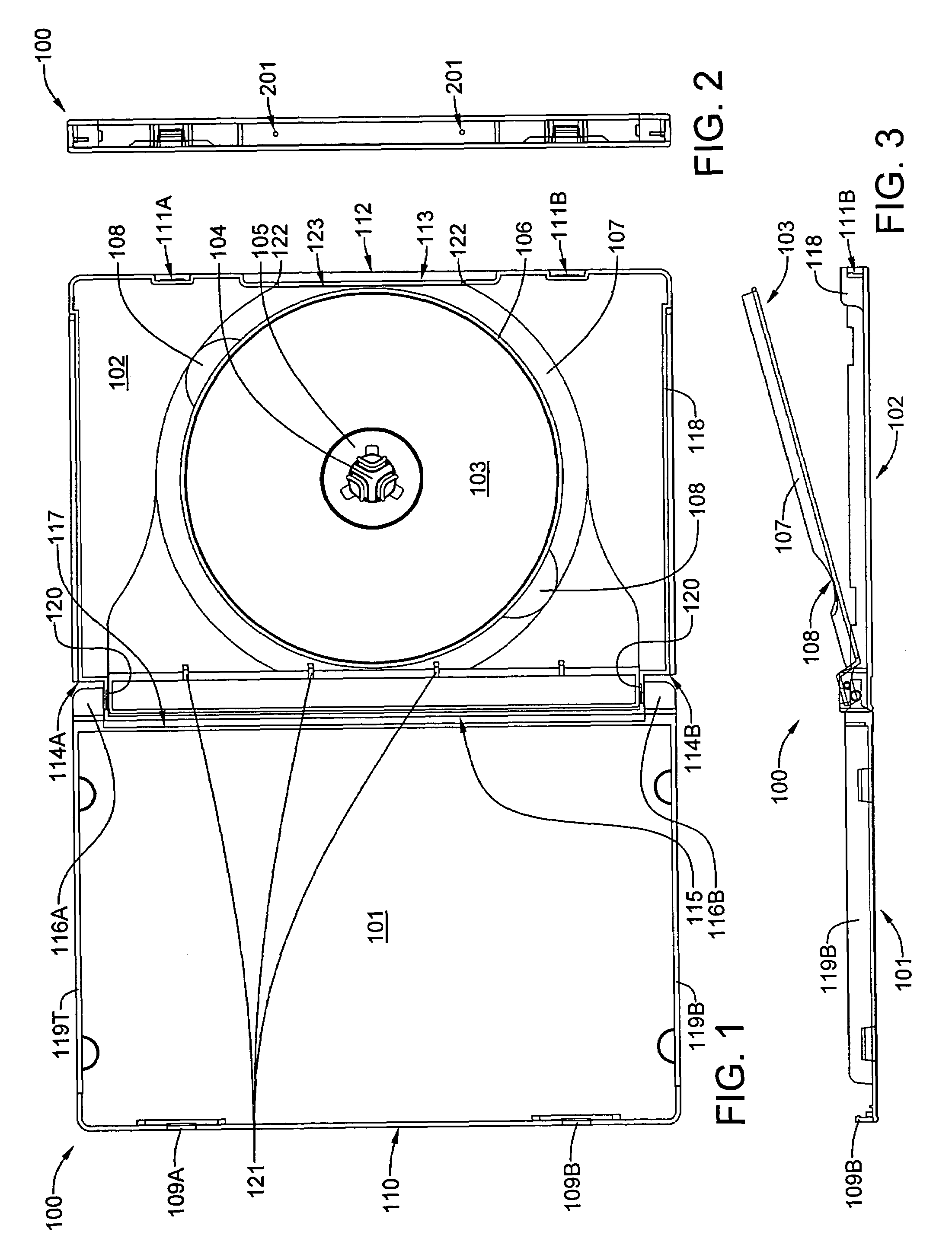

Protective case for information storage disc

InactiveUS20050150791A1More to mechanical damageImprove structural strengthRecord information storageOther accessoriesSolid componentFront edge

A three-piece jewel case for information storage discs, such as CDs and DVDs, is of the clam-shell type, and includes a base portion having a pair of generally rectangular hinge recesses positioned at adjacent corners along a rear side edge thereof, a lid portion having a pair of generally rectangular hinge arms positioned at adjacent corners along a rear side edge thereof, and a media tray having a lid portion supporting hub, which snaps into the base portion. For a preferred embodiment of the case, the media tray is hingeably connected to the base portion along the rear side edge. Each hinge arm has a rectangular solid component that extends from the outer edge to the inner edge and from the front edge to the back edge thereof. This feature rigidifies the rectangular hinge so that it is much more resistant to mechanical damage from crushing or dropping loads.

Owner:OSBORN WARREN R +1

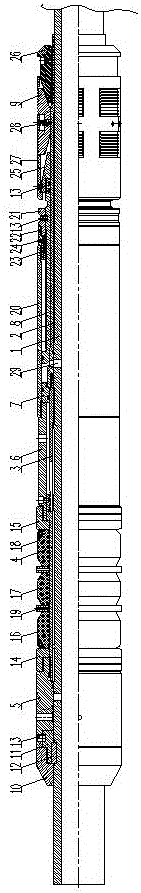

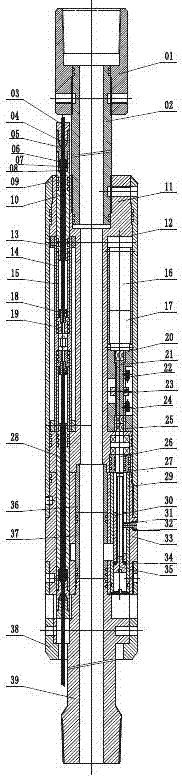

Packer for intelligent well completion

The invention discloses a packer for intelligent well completion. The packer comprises a main pipe body, wherein a rubber tube sealing mechanism for expansion seat sealing and a slip anchoring mechanism for anchoring are sleeved on the main pipe body; and a main channel axially penetrating through and a plurality of parallel pipe cable bypass channels are arranged inside the main pipe body. The lower end of an inner cylinder of the rubber tube is connected with an elastic unsealing claw which is sleeved on the main pipe body and slides relative to the elastic unsealing claw; the rubber tube inner cylinder, the elastic unsealing claw and the main tube body form a built-in thrust structure; a contacted part between the main pipe body and the elastic unsealing claw takes the shape of a conical of which the diameters are reduced from top to bottom; when the packer is positioned in a seat sealing state, the elastic unsealing claw expands in the radial direction; and when the packer is positioned in an unsealing state, the elastic unsealing claw is folded in the radial direction. According to the packer disclosed by the invention, the requirement that a plurality of pipe cables pass in the intelligent well completion process can be met; and the packer has the advantages of favorable sealing effect, firmness in seat sealing, smoothness in unsealing, simple structure, convenience for use and capability of being reused.

Owner:PETROCHINA CO LTD

Transmission synchronizing system, in particular, in the form of a servo synchronizing system

InactiveUS8104597B2Favor ease of productionLower requirementToothed gearingsFriction clutchesEngineeringSynchronization system

The invention relates to a synchronization piece which, as part of a servo synchronization system comprising a sliding sleeve, a clutch body, a synchronizer ring and an idler gear, can synchronize a transmission having toothed wheel gears. The invention furthermore relates to an entire synchronizing system having a synchronization piece according to the invention. A full-servo synchronization system is also presented.

Owner:HOFER PDC

Oil well packer

InactiveCN101382053AReduce pressure requirementsSmall unsealing forceSealing/packingUpper jointEngineering

The invention relates to an oil well packer. The lower part of an upper joint is connected with the upper part of an upper inner pipe, a piston is connected with the upper joint through a seat packing pin, and a piston inner hole is matched with the upper inner pipe. A valve seat is arranged below the upper inner pipe and is connected with a lower inner pipe through a release pin, and the lower part of the lower inner pipe is connected with a lower cone. A fishing head is fixed in the lower inner pipe through an unset pin, an unset lock piece is arranged on the lower inner pipe, and the lower part of the fishing head covers the unset lock piece. A rubber tube shaft is arranged below the piston, a rubber tube is sleeved on the rubber tube shaft which is sleeved on the fishing head, a lock ring is arranged on the rubber tube shaft, a lock sleeve is sleeved on the lower inner pipe, and the lock ring and the lock sleeve can be buckled together. An upper cone is arranged below the rubber tube and is suspended onto the rubber tube shaft, and the upper cone, a slips and the lower cone are arranged inside a slips cover. During a downhole and production process, as the unset pin does not bear a force and does not require a big size, an unset force is small and an unset process is easy. The packer has low bearing requirements on an oil pipe, high execution success ratio, and low operating cost.

Owner:张永祥

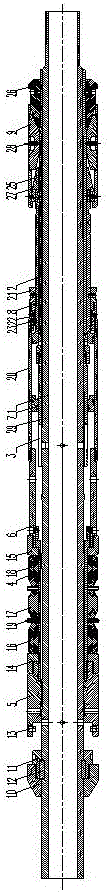

Hydraulic detachable packer with sliding sleeve

The invention relates to a hydraulic detachable packer with a sliding sleeve, and belongs to the field of borehole operation of oil gas wells. The hydraulic detachable packer comprises a central tube, an upper connector, a lower connector, a middle connector, a release sleeve, an upper piston and a lower piston, wherein the lower connector is mounted at one end of the central tube through a connecting tube; an unsealing ball seat is mounted at the other end of the central tube through the release sleeve; the upper connector is mounted at the end of the unsealing ball seat through the middle connector; two ends of the middle connector are respectively connected with the upper connector and the release sleeve through fastening screws. The hydraulic detachable packer is simple and compact in structure, safe and reliable to recycle and particularly applicable to operation such as well drilling, well cementation, testing and well completion, the risk that an rubber cylinder and slips can be stuck by gravels and chippings when the hydraulic detachable packer is unsealed and recycled as an ordinary hydraulic packer is generally relatively low in pressure resistance can be avoided, and the problems of unsealing and recycling difficulties can be solved.

Owner:荆州市赛瑞能源技术有限公司

Compression packer

The invention relates to the technical field of oil field downhole tools, and discloses a compression packer. The compression packer comprises a central pipe. An upper joint is movably connected withthe top of the central pipe in a sleeving mode, a first extrusion cylinder is installed below the upper joint and movably connected to the top of the central pipe in a sleeving mode, and a protectionbody is installed on the first extrusion cylinder. A first rubber cylinder, a metal block, a second rubber cylinder and a third rubber cylinder are fixedly connected to the central pipe in a sleevingmode from top to bottom. According to the compression packer, by means of the designed rubber cylinders with air channels, the radial extrusion force can be provided by the compression of the air channels for the rubber cylinders when the rubber cylinders bear the axial extrusion force, and the sealing speed can be increased; the air channels still provide the radial extrusion force for the rubbercylinders after release operation is accomplished, and the sealing performance of the rubber cylinders to an annular space can be enhanced; and the shape similar to a spring is formed by the air channels and the rubber cylinders, the rubber cylinders can provide the axial resilience force when the packer conducts sealing removal, and sealing removal of the packer can be more convenient.

Owner:大庆华油石油科技开发有限公司

Dry vibration mix for tundish and preparation method thereof

InactiveCN107226683ARaw material environmental protectionEasy to unpackMelt-holding vesselsUltimate tensile strengthImpurity

The invention provides a dry vibration mix for a tundish and a preparation method thereof. Based on the total mass of the dry vibration mix for a tundish, the dry vibration mix for a tundish is prepared from the following components in percentage by mass: 45-65% of fused magnesite, 15-25% of binding agent, 5-10% of aluminum hydroxide micropowder, 5-10% of calcium carbonate powder and the balance of impurity. The dry vibration mix finished product for a tundish is favorable in various technical performance indices; the raw materials are green and environmentally friendly, and can purify molten steel; the dry vibration mix realizes easy tundish removal and tundish turning, lowers the work intensity, increases the service life and saves the cost; and the dry vibration mix is simple in preparation process and is formed by a dry method during construction, thereby realizing a favorable construction environment.

Owner:浙江欣辉耐火材料股份有限公司

Fruit bag

The invention relates to a fruit bag belonging to the field of plant protection. The fruit bag comprises a bag body, a bag mouth, a bag bottom and sealing wires and is characterized in that inwards folding edges are arranged at both sides of the bag body, four corners at both sides of the bag mouth are respectively provided with the sealing wires along the vertical direction, the middle position at the front of the bag mouth is provided with a crescent mouth and a long fruit stalk mouth, the middle position at the back of the bag mouth is provided with a short fruit stalk mouth, the front and the back of the bag bottom are adhered, and waterspouts are respectively arranged at the four corners at both sides of the fruit bag. The invention has the advantages of convenient opening, sealing and bag removal and large application space in the fruit bag.

Owner:宋海涛

Conical valve type automatic downhole blowout preventer and using method thereof

The invention relates to a conical valve type automatic downhole blowout preventer and a using method thereof. The blowout preventer comprises an upper drill rod casing pipe, an inner pipe, a drillingfluid inflow hole, an annular piston, an annular piston rod, a drilling fluid outflow hole, a guide ring fixation rod, a rectangular guiding ring, a rectangular-section guiding rod, a lead screw, a rubber cylinder, a motor fixation rod, a linear motor system, a rubber cylinder positioning ring, a conical valve core, a lower drill rod casing pipe, a drill pipe, and a wellbore. The blowout preventer is controlled by a while-drilling pressure sensor; an acoustic pulse signal transmitted by the drill rod is used for communication; and a signal receiver is installed inside the linear motor system.When the drill bit drills a high pressure layer, the pressure sensor detects the high pressure and sends a pulse signal to the linear motor system; the linear motor is started when the signal is received; the lead screw connected to the conical valve core is drive to rise; and the outlet of the drilling liquid in the pipe is closed. And then the drilling liquid enters the piston cylinder to pushthe piston to move down and the rubber cylinder is extruded to be expanded, so that the annular space in the wellhole is turned off.

Owner:SOUTHWEST PETROLEUM UNIV

Packer

The invention provides a packer, and relates to the field of downhole layered oil production tools. The packer aims to achieve multi-setting by entering a well once. According to the mainly adopted technical scheme, the packer comprises a mandrel, a rubber cylinder assembly, a cone, a slips assembly, a lock pin assembly and an unloader, wherein the upper end and the lower end of the mandrel are provided with an upper connector and a lower connector respectively; the mandrel is used for being arranged outside a center pipe in a sleeving mode; the rubber cylinder assembly is connected with the lower portion of the mandrel through the lower connector; the cone, the slips assembly and the lock pin assembly are arranged in the mode of being sequentially away from the rubber cylinder assembly and arranged on the lower portion of the mandrel in a sliding mode; the portion, corresponding to the lock pin assembly, of the lower portion of the mandrel is provided with a bent sliding rail for guiding the sliding direction of the lock pin assembly; both the lower portion of the mandrel and the cone are provided with pressure transmission holes; the unloader comprises a first sub unloader body and a second sub unloader body detachably connected with the first sub unloader body, the first sub unloader body is connected with the upper portion of the mandrel through the upper connector, and the second sub unloader body adjacent to the rubber cylinder assembly is arranged on the upper portion of the mandrel in a sliding mode.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Sand-blocking-preventing oil-extraction production tubular column

InactiveCN102383764ASimple structureEasy to unpackFluid removalSealing/packingControl layerBiochemical engineering

The invention discloses a sand-blocking-preventing oil-extraction production tubular column, aiming at overcoming the defects that in the existing oil-extraction production tubular column can not be lifted after being blocked by sand and is difficult to deblock so as to cause overhauling of the oil well and the like. The sand-blocking-preventing oil-extraction production tubular column is characterized in that a sealing tube, a hollow bridge plug and a release of a hollow release tubular column are fixedly connected in sequence from bottom to top; the hollow release tubular column is positioned between a production layer and a control layer; the hollow bridge plug is set and is clamped on a sleeve wall; a plug, a screening tube, a core tube, a safety joint, a pressure-difference type safety valve, a release device, a self-sealing-examining packer, a pressure-difference type oil sleeve communicating valve, an oil pump and an oil tube of a plug-in type oil-extraction tubular column are fixedly connected in sequence from bottom to top; the core tube penetrates through the sealing tube of the hollow release tubular column, and a radial sealing device is arranged between the core tube and the sealing tube; the screening tube connected at the lower end of the core tube is positioned on the production layer; and the self-sealing-examining packer is positioned above the control layer. The sand-blocking-preventing oil-extraction production tubular column has the beneficial effects of having simple and convenient structure, not only meeting the production needs, but also being beneficial to deblocking of the tubular column and the later-stage tubular column measure treatment.

Owner:DAGANG OIL FIELD GRP

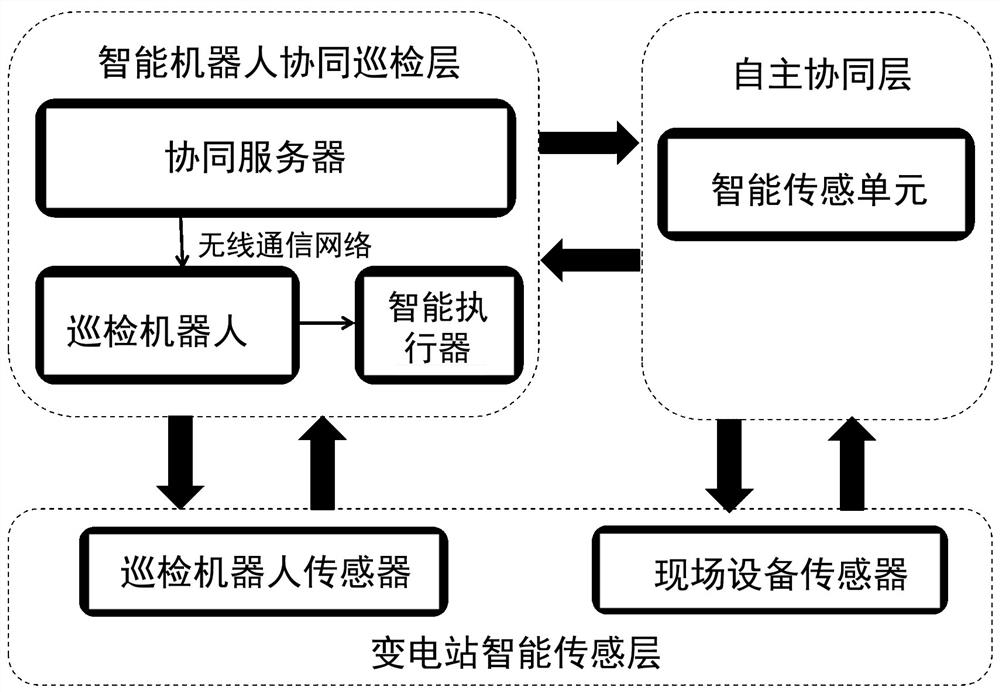

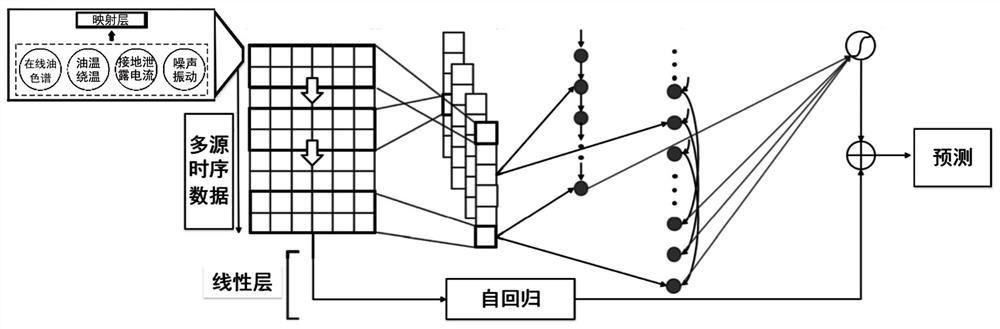

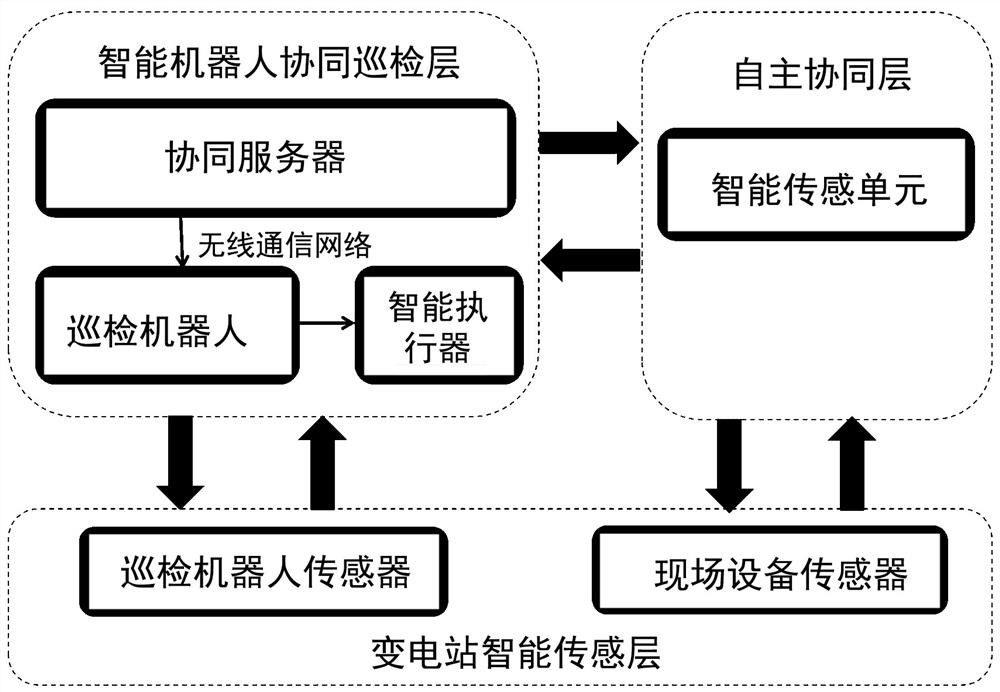

Transformer substation robot intelligent inspection system and method based on active cooperation of intelligent sensor

PendingCN114069838AImprove timelinessImprove maintenance abilityCircuit arrangementsParticular environment based servicesSmart transducerSource data

The invention provides a transformer substation robot intelligent inspection system and method based on intelligent sensor active cooperation. The inspection system comprises an intelligent robot cooperation inspection layer, an autonomous cooperation layer and a transformer substation intelligent sensing layer which form a three-layer intelligent inspection architecture. In the inspection system, the inspection robot performs autonomous path planning to complete image data acquisition, the intelligent sensor senses the state of the detected equipment and performs data preprocessing and analysis, and the inspection robot and the intelligent sensor perform active cooperation through a near field communication mechanism and an intelligent actuator. And a cooperative server performs complex scene identification based on the inspection robot sensing data, and performs multi-source data fusion analysis on the inspection robot sensing data and the intelligent sensor sensing data. The timeliness of inspection tour is remarkably improved, the personnel safety risk in the operation process is avoided, manual intervention in the inspection tour process is reduced, and it is guaranteed that the power transformation inspection tour task is smoothly carried out.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +4

Protective case for information storage disc

InactiveUS7299920B2More to mechanical damageEasy to unpackRecord information storageOther accessoriesSolid componentEngineering

A three-piece jewel case for information storage discs, such as CDs and DVDs, is of the clam-shell type, and includes a base portion having a pair of generally rectangular hinge recesses positioned at adjacent corners along a rear side edge thereof, a lid portion having a pair of generally rectangular hinge arms positioned at adjacent corners along a rear side edge thereof, and a media tray having a lid portion supporting hub, which snaps into the base portion. For a preferred embodiment of the case, the media tray is hingeably connected to the base portion along the rear side edge. Each hinge arm has a rectangular solid component that extends from the outer edge to the inner edge and from the front edge to the back edge thereof. This feature rigidifies the rectangular hinge so that it is much more resistant to mechanical damage from crushing or dropping loads.

Owner:OSBORN WARREN R +1

Layered steam driving packer with combination effect

ActiveCN105178906AImprove sealingGood construction success rateFluid removalSealing/packingUpper jointEngineering

The invention provides a layered steam driving packer with a combination effect. The layered steam driving packer with the combination effect comprises a central tube, an outer central tube and an expanding portion, wherein an upper joint and a lower joint are correspondingly connected to two ends of the central tube through outer threads; a pressure transferring hole is formed in a side wall of the central tube; the outer central tube sleeves the central tube; the upper end of the outer central tube can be connected with the outer side surface of the upper joint in a separating mode; an adjusting ring and a sealing rubber barrel sleeve the outer side of the outer central tube; the expanding portion comprises an expanding inner barrel; the expanding inner barrel sleeves the outer central tube; an expanding jacket sleeves the expanding inner barrel; a sealing cavity is formed between the expanding inner barrel and the expanding jacket and is filled with expanding liquid; the upper end of the expanding jacket is in contact with the lower end of a sealing rubber barrel; and a locking and retaining mechanism is arranged between the expanding inner barrel and the outer central tube. During liquid injection, a pushing portion which can push the expanding portion to move upwards sleeves the central tube, is adjacent to the lower side of the expanding portion, and is hermetically connected with the outer side surface of the lower joint, a sealing ring cavity is formed between the pushing portion and the outer side surface of the lower joint and is connected with the pressure transferring hole, and liquid can be injected into the sealing ring cavity.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com