Hydraulic bridge plug setting tool and bridge plug setting method

A technology of hydraulic fluid and bridge plug, applied in the field of downhole tools in oil and gas fields, can solve the problems of connection, transfer and maintenance, long length, etc., and achieve the effect of convenient maintenance, short length, and efficient setting of bridge plugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

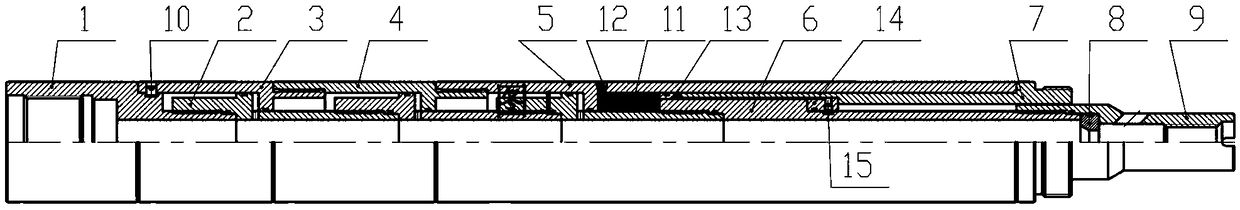

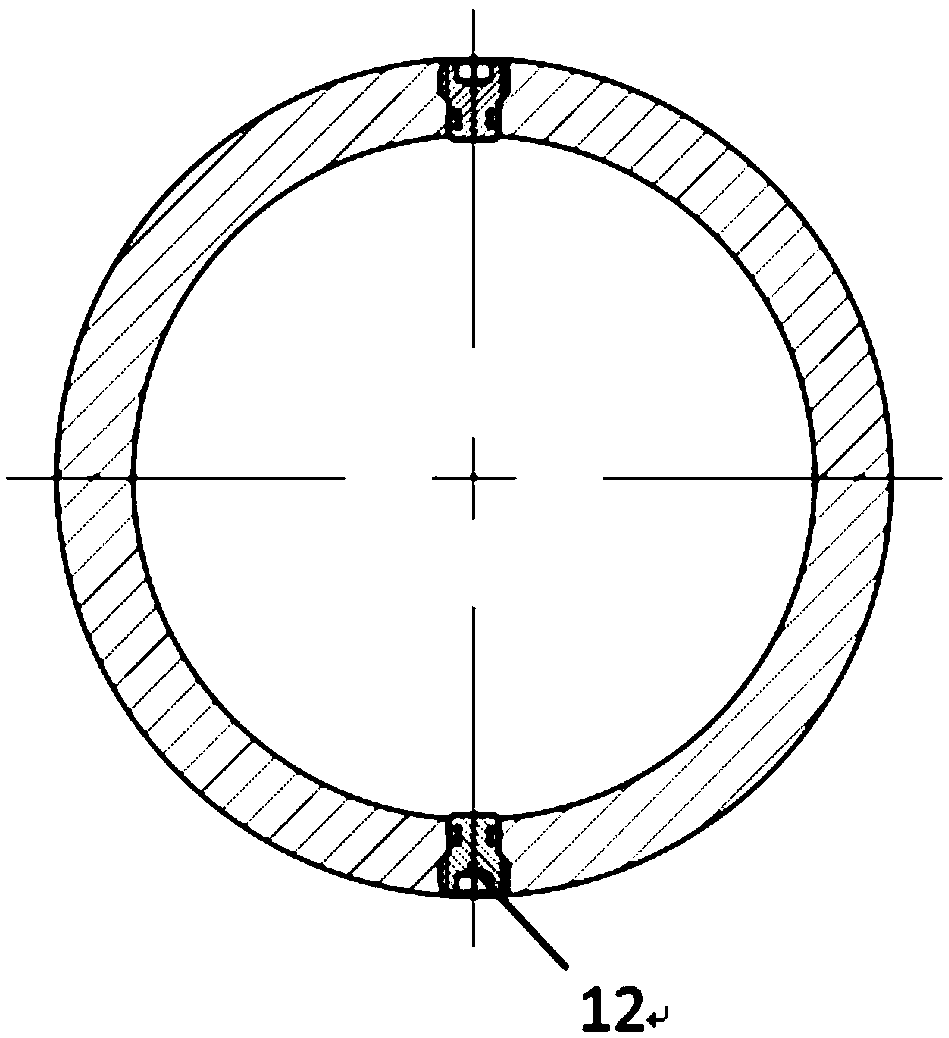

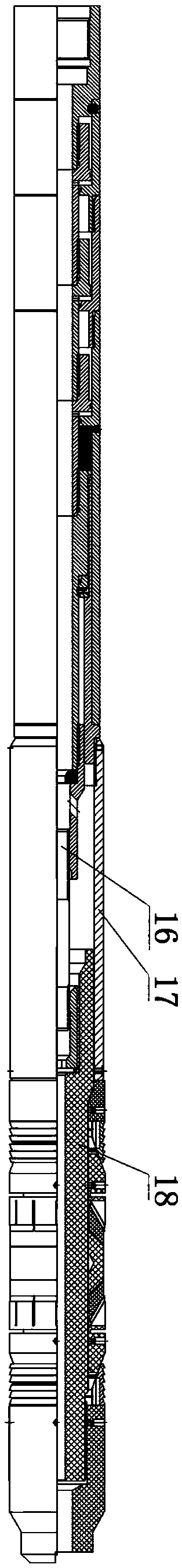

[0027] Examples such as Figures 1 to 3 As shown, the bridge plug hydraulic setting tool of the present invention includes an upper joint 1, a front drive device, a lower center rod 6, a push cylinder connecting sleeve 7, a ball seat 8, a conversion joint 9, a shear pin a10, and a sealing plug 12. Pushing ring 13, composite ring 14, shearing pin b15, upper joint 1 is connected with the front drive device through shear pin a10, push tube connecting sleeve 7 and lower center rod 6 fit up and down on the front drive device, and the front drive Between the device, the lower central rod 6 and the pusher connecting sleeve 7, there is an accommodating sealed cavity for accommodating the liquid. The liquid is an incompressible fluid. 7 can move backwards, when the front drive device compresses and accommodates the sealed cavity, and when the liquid pushes the push ring 13 and the push cylinder connecting sleeve 7 to move backward, an annular ring for accommodating the liquid will be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com