Patents

Literature

249results about How to "Avoid glue overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

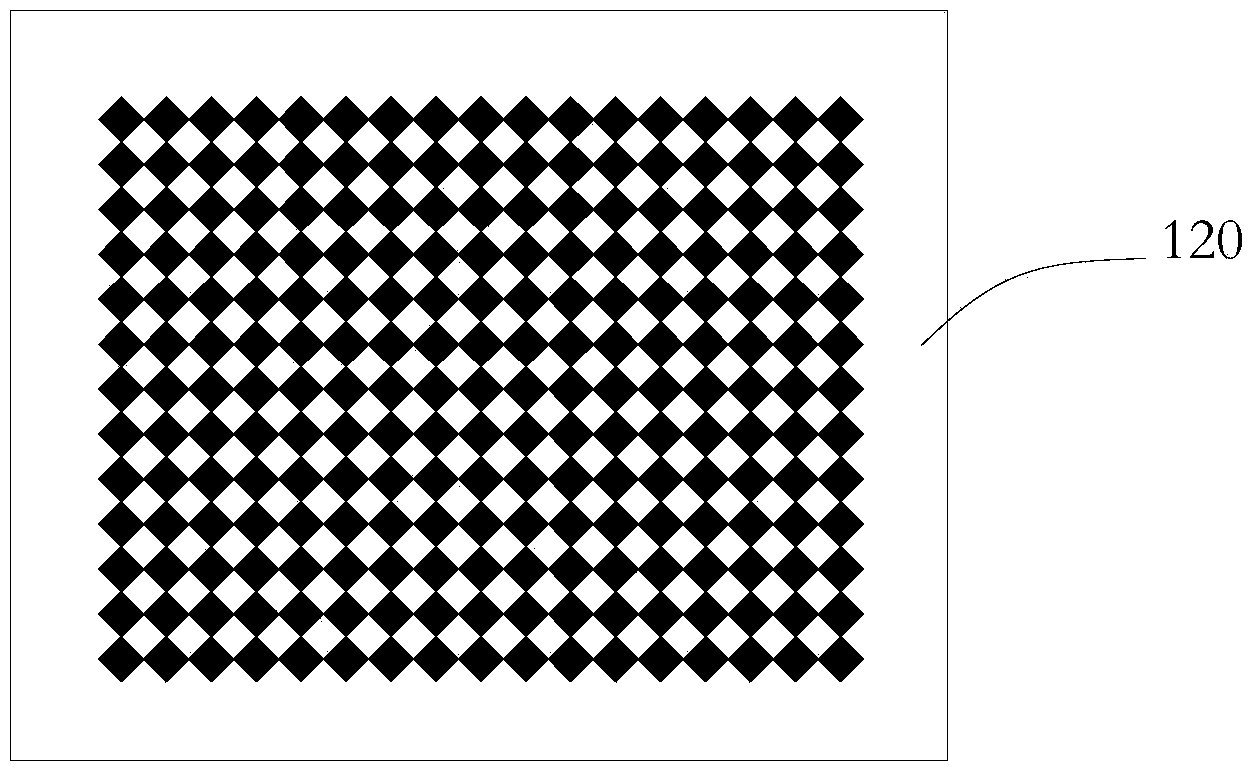

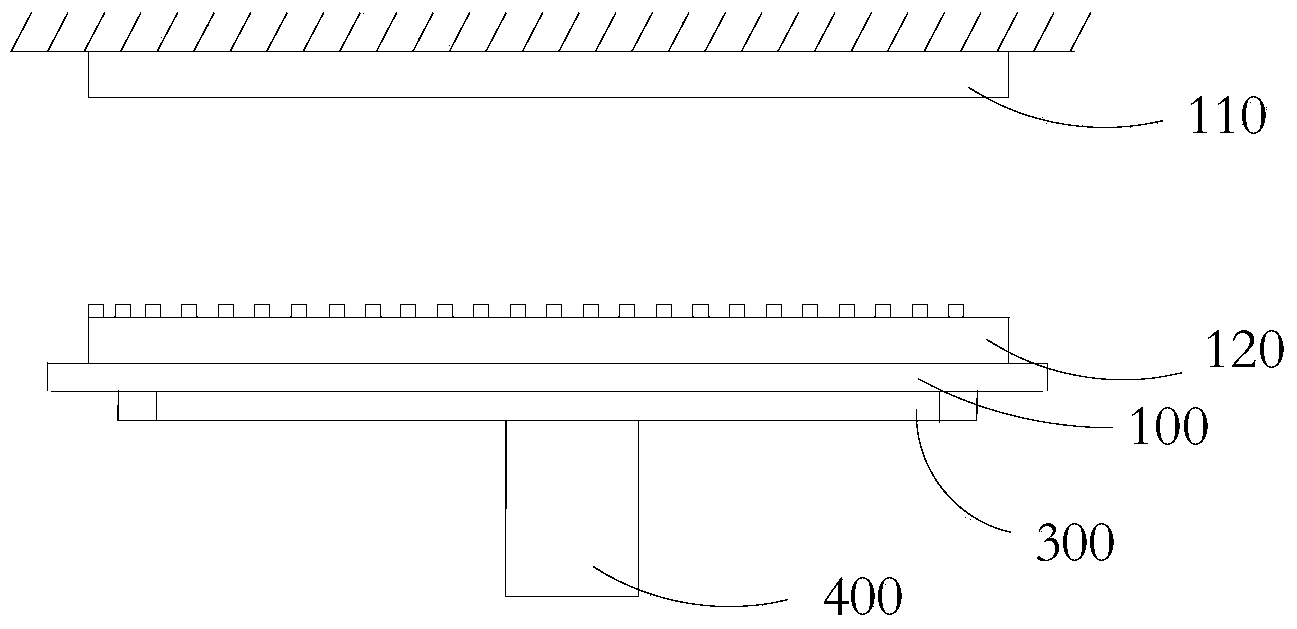

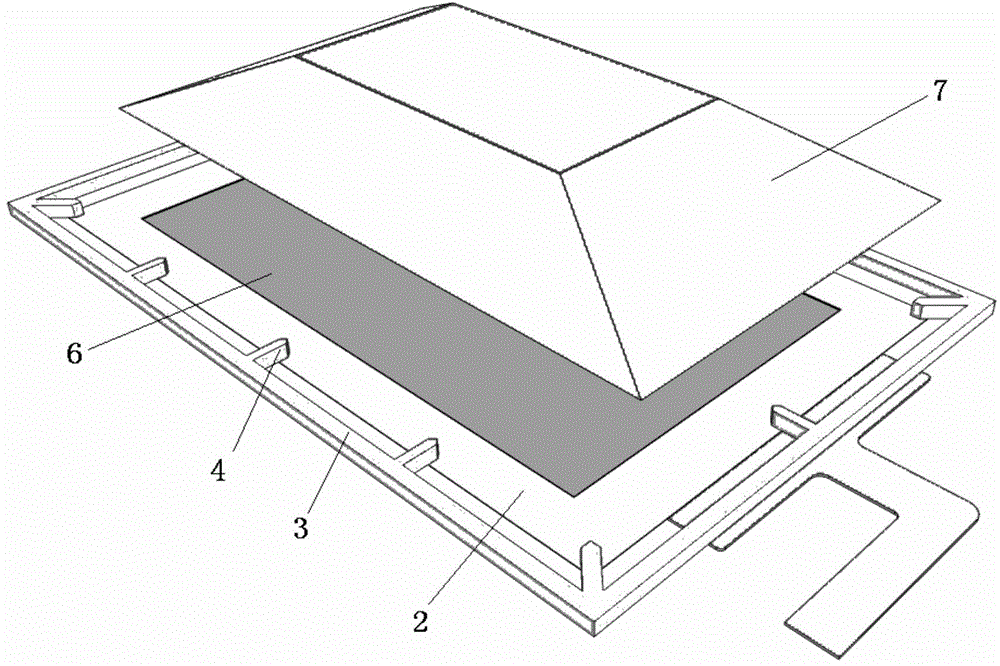

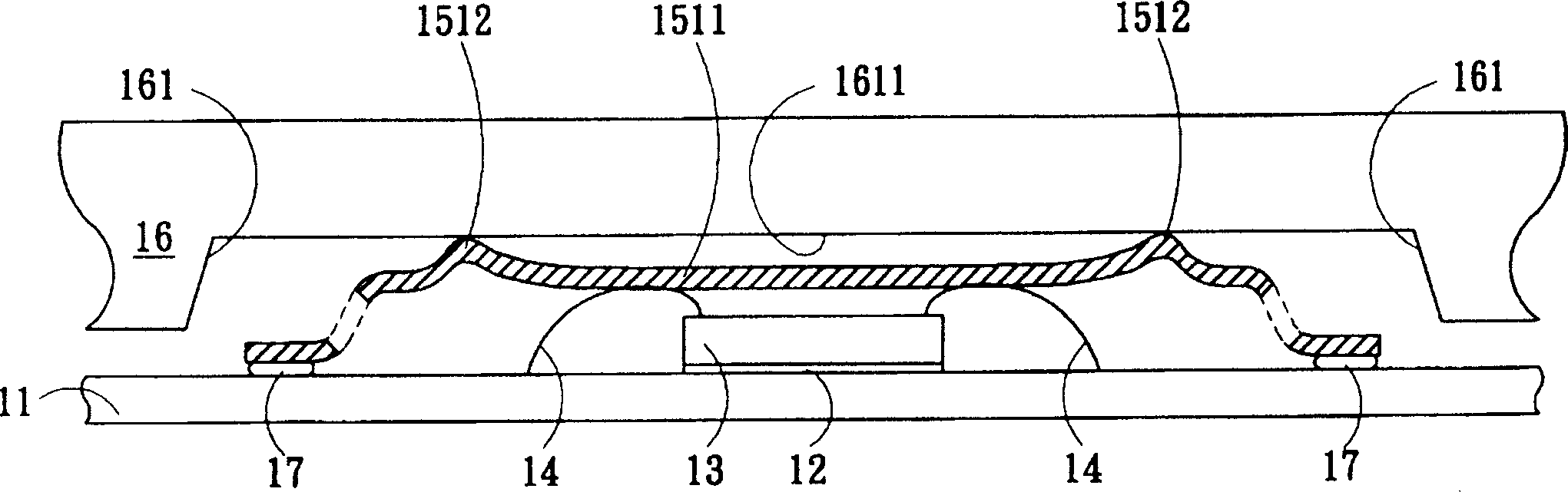

Touch control display device

InactiveCN104777943AIncrease the gapImprove curing yieldLaminationLamination apparatusFlexible circuitsUltraviolet lights

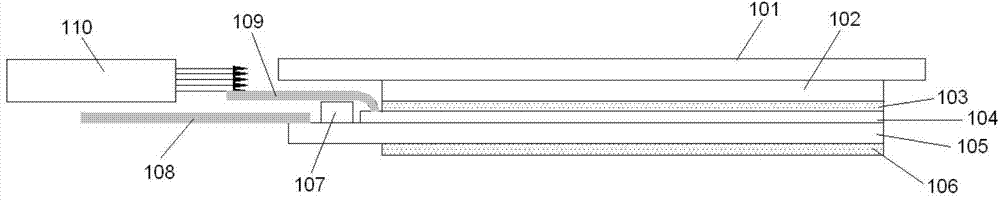

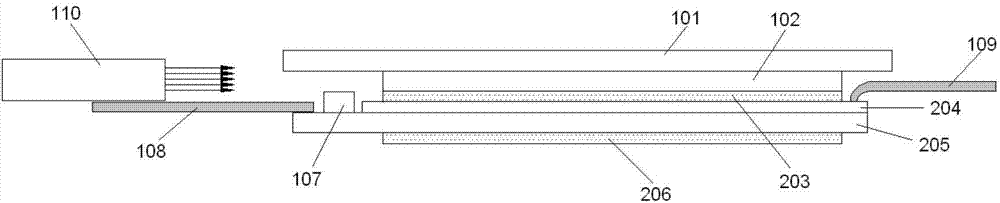

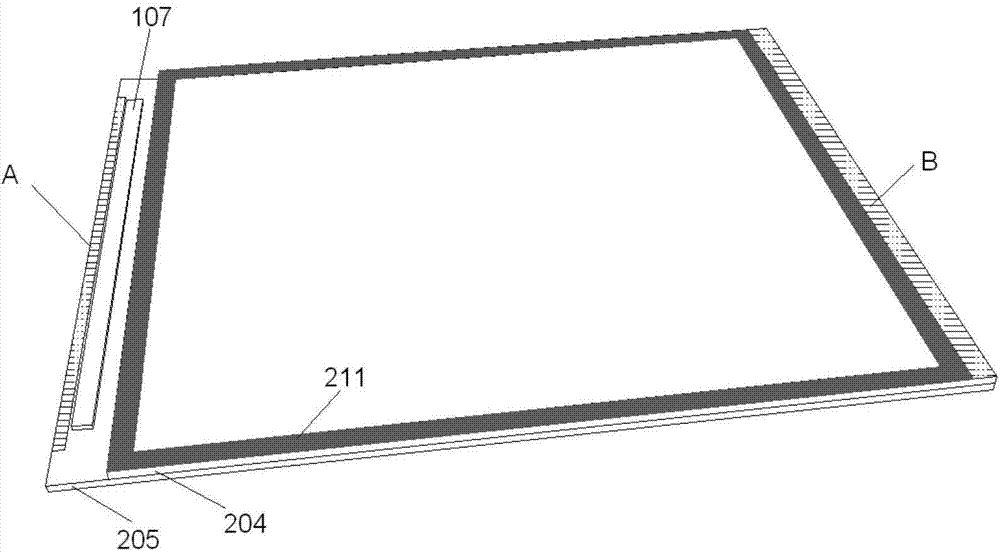

The invention discloses a touch control display device. The touch control display device comprises a display flexible circuit board and a touch control flexible circuit board which are bound to different sides of the touch control display device respectively. The touch control display device can effectively enlarge a gap between a seal cover plate and a display panel during adhesion of the seal cover plate, so that ultraviolet light illuminates optical cement more easily, the curing yield of the optical cement is improved, and the follow-up cement overflow defect is avoided. In addition, avoidance of the structures including a black array, a polaroid and the like is designed on a binding area of the touch control flexible circuit board so that the binding state of the touch control flexible circuit board can be monitored under a microscope after binding of the touch control flexible circuit board is completed, and the binding yield is improved.

Owner:BOE TECH GRP CO LTD +1

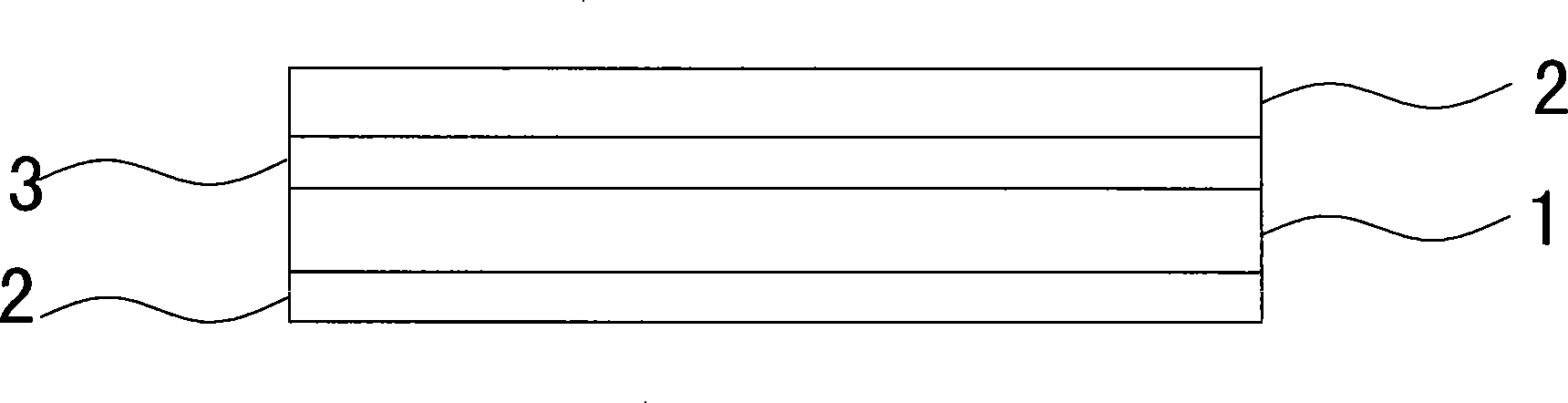

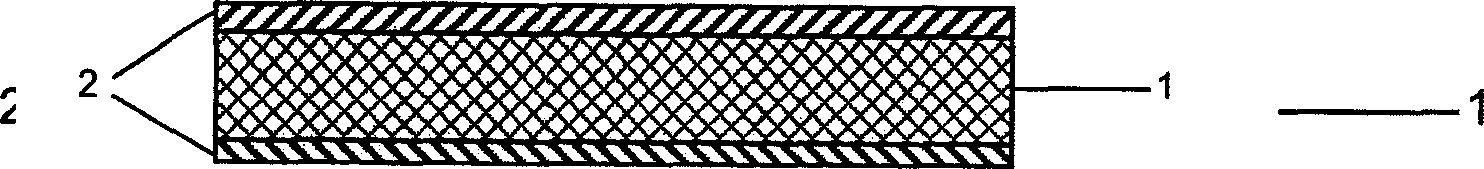

Novel shading rubber belt

InactiveCN101245226AUniform textureAdjustable thicknessFilm/foil adhesivesNon-linear opticsPolyethylene terephthalateThin layer

The invention relates to a shading belt which comprises a light shielding layer and an adhesive layer, and is characterized in that: the light shielding layer is black polyethylene terephthalate thin layer; the adhesive layer is two sided tape and is composed of a substrate layer and adhesive agent layers at two sides; the adhesive layer is fixedly connected with the surface of the light shielding layer by an adhesive layer on the same surface; the two sided tape is compounded on one side or two sides of the black PET thin layer, thus forming light shielding single side tape or light shielding two sided tape. The thickness of the light shielding tape can be adjusted by choosing PET films with different thicknesses and the two sided tapes with different thicknesses, which avoids the adjustment of the thickness of the light shielding tape by using a large amount of glue, and avoids the glue-spilling phenomenon in die-cutting.

Owner:SUZHOU JINFU TECH

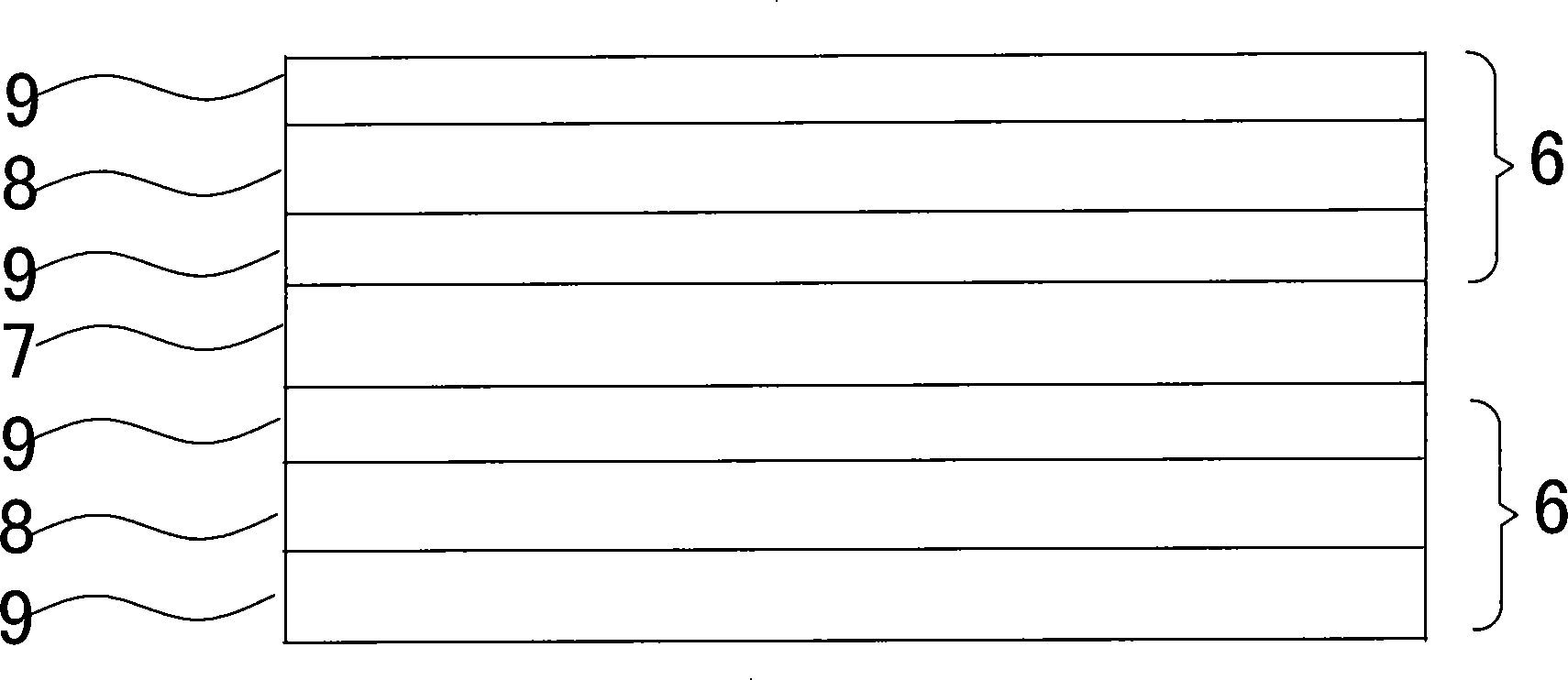

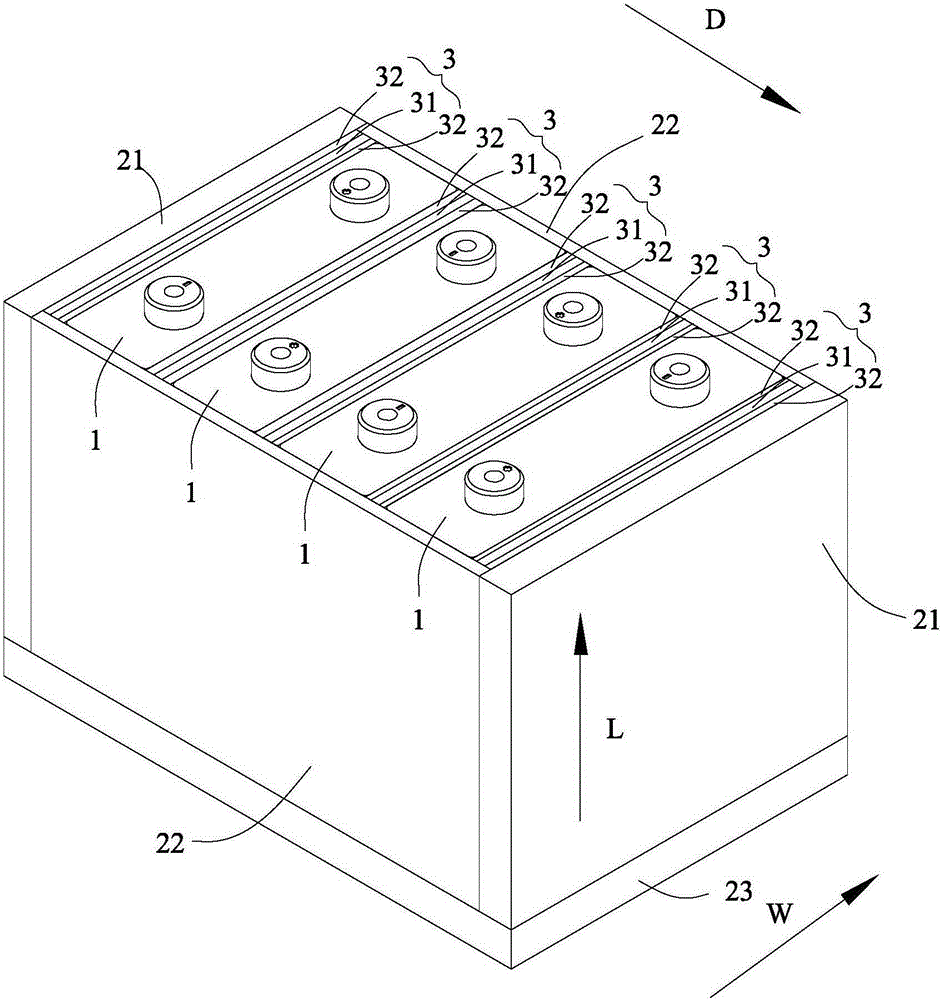

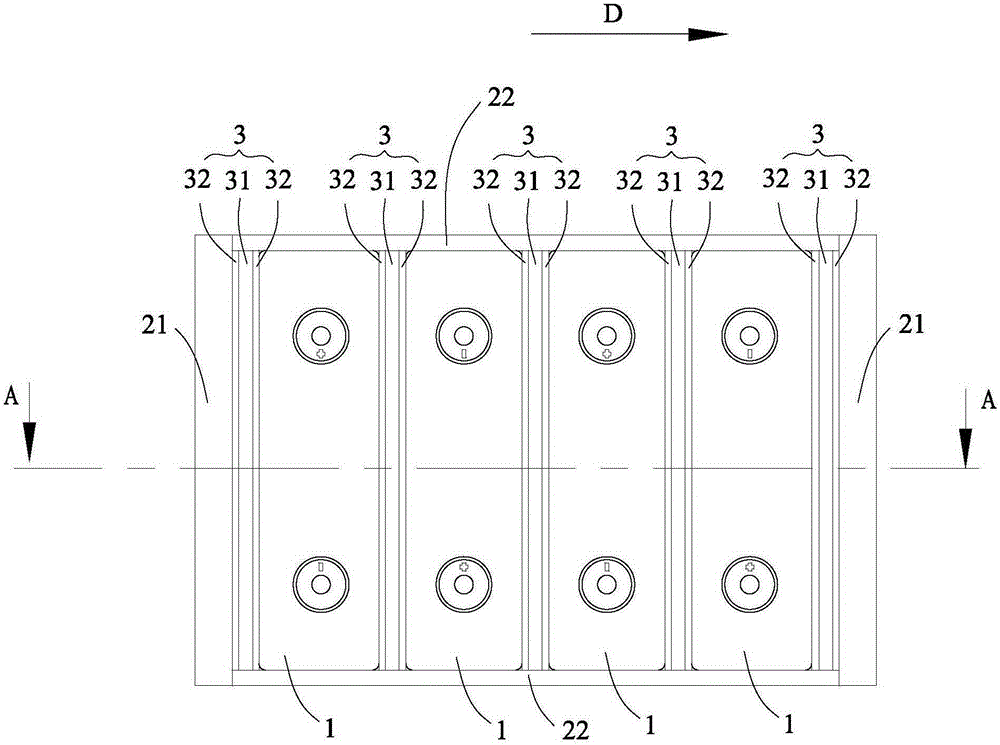

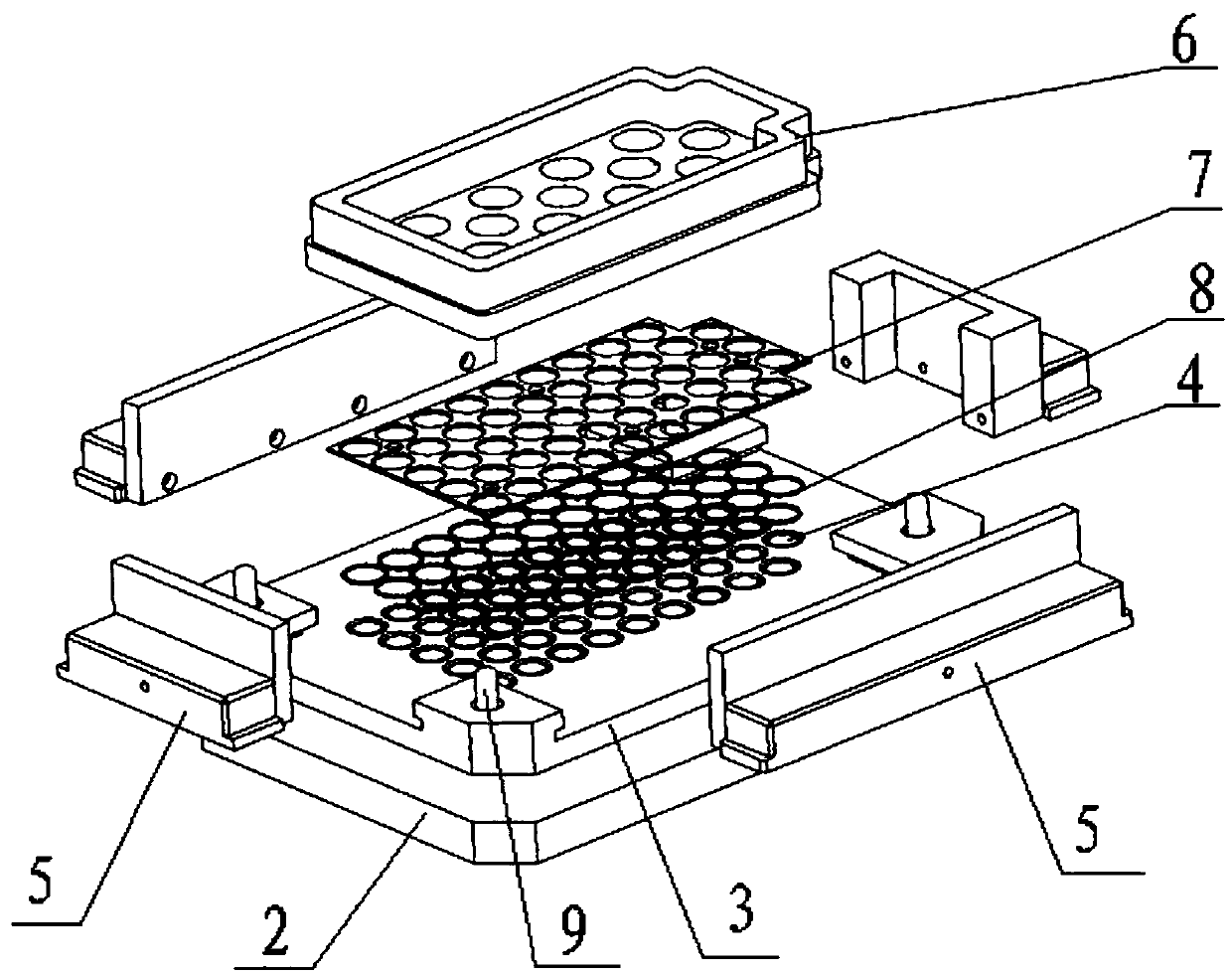

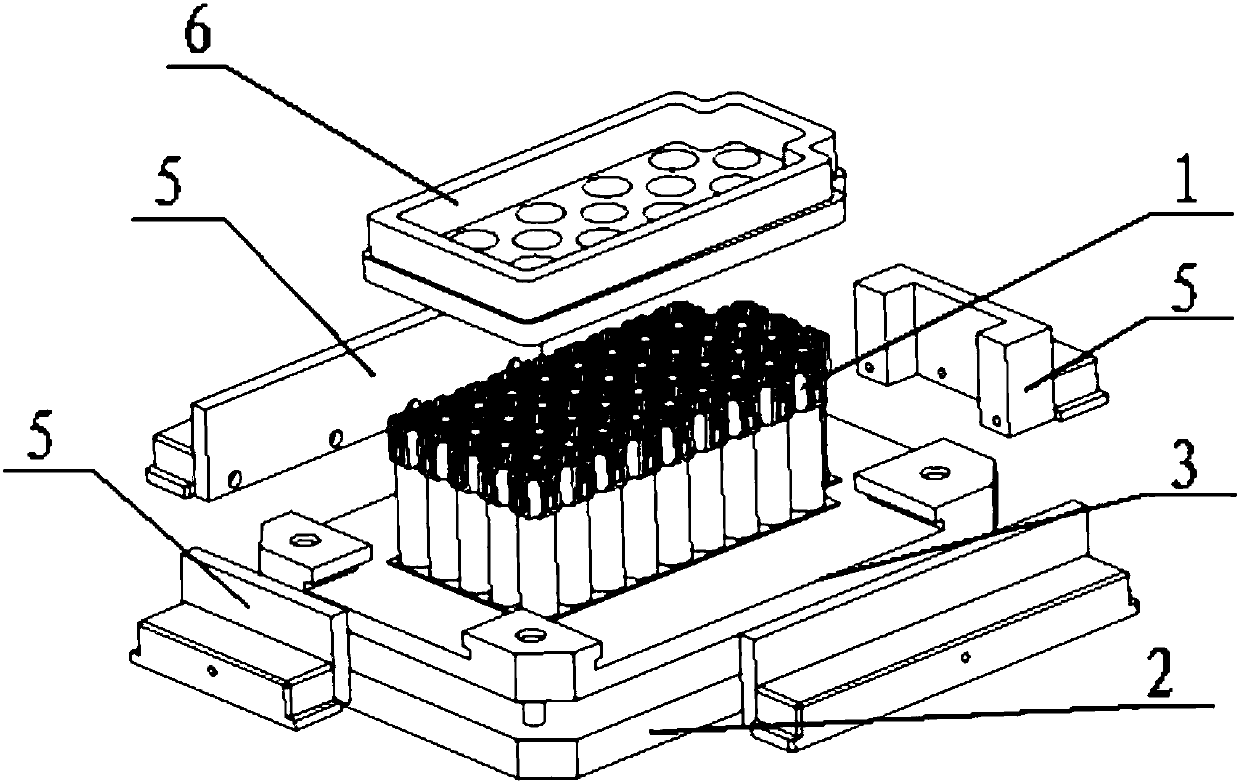

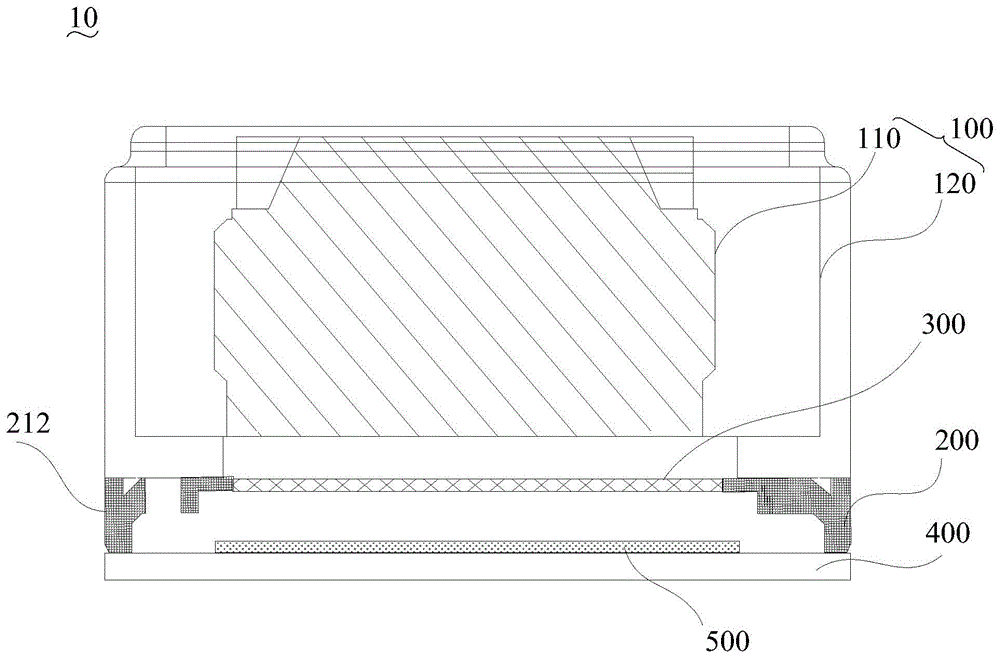

Battery module

PendingCN106450406AExtended service lifeEnhanced shear strengthCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrical batteryAdhesive

Owner:CONTEMPORARY AMPEREX TECH CO

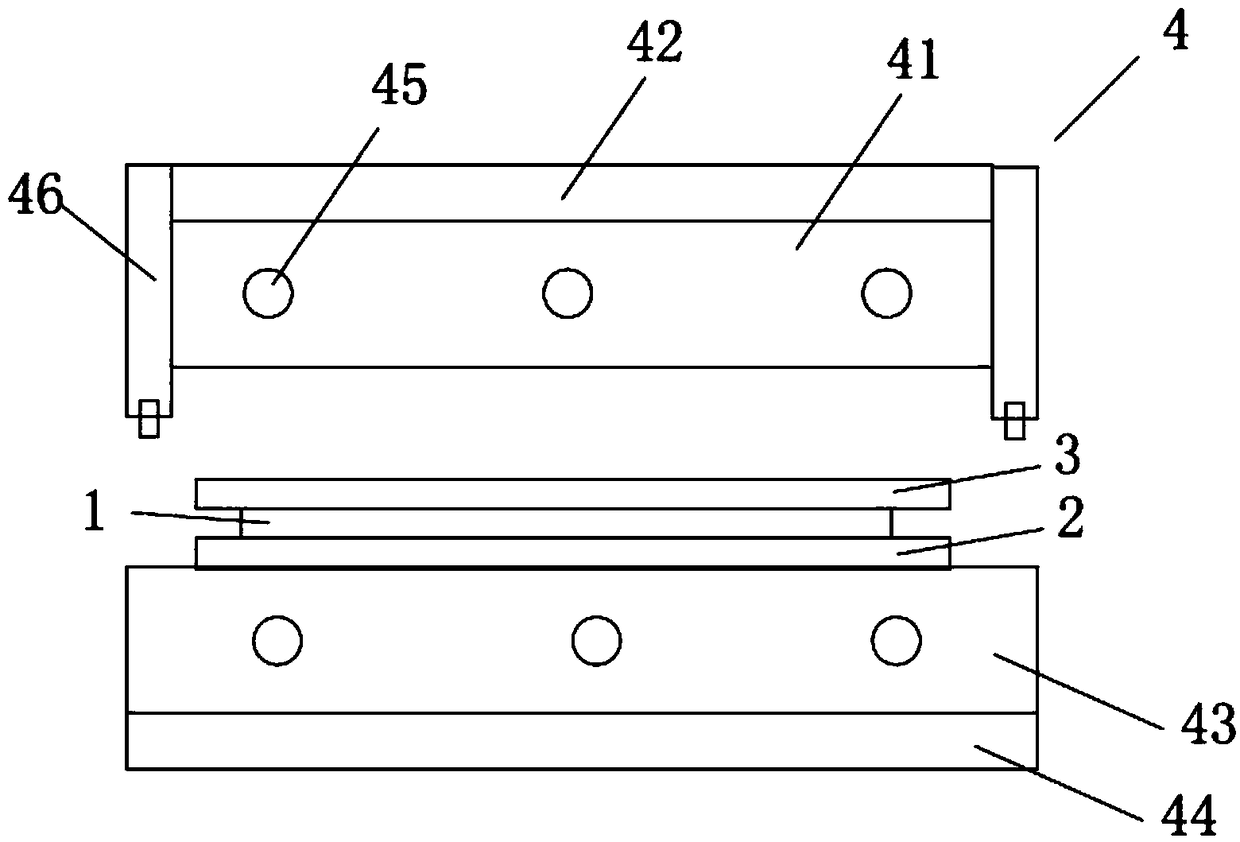

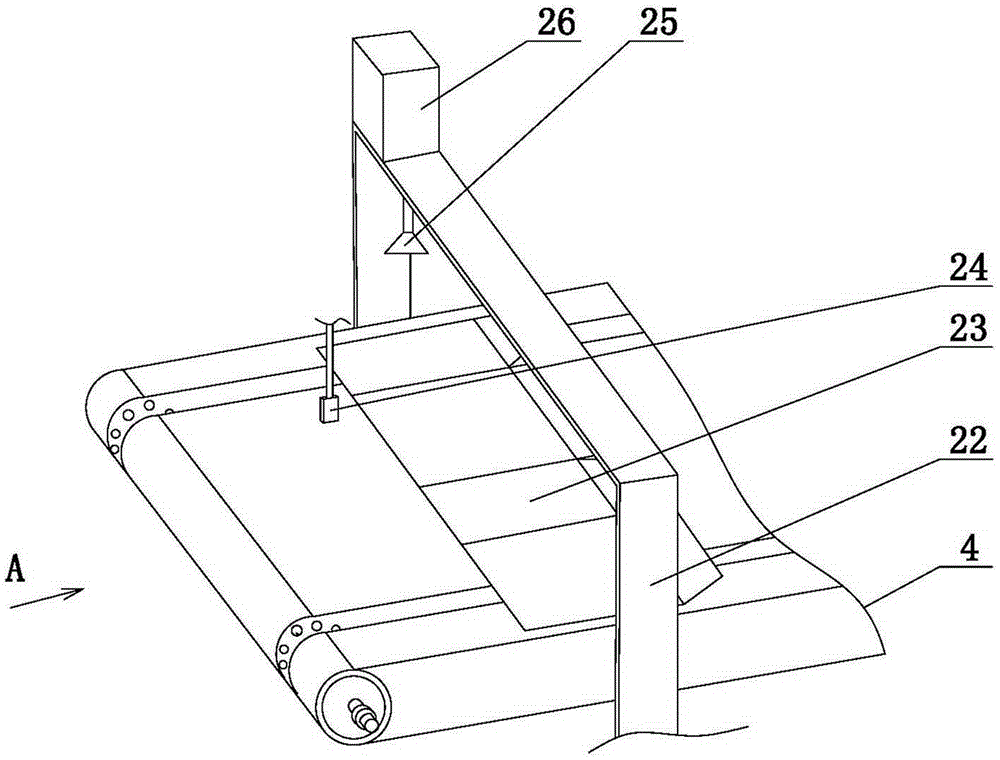

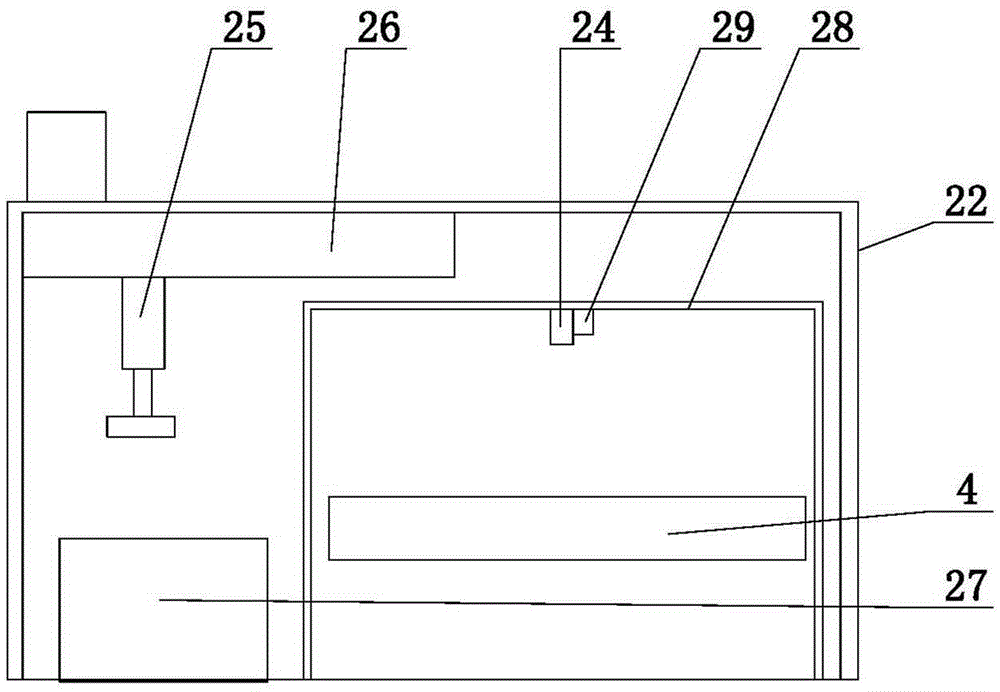

Laminating method and equipment

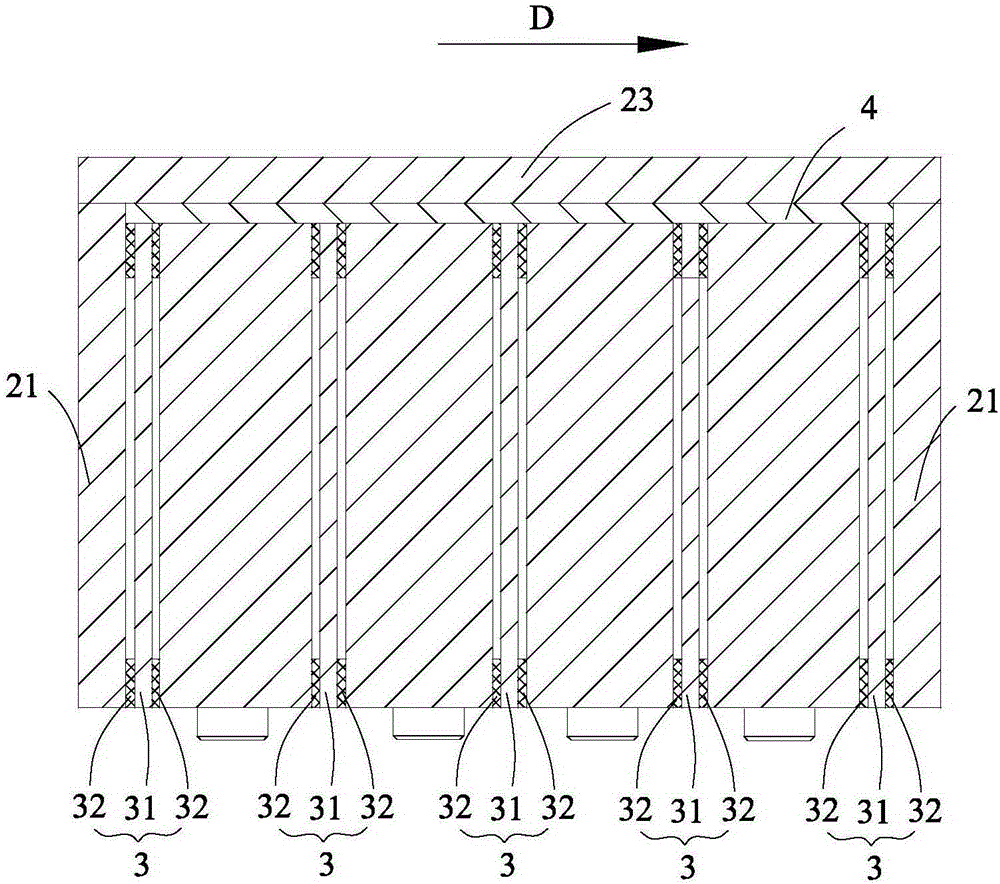

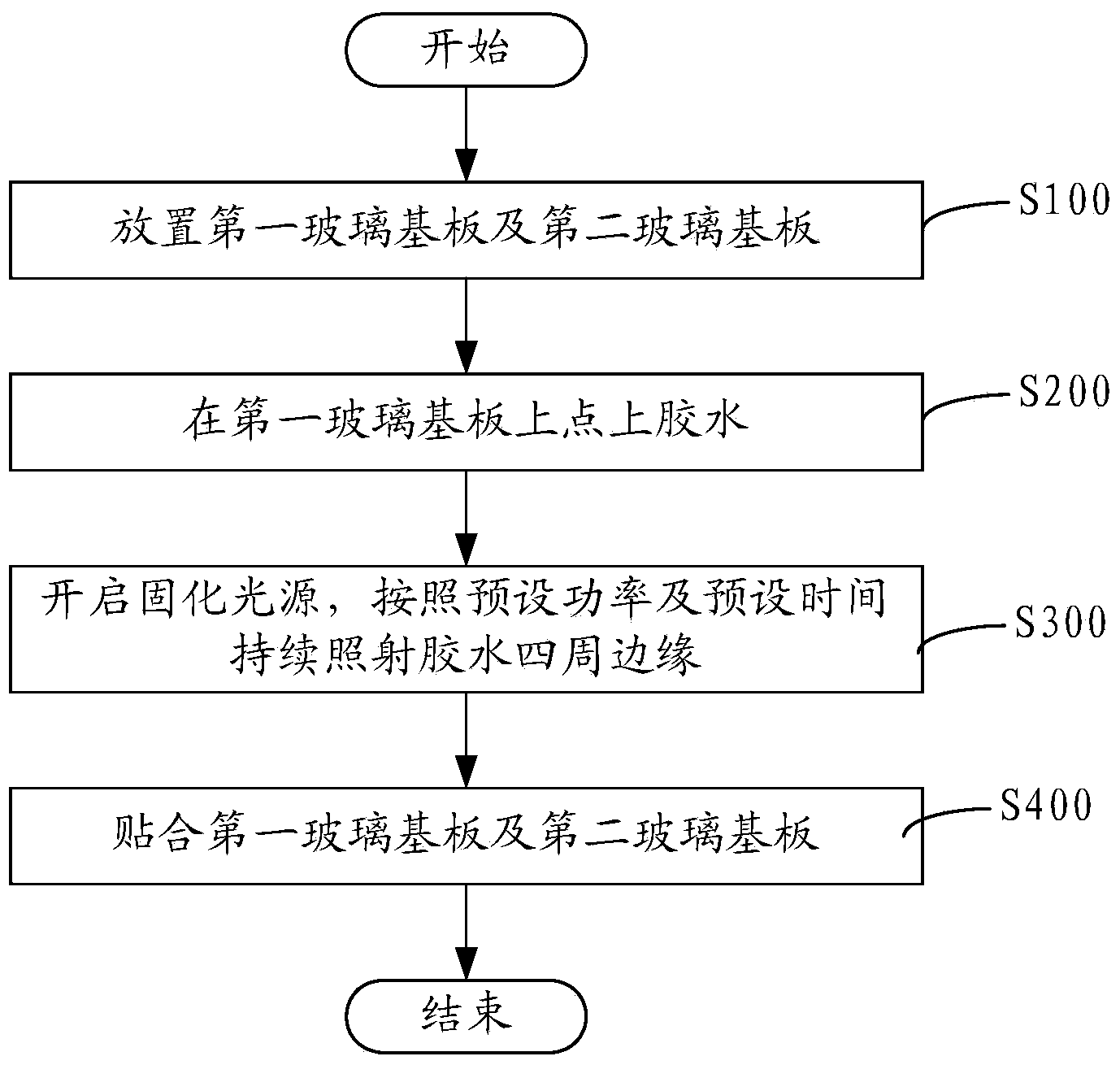

ActiveCN103552354APrevent overflowAvoid glue overflowLamination ancillary operationsLaminationEngineeringLight source

The invention discloses a laminating method. The laminating method comprises the following steps: placing a first glass substrate and a second glass substrate; dispensing glue on the first glass substrate; starting a curing light source and continuously irradiating the periphery of the glue according to preset power and preset time; and laminating the first glass substrate and the second glass substrate. The laminating method has the beneficial effects that the glue at the periphery of the substrates is irradiated before lamination, and the glue on the outer side is firstly cured to form a procured ring, so that the glue in the cured ring is blocked from overflowing outwards, and a glue overflowing phenomenon is effectively prevented.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

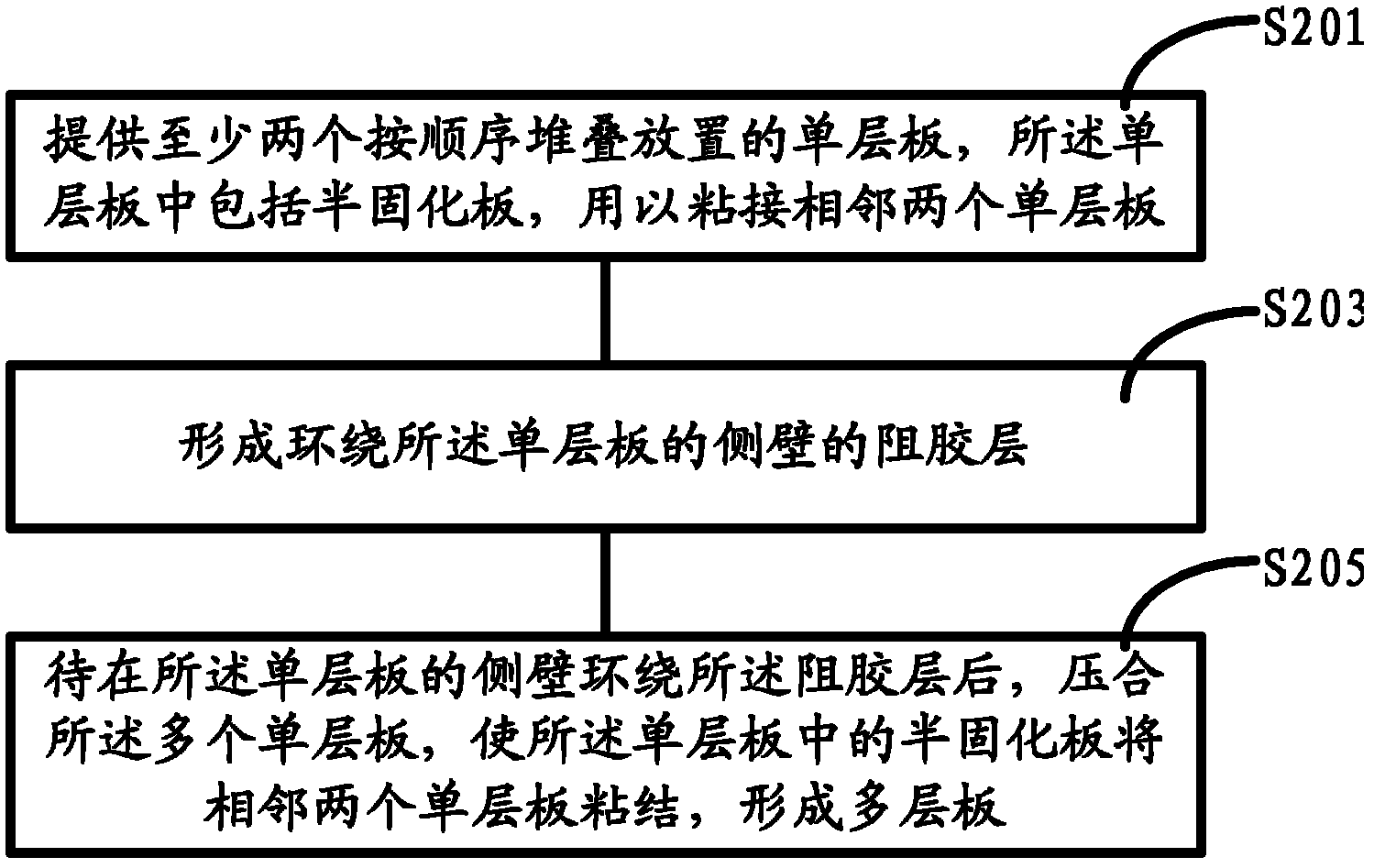

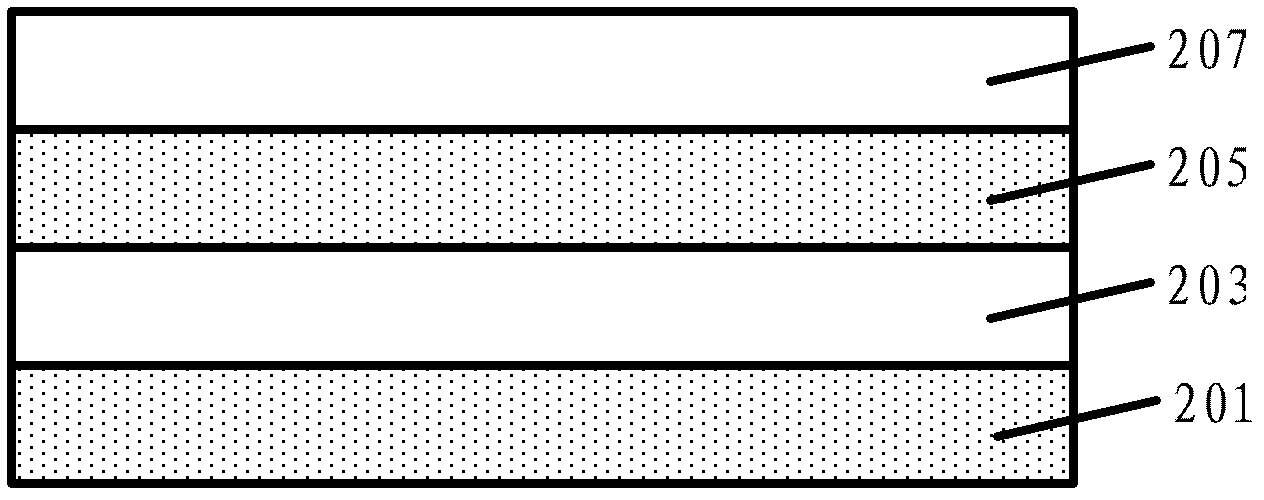

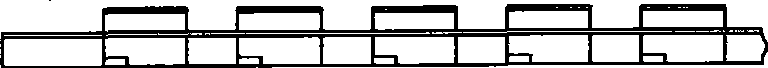

Manufacturing method of printed circuit board

ActiveCN1913753AControl flowReduce or avoid draggingMultilayer circuit manufactureSemi solidEngineering

The invention provides a method for manufacturing PCB, which shows as follow: during the preparing stage for manufacturing the circuit board, there is a surplus region on the semi-solid slices comparing to the core bands in the length and width direction, during the manufacturing stage for the inner pattern, laying the semi-solid slices and the core bands alternately into a layering body, then fixing all the semi-solid slices of the layering body at the surplus region with rivets or staples to make it into an entire body, then laying a copper foil on the top and bottom surface of the entire body, then compressing it, finally, cutting the surplus region with the connecting-pieces off.

Owner:HUAWEI TECH CO LTD

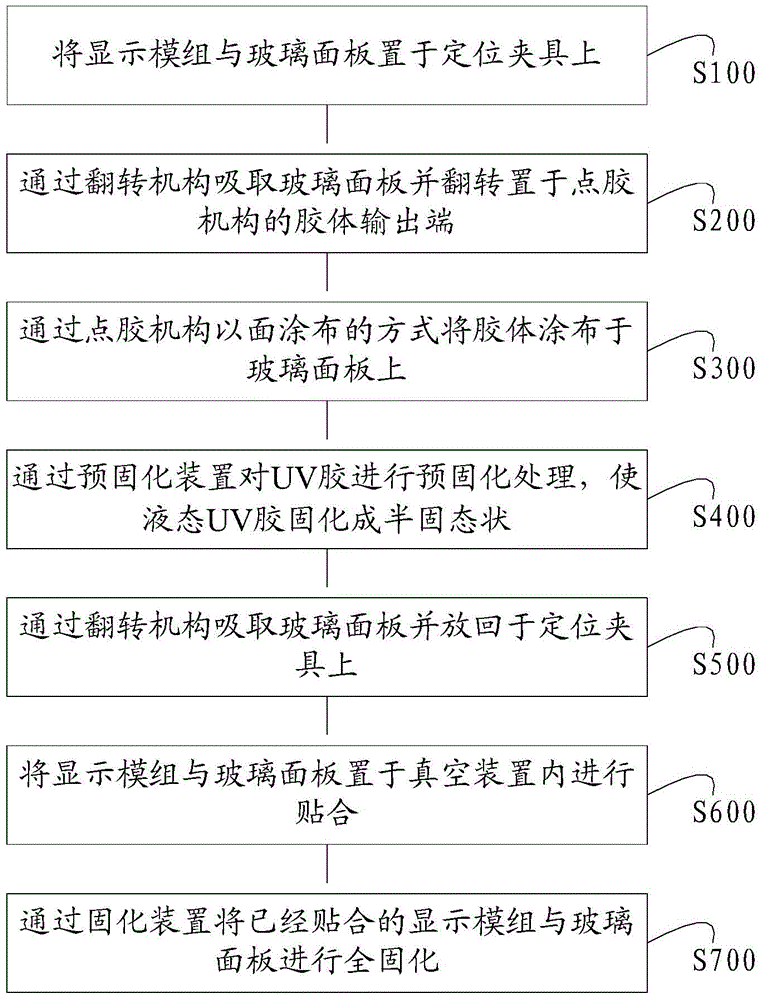

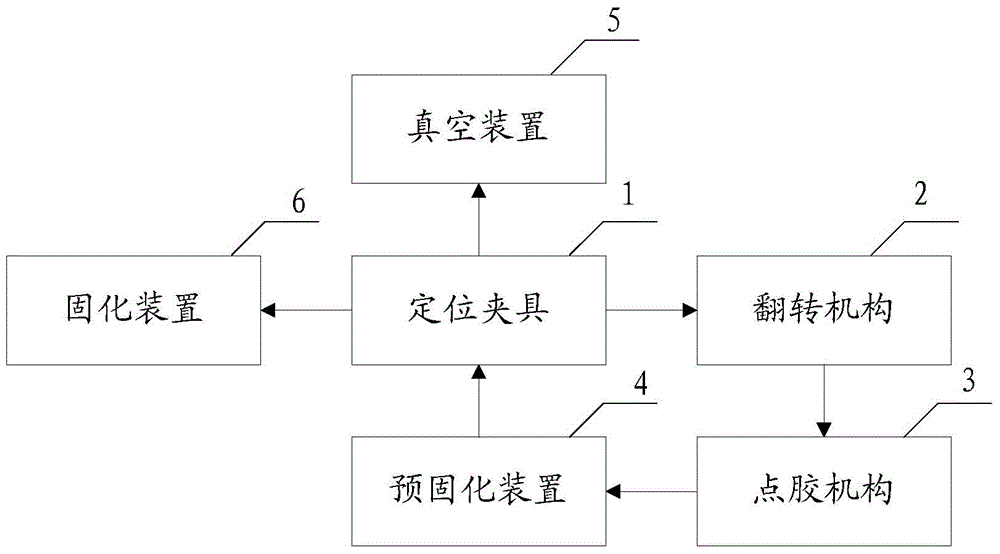

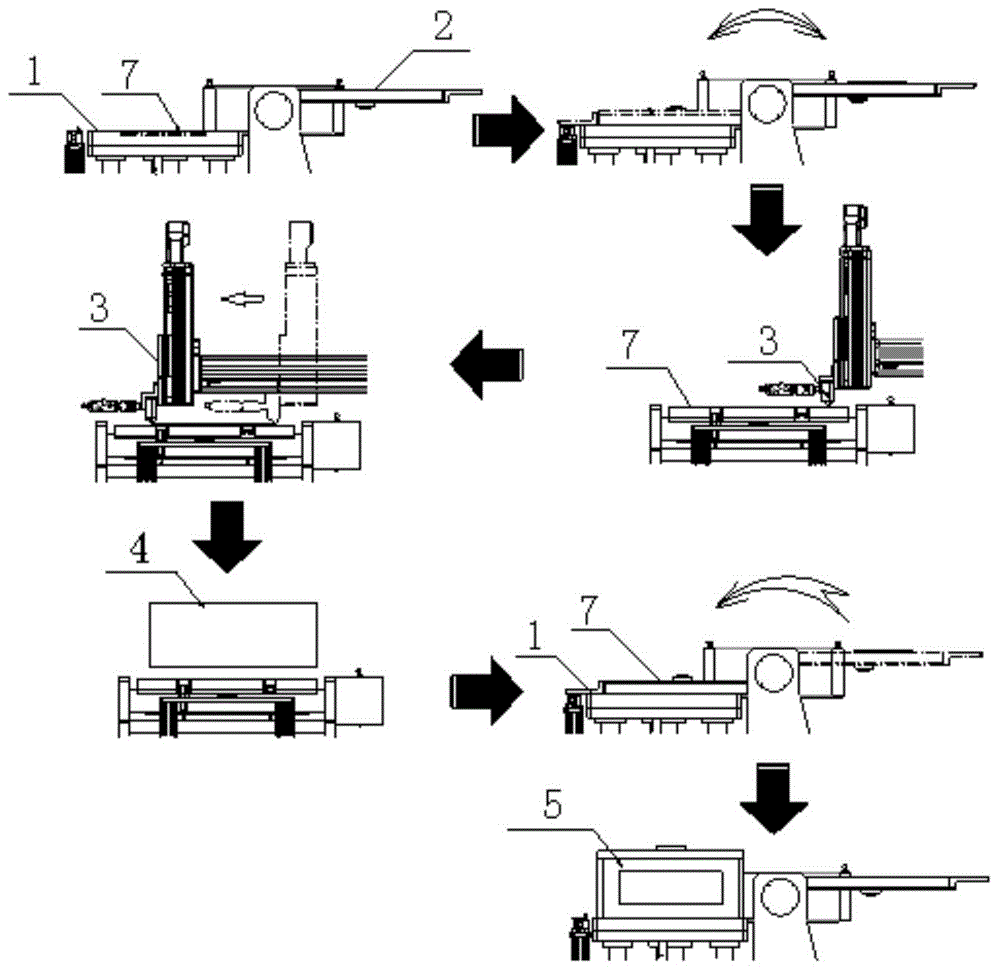

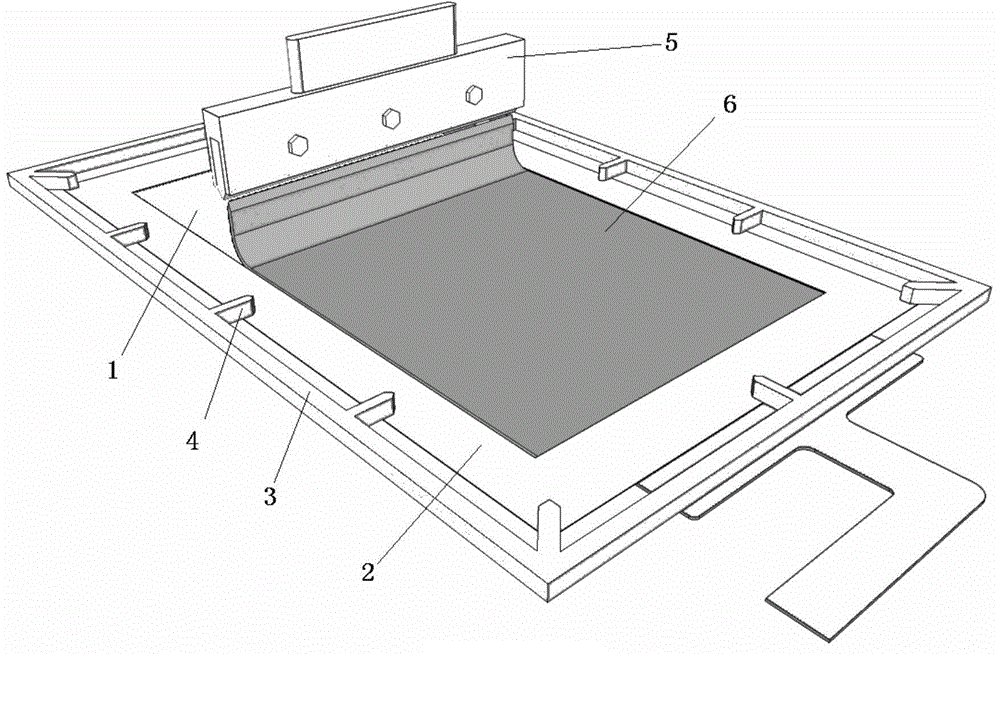

Screen laminating method and system

InactiveCN104571663AReduce cost wasteAvoid glue overflowLamination ancillary operationsLaminationAdhesiveEngineering

The invention belongs to the technical field of screen lamination, and particularly relates to a screen laminating method and system. The screen laminating method comprises the following steps: a, placing a display module and a glass panel on a positioning fixture; b, sucking the glass panel through an overturning mechanism and reversely placing the glass panel at the adhesive output end of an adhesive dispensing mechanism, wherein the adhesive dispensing mechanism is a linear adhesive dispensing valve; c, coating an adhesive on the glass panel in a surface coating way through the adhesive dispensing mechanism; d, sucking the glass panel through the overturning mechanism, placing the glass panel back onto the positioning fixture, and laminating the glass panel with the display module. Adhesive coating is performed through the surface coating way, so that the steps of adhesive scattering or levelling and the like in the existing pinhole type adhesive coating way are omitted, the operation time is saved, and the yield is increased; a UV (Ultraviolet) adhesive is pre-cured, so that the phenomena of adhesive leakage, the adhesive absence, edge unevenness and the like occurring in the laminating process of a liquid UV adhesive are avoided.

Owner:SHENZHEN TENSUN IND EQUIP

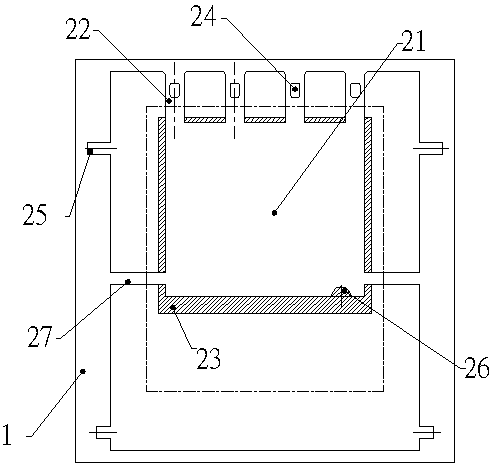

Battery module gluing device

ActiveCN105958107AImprove conductivityAvoid stickingFinal product manufactureSecondary cells manufactureEngineeringCavity wall

The invention relates to the technical field of battery module forming equipment, and in particular relates to a battery module gluing device. The battery module gluing device comprises a supporting component, a clamping component and a gluing component; the supporting component comprises a push plate and a bottom plate; a plurality of through holes are arranged on the push plate; a sealing ring is arranged in the through hole; a thimble is arranged on the bottom plate; the bottom plate is connected to a lifting component; the clamping component comprises a plurality of clamping blocks; the plurality of clamping blocks form a cavity wall for containing glue in an encircling manner; the clamping blocks are connected to a driving component; the gluing component comprises a glue container; the glue container comprises a glue groove; a glue injection hole is arranged at the bottom of the glue groove; and the glue groove is connected to a movable component. The battery module gluing device provided by the invention is used for gluing the middle part of a battery module, wherein a sealed structure is formed through the clamping blocks and the sealing ring; glue can be prevented from overflowing; therefore, glue can be prevented from being stuck on anodes and cathodes; the battery module can be ensured to have good conductivity; simultaneously, the whole process is automatic; the gluing efficiency is increased; the labour cost is saved; and time and labour are saved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

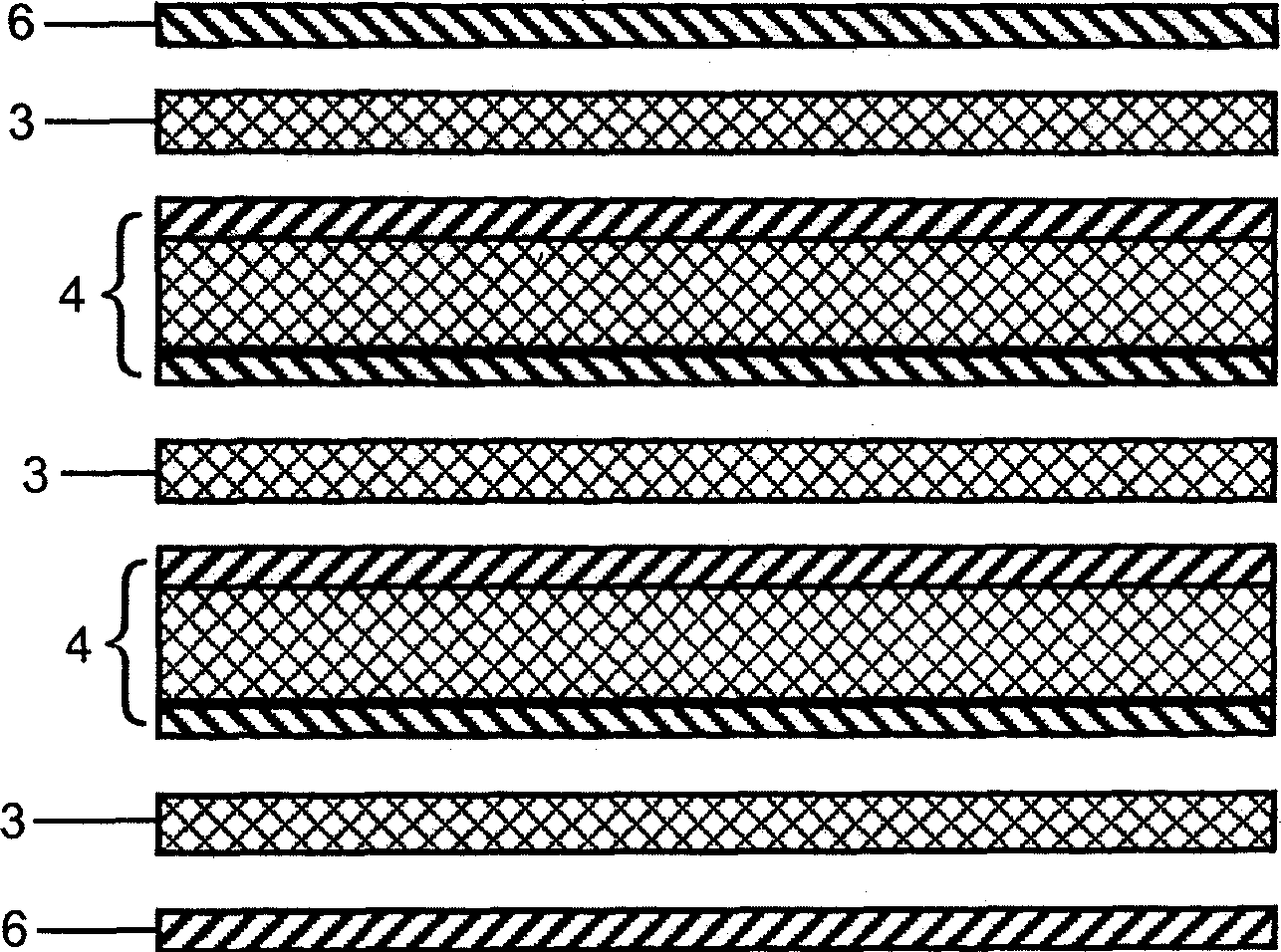

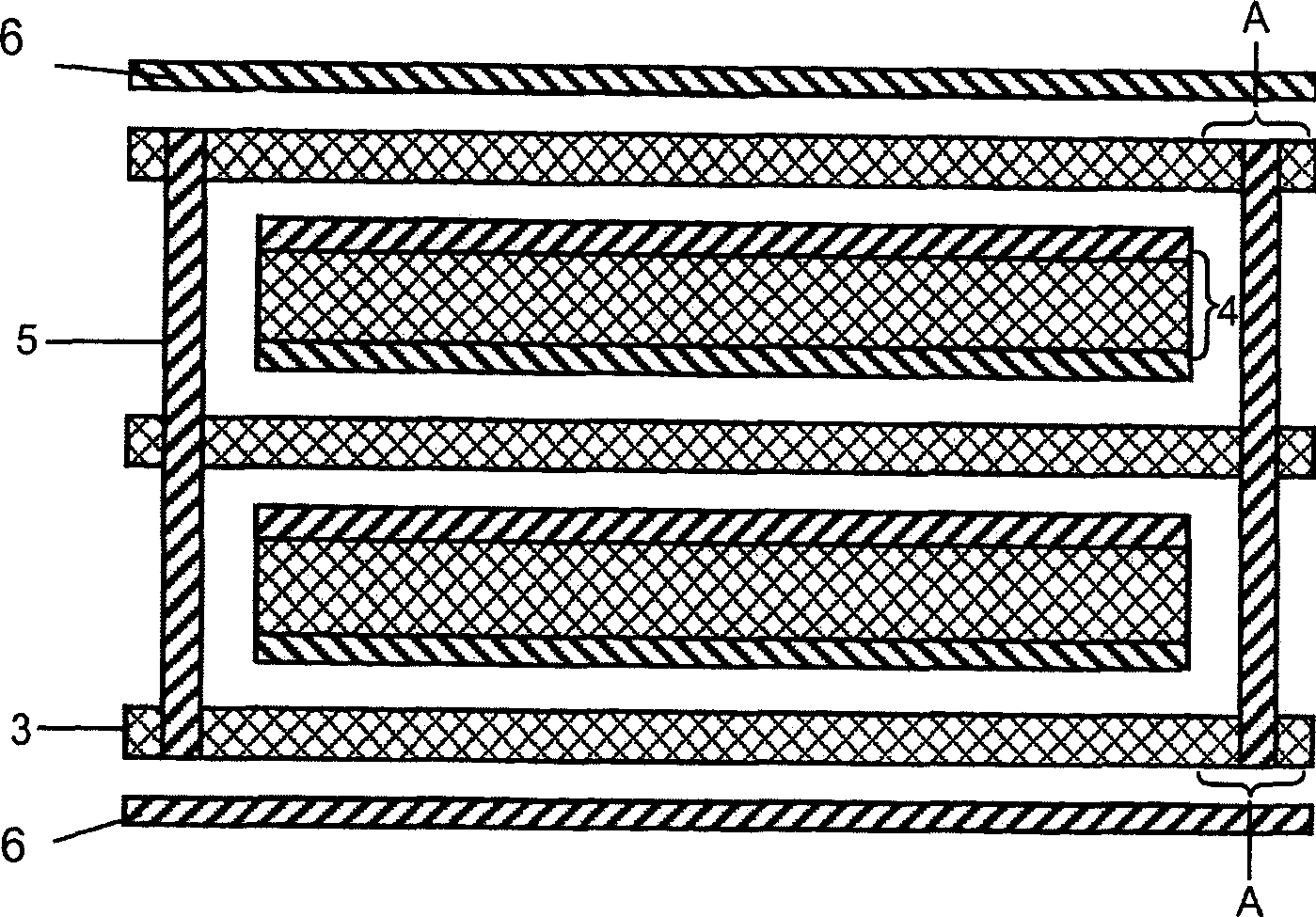

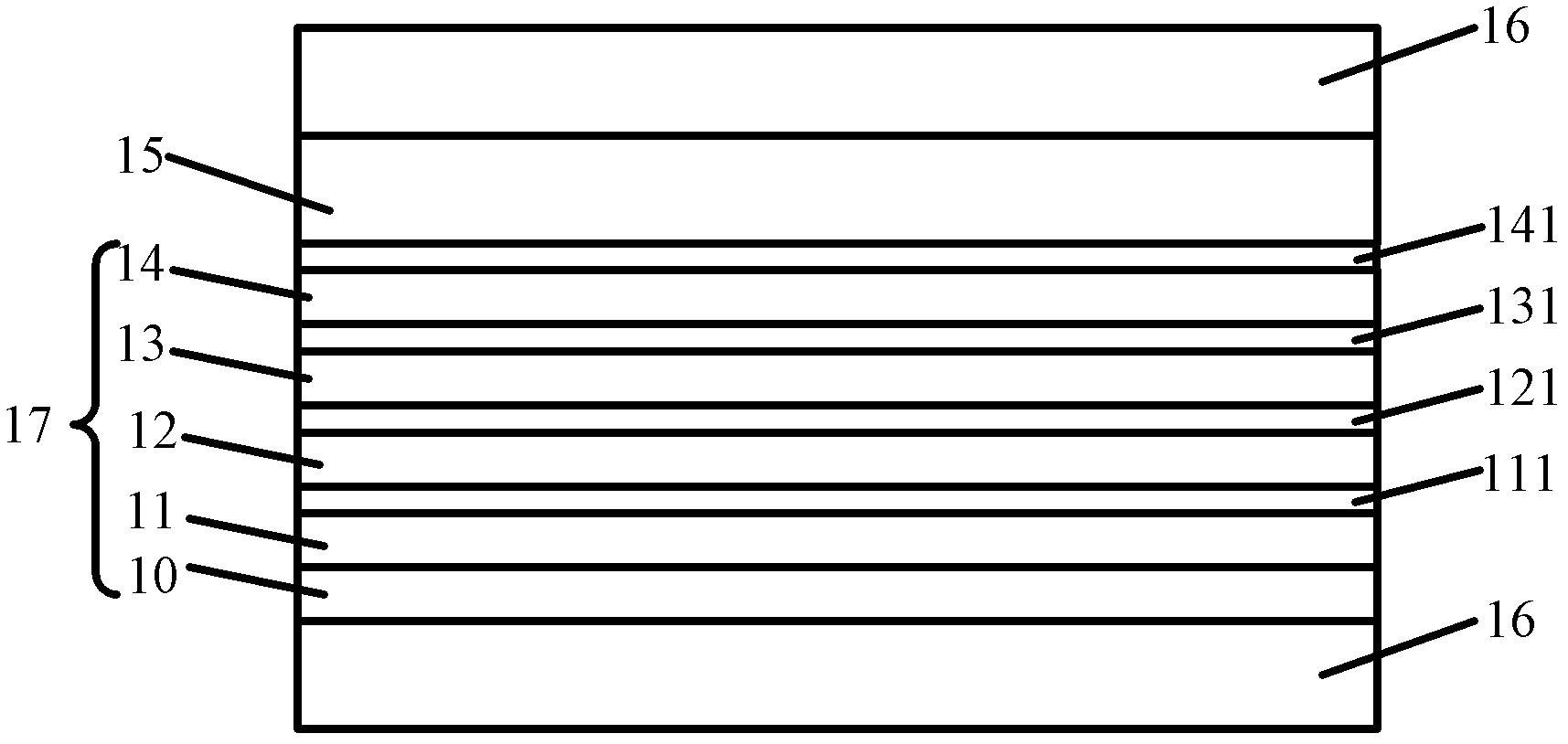

Glue overflow control method of laminar structure

ActiveCN103140058AConvenient and symmetrical placementThe effect of promoting glue curingMultilayer circuit manufactureEngineeringMechanical engineering

Owner:JIANGNAN INST OF COMPUTING TECH

Semiconductor packaging structure and forming method thereof

InactiveCN103531551AReduce usageEasy to useSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Owner:GREAT TEAM BACKEND FOUNDRY (DONGGUAN) LTD

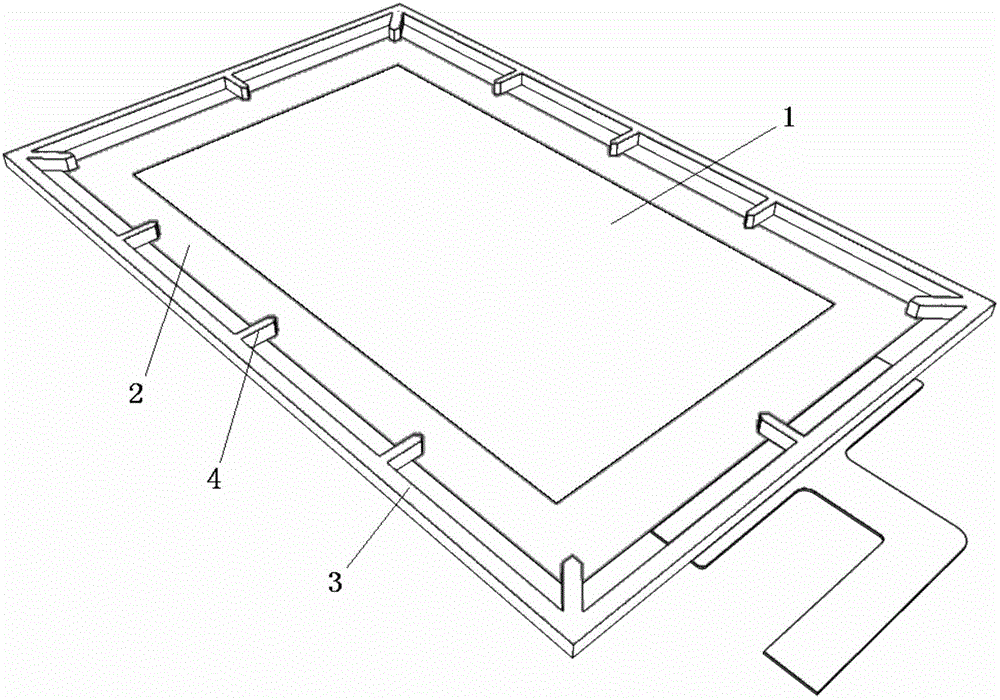

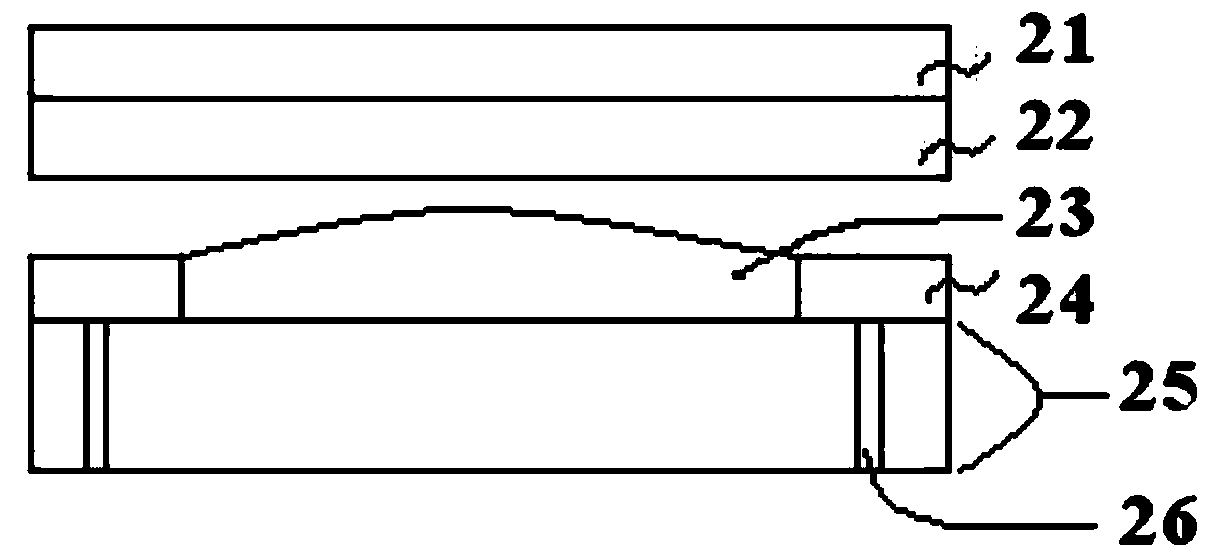

Scraper type jelly glue full binding method

InactiveCN104483769AAvoid glue overflowAvoid lack of glueLaminationLamination apparatusLiquid-crystal displayLiquid state

The invention relates to the technical field of liquid crystal display, in particular to a scraper type jelly glue full binding method. The scraper type jelly glue full binding method includes the steps that a mold is combined with binding faces, the mold is provided with a hollowed-out region, the hollowed-out region of the mold is opposite to the liquid optical cement coating range positions of the binding faces, and the shape and the size of the hollowed-out region are the same as those of the liquid optical cement coating ranges of the binding faces. The whole hollowed-out region of the mold is fully coated with liquid optical cement in a face coating mode; the whole gluing face is precured through an area source, and the liquid optical cement is converted to be in a jelly state; a scraper is tightly attached to the surface of the mold, and redundant glue is horizontally scraped away at a constant speed; the mold is removed; glue is fully bound to the other binding face, and the glue is cured after being bound to the other binding face. By the adoption of the method, the poor phenomena of glue overflow, glue shortage, bubbles and the like after full binding operation are effectively avoided.

Owner:BOE TECH GRP CO LTD +1

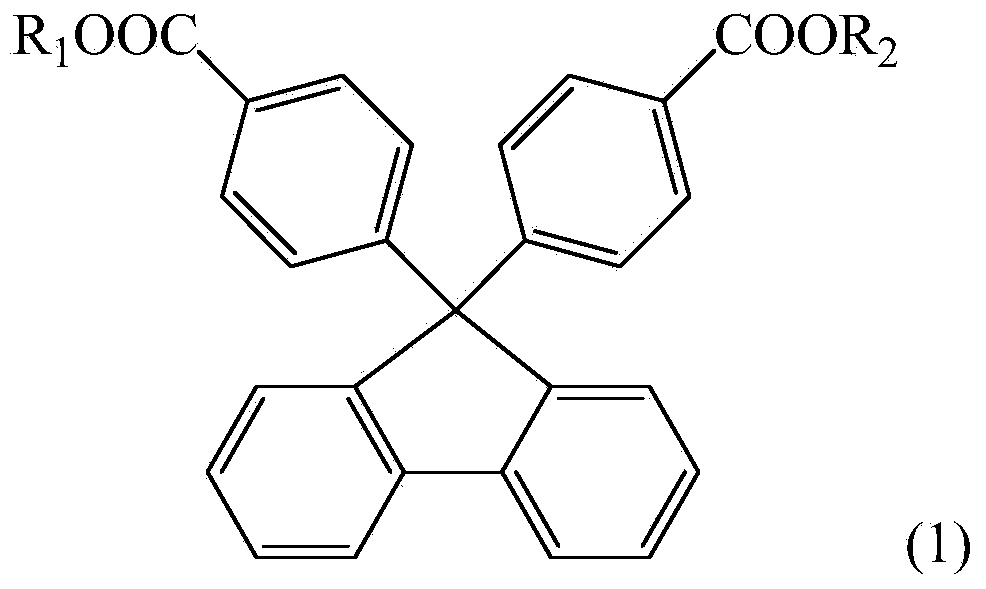

A light curable frame glue material composition

ActiveCN103525354AGood light transmissionHigh refractive indexNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOligomerPlasticizer

The invention provides a light curable frame glue material composition comprising a) (methyl) acrylics oligomer comprising one or more functional groups, b) light initiator, and c) plasticizer with high refractive index. The viscosity value of the frame glue material composition is not less than 8000 cps. The light curable frame glue material composition has both good transmission of light and high refractive index and appropriate liquidity and softness, is easy to cooperate with liquid optical glue (water glue) in order to be used for coating and pasting correlative touch control panels, and does not generate an interface at the junction of the frame glue and the water glue. The light curable frame glue material composition can be used in optical products and simplifies and improves a conventional procedure.

Owner:ETERNAL MATERIALS CO LTD

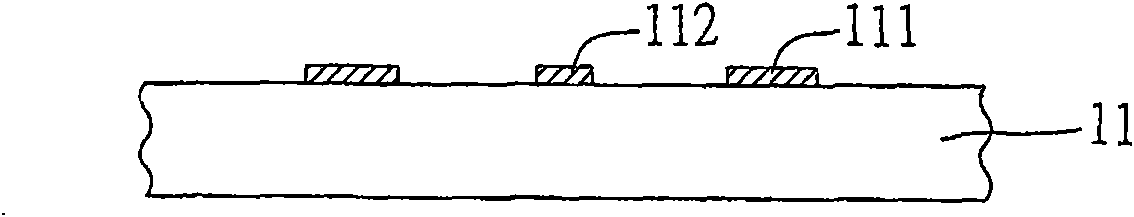

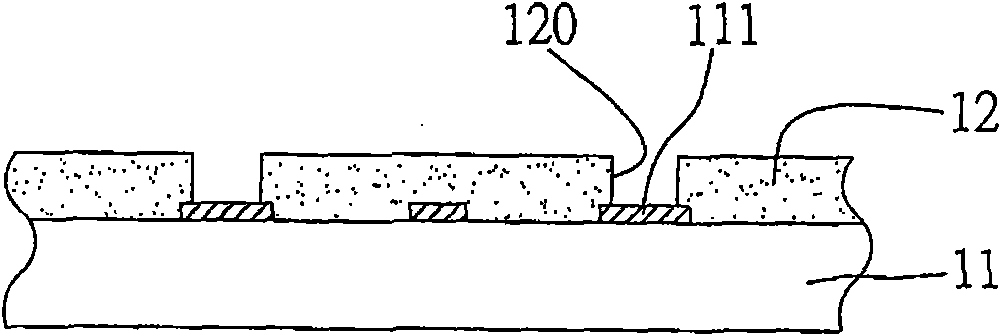

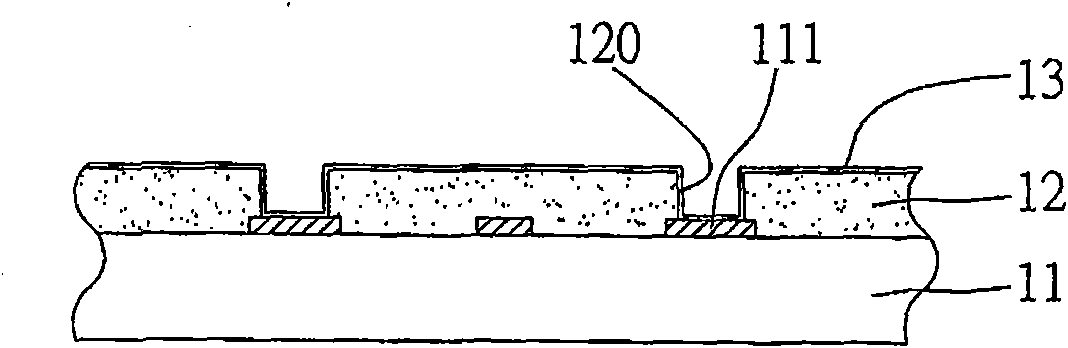

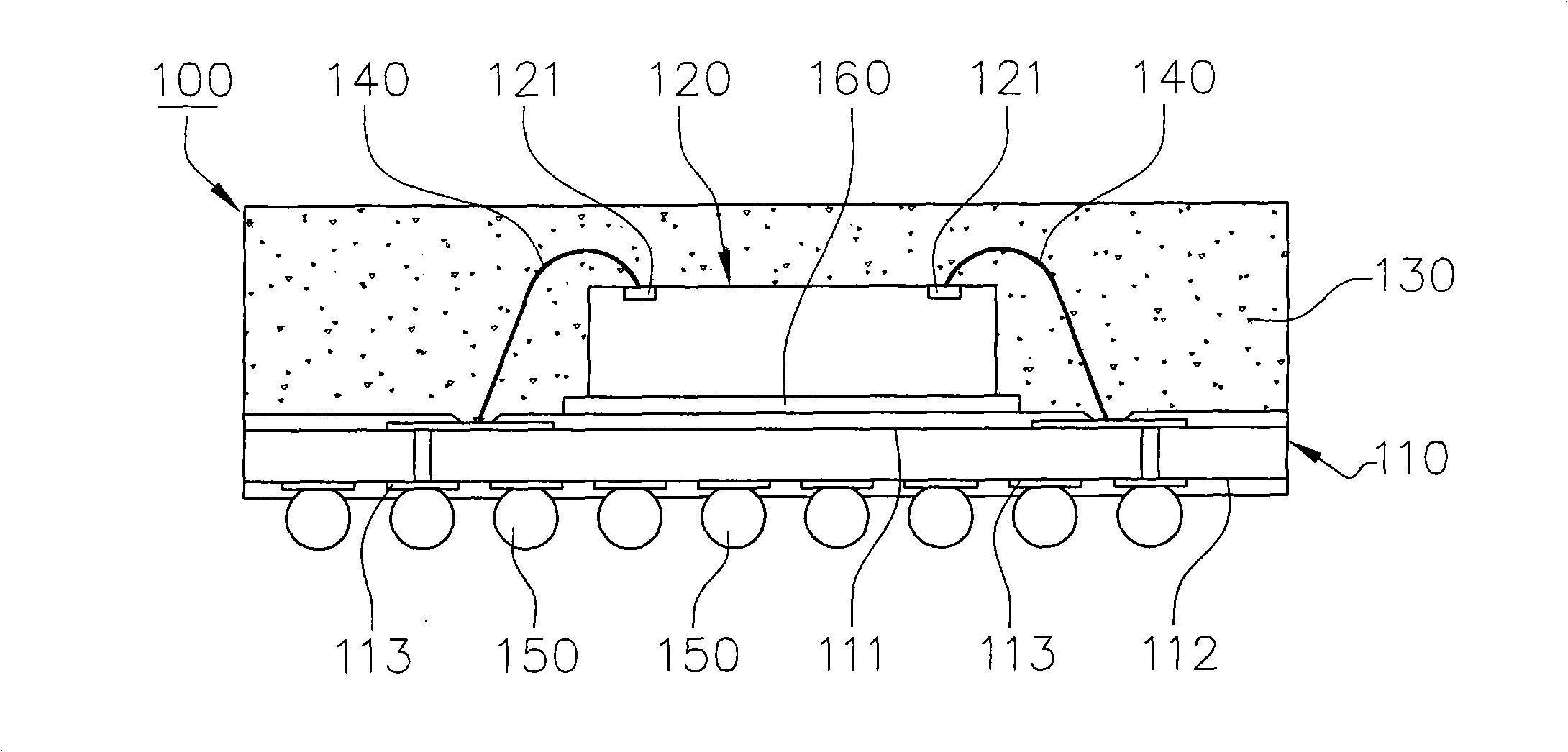

Semiconductor packaging base plate and manufacturing method thereof

ActiveCN101567355AReduce thicknessAvoid stress concentrationSemiconductor/solid-state device detailsSolid-state devicesStress concentrationFilling materials

The invention relates to a semiconductor packaging base plate and a manufacturing method thereof. The semiconductor packaging base plate comprises a base plate body, a plurality of conductive poles and an insulating protection layer, wherein at least one surface of the base plate body is provided with a plurality of electrical connection gaskets; the conductive poles respectively completely wrap each electrical connection gasket; and the insulating protection layer is formed on the surface of the base plate body and is provided with an exposure part for exposing the conductive poles, thus the invention can shorten the distances among the conductive poles, can prevent the stress from being concentrated and the bottom filling materials from overflowing and can also lower the packaging height.

Owner:UNIMICRON TECH CORP

Radiating fin and its packing structure

ActiveCN1855453AAvoid glue overflowImprove yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

The heat sink is designed for an encapsulation process and has a round cambered surface panel. The height of central part of the round cambered surface is equal or higher than the one of ring- shaped bulge. When the horizontal top side of internal cavity of encapsulation mold is pressed down to the heat sink so as to produce a deformation, the cambered surface can not be pressed to oppress the subjacent metal line, and the ring-shaped bulge can also prevent mold-overflow.

Owner:ADVANCED SEMICON ENG INC

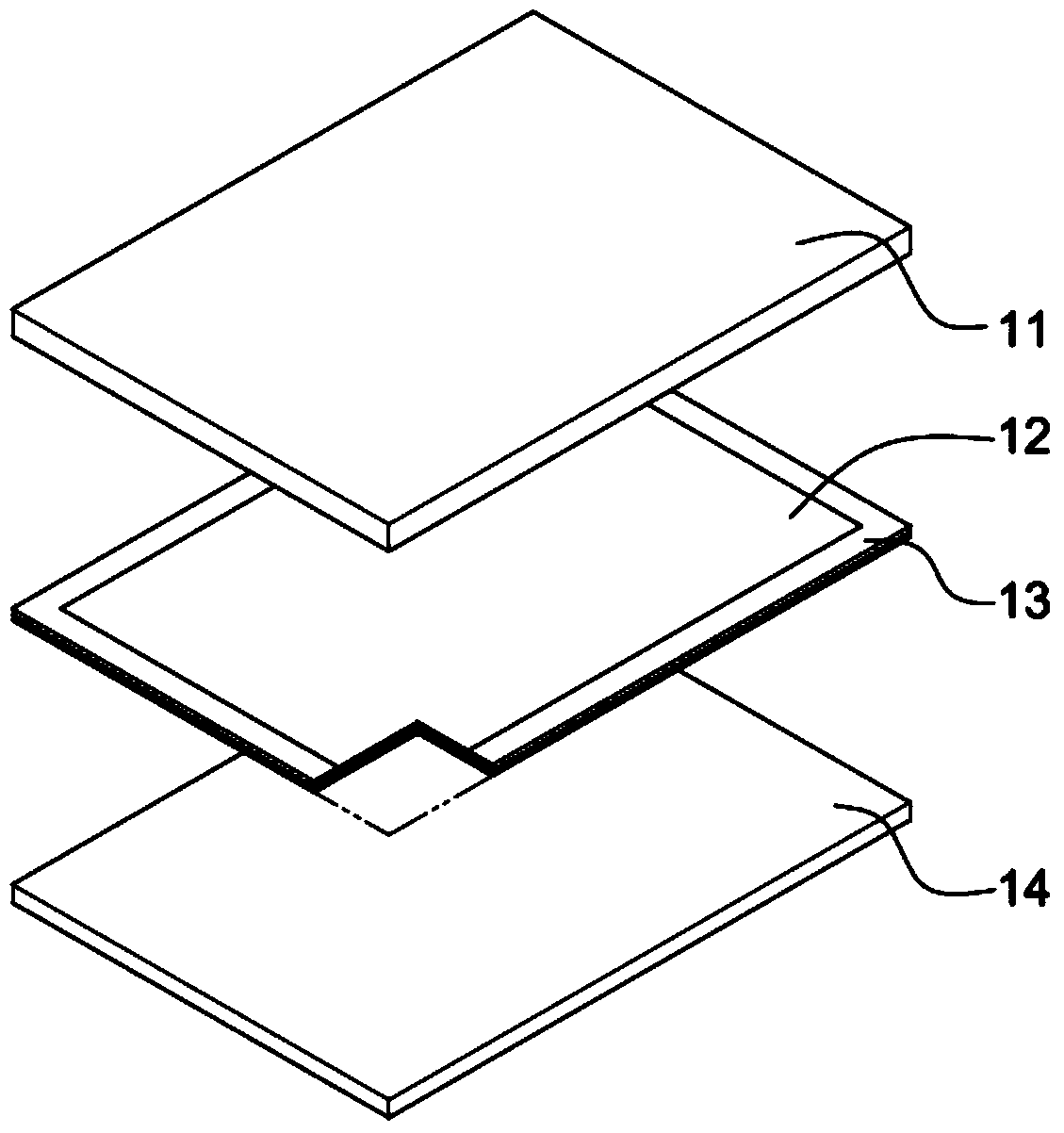

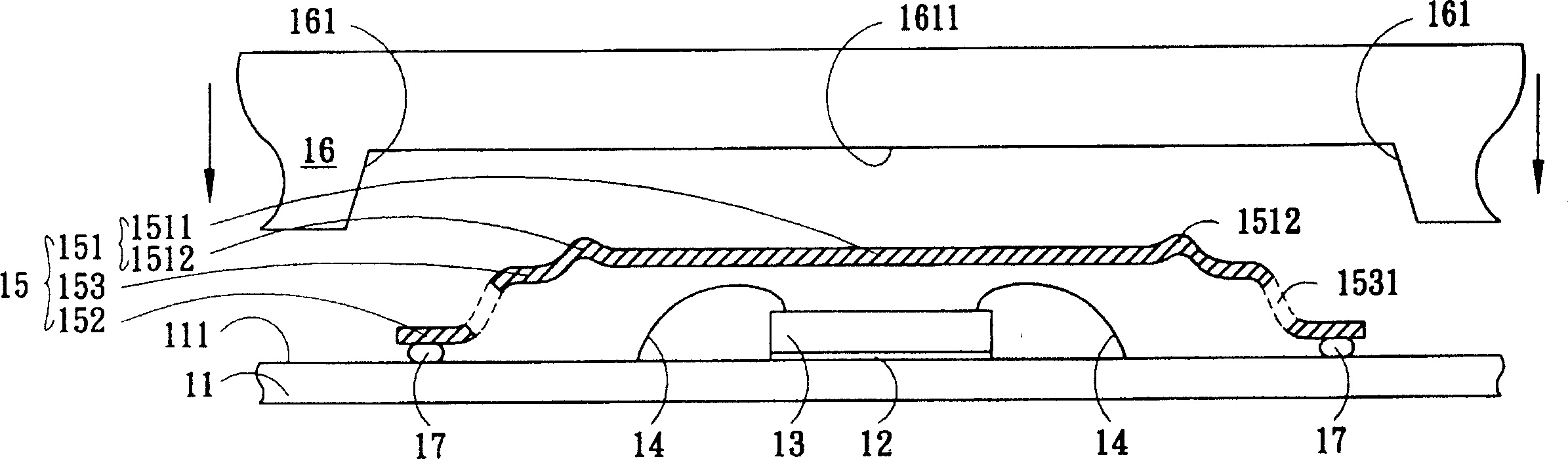

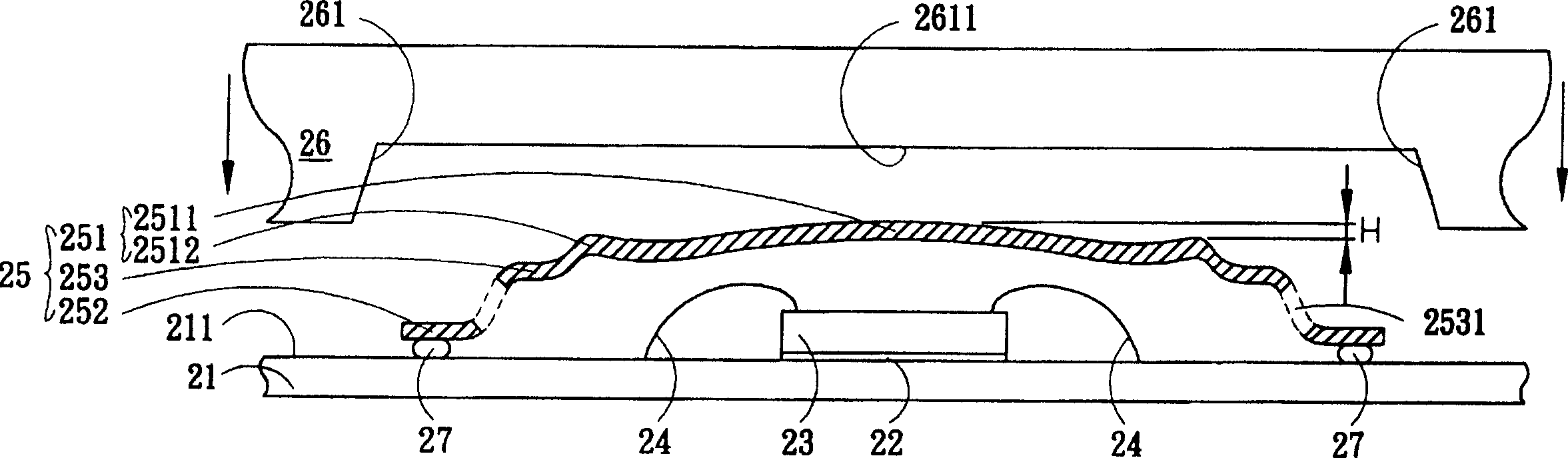

A method of manufacturing an optical adhesive layer for a touch screen and a method of manufacturing the touch screen.

ActiveCN106354290AReduce generationAvoid glue overflowInput/output processes for data processingEngineeringOptical layer

The invention relates to a method of manufacturing an optical adhesive layer for a touch screen and a method of manufacturing the touch screen. The method of manufacturing an optical adhesive layer for a touch screen includes following steps: provide a substrate which has a first surface and a second surface, and provide a liquid optical glue to form an optical adhesive layer of first state on the first surface, then, provide release film, the release film is applied to the optical layer of the first state and pressure is applied to the release film to press the optical layer of the first state, next, the semi-curing treatment is performed so that the optical layer of the first state becomes an optical adhesive layer in a second state, the optical layer of the second state had a definite shape without being subjected to the external force, and will be deformed in the case of an external force. The above production method can effectively avoid the emergence of overflow rubber, and can effectively reduce the bubble generation.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

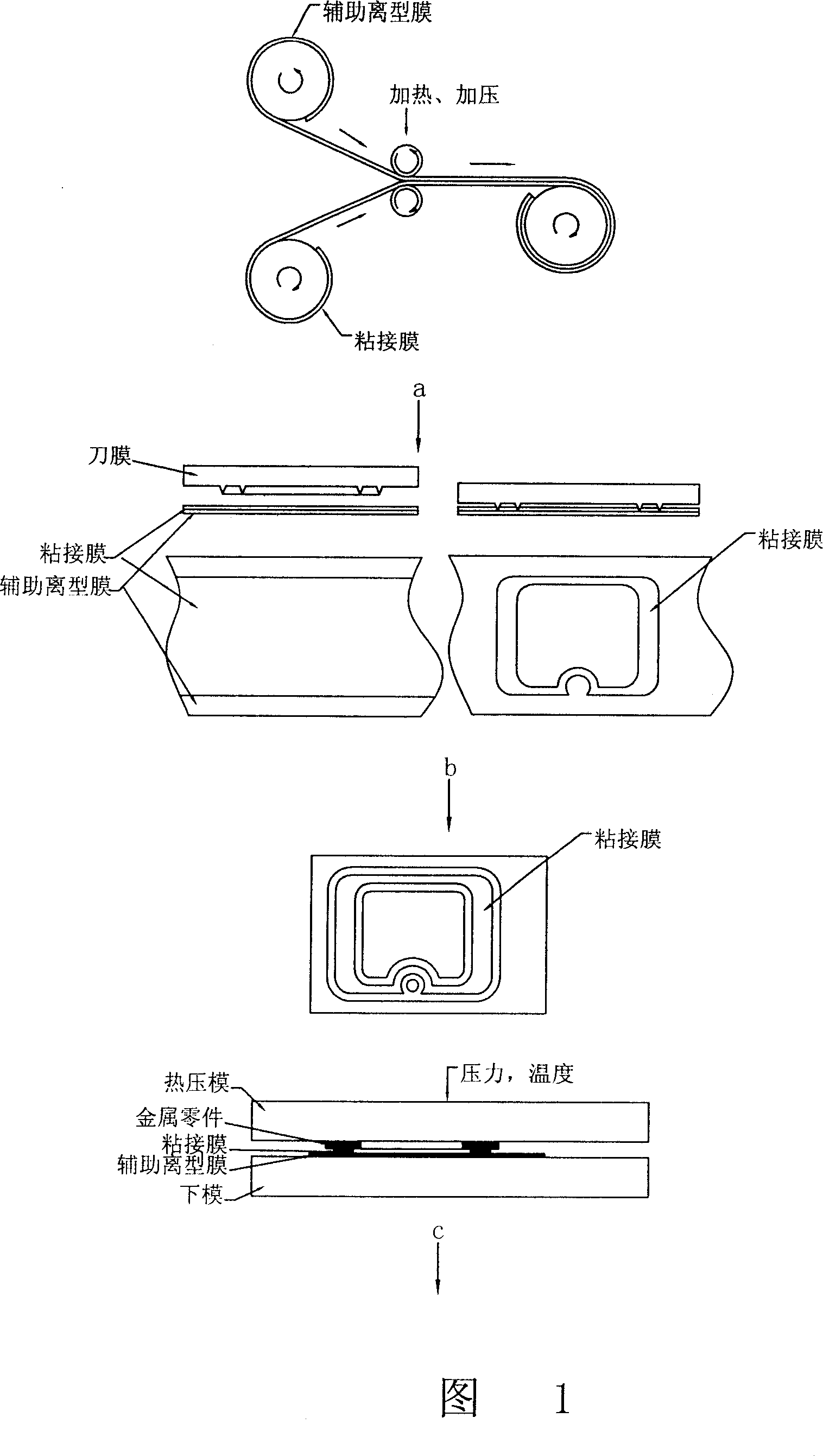

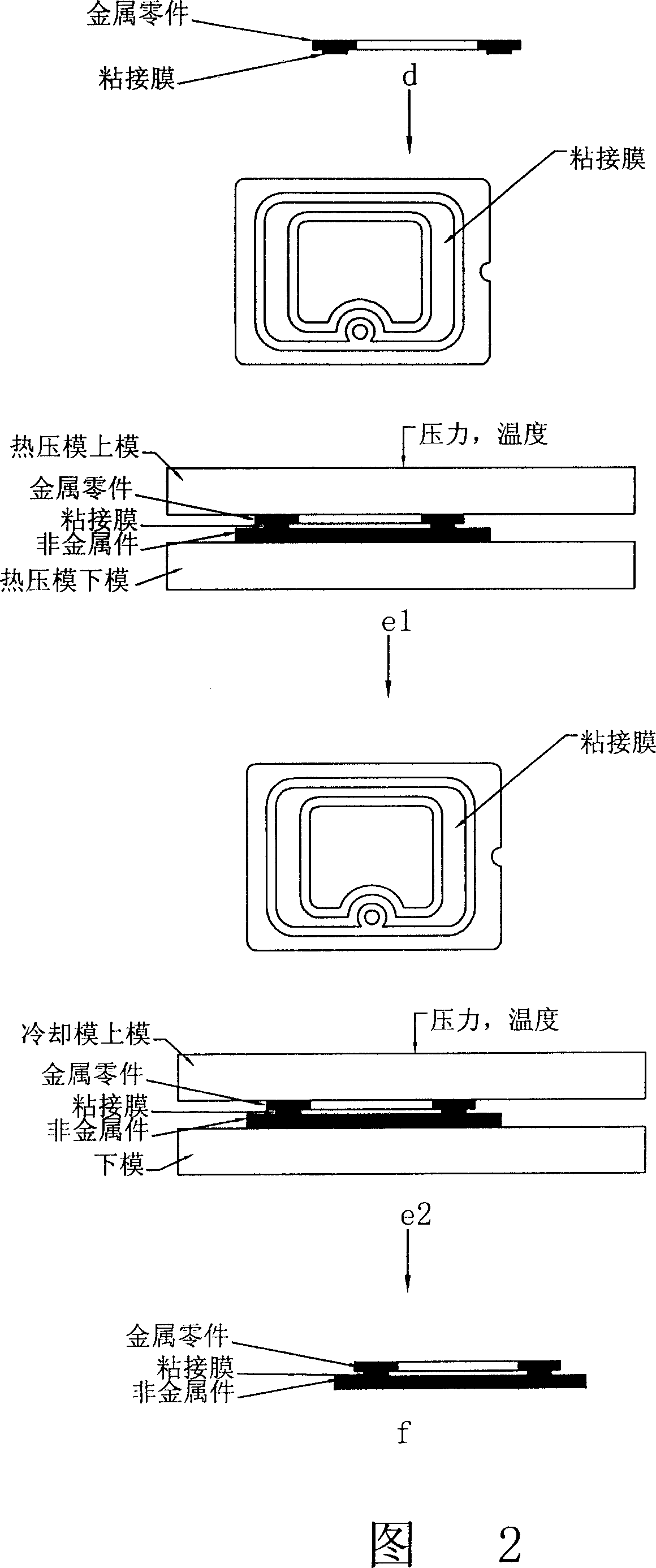

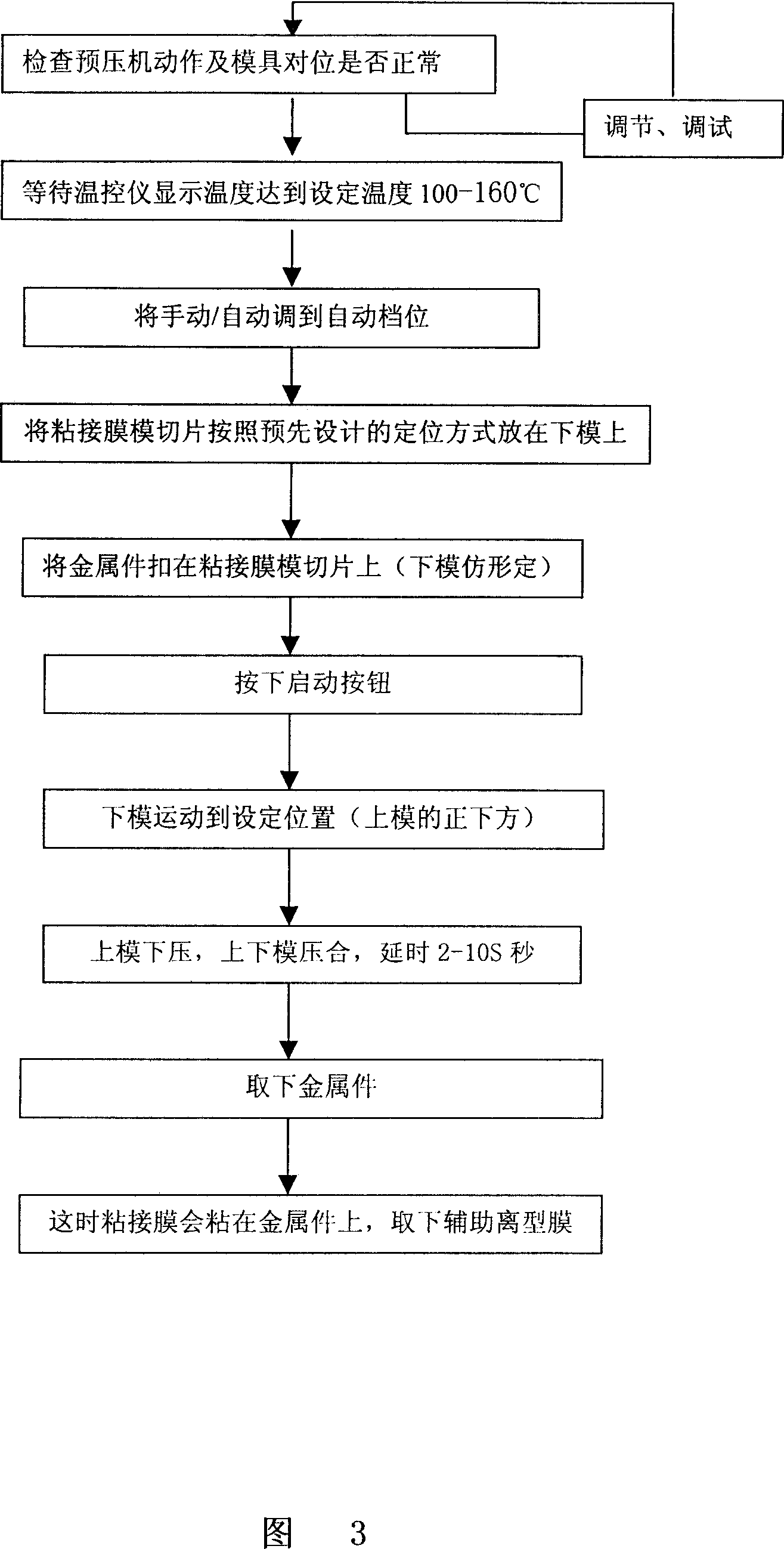

Hot melt adhesion technique

ActiveCN1919952AAccurately control the dosageAvoid pollutionAdhesive processes with adhesive heatingHot meltSolvent

The invention relates the hot melt adhesion technology, comprising the following steps: a heat composite; b cutting; c stitching; d up-stripping and checking; e heat pressing; f checking. The technology can separately control temperature, press and time, has no solvent and environmental pollution; its binding power is ten times than that of pressure-sensitive adhesive; the technology can accurately control the quantity, position and shape of adhesive material; the technology has fast curing speed, short adhesion time; the product made with the technology has advantages of high strength and good property.

Owner:领胜电子科技(深圳)有限公司

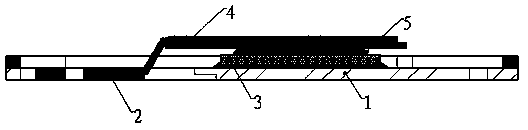

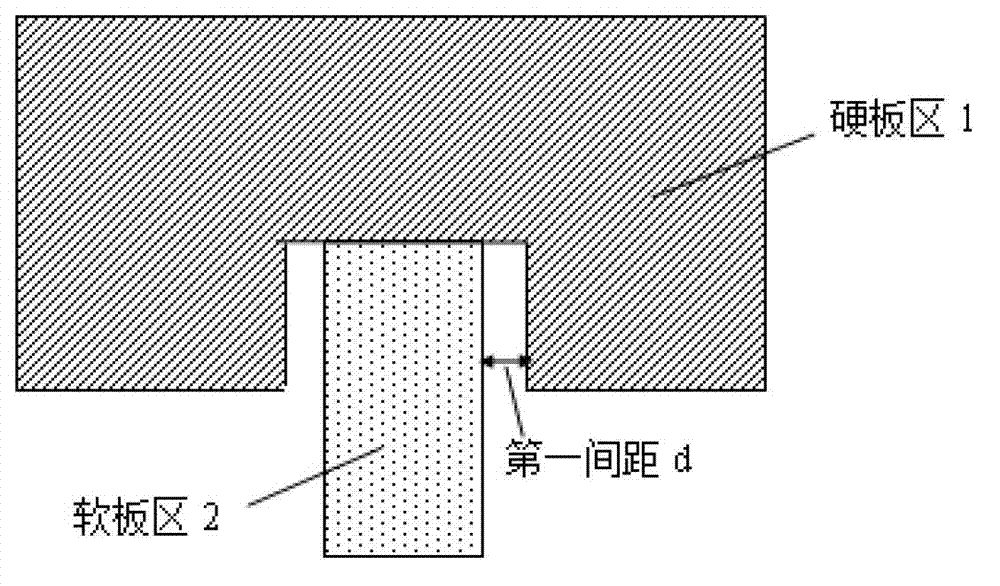

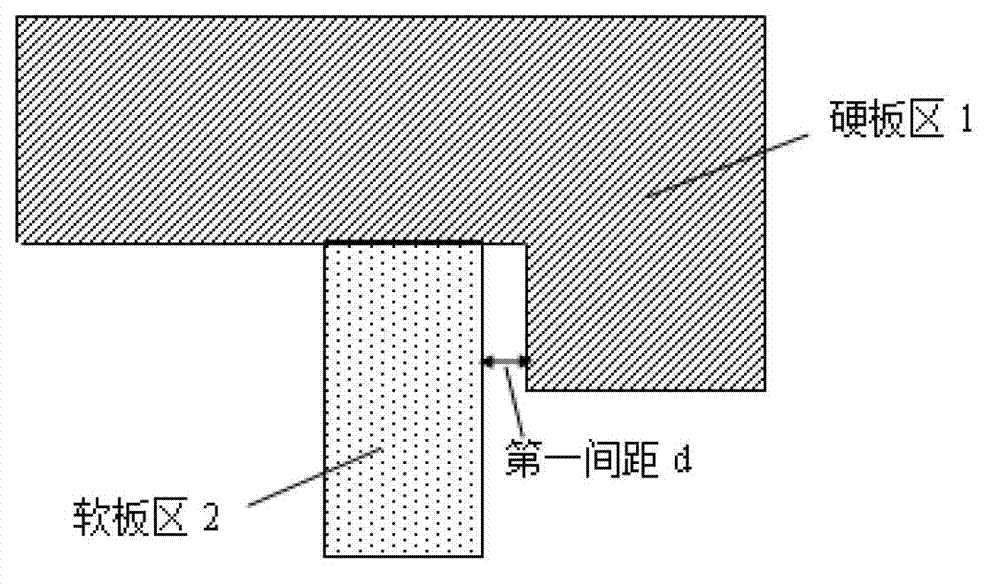

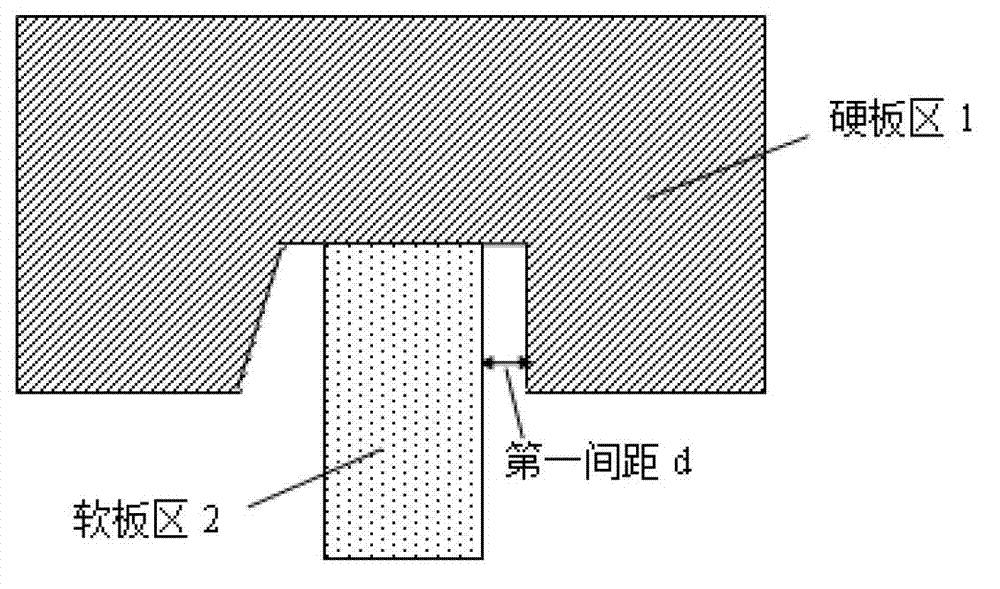

Anti-gluing method for flexible board in groove region of rigid-flexible board

ActiveCN102933042AComplete appearanceAvoid glue overflowPrinted circuit assemblingEngineeringProtection layer

The invention relates to an anti-gluing method for a flexible board in a groove region of a rigid-flexible board, comprising the following steps of: firstly, arranging an adhesive tape above a flexible board region which is adjacent to a rigid board region of the rigid-flexible board and is provided with a groove between the rigid board region and the flexible board region; secondly, laminating the rigid-flexible board; and thirdly, removing the adhesive tape. According to the anti-gluing method for the flexible board in the groove region of the rigid-flexible board provided by the invention, the adhesive tape is directly pasted on the flexible board region as a protection layer, the protection layer is removed after the rigid-flexible board is laminated, and excessive glue also can be removed with the protection layer even the excessive glue overflows in a laminating process of the rigid-flexible board, so that the protection layer can ensure that no residual excessive glue of prepreg is left on a cover film used for protecting the flexible board in the groove region, and further the complete appearance of the cover film is guaranteed.

Owner:JIANGNAN INST OF COMPUTING TECH

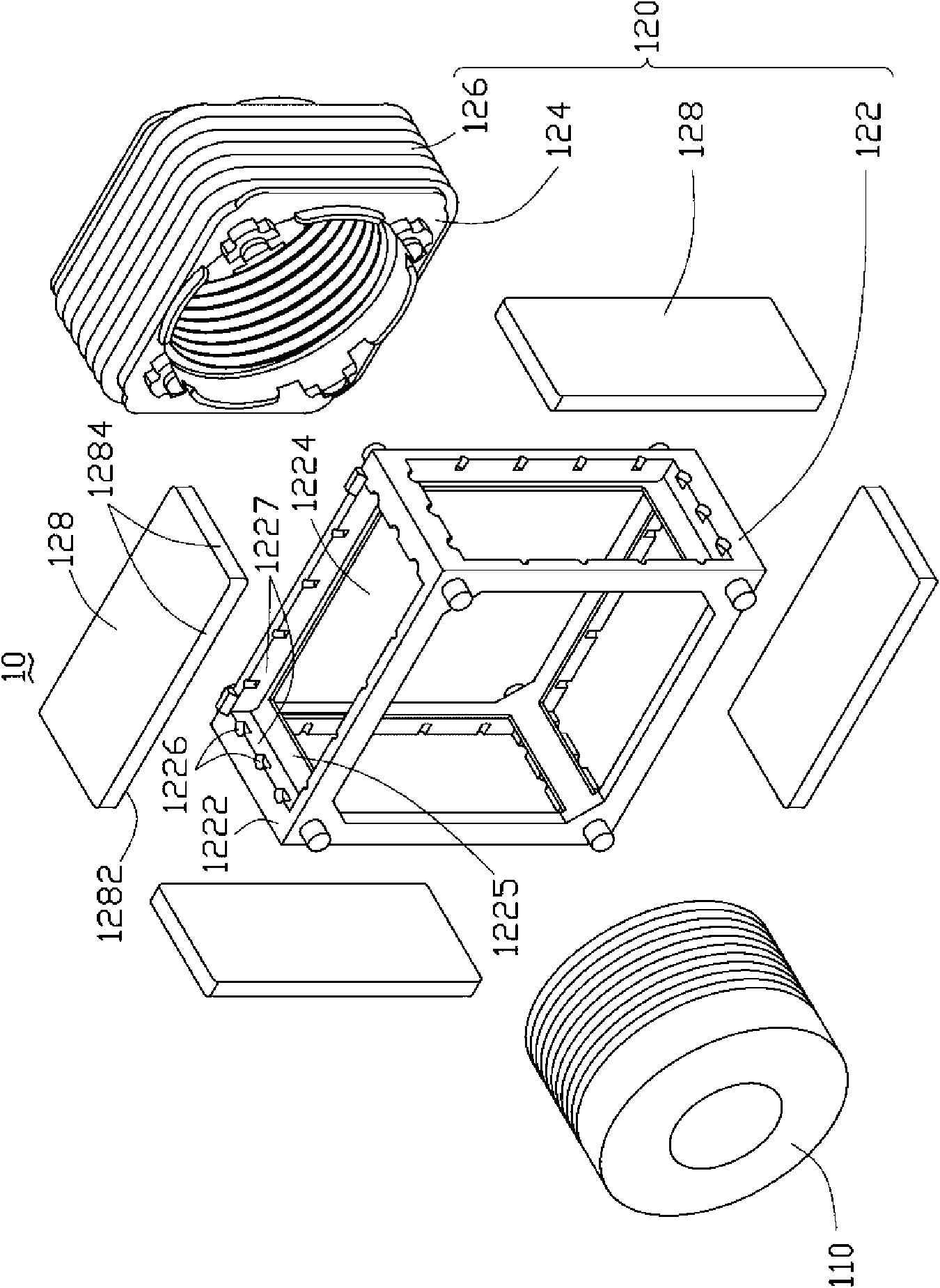

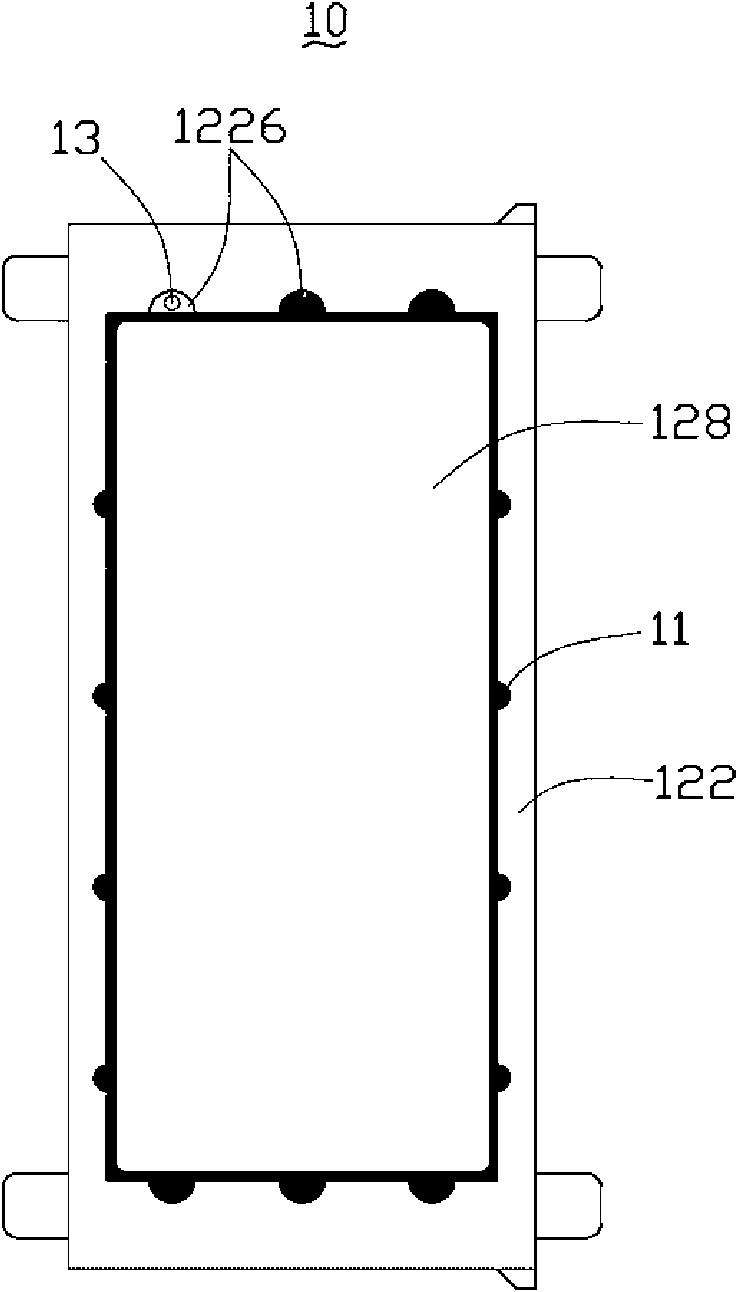

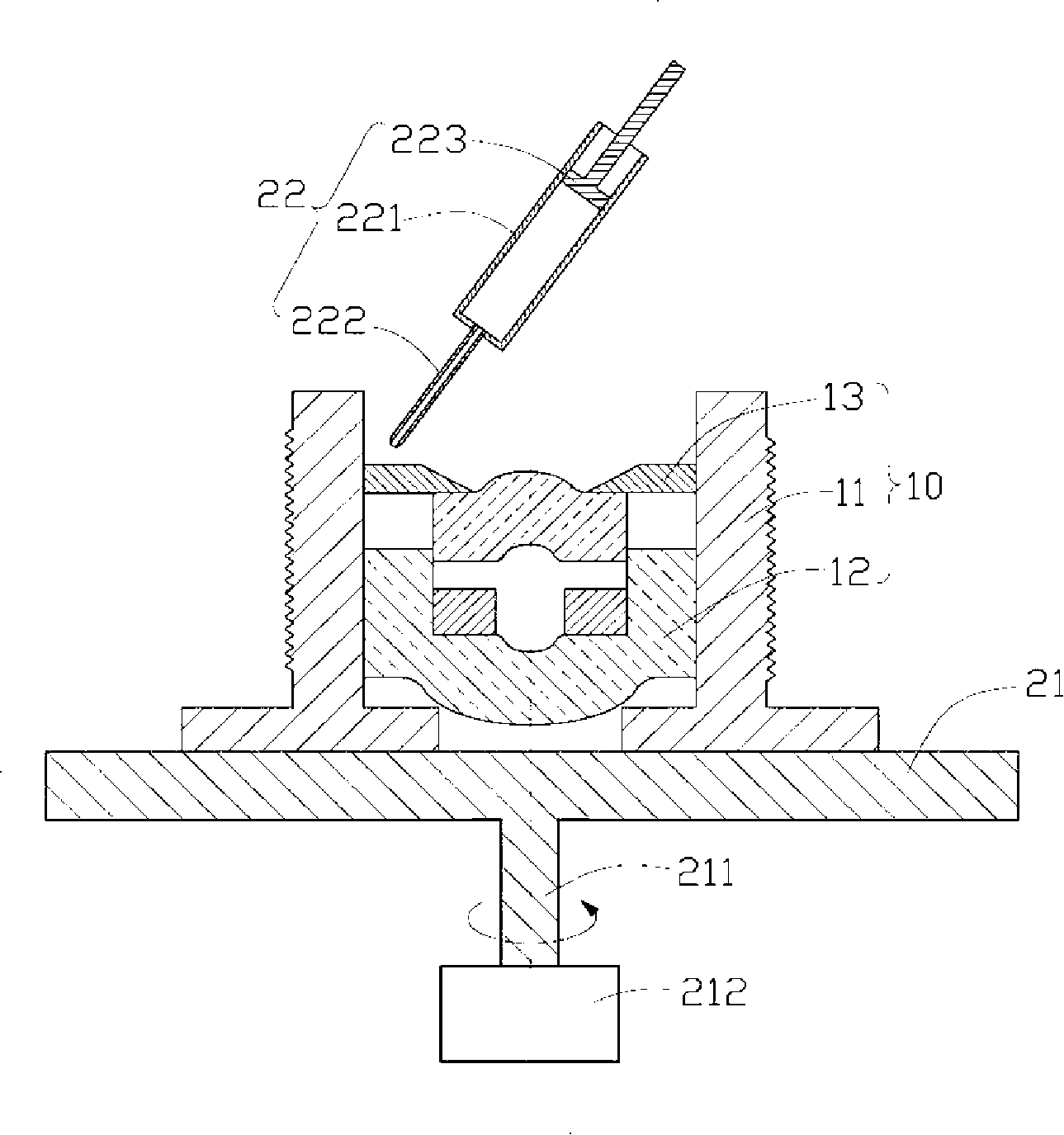

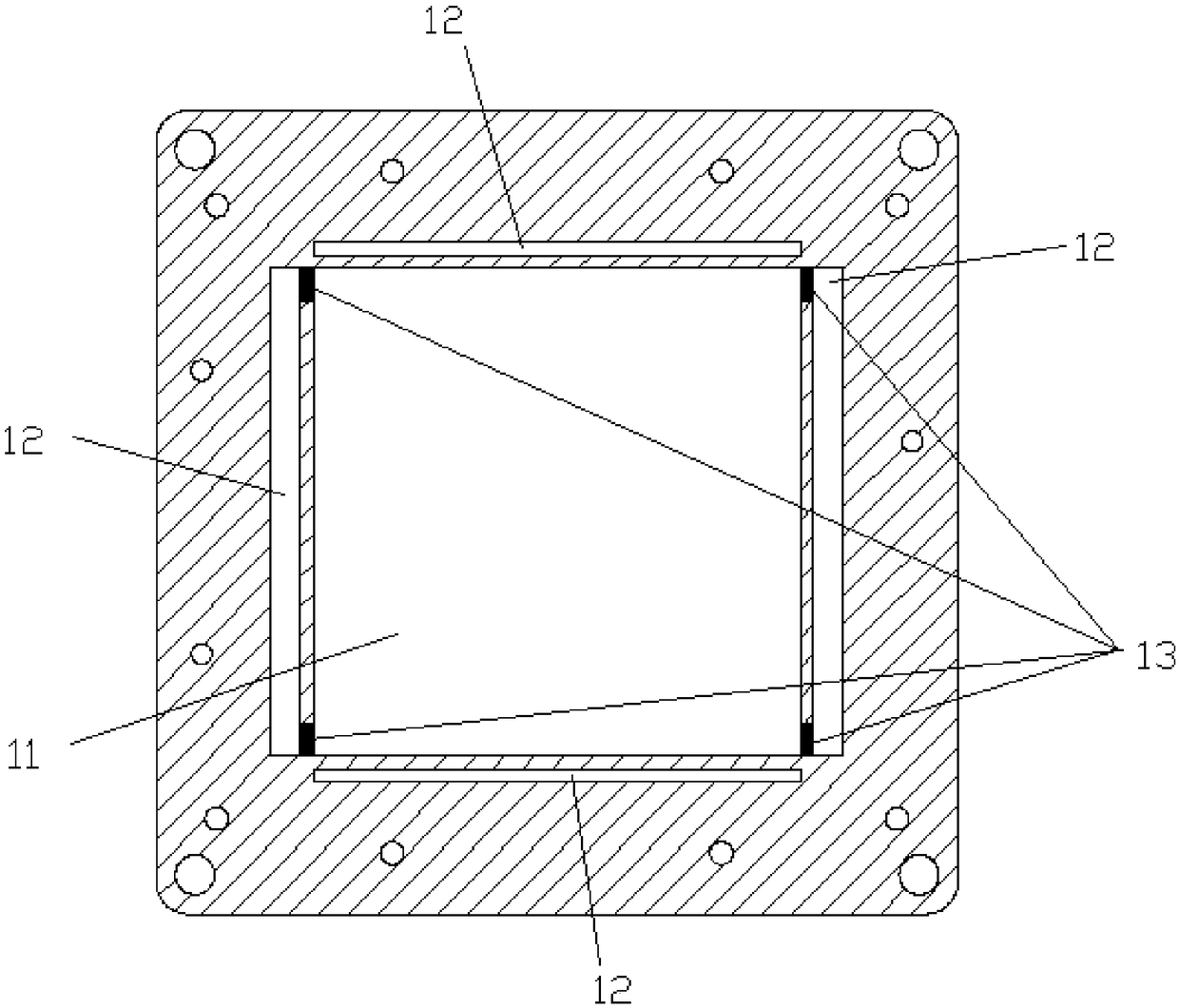

Lens module

InactiveCN101551502AHigh bonding strengthAvoid glue overflowDynamo-electric machinesMountingsCamera lensVoice coil

The invention provides a lens module, comprising a lens and a voice coil motor connected with the lens; wherein the voice coil motor comprises an outer frame, a lens bracket arranged inside the outer frame, a coil sheathed on the lens bracket and at least one permanent magnet fixed on the outer frame; the lens is connected with the lens bracket; the outer frame is provided with at least one storage tank which has a bottom surface and a plurality of lateral surfaces adjacent to the bottom surface and used for containing the permanent magnet; the permanent magnet has a bottom surface and a plurality of lateral surfaces adjacent to the bottom surface; the bottom surface of the permanent magnet contacts the bottom surface of the storage tank; the plurality of lateral surfaces of the permanent magnet are arranged opposite to the plurality of lateral surfaces of the storage tank with clearance; and the outer frame is provided with a plurality of glue dispensing holes which are communicated with the storage tank and the clearance between the lateral surfaces of the permanent magnet and the lateral surfaces of the storage tank.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

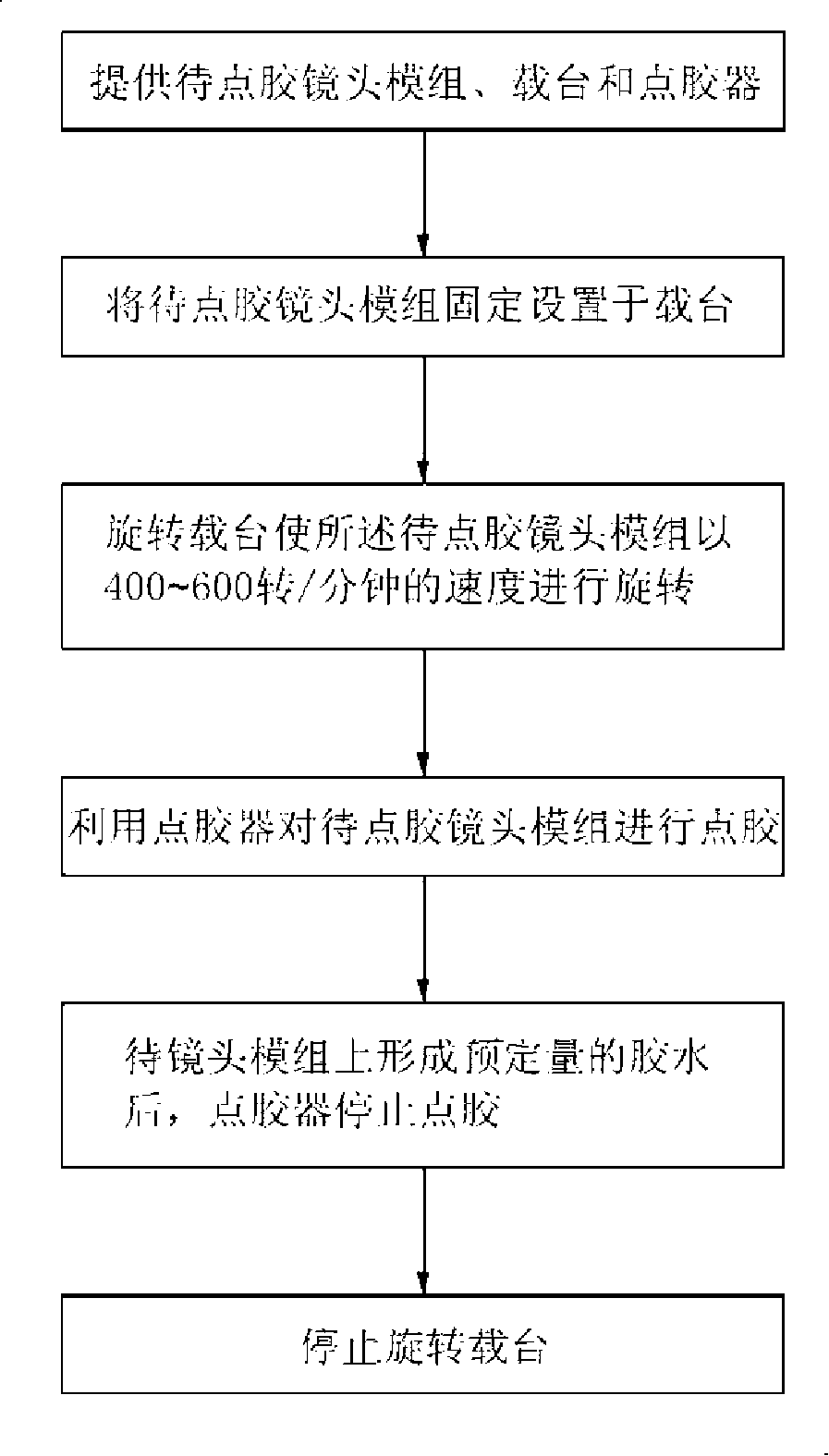

Method for spotting glue for lens module

The invention provides a dispensing method for a lens module group. The invention comprises the steps that a lens module group for dispensing, a stage and a dispensing device are provided; the lens module group for dispensing is fixed and mounted on the stage; the stage is revolved so that the lens module group for dispensing rotates with the speed of 400 to 600 rounds per minute; the dispensing device is used for the dispensing of the lens module group; after the predetermined amount of glue is formed on the lens module group, the dispensing device stops dispensing; the revolution of the stage is stopped. In the technology scheme, the stage rotates continuously with the speed of 400 to 600 rounds per minute, so that the glue is coated on the inner wall of the drawtube and the periphery of the spacing ring exactly due to the great centrifugal force, and the overflow of the glue is prevented. Even the dispensing pinhead has a certain distance with the inner wall of the drawtube during the dispensing process, the glue can be coated by spin on the inner wall of the drawtube and the periphery of the spacing ring exactly due to the centrifugal force, which ensures the dispensing quality of the lens module group.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

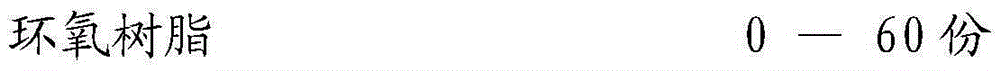

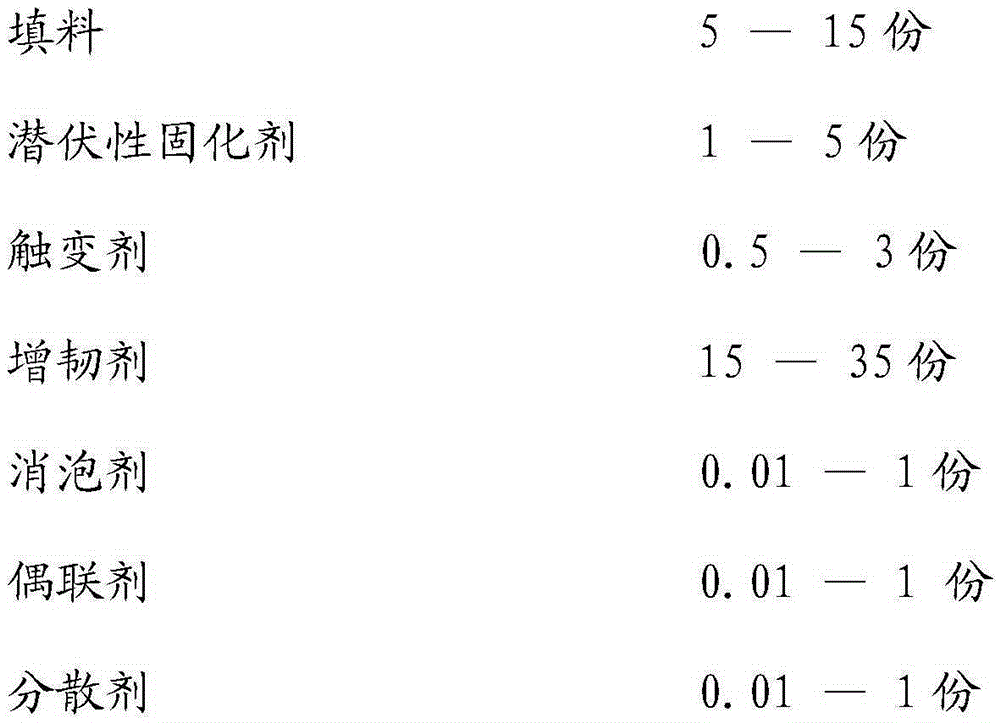

Halogen-free thermosetting epoxy adhesive and application thereof

ActiveCN105385396AThere will be no excessive halogenHalogen-free requirements meetNon-macromolecular adhesive additivesMacromolecular adhesive additivesHalogenHeat resistance

The invention provides a halogen-free thermosetting epoxy adhesive. The halogen-free thermosetting epoxy adhesive comprises, by weight, 0-60 parts of epoxy resin, 5-15 parts of a filler, 1-5 parts of a latent curing agent, 0.5-3 parts of a thixotropic agent, 15-35 parts of a flexibilizer, 0.01-1 part of an antifoaming agent, 0.01-1 part of a coupling agent and 0.01-1 part of a dispersant. The halogen-free thermosetting epoxy adhesive can be applied in E-Paper edge sealing. The epoxy adhesive provided by the invention has the advantages of no halogen, realization of low-temperature rapid solidification, excellent bonding strength and flexibility, high heat resistance, low heat expansion coefficient and high water resistance.

Owner:深圳百丽春新材料科技有限公司

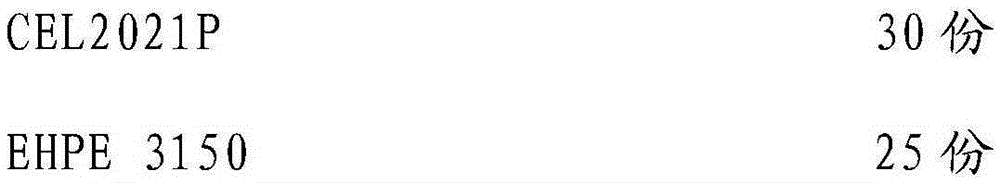

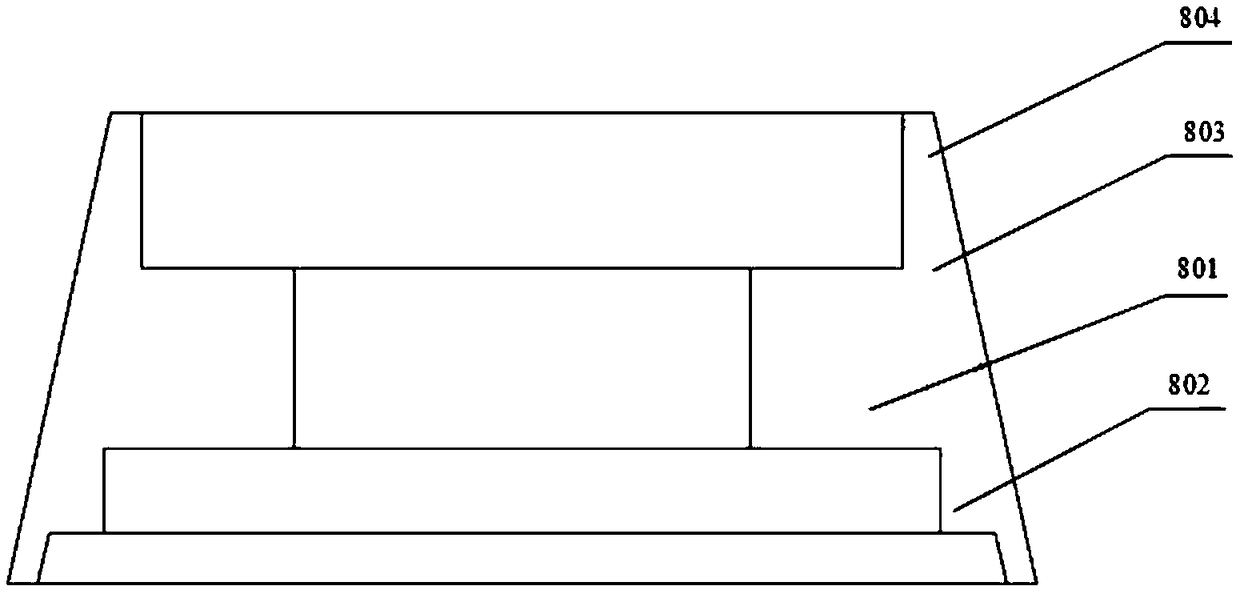

Full-color LED display module, packaging method and display screen of full-color LED display module

InactiveCN108448012ATo achieve a variety of choicesImproved size adaptabilitySolid-state devicesSemiconductor/solid-state device manufacturingLED displayEngineering

The invention discloses a packaging method of a full-color LED display module. The method comprises the steps of 1, coating the package resin on a separation film; 2, placing a separation plate on a first jig, and placing the separation film coated with the package resin on the separation plate, wherein the side of the separation film with the package resin is placed upwards; 3, placing the solid-crystal full-color LED display module substrate on the package resin, placing the chip of a full-color LED display module substrate to be downwards, and then placing a second jig; 4, combining the first jig and the second jig, and putting the first jig and the second jig into a vacuum air compressor for vacuum lamination; 5, after the lamination is completed, taking out the full-color LED displaymodule substrate, tearing off the separation film, and finishing the packaging operation. Correspondingly, the invention further provides a full-color LED display module and a display screen of the full-color LED display module. By the adoption of the method, the diversified selection of packaging sizes and packaging materials can be realized. The packaging quality is good, and the foaming is avoided. The requirement on packaging equipment is low.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

Preparation method of self-adhesive label

ActiveCN104626722ASolve the problem of glue overflowMeet technical requirementsLaminationLamination apparatusSurface layerEngineering

The invention belongs to the field of self-adhesive labels, and particularly relates to a preparation method of a self-adhesive label. The preparation method comprises the steps of putting release paper into an unreeling shaft by adopting two kinds of release paper with different release force as raw materials, and by adopting the release paper with relatively high release paper as a base material, melting a pressure-sensitive adhesive, starting up a coating machine, coating the base material with the hot melt adhesive by a coating head uniformly, laminating the base material after adhesive coating and the release paper with relatively low release force together by two adhesive rollers, reeling the combined double-faced adhesive by a reeling shaft, placing at normal temperature so as to prepare the hot melt pressure-sensitive double-faced adhesive material; stripping the release paper with relatively low release force in the hot melt pressure-sensitive double-faced adhesive layer, exposing the coated pressure-sensitive adhesive layer, laminating the label surface layer and the exposed pressure-sensitive adhesive layer by the adhesive roller, and then carrying out automatic die cutting and reeling to obtain a product. The self-adhesive label is convenient to produce by utilizing the difference of the stripping intensity of the release paper and the technical characteristics of the pressure-sensitive adhesive, can meet the technical requirement of cold combination of reeled materials so as to solve the adhesive overflow phenomenon generated by thermal combination.

Owner:CHINA COMMERCE NETWORKS SHANGHAI

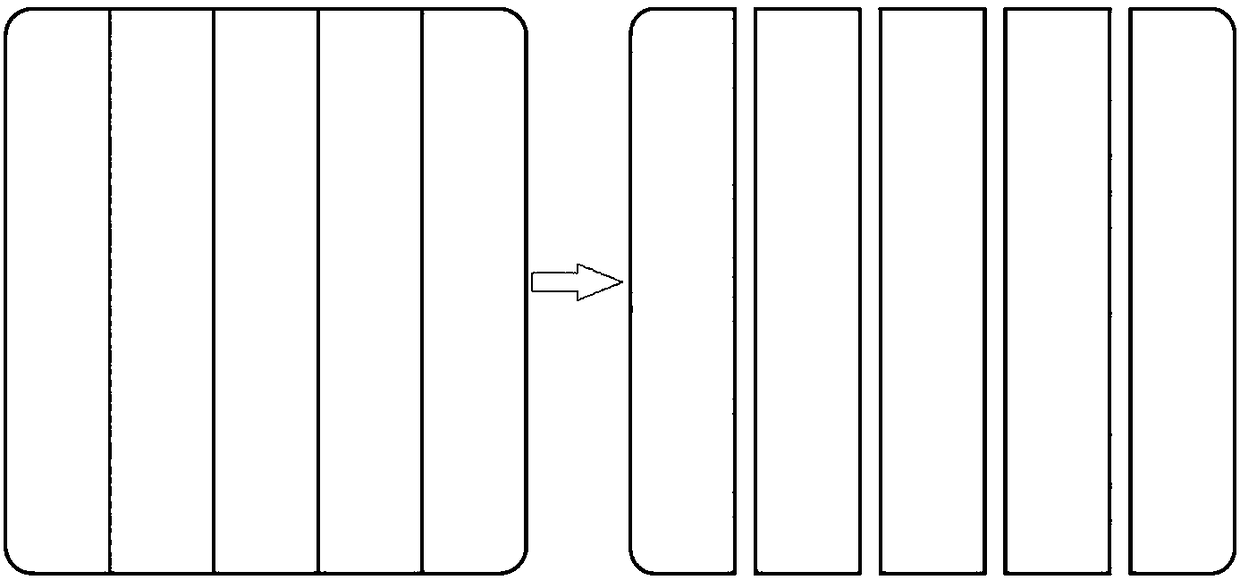

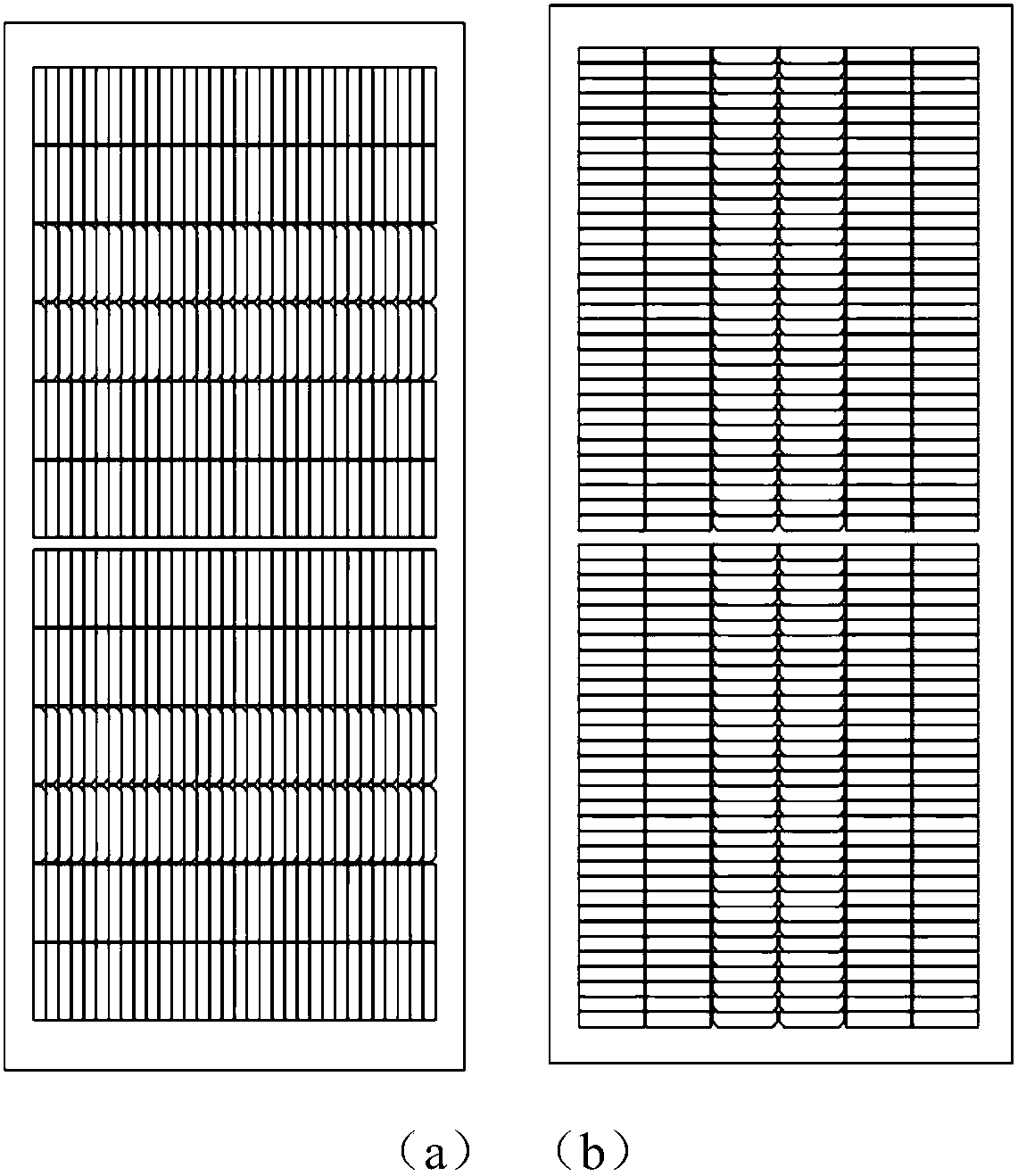

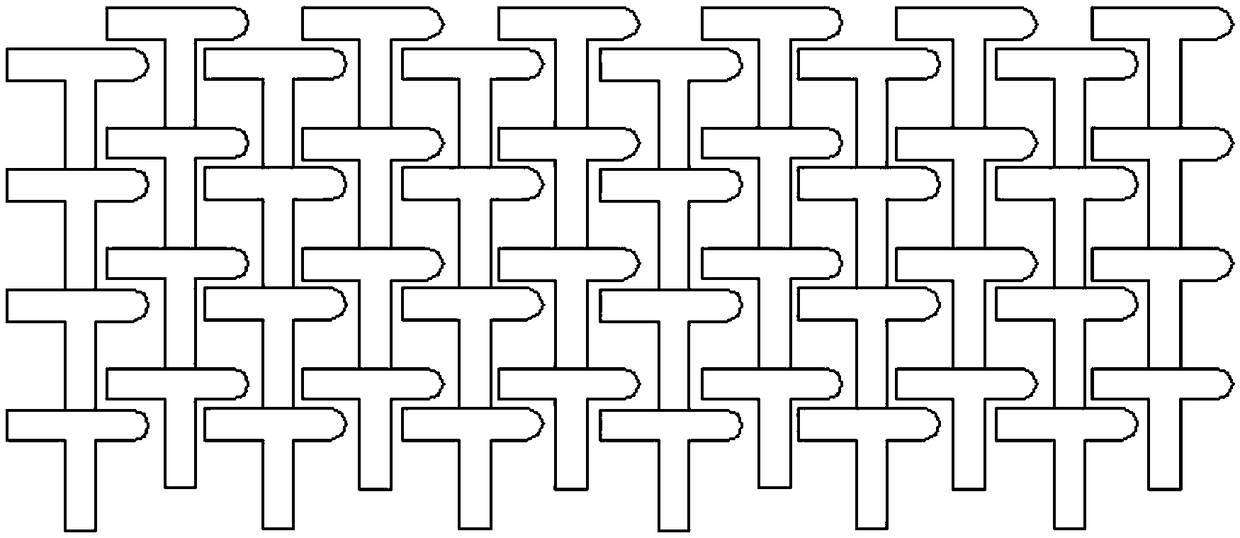

Solar cell grid line structure, solar cell sheet and solar laminate module

PendingCN108538948AElectrical performance impactImprove conductivityPhotovoltaic energy generationSemiconductor devicesConductive pasteElectricity

The invention provides a solar cell grid line structure, a solar cell sheet and a solar lamination module. The grid line structure comprises a plurality of sub grid lines arranged on a silicon wafer and a main grid line perpendicular to the sub grid lines. The main grid line is formed by a grid-like porous structure. When the main grid line is coated with a conductive paste, grid holes are filledwith a part of the conductive paste. Since the materials of the conductive paste and the main grid line have good electrical conductivity, when the above grid lines are sufficiently dense, the use ofa grid pattern instead of a solid pattern does not seriously affect the electrical performance of a module. The deformation of the conductive paste and the diffusion on a cell shell texture covered bysilicon nitride are limited by the grid pattern of the main grid line and are limited in the grid pattern, and thus paste overflow and bleeding are avoided.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Camera pedestal and mobile terminal camera

InactiveCN105577990APrevents spillage on the outside wall of the base bodyAvoid glue overflowTelevision system detailsColor television detailsAdhesiveEngineering

The invention relates to a camera pedestal and a mobile terminal camera. The camera pedestal comprises a pedestal main body, which is provided with a first surface, a second surface opposite to the first surface, and an outer side wall used for connecting the first surface and the second surface. The pedestal main body is provided with a light-transmitting hole penetrating the first surface and the second surface. The first surface is used for the connection with a substrate of a camera, and the second surface is used for arranging of adhesive to be bond with a voice coil motor of the camera. The second surface is provided with an anti-overflow adhesive groove, which is used to accommodate the adhesive flowing toward the outer side wall, when the voice coil motor is contacted with the second surface, and is used to cover the anti-overflow adhesive groove. The camera pedestal can be used to effectively prevent the overflowing of the adhesive.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

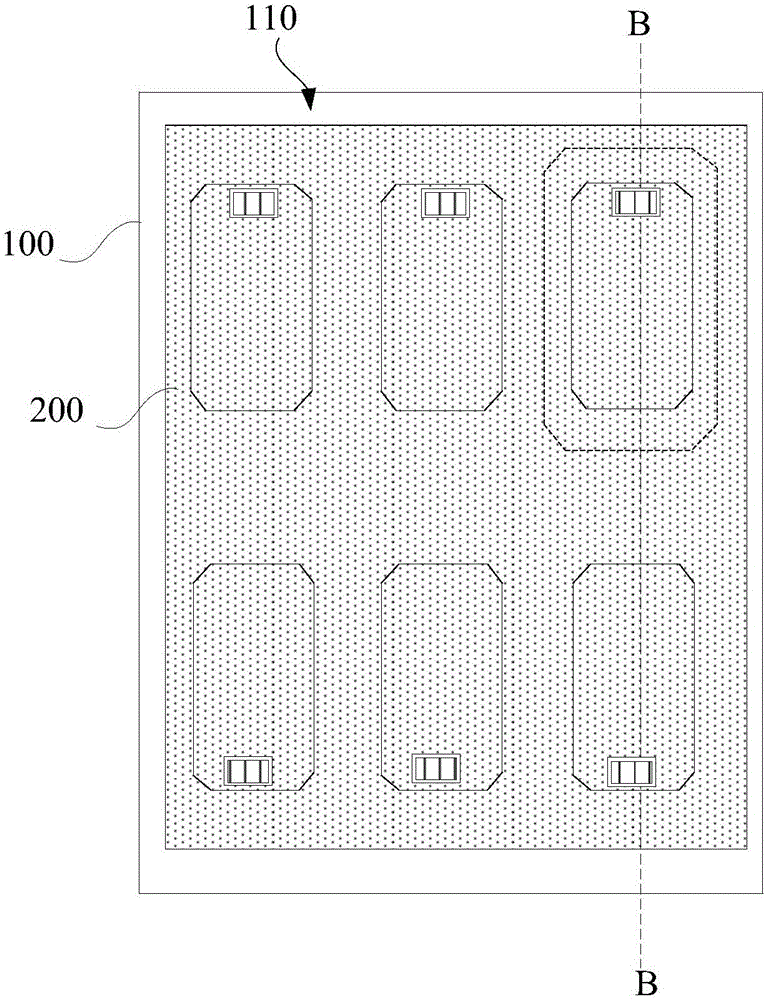

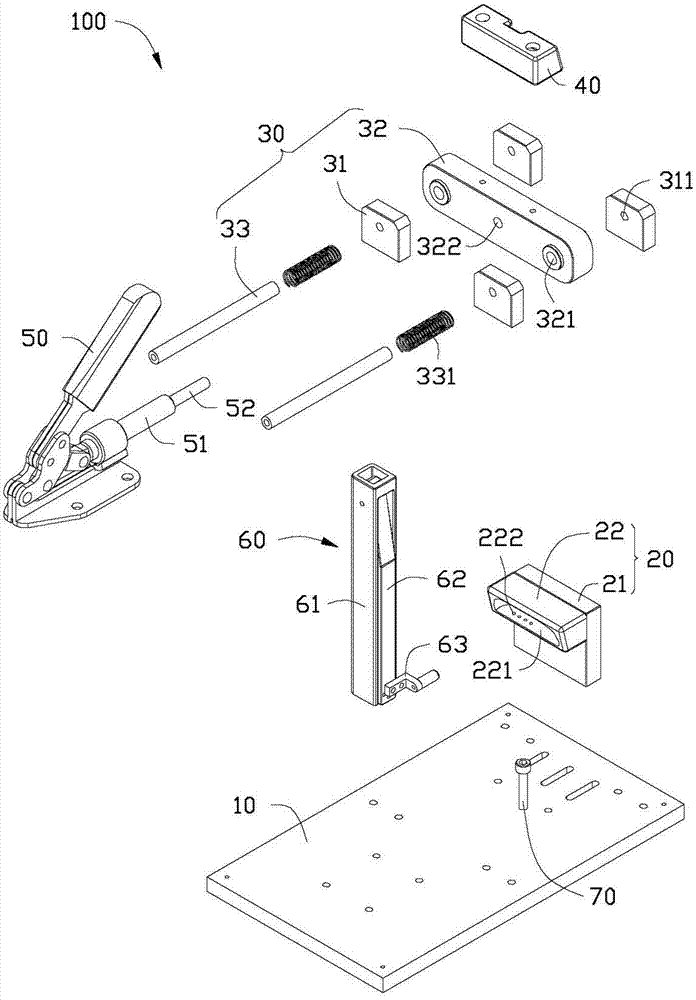

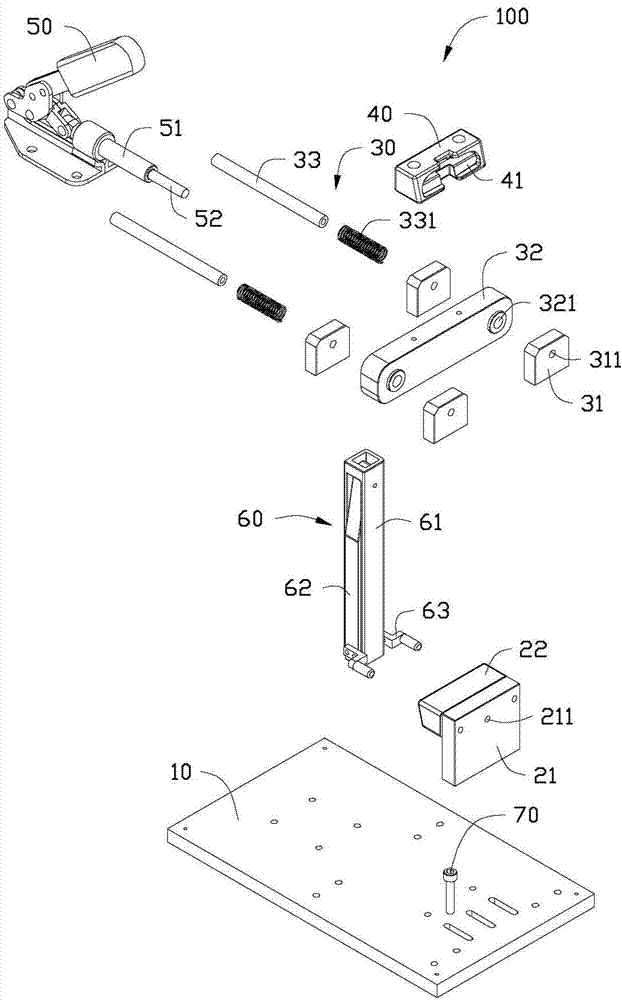

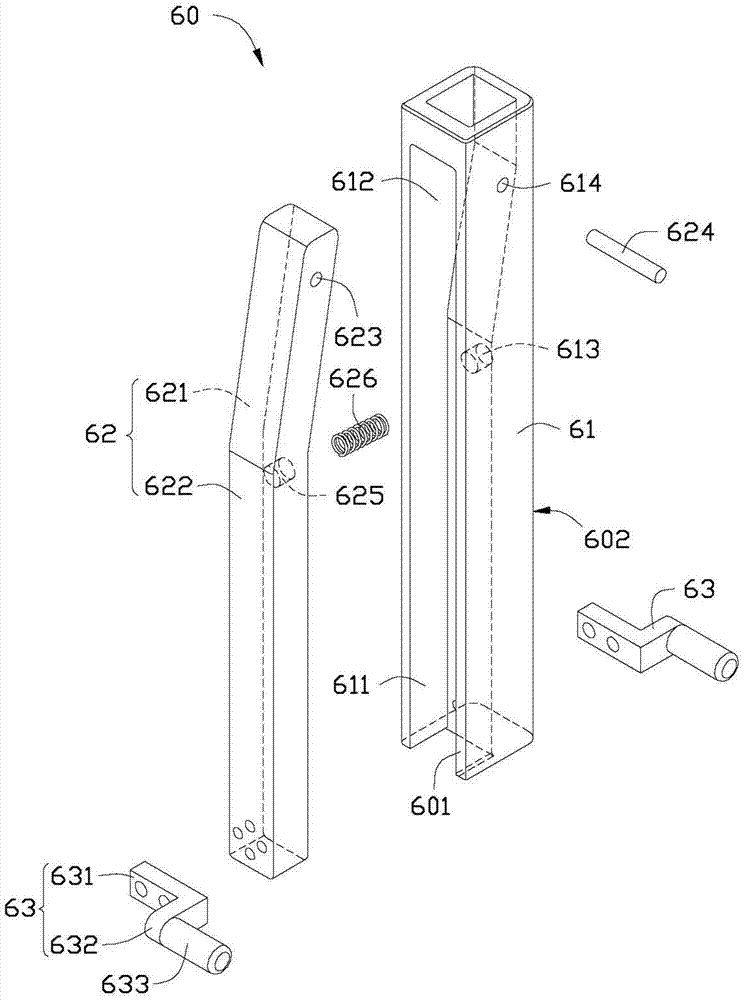

Assembling jig for antenna casing

InactiveCN102790258AEasy to assembleEasy to operateAntenna supports/mountingsRadiating element housingsEngineering

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

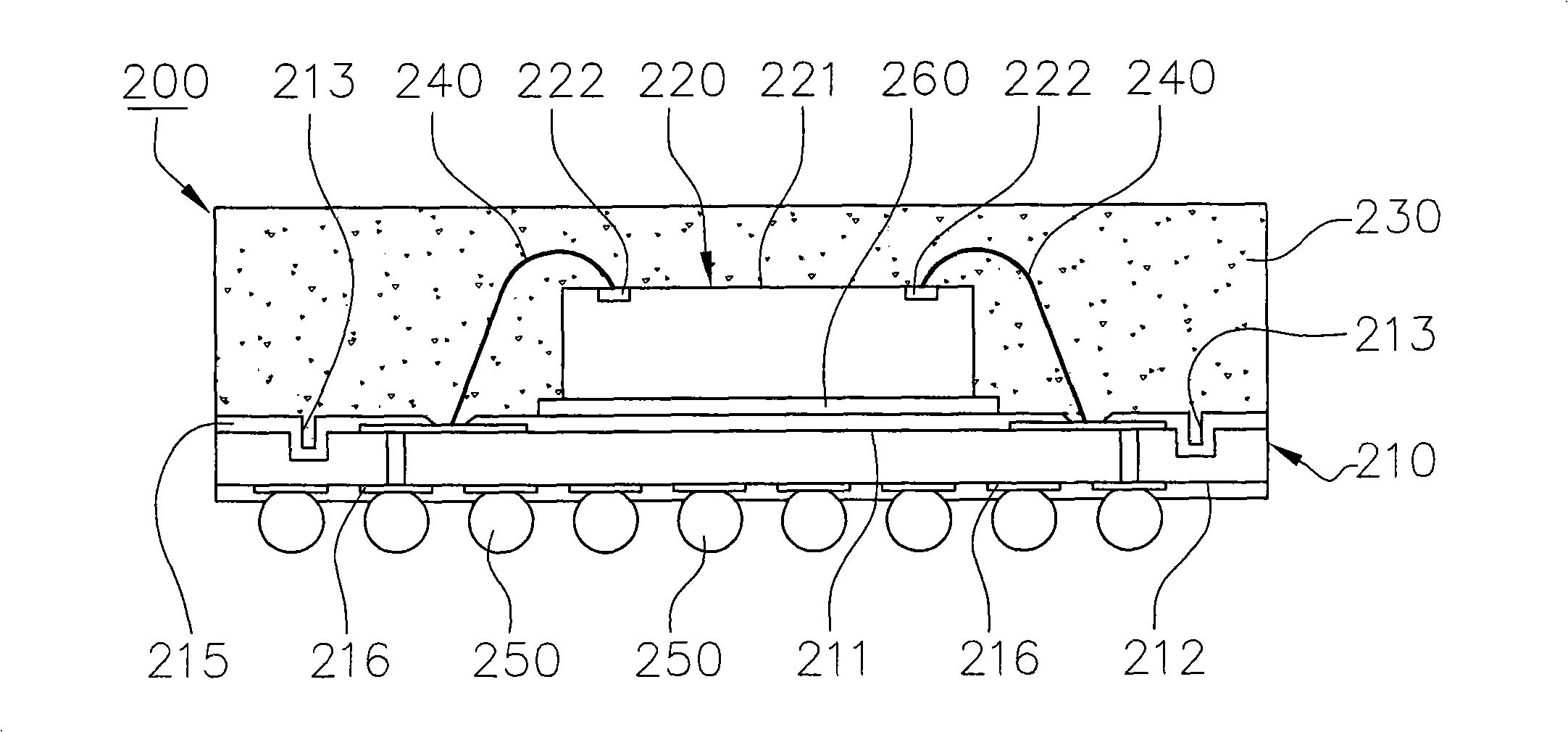

Semiconductor encapsulation construction

InactiveCN101295697AIncrease binding areaProlonged intrusion pathSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceSemiconductor package

The invention discloses a semiconductor seal structure, comprising a substrate which is provided with an upper surface and a plurality of steel pits formed on the upper surface, the upper surface is defined with a wafer arrangement area, the steel pits are arranged on the blank area of a line outside the wafer arrangement area and do not penetrate the substrate; a wafer which is arranged on the upper surface of the substrate and in the wafer arrangement area; a seal body which is formed on the upper surface of the substrate to seal the wafer; thereby being capable of increasing the seal compound area and the wet air invading paths under the situation of not changing the appearance of a product and reaching the effect that wet air resistance is not peeled off from heat resistance.

Owner:POWERTECH TECHNOLOGY

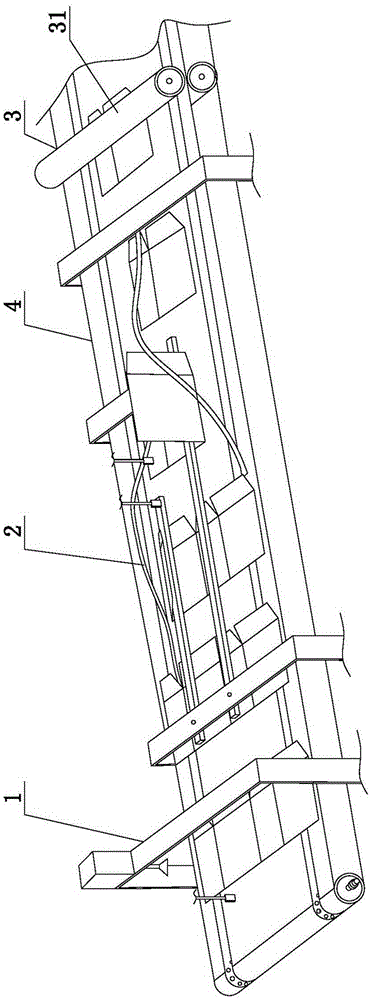

Automatic carton folding production line

InactiveCN106739140AImprove reliabilityImprove pass rateBox making operationsPaper-makingProduction lineCardboard

The invention provides an automatic carton folding production line and relates to an improvement in the structure of the automatic carton folding production line. The automatic carton folding production line provided by the invention has the advantages that the reliability is high, the degree of automation is high, and the product quality is guaranteed. The automatic carton folding production line comprises a carton folding-forming mechanism, and is characterized in that a carton raw-material cardboard automatic detecting device is arranged at the front end of the carton folding-forming mechanism; a rolling mechanism is arranged at the rear end of the carton folding-forming mechanism; the carton folding-forming mechanism comprises a conveying belt; and a left folding belt and a right folding belt are arranged on the conveying belt. The carton folding-forming mechanism is characterized in that a front mounting frame, a middle supporting frame and a rear mounting frame are arranged above the conveying belt; the tail end of the left folding belt is arranged on the middle supporting frame; a left pressing rod corresponding to the left folding belt is arranged on the front mounting frame; a gluing nozzle is arranged at the position, corresponding to the tail end of the left folding belt, above the conveying belt; a drying air duct is arranged at the back of the gluing nozzle; and the rear mounting frame is connected with the tail end of the right folding belt.

Owner:沈阳恒德包装制品股份有限公司

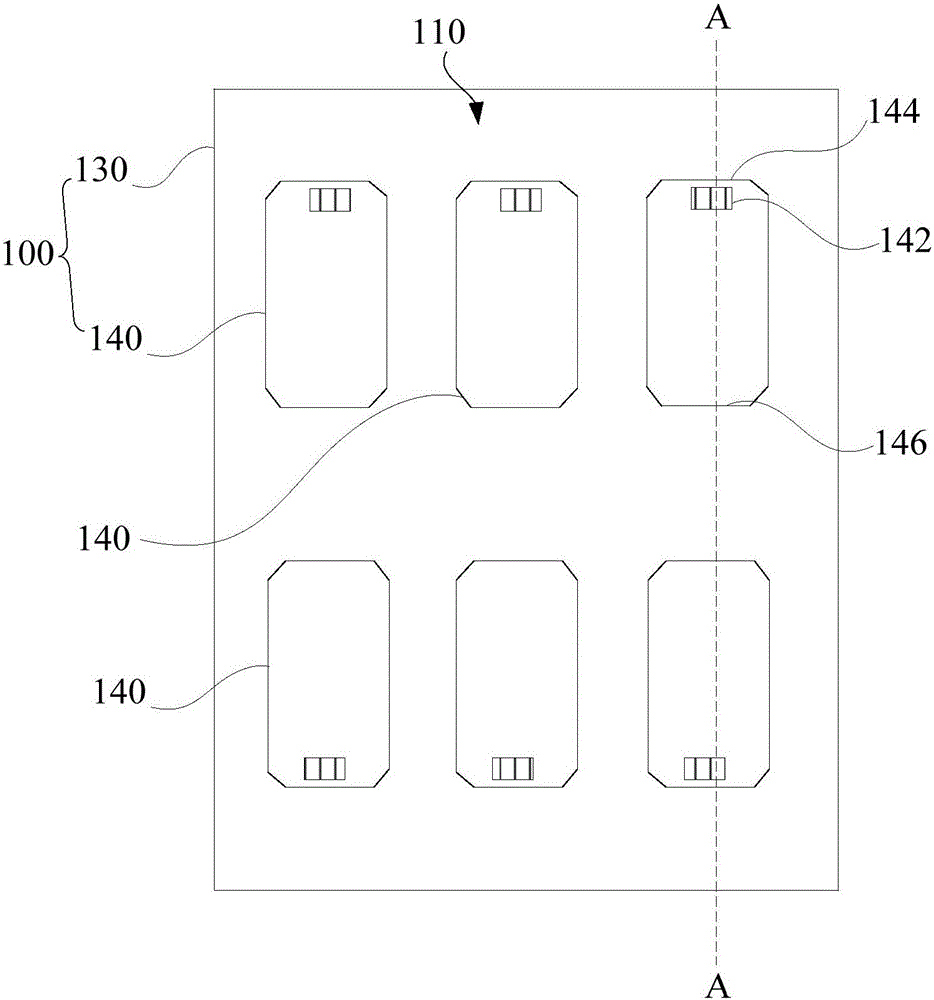

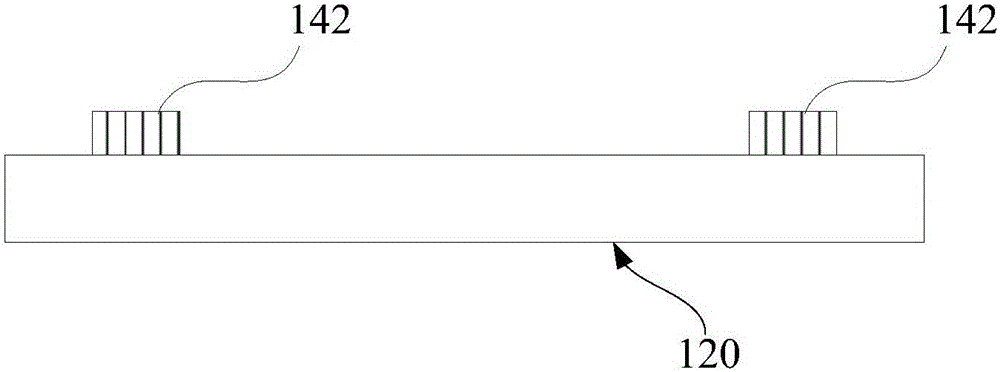

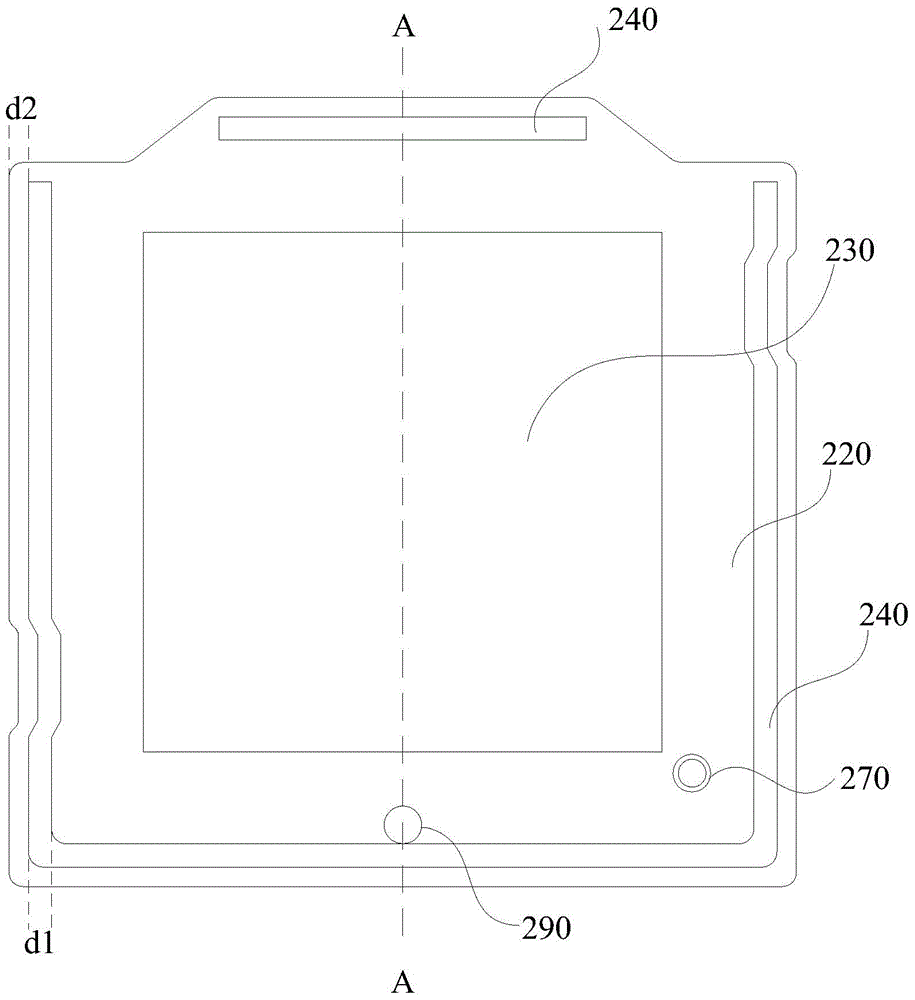

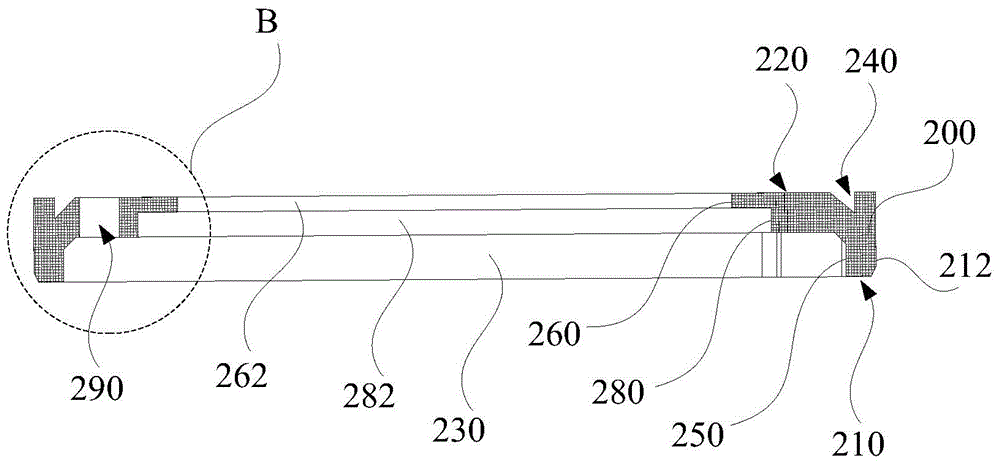

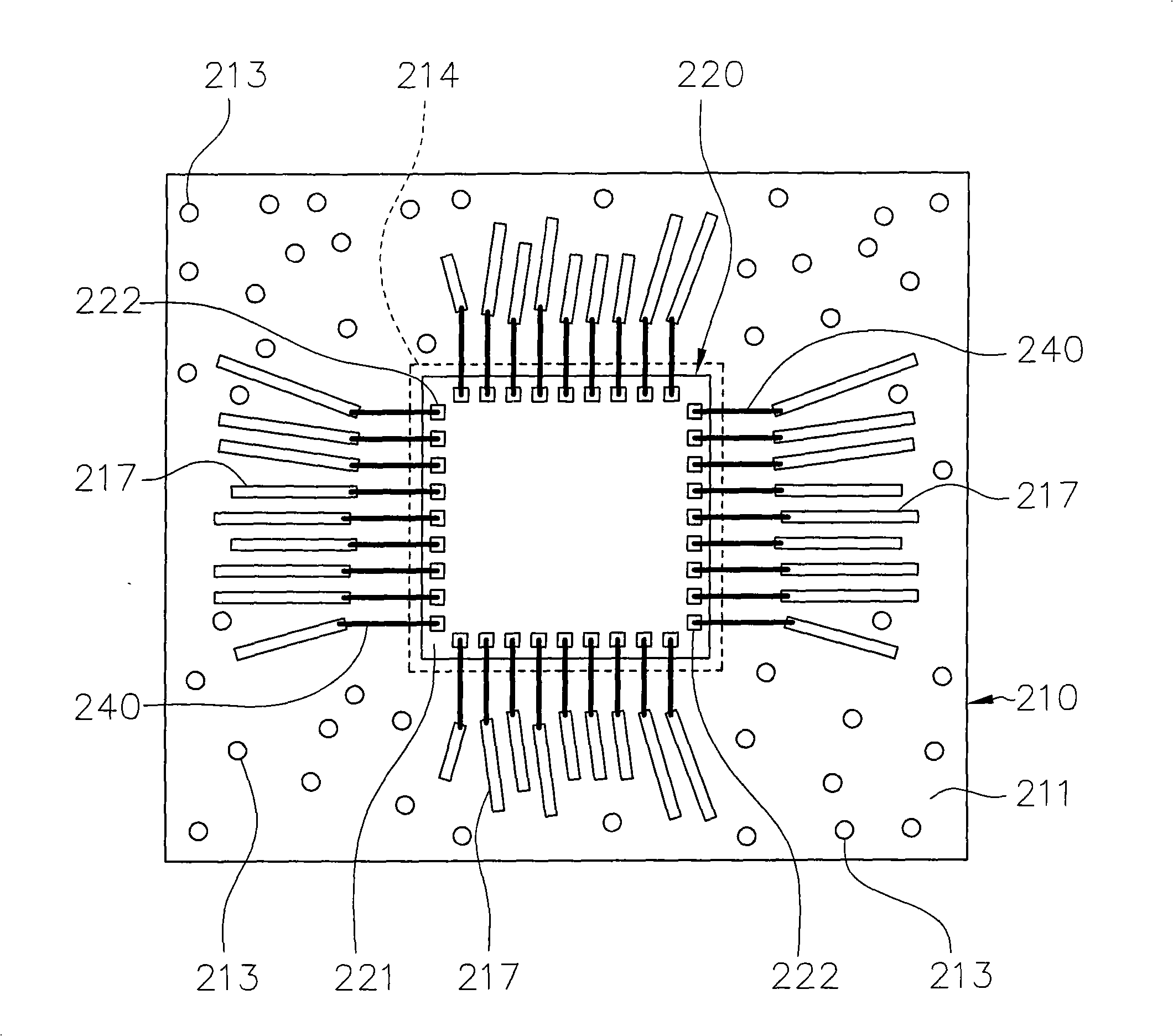

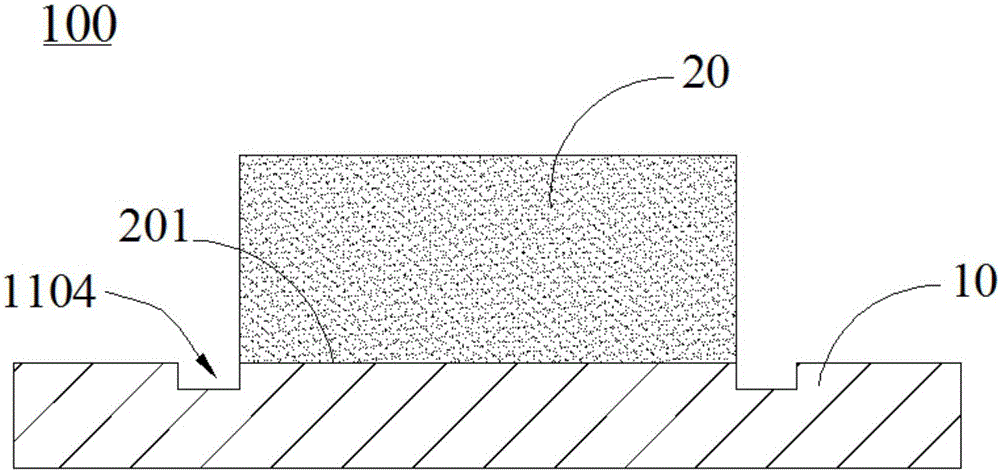

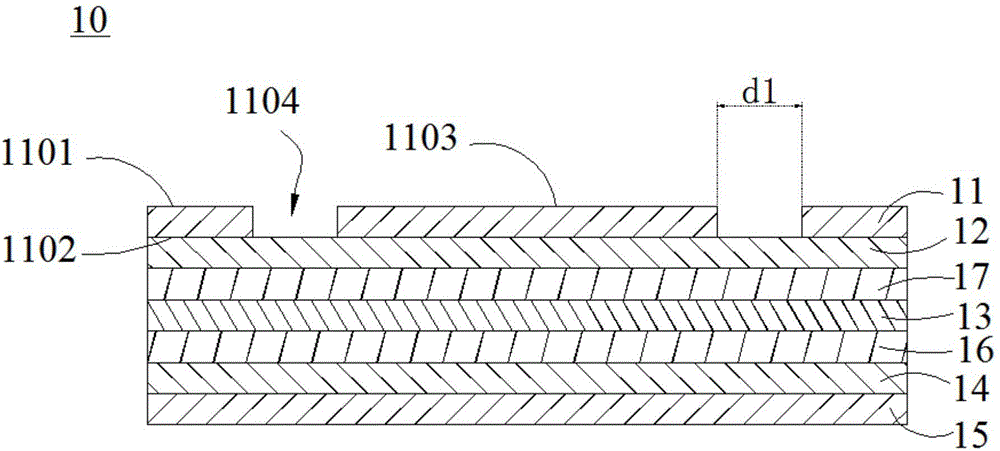

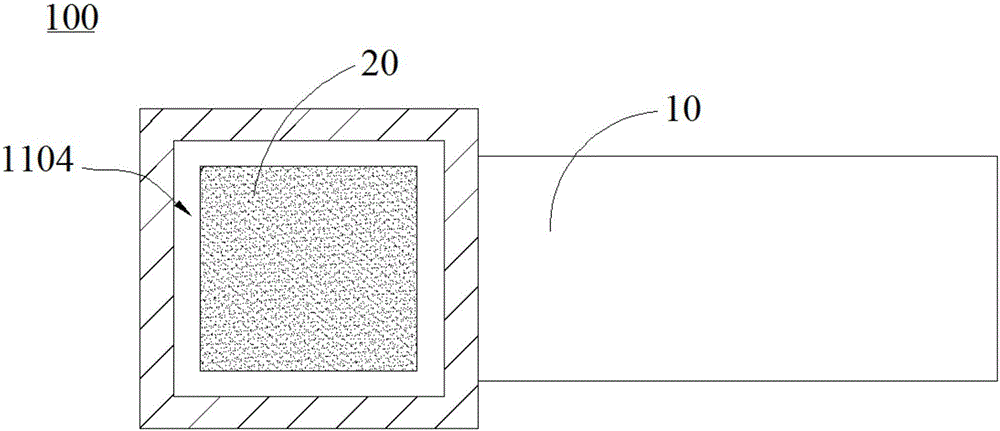

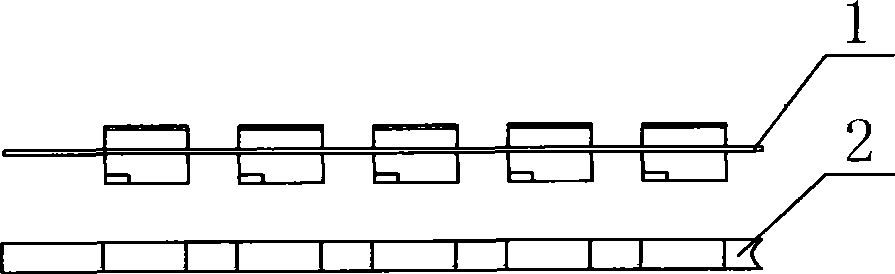

Fingerprint identification module and flexible circuit board thereof

InactiveCN106061113AAvoid glue overflowPrevents spillage on the outside wall of the flexible circuit boardPrinted circuit assemblingPrinted circuit aspectsAdhesive glueFingerprint

The invention discloses a flexible circuit board. The flexible circuit board comprises a first cover film layer which comprises a first top surface and a second surface arranged oppositely to the first top surface; and a first conductive layer which is arranged on the second surface of the first cover film layer, wherein the first top surface comprises a chip mounting area; a through groove around the chip mounting area is formed in the first top surface; and the through hole runs through the first top surface and the second surface. The through hole is used for containing adhesive glue which flow outwards when the fingerprint identification chip is fixed with the flexible circuit board, so that the condition that the adhesive glue overflows at the outer sidewall of the flexible circuit board in an assembling process of the fingerprint identification module can be prevented efficiently, and excessive glue also can be prevented efficiently. Meanwhile, the fingerprint identification module applying the flexible circuit board is also provided.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

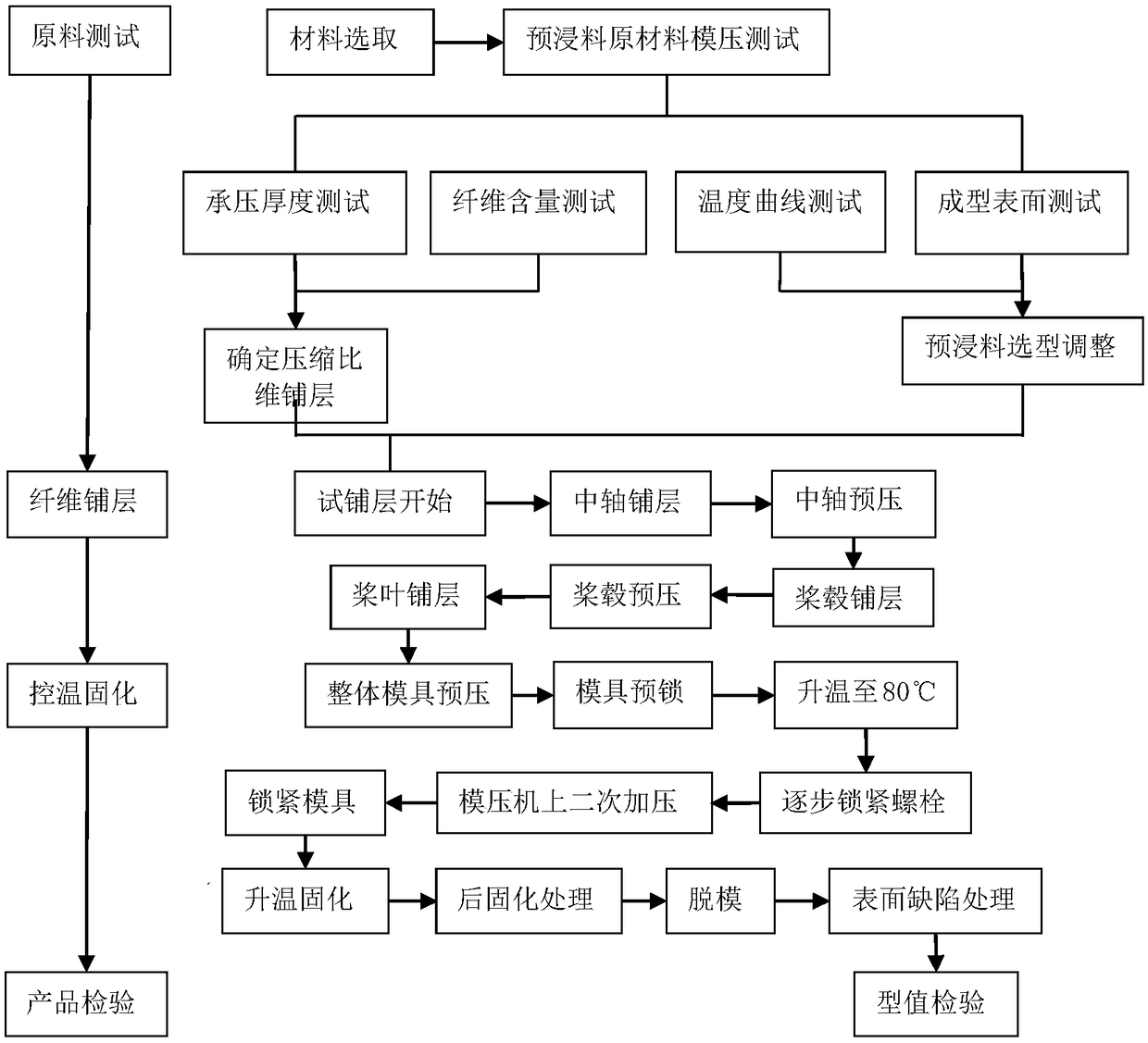

Carbon fiber composite material propeller pressing molding process

The invention discloses a carbon fiber composite material propeller pressing molding process, which comprises: S1, selecting a carbon fiber prepreg, controlling a press molding environment, and inspecting and treating a mold; S2, testing the compressive thickness, the fiber content, the temperature curve and the molding surface of the carbon fiber prepreg; S3, molding a propeller billet mold by using a prepreg pressing molding process; and S4, continuously adhering the carbon fiber prepreg on the surface of the billet mold, and carrying out pressing molding again to prepare the composite material propeller. According to the present invention, with the carbon fiber composite material propeller pressing molding process, the composite material propeller pressing molding is divided into two molding, the first molding uses the prepreg pressing molding process to mold the propeller billet mold, the prepreg is continuously adhered on the surface of the billet mold, and the pressing molding isperformed again to prepare the composite material propeller, such that the strength of the product can be ensured, the precision of the product can be ensured, and the molded product has advantages of good integrity, small molding value deviation, stable process, high strength and high propulsion efficiency.

Owner:武汉源海博创科技有限公司 +1

Method for shaping patch type LED optical lens model

ActiveCN101442088ANot easy to fall offReduce operating proceduresSolid-state devicesSemiconductor/solid-state device manufacturingSheet steelEngineering

The invention discloses a method for forming an LED optical lens mould of a SMD type. The method is characterized by comprising the following steps: (1) dehumidifying and plasma cleaning an LED bracket; (2) replacing a corresponding optical lens mould in a mould making machine; (3) arranging a sheet steel which prevents gel from overflowing on the LED bracket; (4) putting the optical lens mould on the mould making machine, and adding transparent resin or transparent gel; (5) roasting in a oven; and (6) finally, cutting clubfoot. The sheet steel is a bulk substrate, wherein the substrate is distributed with holes which have the same thickness with a translucent shell on the LED bracket; the substrate is distributed with the holes in matrix form; and the substrate is a plate. The method has the advantages that the method makes transparent resin or transparent silica gel and the translucent shell on the LED plastic bracket form the optical lens one time, and speeds up the production, and makes the optical lens bond firmly and not easy to fall off.

Owner:HONGLI ZHIHUI GRP CO LTD

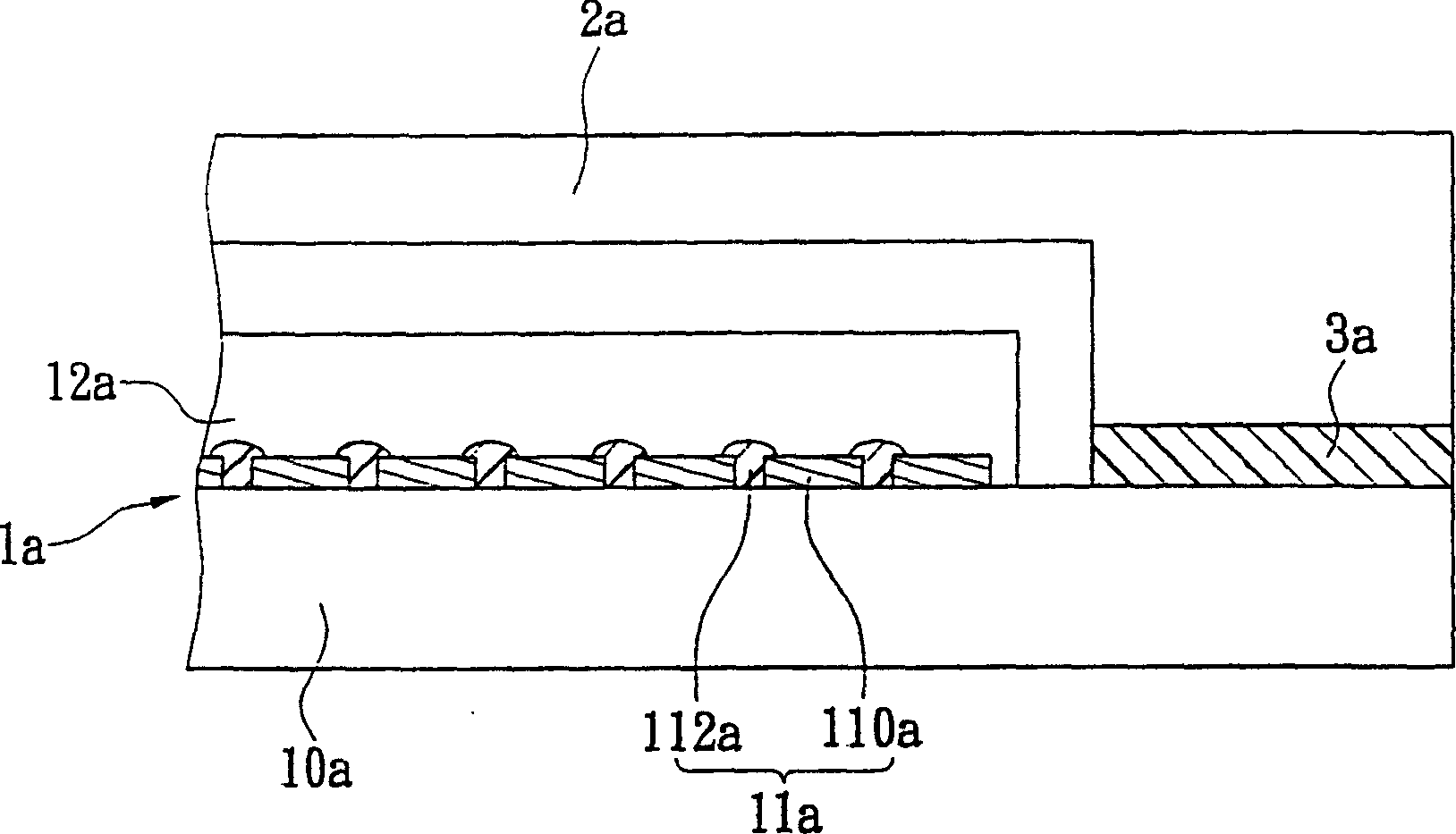

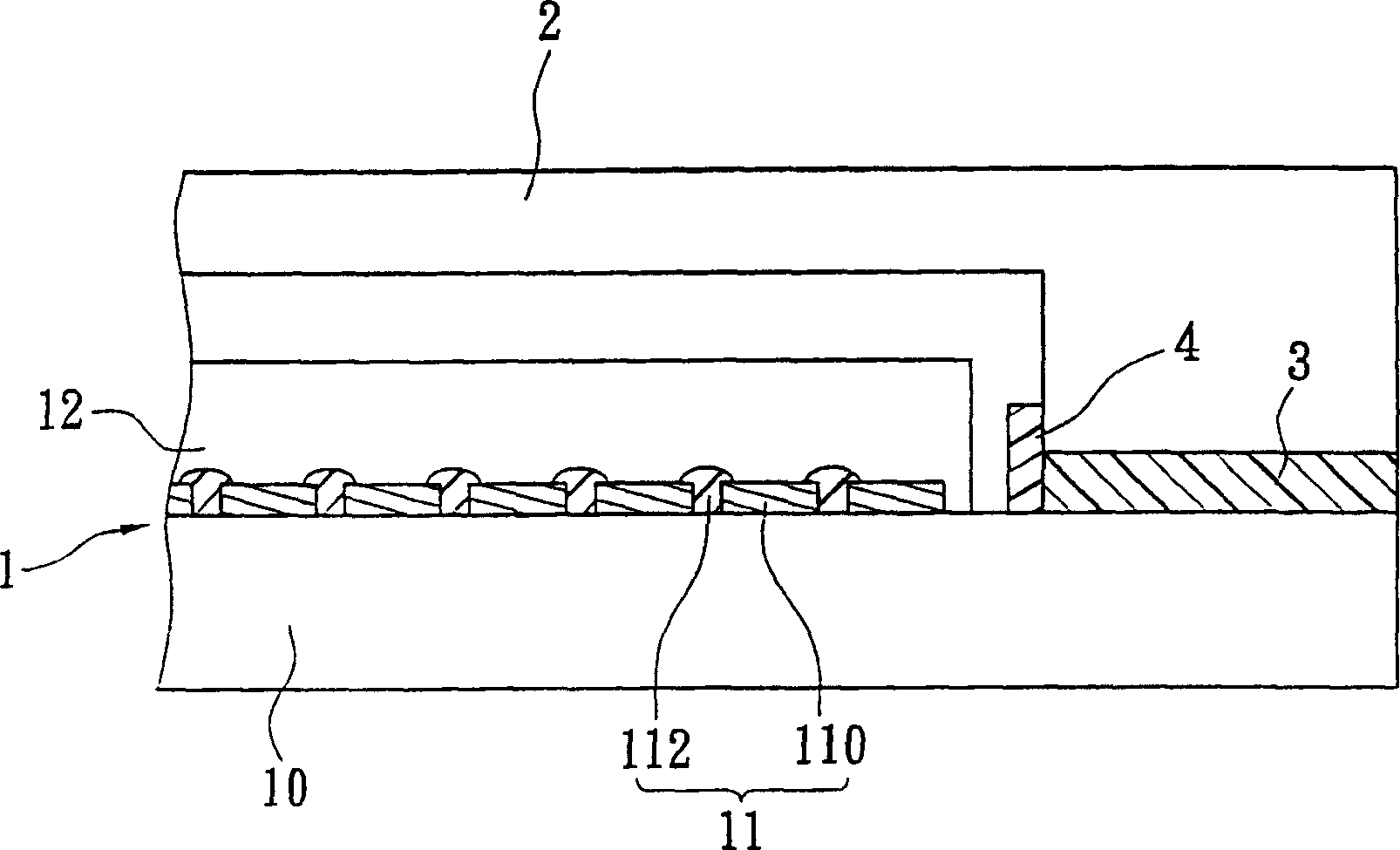

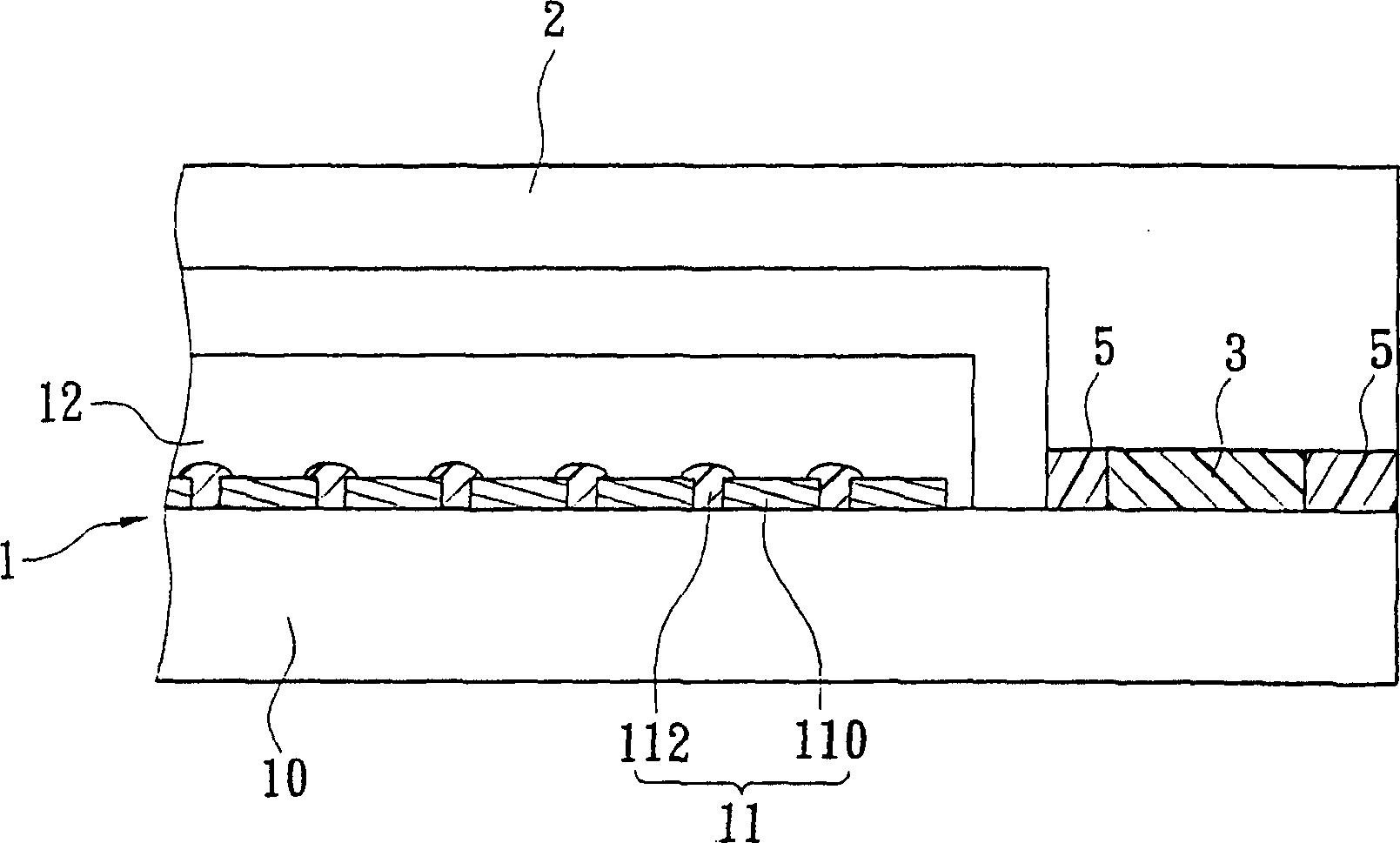

Glue sealing structure for organic electroluminescent planar display device and production thereof

InactiveCN1780508AControl Package HeightReduced service life impactElectrical apparatusElectroluminescent light sourcesBaseboardAdhesive

The sealant structure consists of glass baseboard, closing cap adhesive layer and blockage region. There is a luminous display structure and an organic luminescence structure covering the luminous display structure above formed on the glass baseboard. The closing cap and the glass baseboard are sealed together. The adhesive layer is located between the glass baseboard and the closing cap. The blockage region is formed on the glass baseboard, and sits beside one side of the adhesive layer to prevent internal structure from overflow of adhesive from the adhesive layer.

Owner:UNIVISION TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com