A kind of incomplete curing type oca optical adhesive of multi-layer structure and preparation method thereof

An incomplete, curing technology, applied in the field of optical adhesives, which can solve the problems of unstable yield, easy flow, and difficult production process standards for TSP manufacturers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

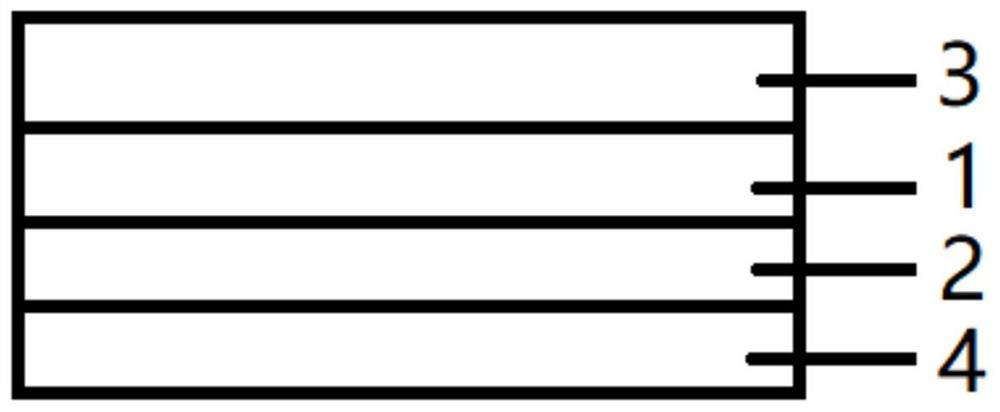

Image

Examples

Embodiment 1

[0024] The preparation method of the incompletely cured type OCA optical adhesive of a kind of multi-layer structure of the present embodiment, comprises the following steps:

[0025] Step 1: Preparation of OCA coating solution

[0026] In parts by weight, 650 parts of 2-ethylhexyl acrylate, 15 parts of isobornyl acrylate, 20 parts of 2-hydroxyethyl acrylate and 0.01 part of 1-hydroxycyclohexyl benzophenone as photoinitiator Prepare a monomer premix, and partially polymerize the mixture by exposing it to ultraviolet radiation under a nitrogen-protected environment, so as to obtain a prepolymer with a viscosity of 300 centipoise; Add 1-hydroxycyclohexylbenzophenone, 1,6-hexanediol diacrylate, and trimethylolpropane triacrylate at 0.1%, 0.1%, filter with 480-mesh filter cloth after stirring for 10 minutes, and vacuum for 20 minutes Afterwards, the OCA coating solution is prepared;

[0027] Step 2: Preparation of fully cured first OCA layer

[0028] Pour the OCA coating liquid...

Embodiment 2

[0035] The preparation method of the incompletely cured type OCA optical adhesive of a kind of multi-layer structure of the present embodiment, comprises the following steps:

[0036] Step 1: Preparation of OCA coating solution

[0037] In parts by weight, 650 parts of 2-ethylhexyl acrylate, 15 parts of isobornyl acrylate, 20 parts of 2-hydroxyethyl acrylate and 0.01 part of 1-hydroxycyclohexyl benzophenone as photoinitiator Prepare a monomer premix, and partially polymerize the mixture by exposing it to ultraviolet radiation under a nitrogen-protected environment, so as to obtain a prepolymer with a viscosity of 300 centipoise; Add 1-hydroxycyclohexylbenzophenone, 1,6-hexanediol diacrylate, trimethylolpropane triacrylate at 0.1%, 0.1%, filter with 480-mesh filter cloth after stirring for 40 minutes, and vacuum for 60 minutes Afterwards, the OCA coating solution is prepared;

[0038] Step 2: Preparation of fully cured first OCA layer

[0039] Pour the OCA coating solution bet...

Embodiment 3

[0046] The preparation method of the incompletely cured type OCA optical adhesive of a kind of multi-layer structure of the present embodiment, comprises the following steps:

[0047] Step 1: Preparation of OCA coating solution

[0048] In parts by weight, 650 parts of 2-ethylhexyl acrylate, 15 parts of isobornyl acrylate, 20 parts of 2-hydroxyethyl acrylate and 0.01 part of 1-hydroxycyclohexyl benzophenone as photoinitiator Prepare a monomer premix, and partially polymerize the mixture by exposing it to ultraviolet radiation under a nitrogen-protected environment, so as to obtain a prepolymer with a viscosity of 300 centipoise; Add 1-hydroxycyclohexylbenzophenone, 1,6-hexanediol diacrylate, trimethylolpropane triacrylate at 0.1%, 0.1%, filter with 480-mesh filter cloth after stirring for 30 minutes, and vacuum for 50 minutes Afterwards, the OCA coating solution is prepared;

[0049] Step 2: Preparation of fully cured first OCA layer

[0050] Pour the OCA coating solution b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com