Well-flushing step-by-step unsetting packer

A packer and well flushing technology, applied in the directions of sealing/packing, flushing wellbore, wellbore/well components, etc., can solve the problems of lax shutoff, easy blockage of well flushing channels, etc., and achieve the effect of easy unsealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

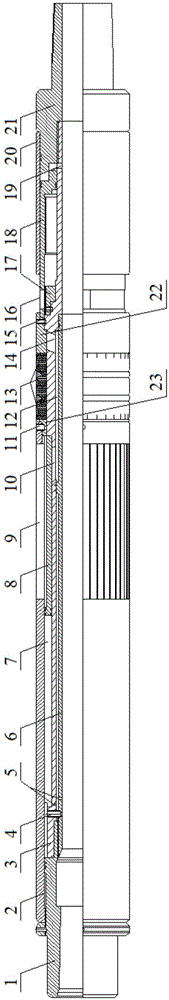

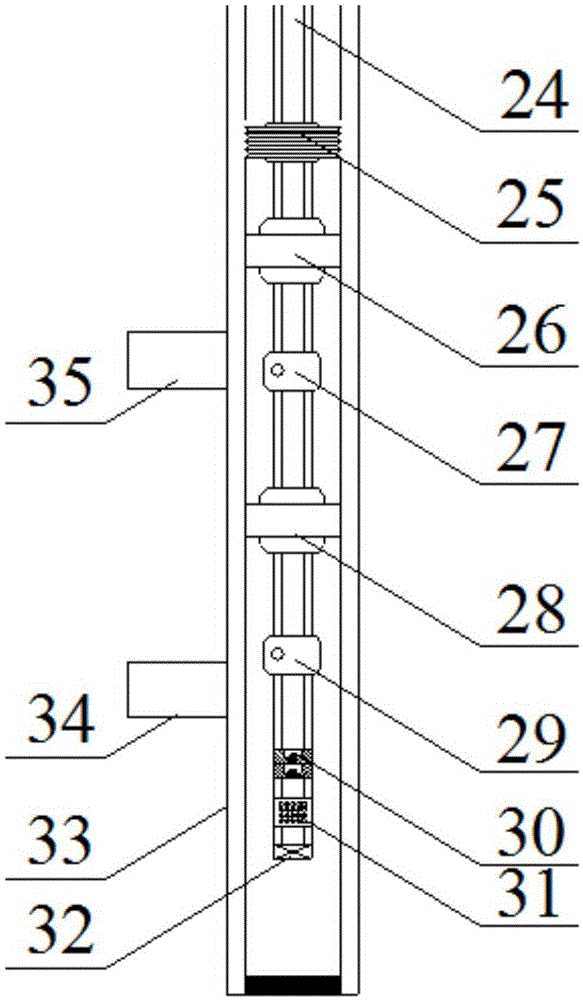

[0024] The embodiments of the present invention provide a washable well-flushable step-by-step unpacking packer to solve the technical problem that the well-flushable packer in the prior art is easily blocked or not tightly closed.

[0025] An embodiment of the present invention provides a well-flushable step-by-step unpacking packer, including:

[0026] upper connector;

[0027] The well-flushing cylinder is connected with the upper joint, the end of the well-flushing cylinder away from the upper joint is provided with a slit liquid inlet hole, and the end of the well-flushing cylinder away from the upper joint is passed through a shear pin fixed with the upper pressure ring;

[0028] The rubber cylinder shaft is arranged in the well cleaning cylinder and connected with the upper joint, the end of the rubber cylinder shaft close to the upper joint is provided with a first liquid inlet hole, and the rubber cylinder shaft is far away from the upper joint. One end of the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com