Layered pressure control combined drainage-production device for double coal-beds prone to dust and sand spraying

A double coal seam drainage technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of coal seam permeability decrease, fracture closure rate acceleration, upper coal seam drainage radius shortening, etc., to achieve extended The effect of checking the pump cycle, eliminating interlayer interference, and reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

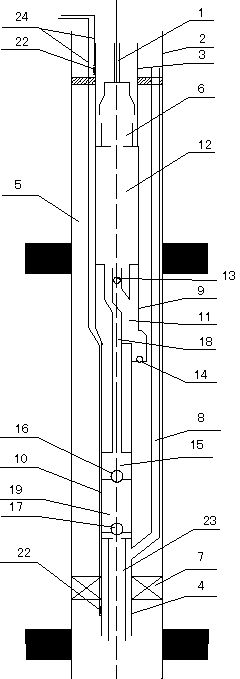

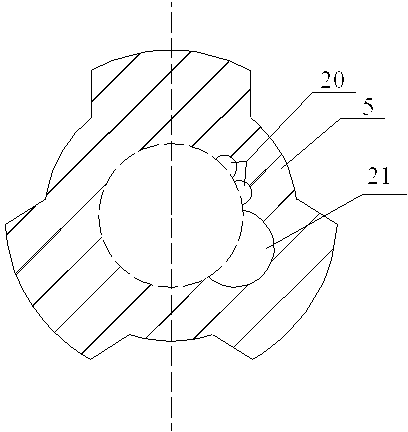

[0018] Such as figure 1 and figure 2 As shown, the layered pressure control combined drainage device of the present invention for double coal seams that are prone to powder and sand discharge includes a sucker rod 1, an oil pipe and a sub-pump 6, the sucker rod 1 is connected to the sub-pump 6, and the oil pipe includes The upper oil pipe 3 and the lower oil pipe 4, the top of the sub-pump 6 communicates with the upper oil pipe 3, the bottom end of the sub-pump 6 communicates with the lower oil pipe 4, the sucker rod 1 is located in the upper oil pipe 3 and is connected with the sub-pump 6, A centralizer 5 is arranged on the upper oil pipe 3 , and a cable passage 20 and an auxiliary communication pipe passage 21 are arranged on the centralizer 5 .

[0019] The sub-extraction pump includes a first extraction pump 9 and a second extraction pump 10, the edges of the first extraction pump 9 and the second extraction pump 10 are connected in a sealed manner, and the first extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com