A method of manufacturing an optical adhesive layer for a touch screen and a method of manufacturing the touch screen.

A technology of an optical adhesive layer and a manufacturing method, which is applied in the input/output process of data processing, instruments, electrical digital data processing and other directions, and can solve problems such as bad bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The manufacturing method of the optical adhesive layer for the touch screen and the manufacturing method of the touch screen will be further described below in conjunction with the accompanying drawings and specific embodiments.

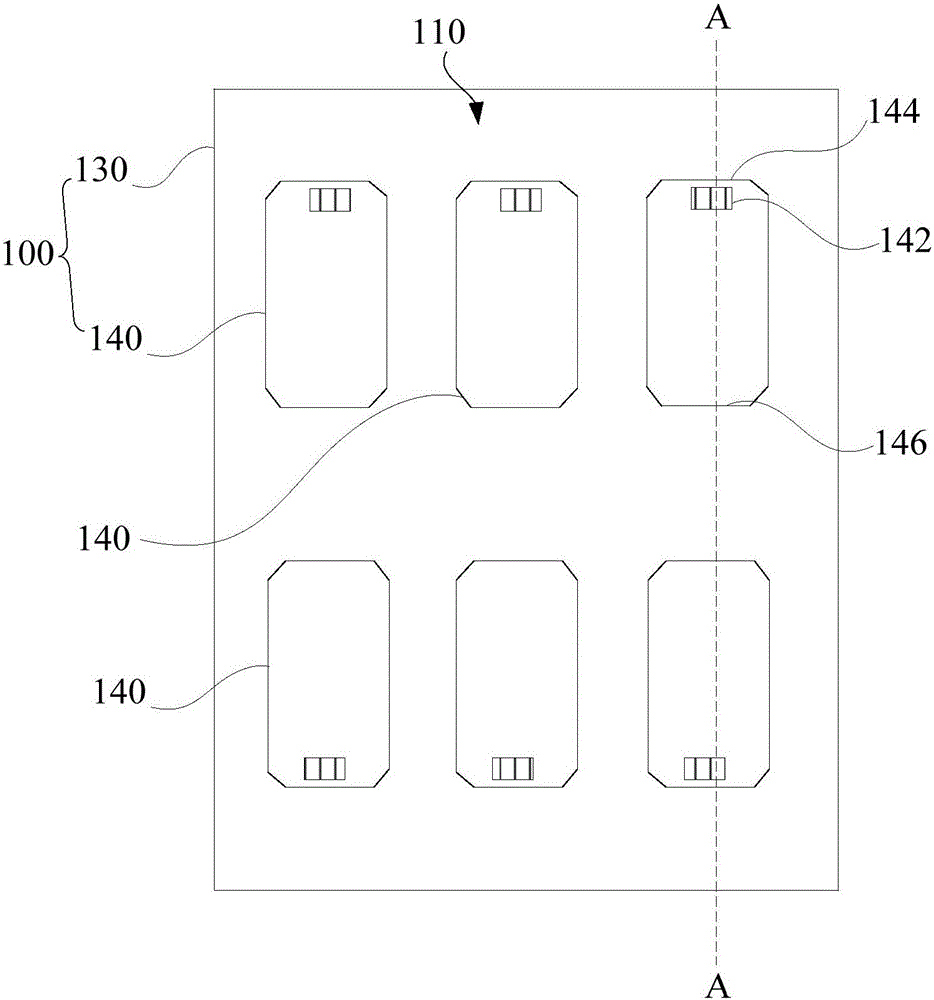

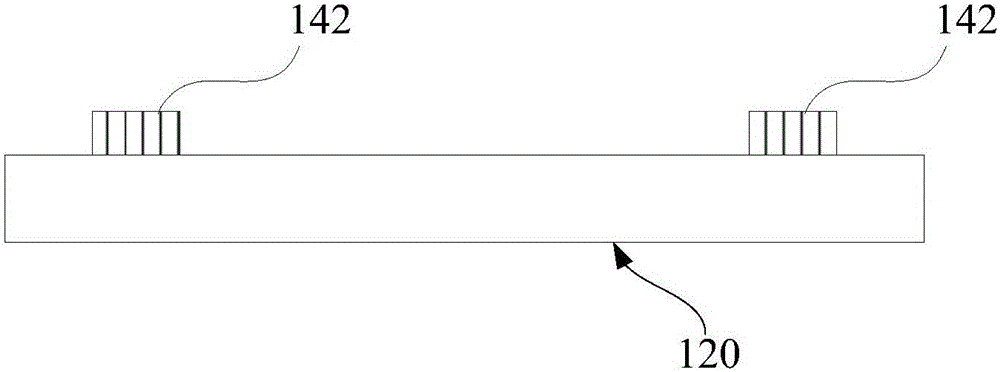

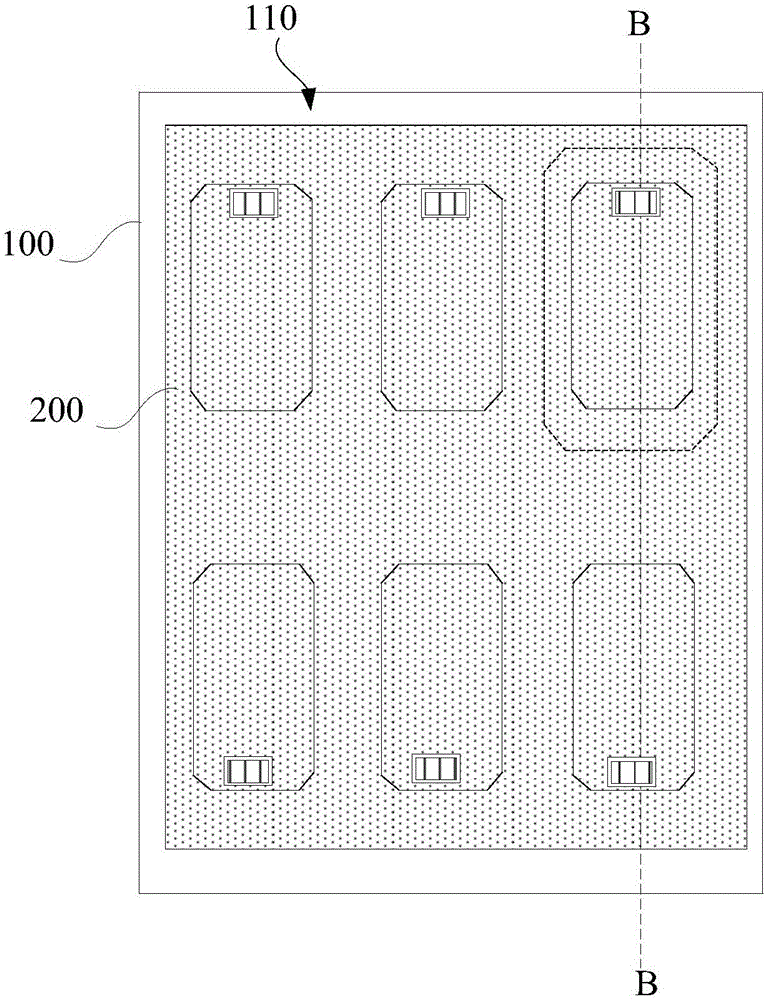

[0042] Step S11 , providing a substrate 100 . Such as figure 1 and figure 2 As shown, the substrate 100 has a first surface 110 and a second surface 120 opposite to each other.

[0043] In this embodiment, the substrate 100 is a touch sensing unit. The substrate 100 includes a base 130 and a touch sensor 140 formed on the base 130 . The touch sensor 140 has a binding area 142 for binding with the flexible circuit board of the touch screen. The surface of the substrate 130 away from the touch sensor 140 is the second surface 120 , the area of the substrate 130 away from the second surface 120 and not covered by the touch sensor 140 and the side of the touch sensor 140 away from the second surface 120 together constitute the first surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com