Radial block copolymers and adhesives based thereon with improved die-cutting performance

a technology of copolymer composition and adhesive layer, which is applied in the direction of adhesives, etc., can solve the problems of difficult and inconsistent die-cutting, difficult to cut or break adhesive film, and limit the ease of conversion of adhesive layer, so as to improve the die-cutting performance and reduce melt viscosity , the effect of improving the shear resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

The following Examples A and B illustrate the Production of High Diblock / Radial Block copolymer Mixtures via control of coupling efficiency.

example a

To a 5 gallon stirred reactor under a nitrogen atmosphere were added 12.5 kg of cyclohexane solvent and 84.0 g of a 0.17 M solution of sec-butyl lithium in cyclohexane. The temperature of the reactor was brought to 75° C. and 339 g of styrene was added. Polymerization of the styrene was allowed to continue for 36 minutes. The reaction mixture was cooled to 57° C. and 1692 g of isoprene was added. The isoprene was allowed to polymerize for 46 minutes, during which the reaction temperature reached a maximum of 92° C. At the end of the 46 minutes, 10 grams of butadiene was added at 71° C. and it was allowed to polymerize for an additional 34 minutes. Then 1.0 g of 0.87 M SiCl4 in cyclohexane was added all at once. The reaction was allowed to continue for another 26 minutes before the reaction was terminated by addition of 3.0 ml of isopropanol.

The resulting polymer was analyzed by GPC, and found to contain 82.0% diblock and 18.0% coupled radial block polymer. The radial block copoly...

example b

To a 5 gallon stirred reactor under a nitrogen atmosphere were added 12.5 kg of cyclohexane solvent and 79.1 g of a 0.17 M solution of sec-butyl lithium in cyclohexane. The temperature of the reactor was brought to 82° C. and 339 g of styrene was added. Polymerization of the styrene was allowed to continue for 37 minutes. The reaction mixture was cooled to 58° C. and 1692 g of isoprene was added. The isoprene was allowed to polymerize for 26 minutes, during which the reaction temperature reached a maximum of 95° C. At the end of the 26 minutes, 10 grams of butadiene was added at 71° C. and it was allowed to polymerize for an additional 43 minutes. Then 3.1 g of 0.87 M SiCl4 in cyclohexane was added all at once. The reaction was allowed to continue for another 31 minutes before the reaction was terminated by addition of 3.0 ml of isopropanol.

The resulting polymer was analyzed by GPC, and found to contain 49.1% diblock, about 1% polystyrene homopolymer and the remainder coupled rad...

PUM

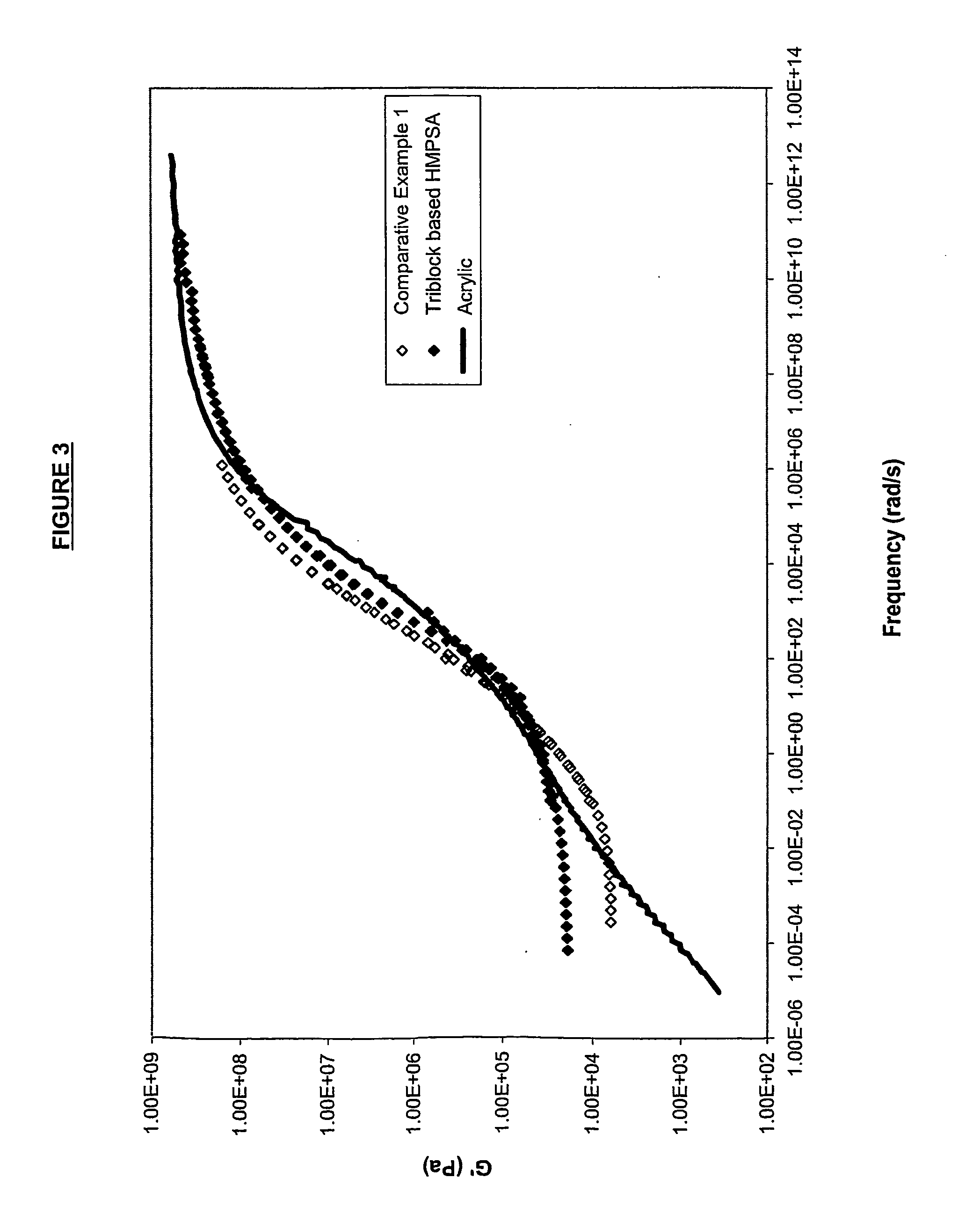

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com