Patents

Literature

35results about How to "Die-cut effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radial block copolymers and adhesives based thereon with improved die-cutting performance

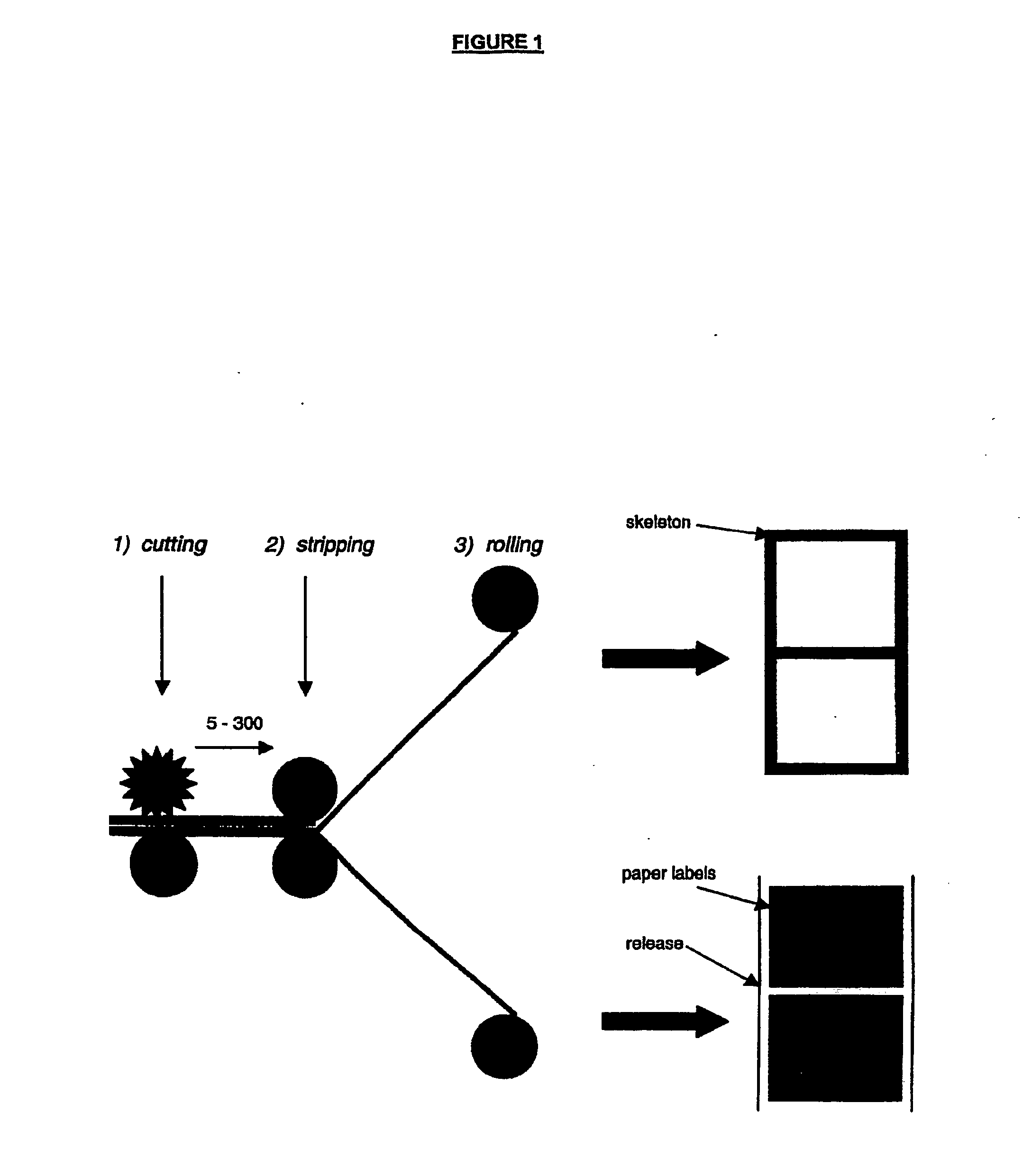

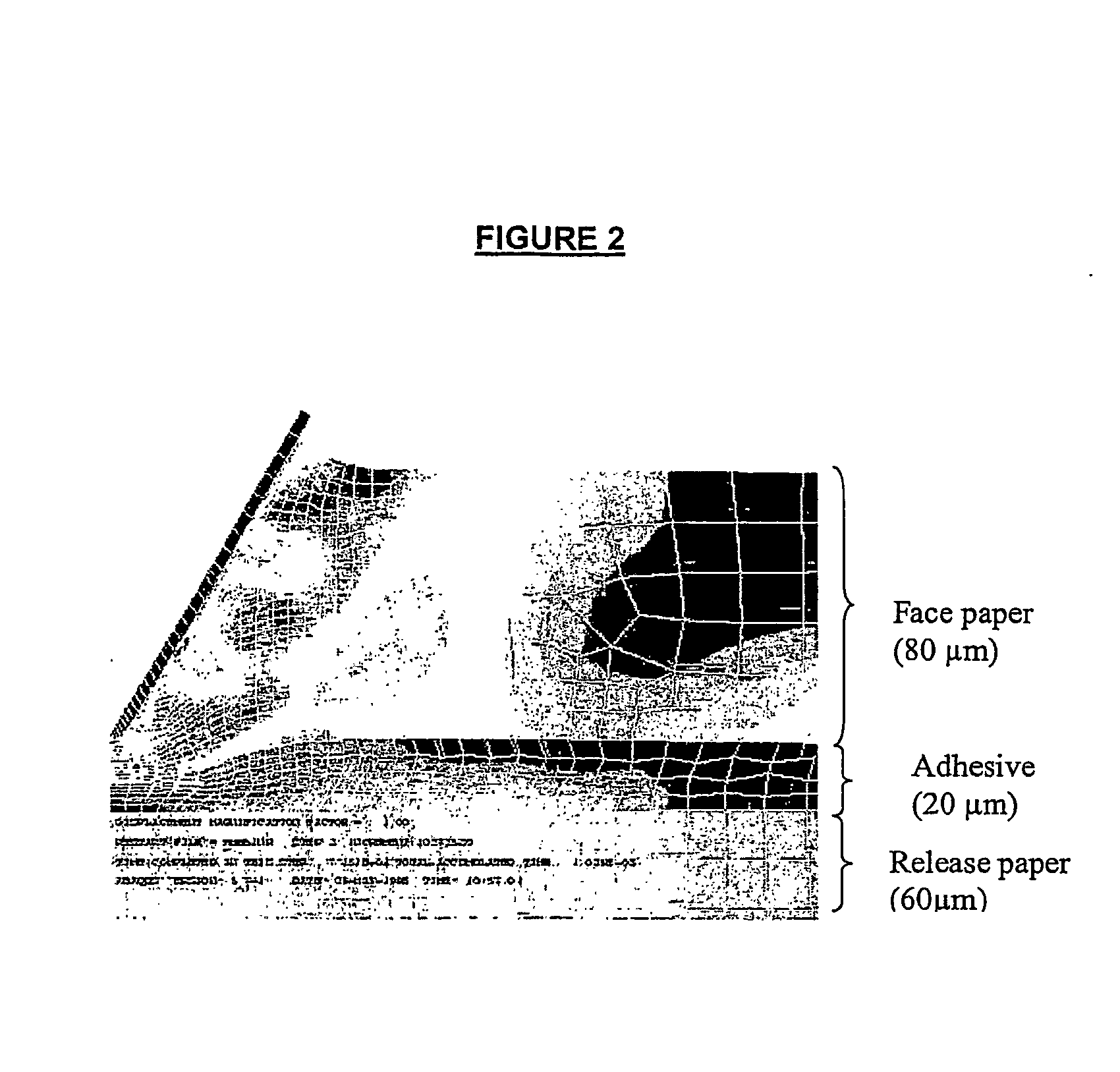

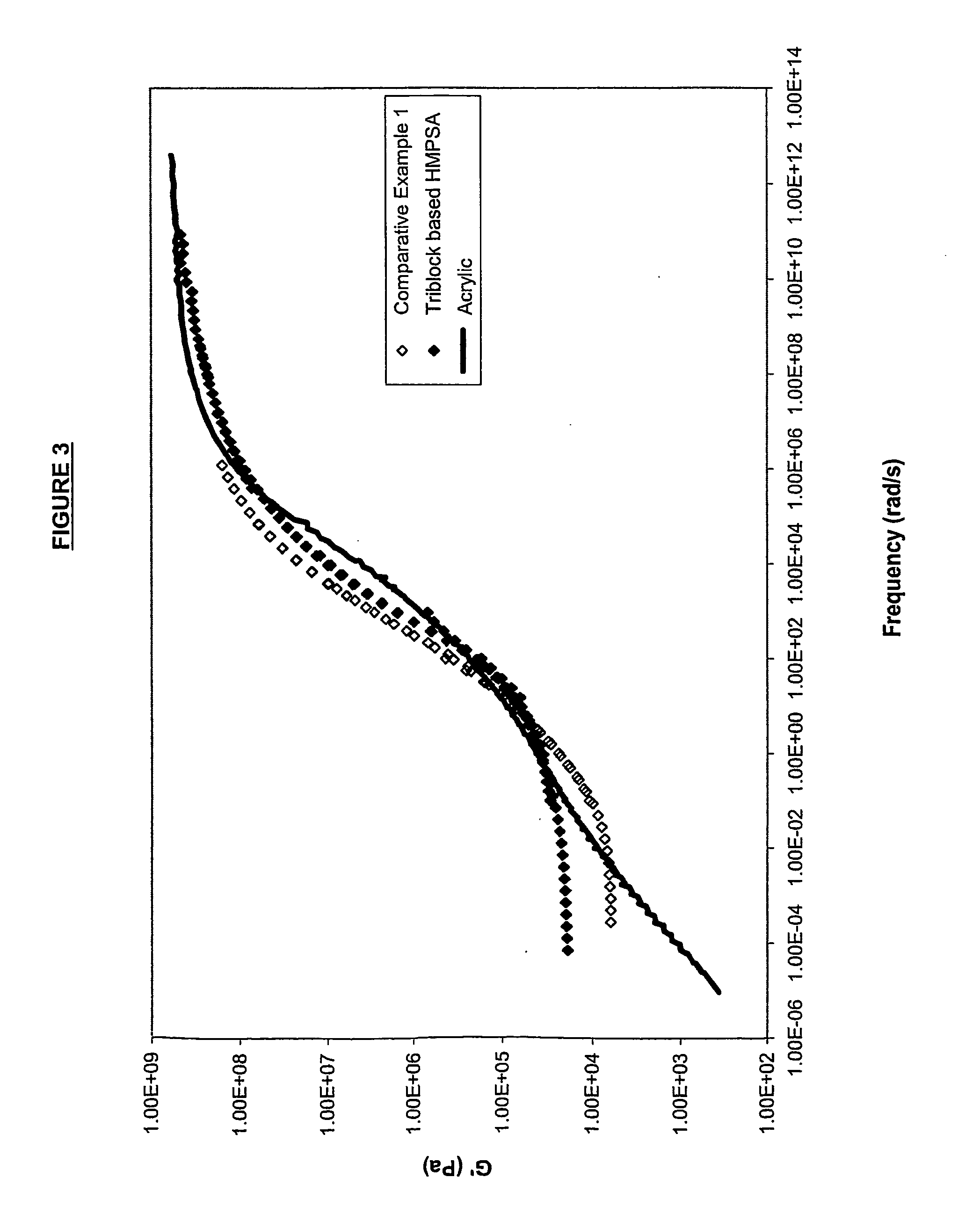

Improved adhesives are provided through the use of styrenic radial block copolymers, containing at lest 40 wt % diblock copolymers, the adhesives have improved adhesive properties and a reduced elastic behaviour under die-cutting conditions. Compared to conventional linear block copolymers of similar molecular weight, radial copolymers offer higher holding power and lower melt viscosity for the adhesive. They therefore contribute to an improved balance between processability and end-use properties.

Owner:EXXONMOBIL CHEM PAT INC +1

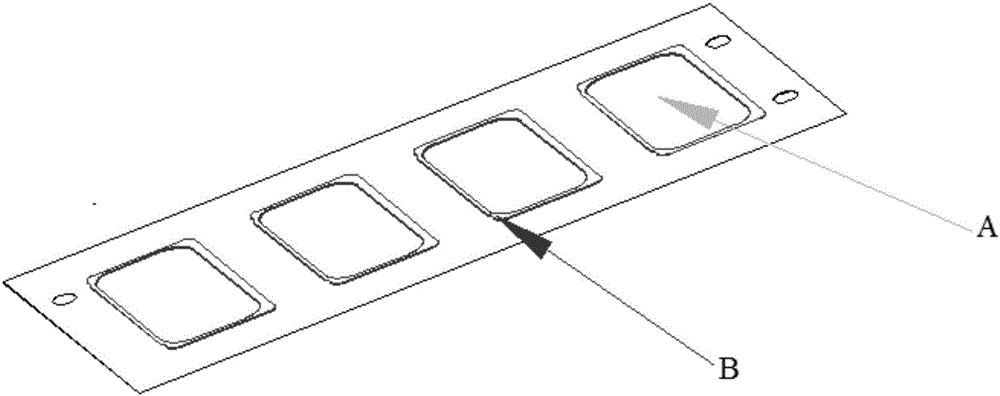

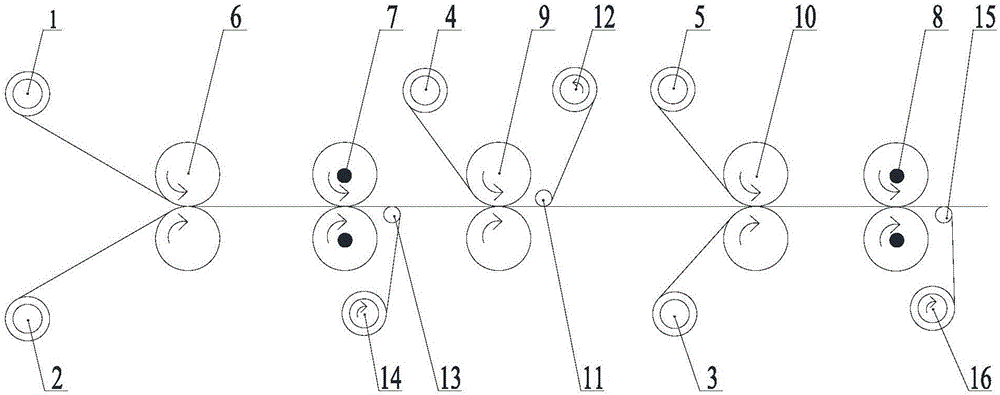

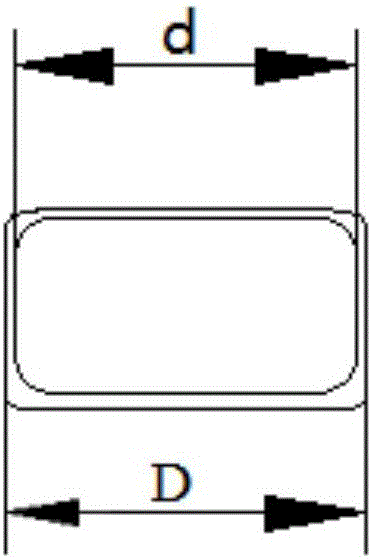

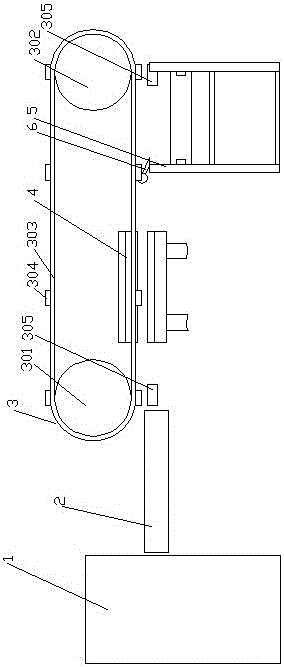

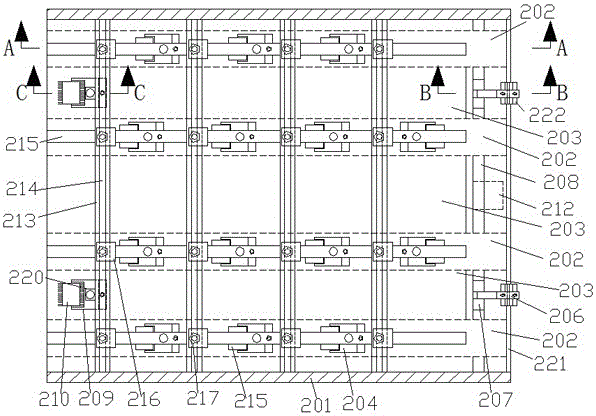

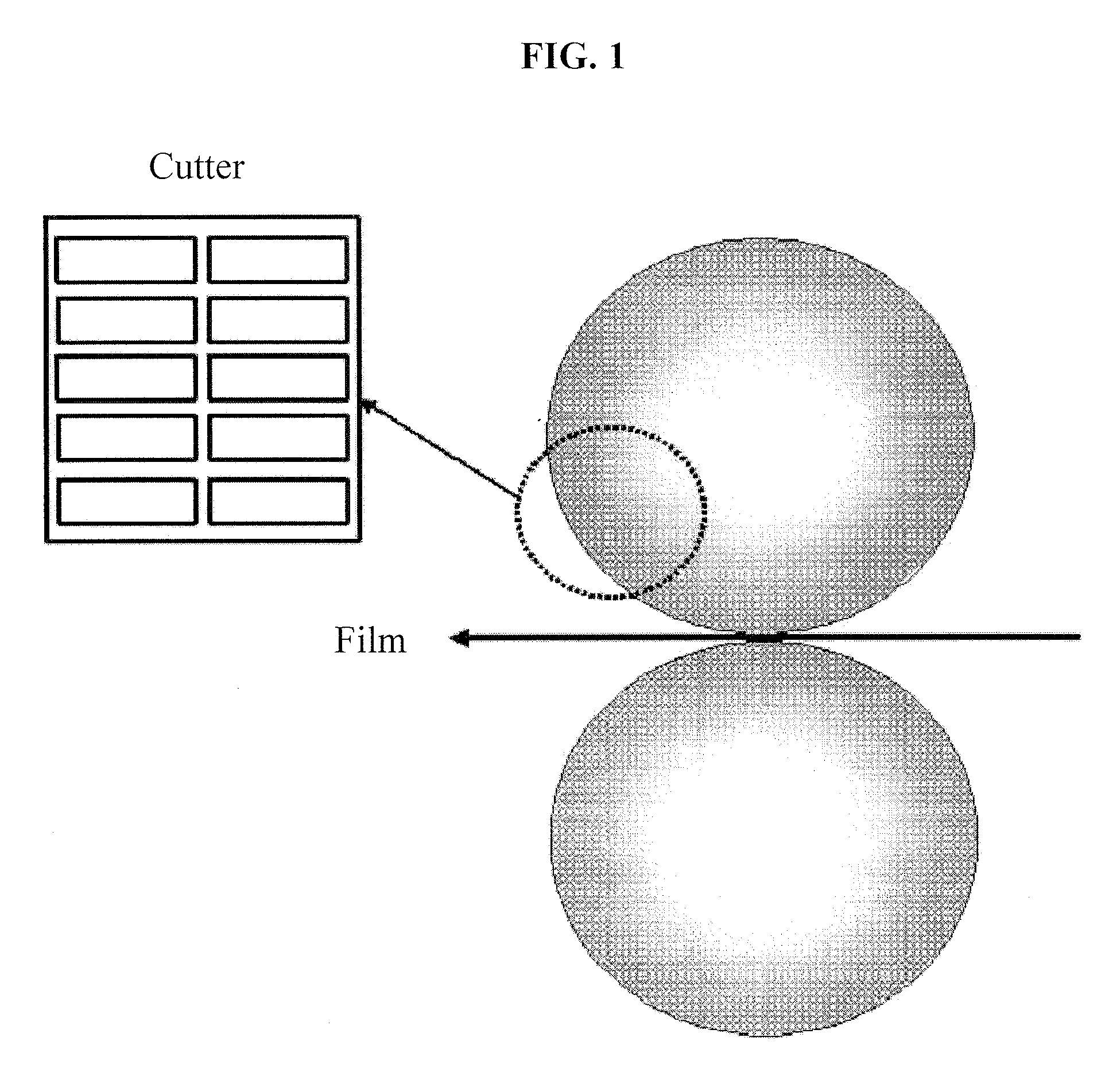

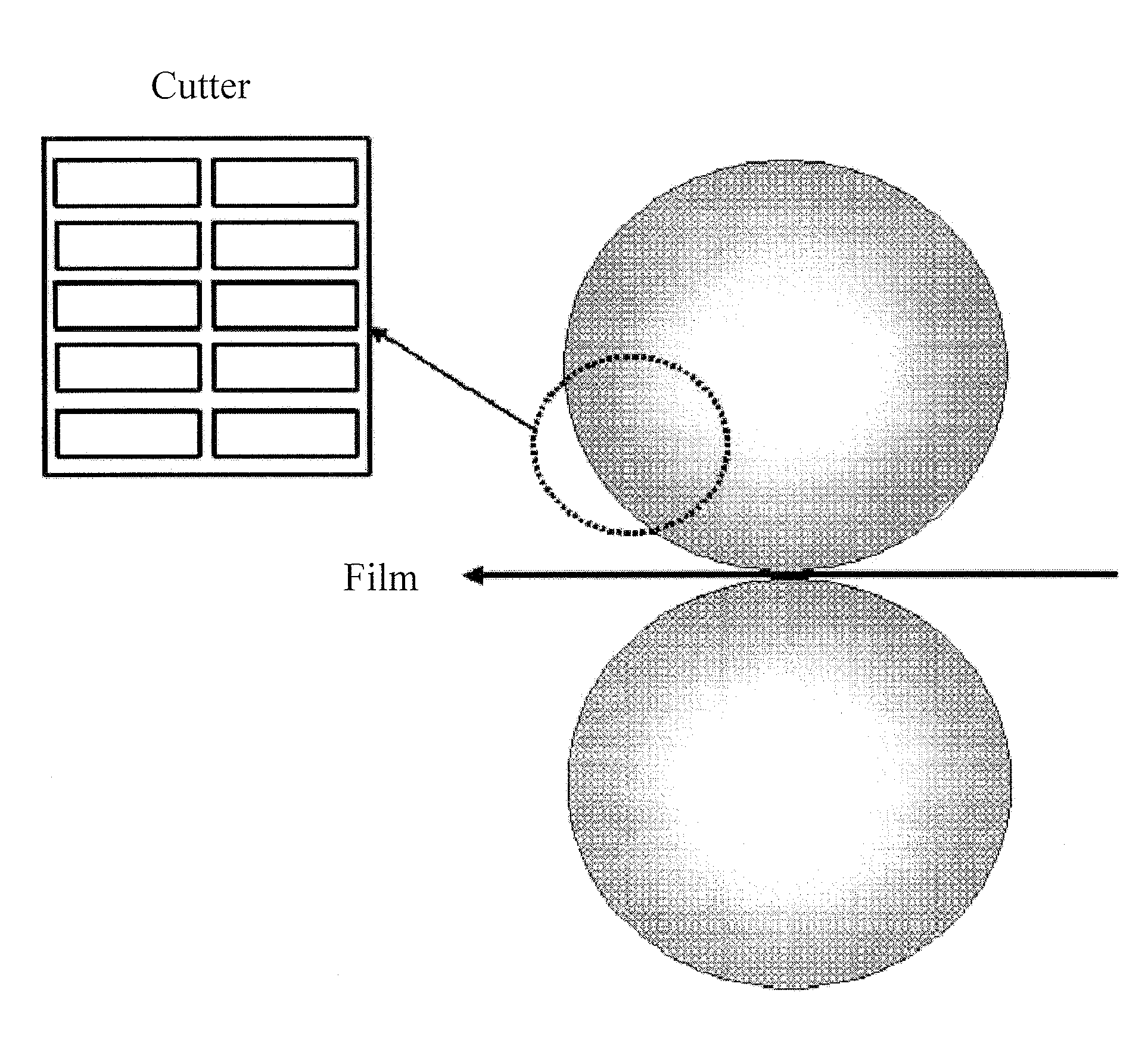

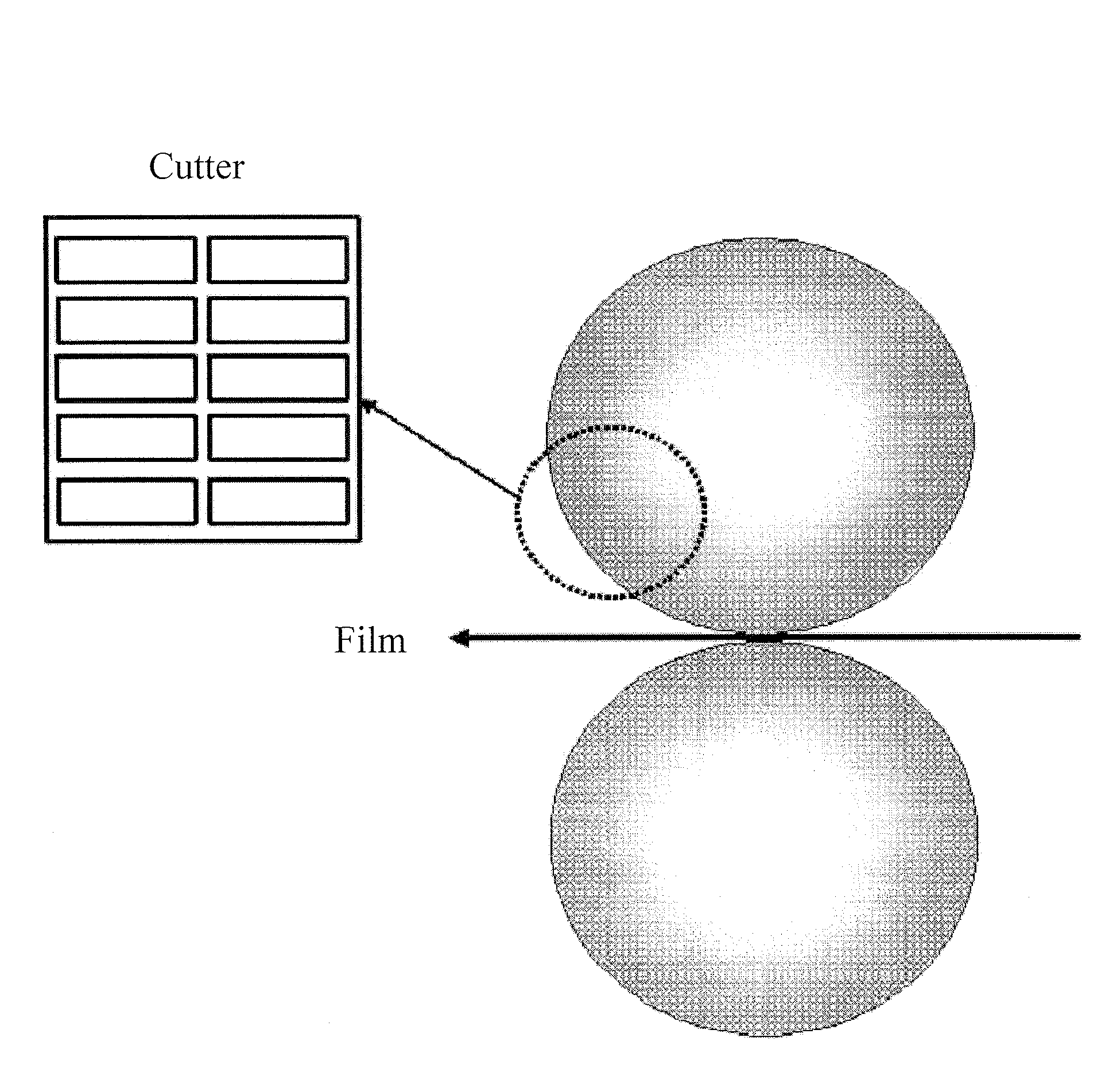

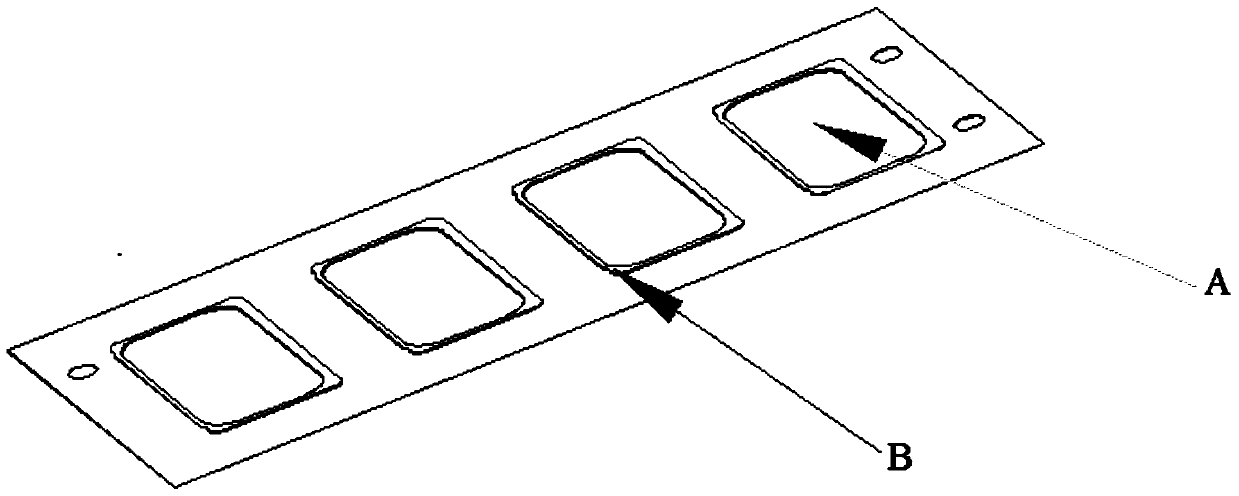

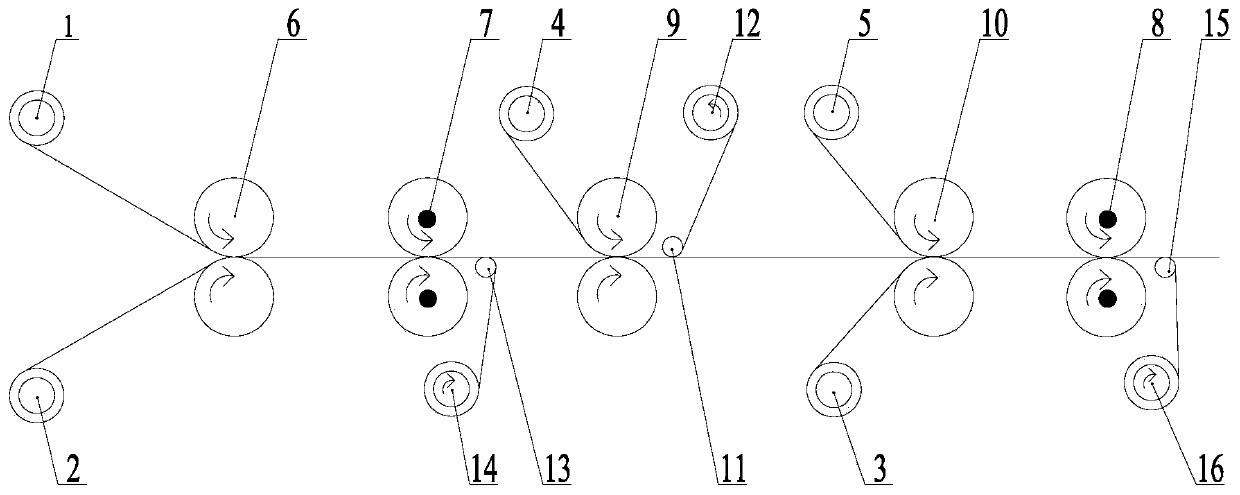

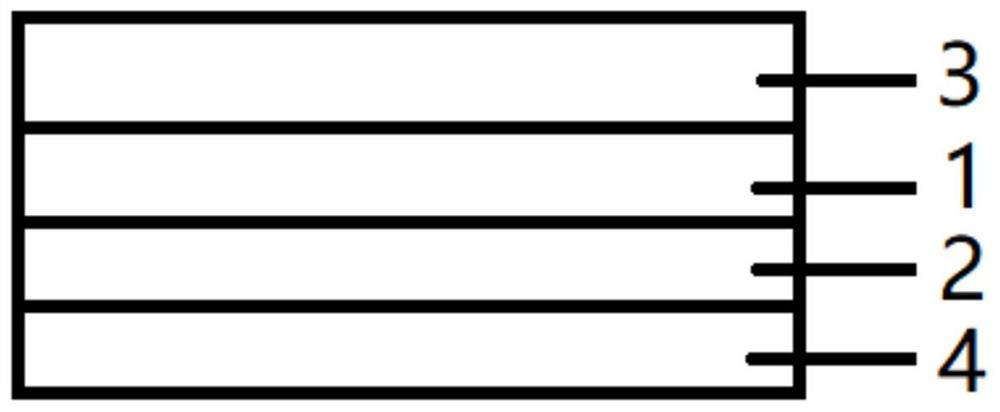

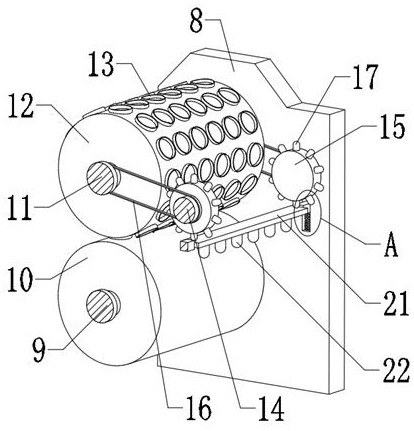

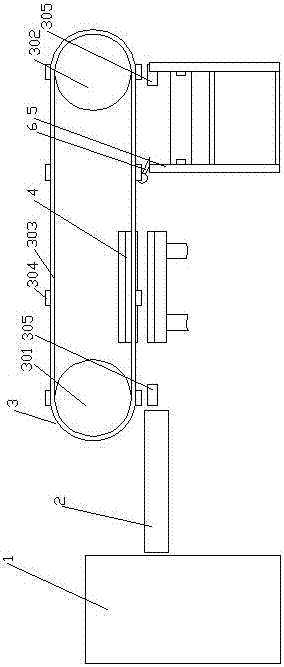

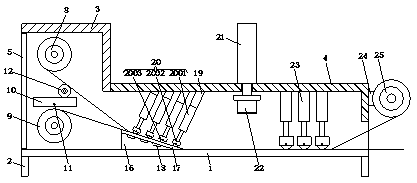

Die-cutting waste discharge device with inner frame die-cutting piece and die-cutting waste discharge method

InactiveCN106541449AGood waste discharge effectThe waste disposal process went smoothlyMetal working apparatusTectorial membranePunching

The invention relates to a die-cutting waste discharge device with an inner frame die-cutting piece and a die-cutting waste discharge method. The die-cutting waste discharge device comprises a first opposite-pressing roller, first-stamping die-cutting cutters, first waste discharge rollers, a second opposite-pressing mechanism, second-stamping die-cutting cutters and second waste discharge rollers which are arranged sequentially. The first opposite-pressing roller attaches a first single face gummed protective film to a first release film; indent inner frames are punched in first stamping by the first-stamping die-cutting cutters; the first waste discharge rollers is used to take up the first single face gummed protective films attached to wastes of the inner frames after the first-stamping punching; the second opposite-pressing mechanism attaches a second single face gummed protective film to the non-release surface of the first release film, and sequentially attaches double faced adhesive tape and a second release film to the release surface of the first release film; normal inner frames are punched in second-stamping by the second-stamping die-cutting cutters; the second waste discharge rollers are used to take up the second single face gummed protective films attached to wastes of the inner frames after the second-stamping punching; and the size of each normal inner frame is bigger than the size of each indent inner frame. Compared with the prior art, the die-cutting waste discharge device has the advantages that the effect of waste discharge is good, the product has no deformation, and efficiency is high.

Owner:YUANRANG IND SHANGHAI

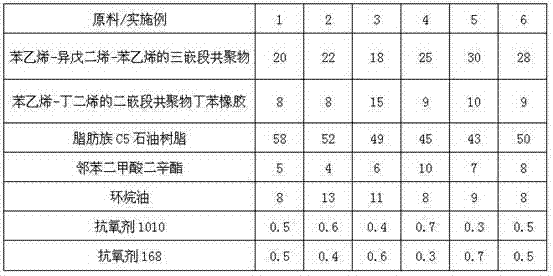

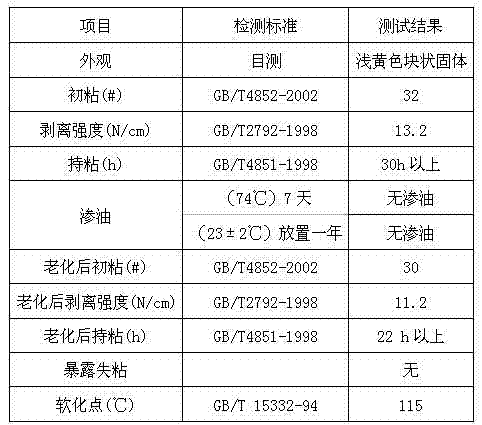

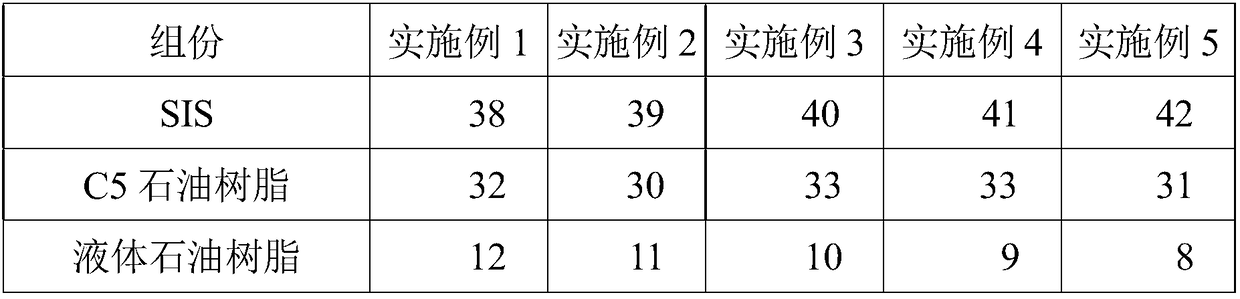

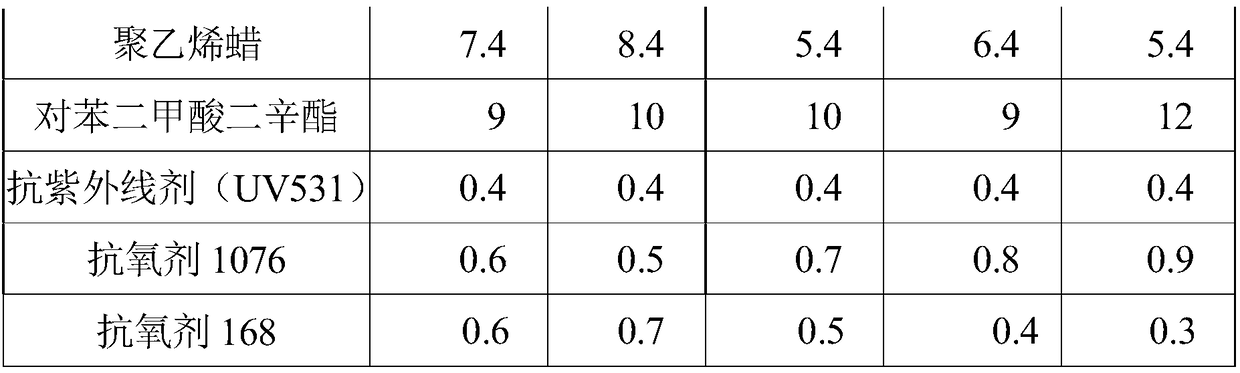

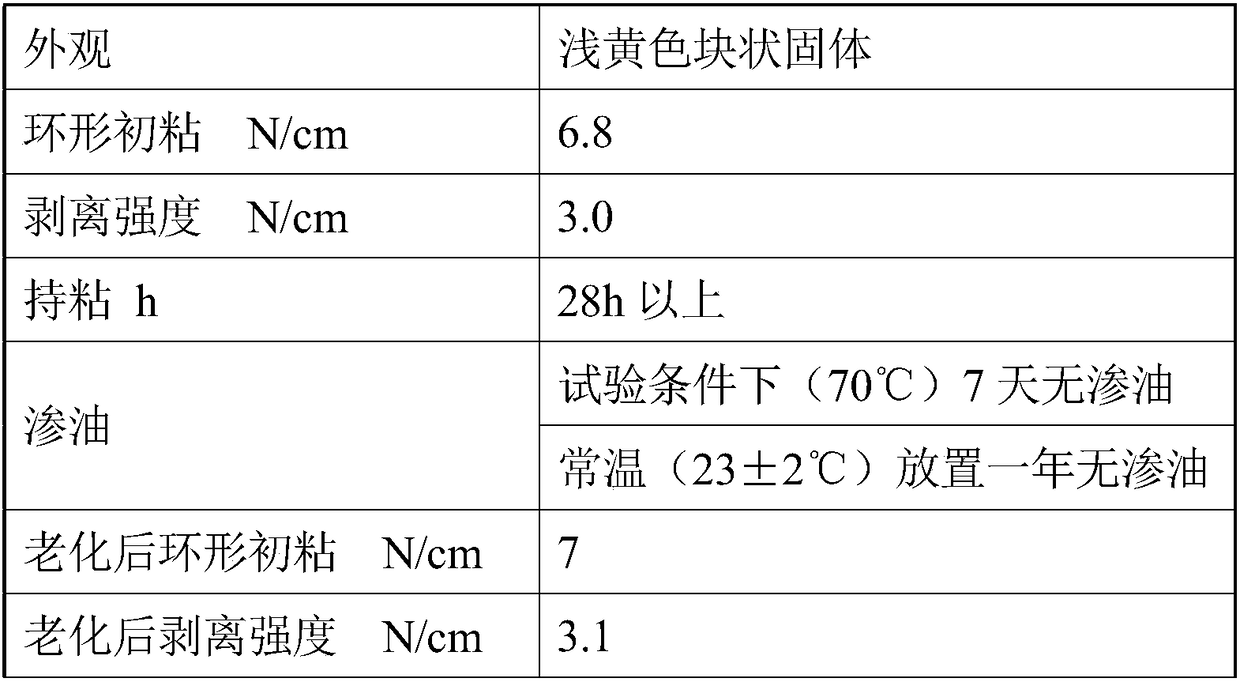

Hot melt pressure sensitive adhesive and preparation method thereof

ActiveCN102504735ASmall temperature changeGood initial adhesionMineral oil hydrocarbon copolymer adhesivesConjugated diene hydrocarbon adhesivesPlasticizerHot melt

The invention provides a hot melt pressure sensitive adhesive and a preparation method thereof, which solve the problems of improving initial tack, oil penetration and die cutting property, etc. The hot melt pressure sensitive adhesive comprises the following components by weight: 25-40 parts of matrix resin, 48-60 parts of tackifier, 12-22 parts of plasticizer and 0.6-1.2 part of a stabilizing agent, wherein the matrix resin comprises triblock copolymer of styrene-isoprene-styrene and diblock copolymer solution-polymerized styrene butadiene rubber of styrene-butadiene in a weight ratio of 1.2-3.1. The hot melt pressure sensitive adhesive provided by the invention has better initial tack, high peel strength and standard holding power; the hot melt pressure sensitive adhesive is free of oil penetration for seven days under heat temperature testing conditions and can be stored for one year at the normal temperature without oil penetration; the adhesive has better die cutting property; and the softening point reaches to 115 DEG C. The hot melt pressure sensitive adhesive of the invention can totally meet the requirement on fabricating back adhesive bags, labels and adhesive tapes.

Owner:河北方大新材料股份有限公司

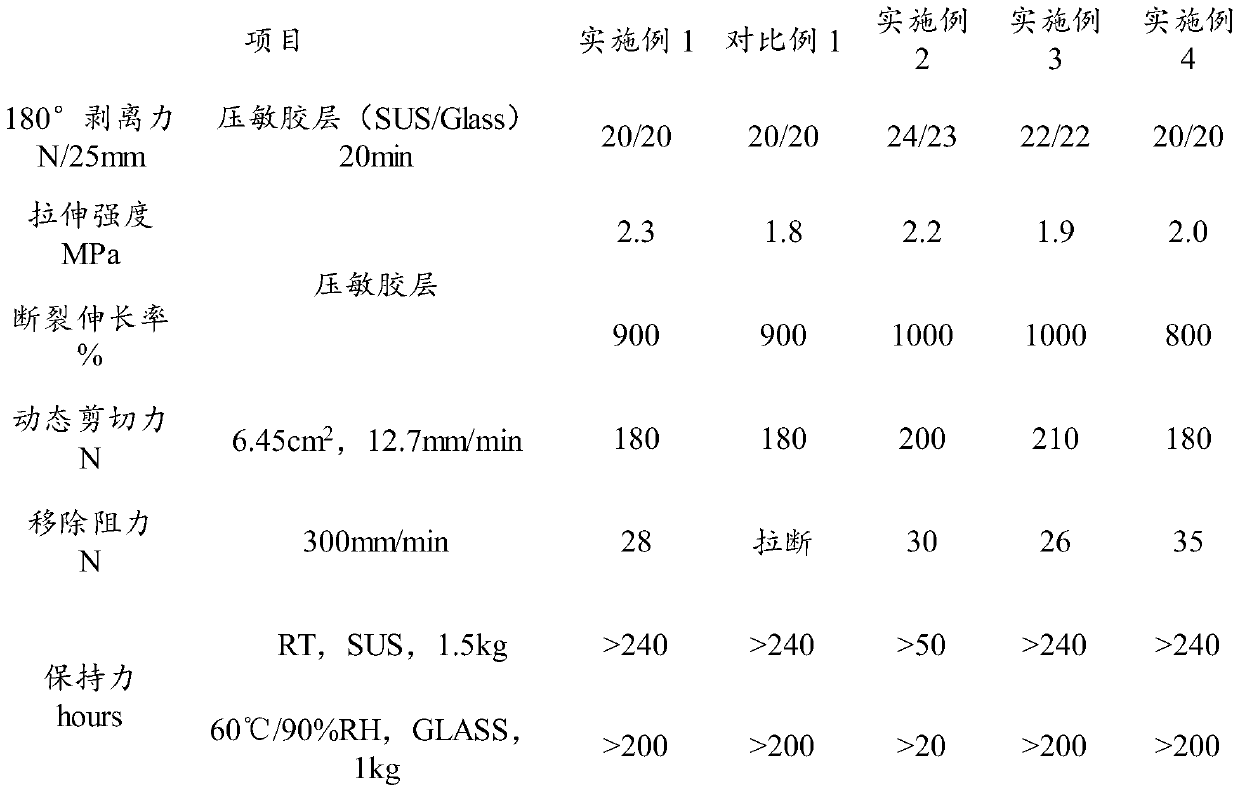

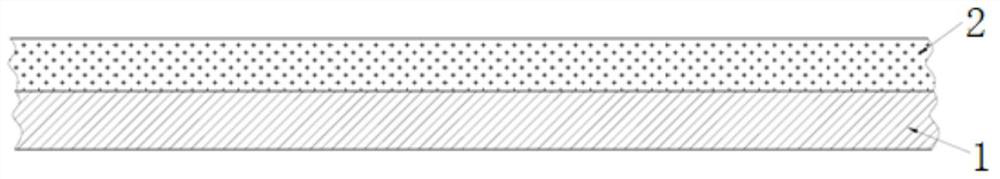

Foam double-sided tape and preparation method and application thereof

ActiveCN110003814AGood adhesionGood resistance to curved surface and anti-warpingNon-macromolecular adhesive additivesMacromolecular adhesive additivesPressure sensitiveHigh adhesion

The invention provides a foam double-sided tape and a preparation method and application thereof. The foam double-sided tape comprises a base material and a pressure sensitive adhesive layer compounded at two sides of the base material. The base material is a stretchable foam layer with at least a stretchable film compounded at one side thereof. Elongation at break of the stretchable film is greater than 300%, and tensile strength is greater than 10 MPa; elongation at break of the stretchable foam layer is greater than 300%, and tensile strength is greater than 1 MPa. Elongation at break of the pressure sensitive adhesive layer is 150-3000%, tensile strength is 1MPa-30MPa, and 180-degree peel strength is greater than 5N / 25mm. By the adoption of the functional layer with specific performance parameters, good interaction is realized under a specific structure, and the foam double-sided tape has excellent adhesion, excellent resistance to curved surface and warp, good buffer performance and excellent shear resistance, has high adhesion and die cutting performance to various surfaces of glass, PC, stainless steel, ABS, etc., can be removed tracelessly from various surfaces by simply stretching the whole tape, and is applicable to bonding and assembling of components of electronic products.

Owner:安徽屹珹新材料科技有限公司

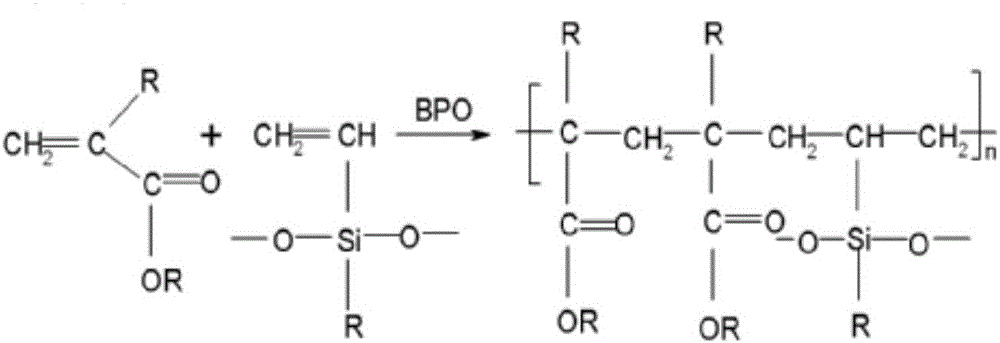

High temperature and die cutting resistant pressure-sensitive adhesive and preparation method thereof

InactiveCN106589221AGood film formingExcellent adhesionEster polymer adhesivesCross-linkOrganic solvent

The invention relates to a high temperature and die cutting resistant pressure-sensitive adhesive. The adhesive is characterized in that adhesive comprises, by mass, 100 parts of a main monomer, 0.1-1.0 part of an initiator, 0.1-5.0 parts of a cross-linking agent, and 40-60 parts of an organic solvent, wherein the main monomer comprises a soft monomer, a hard monomer, a cross-linking monomer and organic silicon resin, and a mass ratio of the soft monomer to the hard monomer to the cross-linking monomer to the organic silicon resin is (60-80):(8-35):(5-15):(1-10). The invention also relates to a preparation method of the pressure-sensitive adhesive. The pressure-sensitive adhesive has the advantages of excellent high temperature resistance, good die cutting performance, and no die cleaning after 20,000 or above time die cutting. The pressure-sensitive adhesive has the common characteristics of an organosilicone adhesive and an acrylic acid adhesive, has good film forming property, has good adhesion strength (1000-2000g / 25mm), and has good adhesion to a substrate. A preparation method of the pressure-sensitive adhesive has the advantages of simplicity, easiness in control, and facilitation of reduction of the production cost of the pressure-sensitive adhesive.

Owner:NINGBO SOKEN CHEM

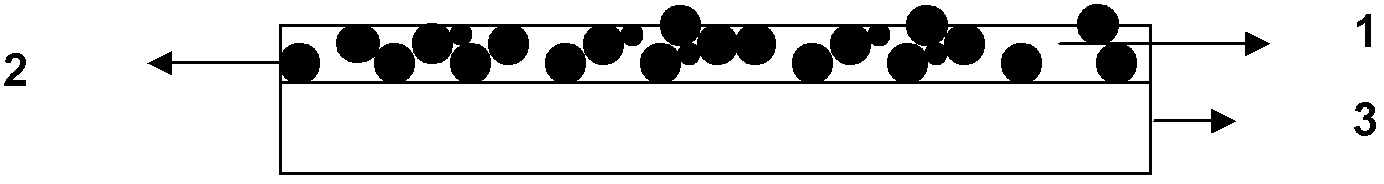

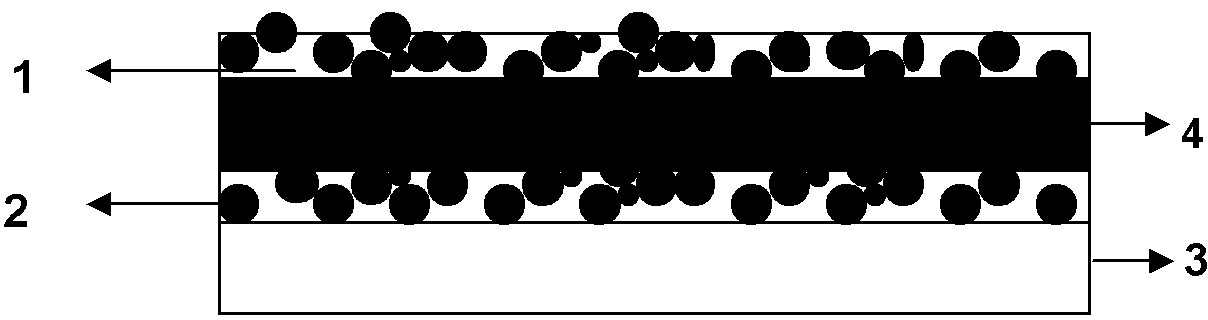

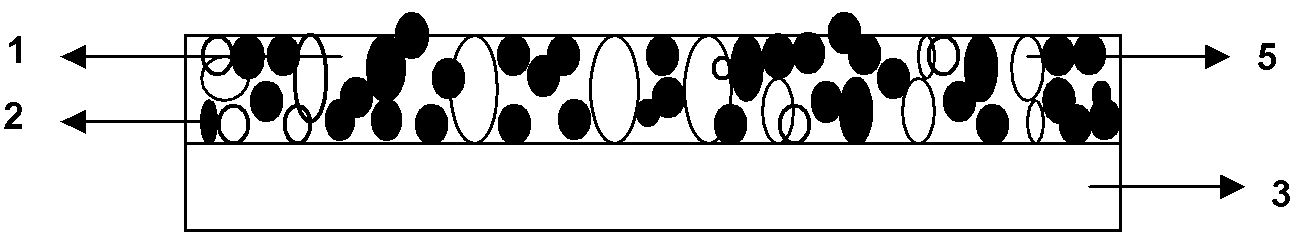

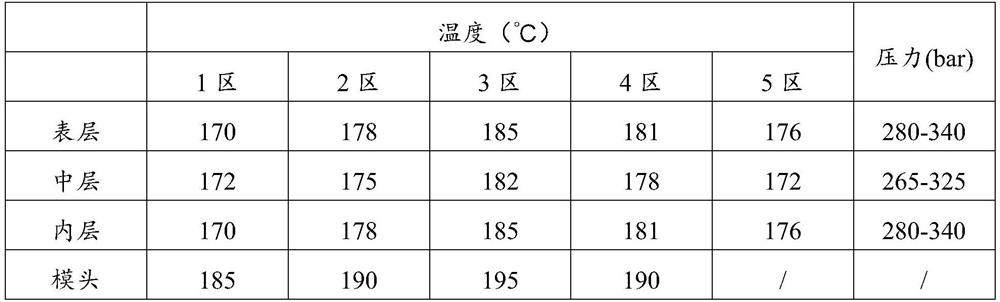

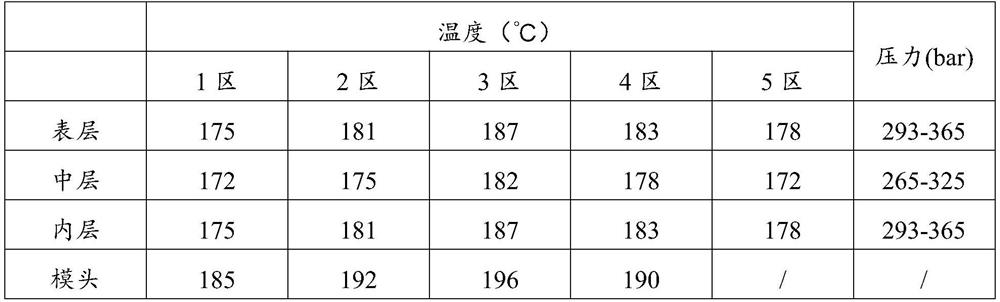

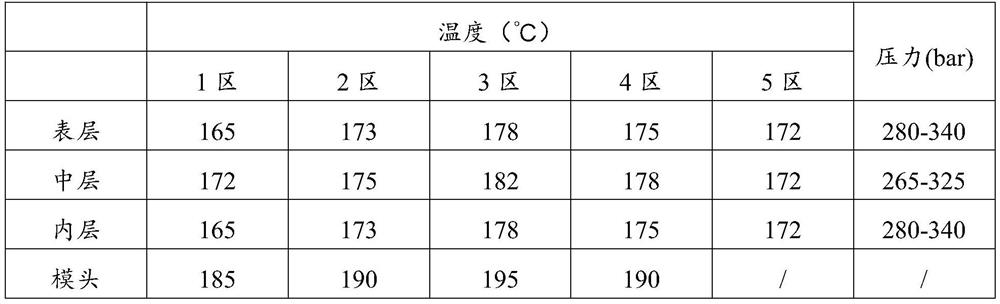

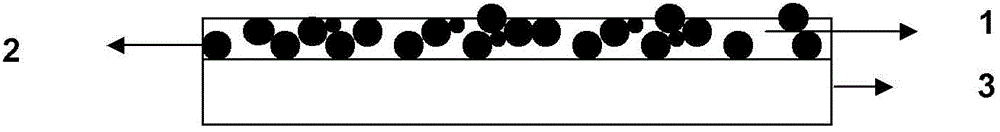

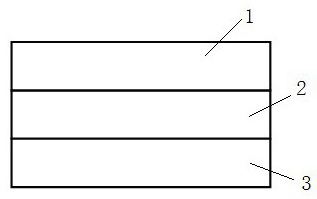

Three-layer coextruded polyethylene label film and preparation method thereof

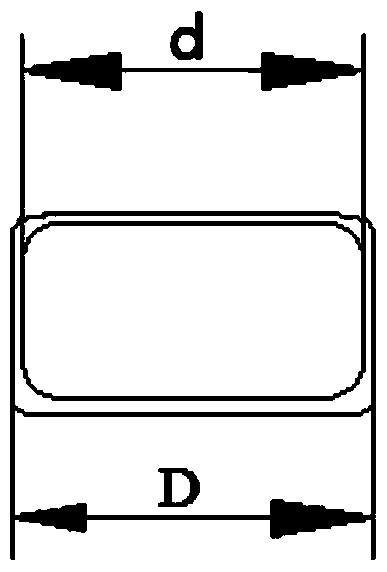

ActiveCN109532177APhysical performance balanceDie-cut effect is goodStampsSynthetic resin layered productsCo extrusionMedium-density polyethylene

The invention relates to a printing and die-cutting three-layer film structure label material, in particular to a three-layer co-extruded polyethylene label film and a preparation method thereof. Thepolyethylene label film comprises an outer layer, an intermediate layer and an inner layer, the label film is prepared from the outer layer, the intermediate layer and the inner layer through a three-layer co-extrusion up-blowing forming process, and the blowup ratio is controlled to be 2-3.5. The outer layer is prepared from the following components in percentage by mass: 70-85% of high-density polyethylene, 10%-20% of metallocene catalyzed polyethylene and 5%-10% of low-density polyethylene, wherein the sum of the mass percentages of all the components is 100%. The intermediate layer is prepared from the following components in percentage by mass: 75-90% of high-density polyethylene and 10%-25% of metallocene catalyzed polyethylene. The inner layer is prepared from the following components in percentage by mass: 70%-90% of medium-density polyethylene and 10%-30% of low-density polyethylene. The label film provides sufficient stiffness and excellent die-cutting performance and has good vertical and horizontal balanced physical properties.

Owner:广东超维塑料薄膜有限公司

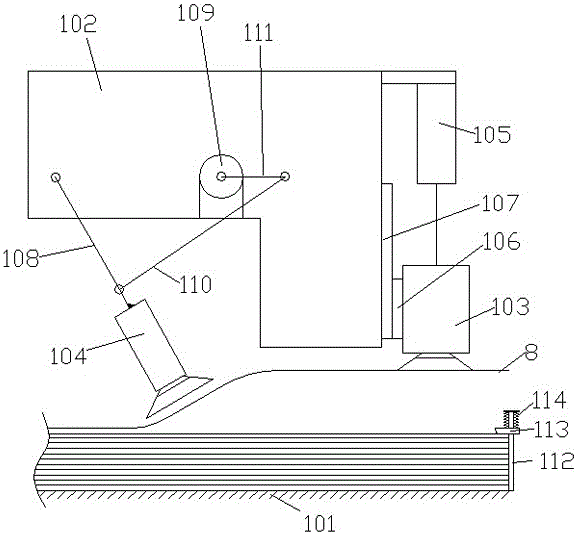

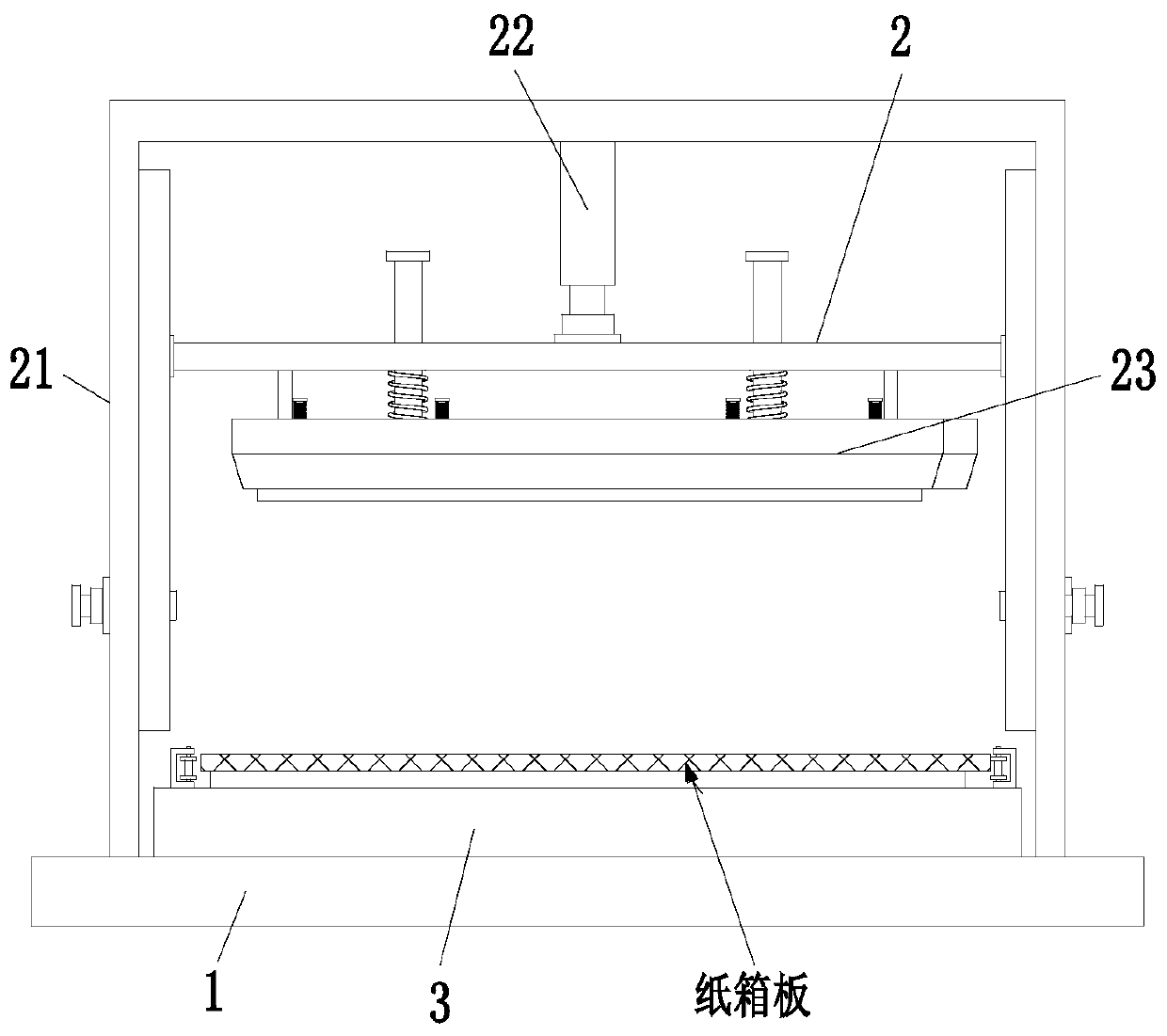

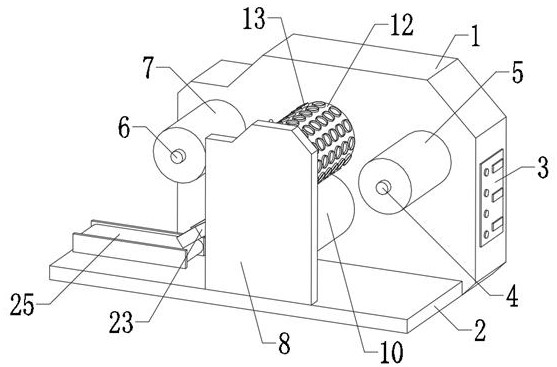

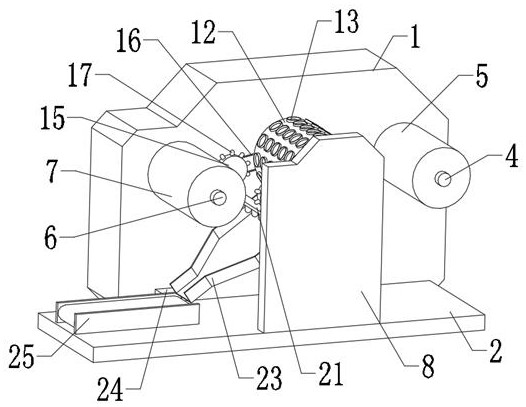

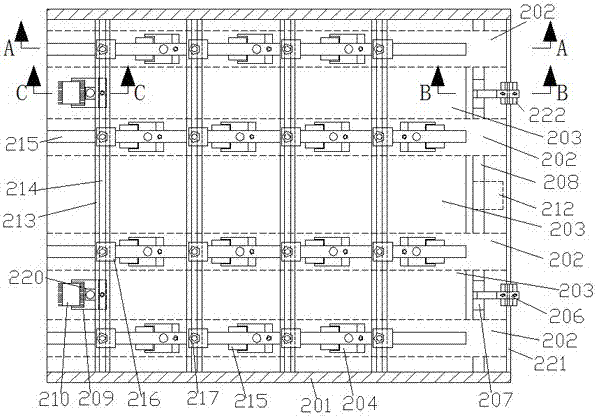

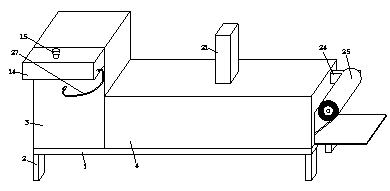

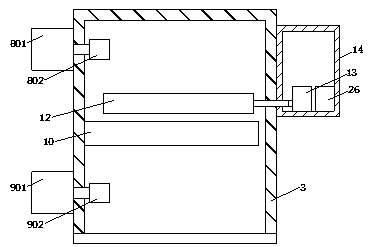

Die-cutting machine of packaging box

The invention relates to a die-cutting machine of a packaging box. The die-cutting machine comprises a feeding mechanism, a conveying mechanism, a die-cutting mechanism and a discharging mechanism which are sequentially arranged from the input direction to the output direction. A gripper row mechanism is arranged between the die-cutting mechanism and the discharging mechanism in a penetrating manner and comprises a driving wheel and a driven wheel. The driving wheel and the driven wheel are in transmission through a chain. Gripper rows are evenly distributed on the chain. The lower portion of the driving wheel and the lower portion of the driven wheel are each provided with a gripper opening device. The die-cutting mechanism is located on the lower rear side of the driving wheel. The discharging mechanism is located below the gripper opening device on the lower portion of the driven wheel. The die-cutting machine is simple in structure, suitable for die-cutting machining of membranes, stable in conveying, good in die-cutting effect and high in machining efficiency.

Owner:FUJIAN YINGHAO CULTURAL & CREATIVE CO LTD

Hot melt pressure sensitive adhesive for high speed automatic labeling and preparation method thereof

InactiveCN102618194ALow costHigh initial tack and sticking powerMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPressure sensitiveChemistry

The invention discloses a hot melt pressure sensitive adhesive for high speed automatic labeling, which comprises, by weight percentage, 40-45% of petroleum resins, 35-45% of styrene-isoprene-styrene, 10-15% of naphthenic oil, 2-5% of calcium carbonate, 1-3% of polyethylene wax and 1-2% of antioxidants. A preparation method of the hot melt pressure sensitive adhesive for high speed automatic labeling is further disclosed. Compared with prior art, the hot melt pressure sensitive adhesive has the advantages of being environment-friendly, low in cost, high in initial bonding strength and enduring bonding strength, excellent in die cutting performance, and applicable to the high speed automatic labeling.

Owner:佛山南宝高盛高新材料有限公司

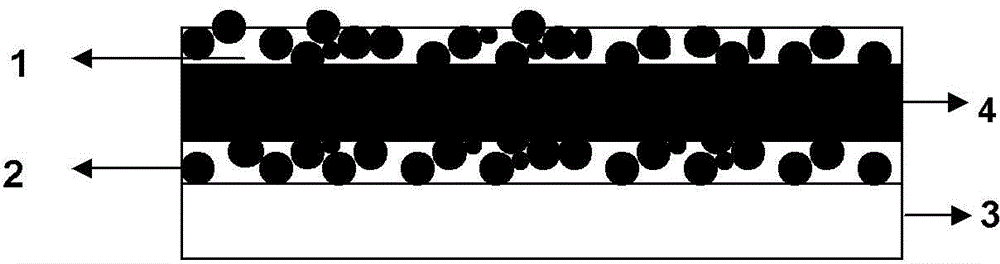

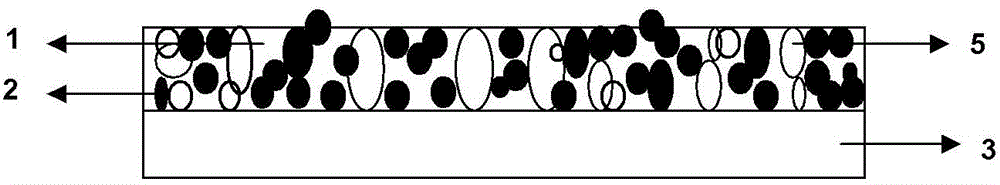

Ultrathin foam conductive adhesive tape

ActiveCN103320037ALow costGood flexibilityFilm/foil adhesivesEster polymer adhesivesCore shellViscosity

The invention provides an ultrathin foam conductive adhesive tape which comprises a pressure-sensitive adhesive layer and a release film on at least one side of the pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer comprises a (methyl) acrylate copolymer base, and expanded polymer core-shell particles and conductive particles dispersed in the base; and the thickness of the pressure-sensitive adhesive layer is 2-500 micrometers. The ultrathin foam conductive adhesive tape has lower cost, adjustable compressible characteristic, favorable viscosity and favorable conductivity.

Owner:明尼苏达矿业制造特殊材料(上海)有限公司

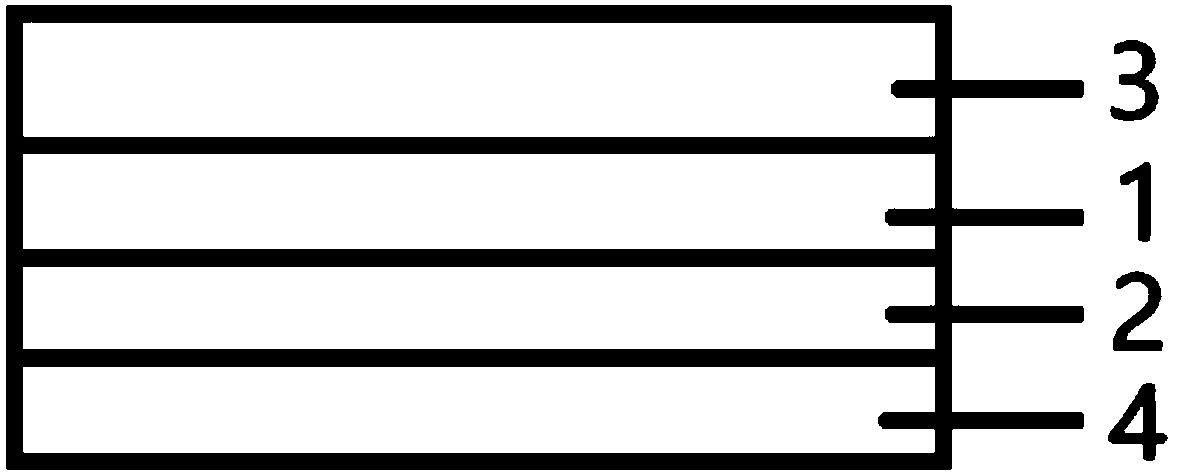

Polyethylene composite film as well as preparation method and application thereof

ActiveCN112976744AUltra-thinImprove stiffnessSynthetic resin layered productsLow-density polyethylenePolymer science

The invention belongs to the technical field of polyethylene materials, and particularly relates to a polyethylene composite film as well as a preparation method and application thereof. The polyethylene composite film provided by the invention comprises a surface layer, a middle layer and an inner layer which are sequentially bonded; the surface layer comprises first low-density polyethylene, first high-density polyethylene and a first processing aid; the middle layer comprises second low-density polyethylene, metallocene linear low-density polyethylene, second high-density polyethylene and a second processing aid; the inner layer comprises third low-density polyethylene, third high-density polyethylene and a third processing aid; and the thickness of the polyethylene composite film is 40 microns. Experimental results show that the polyethylene composite film provided by the invention has both thinning and good stiffness.

Owner:江门市华龙膜材股份有限公司

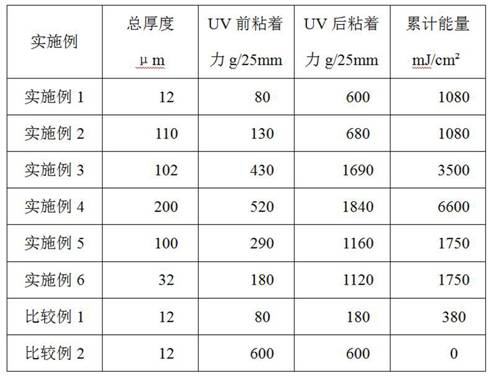

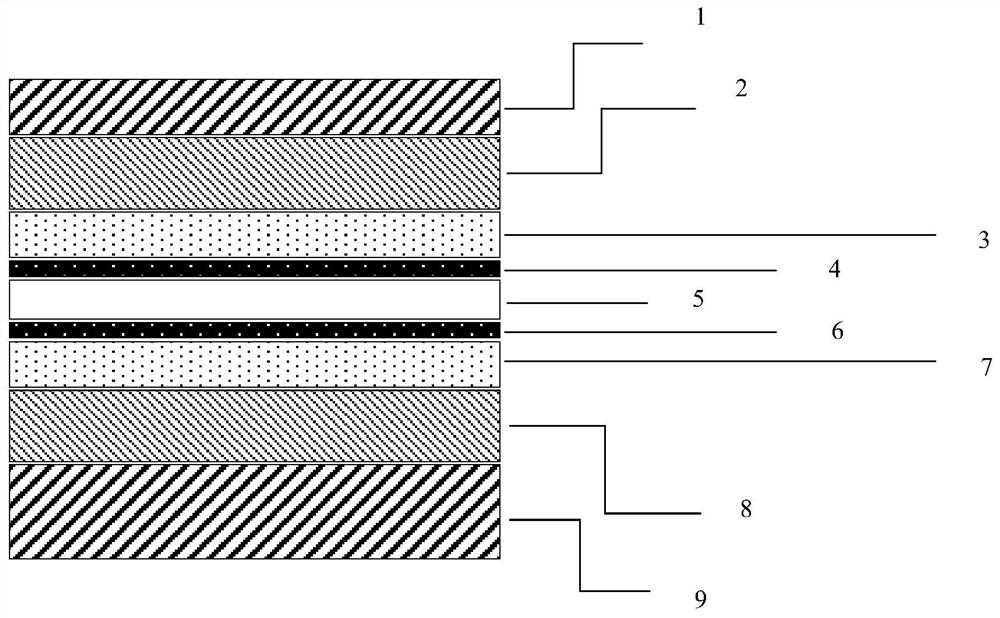

Incompletely cured OCA optical adhesive with multilayer structure and preparation method thereof

ActiveCN109096929AThere will be no phenomenon such as stratificationSolve the problem of interface binding forceOrganic non-macromolecular adhesiveFilm/foil adhesive release linersAdhesivePhysical property

The invention discloses an incompletely cured OCA optical adhesive with a multilayer structure and a preparation method thereof. An completely cured first OCA layer and an incompletely cured second OCA layer are composited, the incompletely cured second OCA layer laminates a cover plate glass to meet the filling of an ink section difference, the completely cured first OCA layer is used to improvethe overall cohesion, and the excellent die cutting property is met to adapt to weather changes in various seasons, and various problems in the transportation process are solved. The incompletely cured OCA optical adhesive is a low-elasticity product, but has different physical properties, and has die-cutting stability and environmental adaptability which are not possessed by a single-layer product in use and preservation. According to the incompletely cured OCA optical adhesive, the problem of interface bonding force between multi-layer structure OCAs is solved at the same time, and it is ensured that the incompletely cured OCAs with the multilayer structure are not subjected to layering and the like when an adherend is attached to the incompletely cured OCAs before or after the curing.

Owner:新纶电子材料(常州)有限公司

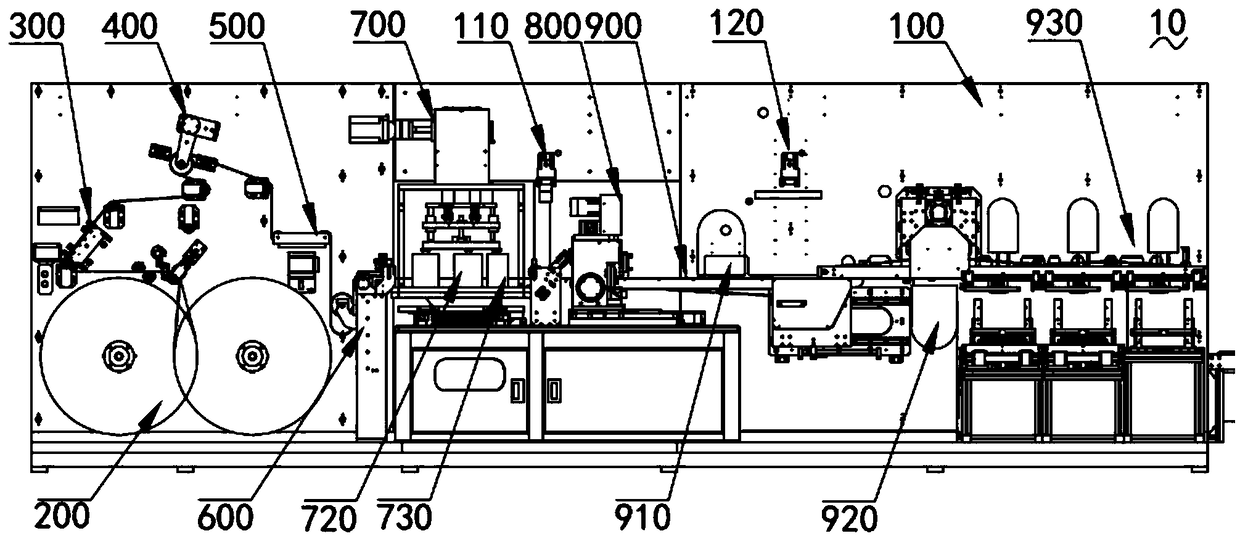

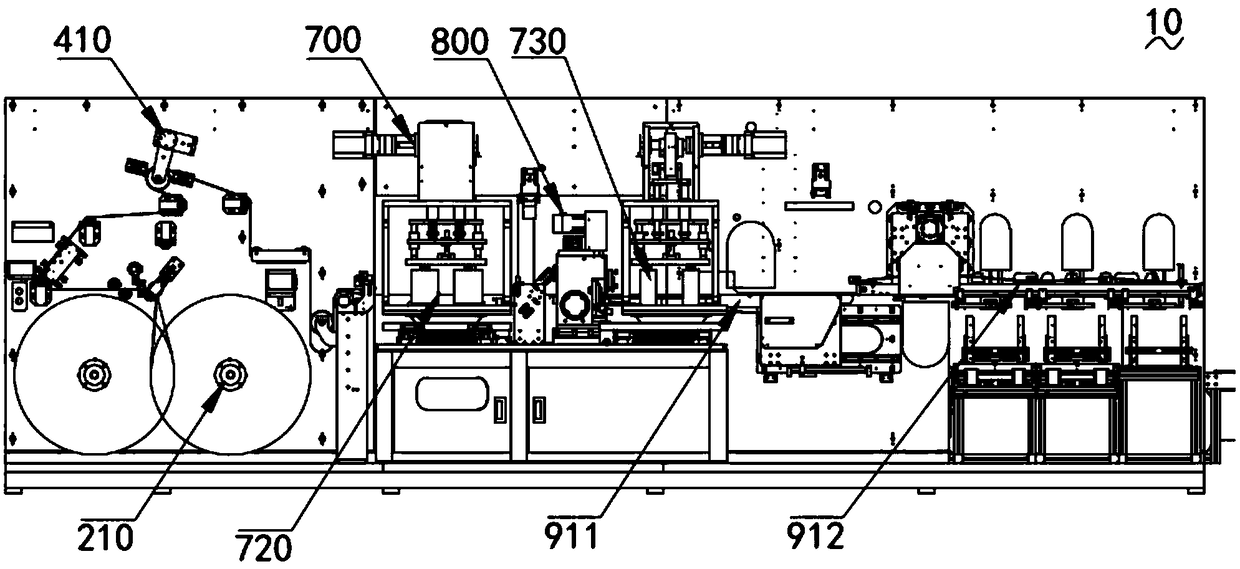

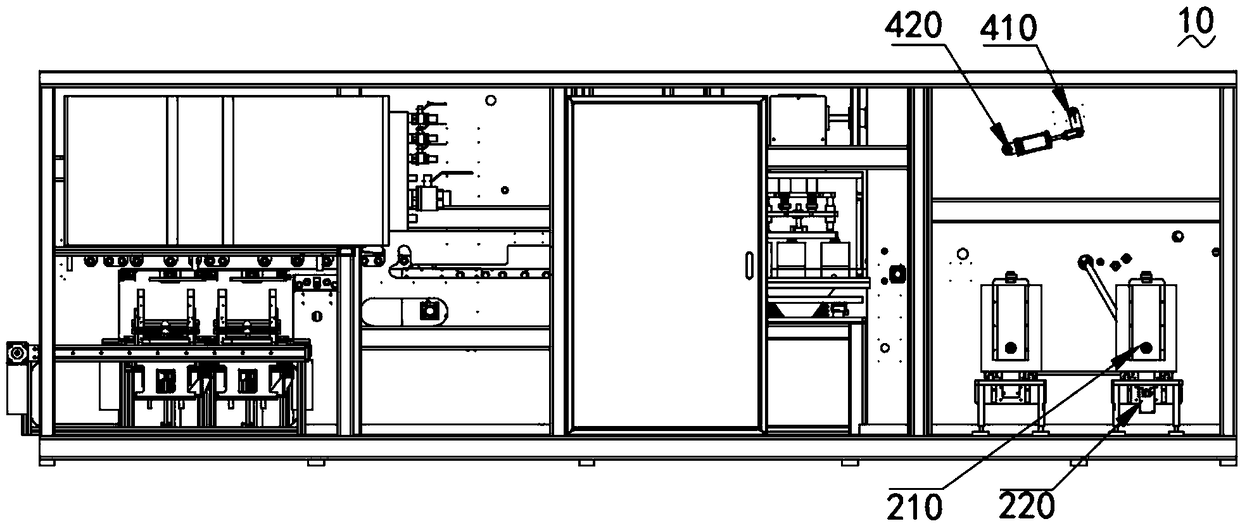

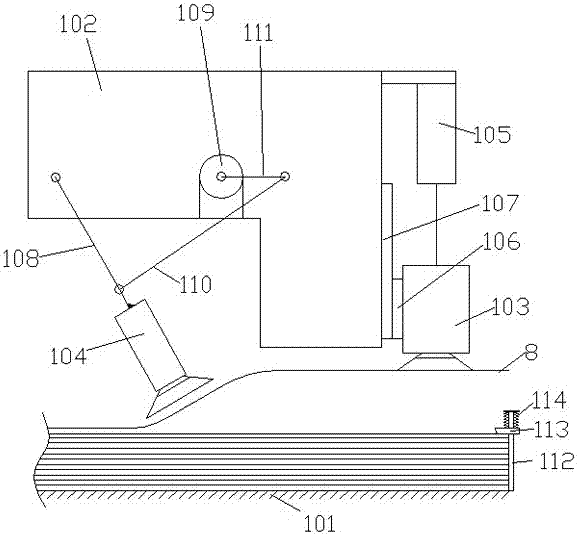

Die cutting mechanism with pole piece corner cutting, system comprising die cutting mechanism and method

The invention relates to the technical field of pole piece die cutting, in particular to a die cutting mechanism with pole piece corner cutting, a system comprising the die cutting mechanism and a method. The die cutting mechanism comprises a tab cutting mould, a regulating mechanism and a corner cutting mould, wherein the tab cutting mould is used for cutting out a tab for a pole piece; the regulating mechanism is used for regulating the tab cutting mould to adapt different sizes of pole pieces to cut out the tabs; and the corner cutting mould is arranged on one side of the tab cutting mouldand is used for cutting the corner of the pole piece with the tab. The regulating mechanism comprises at least one groups of X regulating modules and Y regulating modules regulated and transmitted tothe X regulating modules. The tab cutting mould is connected with a driving component and a support used for fixedly installing the driving component, and the support is arranged at the Y regulating modules. The moulds of the die cutting mechanism have certain universality, the die cutting mechanism can die-cut out different sizes of pole pieces by only needing to store the same two kinds of moulds, and the storage amount and the cost of the moulds are reduced. The mould becomes smaller after being separated, the difficulty in mould processing is reduced, and the service life of the mould is long.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

Heat-shrinkable polyester film

The present invention relates to a heat-shrinkable polyester film, which has a heat-shrinkage of 20% or more in both the longitudinal and transverse directions when treated with 80° C. water for 30 seconds and a bidirectional balance parameter in the range of 0.25 to 2.5 and exhibits an excellent properties in die-cutting and removing from a container such as a glass bottle for recycling by washing with hot water.

Owner:SK MICROWORKS CO LTD

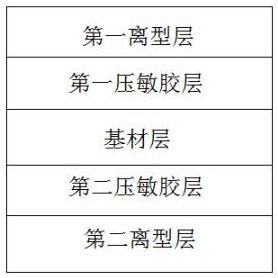

Novel double-sided tape

PendingCN113249046AImprove initial tack performanceLow peel strengthFilm/foil adhesive release linersPolymer scienceAdhesive

The invention discloses a novel double-sided tape, comprising a first release layer, a first pressure-sensitive adhesive layer, a base material layer, a second pressure-sensitive adhesive layer and a second release layer, wherein the first release layer is arranged above the pressure-sensitive adhesive layer, the first pressure-sensitive adhesive layer is arranged above the base material layer, the second pressure-sensitive adhesive layer is arranged below the base material layer, and the second release layer is arranged below the second pressure-sensitive adhesive layer. According to the invention, the first pressure-sensitive adhesive layer and the second pressure-sensitive adhesive layer which are prepared from a post-curing acrylic acid UV pressure-sensitive adhesive are subjected to coating so as to form the tape, so the tape is high in initial viscosity at an initial stage, low in peel strength and convenient to position and rework; and after being irradiated by UV light, the tape is improved in adhesion degree, the peel strength of the tape is sharply increased to achieve a firm adhesion effect, and meanwhile, the temperature resistance of the tape is also greatly improved. A PET thin film, a PI thin film, a PVC thin film, a TPU thin film or a non-woven fabric is used as the base material layer, so a die-cutting property is excellent, the problems of adhesive overflowing, wire drawing and the like during die cutting can be avoided, and production yield is high.

Owner:宁波启合新材料科技有限公司

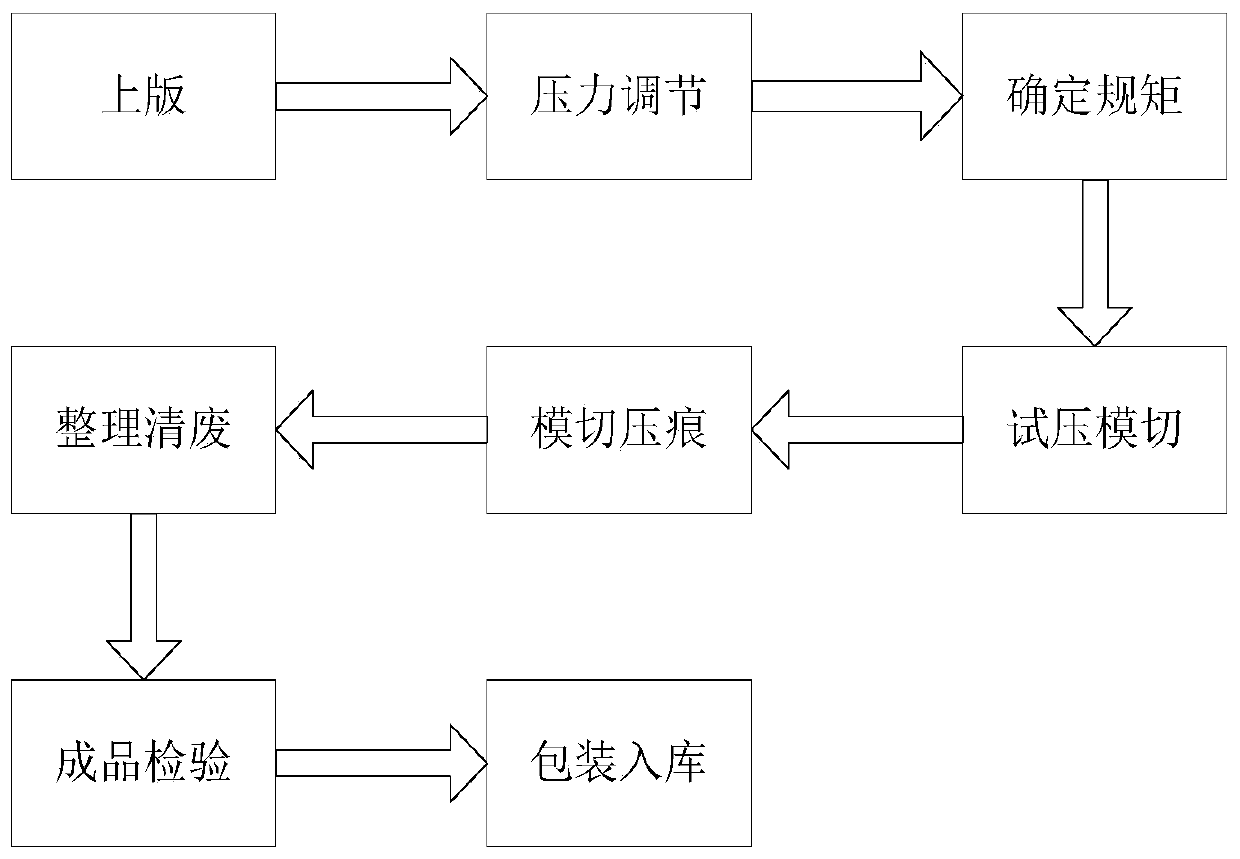

Packaging carton die cutting process and die cutting machine thereof

InactiveCN110039823AEase of mass productionImprove work efficiencyBox making operationsPaper-makingCarton

The invention relates to a packaging carton die cutting process and a die cutting machine thereof. The packaging carton die cutting machine comprises a mounting plate, a die cutting device and a pressing plate, wherein the die cutting device is arranged at the upper end of the mounting plate, the pressing plate is arranged below the middle part of the die cutting device, and the pressing plate isarranged in the middle part of the upper end of a bottom plate. The packaging carton die cutting process and the die cutting machine thereof can be used for solving the problems at present that when apackaging carton is produced, in general, the working efficiency is low, disassembly and maintenance are inconvenient, and the large-scale production of enterprises can not be facilitated; and meanwhile, in the die cutting process of the carton, the die cutting effect is poor, redundant leftover materials and burrs are easily generated, and the pressure of a line pressing cutter during die cutting can not be accurately adjusted. The process and the machine have the advantages of being high in working efficiency, convenient to disassemble and maintain, and good in die cutting effect; and moreover, deformation caused by uneven stress on the outer end of a carton board can be prevented, and redundant leftover materials and burrs generated on the die-cut carton board are avoided.

Owner:宛群

Heat-shrinkable polyester film

ActiveUS8512833B2Satisfactory die-cutting propertyImprove shrinkageWrappers shrinkageBottlesPolyesterBottle

The present invention relates to a heat-shrinkable polyester film, which has a heat-shrinkage of 20% or more in both the longitudinal and transverse directions when treated with 80° C. water for 30 seconds and a bidirectional balance parameter in the range of 0.25 to 2.5 and exhibits an excellent properties in die-cutting and removing from a container such as a glass bottle for recycling by washing with hot water.

Owner:SK MICROWORKS CO LTD

Ultrathin foam conductive adhesive tape

ActiveCN103320037BLow costGood flexibilityFilm/foil adhesivesEster polymer adhesivesCore shellViscosity

The invention provides an ultrathin foam conductive adhesive tape which comprises a pressure-sensitive adhesive layer and a release film on at least one side of the pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer comprises a (methyl) acrylate copolymer base, and expanded polymer core-shell particles and conductive particles dispersed in the base; and the thickness of the pressure-sensitive adhesive layer is 2-500 micrometers. The ultrathin foam conductive adhesive tape has lower cost, adjustable compressible characteristic, favorable viscosity and favorable conductivity.

Owner:明尼苏达矿业制造特殊材料(上海)有限公司

A die-cut waste discharge device and a die-cut waste discharge method for die-cut parts with an inner frame

InactiveCN106541449BGood waste discharge effectThe waste disposal process went smoothlyMetal working apparatusTectorial membranePunching

The invention relates to a die-cutting waste discharge device with an inner frame die-cutting piece and a die-cutting waste discharge method. The die-cutting waste discharge device comprises a first opposite-pressing roller, first-stamping die-cutting cutters, first waste discharge rollers, a second opposite-pressing mechanism, second-stamping die-cutting cutters and second waste discharge rollers which are arranged sequentially. The first opposite-pressing roller attaches a first single face gummed protective film to a first release film; indent inner frames are punched in first stamping by the first-stamping die-cutting cutters; the first waste discharge rollers is used to take up the first single face gummed protective films attached to wastes of the inner frames after the first-stamping punching; the second opposite-pressing mechanism attaches a second single face gummed protective film to the non-release surface of the first release film, and sequentially attaches double faced adhesive tape and a second release film to the release surface of the first release film; normal inner frames are punched in second-stamping by the second-stamping die-cutting cutters; the second waste discharge rollers are used to take up the second single face gummed protective films attached to wastes of the inner frames after the second-stamping punching; and the size of each normal inner frame is bigger than the size of each indent inner frame. Compared with the prior art, the die-cutting waste discharge device has the advantages that the effect of waste discharge is good, the product has no deformation, and efficiency is high.

Owner:YUANRANG IND SHANGHAI

A kind of incomplete curing type oca optical adhesive of multi-layer structure and preparation method thereof

ActiveCN109096929BThere will be no phenomenon such as stratificationSolve the problem of interface binding forceOrganic non-macromolecular adhesiveFilm/foil adhesive release linersAdhesiveInterfacial binding

The invention discloses an incompletely cured OCA optical adhesive with a multi-layer structure and a preparation method thereof. The fully cured first OCA layer and the incompletely cured second OCA layer are combined, and the incompletely cured second OCA layer To fit the cover glass, meet the filling of the ink step difference, fully cured the first OCA layer to improve the overall cohesion, meet the excellent die-cutting performance, adapt to the weather changes in various seasons, and various problems during transportation. The present invention is a product with low elastic modulus, but has different physical properties, and has die-cutting stability and environmental adaptability that single-layer products do not have in use and storage; The problem of interfacial bonding force ensures that the incompletely cured OCA of the multi-layer structure of the present invention will not delaminate after being attached to the adherend before and after curing.

Owner:新纶电子材料(常州)有限公司

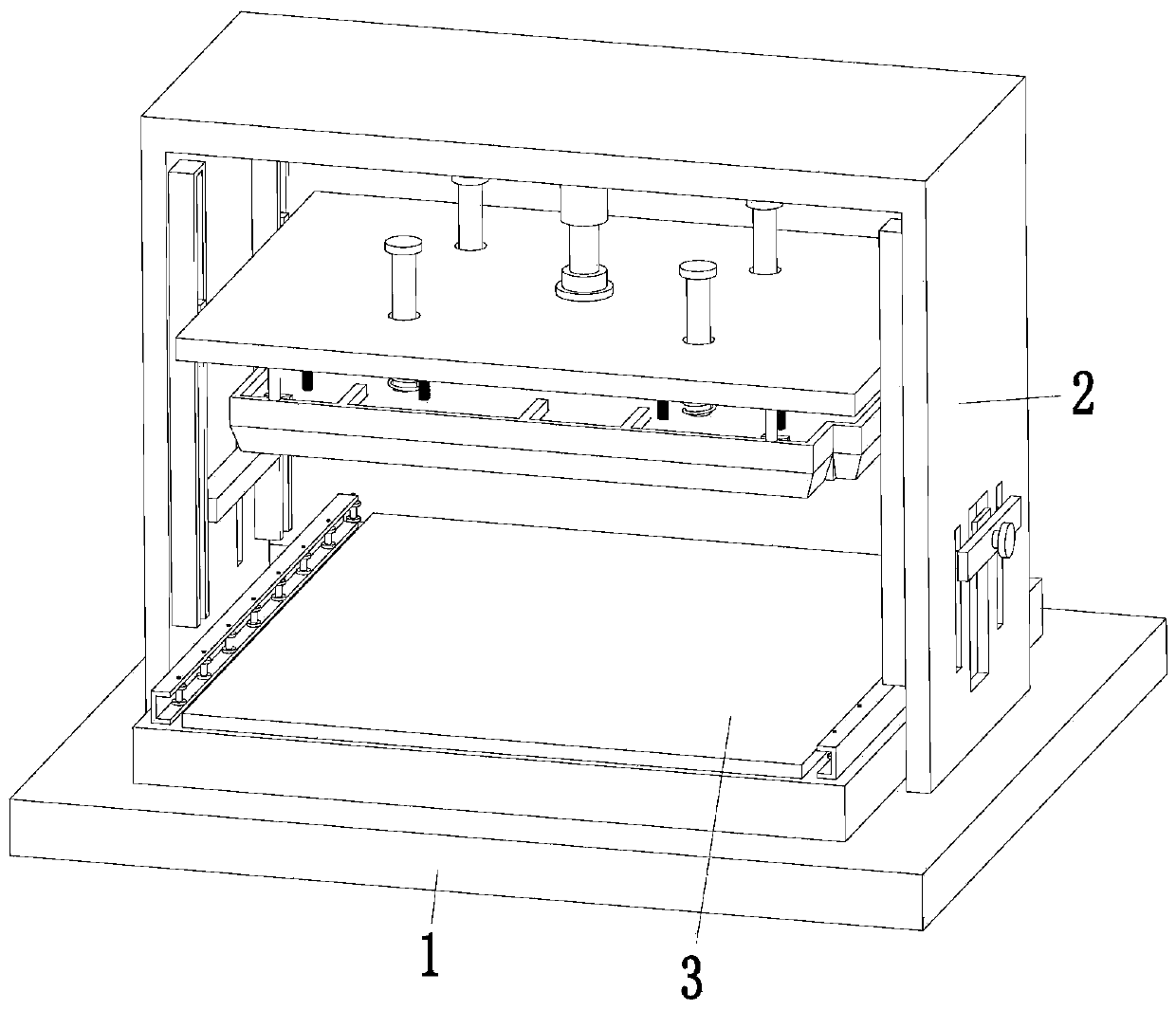

Intelligent die-cutting machine for polyester plastic film sheet material preparation

The invention relates to the technical field of die-cutting machines, in particular to an intelligent die-cutting machine for polyester plastic film sheet material preparation, which comprises an electric control cabinet and a bottom plate. A vertical plate is mounted outside the bottom plate, and a stripping mechanism is arranged between the electric control cabinet and the vertical plate; the stripping mechanism comprises a transmission shaft A and a transmission shaft B which are rotationally connected between the electric control cabinet and the vertical plate, a connecting shaft is installed on the sides, close to each other, of the electric control cabinet and the vertical plate, a rotating disc is installed outside the connecting shaft, a belt is jointly wound between the connecting shaft and the transmission shaft B, a plurality of matching rods are installed outside the rotating disc, and limiting grooves are formed in the sides, close to each other, of the electric control cabinet and the vertical plate. The die-cutting machine has the advantages that cut materials are prevented from being adhered to raw materials, the working efficiency of polyester plastic film sheet material preparation is improved, the cost of polyester plastic film sheet material preparation is reduced, the die cutting effect is better, damage to the cutter head is reduced, and the service life of the cutter head is prolonged.

Owner:温州合盛塑料薄膜包装有限公司

Optical transparent double-side adhesive tape

InactiveCN106753001AWide thickness rangeLow costFilm/foil adhesivesNon solventPolyethylene terephthalate

The invention discloses an optical transparent double-side adhesive tape, which comprises three layers which are sequentially an OCA (optically clear adhesive) layer, a transparent substrate layer and an OCA layer, wherein the transparent substrate layer is made of a PET (polyethylene terephthalate) material, a PC (polycarbonate) material or a PMMA (polymethylmethacrylate) material. The thickness of the OCA layer is not greater than 0.6mm; the thickness of the transverse substrate layer is not greater than 2.0mm; the optical transparent double-side adhesive tape can be easily made to be thick; through the design of a three-layer structure, the thickness range is wider; the integral thickness can be realized through regulating the thickness of the OCA layers at the two sides and the transparent substrate layer in the middle; the wide thickness range can be realized regardless of using a solvent method or a non-solvent method; a transparent substrate is used for blocking between the OCA optical adhesive, so that the qualification rate in the die cutting process is effectively improved; the cost of the single optical transparent double-side adhesive tape is reduced.

Owner:任太荣

A kind of removable hot-melt pressure-sensitive adhesive and preparation method thereof

ActiveCN106318292BGood initial adhesionExcellent adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesUltravioletTackifier

Owner:河北方大新材料股份有限公司

Box Die Cutting Machine

The invention relates to a die-cutting machine of a packaging box. The die-cutting machine comprises a feeding mechanism, a conveying mechanism, a die-cutting mechanism and a discharging mechanism which are sequentially arranged from the input direction to the output direction. A gripper row mechanism is arranged between the die-cutting mechanism and the discharging mechanism in a penetrating manner and comprises a driving wheel and a driven wheel. The driving wheel and the driven wheel are in transmission through a chain. Gripper rows are evenly distributed on the chain. The lower portion of the driving wheel and the lower portion of the driven wheel are each provided with a gripper opening device. The die-cutting mechanism is located on the lower rear side of the driving wheel. The discharging mechanism is located below the gripper opening device on the lower portion of the driven wheel. The die-cutting machine is simple in structure, suitable for die-cutting machining of membranes, stable in conveying, good in die-cutting effect and high in machining efficiency.

Owner:FUJIAN YINGHAO CULTURAL & CREATIVE CO LTD

Expanded polytetrafluoroethylene film of composite conducting layer and preparation method of expanded polytetrafluoroethylene film

PendingCN113004564AGuaranteed stabilityGood flexibilitySpecial surfacesElectrically-conductive paintsWeather resistanceMetallic materials

The invention relates to an expanded polytetrafluoroethylene film of a composite conducting layer and a preparation method of the expanded polytetrafluoroethylene film. The expanded polytetrafluoroethylene film of the composite conducting layer comprises an expanded polytetrafluoroethylene layer and a conducting layer, wherein the conductive layer is compounded on the surface of the expanded polytetrafluoroethylene layer through hot pressing. The preparation method comprises the steps of stretching the expanded polytetrafluoroethylene layer to obtain a base material, preparing conductive liquid, coating the surface of the base material with the conductive liquid, drying, and finally compounding the conductive liquid on the surface of the base material in a hot pressing manner to obtain the expanded polytetrafluoroethylene film of the composite conductive layer. Compounding is carried out in a hot pressing mode, the stability of the conducting layer can be ensured, and compared with a metal material, the expanded polytetrafluoroethylene is high in flexibility, good in die cutting performance and excellent in weather resistance.

Owner:士彩材料科技(苏州)有限公司

A kind of three-layer co-extrusion polyethylene label film and preparation method thereof

ActiveCN109532177BPhysical performance balanceDie-cut effect is goodStampsSynthetic resin layered productsCo extrusionMedium-density polyethylene

The invention relates to a printing and die-cutting three-layer film structure label material, in particular to a three-layer co-extruded polyethylene label film and a preparation method thereof. Thepolyethylene label film comprises an outer layer, an intermediate layer and an inner layer, the label film is prepared from the outer layer, the intermediate layer and the inner layer through a three-layer co-extrusion up-blowing forming process, and the blowup ratio is controlled to be 2-3.5. The outer layer is prepared from the following components in percentage by mass: 70-85% of high-density polyethylene, 10%-20% of metallocene catalyzed polyethylene and 5%-10% of low-density polyethylene, wherein the sum of the mass percentages of all the components is 100%. The intermediate layer is prepared from the following components in percentage by mass: 75-90% of high-density polyethylene and 10%-25% of metallocene catalyzed polyethylene. The inner layer is prepared from the following components in percentage by mass: 70%-90% of medium-density polyethylene and 10%-30% of low-density polyethylene. The label film provides sufficient stiffness and excellent die-cutting performance and has good vertical and horizontal balanced physical properties.

Owner:广东超维塑料薄膜有限公司

Adhesive film and preparation method thereof

PendingCN114381220AImprove temperature resistanceImprove waterproof performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

The invention belongs to the technical field of electroacoustic materials, and particularly relates to an adhesive film and a preparation method thereof, and the preparation method comprises the following steps: (1) preparing an adhesive; and (2) coating, rolling and curing. The adhesive film sequentially comprises a light release film layer, an adhesive layer and a heavy release film layer from top to bottom. The prepared adhesive film is excellent in performance, the technological operation is convenient, the defects of a dispensing technology are greatly overcome, the adhesive film is resistant to high temperature, waterproof and sealed, firm in bonding and uniform in thickness, meanwhile, the temperature of a vibrating diaphragm can be effectively reduced through the heat conduction performance, and the stability and reliability of the acoustic performance of an electronic product are greatly guaranteed.

Owner:潍坊同有新材料科技有限公司

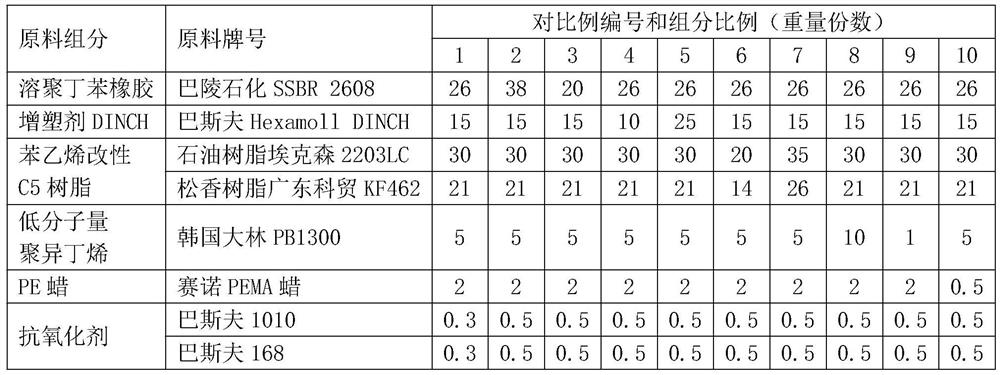

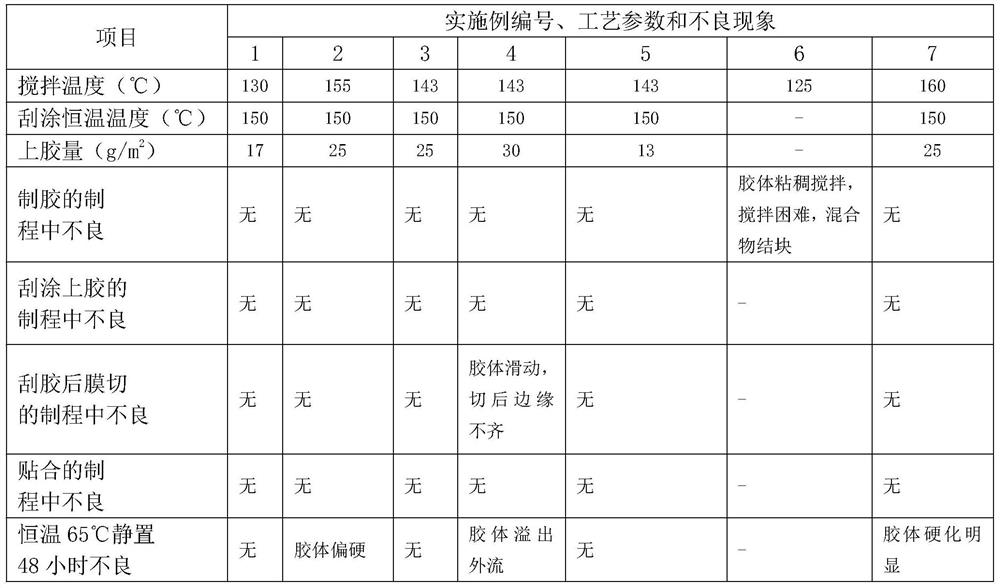

Anti-wrinkle environmentally friendly hot melt adhesive for film adhesive bags and its preparation method and application

ActiveCN111647377BIncrease internal stressHas an anti-wrinkle effectMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePlasticizer

The invention discloses an anti-wrinkle environment-friendly hot-melt adhesive for film adhesive bags, which is prepared according to parts by weight, and comprises the following raw material components: 25-35 parts of solution polystyrene butadiene, 12-20 parts of plasticizer DINCH, 40 parts ‑55 parts of styrene-modified C5 resin, 3‑8 parts of low molecular weight polyisobutylene, 1‑3 parts of PE wax and 1‑1.5 parts of antioxidant, using solution polystyrene butadiene system, with good die-cutting performance and low shrinkage With DINCH as the plasticizer, the viscosity and tensile strength of the polymer can be significantly reduced, and the plasticizer DINCH and polyisobutylene can synergistically reduce the internal stress of the colloid, so as to achieve anti-wrinkle for the label applied to the film type adhesive bag after coating The effect, and has excellent die-cutting performance. The present invention also proposes a method for preparing the wrinkle-resistant environmentally friendly hot-melt adhesive for film adhesive bags, and a method for preparing film adhesive bags using the wrinkle-resistant environmentally friendly hot-melt adhesive for film adhesive bags, The process is simple and easy to operate.

Owner:GUANGDONG RURGA NEW MATERIAL TECH +1

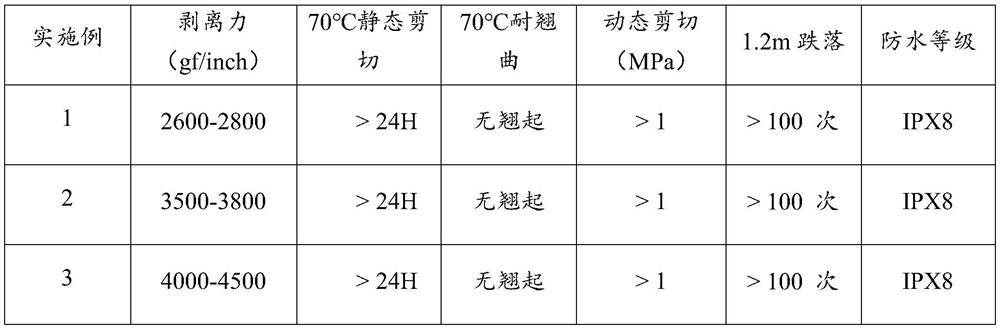

A kind of waterproof adhesive tape, its preparation method and electronic product

ActiveCN111777962BIncrease stickinessImprove waterproof performanceFilm/foil adhesive primer layersElastomerPolymer science

The invention discloses a waterproof adhesive tape, which comprises from top to bottom: a first isolation layer, a first acrylic adhesive layer, a first black thermoplastic elastomer layer, a first primer layer, a base material layer, and a second primer layer layer, a second black thermoplastic elastomer layer, a second acrylic adhesive layer, and a second release layer. The invention also discloses a preparation method of the waterproof tape and electronic products containing the waterproof tape. The waterproof adhesive tape of the invention has excellent water resistance, cushioning properties and light-shielding properties, and can be applied to permanent bonding of electronic component frames.

Owner:太仓斯迪克新材料科技有限公司

A kind of label adhesive for small-bore glass bottles and preparation method thereof

ActiveCN110669462BImprove initial viscosityIncrease stickinessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAdhesive cementPolymer science

Owner:嘉好(太仓)新材料股份有限公司

Automatic die cutting assembly line

The invention discloses an automatic die cutting assembly line. The automatic die cutting assembly line comprises a flat plate, supporting legs, a first fixing cover, a second fixing cover, a door plate, a hinge, a hasp lock, a first material cylinder, a first motor, a first three-jaw chuck, a second material cylinder, a second motor, a second three-jaw chuck, a glue receiving disc, a glue returnhole, a glue solution brush, bristles, fine holes, a straight pipe, a glue outlet pump, a glue solution box, a sealing cover, a triangular seat, a heat conduction plate, a heating sheet, a fixing seat, a first pressing structure, a first air cylinder, a fixing frame, a pressing roller, a second air cylinder, a die cutting knife, a second pressing structure, a fixing strip plate, a residual material cylinder, a third motor, a third three-jaw chuck, a material return pump, a connecting pipe, a gooseneck pipe and a hose. The automatic die cutting assembly line is reasonable in structure, manual die cutting does not need to be carried out manually, the labor intensity is low, the concentricity is high, the structure is compact and not dispersed, two materials can be attached and glued througha glue solution brushing structure, meanwhile, redundant glue solution can be recycled, and the glue solution can be recycled into the glue solution brushing structure.

Owner:徐州协盈电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com