Construction method for reinforcing steel-bar net mortar thin layer

A construction method and technology of steel mesh, which can be used in building maintenance, construction, building construction, etc., can solve the problems of composite mortar unable to achieve reliable bonding, shear peeling damage, poor bonding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

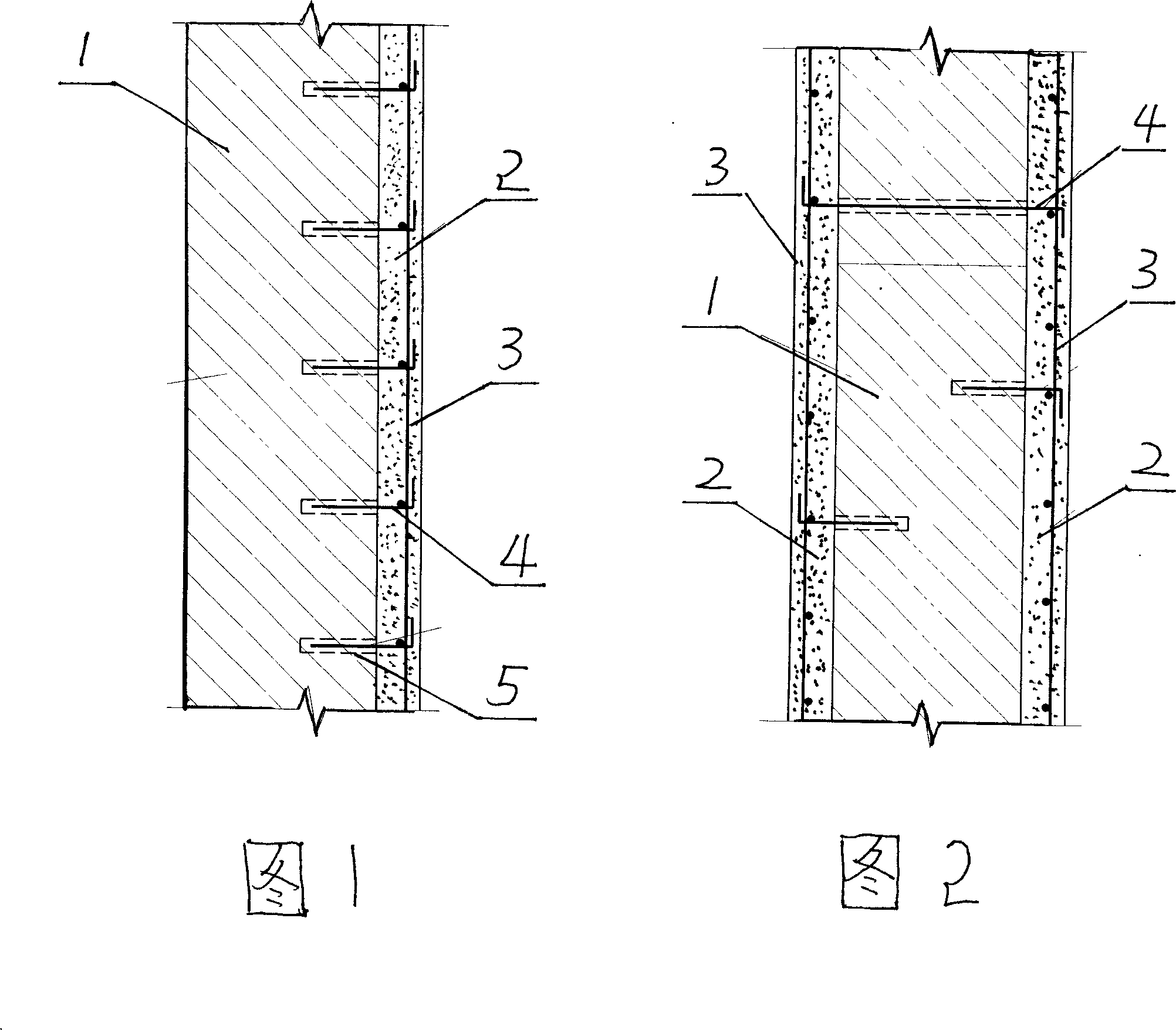

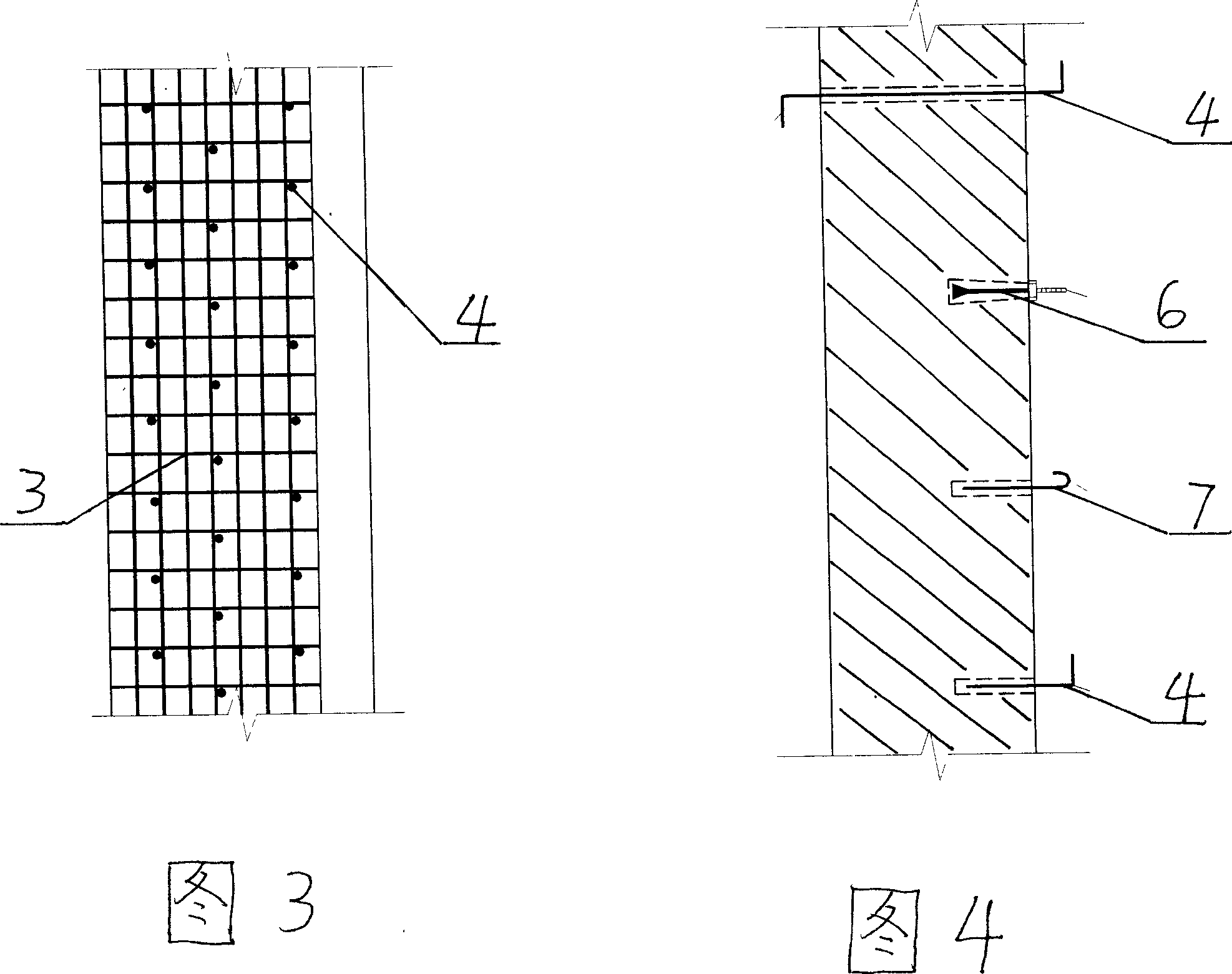

[0016] With reference to Fig. 1, Fig. 2, Fig. 3, Fig. 4, the construction method of reinforcing and reinforcing the reinforced mesh mortar thin layer includes the following steps:

[0017] (1) Component surface treatment: use physical and chemical methods to treat the surface of the component, and use non-metallic sand such as river sand, silica sand, silicon carbide or alumina dry sandblasting to blow off, or stick a high-efficiency detergent brush with a hard bristle brush Remove surface grease; use hammer and chisel to borrow manpower or machinery to beat the new and old concrete bonding surface to form random unevenness, increase the surface area of the adherend, and improve the bonding force; then blow off the dust with clean compressed air and particles;

[0018] (2) Implanting shear pins on the surface of the component: first drill holes 5 on the surface of the original component 1, the hole diameter 5 is generally about 2-3mm larger than the pins 4, 6, and 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com