Sand-blocking-preventing oil-extraction production tubular column

A technology for producing pipe strings and production pipes, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of pipe string stuck, oil well overhaul, immobility, etc., and achieves a simple structure of pipe string. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

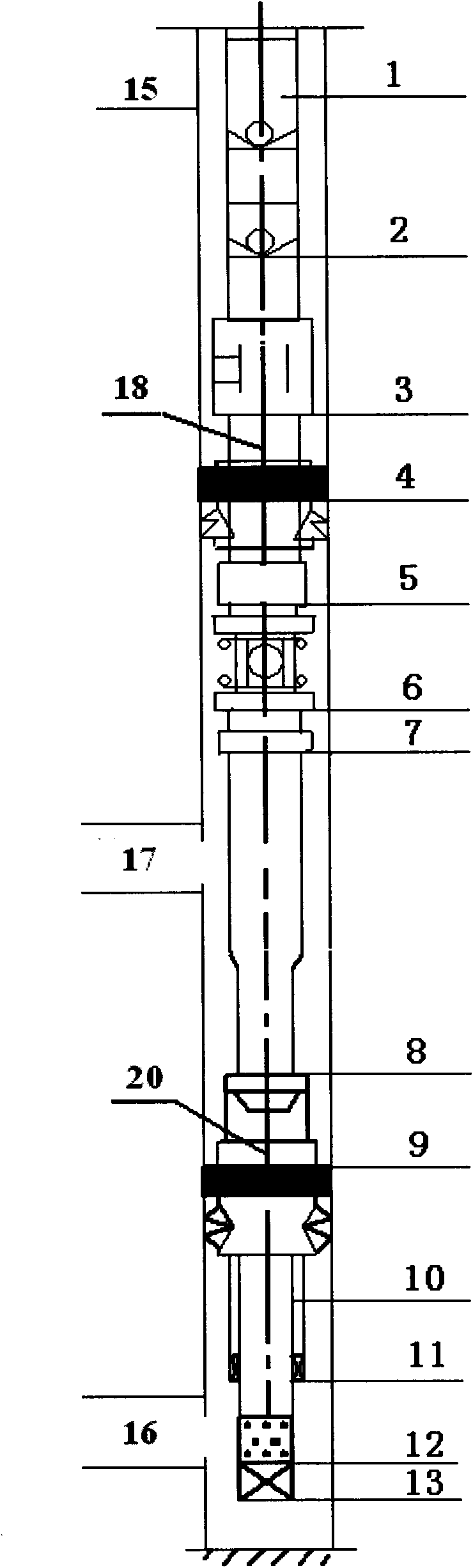

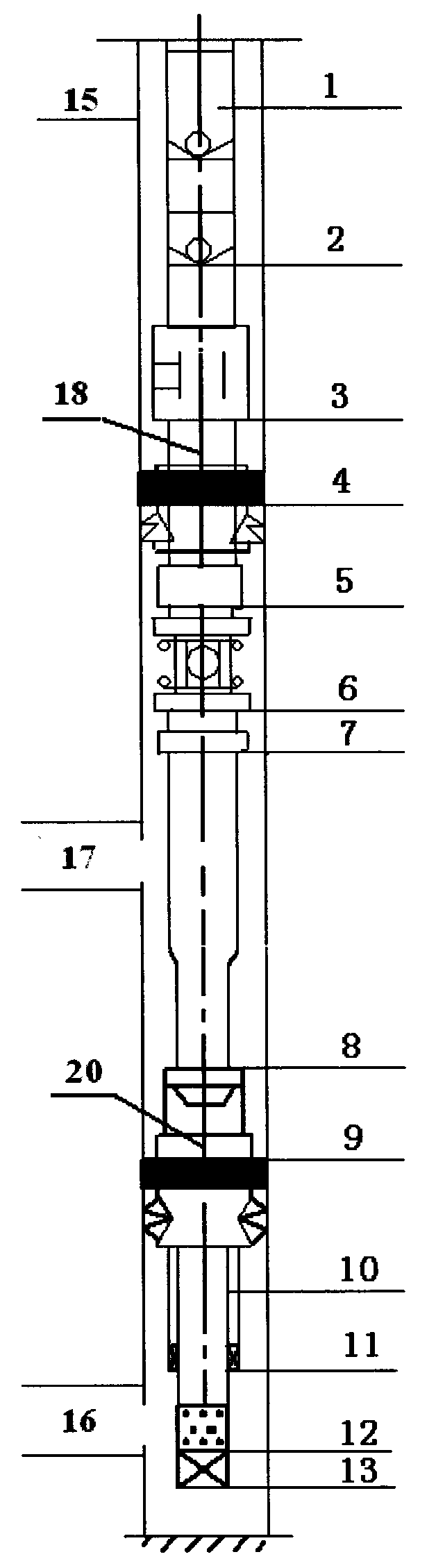

[0012] The first embodiment of the present invention is: the oil recovery production string for sand prevention includes a hollow throw-away string 20 and a plug-in oil recovery string 18 . The hollow drop string 20 is composed of a sealing tube 11, a hollow bridge plug 9, and a drop 8 which are sequentially fixedly connected from bottom to top. Plug 13, screen pipe 12, core pipe 10, safety joint 7, differential pressure normally open valve 6, release device 5, self-inspection seal packer 4, differential pressure oil sleeve connecting valve of plug-in production string 18 3. Oil well pump 2 and oil pipe 1 are fixedly connected sequentially from bottom to top.

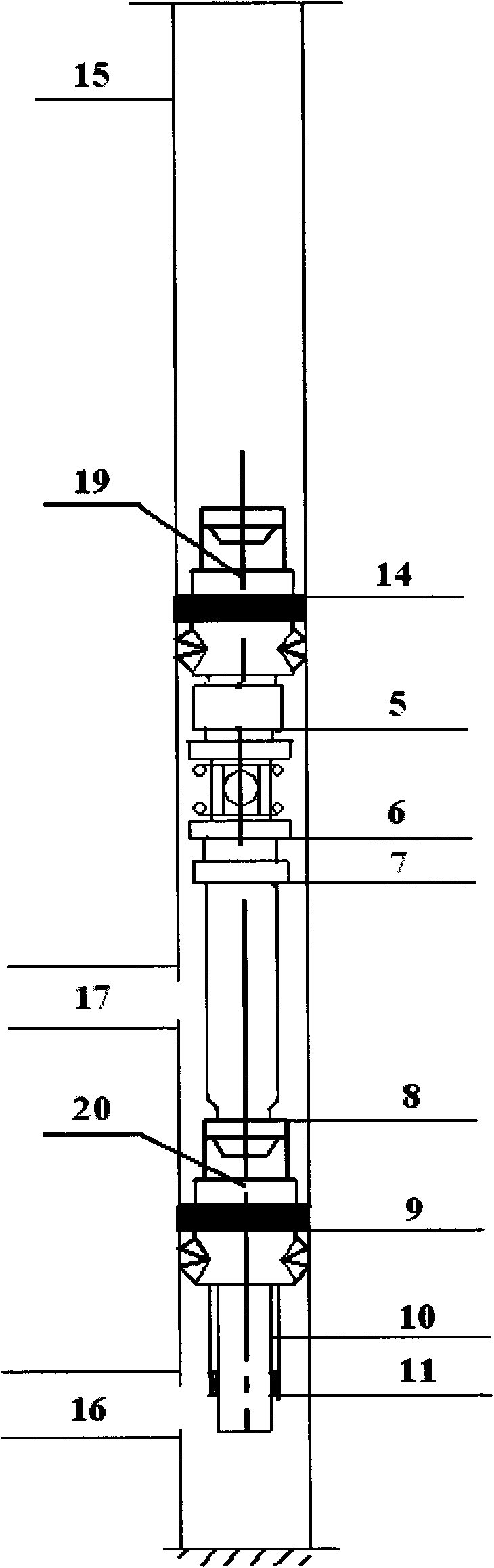

[0013] The second embodiment of the present invention is: the oil recovery production string for preventing sand jam includes a hollow hands-off string 20 and a hands-off oil production string 19 . The hollow drop string 20 is composed of a sealing tube 11, a hollow bridge plug 9, and a drop 8 which are sequentially fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com