Novel double-sided tape

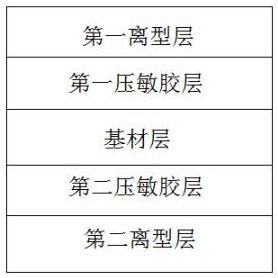

A double-sided tape, a new technology, applied in the direction of adhesives, film/sheet adhesives, film/sheet release liners, etc., can solve the problems of expensive VHB tape, low bonding strength, and large equipment investment , to achieve the effect of low peel strength, high initial tack and high production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of post-curing acrylic UV pressure-sensitive adhesive is as follows:

[0023] 1. Dissolve a certain proportion of butyl acrylate (BA), methyl methacrylate (MMA) and glycidyl methacrylate (GMA) monomers in ethyl acetate, add the initiator under the condition of feeding N2 Under reaction for 4-6h, polyacrylate prepolymer is obtained;

[0024] 2. Mix polyacrylate prepolymer with reactive diluent, photoinitiator, isocyanate crosslinking agent, etc. to prepare post-curing acrylic UV pressure-sensitive adhesive.

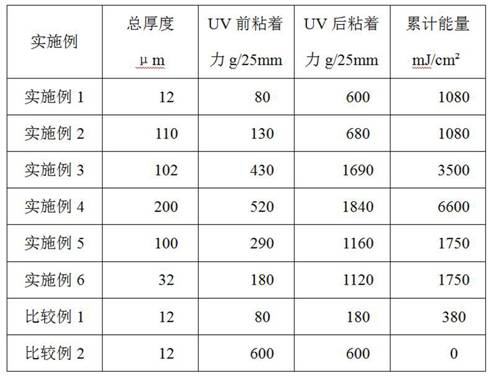

Embodiment 1

[0026] Apply the post-curing acrylic UV pressure-sensitive adhesive prepared above on the surface of the PET silicone heavy-release release film, the thickness of the coating is 5um, and after drying in the oven, it is bonded with the 2μm PET substrate layer to obtain a pressure-sensitive adhesive tape a project;

[0027] Apply the post-curing acrylic UV pressure-sensitive adhesive on the surface of the PET silicone release film, the thickness of the coating is 5um, and after drying in the oven, it is laminated with the uncoated surface of the substrate layer of the pressure-sensitive tape-engineering product. The semi-finished product is made, and the winding is completed and placed at a certain temperature for curing;

[0028] When testing and using, UV light is irradiated. When the illuminance is 58-60mW / cm², irradiate for 15s, and the cumulative energy is 1080mJ / cm² for performance testing;

Embodiment 2

[0030] Apply the post-curing acrylic UV pressure-sensitive adhesive prepared above on the surface of the PET silicone heavy release release film, the thickness of the coating is 5um, and after drying in the oven, it is bonded with the 100μm PET substrate layer to obtain a pressure-sensitive adhesive tape a project;

[0031] Apply the post-curing acrylic UV pressure-sensitive adhesive on the surface of the PET silicone release film, the thickness of the coating is 5um, and after drying in the oven, it is laminated with the uncoated surface of the substrate layer of the pressure-sensitive tape-engineering product. The semi-finished product is made, and the winding is completed and placed at a certain temperature for curing;

[0032] When testing and using, UV light is irradiated. When the illuminance is 58-60mW / cm², irradiate for 15s, and the cumulative energy is 1080mJ / cm² for performance testing;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com