Method for mixing solid compound additives

A technology of compound additives and solid additives, which is applied in food ingredients as thickeners, food ingredients as emulsifiers, food preparation, etc. It can solve problems such as unsatisfactory, large total materials, and failure to achieve uniform mixing, and achieve performance Stable, good mixing effect, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

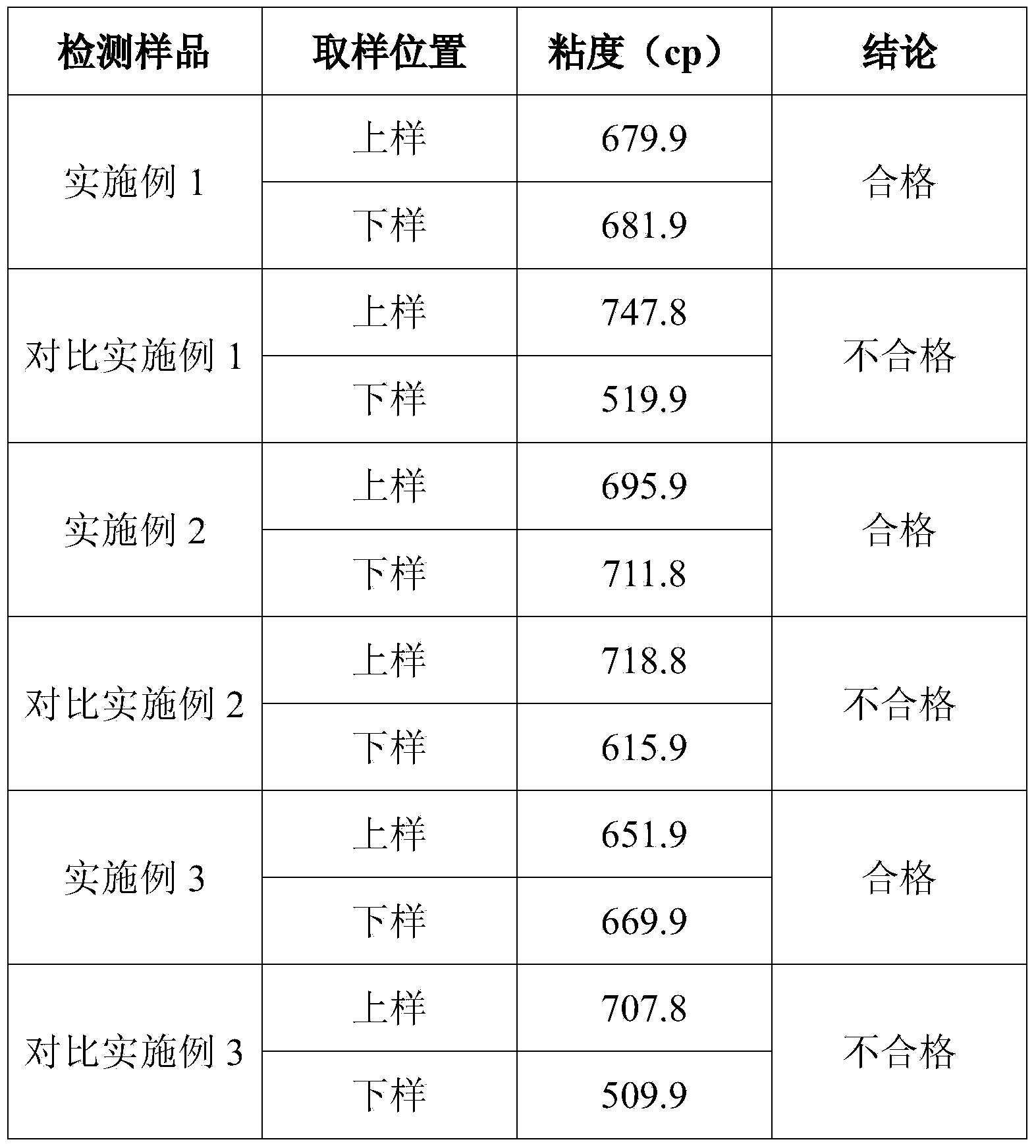

Embodiment 1

[0015] The mixing of embodiment 1 compound thickener

[0016] Ingredients: xanthan gum 150kg, CMC 750kg, microcrystalline cellulose 20kg, sodium stearoyl lactylate 50kg, sodium tripolyphosphate 30kg.

[0017] Put 20kg of microcrystalline cellulose, 50kg of sodium stearoyl lactylate, 30kg of sodium tripolyphosphate, and 100kg of CMC into a blender for premixing, mix for 10 minutes, and then put them into packaging bags for use.

[0018] Weigh 300kg of CMC and put it into the mixer, then put in the premixed 200kg of premixed material, then put in the remaining 350kg of CMC, mix for 15 minutes, and then pack.

Embodiment 2

[0022] The mixing of embodiment 2 compound thickeners

[0023] Ingredients: CMC950kg, sodium citrate 50kg.

[0024] Sodium citrate 50kg and CMC50kg are put into the blender, mixed for 10 minutes, then put into the packaging bag for use.

[0025] Weigh 450kg of CMC and put it into the mixer, then put into the premixed 100kg of premixed material, then put in the remaining 450kg of CMC, mix for 15 minutes, and then pack.

Embodiment 3

[0029] The mixing of embodiment 3 compound emulsifiers

[0030] Ingredients: 250kg monoglyceride, 10kg carrageenan, 30kg sodium tripolyphosphate, 30kg sodium hexametaphosphate, 50kg sucrose ester, 20kg microcrystalline cellulose, 300kg polyglycerol fatty acid ester, 150kg sodium stearoyl lactylate, 200kg xanthan gum , gellan gum 110kg.

[0031] Put 10kg of carrageenan, 30kg of sodium tripolyphosphate, 30kg of sodium hexametaphosphate, 50kg of sucrose ester, and 20kg of microcrystalline cellulose into the mixer, weigh 140kg of monoglyceride and put it into the mixer, mix for 10 minutes, and then put into the packaging bag for use,

[0032] Put the remaining 110kg of monoglyceride into the mixer, then put into 300kg of polyglycerol fatty acid ester, put into 280kg of premix, then put into 150kg of sodium stearoyl lactylate, 200kg of xanthan gum, 110kg of gellan gum, mix for 15 minutes , and then wrap it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com