Adhesive film and preparation method thereof

A technology for bonding adhesive films and adhesives, applied in the directions of adhesives, adhesive types, conjugated diene adhesives, etc. Unequal problems, to achieve the effect of improving die-cutting performance and thermal conductivity, reducing temperature, and bonding firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

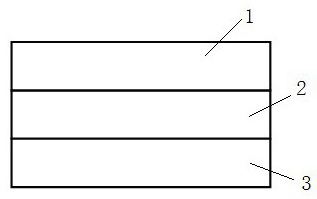

Image

Examples

Embodiment 1

[0027] The raw materials for the preparation of the adhesive layer include the following components in parts by weight: 100 parts of solution-polymerized styrene-butadiene rubber Nipol NS616, 50 parts of terpene resin, 1.0 part of sulfur, 0.5 part of TMTD, 2,2'-methylenebis(4- Methyl-6-tert-butylphenol) 4.0 parts, graphite powder 10 parts.

[0028] The preparation method of adhesive is as follows:

[0029] (1) Dissolve the solution-polymerized styrene-butadiene rubber Nipol NS616 in toluene, and the solid content of the prepared rubber solution is 50%.

[0030] (2) Dissolve the tackifying resin with toluene, and the solid content of the prepared resin solution is 50%.

[0031] (3) Put the rubber solution in (1) above in a stirring device, add the tackifying resin solution in (2) above; then add sulfur, vulcanization accelerator TMTD, 2,2'-methylene Bis(4-methyl-6-tert-butylphenol) and graphite powder; fully dissolved and stirred into a uniform and stable viscous liquid, that...

Embodiment 2

[0034] The raw materials for the preparation of the adhesive include the following components in parts by weight: 100 parts of solution polymerized styrene-butadiene rubber Nipol NS616, 60 parts of terpene phenolic resin, 0.5 part of sulfur, 1.0 part of CZ, 2,6-di-tert-butyl p-cresol 5.0 parts, 20 parts of graphene.

[0035] The preparation method of adhesive is as follows:

[0036] (1) Dissolve solution polystyrene butadiene rubber Nipol NS616 with ethyl acetate, and the solid content of the prepared rubber solution is 30%;

[0037] (2) Dissolve the tackifying resin with ethyl acetate, and the solid content of the prepared resin solution is 40%.

[0038] (3) Put the rubber solution in (1) above in a stirring device, add the tackifying resin solution in (2) above; then add sulfur, vulcanization accelerator CZ, 2,6-di-tert-butyl P-cresol and graphene; fully dissolved and stirred into a uniform and stable viscous liquid, that is, a rubber-type pressure-sensitive adhesive (adhe...

Embodiment 3

[0041] The raw materials for the preparation of the adhesive include the following components in parts by weight: 100 parts of solution-polymerized styrene-butadiene rubber Nipol NS616, 70 parts of rosin resin, 2.0 parts of sulfur, 2.0 parts of NA-22, tetrakis[β-(3,5-ditertiary 1.0 parts of butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 5 parts of carbon nanotubes.

[0042] The preparation method of adhesive is as follows:

[0043] (1) Dissolve solution-polymerized styrene-butadiene rubber Nipol NS616 with ethyl acetate, and the solid content of the prepared rubber solution is 40%;

[0044] (2) Dissolve the tackifying resin with ethyl acetate, and the solid content of the prepared resin solution is 55%.

[0045] (3) Put the rubber solution in (1) above in a stirring device, add the tackifying resin solution in (2) above; then add sulfur, vulcanization accelerator NA-22, tetrakis[β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and carbon n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com