A kind of waterproof adhesive tape, its preparation method and electronic product

A waterproof tape, acrylic adhesive technology, applied in the direction of adhesive, film/sheet release coating, film/sheet adhesive, etc., can solve the problem of acid-free waterproof tape without shading, unable to meet the requirements of border tape, etc. Achieve the effect of excellent cushioning, good temperature resistance and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides the preparation method of the above water repellent tape, comprising the steps of:

[0039] The primer coating is applied to both sides of the substrate to obtain a first primer coating and a second primer coating;

[0040] The black thermoplastic elastomer glue was applied to the release film, and then transferred to the first undercoat layer and the second undercoat layer to obtain a first black thermoplastic elastomer layer and a second black thermoplastic elastomer layer. Uncover the immersion film;

[0041] The acrylic adhesive was applied to the release film, and then transferred to the first black thermoplastic elastomer layer and the second black thermoplastic elastomer layer, and found in 35 ° C - 70 ° C for 1-5 days, and the product was obtained.

[0042] Further, in the above-described preparation method, the formulation method of the primary coating is: mix the SBC with the organic solvent, dissolve with high speed shear dispe...

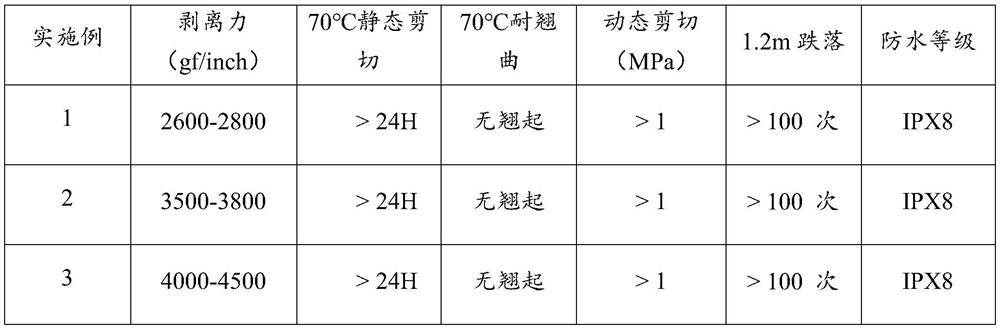

Embodiment 1

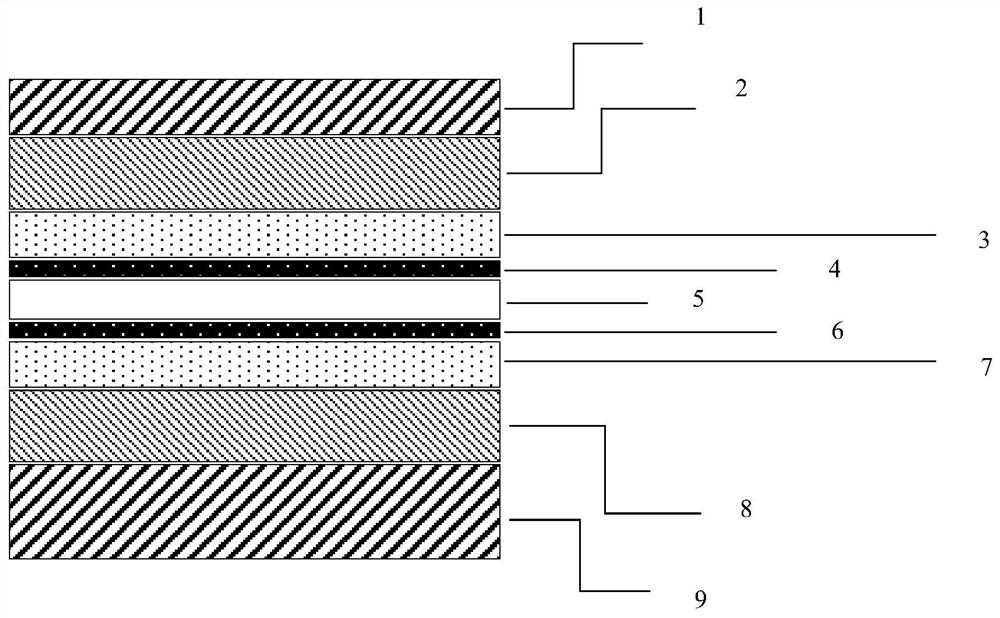

[0048] This embodiment provides a waterproof tape, which is from top to bottom, including the release layer (thickness 50 μm, release force 10g), acrylic adhesive layer (thickness 36 μm), black thermoplastic elastomer layer (thickness 28 μm), rubber bottom Coating (thickness 4 μm), black translucent PET (thickness 12 μm), rubber undercoat layer (thickness 4 μm), black thermoplastic elastomer layer (thickness 29 μm), acrylic adhesive layer (thickness 36 μm), release layer (thickness 75 μm) 15g of the release force), the tape thickness is 150 μm.

[0049] The formulation of the acrylic adhesive layer is: 100 parts of polyacrylic acid glue, 0.36 isocyanate curing agents, and 0.06 oxygen curing agents.

[0050] The formulation of the black thermoplastic elastomer is: 100 parts of SBS rubber, 100 solid terpene resins, 20 parts of liquid terpene resin, 0.5 antioxidants, 1 foam microsphere, 3 parts of black ink.

Embodiment 2

[0052] This embodiment provides a waterproof tape which is from top to bottom, including the release layer (thickness 50 μm, release force 10g), acrylic adhesive layer (thickness 70 μm), black thermoplastic elastomer layer (thickness 38 μm), rubber bottom Coating (thickness 4 μm), black translucent PET (thick 25 μm), rubber undercoat layer (thickness 4 μm), black thermoplastic elastomer layer (thickness 39 μm), acrylic adhesive layer (thickness 70 μm), release layer (thickness 75 μm) 15g of the release force), the tape thickness is 250 μm.

[0053] The formulation of the acrylic adhesive layer is: 100 parts of polyacrylic acid glue, 0.58 of isocyanate curing agents, 0.07 epoxy curing agents.

[0054] The formulation of the black thermoplastic elastomer is: 100 parts of SBS rubber, 80 parts of solid terpene resin, 16 parts of liquid terpene resin, 0.7 antioxidants, 3 bubble microspheres, and 2 black ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com