Battery module

A technology for battery modules and single cells, which is applied in the manufacturing of batteries, battery pack components, and secondary batteries, etc., which can solve the high cost of the coating treatment process, the inability to solve the environmental pollution of overflowing glue, and the insulation requirements of the battery surface. Advanced problems, to achieve the effect of improving the utilization rate of glue, meeting the strength, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The battery module according to the present invention will be described in detail below with reference to the accompanying drawings.

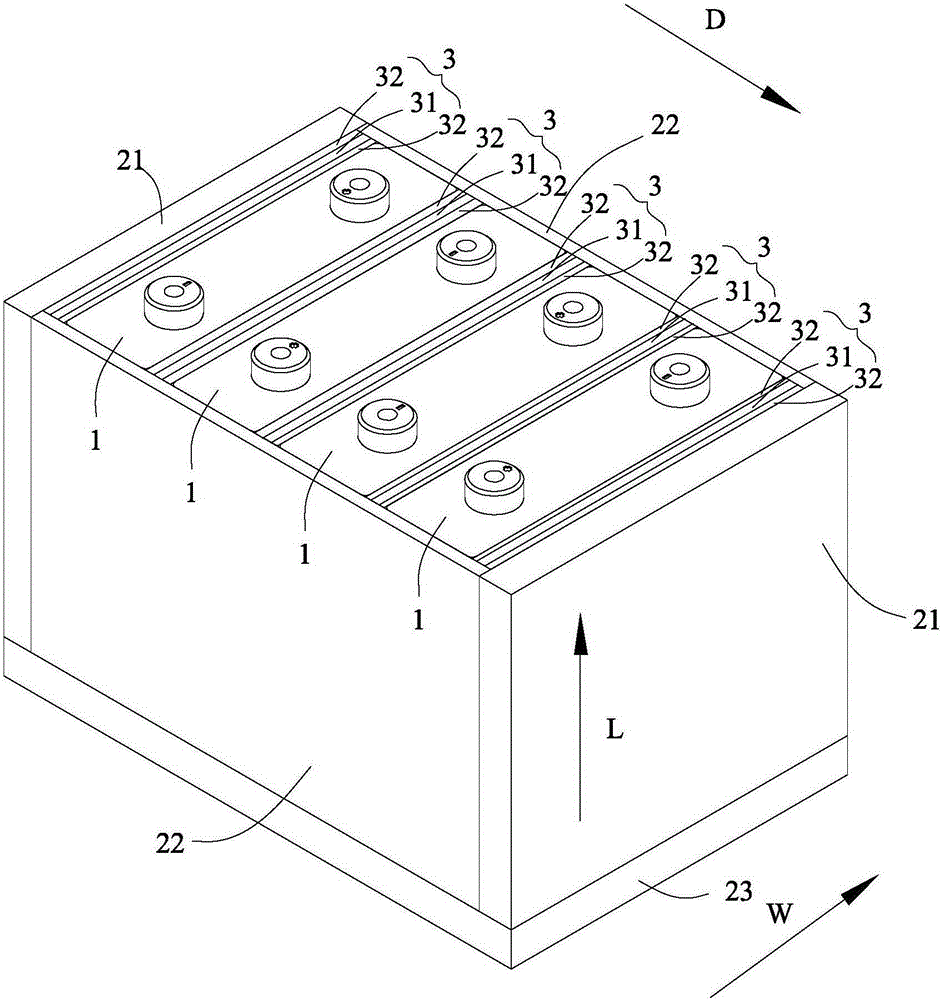

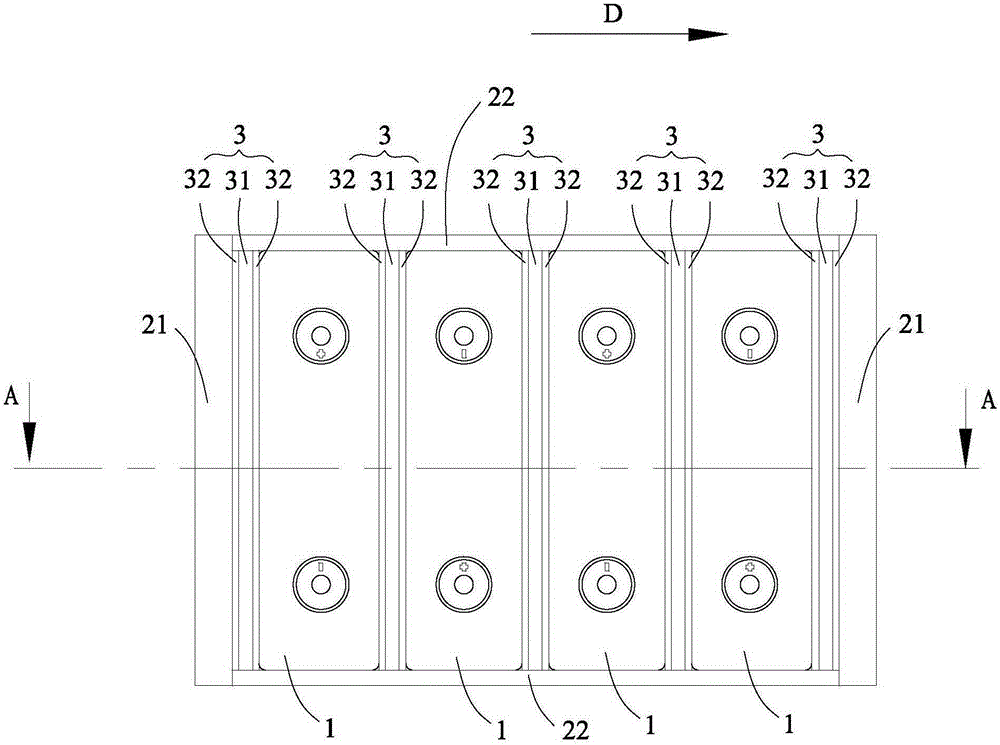

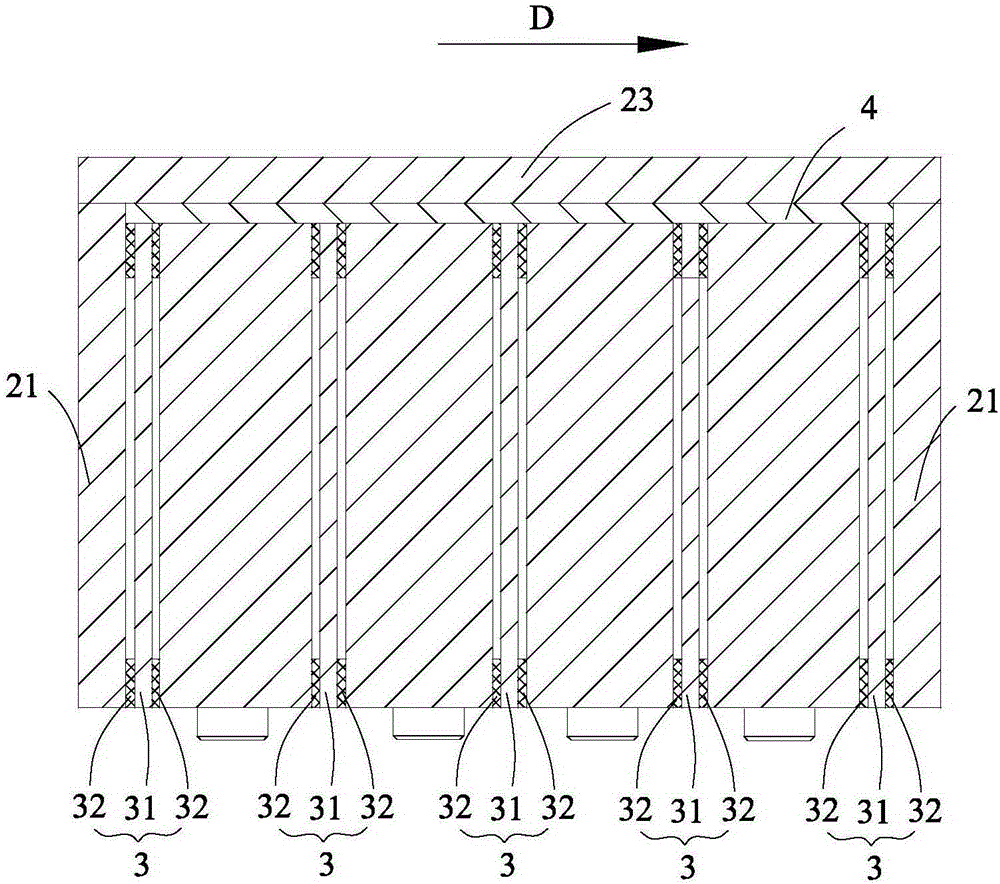

[0037] refer to Figure 1 to Figure 16 , the battery module according to the present invention includes: a plurality of single cells 1 , a fixing mechanism 2 and an insulating film 3 .

[0038] A plurality of single cells 1 are arranged side by side.

[0039] The fixing mechanism 2 is used to fix and accommodate the plurality of single batteries 1 .

[0040] The insulating film 3 is disposed between two adjacent single cells 1 to bond the two adjacent single cells 1 together and to insulate the two adjacent single cells 1 . Each insulating film 3 comprises: insulating substrate 31; The single cells 1 are glued together.

[0041] In the battery module according to the present invention, the insulating film 3 is arranged between two adjacent single cells 1 to bond the two adjacent single cells 1 together and make the gap between the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com