Patents

Literature

1082 results about "Shear pin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A shear pin is a mechanical detail designed to allow a specific outcome to occur once a predetermined force is applied. It can either function as a safeguard designed to break to protect other parts, or as a conditional operator that will not allow a mechanical device to operate until the correct force is applied.

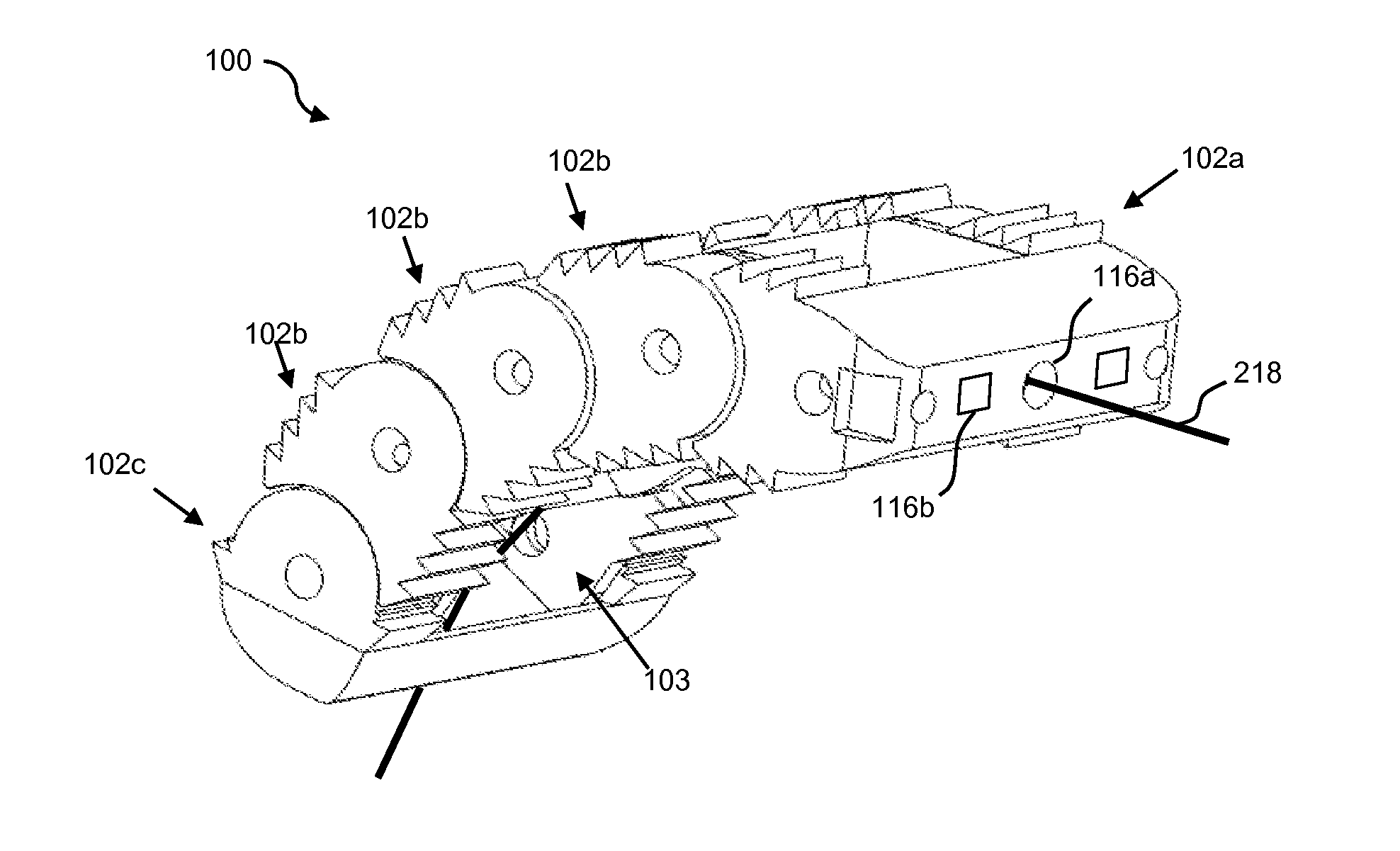

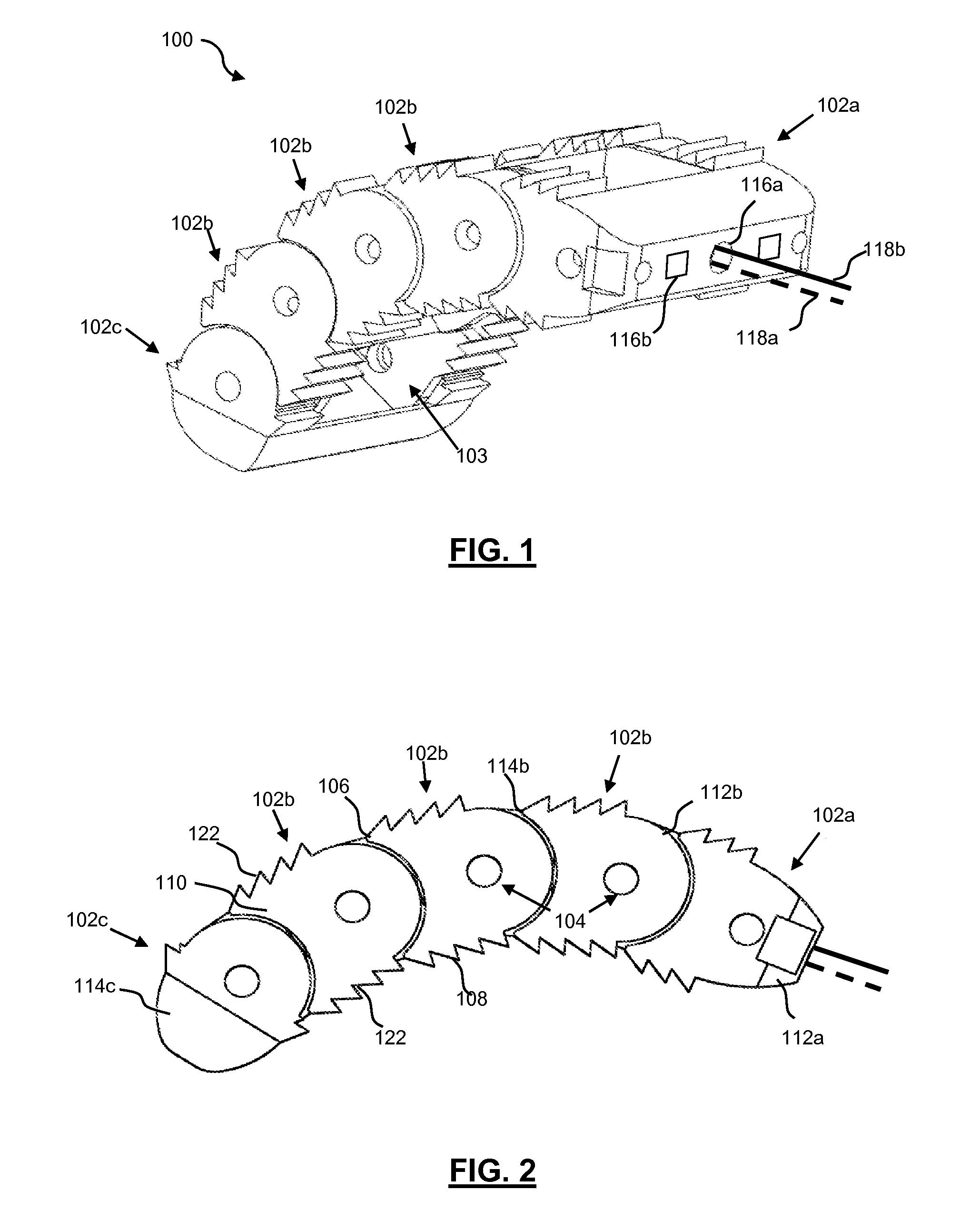

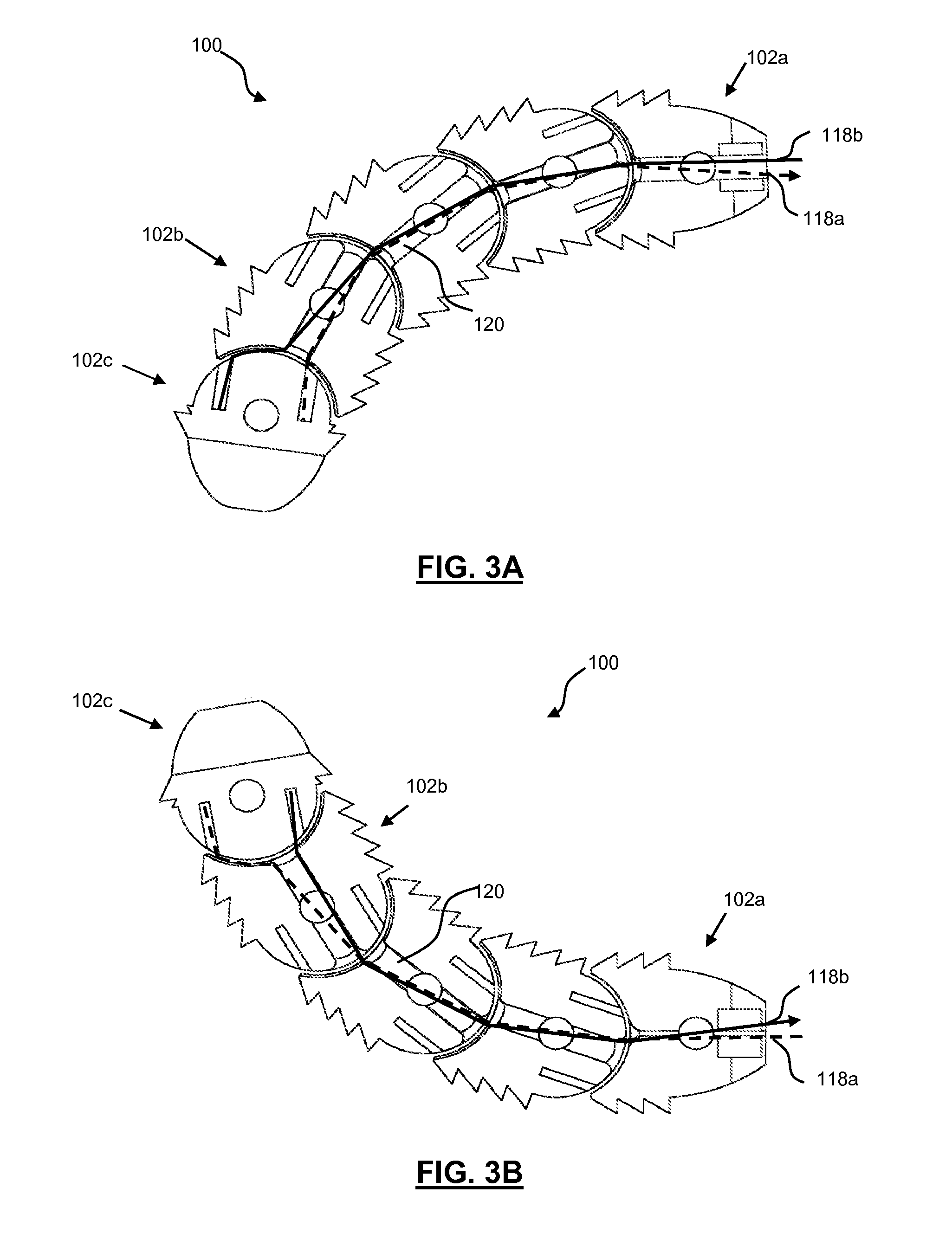

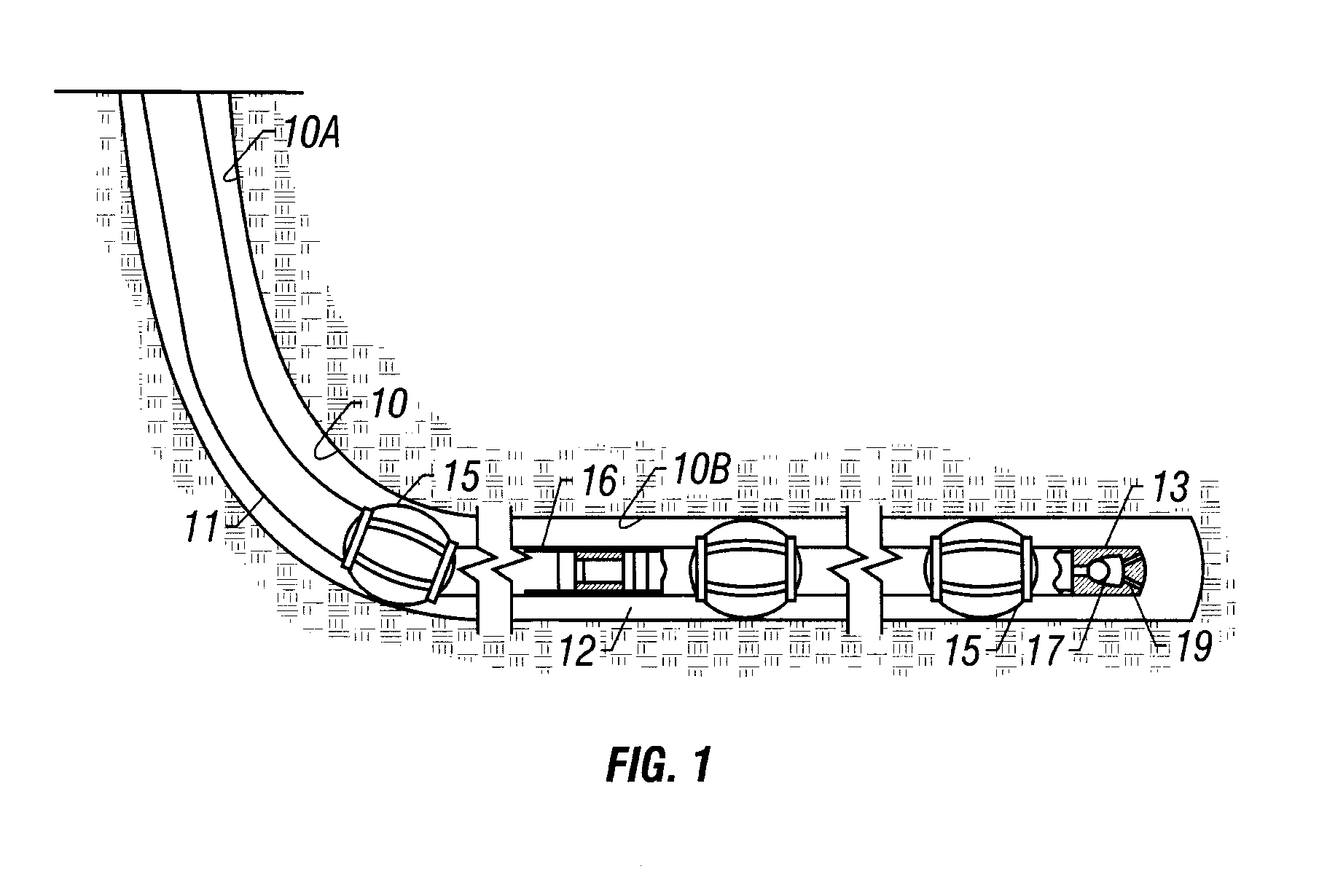

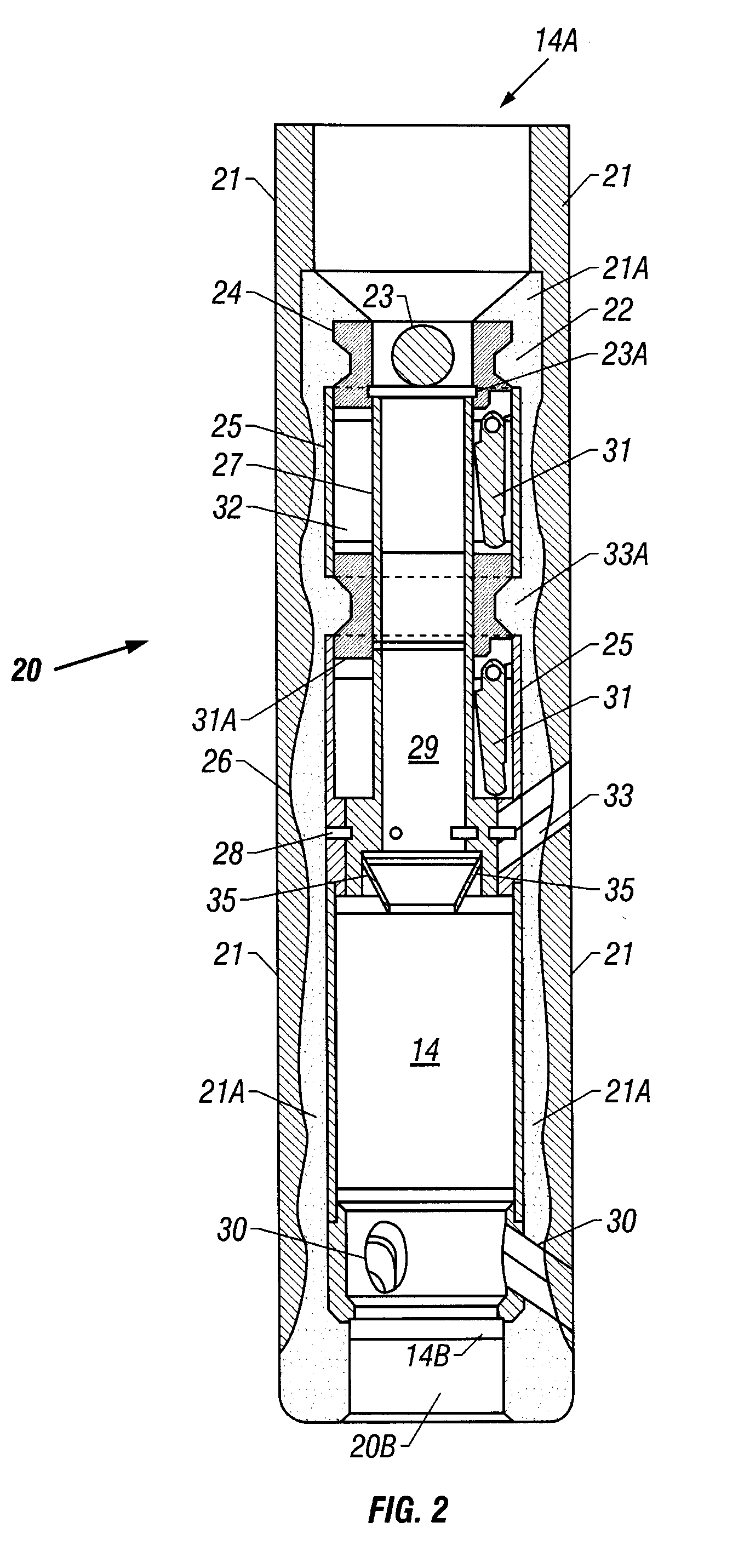

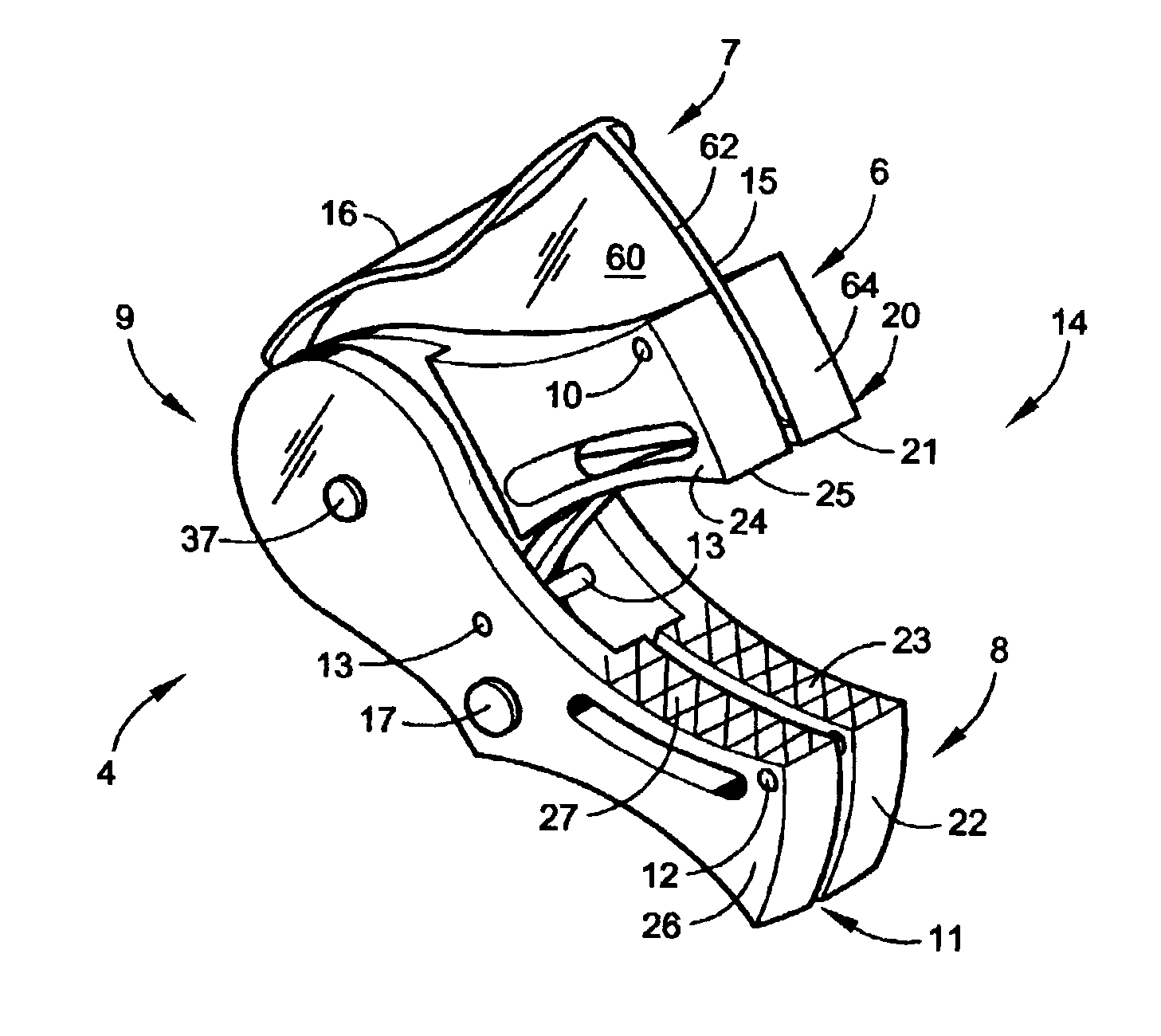

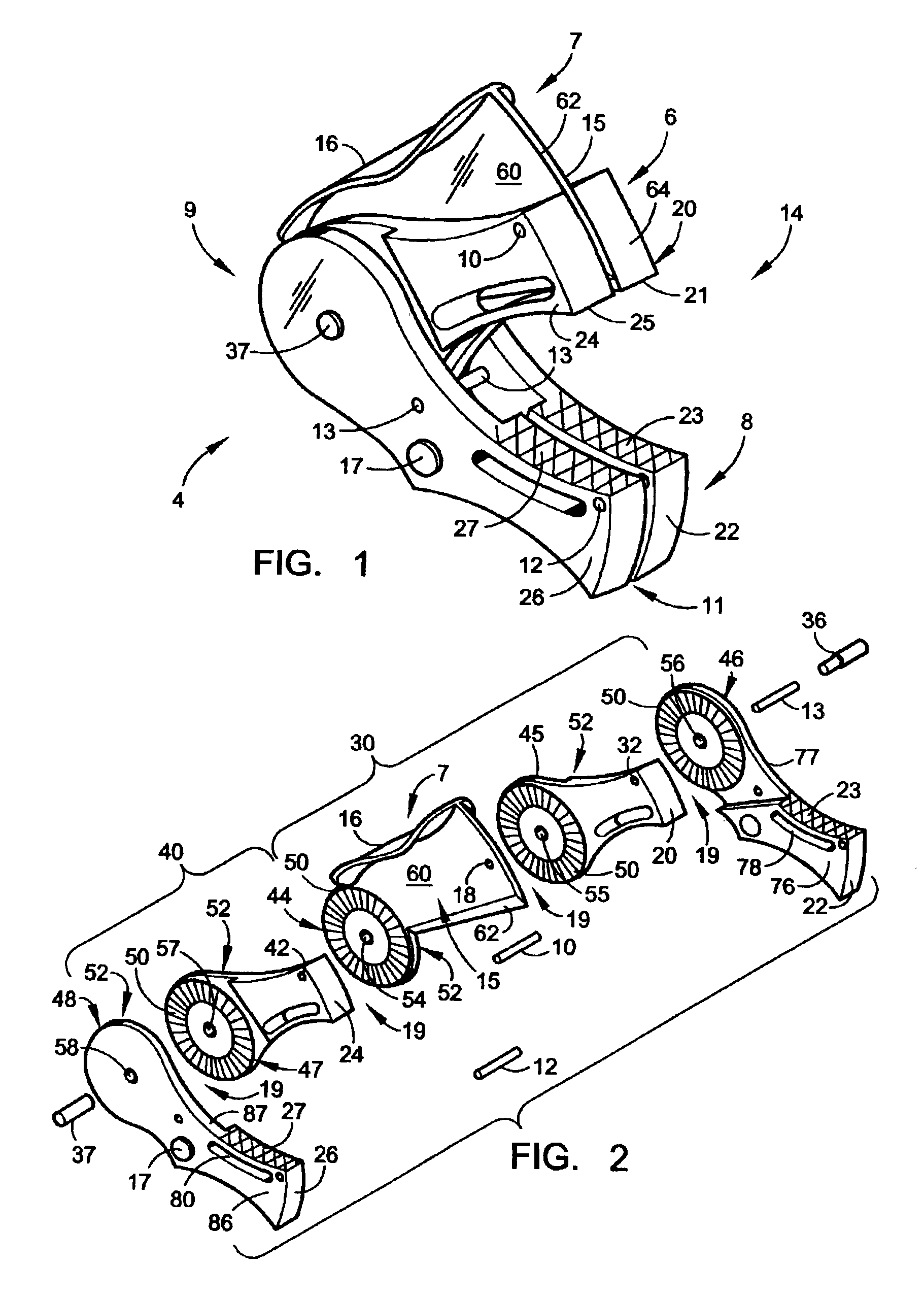

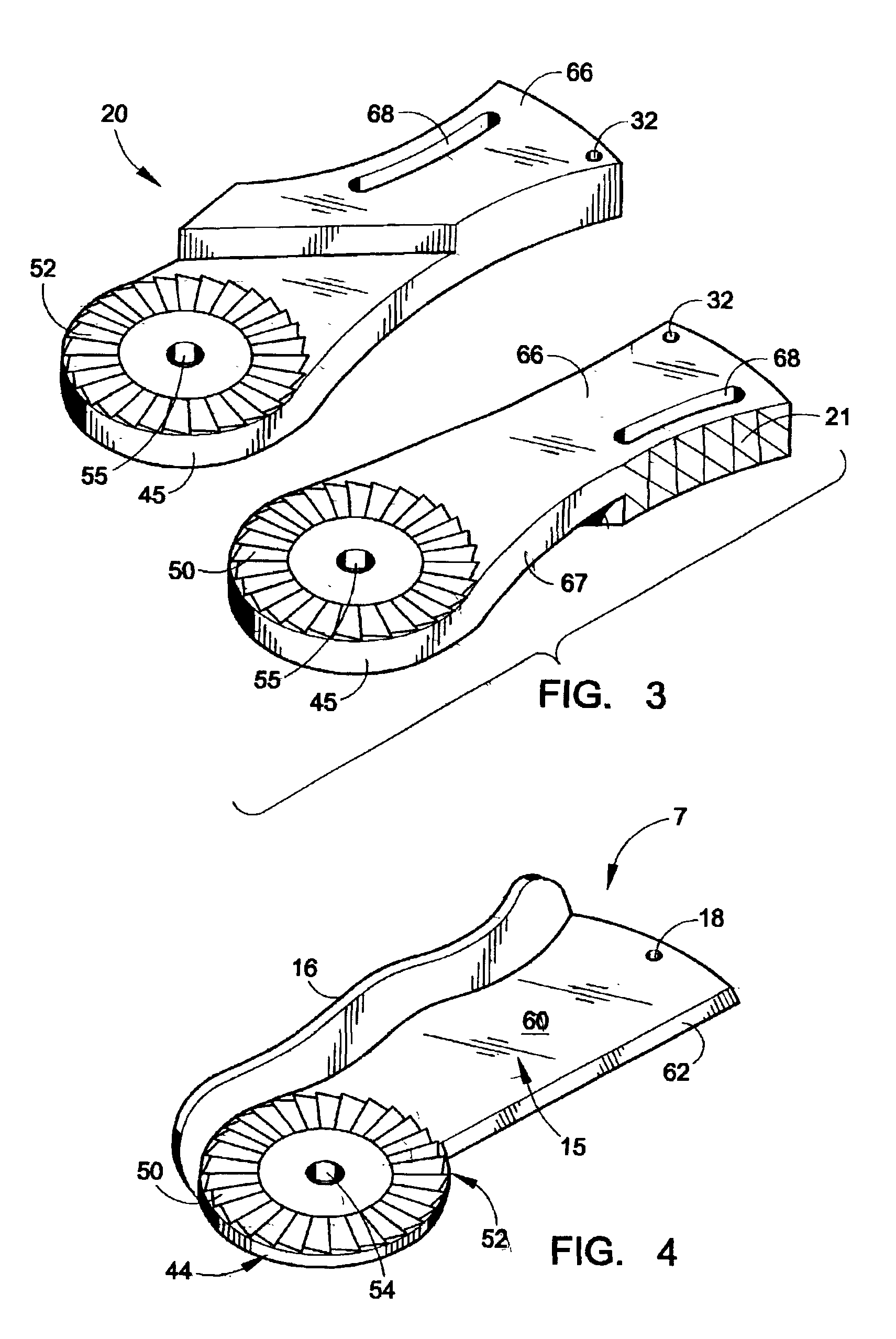

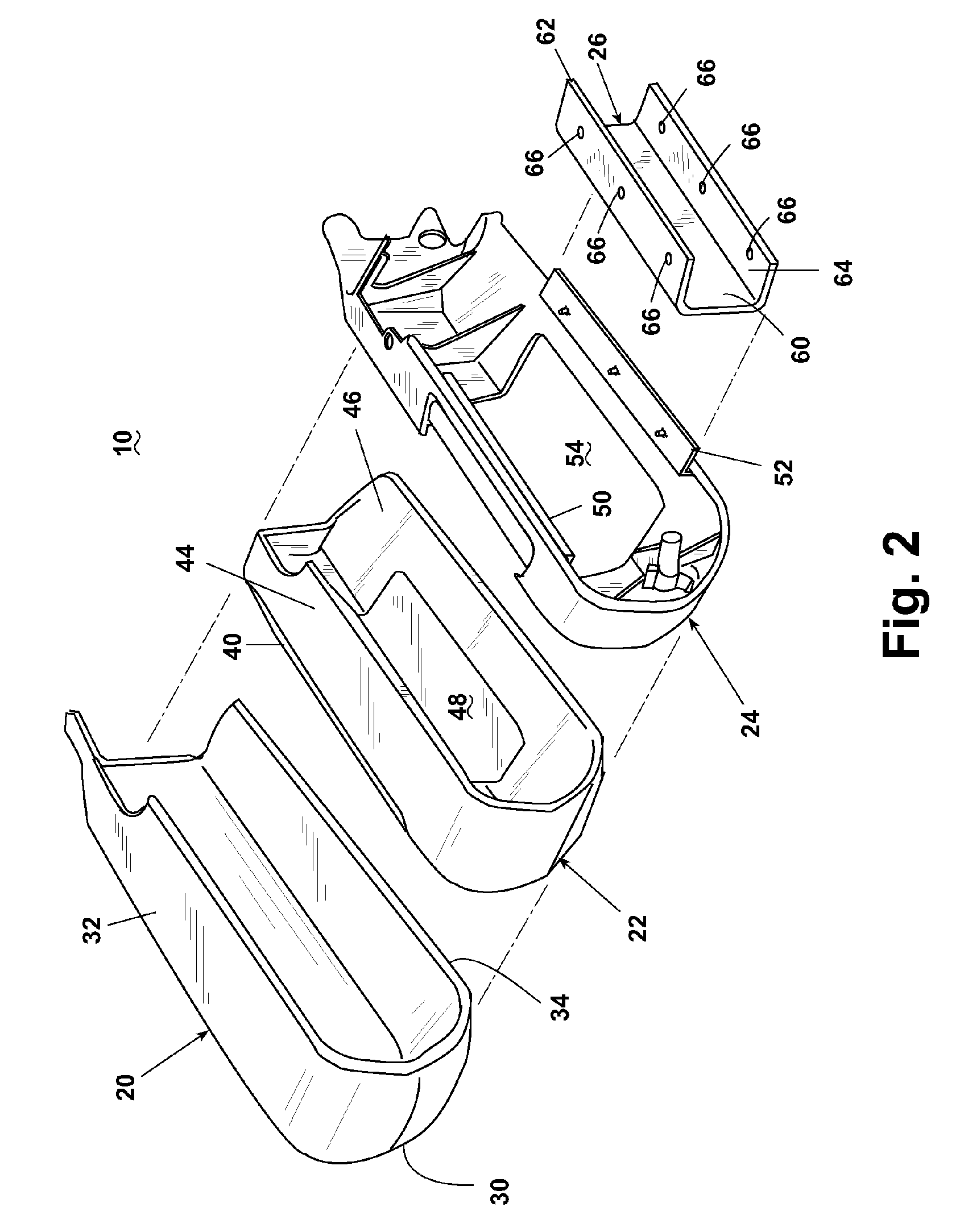

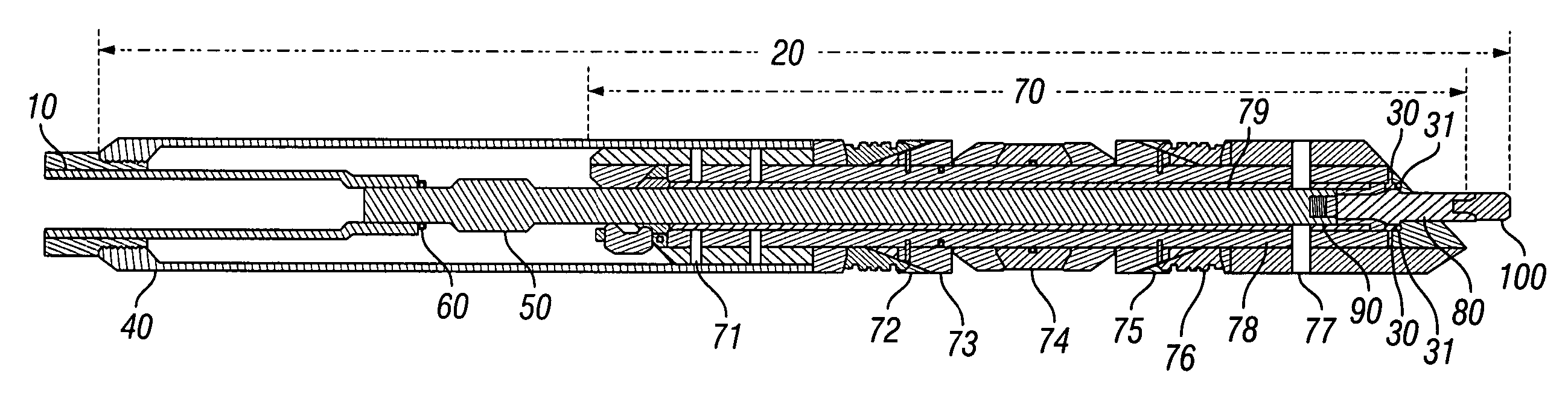

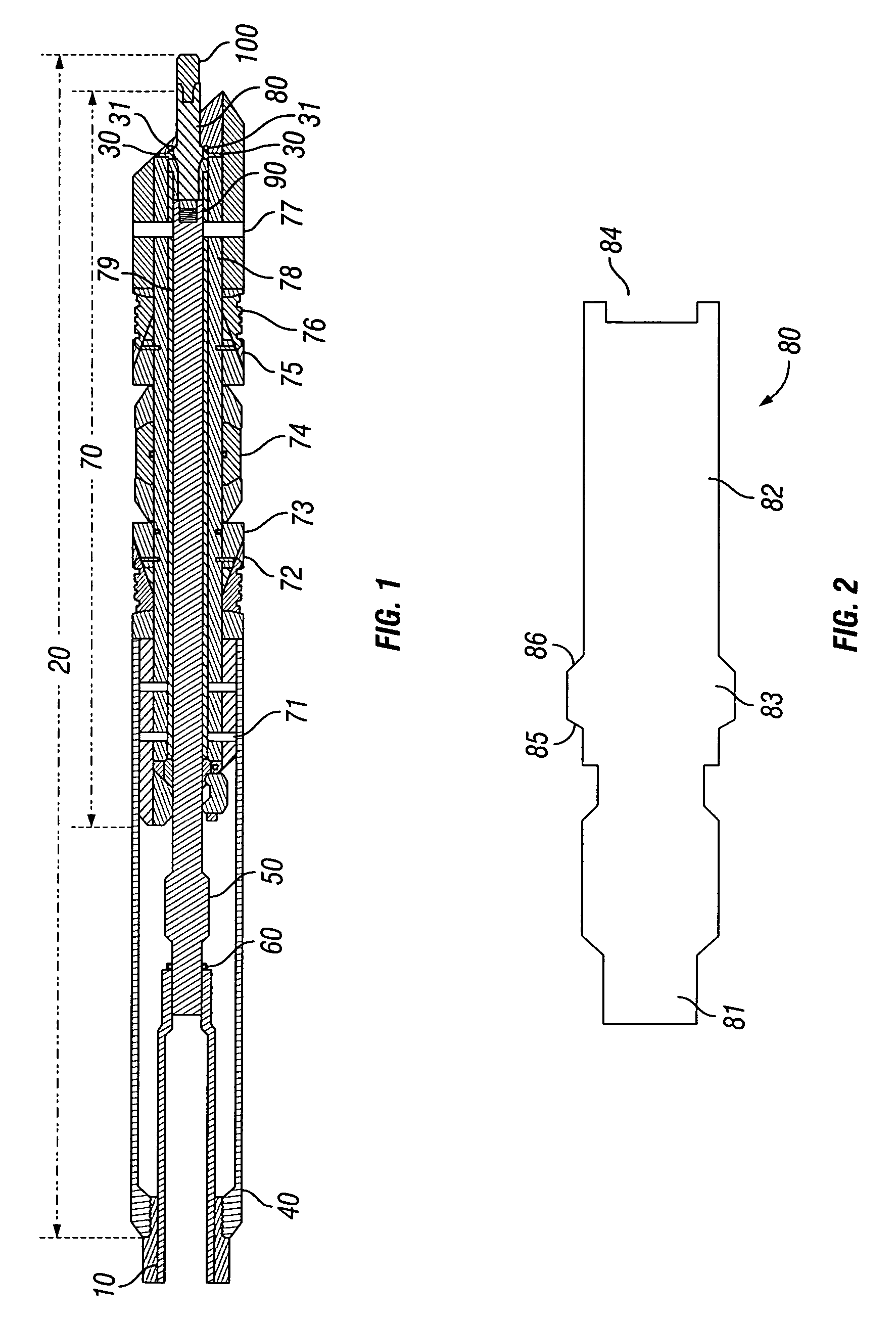

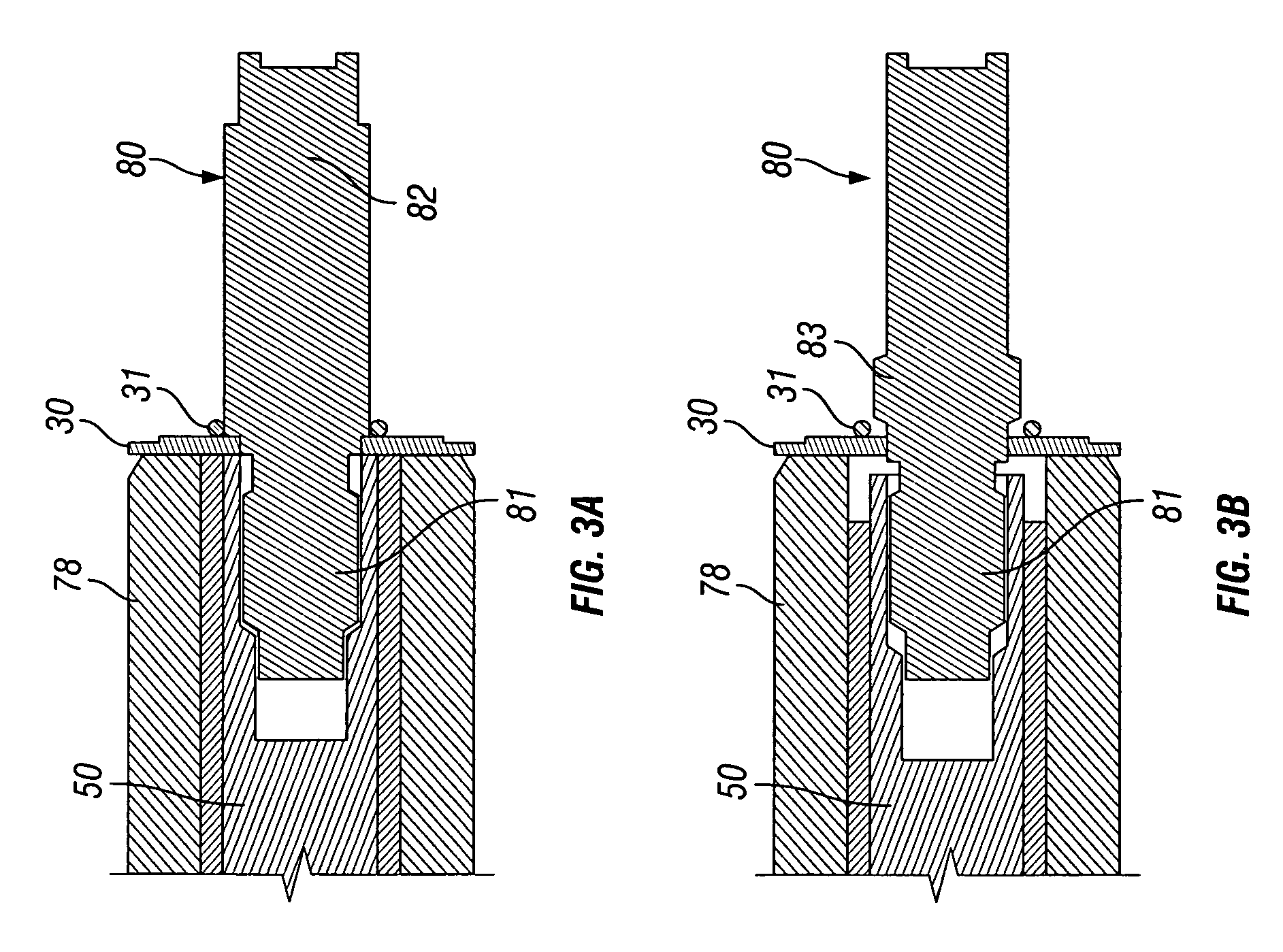

Steerable spine implant and system

Embodiments of the invention being disclosed are directed to a spine implant that allows for in situ adjustment or steering during implantation which allows for precise placement. The structure of the device is composed of a series of hinged link components connected by dowel or shear pins allowing for the links to rotate with respect to each other. The steering feature of the device is activated by a series of tension members connected or coupled to the links. As the tension members are placed in tension, typically by pulling the appropriate member, forces are placed on the individual links to actuate / rotate them in a clockwise or counterclockwise direction. By controlling the rotation of the links, the device may be steered in the desired direction.

Owner:ALPHATEC SPINE INC

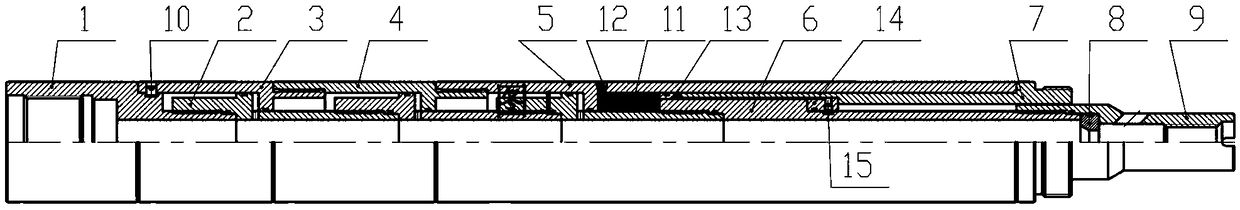

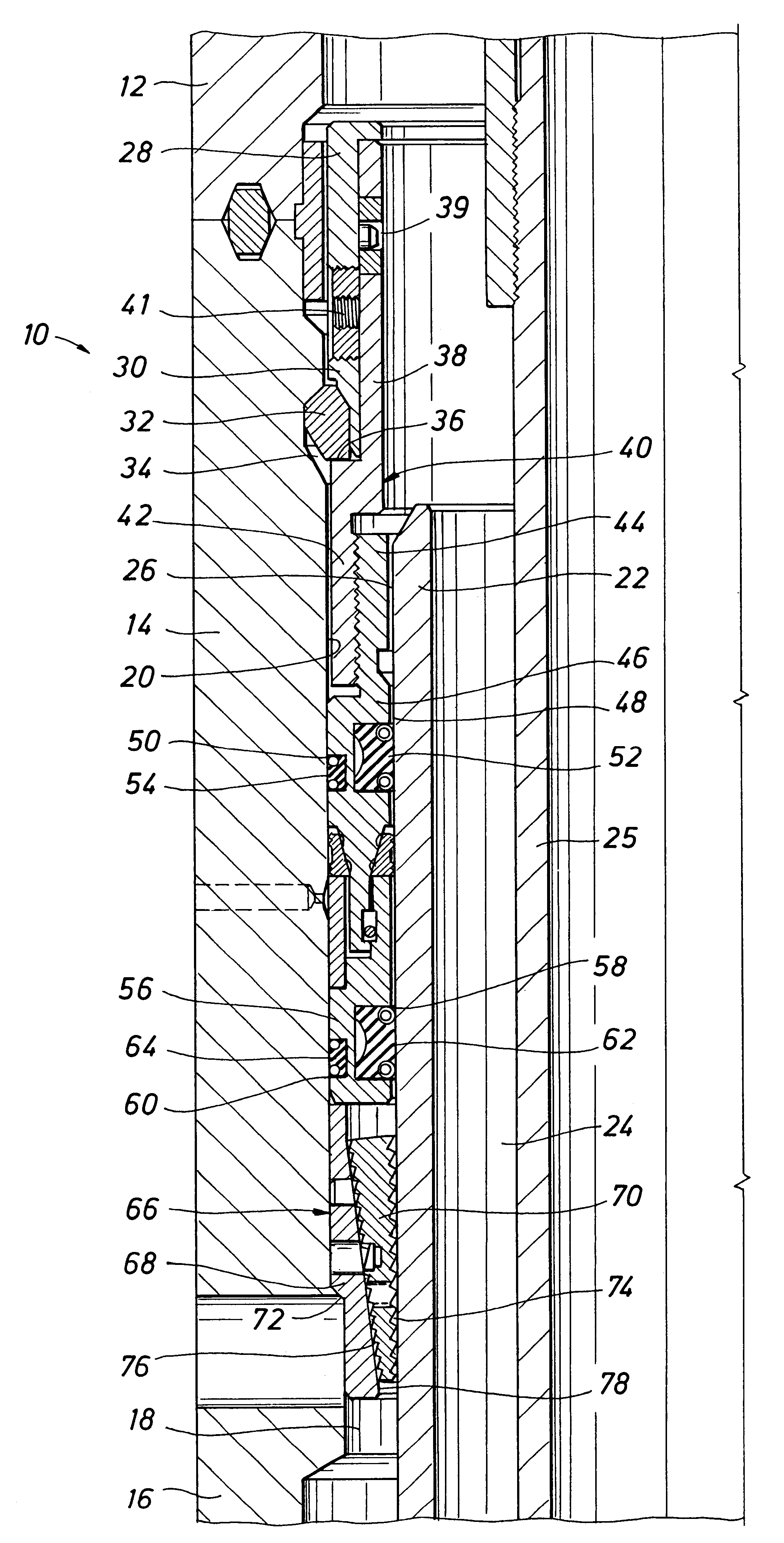

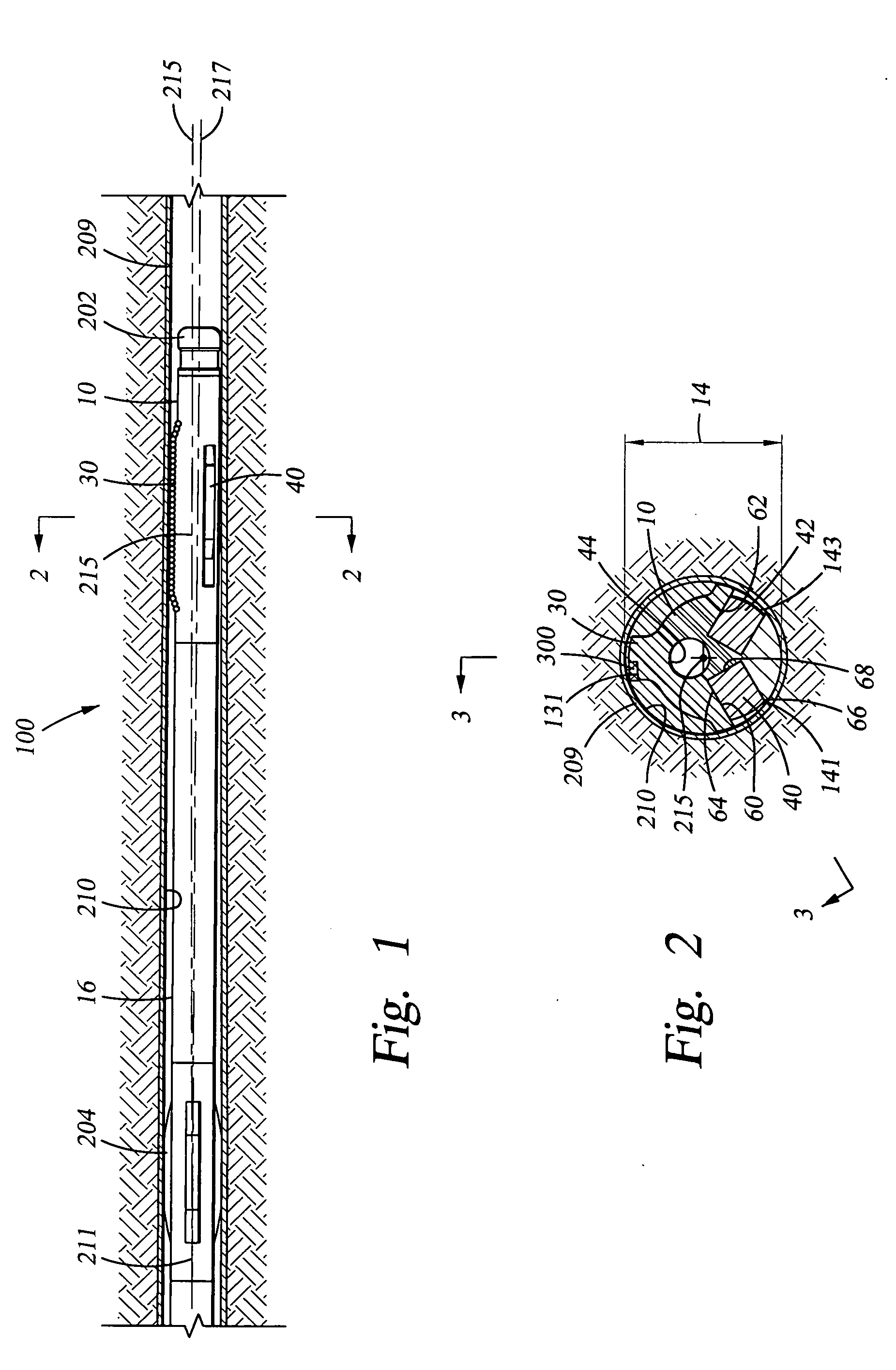

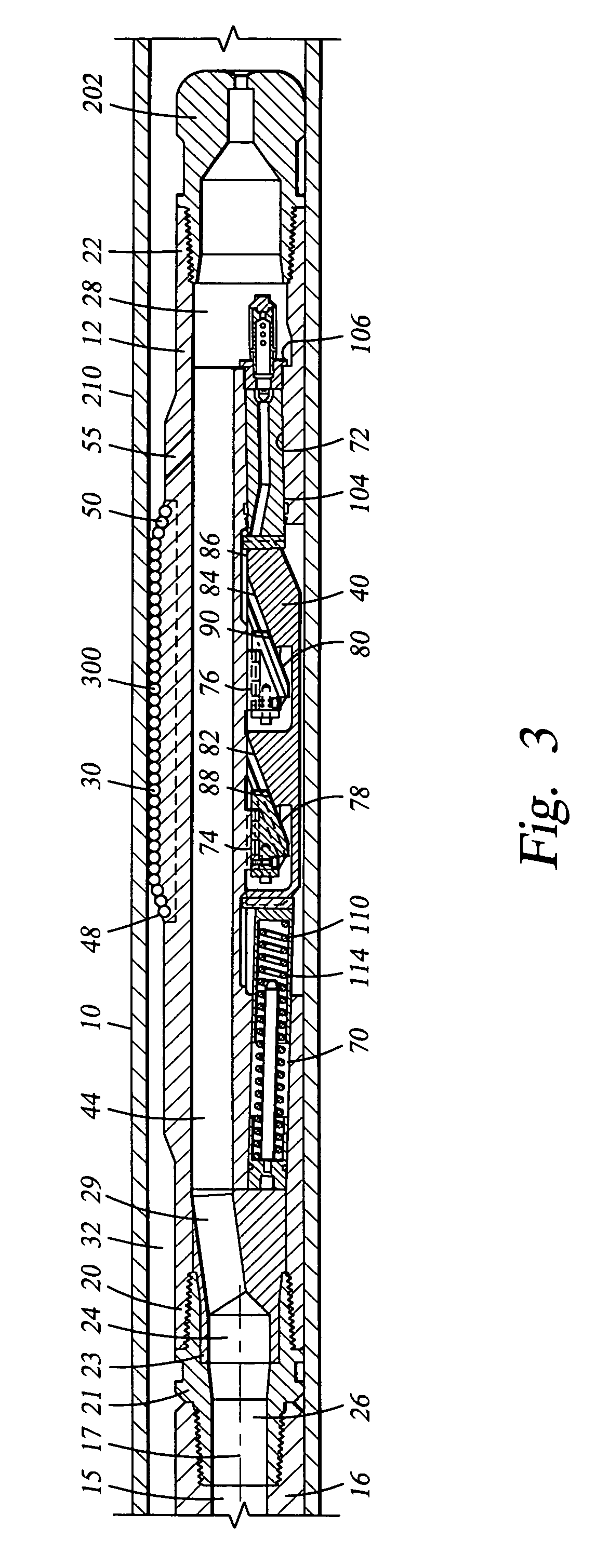

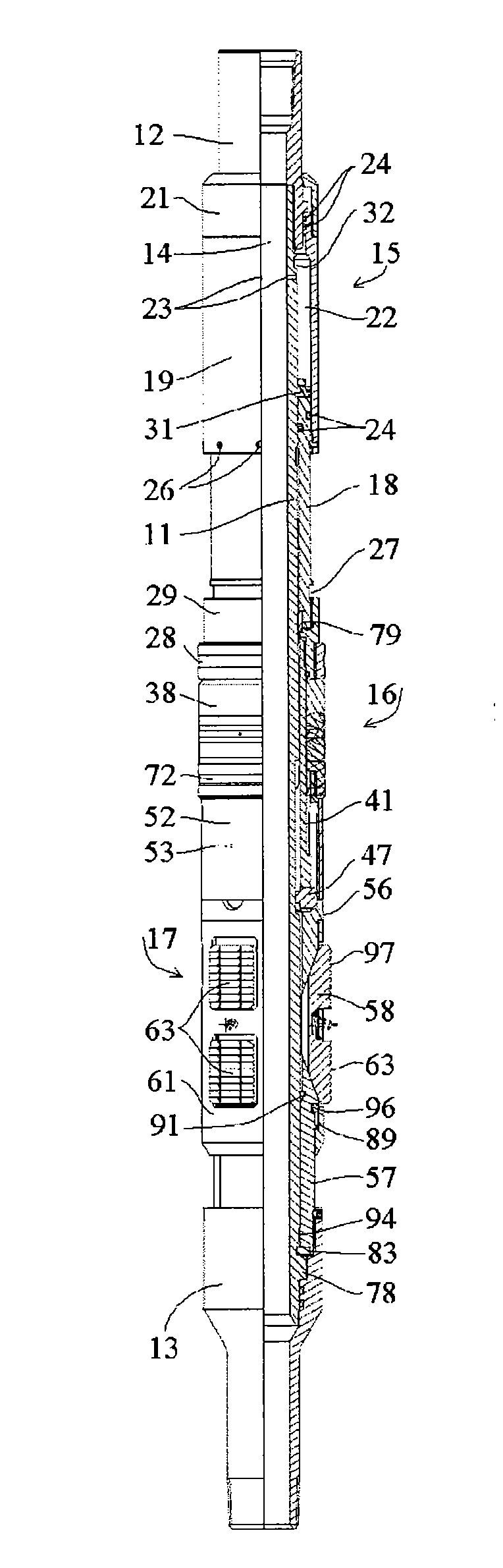

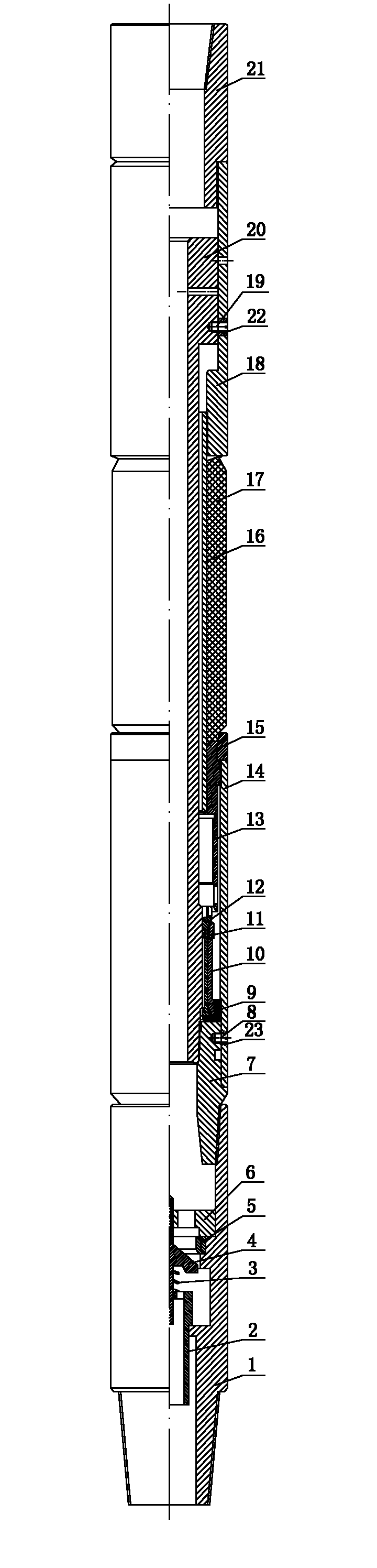

Hydraulic bridge plug setting tool and bridge plug setting method

PendingCN108868675ARealize the purpose of setting bridge plugShorten the lengthSealing/packingUpper jointShort length

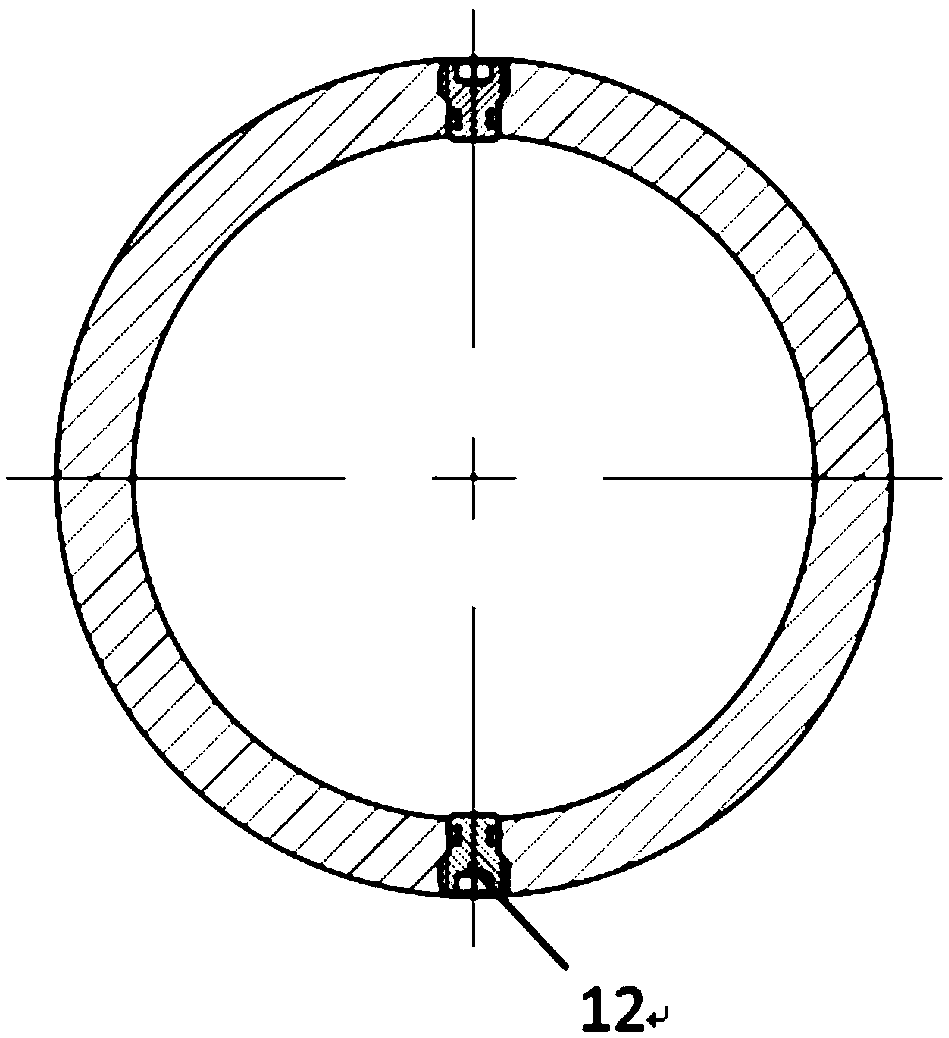

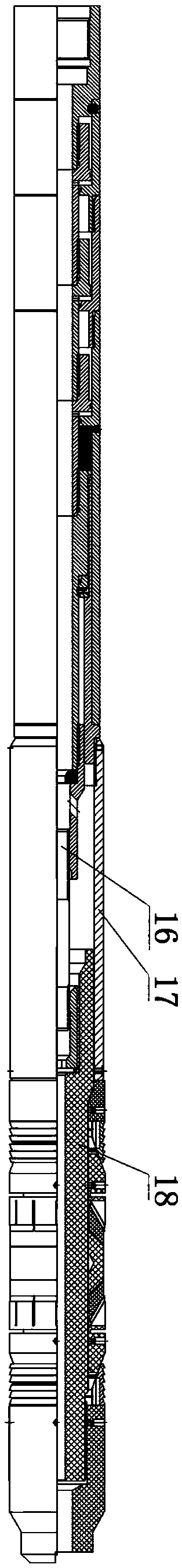

The invention discloses a hydraulic bridge plug setting tool, which comprises an upper joint, a shear pin a, a front drive device, a lower center rod, a push cylinder connection sleeve, a sealing plug, a push ring, a composite ring, a shear pin b, a ball seat, a conversion joint, wherein the upper joint is connected to the front drive device by the shear pin a, the push cylinder connection sleeveand the lower center rod sleeve fitly and snugly the front drive device, and a containing sealed cavity for holding fluid is defined among the front drive device, the lower center rod and the push cylinder connection sleeve; the push ring and the push cylinder connection sleeve are movable backwards, and the containing sealed cavity is formed between the front drive device and the lower center rodafter the movement; the composite ring is connected to the lower center rod through the shear pin b, the sealing plug is arranged on the front drive device, the conversion joint is connected with thelower center rod, and the ball seat is arranged in the inner cavity of the conversion joint. The tool has the advantages of shorter length, convenient use, connection, and maintenance, lower cost, reusability and more efficient bridge plugging. The invention further discloses a bridge plug setting method.

Owner:JEREH ENERGY SERVICES

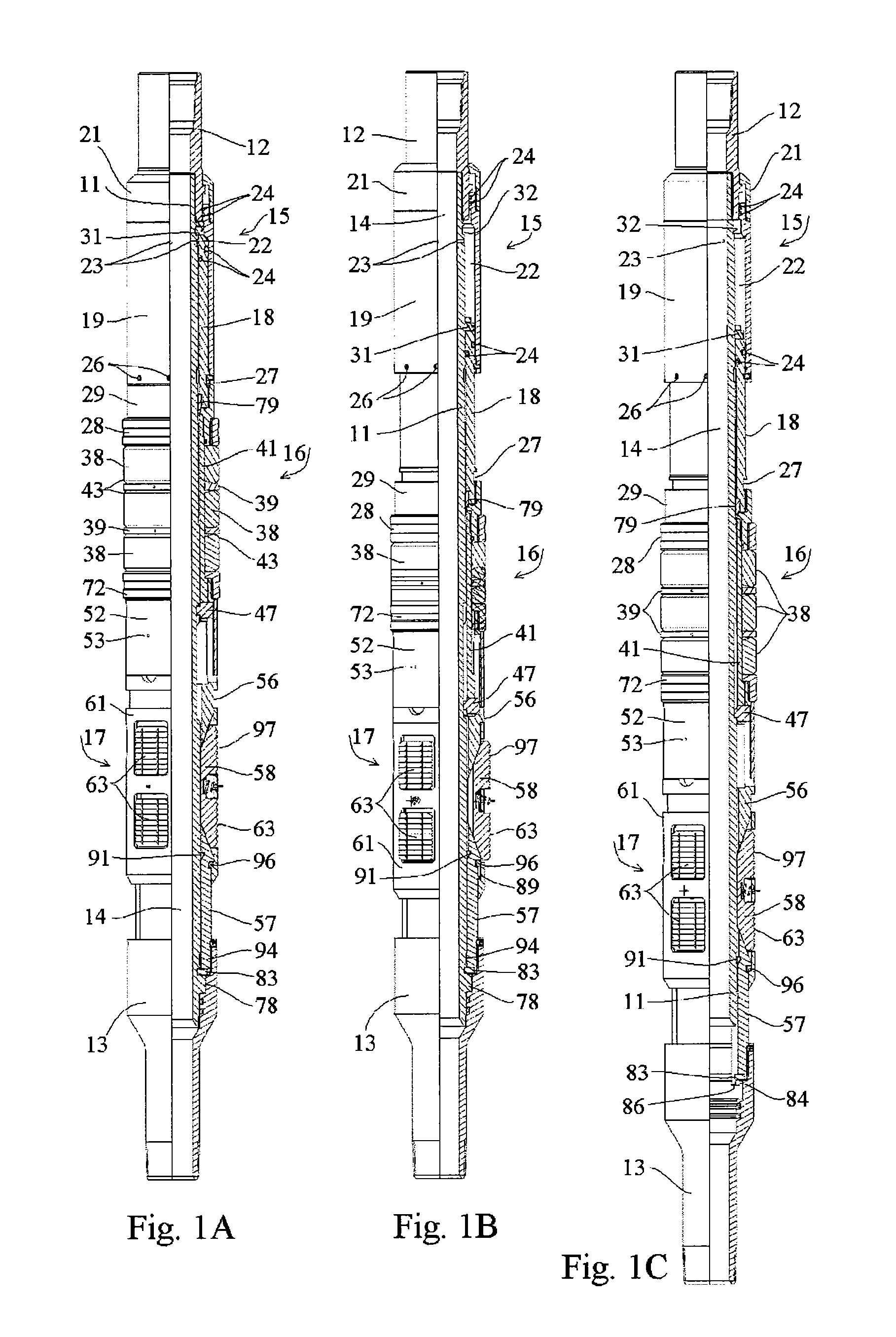

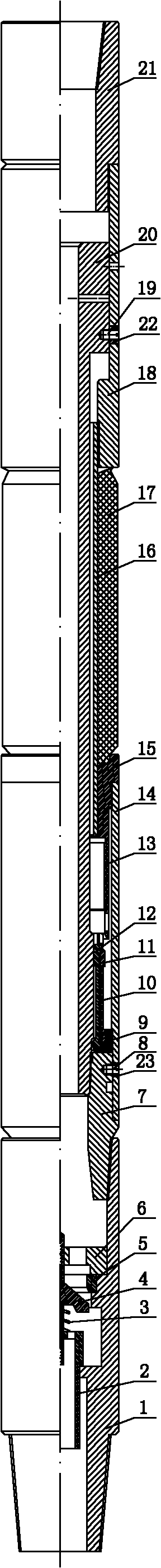

Starting pup joint with second-time opening function

PendingCN110080707AWith secondary opening functionAvoid resetFluid removalUpper jointDifferential pressure

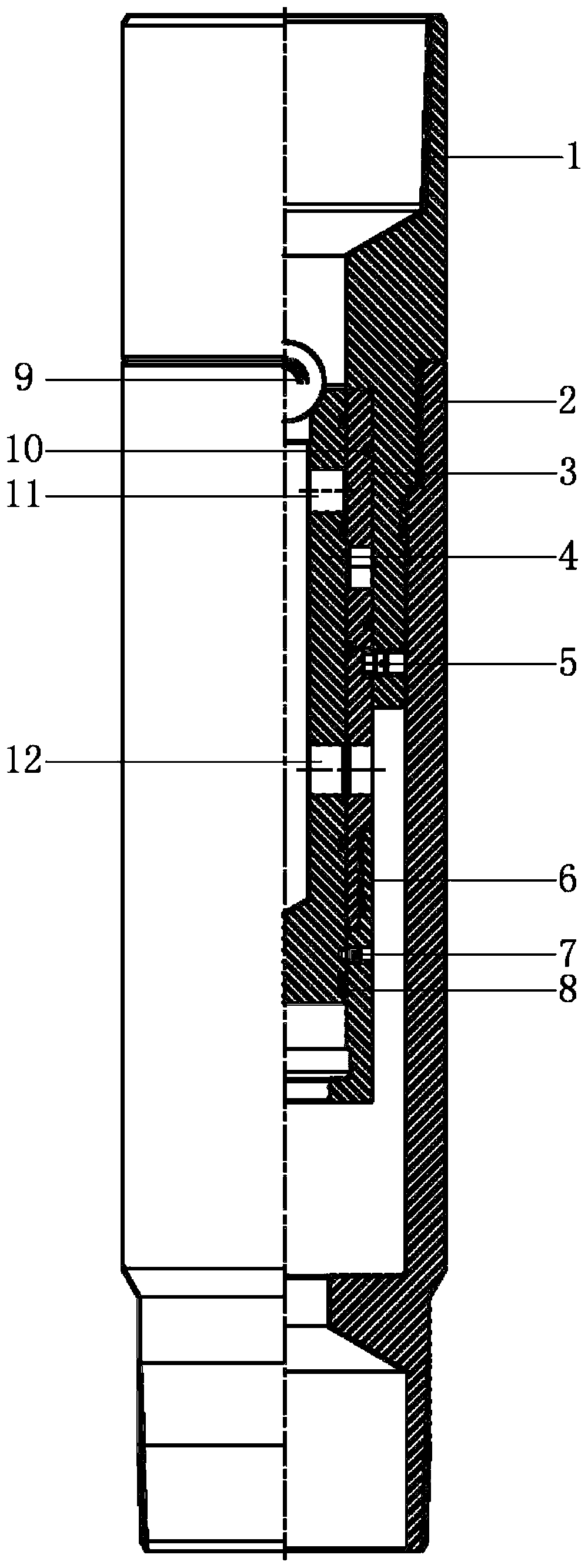

The invention discloses a starting pup joint with a second-time starting function. The starting pup joint comprises a core shaft and a setting ball. The core shaft is connected with a sliding sleeve,the setting ball is connected with the core shaft, the sliding sleeve is connected with an outer sleeve, the outer sleeve is connected with the core shaft through a first-stage shear pin, a groove isformed in the core shaft, a baffle ring can be embedded into the groove, the baffle ring is in contact with the outer sleeve, the sliding sleeve is connected with an upper joint, the upper joint is connected with a lower joint, the upper joint, the sliding sleeve and the core shaft are sequentially connected in a step mode, the core shaft is provided with a fluid channel and a fracturing channel,and the sliding sleeve is provided with a fluid channel and a fracturing channel. Setting of a packer can be achieved when the packer is opened for the first time, and when the differential pressure sliding sleeve cannot be opened normally, the starting pup joint is started for the second time, and the fracturing channel is opened.

Owner:JEREH ENERGY SERVICES

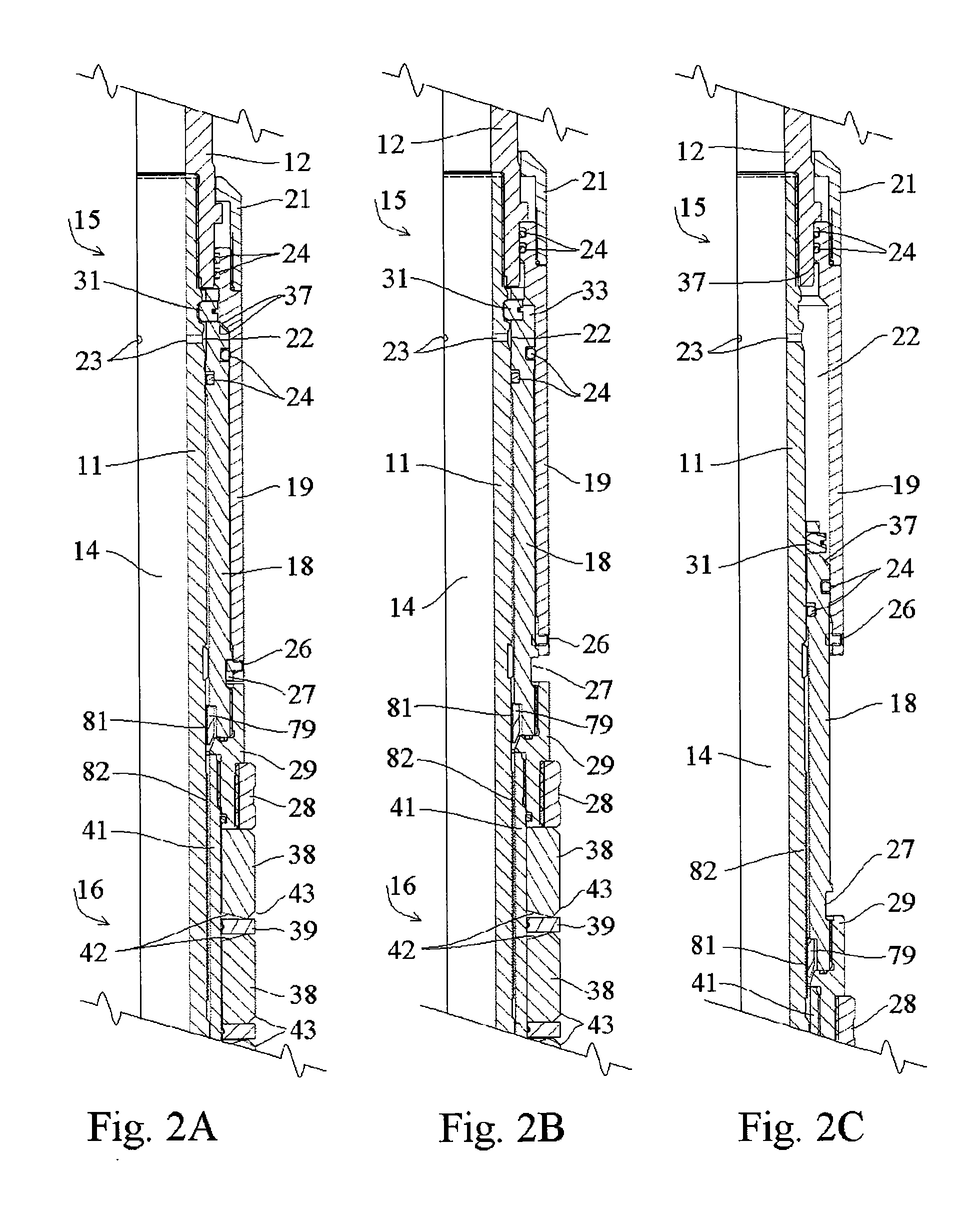

Lock mechanism for a sliding sleeve

ActiveUS7503390B2Relieve stressFluid removalWell/borehole valve arrangementsLocking mechanismRelative motion

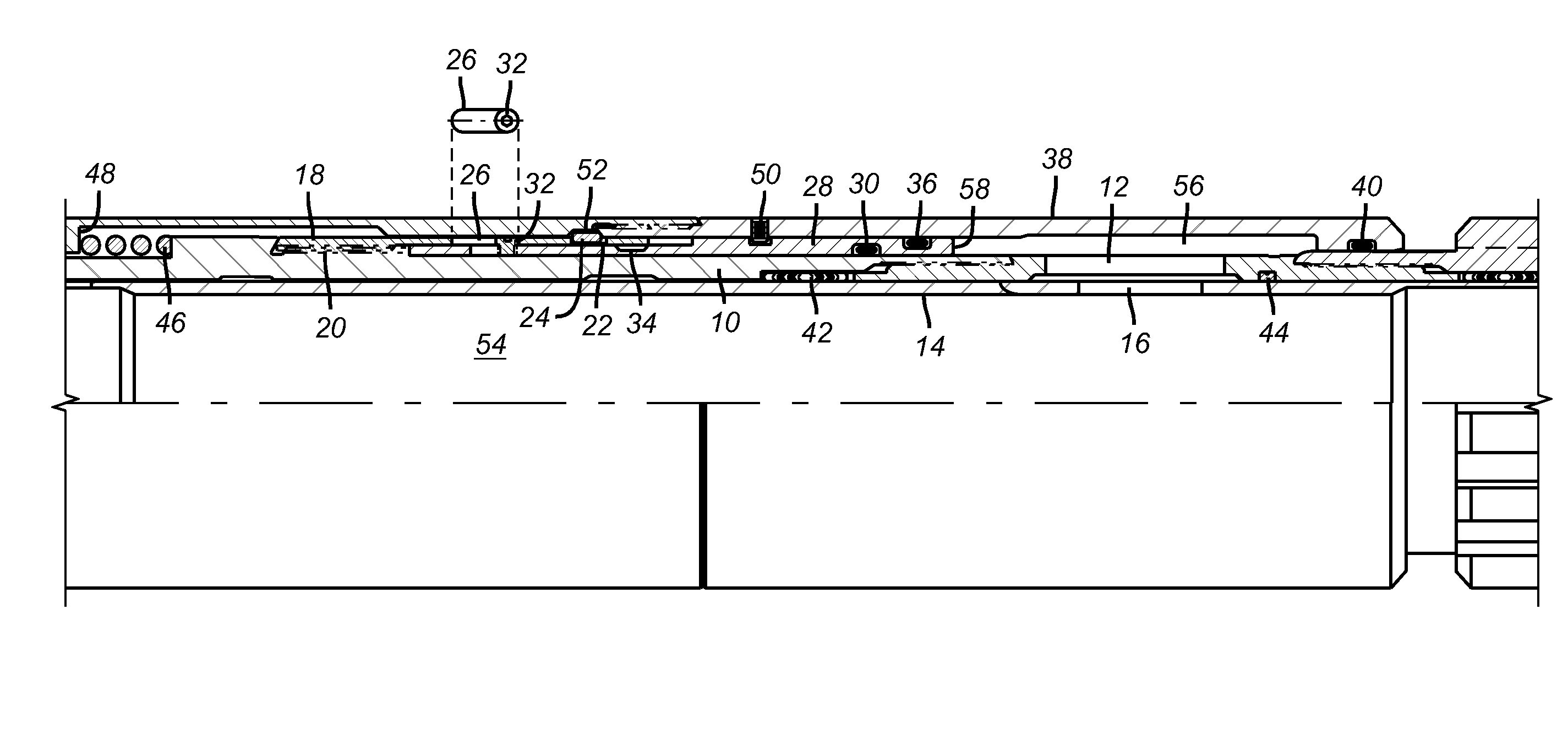

A locking device prevents stressing of other components used to hold tool portions against relative movement until a desired location is reached. A locking dog holds a first component, such as a sliding sleeve to a second component, such as a mandrel until pressure can move a piston and remove support for the dog. The same pressure that removes support for the dog to unlock the lock also forces a retainer, such as a shear pin that holds a sleeve to break to allow the sleeve to shift. The locking dog keeps stress off the shear pin when the locking dog is supported in the run in configuration. An alternative design uses a grease filled cavity to dampen shocks that could load a shear pin to the point of failure.

Owner:BAKER HUGHES INC

Release mechanism for downhole tool

A release mechanism for a downhole tool is actuated by radial movement of a locking member. The locking member provided as much as full circumferential support in the locked position and once released can be prevented from re-gripping the previously connected elements. Illustrative examples of the mechanism for radial movement for release comprise sleeves that expand and radially oriented pistons. Shear pins or collets are not used to hold the components together in the preferred embodiment. Internal pressure fluctuations before initiating the release sequence will not cause unwanted release. The mechanism is applicable to a variety of downhole tools and is illustrated in the context of a hydraulic release.

Owner:BAKER HUGHES INC

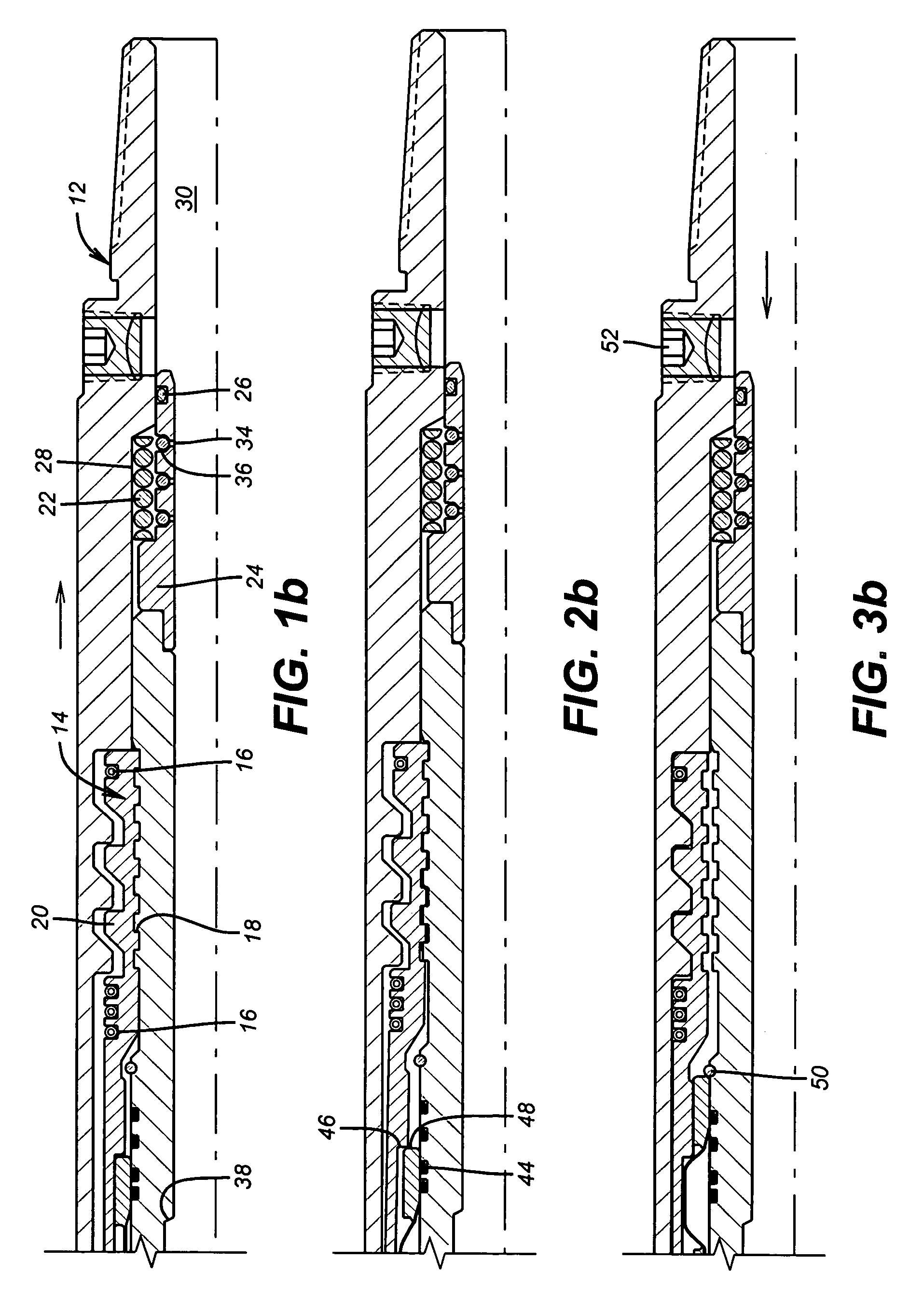

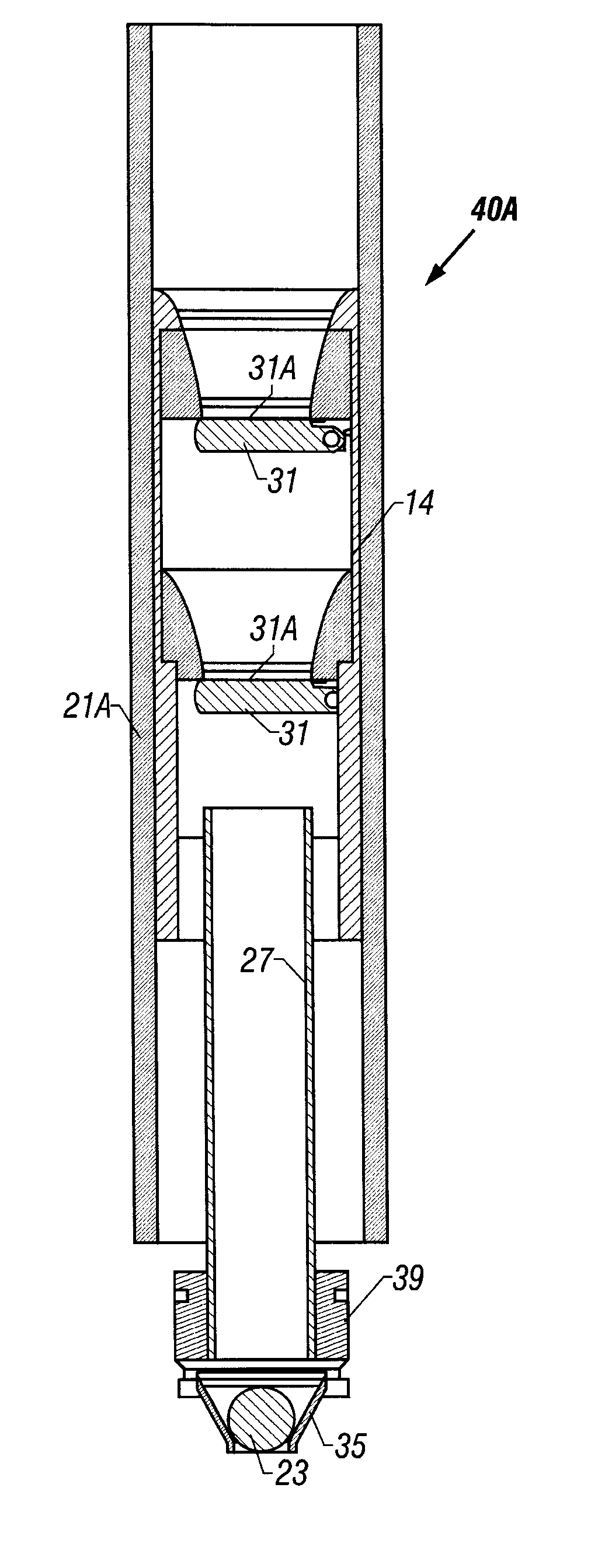

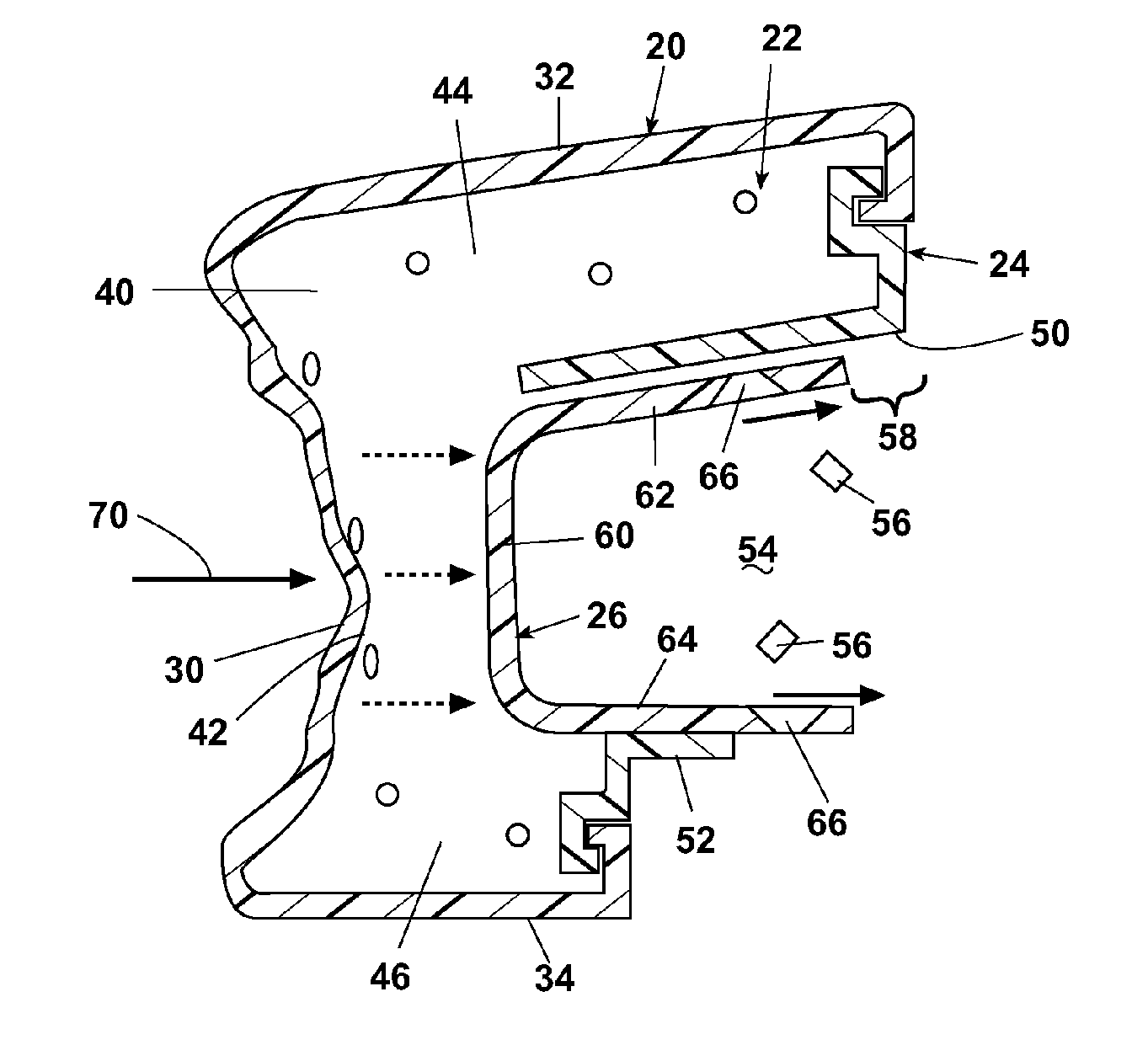

Multi-purpose float equipment and method

A float shoe / collar apparatus and method for multi-purpose use in running a tubular string such as a casing string or liner into a wellbore and for optimizing cementing operations. In one presently preferred embodiment, the apparatus permits auto filling of the tubular string as the string is lowered into the wellbore. Circulation can be effected through down jets for washing the wellbore as necessary. After the tubular string is positioned, the down jets can be blocked off and up jets opened to thereby direct cement upwardly to optimize cement placement. Check valves can also be activated to prevent flow from the wellbore into the tubular string. In one embodiment, the apparatus comprises an inner member and tubular member. The inner member is movable upon release of shear pins to cause longitudinal movement relative to the outer member. The movement of the inner member may close a plurality of downward jets and may also open a plurality of upward jets, if desired. The apparatus may also be equipped with a set of check valves which can be held open on run in, and subsequently activated to thereby automatically close upon cementing to prevent "u-tubing" of fluid back into the casing. In another embodiment a float collar comprises the same valve / valves as the float shoe, without jets. This float collar may be run in conjunction with a guide shoe, with or without jets.

Owner:FORUM US

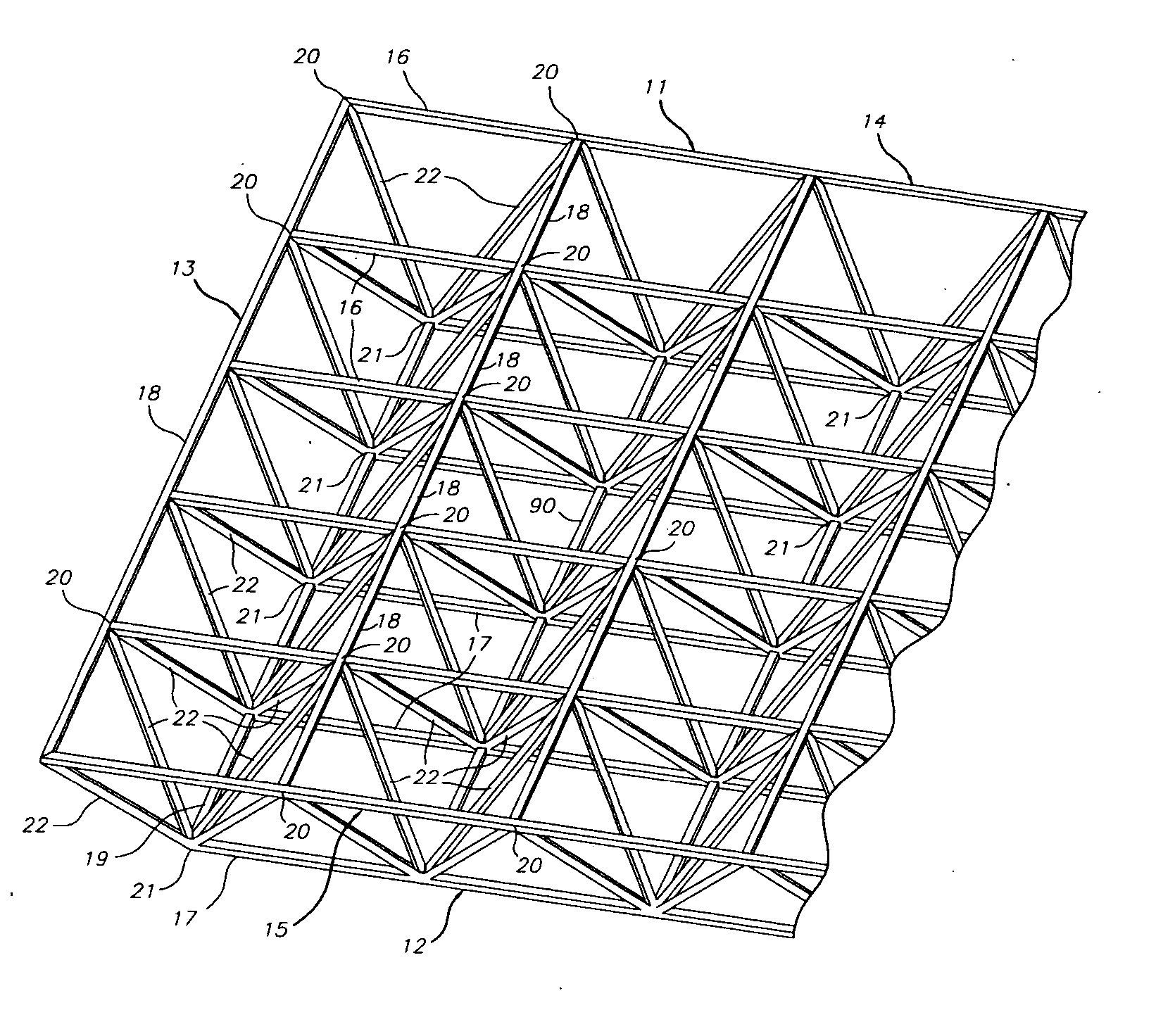

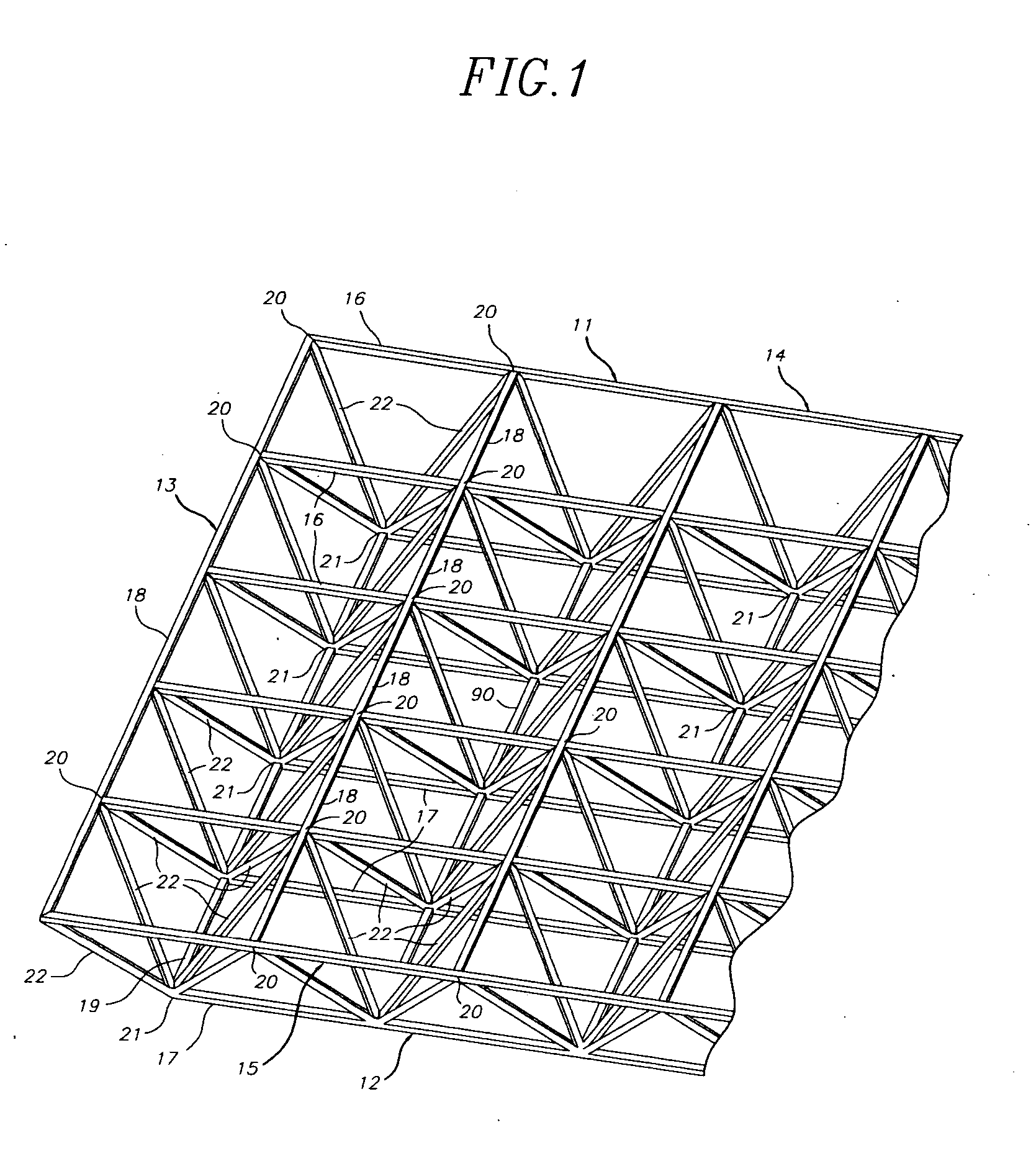

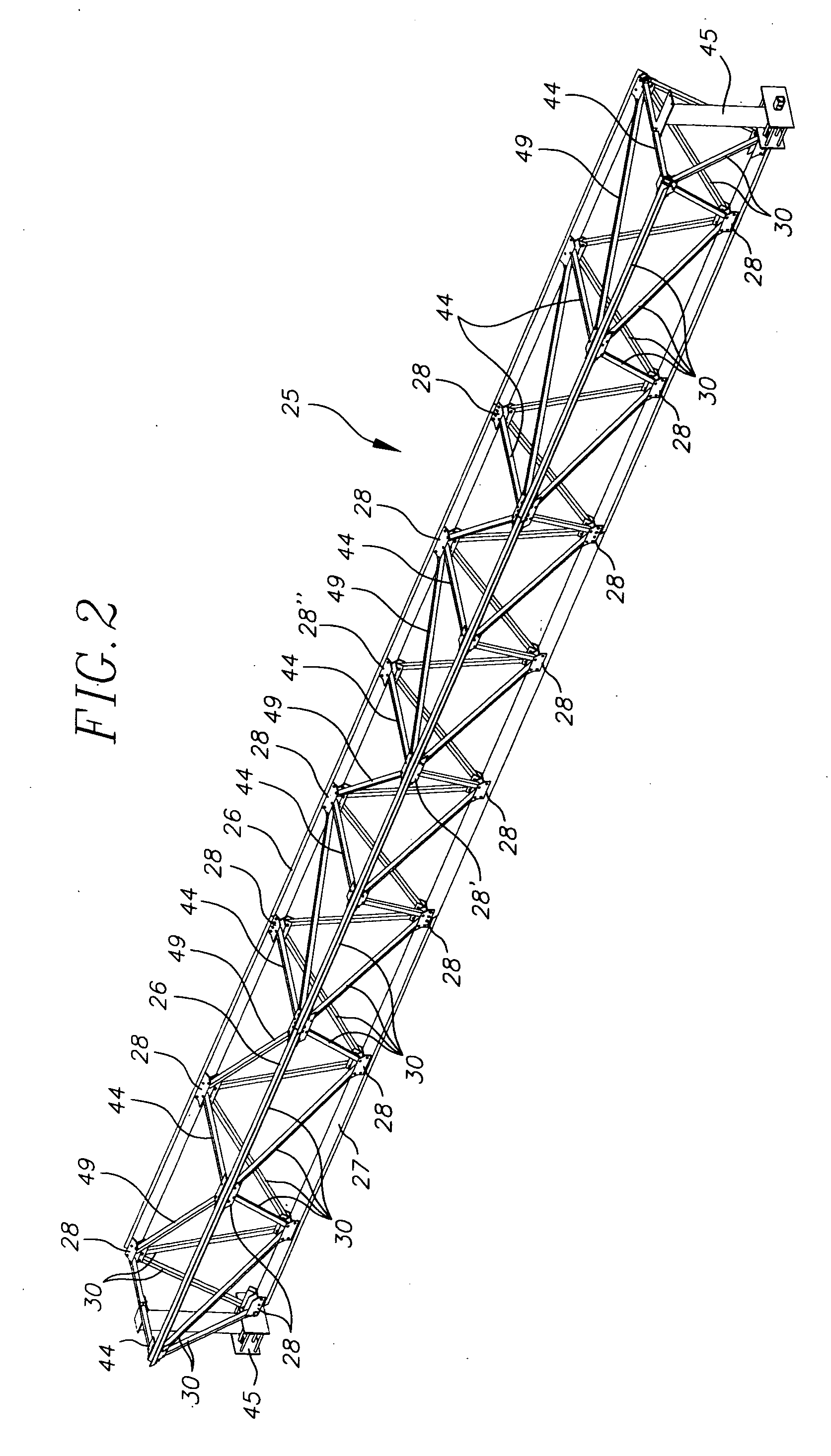

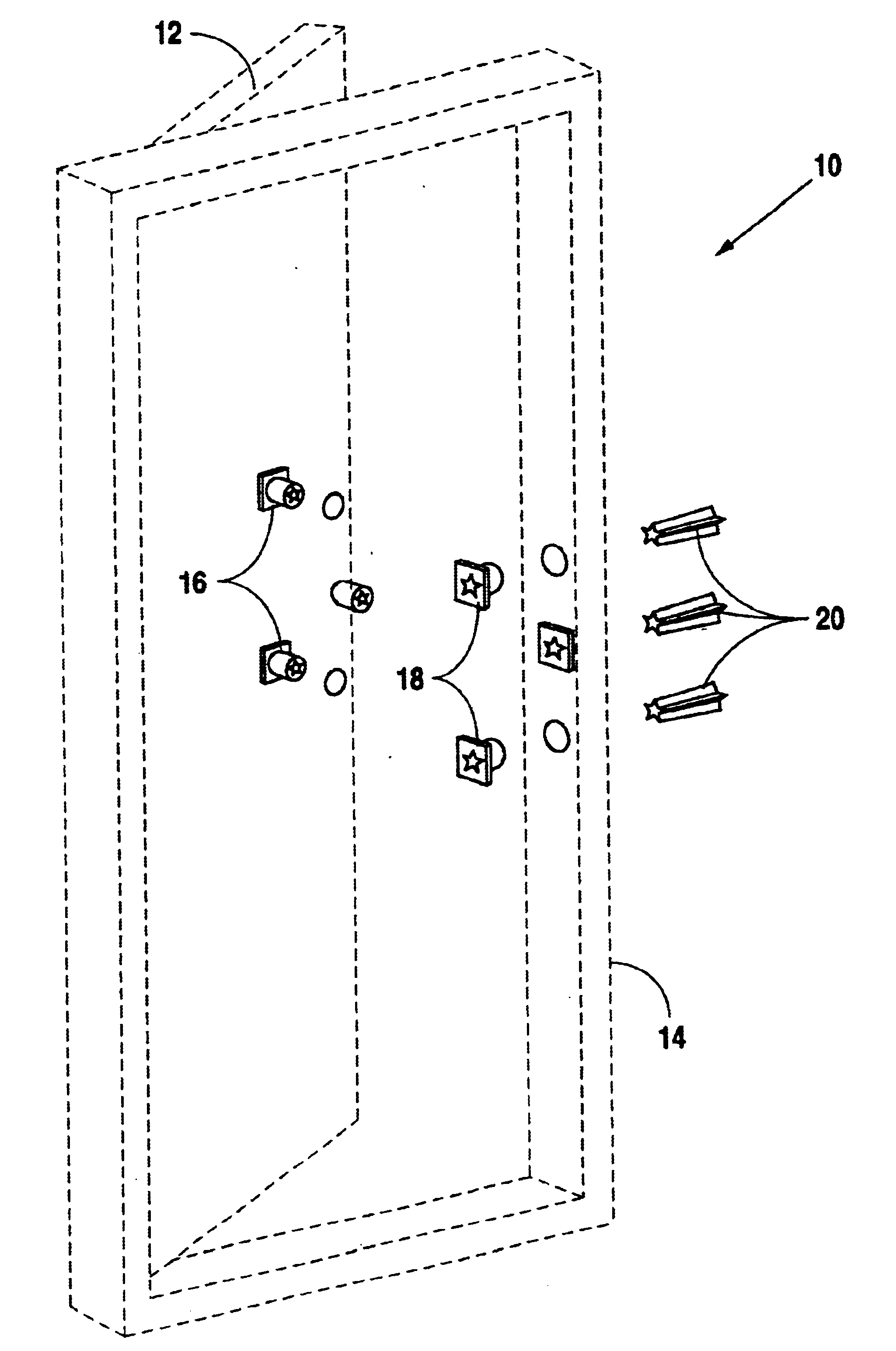

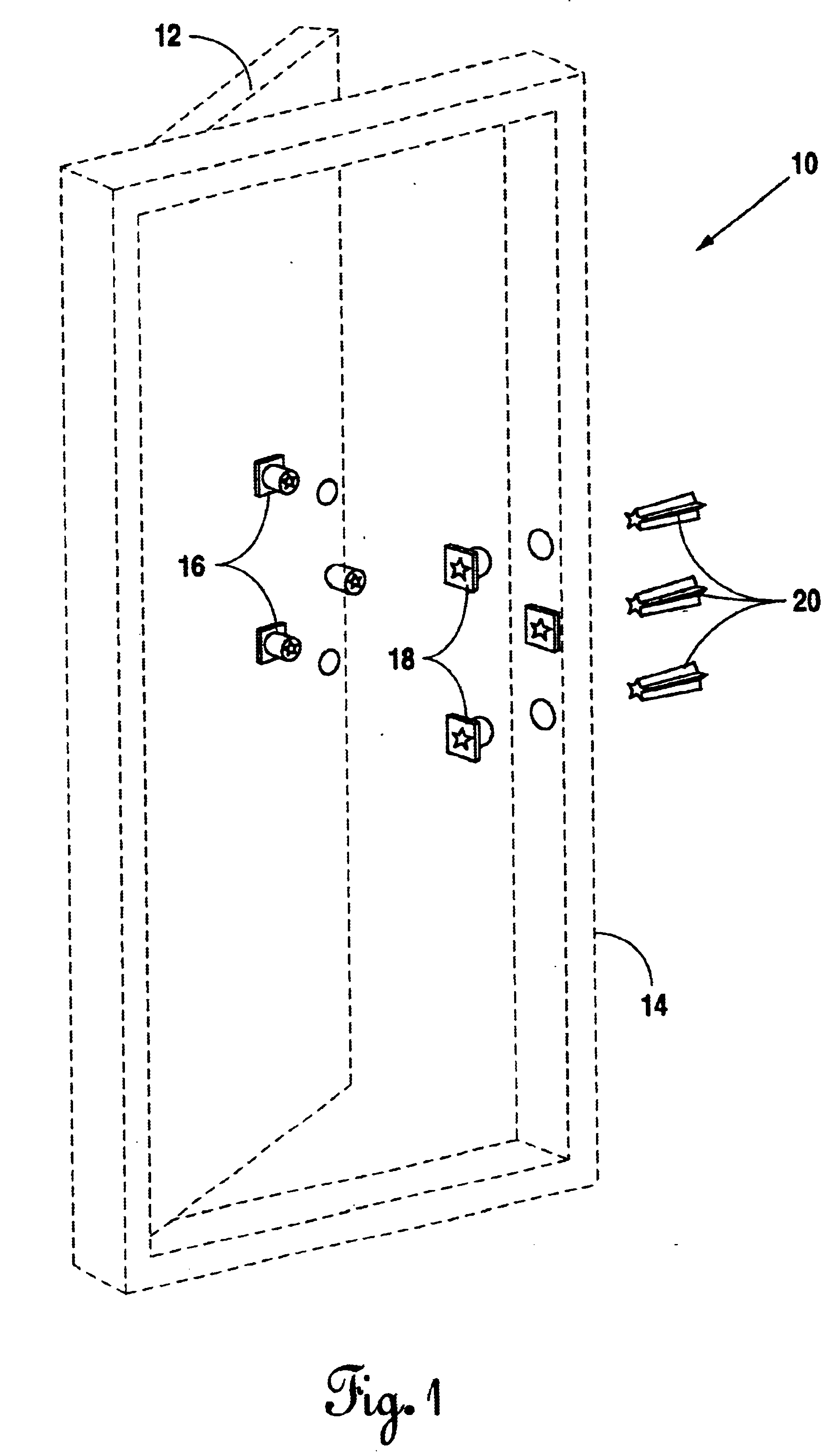

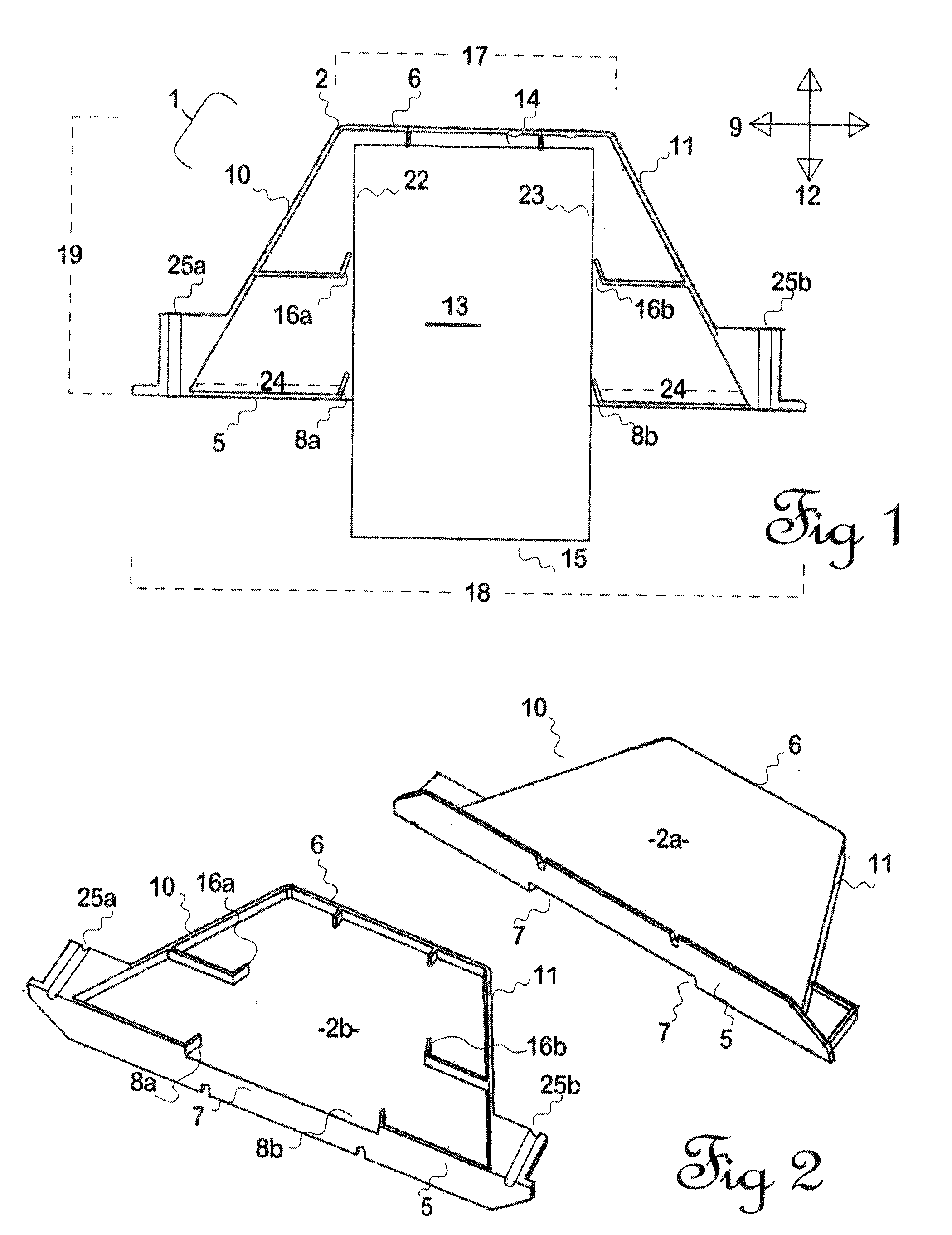

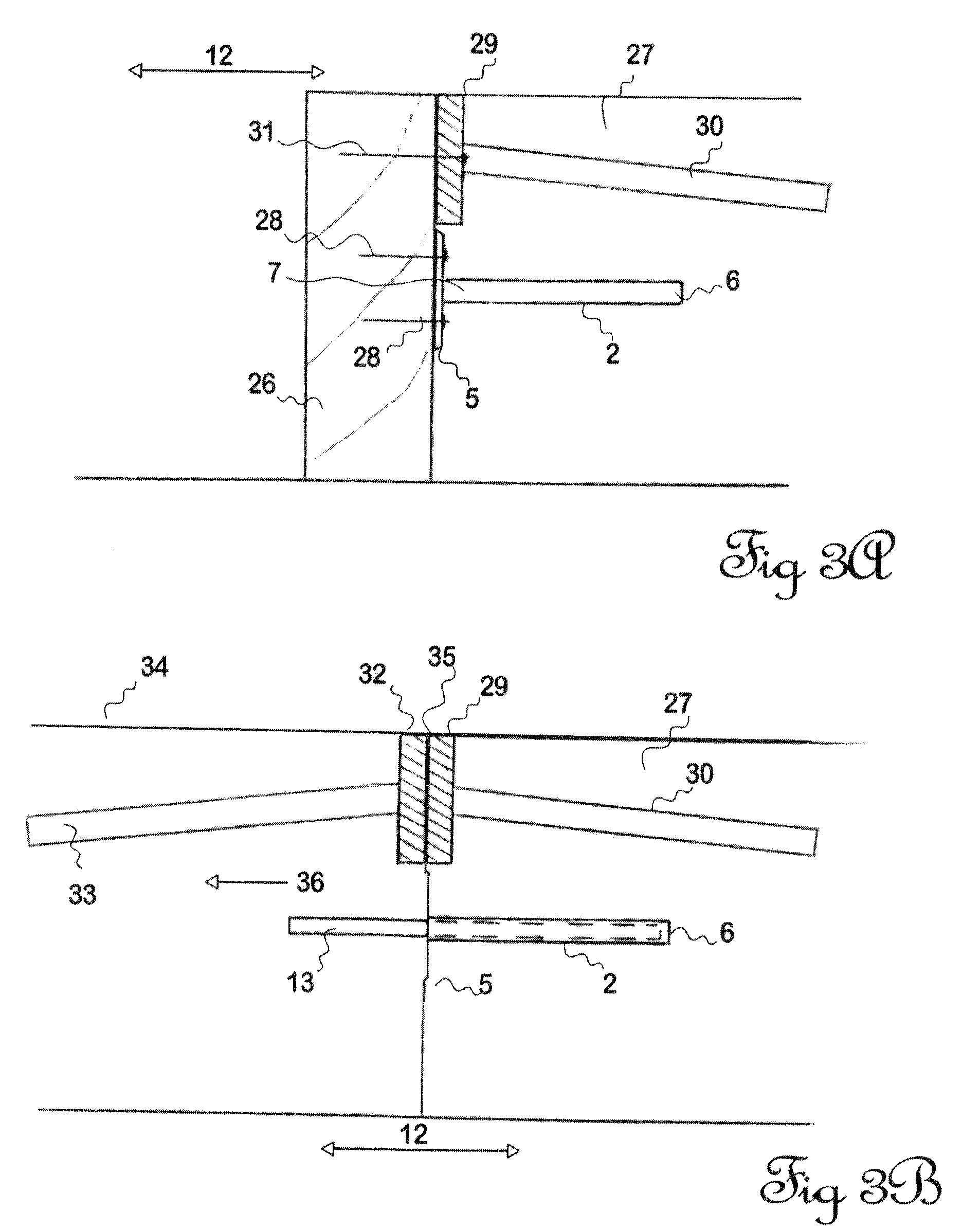

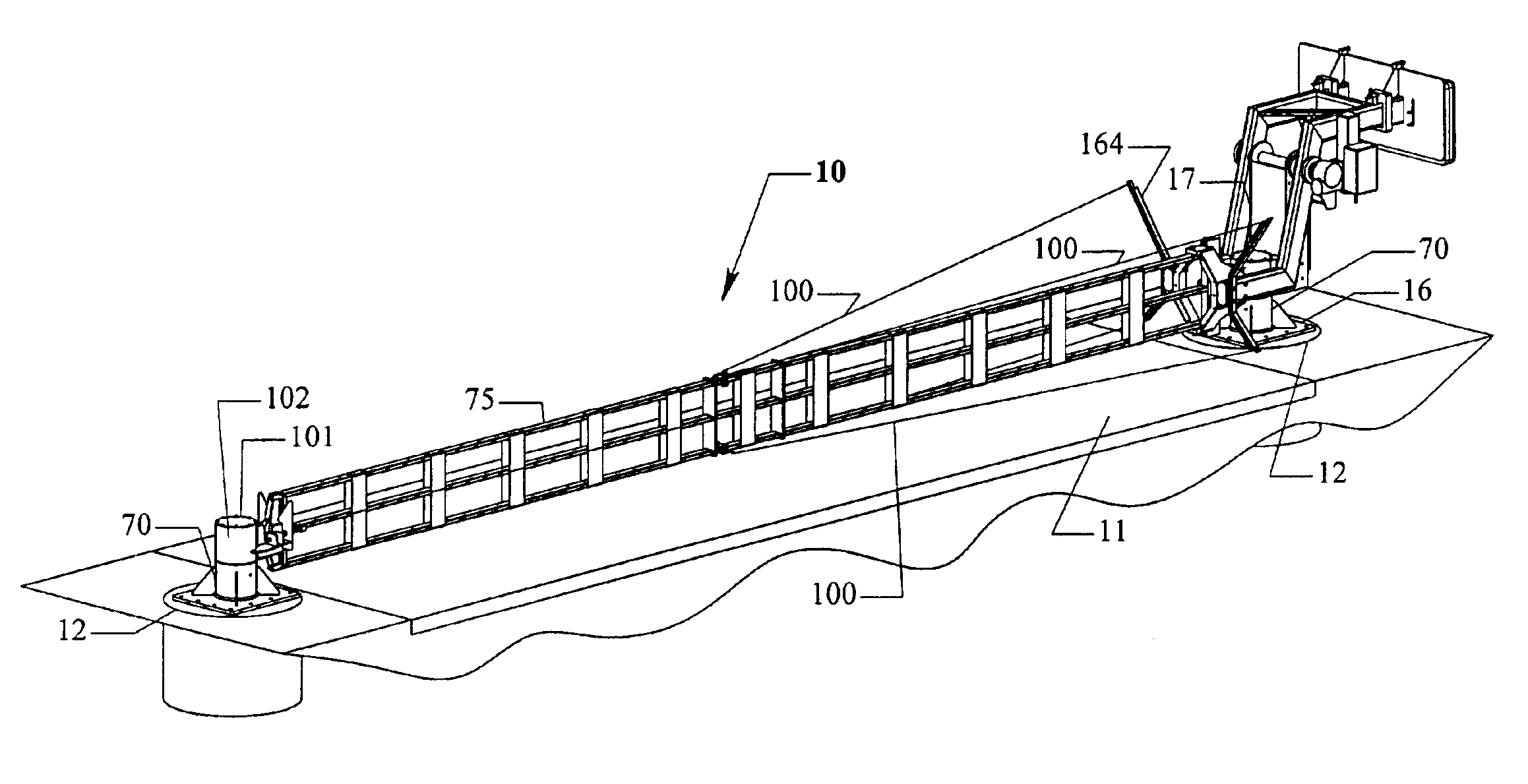

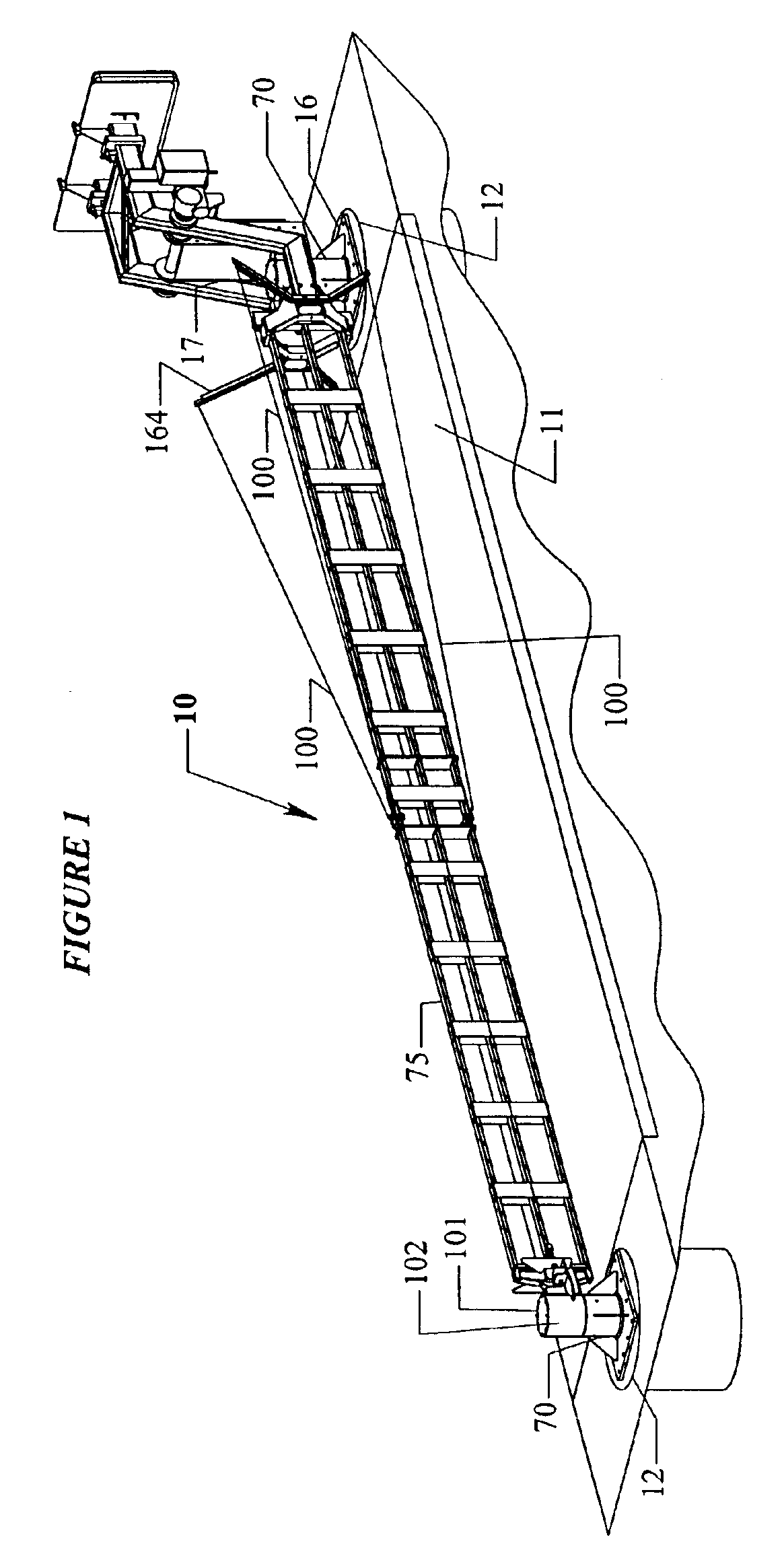

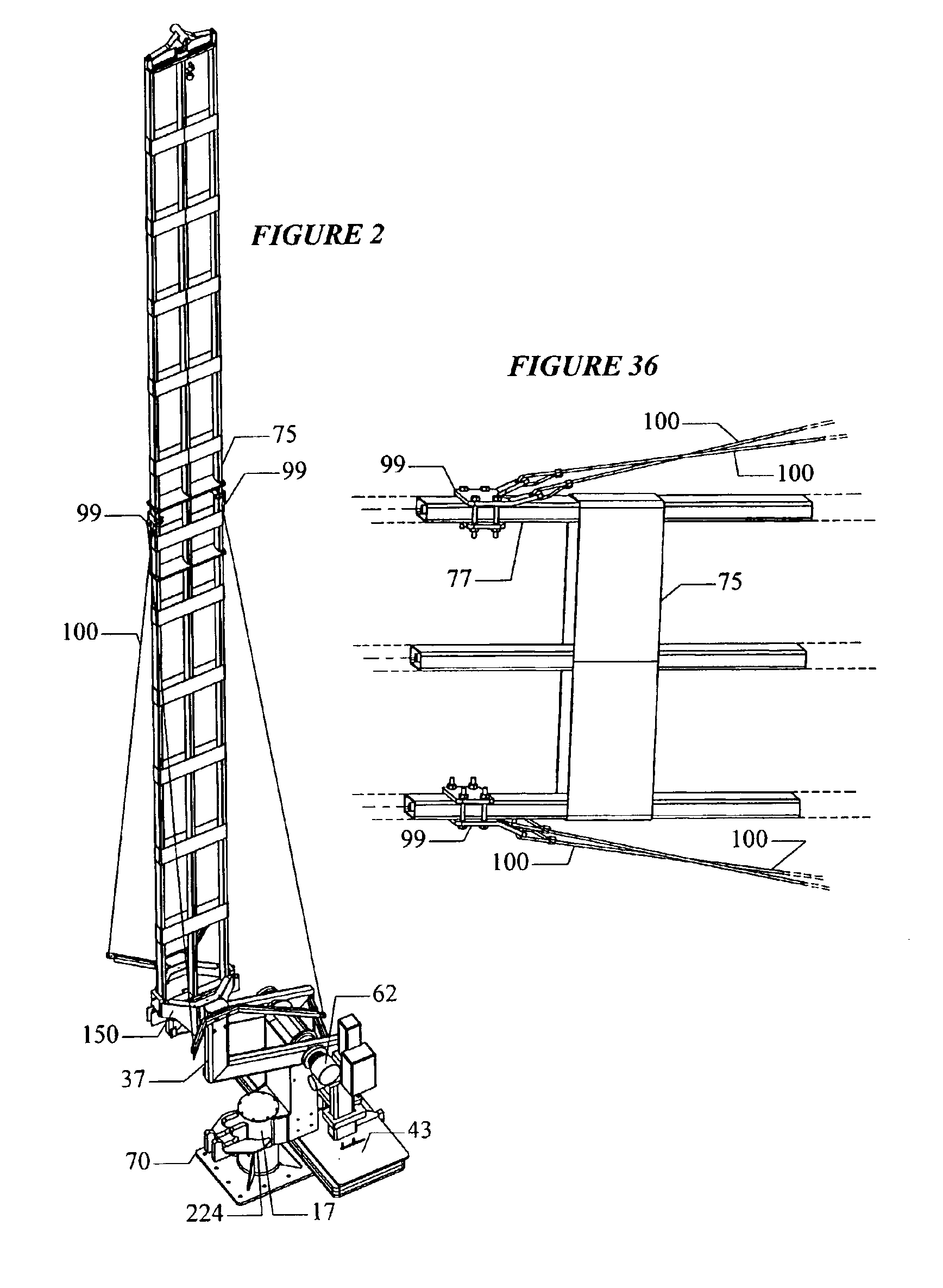

Space frames and connection node arrangement for them

ActiveUS20070011983A1Easy to useEfficiently carry design loadSolar heating energySolar heat devicesEngineeringSpace frame

A node connector in a double layer grid-type of space frame preferably is an extrusion which includes an open-ended tubular portion for snugly at least substantially encircling a frame chord member of desired cross-sectional configuration which is disposable in the passage. The node connector has fixed external elements which extend along the connector parallel to the passage. Those elements define facing parallel flat surfaces arranged in at least two pairs of such surfaces. The surfaces of each pair lie equidistantly from a center plane between them. Each center plane is parallel to the passage axis and preferably includes the passage axis. Each pair of facing flat surfaces of the node connector can cooperate closely with opposite flat surfaces at the end of each of other frames framing member placed between the facing surfaces. The node connector can be secured to a chord member in its passage and to ends of other framing members by shear pins which have zero clearances in node connector holes and in holes or passages through the respective framing members. The space frame can be a movable armature for a curved solar reflector, the space frame having a V-shaped major surface. At least some of the framing members can be thin wall tubes modified to have opposing, flat-exterior wall zones along the length of each tube and in which the wall thickness is locally increased and through which shear pin holes are defined.

Owner:GOSSAMER SPACE FRAMES

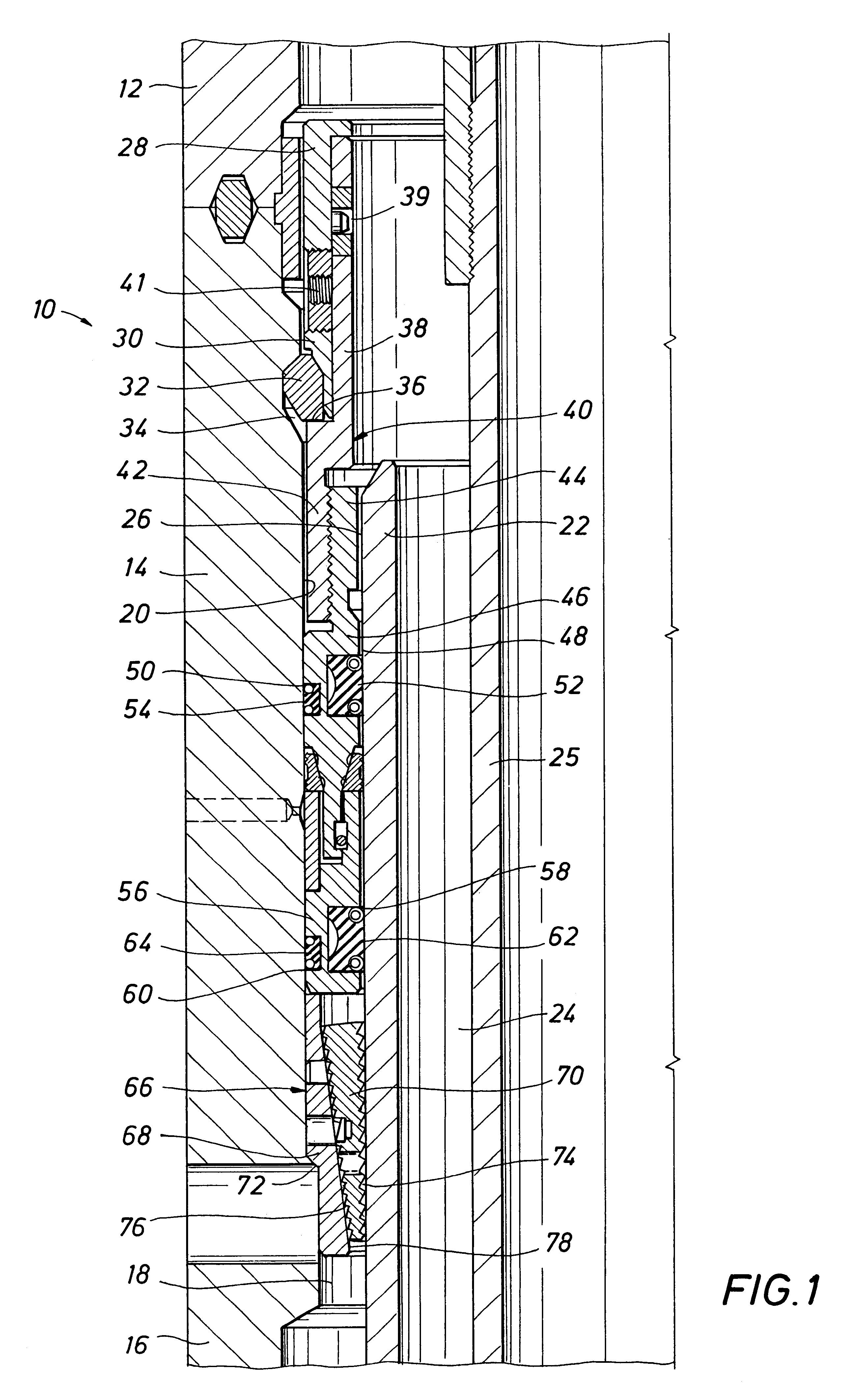

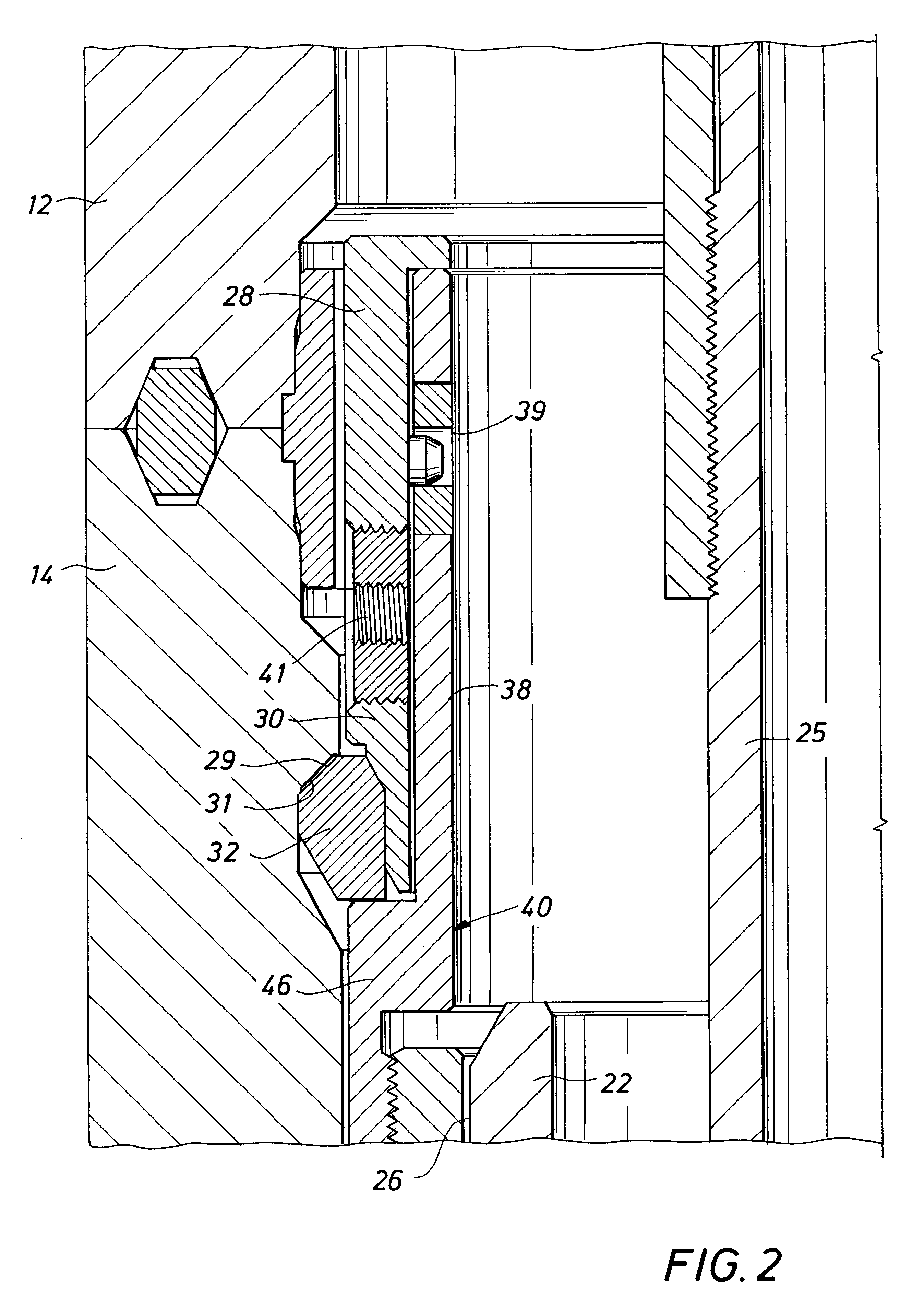

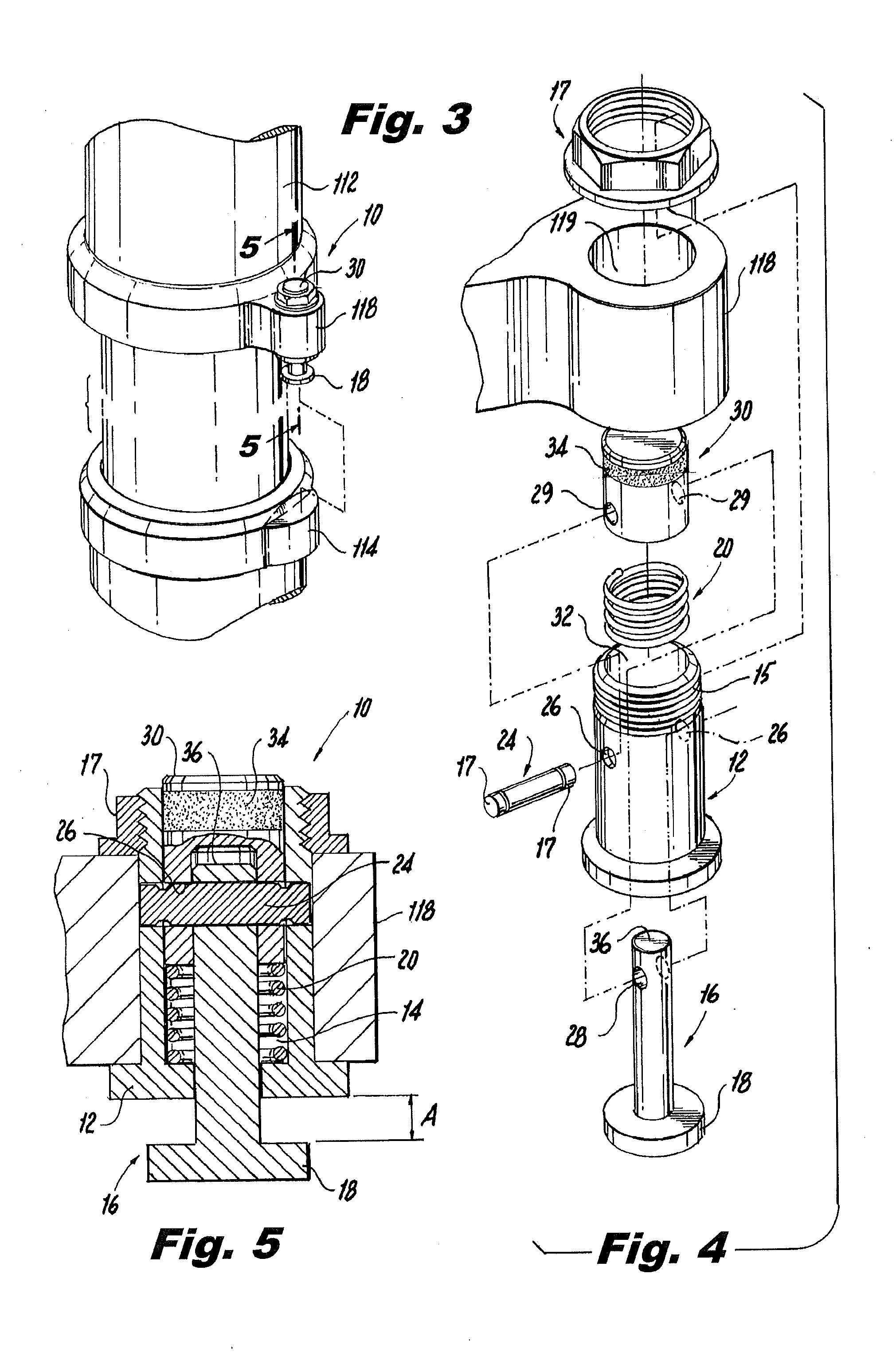

Energized sealing cartridge for annulus sealing between tubular well components

InactiveUS6510895B1Effective control of the sealing capability of the seal cartridgeFluid pressure sealed jointsConstructionsElastomerRespirator

A mechanically energized annular packoff seal cartridge for metal-to-metal sealing with substantially concentrically arranged tubular members, such as the tubular wellhead housing and well casing of an oil and gas well. A tubular pressure responsive energizing mandrel having downwardly converging frusto-conical seal actuating surfaces is of a dimension for entry into the annulus between the wellhead seal bore and the rough outer surface of the well casing. Elastomer seals are carried by the energizing mandrel and establish sealing of the energizing mandrel with the wellhead housing and well casing A pair of soft metal seal rings are carried by the seal cartridge and are forced radially into metal-to-metal sealing with the wellhead housing and the rough outer surface of the well casing respectively by the double tapered seal actuating surfaces responsive to pressure induced downward force on the energizing mandrel. A locking mandrel and the seal actuating mechanism are restrained against actuating movement during running of the seal cartridge by a running tool by shear pins, thus enabling the cartridge to pass through various well equipment. The shear pin of the locking mandrel is sheared by downward force applied by the running tool to lock the seal cartridge within the wellhead housing. The shear pin of the seal actuating mechanism is sheared, after locking of the cartridge to the wellhead housing, by the force of pressure introduced into the wellhead above the seal cartridge which acts to develop a pressure differential across the elastomer seals of the cartridge.

Owner:FMC TECH INC

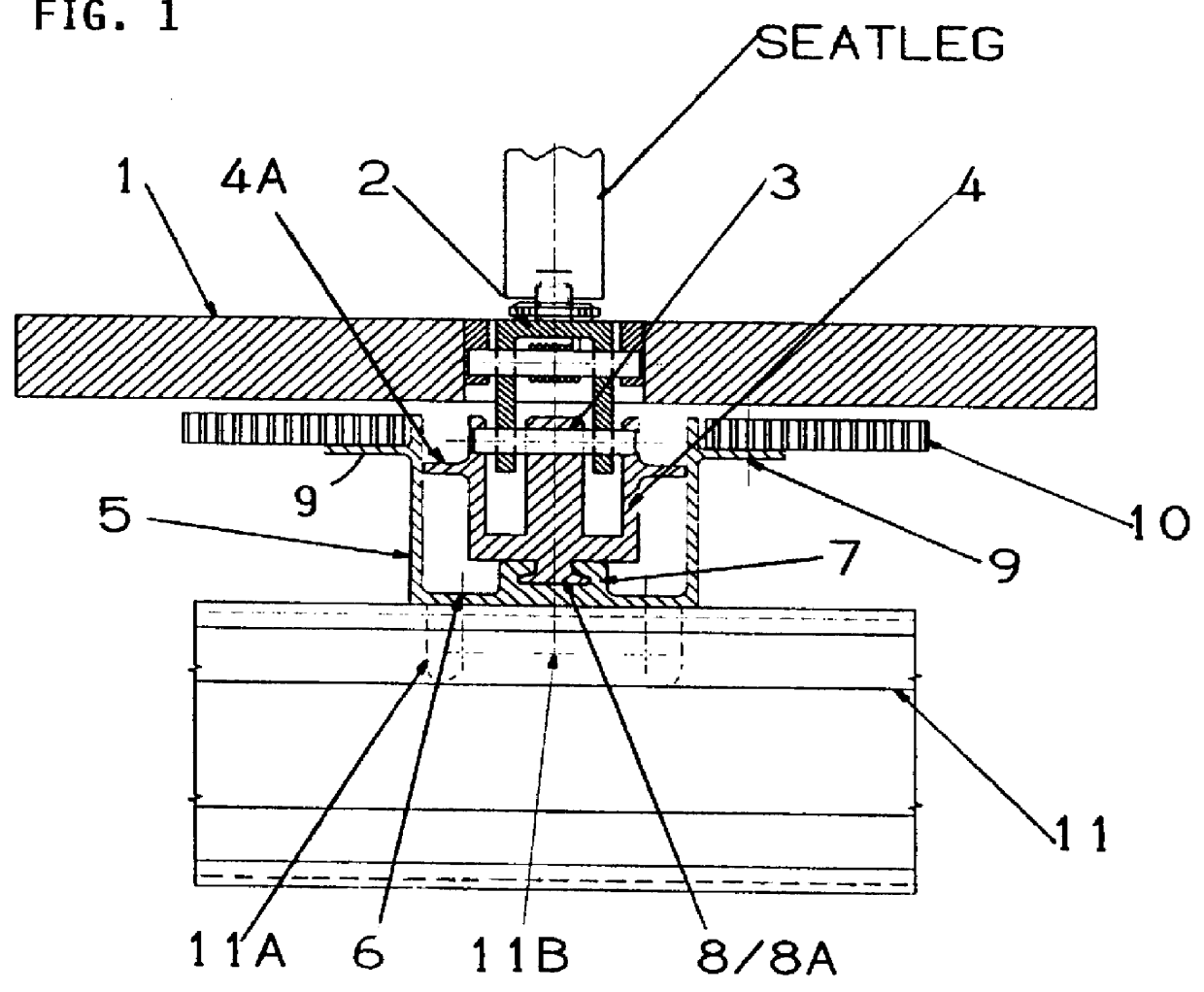

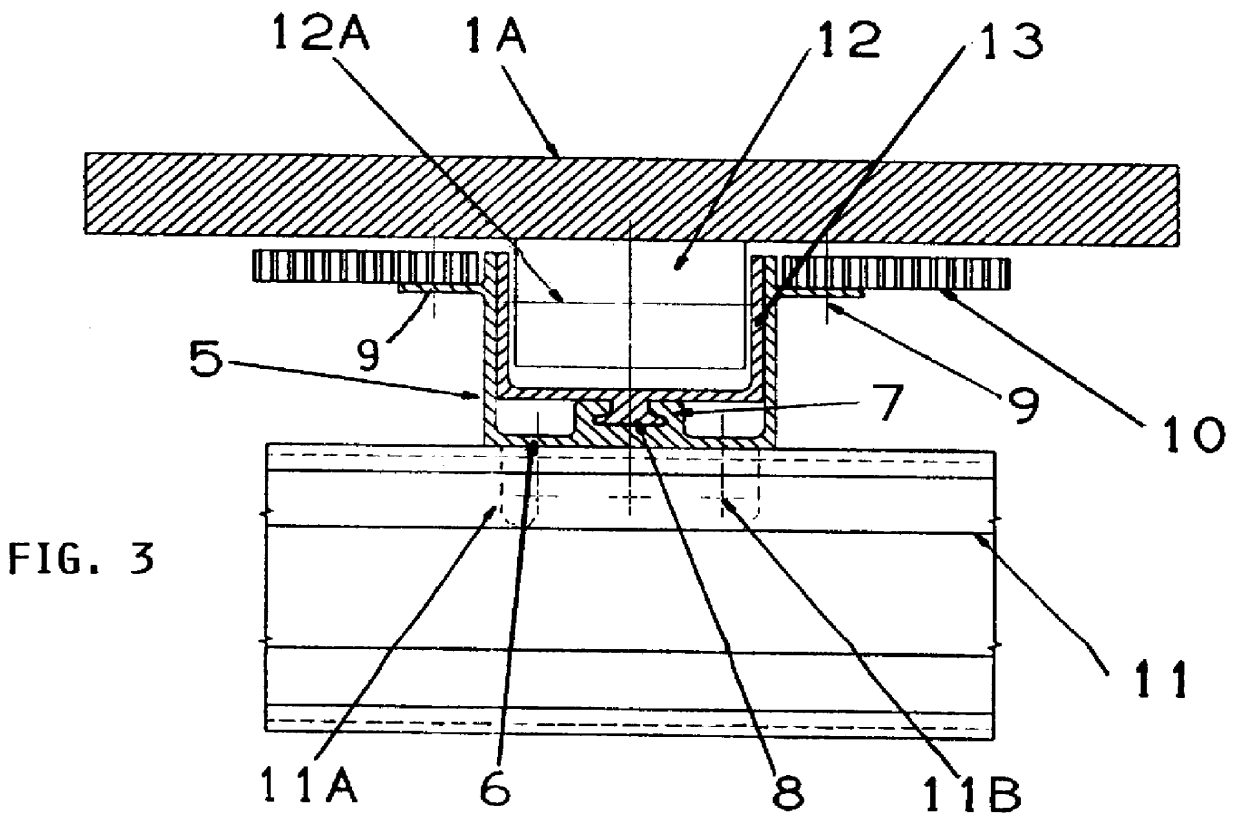

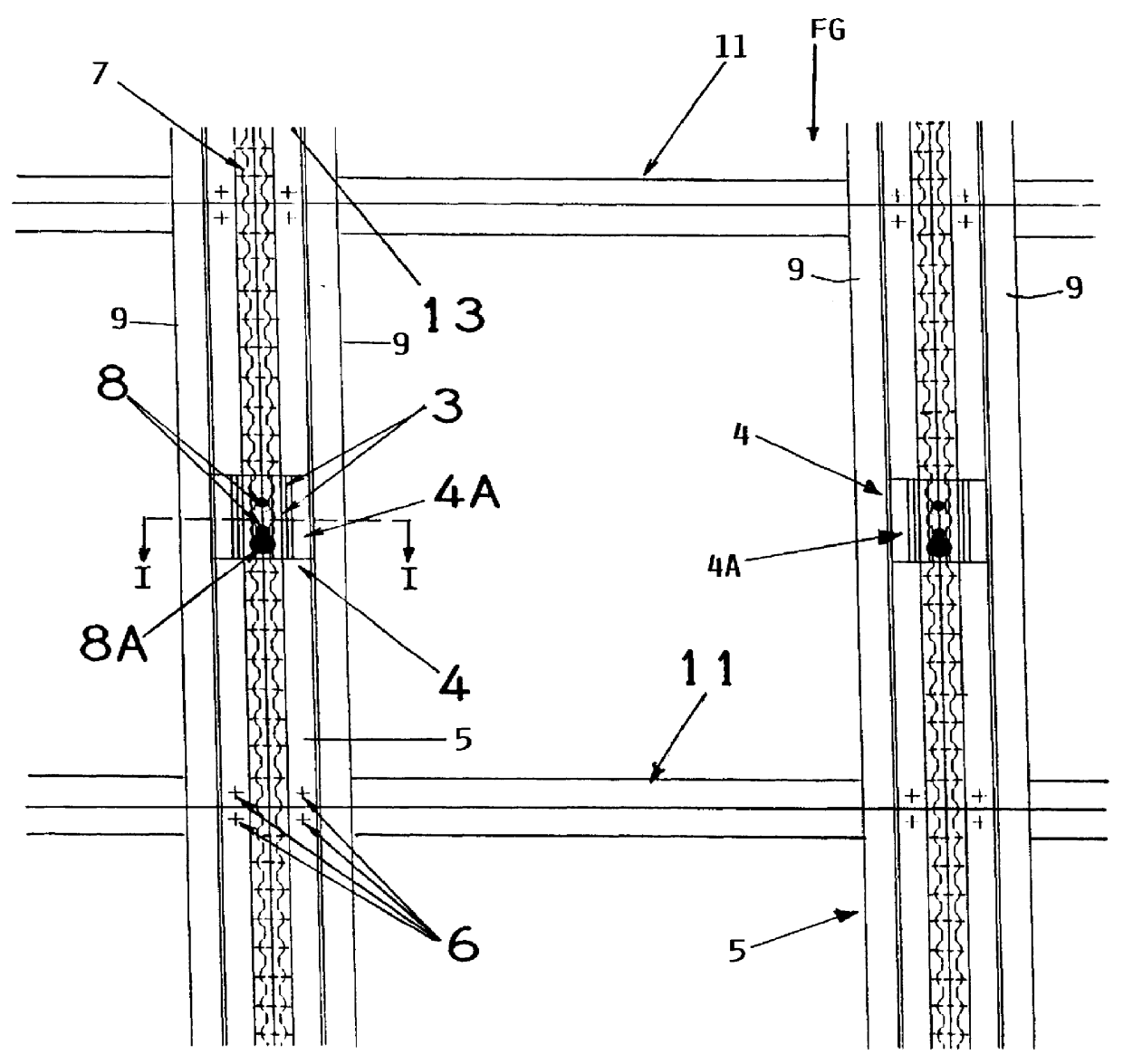

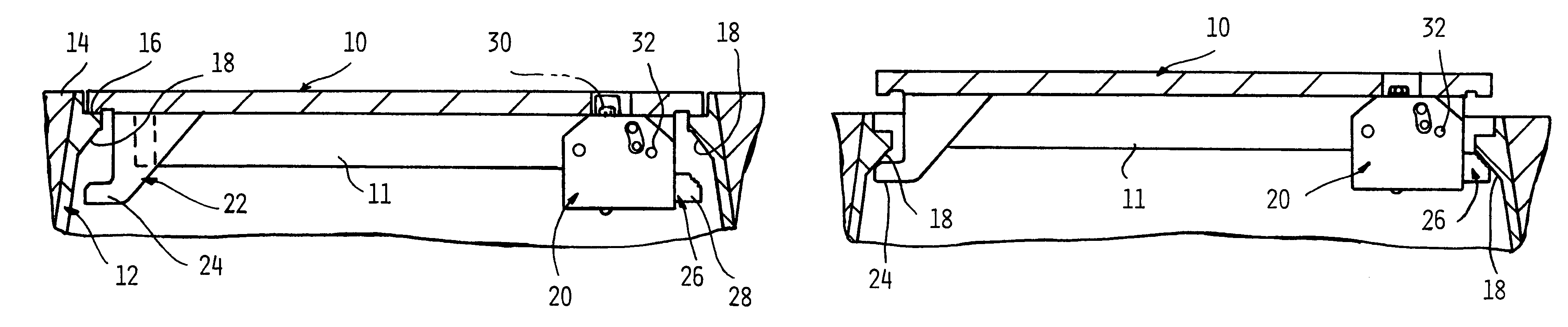

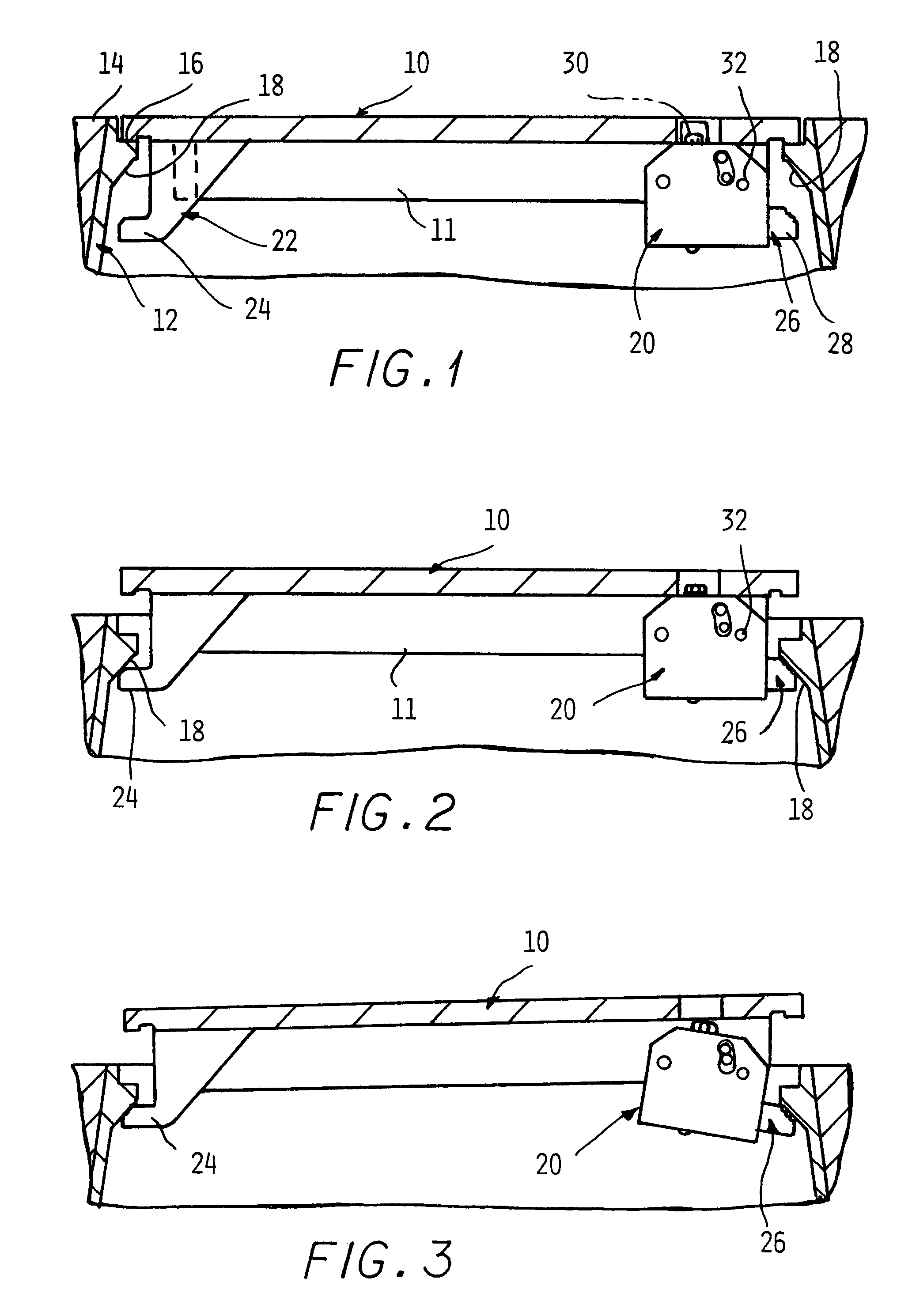

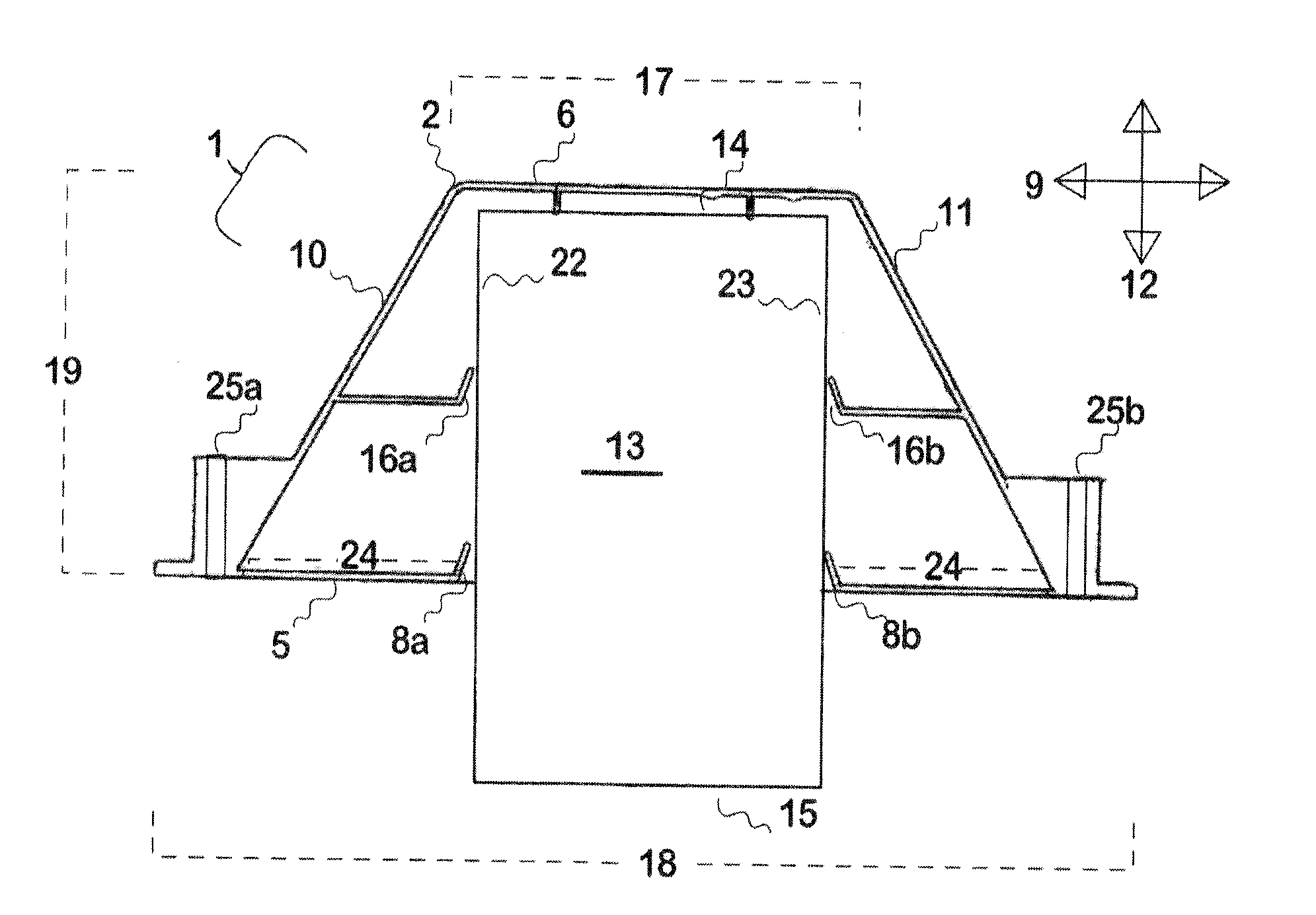

System for securing a support to an aircraft floor

Supports such as a pallet carrying aircraft passenger seats or a bottom of a freight container are secured to a floor structure in an aircraft. For this purpose the floor structure includes floor stringers (5) supported on and secured to floor joists (11). The stringers (5) are U-rails having an upwardly open U-cross-section with a first interlocking member (8) in the U-cross-section. An adapter (4, 13) having a present existing stud (8) and shear pin system (8A) is secured in the U-rail of the stringers (5). The adapter (4) is secured to or securable to the support by a latching (2, 3). Another adapter (13) carries rotatable rollers or roller balls that project slightly above an upwardly facing floor level to permit, for example, freight containers or seat pallets to roll along the floor. Instead of adapter (13) it is also possible to install a present existing container latch carrier (14) in the present stringer (5).

Owner:DAMELERKLESLER AVIATION

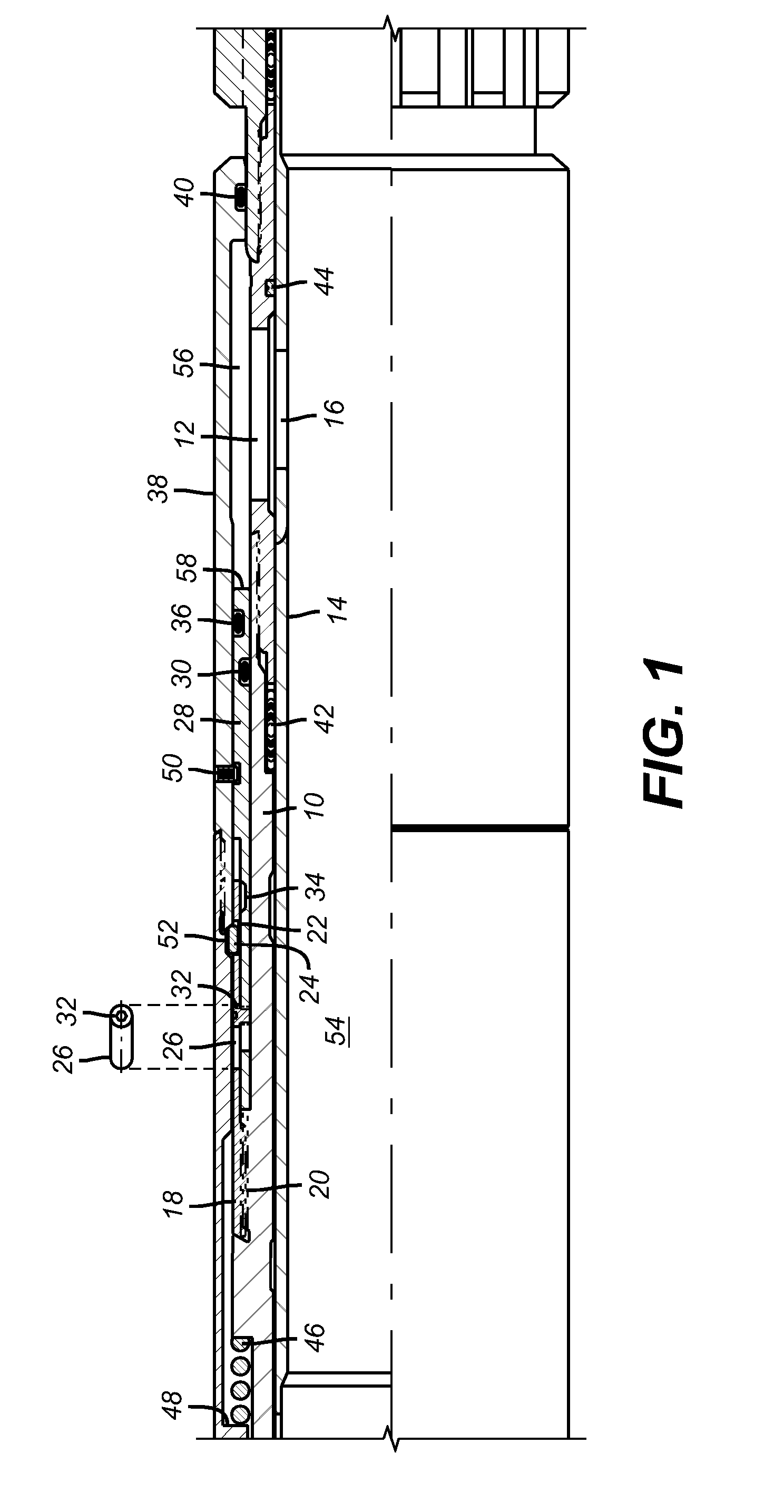

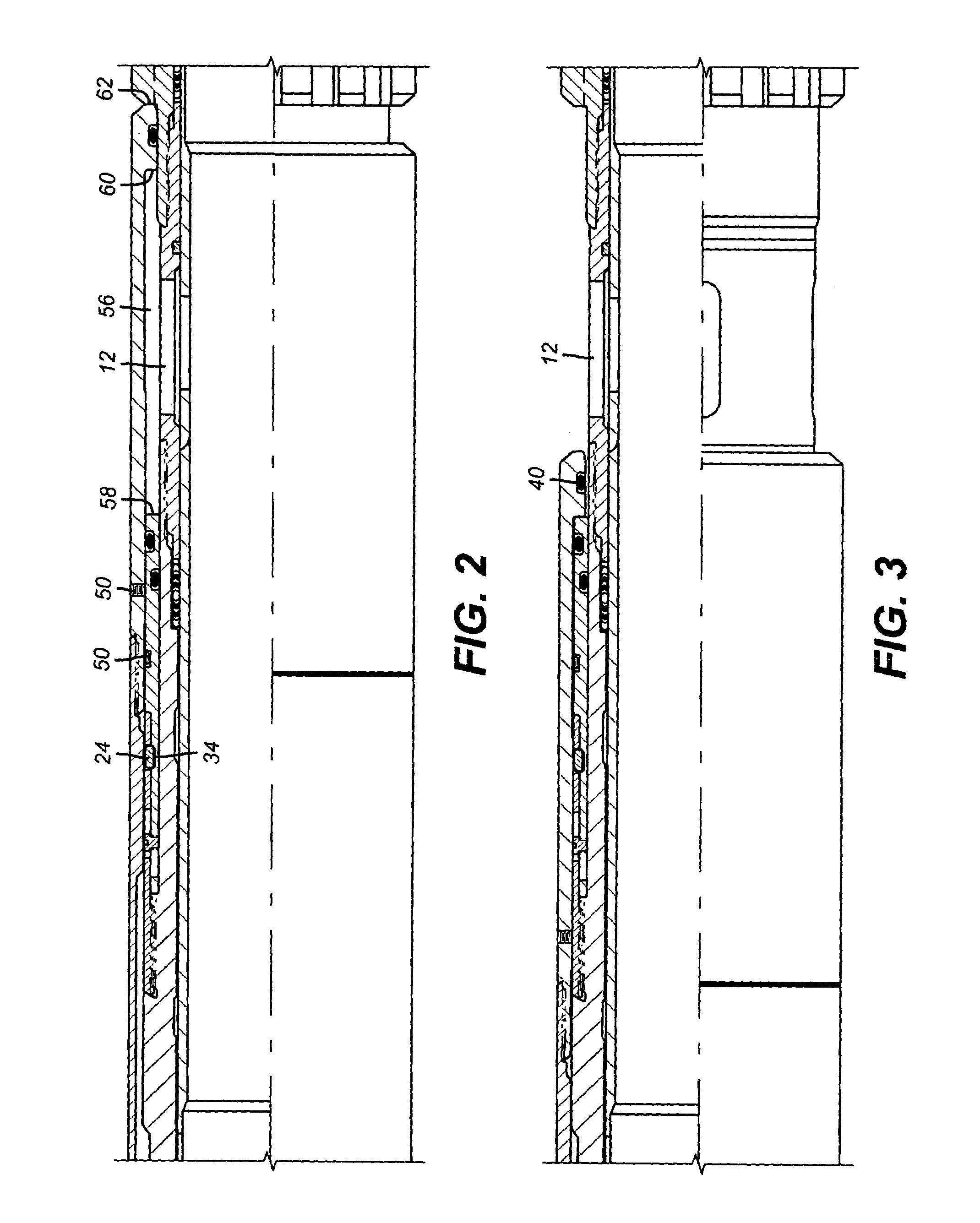

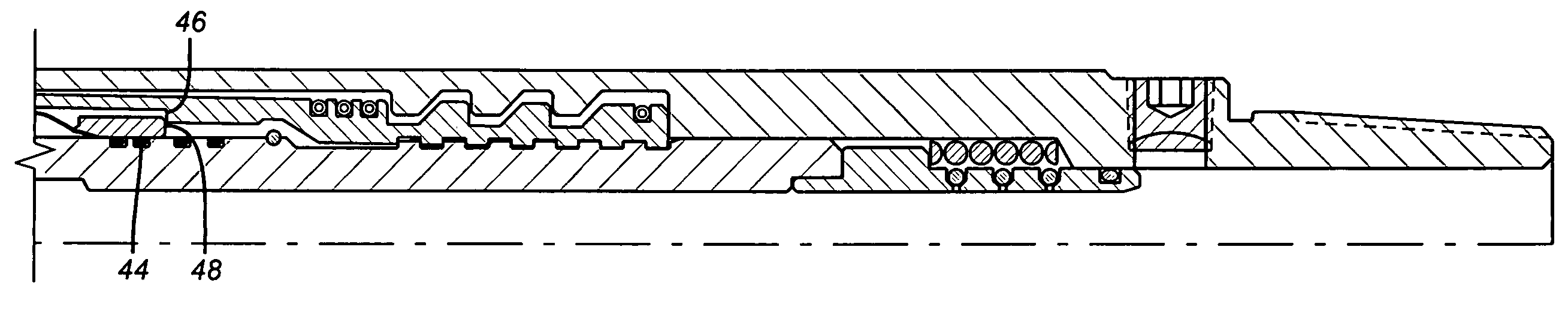

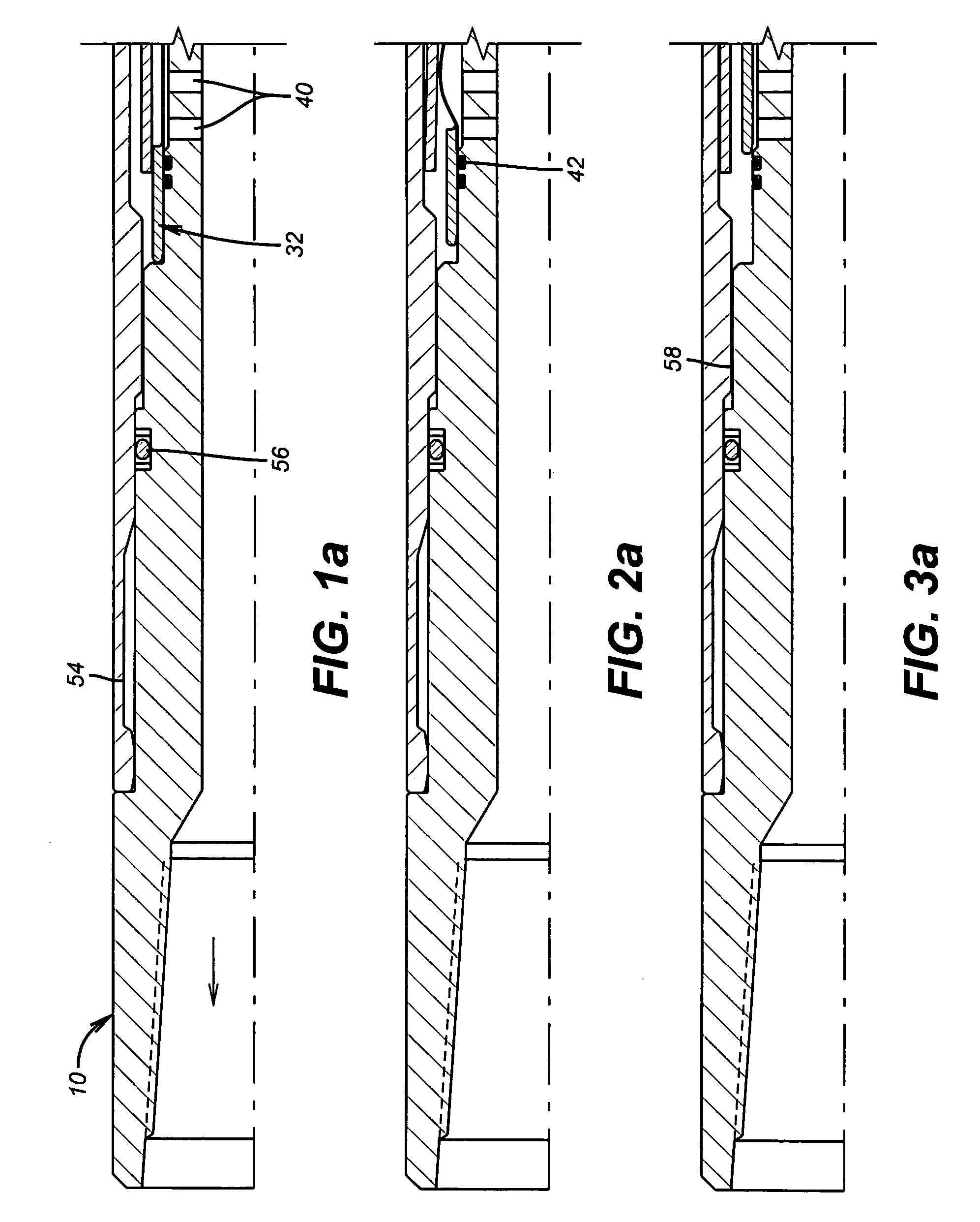

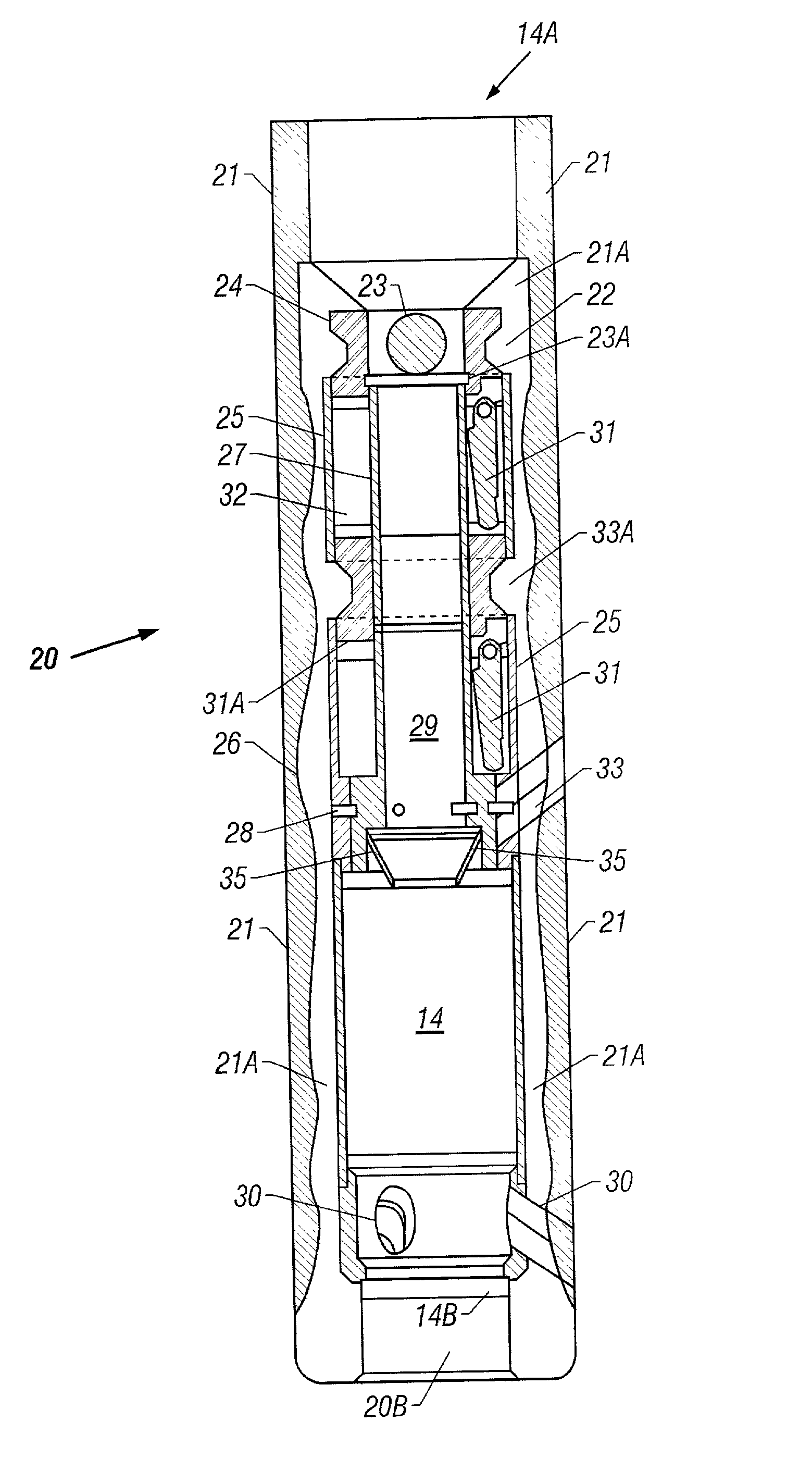

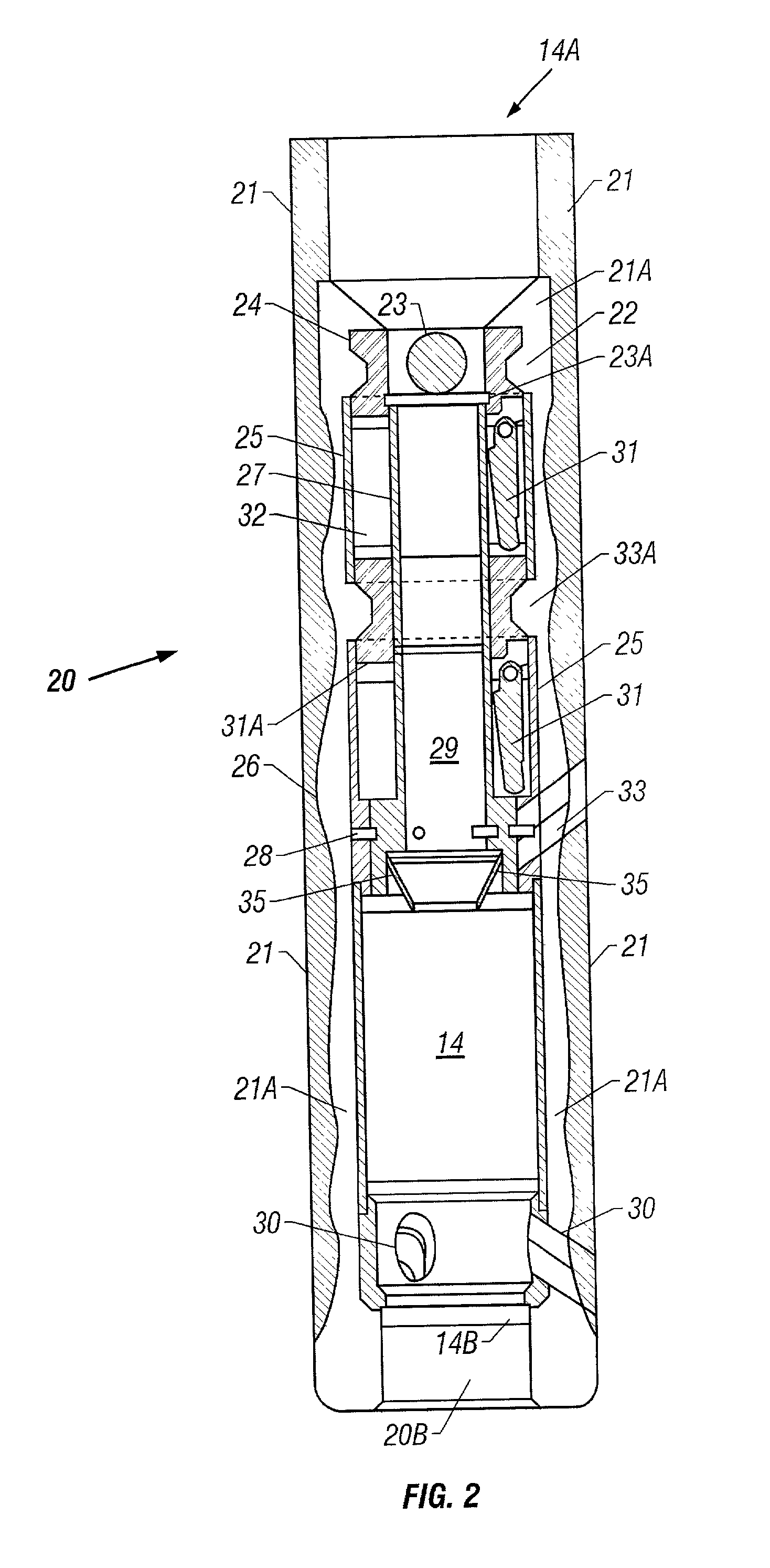

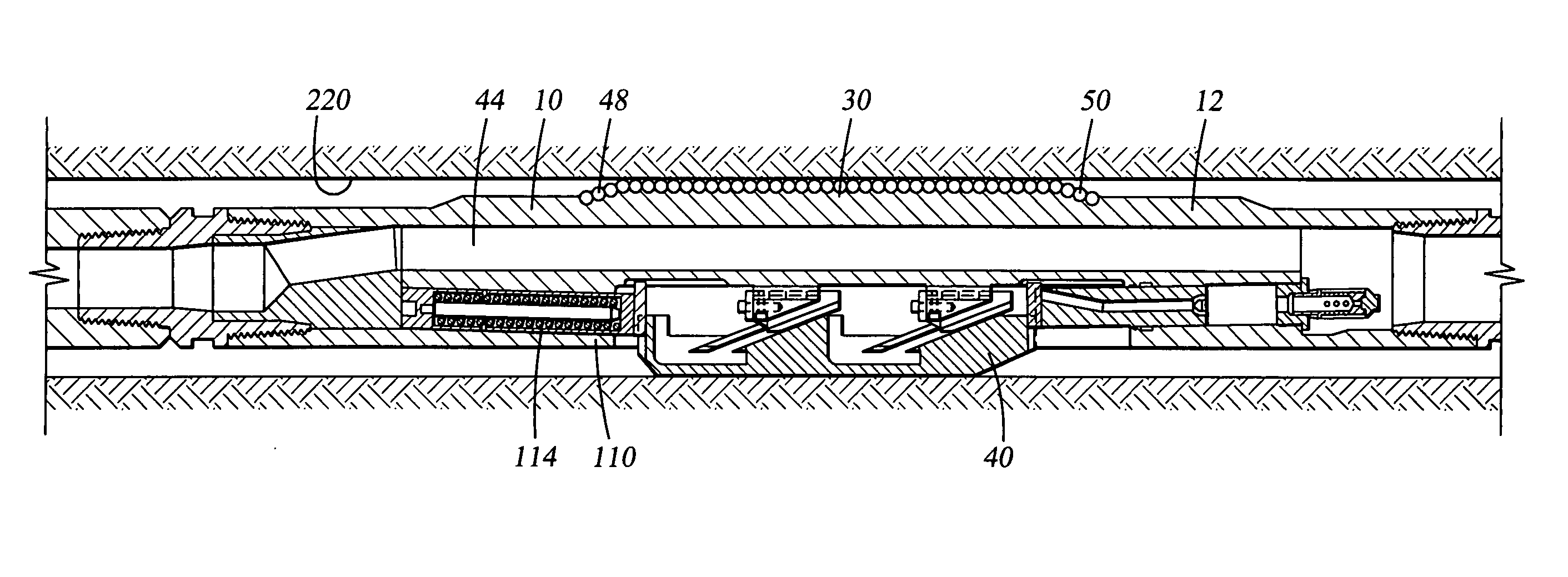

Multi-purpose float equipment and method

A float shoe / collar apparatus and method is disclosed for multi-purpose use in running a tubular string such as a casing string or liner into a wellbore and for optimizing cementing operations. In one presently preferred embodiment, the present invention permits auto filling of the tubular string as the string is lowered into the wellbore. If desired, circulation can be effected through down jets for washing the wellbore as necessary. After the tubular string is positioned, the down jets can be blocked off and up jets opened to thereby direct cement upwardly to optimize cement placement. Check valves can also be activated in accord with the present invention to prevent flow from the wellbore into the tubular string. In one embodiment, the invention comprises an inner member and tubular member. The inner member is movable upon release of shear pins to cause longitudinal movement relative to the outer member. The movement of the inner member may close a plurality of downward jets and may also open a plurality of upward jets, if desired. The apparatus may also be equipped with a set of check valves which can be held open on run in, and subsequently activated to thereby automatically close upon cementing to prevent "u-tubing" of fluid back into the casing. In another embodiment a float collar comprises the same valve / valves as the float shoe, without jets. This float collar may be run in conjunction with a guide shoe, with or without jets.

Owner:FORUM US

Medical knife assembly and method of using same

InactiveUS6852117B2Preventing and at least greatly reducing flow of bloodPrecise positioningSurgical veterinaryObstetrical instrumentsEngineeringUmbilical cord

A medical knife assembly includes an outer clamp assembly and an inner clamp blade assembly having a cutting blade assembly. The inner and outer clamp assemblies are pivotally connected at about their proximate ends so they may be squeezed together with one hand to affect a novel method of clamping and cutting in a single motion operation. A set of shear pins holds the component parts of the inner and outer assemblies together in a ready position that enables a user to properly position the knife assembly for severing an umbilical cord at the time of birth. Once the umbilical cord is severed, the component parts of the inner and outer assemblies separate providing independent clamps, one staying with an infant segment of the umbilical cord and one staying with a maternal segment of the umbilical cord. The two independent clamps operate to clamp the umbilical cord on both sides of the cutting blade assembly thereby preventing or at least greatly

Owner:MEDICAL DEVICES GROUP

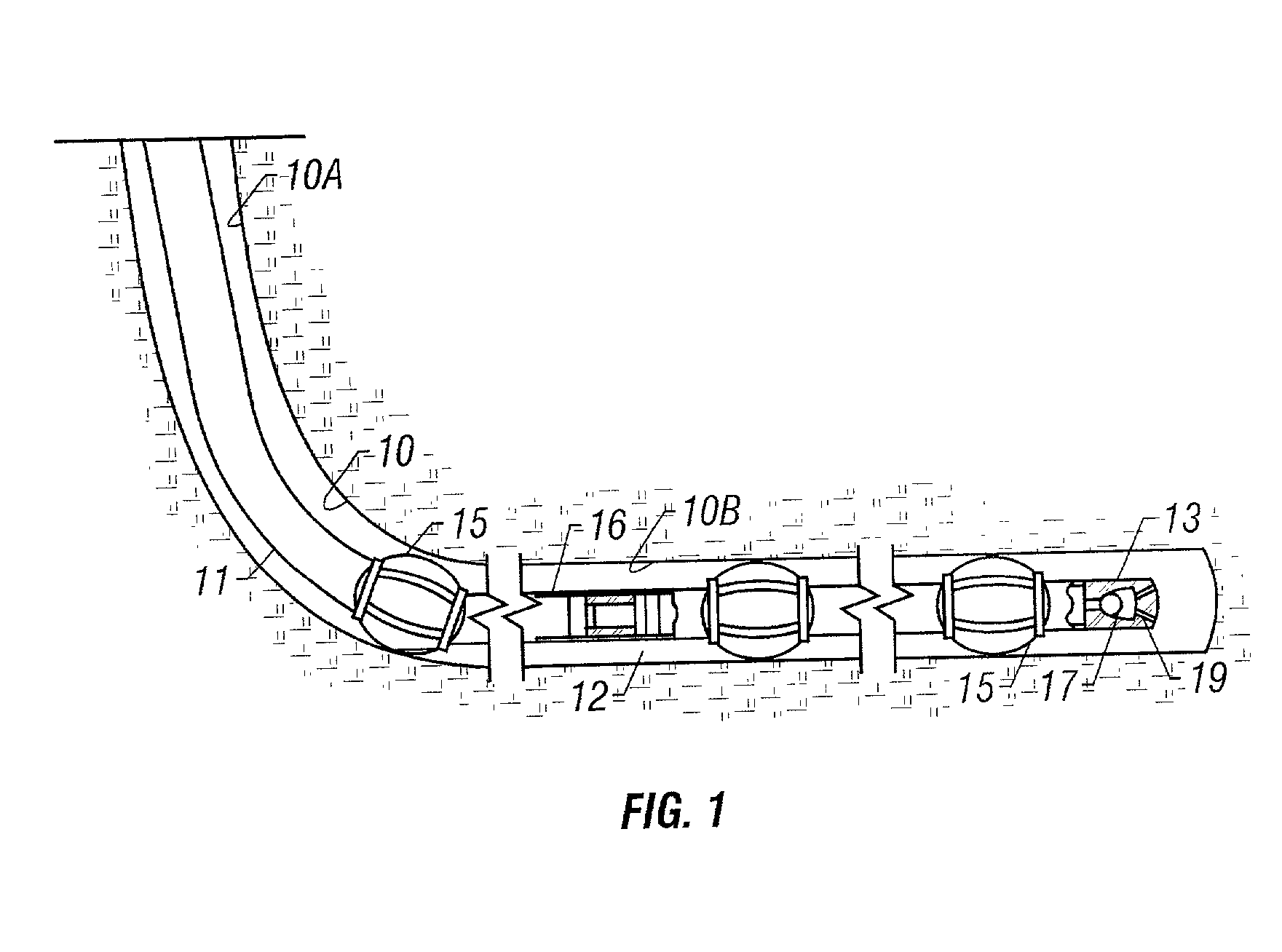

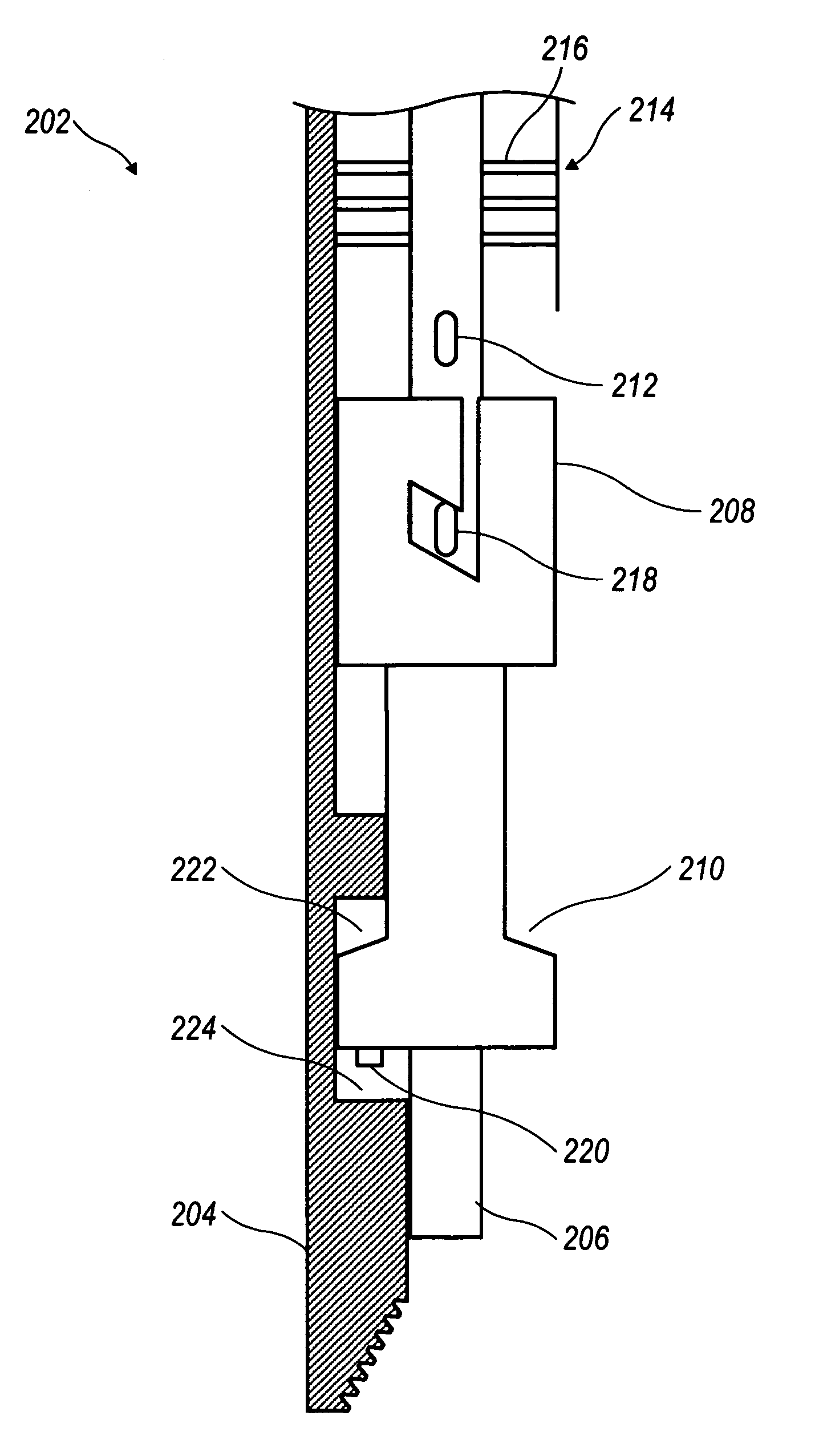

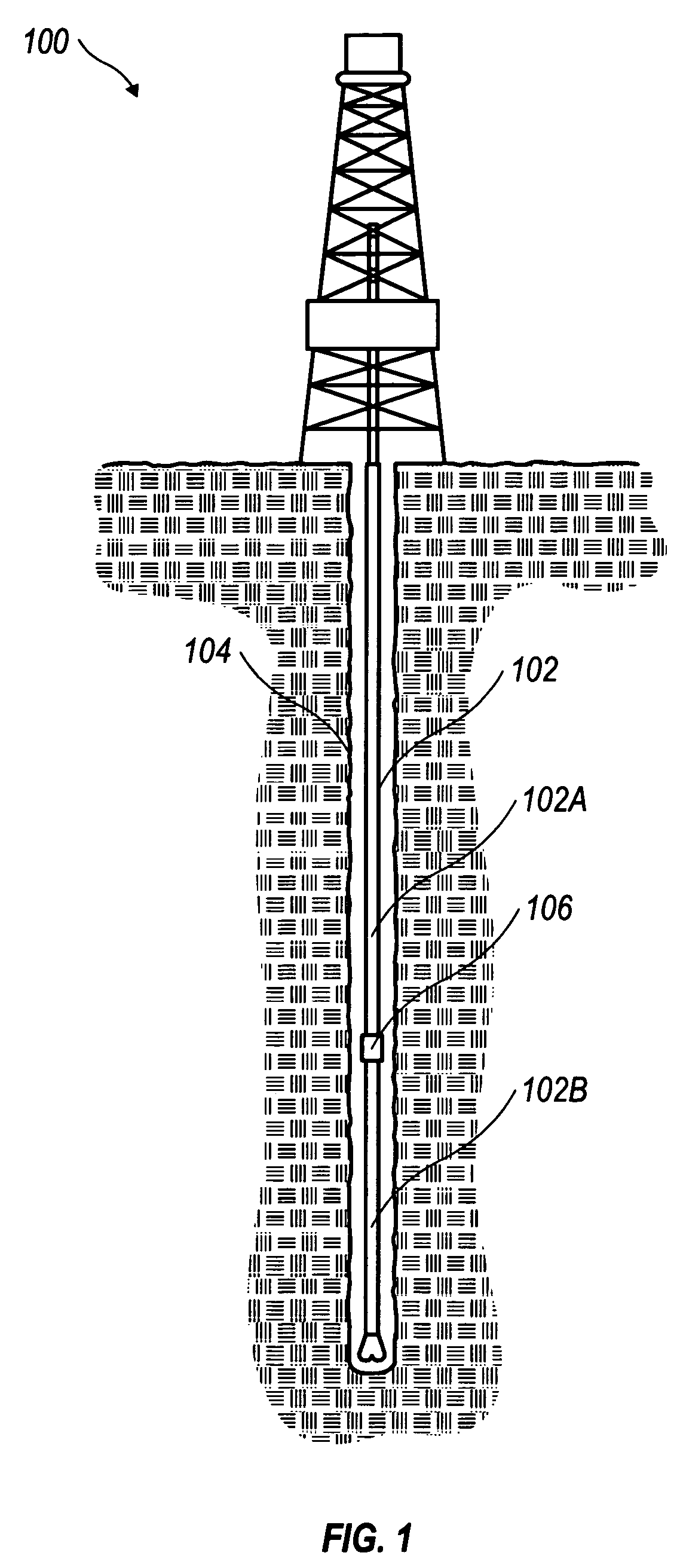

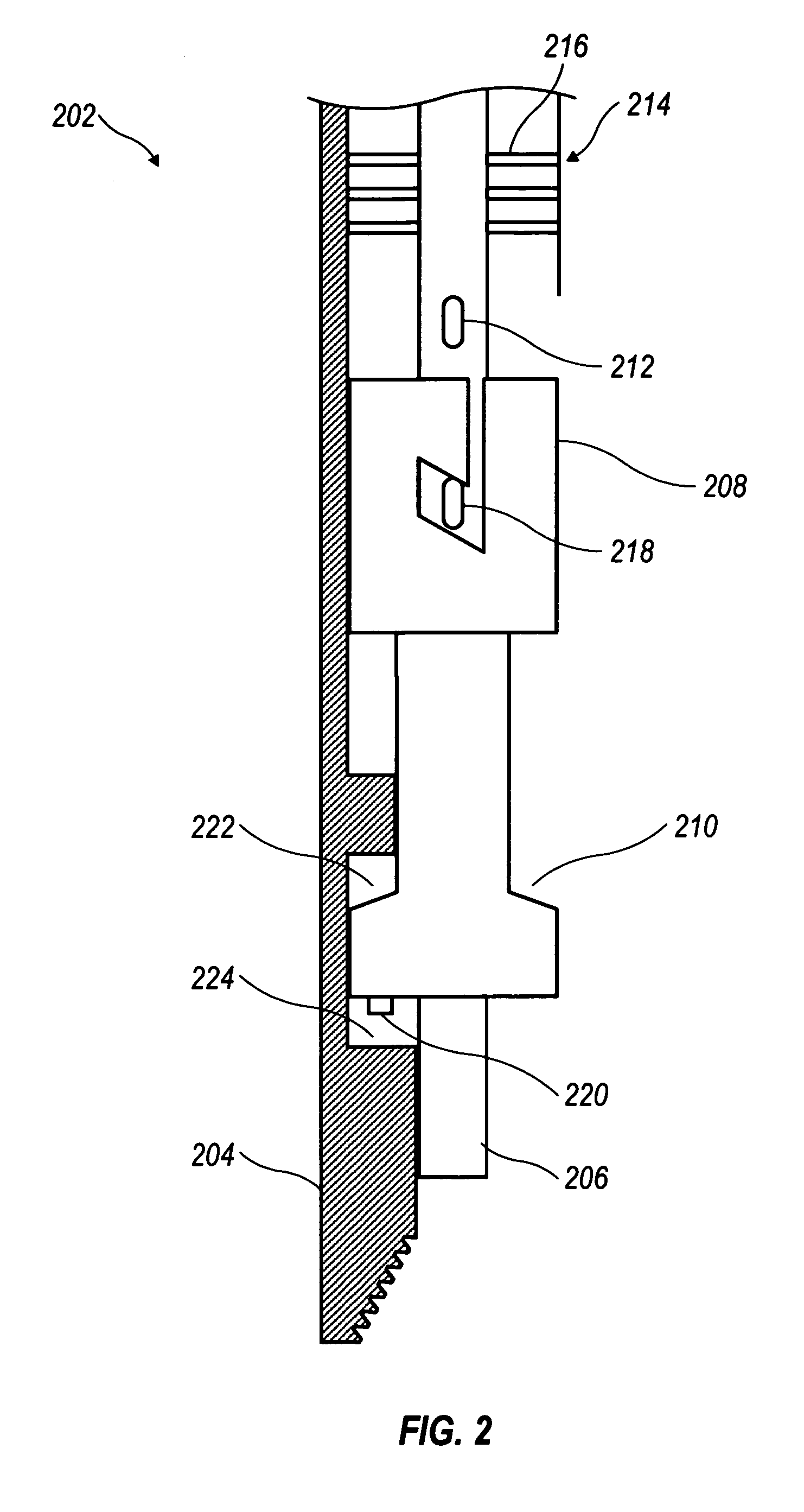

Apparatus and method for drilling and reaming a borehole

A drilling assembly and an eccentric, adjustable diameter reamer are disclosed. The reamer includes cutter elements mounted on at least a first fixed blade for reaming a previously-formed borehole or for forming a borehole of increased diameter beneath an existing cased borehole. The method and apparatus provide for stabilizing the drilling assembly so that the reamer may be used in back reaming the hole. Retainer means, such as shear pins or spring-biased reciprocating latch members, are provided to prevent premature extension of the reamer's moveable members, including blades and pistons. The shear pins are preferably accessible from the outer surface of the reamer housing so as to expedite field replacement of the shear pins without requiring disassembly of the reamer. The spring-biased latching members repeatedly latch and unlatch so that field replacement is not required, and so that the movable members may be extended and contracted multiple times while the reamer is downhole.

Owner:HALLIBURTON ENERGY SERVICES INC

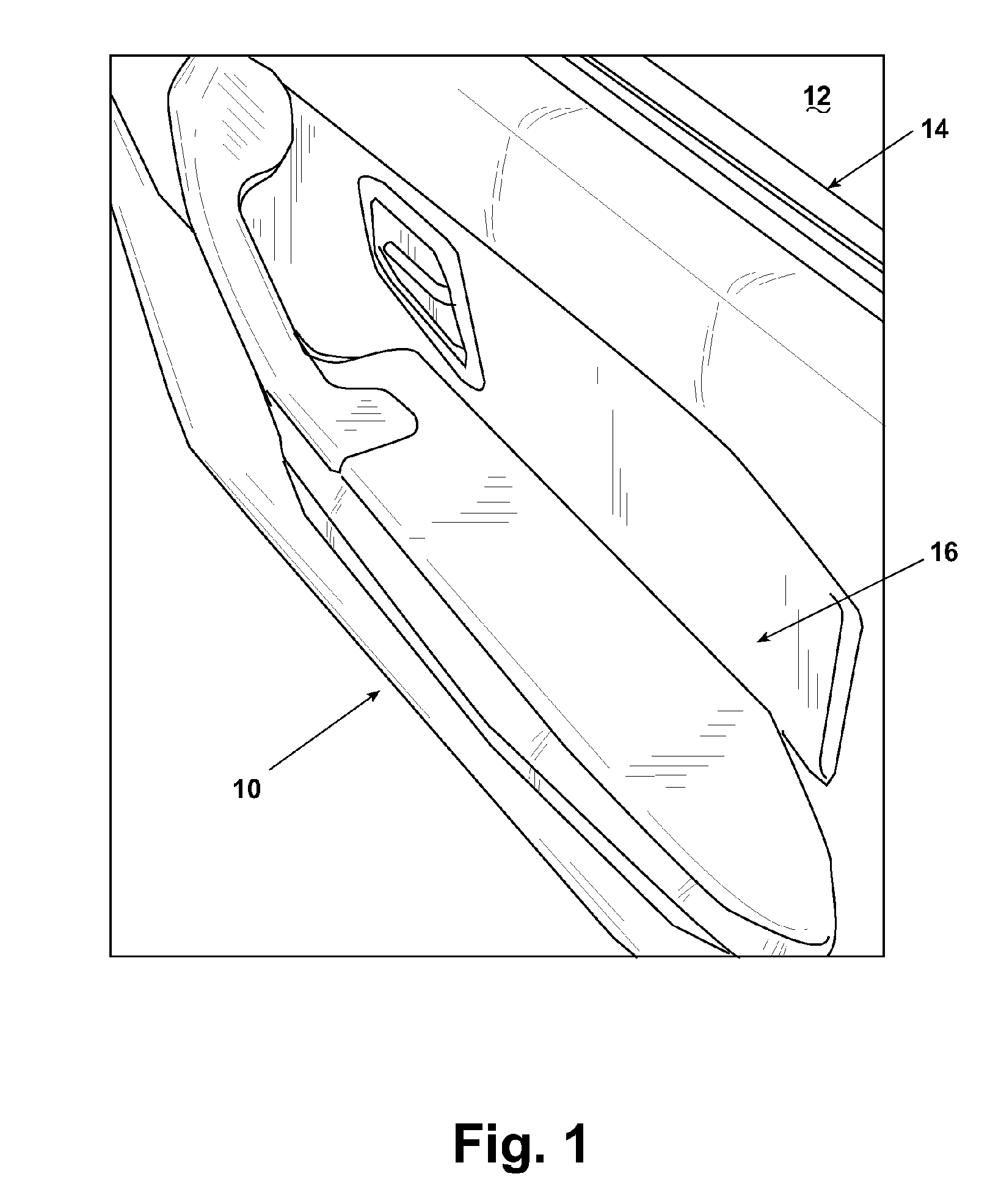

Armrest with side impact resistance feature

Owner:LEON INTERIORS INC CO ACR II MOTUS INTEGRATED TECH COOPERATIEF U A

Downhole packer tool with safety systems for preventing undue set and release operations

ActiveUS20120160523A1Simple andNot to hamper and impede tool movementFluid removalSealing/packingEngineeringActuator

A packer tool has safety devices to prevent premature and reverse setting and release operations. The safety devices are independent of shear-pin safety systems. Confined annular segments prevent a setting actuator piston from moving absent tool-setting hydraulic pressure. The setting pressure first moves a cylinder in an opposite direction to unroof the segments allowing them to exit confinement and free the piston to set the packing and the anchor slips. Release safety pins extend radially inward from a packing-holder collar into short slots formed on a mandrel surface, preventing the mandrel from being turned. Previous set motion causes the pins to leave the slots thereby freeing the mandrel to turn only after the tool has been set. A third safety device comprises an expanded ring which is dragged by the release cone during release motion until it lodges in a circumferential groove in the mandrel, locking against reverse movement.

Owner:TEXPROIL S R L SUCURSAL COLOMBIA

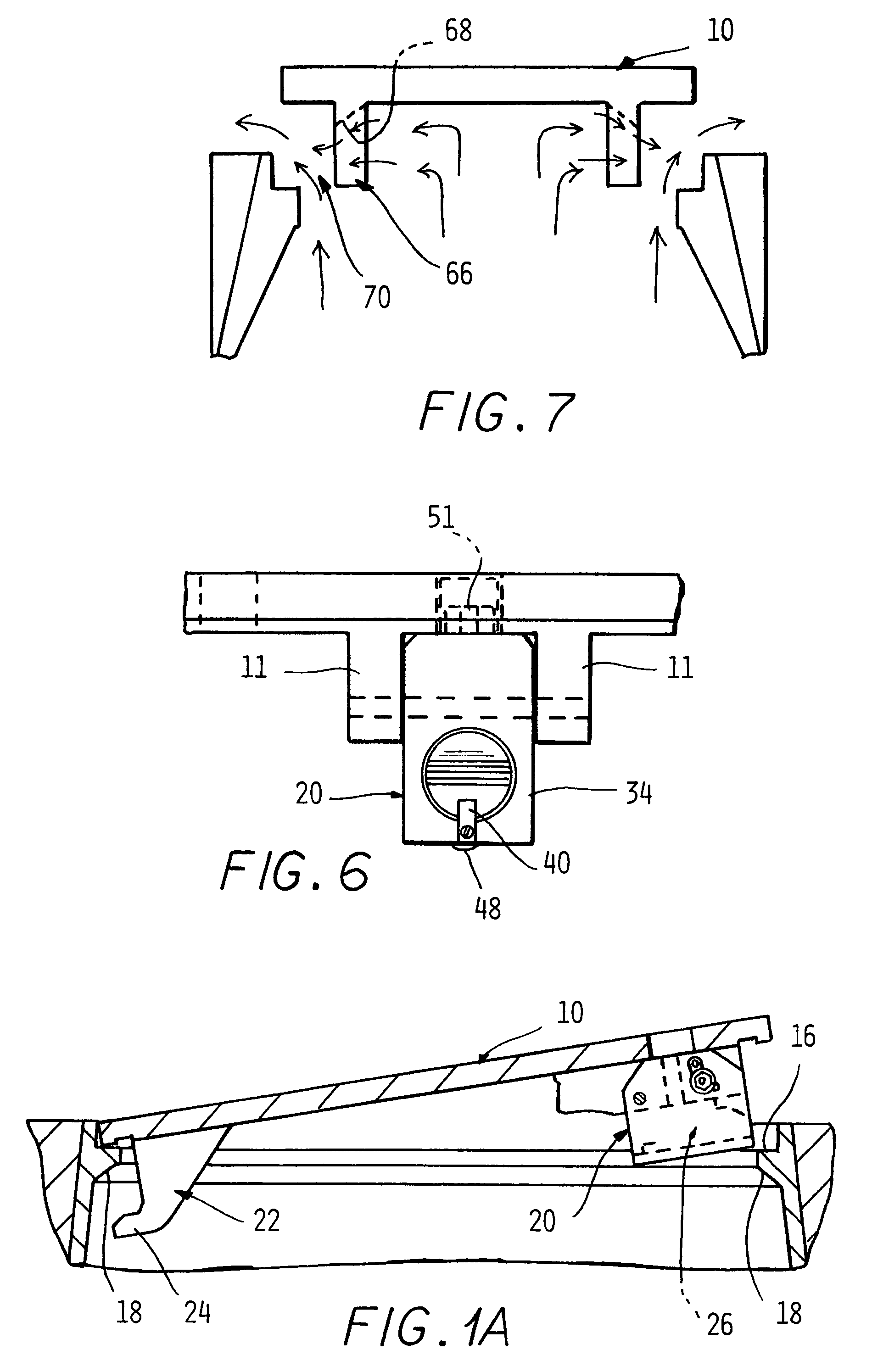

Manhole cover security lock with controlled pressure release

ActiveUS7484908B2Preventing the manhole cover from being blownOptimized areaBuilding roofsArtificial islandsEngineeringShear pin

A controllably releasable security locking arrangement for a manhole cover allows a manhole cover to be locked into position but allows the manhole cover to rise up in stages upon development of upward forces in an explosion to vent gases developed by the explosion. A lock body mounts a latch slide which has an outer end and which can be extended to prevent removal of the manhole cover. When a shear pin fails the lock body pivots down, to a limited extent, and a secondary shear pin can also be included allowing the cover to be blown completely free upon development of pressures of a great magnitude. A slotted skirt directs venting gas flow so as to retard the inflow of free air and attenuate the explosion.

Owner:NEENAH FOUNDRY

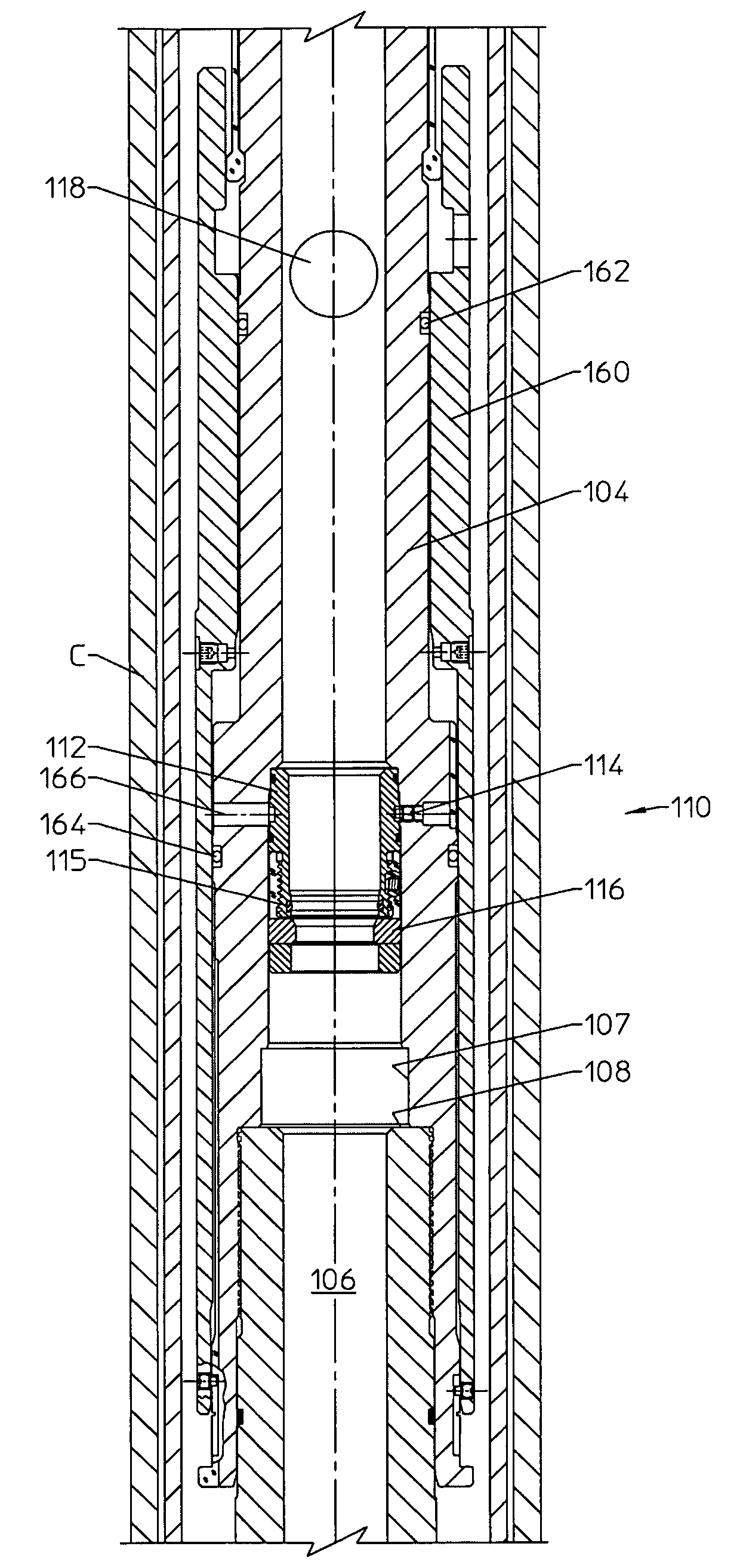

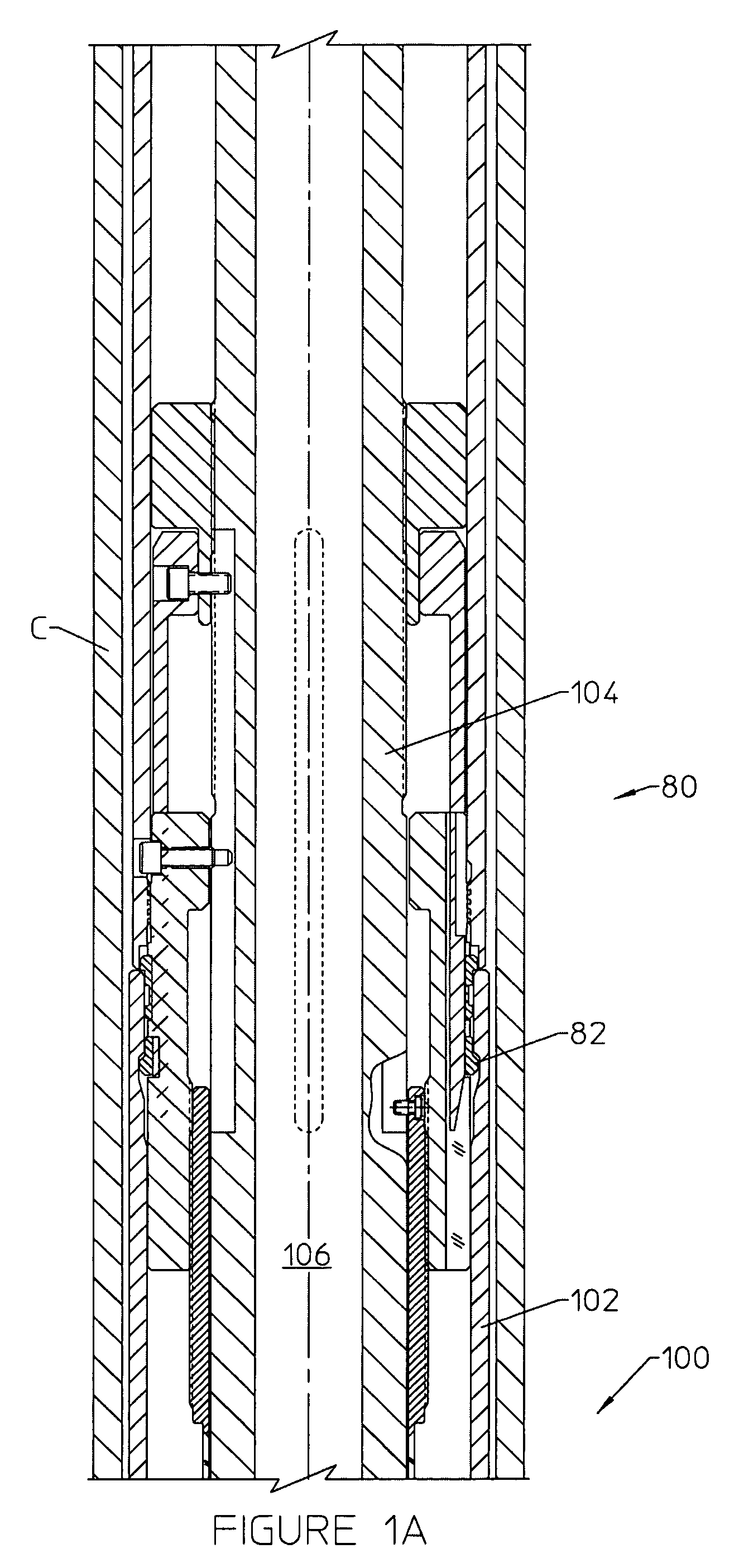

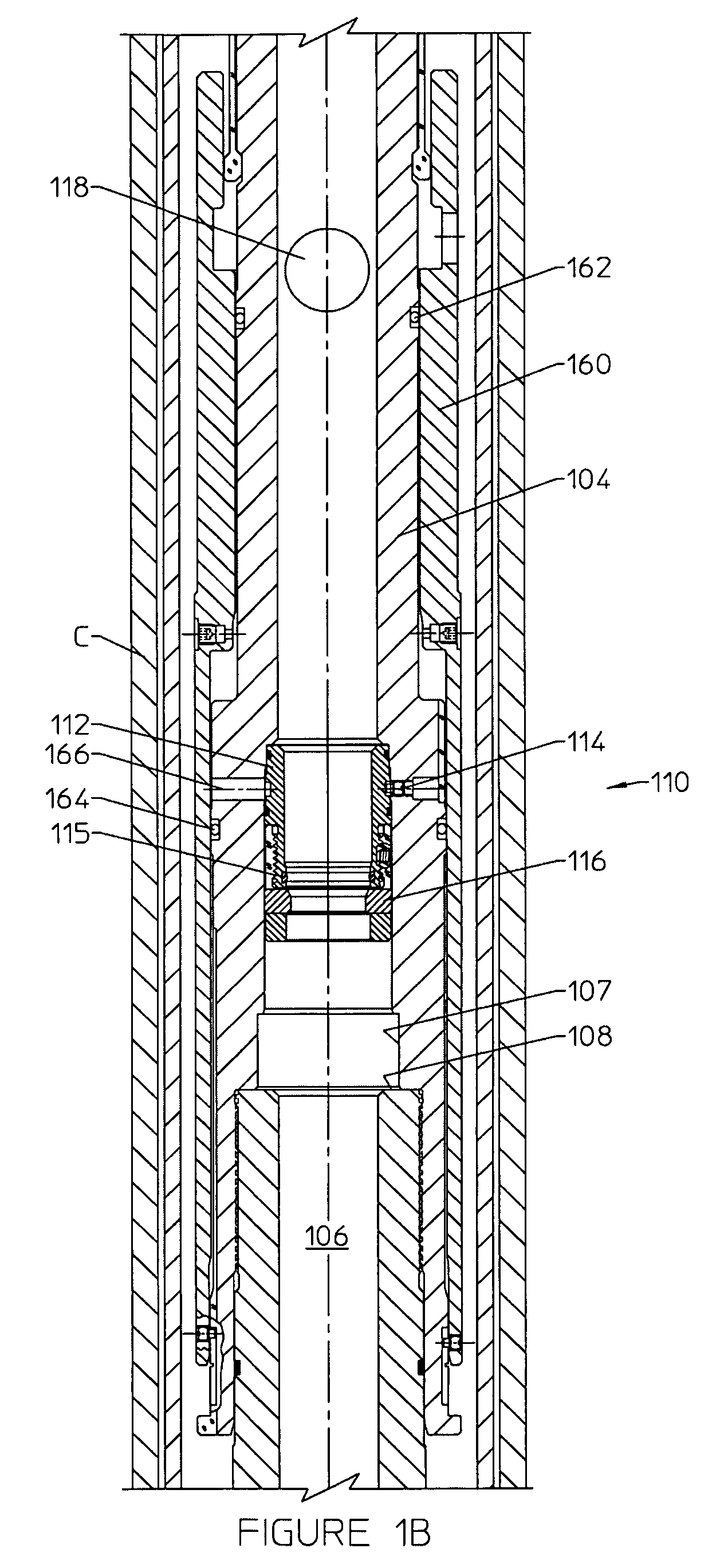

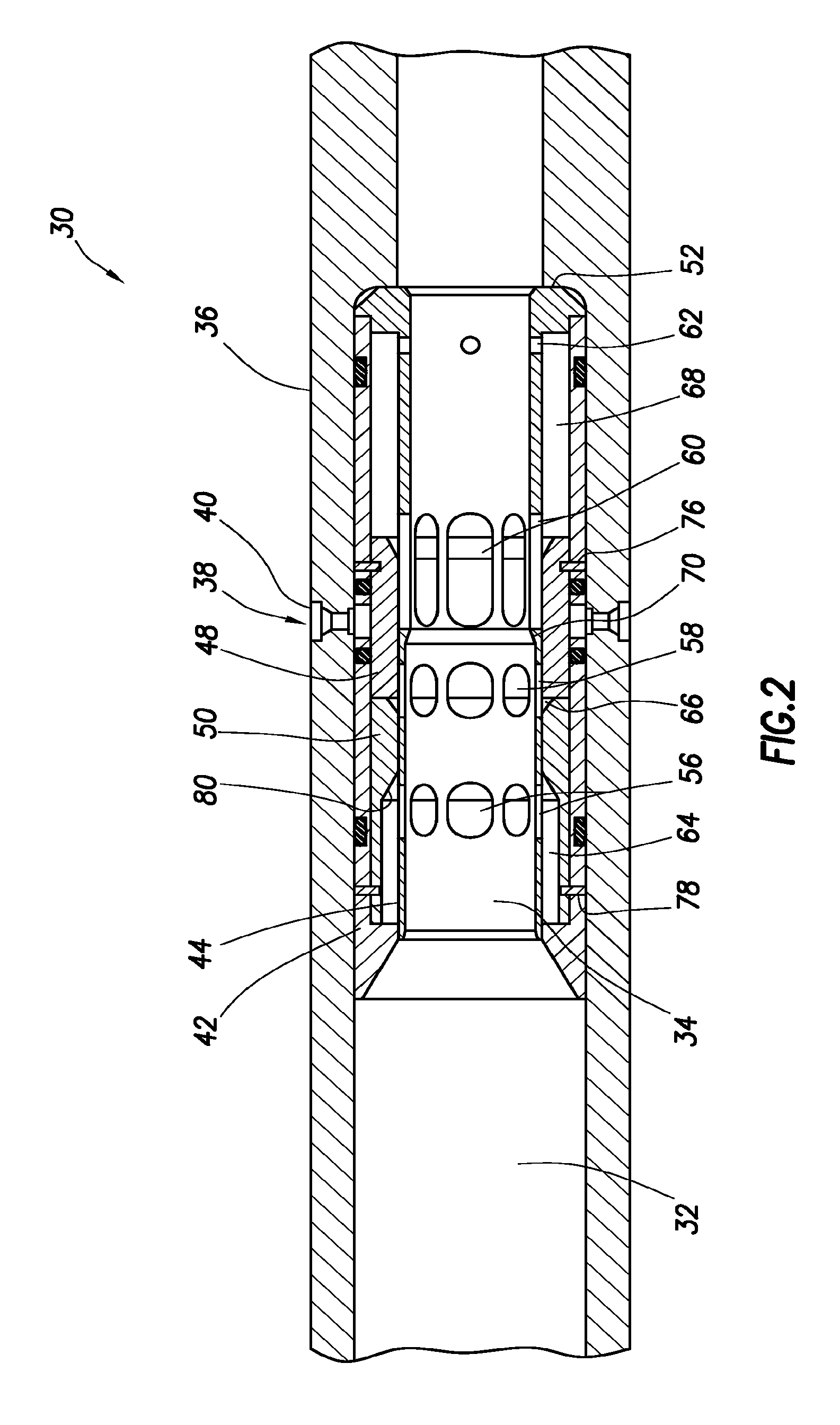

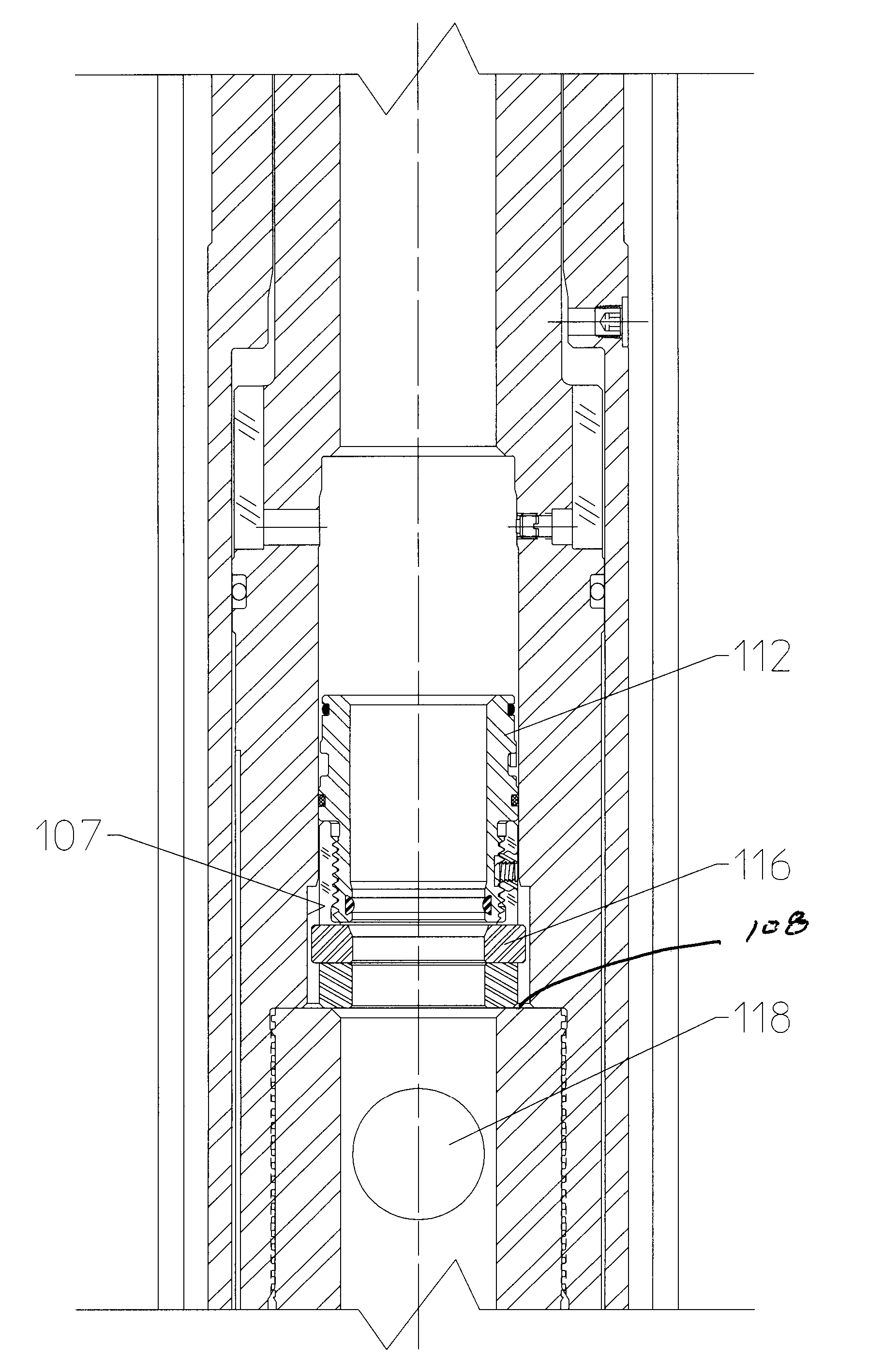

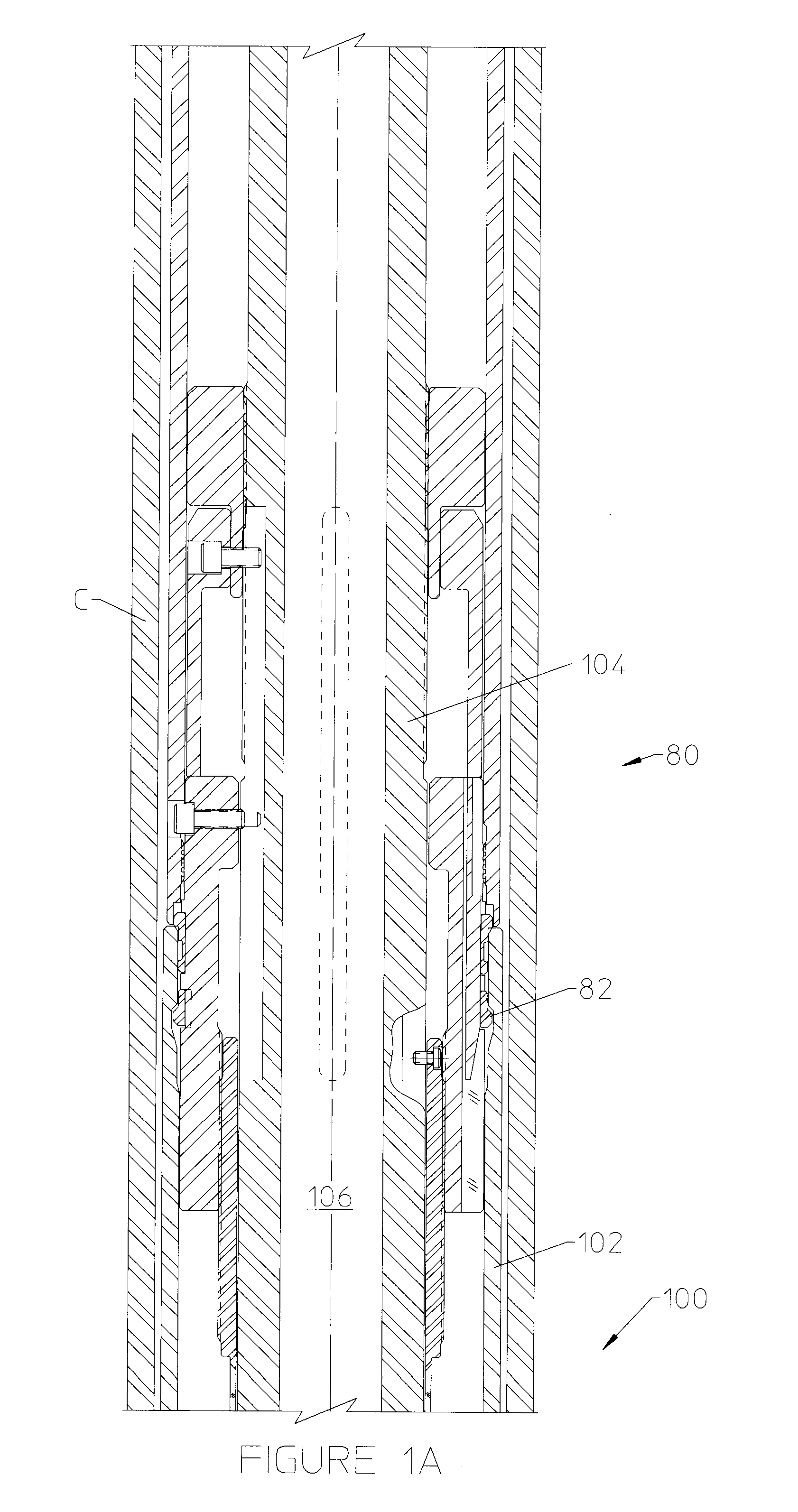

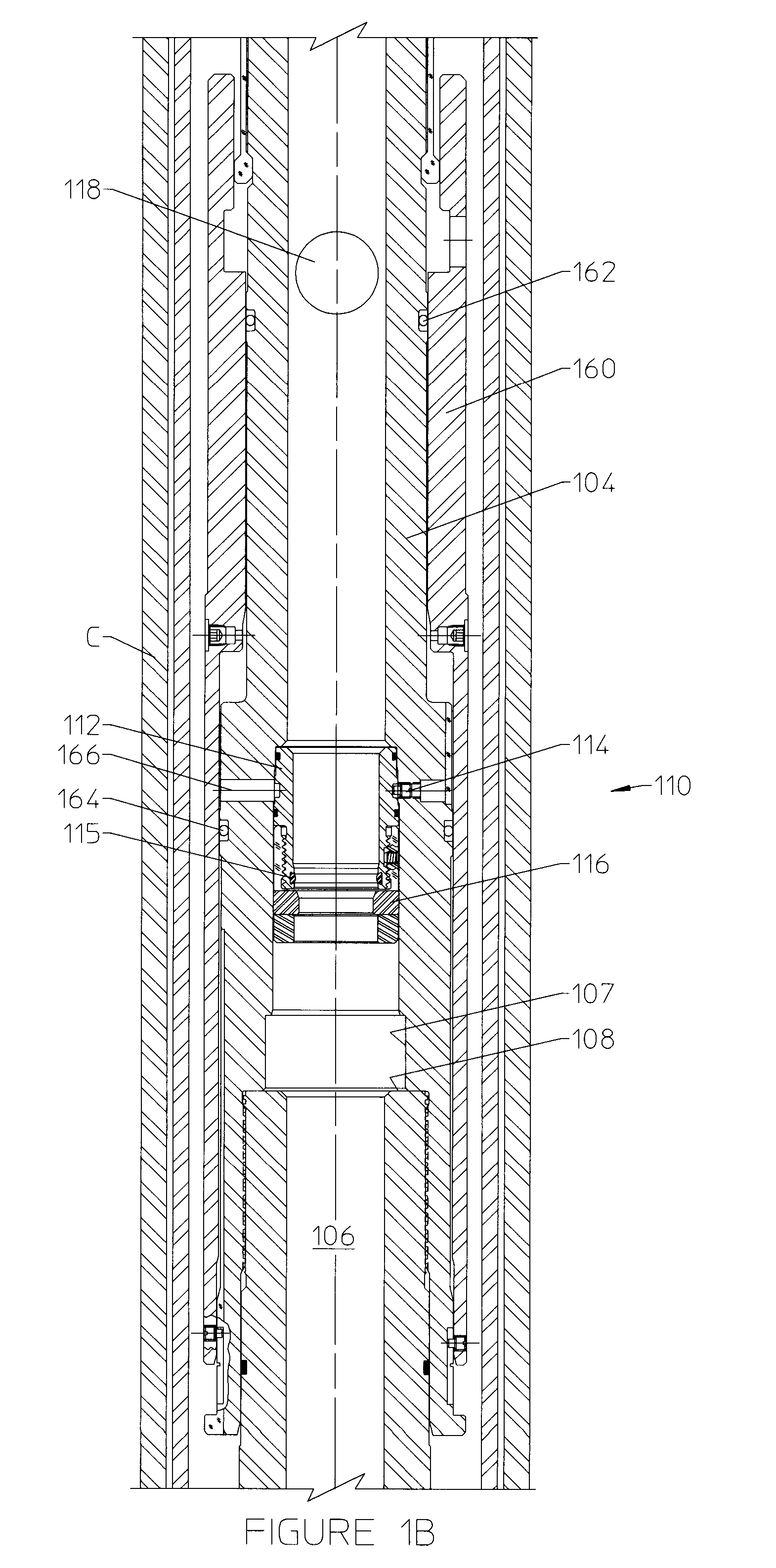

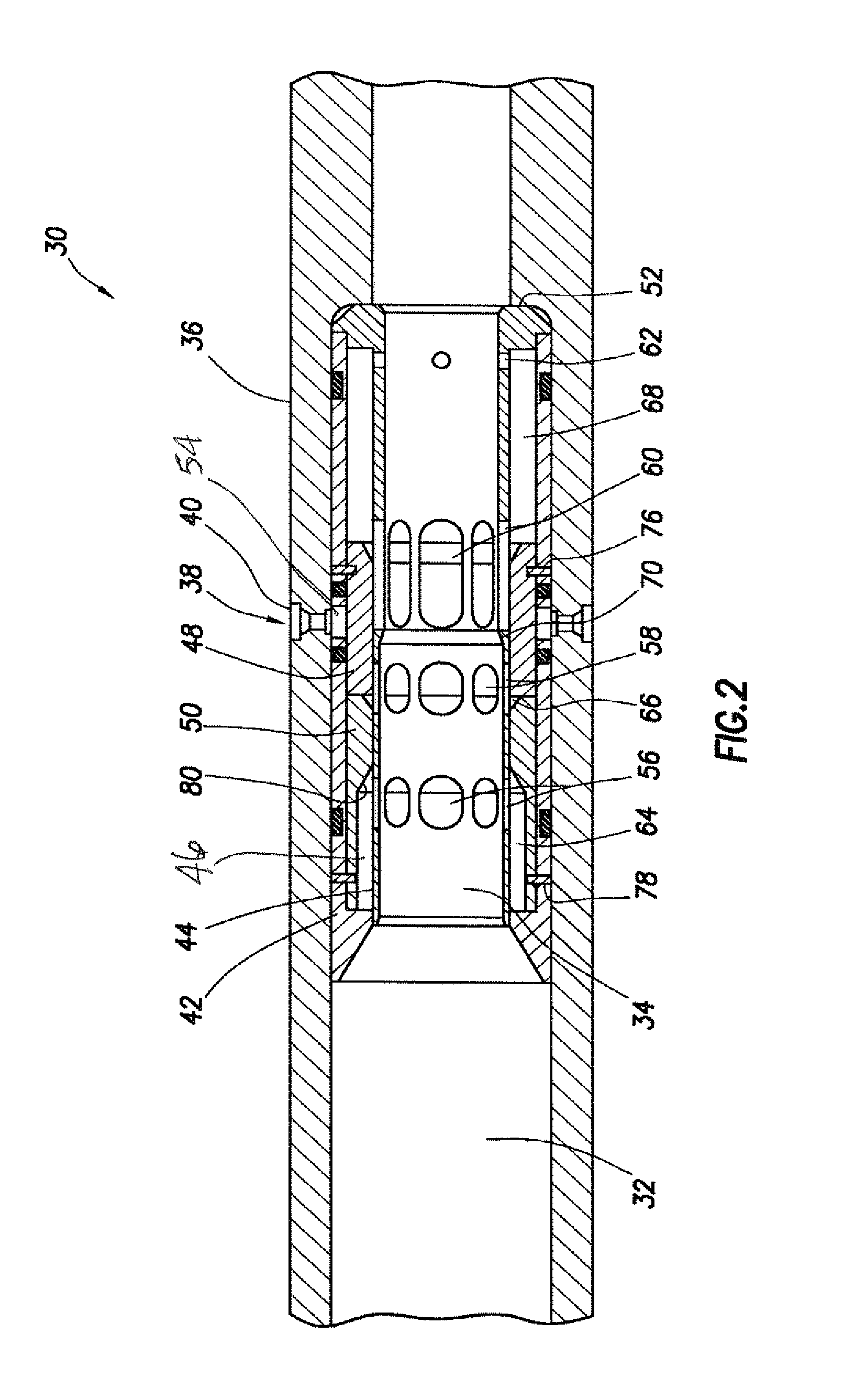

Downhole tool with C-ring closure seat and method

A downhole tool 100 includes a closure seat 116, 176 for seating with a closure, such as a ball. Shear pins or other connectors temporarily limit axial movement of the closure seat which is initially housed within a restricted diameter portion of the central throughbore in the tool body. The closure seat may be lowered to engage a stop 108, 157, thereby positioning the seat within an enlarged diameter bore portion of the tool and allowing radial expansion of a closure seat to release the ball.

Owner:DRIL QUIP

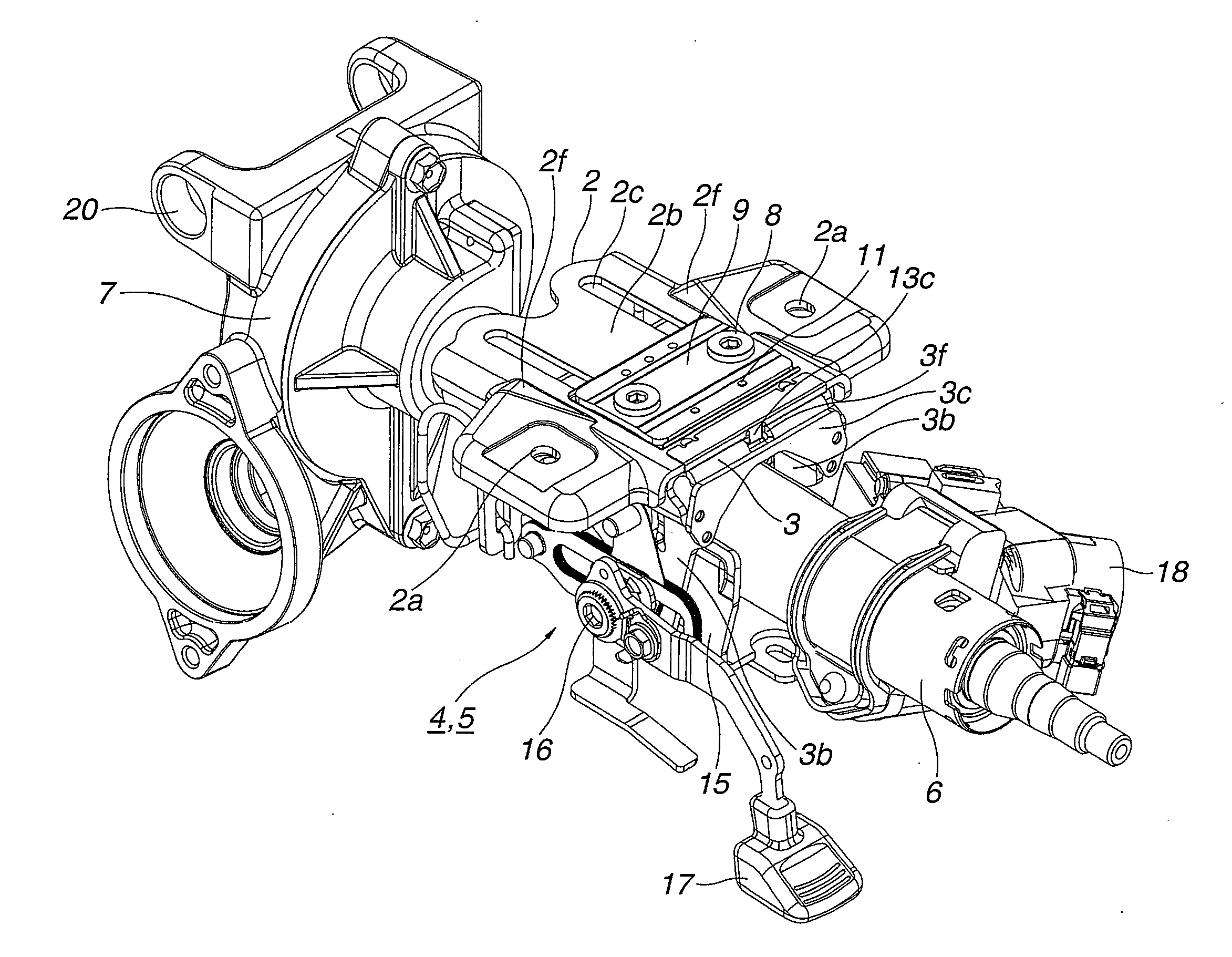

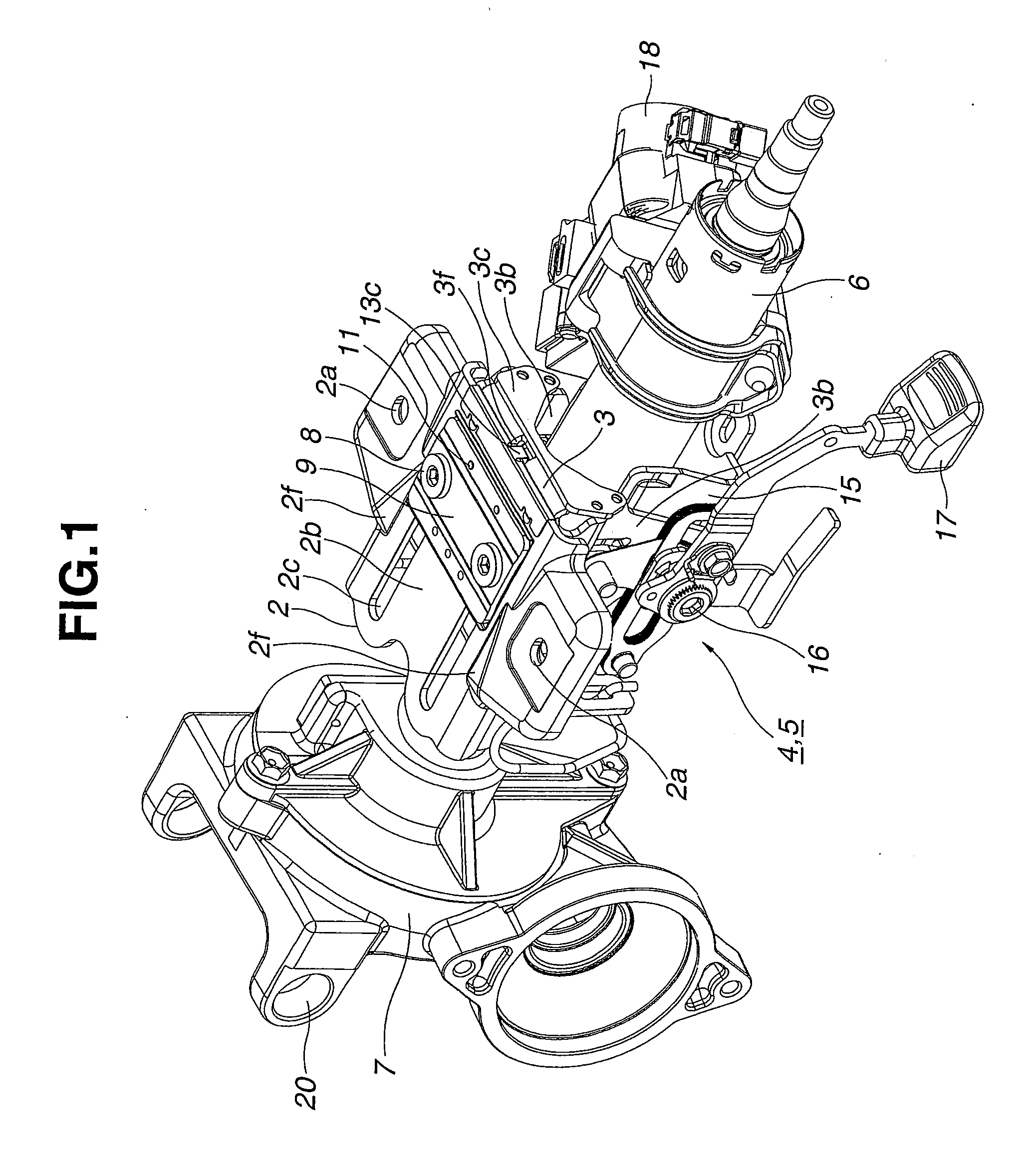

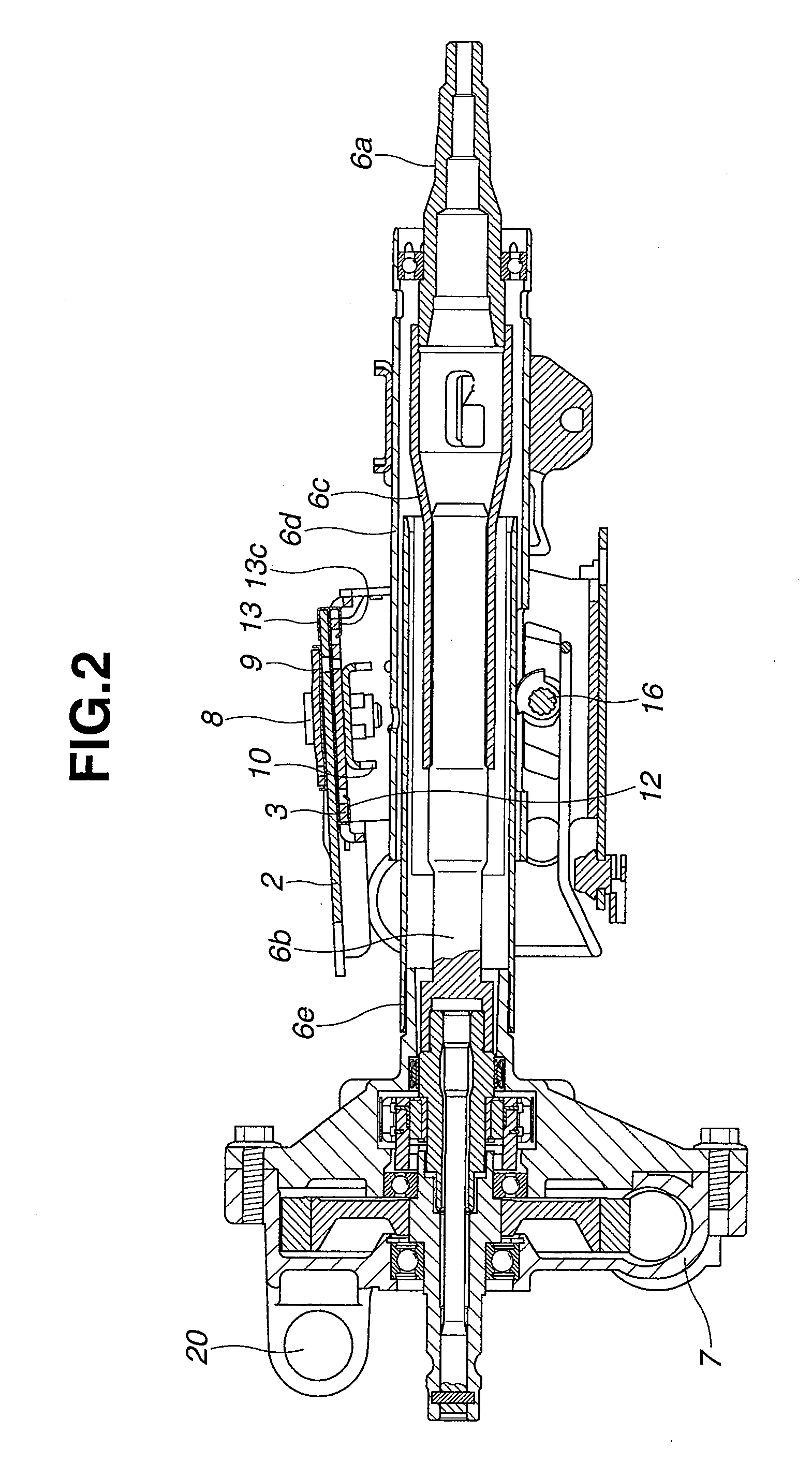

Steering column apparatus

A steering column apparatus has a fixed bracket fixed to a vehicle body and having a pair of long holes extending parallel to each other along a backward-and-forward direction; a movable bracket arranged movably in the backward-and-forward direction; a pair of bolts and a pair of nuts for fixing the movable bracket to a rear portion of the fixed bracket so that the movable bracket can move in the backward-and-forward direction with respect to the fixed bracket; a spring plate having pressing portions for holding the movable bracket at the rear portion of the fixed bracket by pressing the fixed bracket against the movable bracket; a shear pin connecting the fixed bracket and the movable bracket at the rear portion of the fixed bracket; and first and second low friction elements. Upon a secondary collision, the movable bracket smoothly moves toward a vehicle front side together with the spring plate.

Owner:JTEKT CORP +1

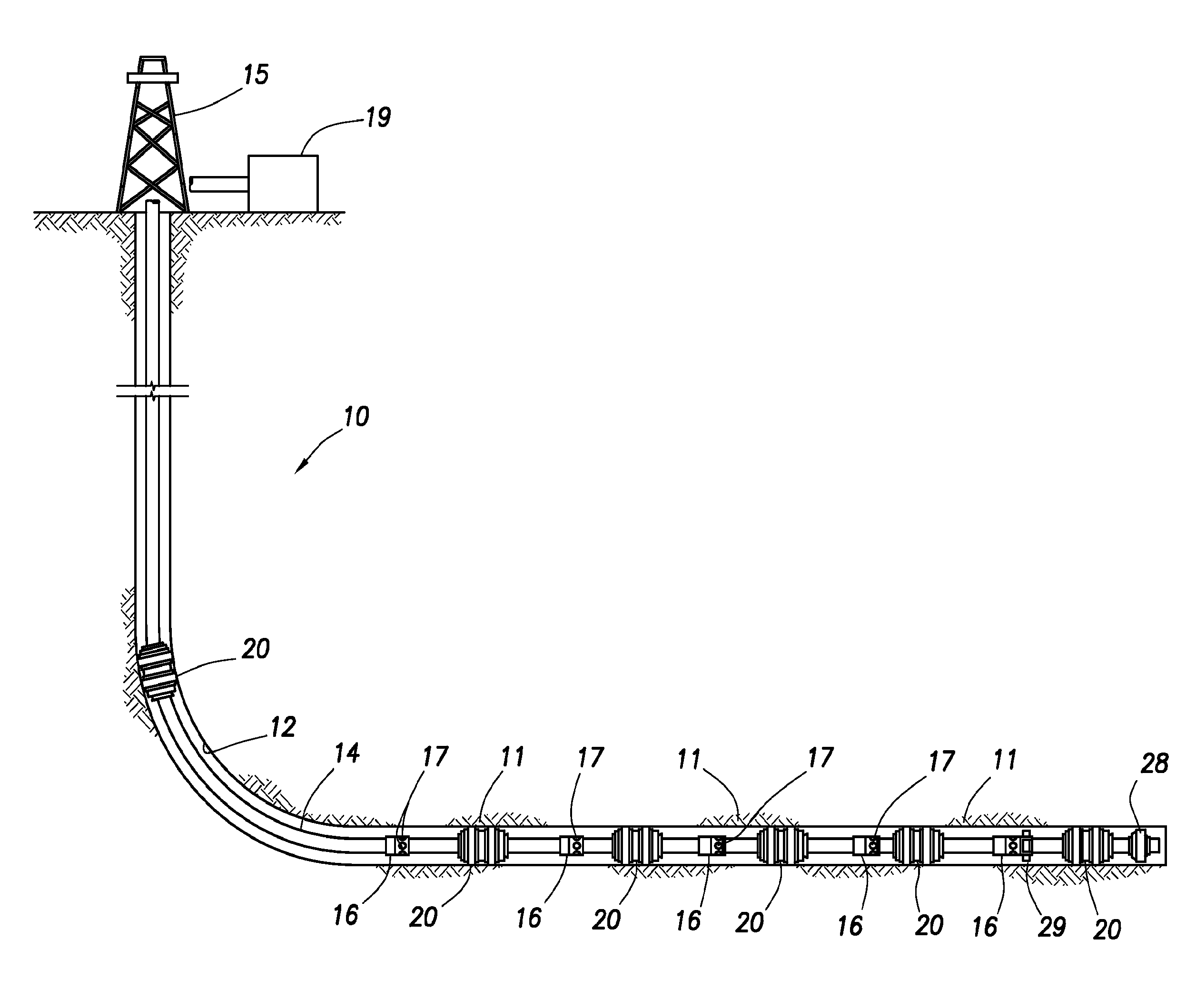

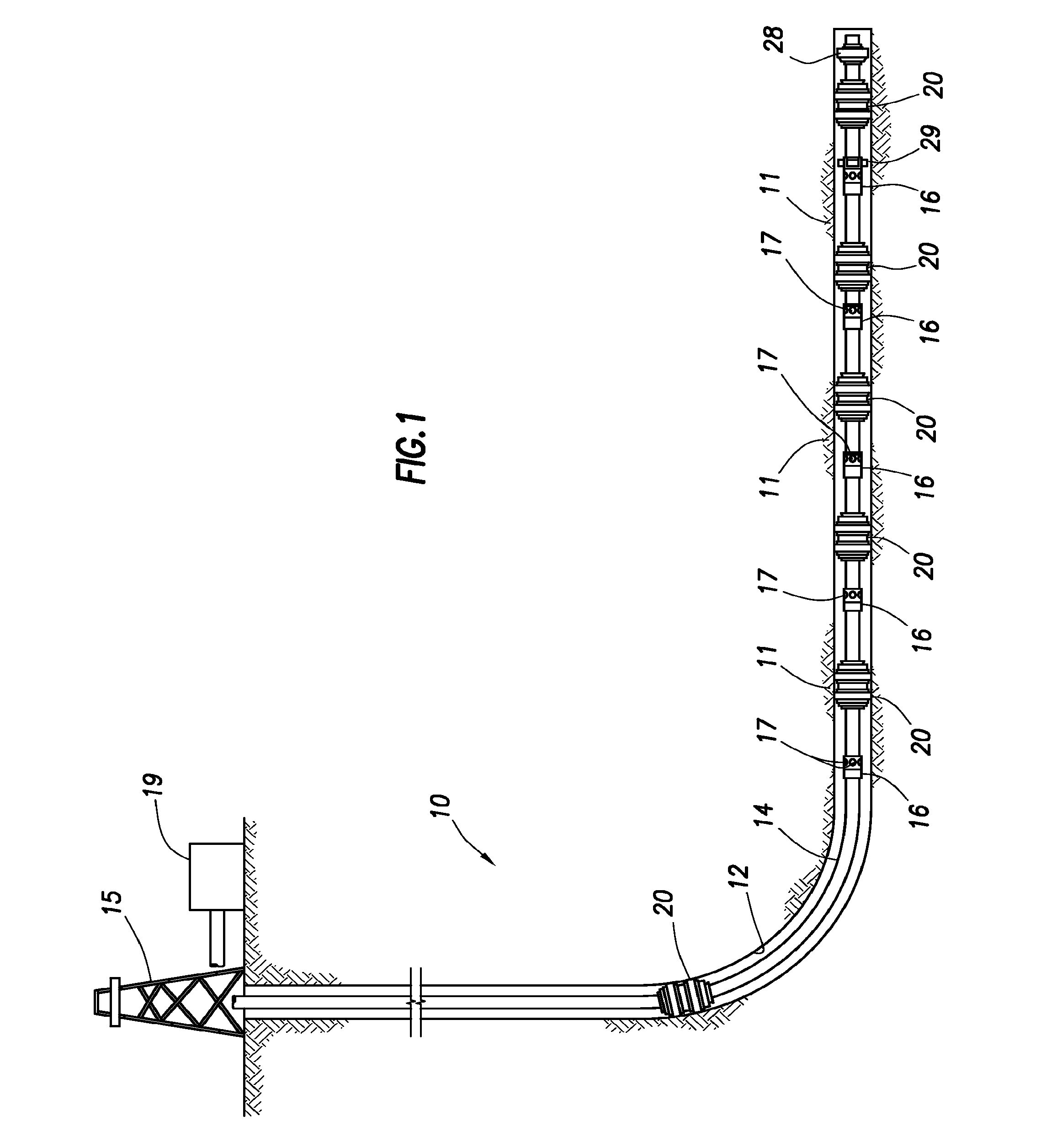

Sliding sleeve bypass valve for well treatment

InactiveUS20140262312A1Without riskReduce positioningConstructionsFluid removalDifferential pressureEngineering

A downhole bypass valve utilizes a stationary sleeve defining an interior ball-seat. When a dropped ball is seated, fluid differential pressure is diverted to an annular area adjacent a first sliding sleeve. The sleeve slides in response to the pressure differential upon shearing of a shear pin, or similar, and opens ports to the wellbore annulus. Treatment or maintenance operations can then occur through the ports, which can be fitted with nozzles. A second sliding sleeve, independent from the first, is operated in response to dropping a second ball into the device. The second ball diverts fluid differential pressure to an annular area adjacent the second sleeve and movement occurs when a shear pin shears. The second sleeve covers the ports to the wellbore annulus and closes the valve. After a sliding sleeve shifts, pressure across the sleeve is equalized, allowing reverse flow without risk of accidental sleeve actuation.

Owner:HALLIBURTON ENERGY SERVICES INC

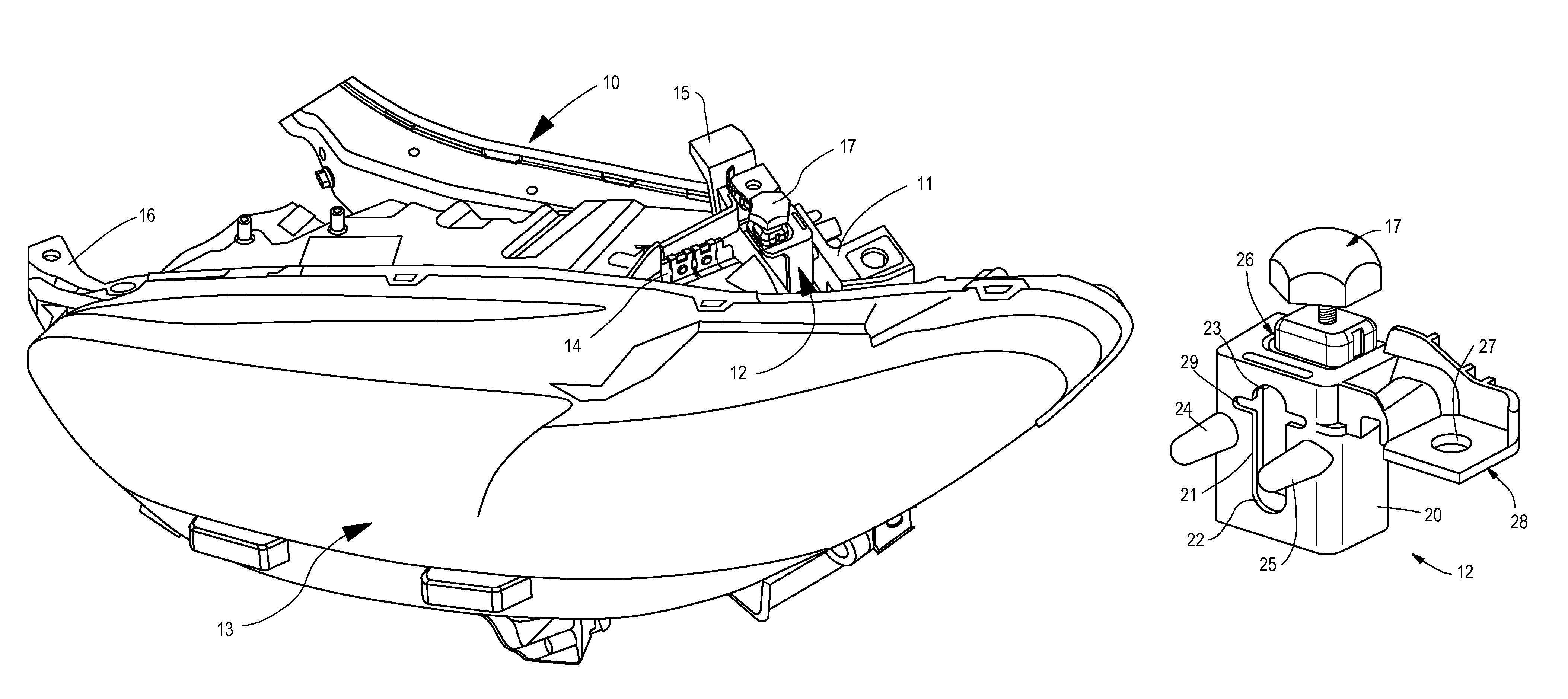

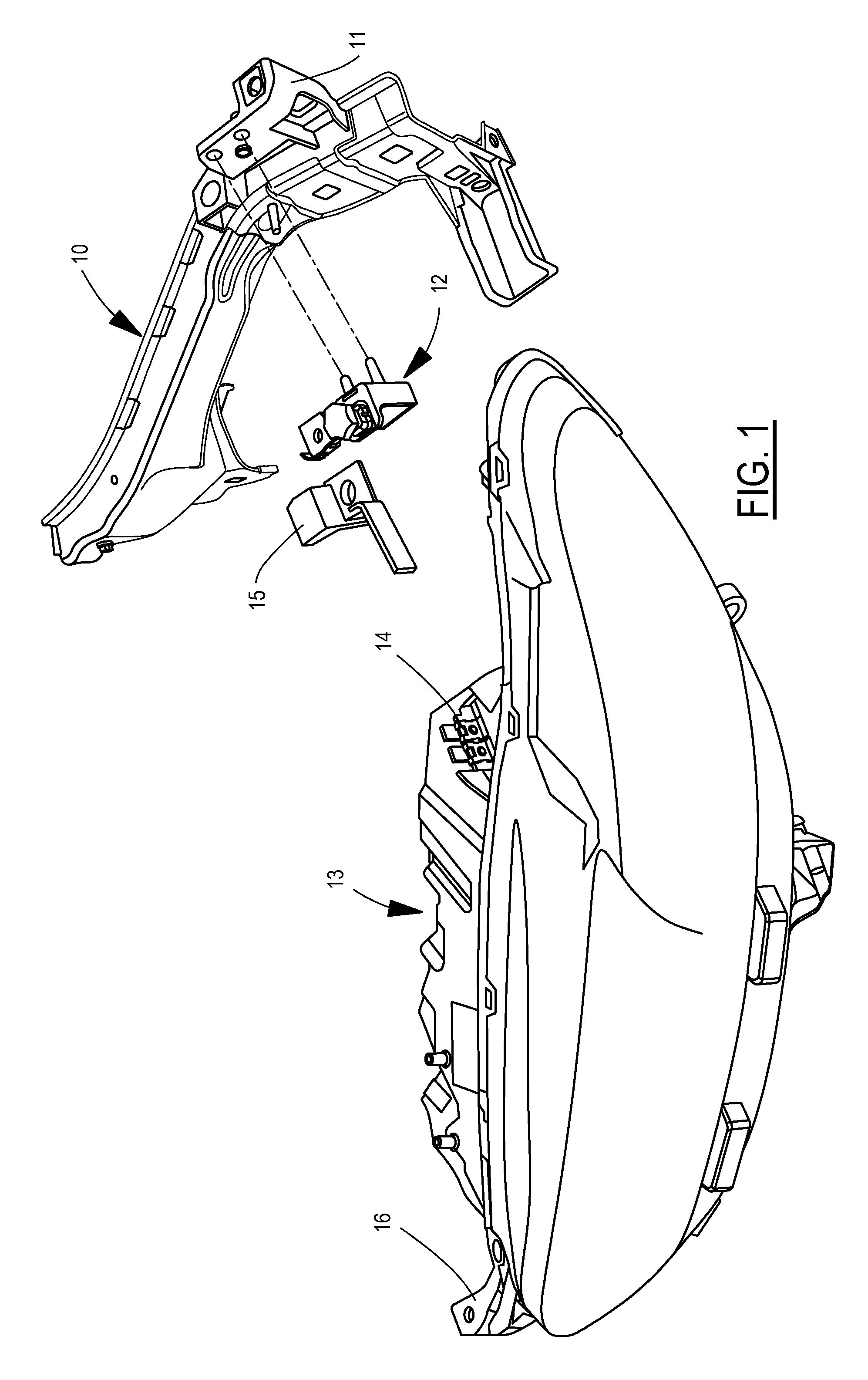

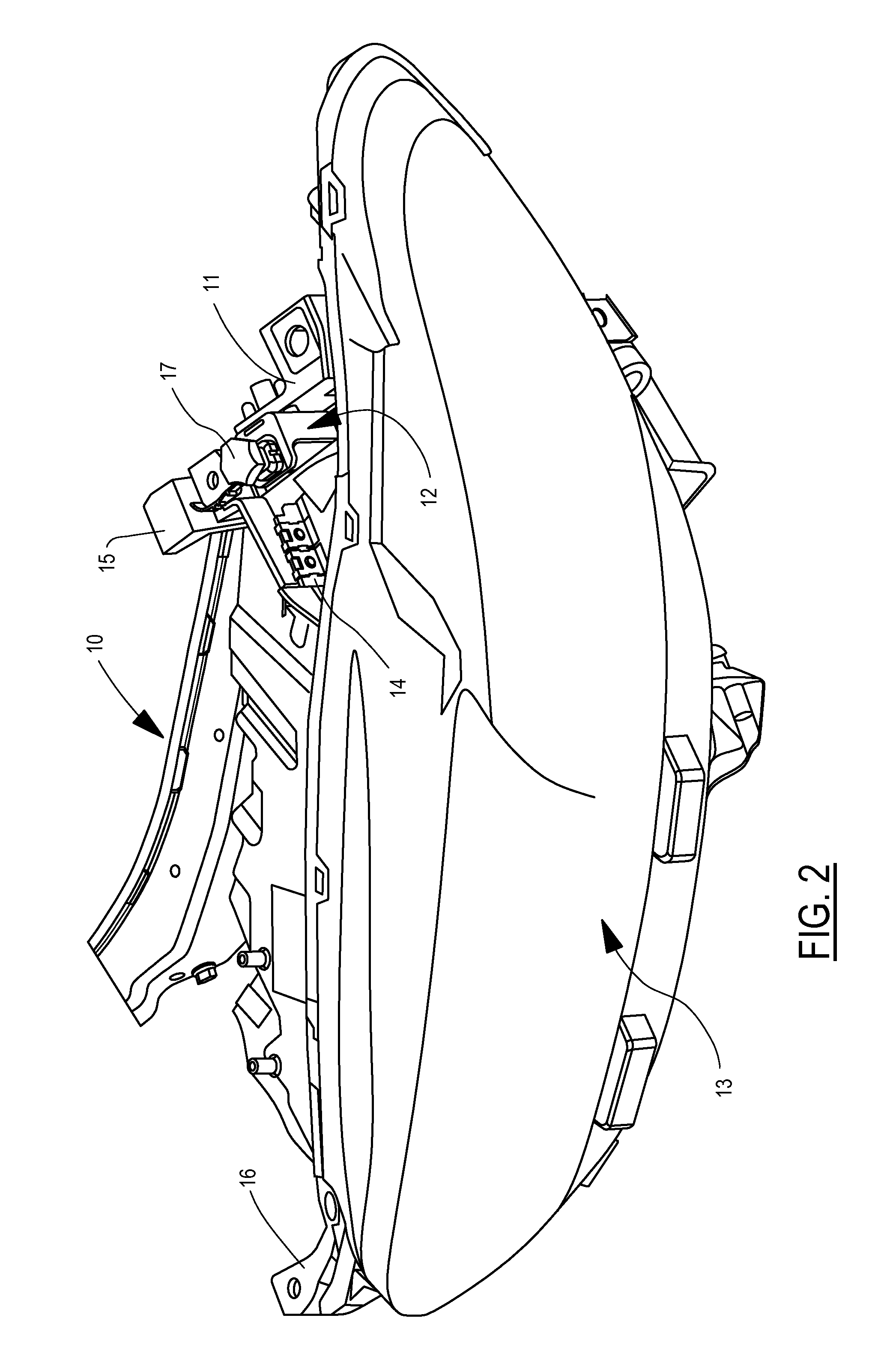

Integrated hood bump-stop and headlamp attachment for pedestrian protection

A vehicle apparatus comprises a slider body having a substantially vertical slide slot and a substantially horizontal shear pin. The slider body further includes a headlamp mounting section and a hood bump-stop mounting section. An adjustable bumper is received by the hood bump-stop mounting section with an adjustable height. A reinforcement member is configured to be fixed with respect to a grille opening of the vehicle. The reinforcement member has a bore aligned with the slide slot for receiving a fastening pin and an aperture receiving the shear pin. A force greater than a predetermined force applied to the adjustable bumper results in the shear pin breaking off in the bore and the fastening pin sliding along the slide slot as the slider body moves downward.

Owner:FORD GLOBAL TECH LLC

Downhole Tool with Hydraulic Closure Seat

A downhole tool 100 includes closure seats 116, 176 for seating with a closure, such as a ball. Shear pins or other connectors temporarily limit axial movement of each closure seat which is initially housed within a restricted diameter portion of the central throughbore in the tool body. A piston axially moves in response to fluid pressure to pressurize fluid in a chamber and controllably release fluid through one or more restrictions. The closure seat may be lowered to engage a stop 108, 159, such that the seat may move axially to an enlarged diameter bore portion of the tool, thereby allowing radial expansion of a closure seat to release the ball.

Owner:DRIL QUIP

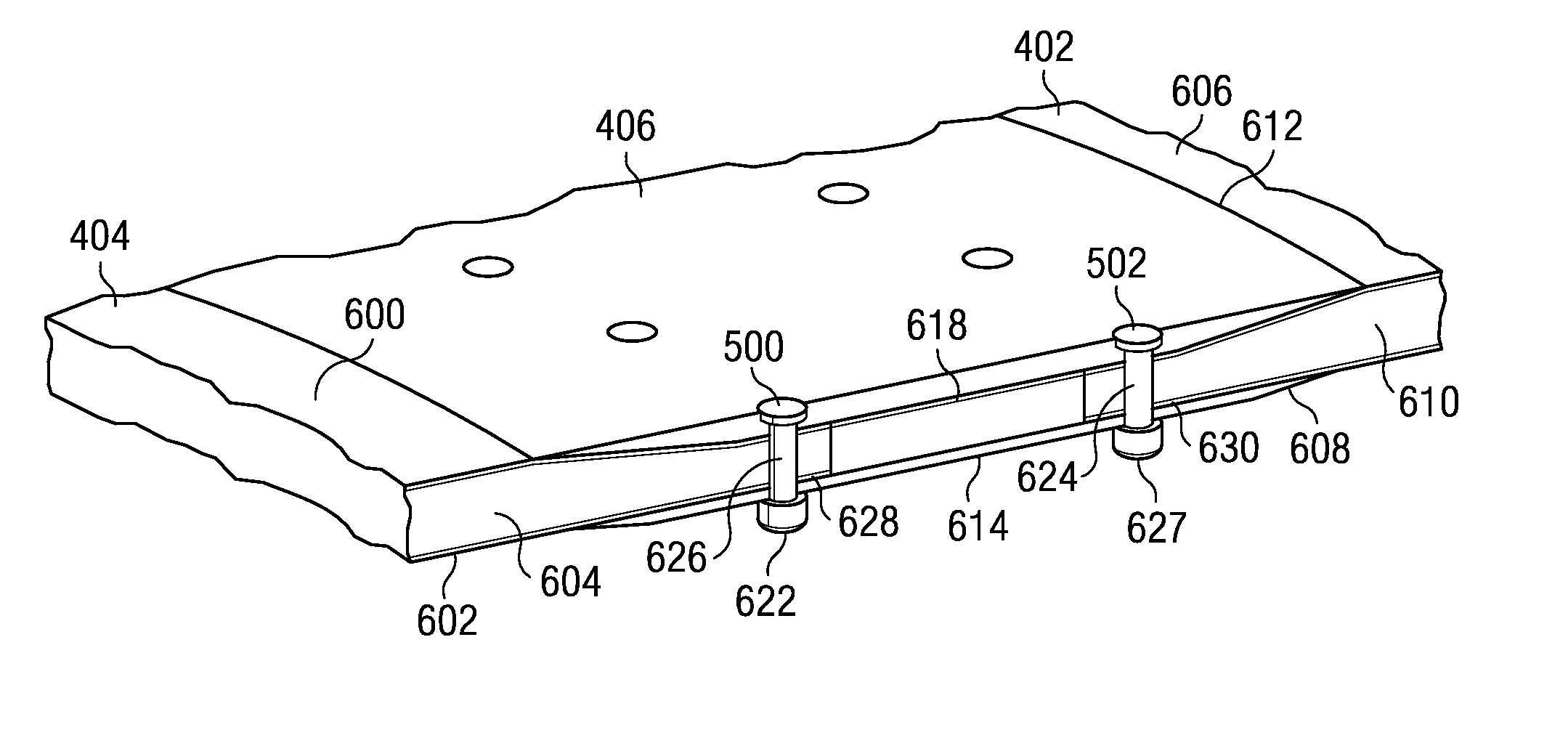

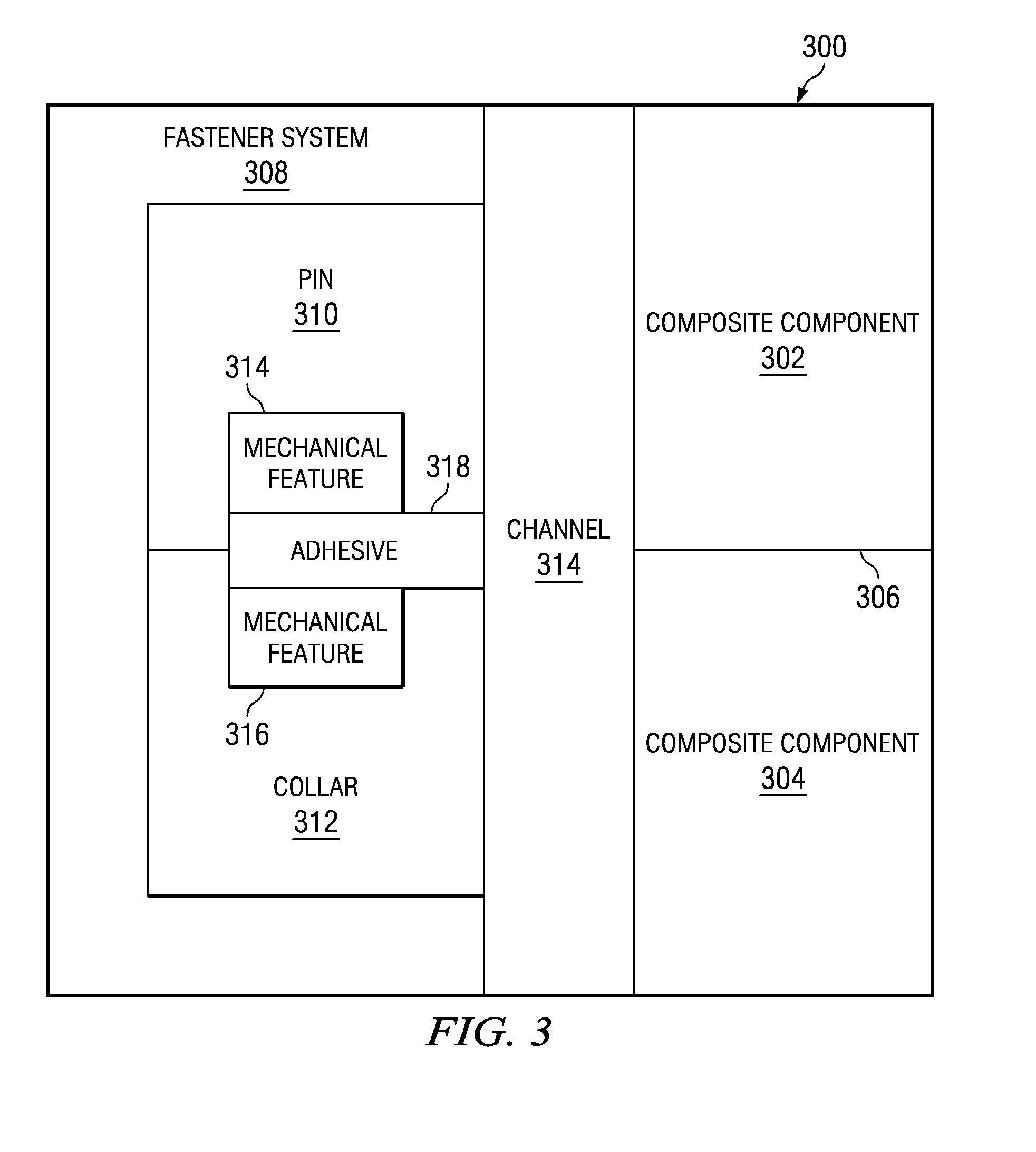

Method and apparatus for reinforcing composite structures

A computer implemented method and apparatus for creating a structural joint for an aircraft. A first composite component and a second composite component are co-joined to form the structural joint for the aircraft. A hole through the first composite component and the second composite component is created. A composite shear pin is placed through the hole. A composite collar is bonded to the composite shear pin with an adhesive.

Owner:THE BOEING CO

Deformable release device for use with downhole tools

InactiveUS20070151722A1Prevent upward movementMinimize damageFluid removalSealing/packingBiomedical engineeringWellbore

A deformable release device is disclosed to be used with downhole setting tools. The deformable release device may provide a releasable detachment to any customary setting tool, such as electric line, hydraulic, hydrostatic, and mechanical setting tools, used to set a downhole packer-type device. The deformable release device allows for the automatic release of downhole setting tools at the application a predetermined force, similar to a shear pin or shear stud. However, since the deformable release device deforms rather than shears or breaks, the releasing device minimizes the debris or remnants of the device left in the wellbore.

Owner:BJ SERVICES CO

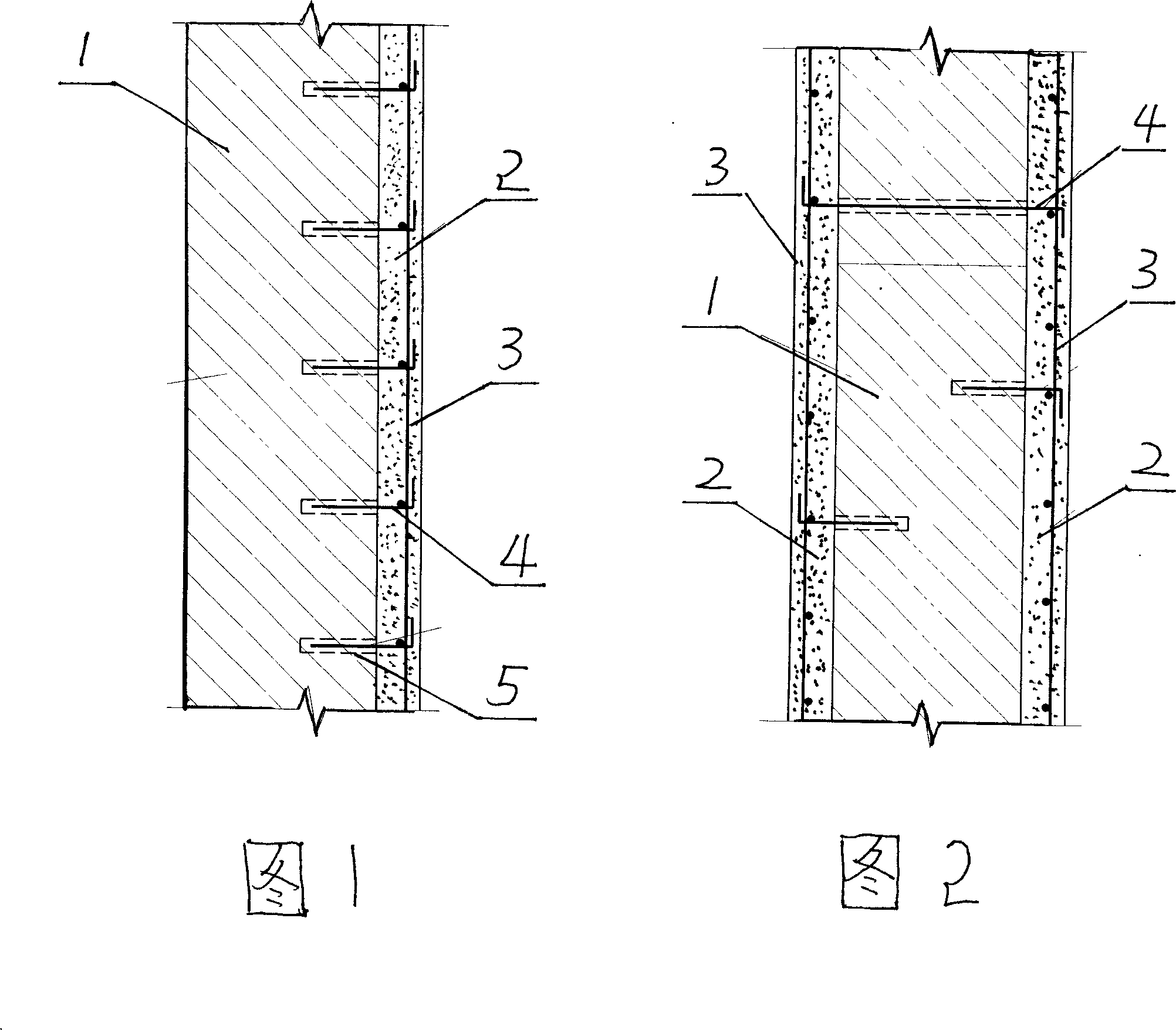

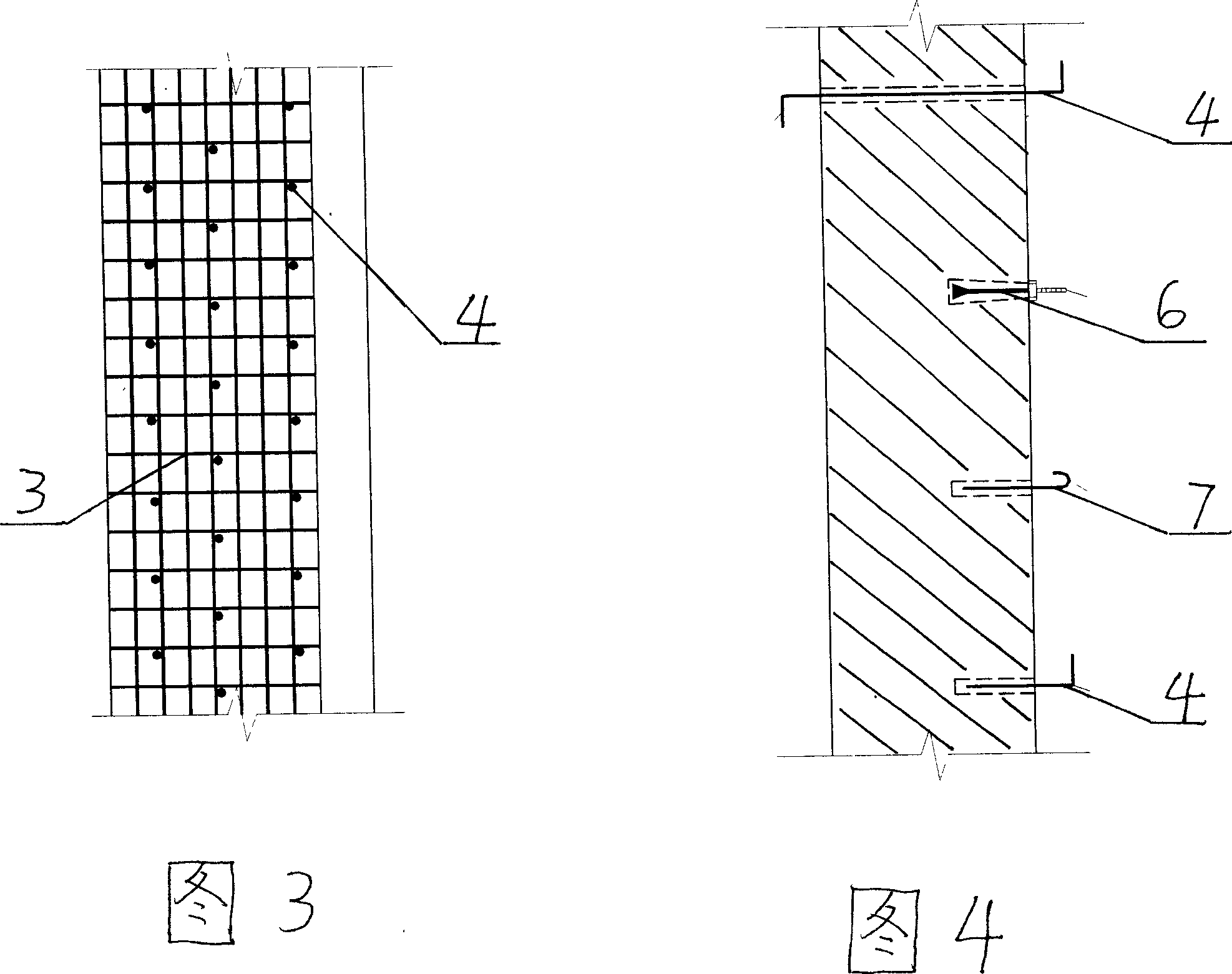

Construction method for reinforcing steel-bar net mortar thin layer

InactiveCN1978843AImprove shear resistanceIncrease the amount of reinforcementBuilding repairsThin layerRebar

The invention discloses mat reinforcement mortar thin layer reinforcing construction method. It includes the following steps: component surface treatment; component surface inserting shear pin; laying mat reinforcement and fixing; coating mortar on the mat reinforcement and the component surface. The mat reinforcement and the shear pin are fixed to enhance the shear resistant between the mortar thin layer and the original component, accordingly increase structural member rigidity, tensile, compression resistant, bending resistant and shearing strength.

Owner:HUNAN UNIV

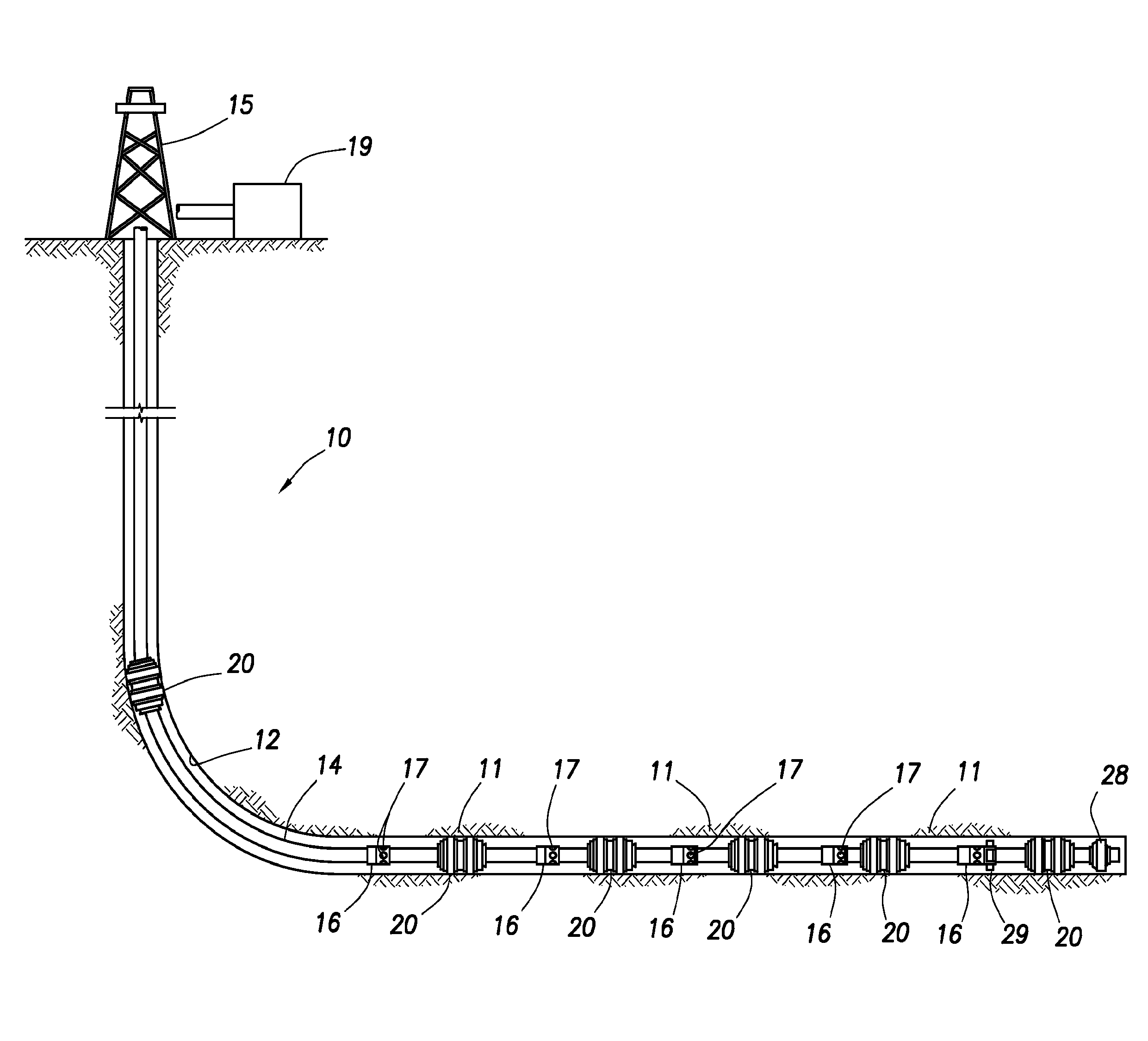

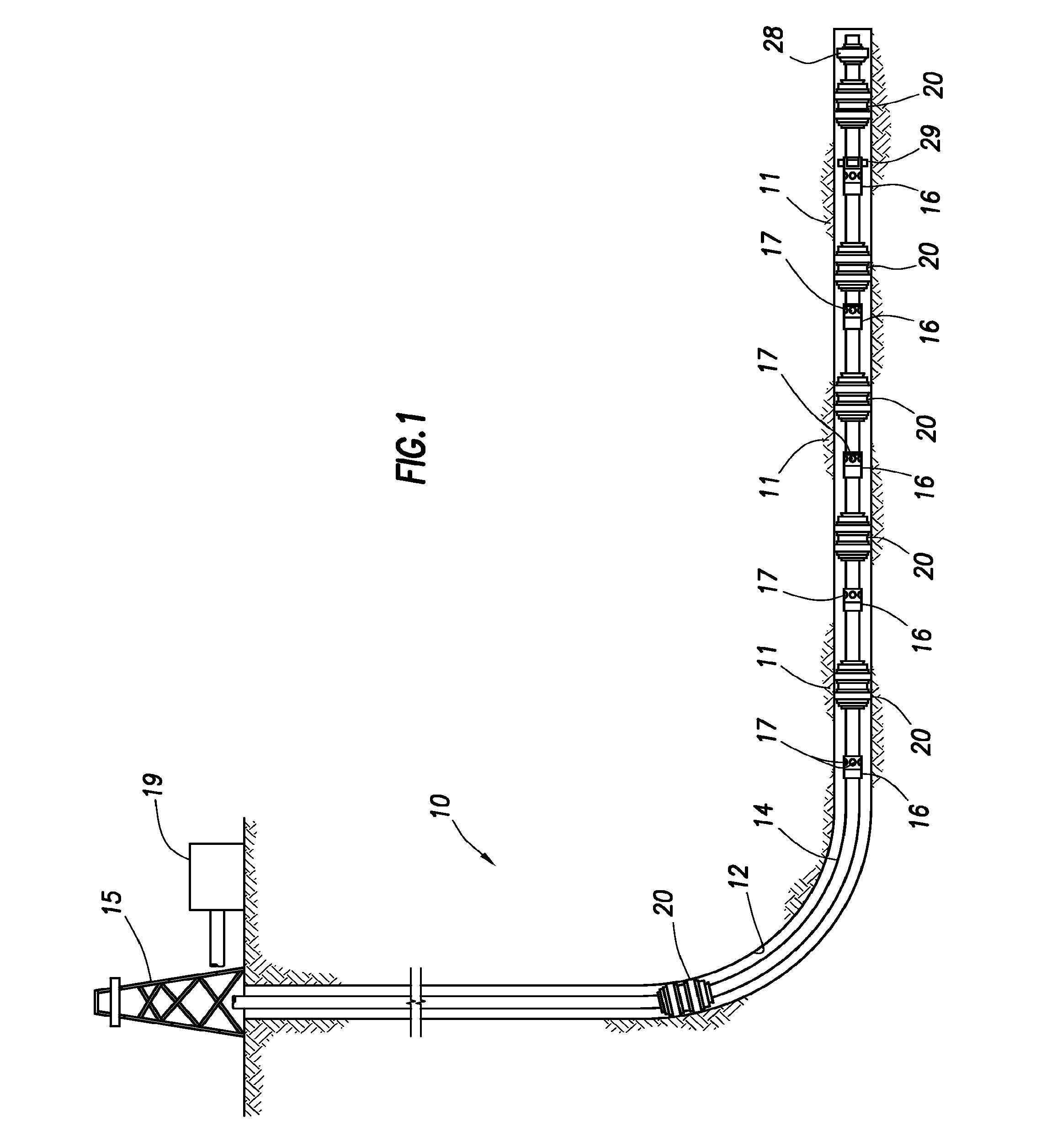

Sliding sleeve bypass valve for well treatment

InactiveUS8978773B2Without riskReduce positioningConstructionsFluid removalDifferential pressureEngineering

A downhole bypass valve utilizes a stationary sleeve defining an interior ball-seat. When a dropped ball is seated, fluid differential pressure is diverted to an annular area adjacent a first sliding sleeve. The sleeve slides in response to the pressure differential upon shearing of a shear pin, or similar, and opens ports to the wellbore annulus. Treatment or maintenance operations can then occur through the ports, which can be fitted with nozzles. A second sliding sleeve, independent from the first, is operated in response to dropping a second ball into the device. The second ball diverts fluid differential pressure to an annular area adjacent the second sleeve and movement occurs when a shear pin shears. The second sleeve covers the ports to the wellbore annulus and closes the valve. After a sliding sleeve shifts, pressure across the sleeve is equalized, allowing reverse flow without risk of accidental sleeve actuation.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for utilizing downhole safety joint

Owner:HALLIBURTON ENERGY SERVICES INC

Shear dowel assembly

InactiveUS20100054858A1Increased differential movementMaintain carrying capacityPaving detailsCarrying capacityLoad carrying

This invention relates to a shear dowel assembly for distributing loads between adjacent concrete slabs, separated by a joint. The shear dowel assembly includes a dowel sheath having a front face and a rear face. The rear face of the dowel sheath is imbedded within the first concrete slab, whereas the front face is left substantially flush with the side of said first concrete slab. The front face also has a portion defining an opening therein. There is also provided a shear dowel adapted to be inserted into the opening in the dowel sheath, with a first end of the shear dowel abutting the rear face of the dowel sheath, and a second end of the shear dowel extending out from the opening in the dowel sheath, whereby the shear dowel may be embedded within a second adjacent concrete slab to be poured. The shear dowel has a width of constant cross section, and is preferably trapezoidal (or in the shape of a trapezium) in plan view. The shear dowel assembly allows for increased differential movement of the adjacent concrete slabs, as the joint gap between the concrete slabs increases, whilst retaining the load carrying capacity of the shear dowel at all times.

Owner:PCLN HLDG

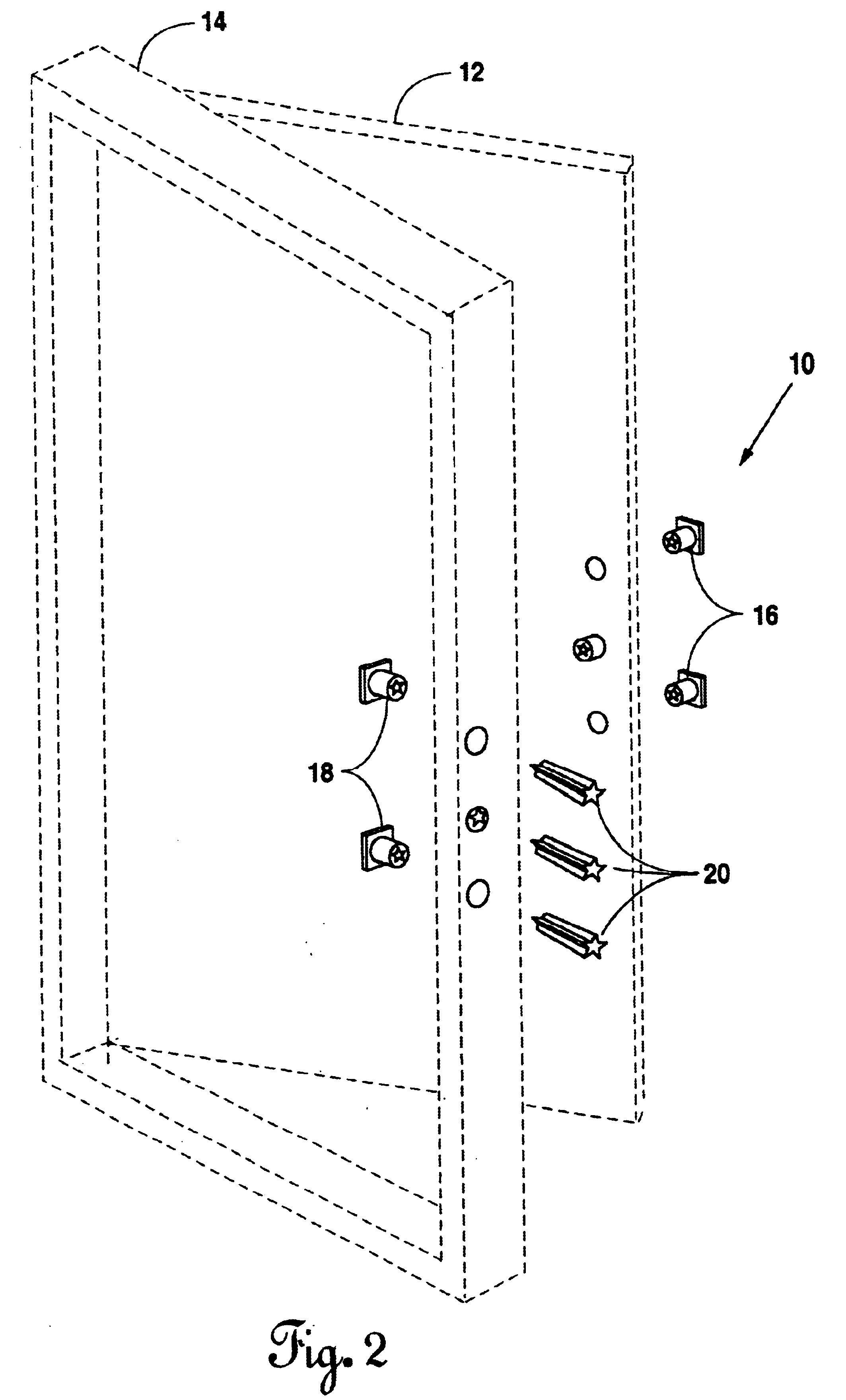

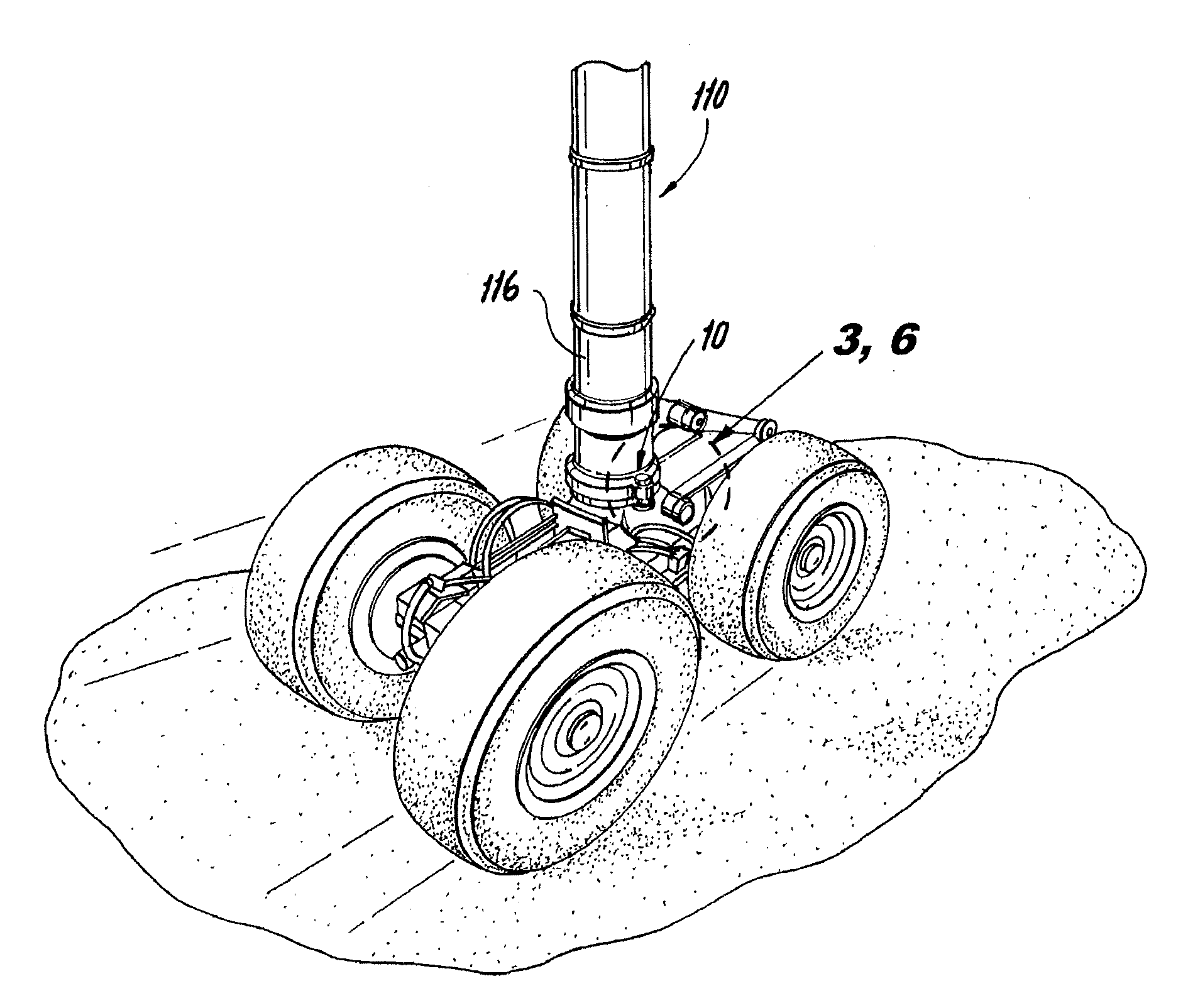

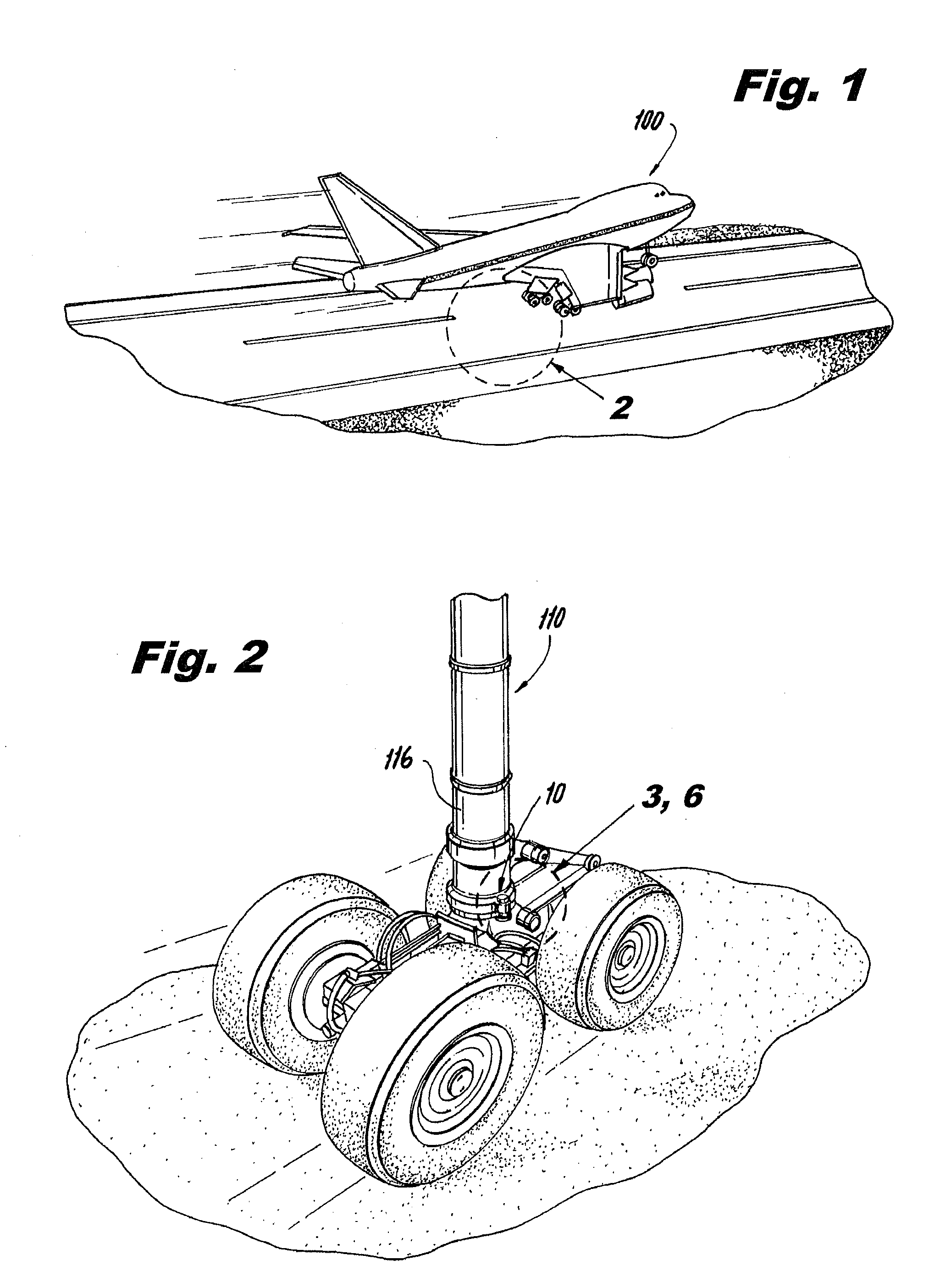

System for indicating an airplane hard landing

ActiveUS20110214601A1Easy to seeAvoid using forceAlighting gearApparatus for force/torque/work measurementJet aeroplaneAircraft landing

An indicator assembly for an aircraft landing gear for providing indication of a hard landing. The indicator assembly including a actuator member movable when the pressure on a shock strut of the aircraft landing gear exceeds a desired load and stroke threshold indicative of a hard landing. A shear pin is coupled to the actuator member which is configured to shear when a desired level of force is applied to at least a portion of the shear pin. A visibly recognizable indictor is moved from a non-indicating position to an indicating position upon shearing of the shear pin.

Owner:THE BF GOODRICH CO

Vehicle crash barrier

InactiveUS6857227B2Easy to replaceImproved latchWing suspension devicesTraffic restrictionsEngineeringVertical axis

The present invention is a pivoting crash barrier for arresting an impacting vehicle without causing excessive injury to the driver. The crash barrier has an easily replaceable expendable gate which houses multiple plastically deformable cables mounted within for absorbing the energy of the impacting vehicle. The crash barrier design causes the cables to deform as an unit, rather than separately. The crash barrier gate is pivotally supported on a horizontal shaft by an operator unit positioned on a first side of a roadway. An engagement stanchion engageable by the outer tip of the lowered gate supports the lowered gate on the second, opposed side of the roadway. The upper sections of both crash barrier stanchions consist of operator heads that can pivot about the vertical axes of their respective mounting posts after the shearing of restraining shear pins whenever a vehicle impact occurs. This swiveling reduces the tendency for the components of the crash barrier other than the gate to sustain significant damage during vehicle impacts. The crash barrier gate further has a latch on the engagement stanchion side that prevents inadvertent gate unlatching from uplift forces to the gate and a simplified method of balancing the crash barrier with counterweights.

Owner:AUTOMATIC POWER

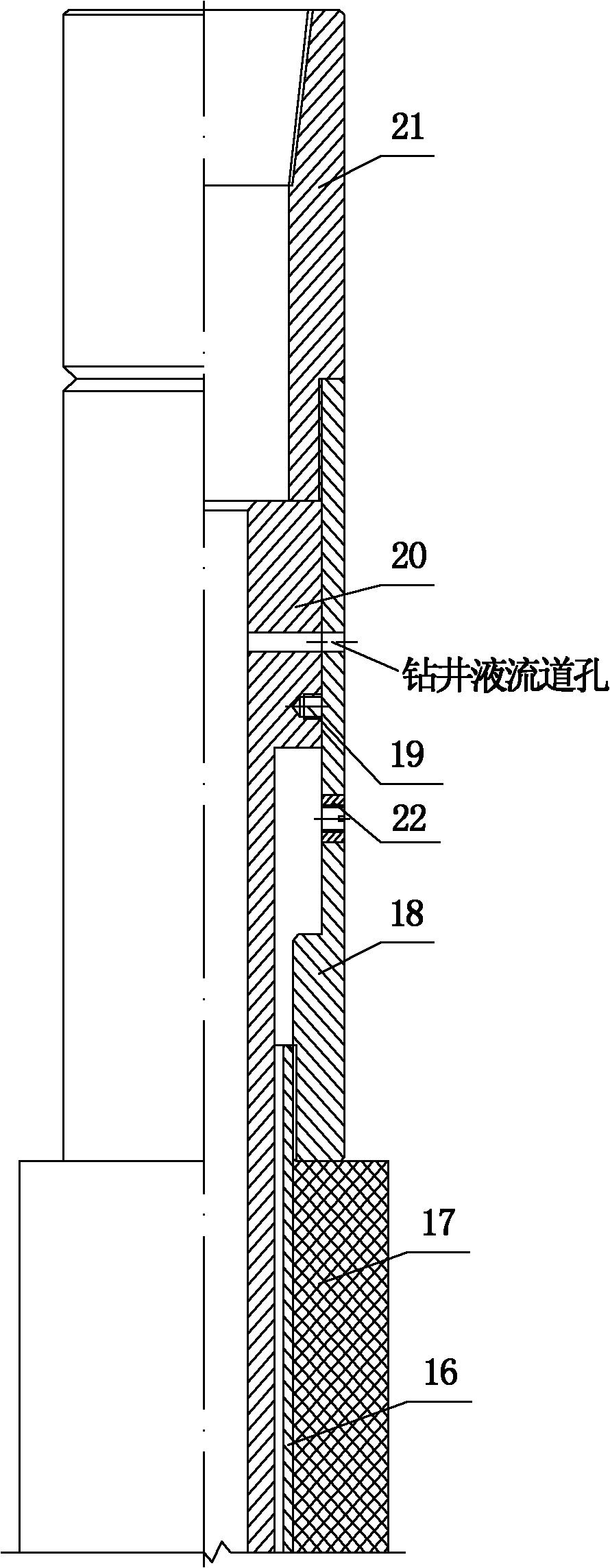

Mechanical underground all-in-one blowout preventer

InactiveCN101812981ASimple structureTo achieve the function of blowout preventionWell/borehole valve arrangementsSealing/packingBlowout preventerCheck valve

The invention relates to a mechanical underground all-in-one blowout preventer, which belongs to the well control equipment. The blowout preventer mainly comprises two parts, an arrow-type check valve and an outer annular packer, wherein the arrow-type check valve adopts the principle of one-way conduction of a valve core to realize annular blowout prevention in a drill stem, and the outer annular packer mainly comprises a plastic cylinder, a set shear pin, an unset shear pin, a locking component and the like. When the set shear pin is cut off, an upper jacket compresses the plastic cylinder downwards to realize sealing under the effect of the gravity of the upper drill stem, and simultaneously drilling fluid circulating runner ports arranged on an inner sleeve and the upper jacket are communicated to realize circulation of the drilling fluid. The invention adopts the fully mechanical operating principle, has the advantages of simple and reliable structure and easy realization, and can realize the sealing of the internal and external annular sealing of the underground drill stem, thereby achieving the function of preventing the blowout, improving the handling efficiency of underground accidents, and reducing the well control risk.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com