Lens module

A lens module and lens technology, applied in installation, optics, instruments, etc., can solve the problems of lowering assembly yield, overflowing glue, insufficient bonding strength between permanent magnet and outer frame, etc., so as to improve assembly yield and increase bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

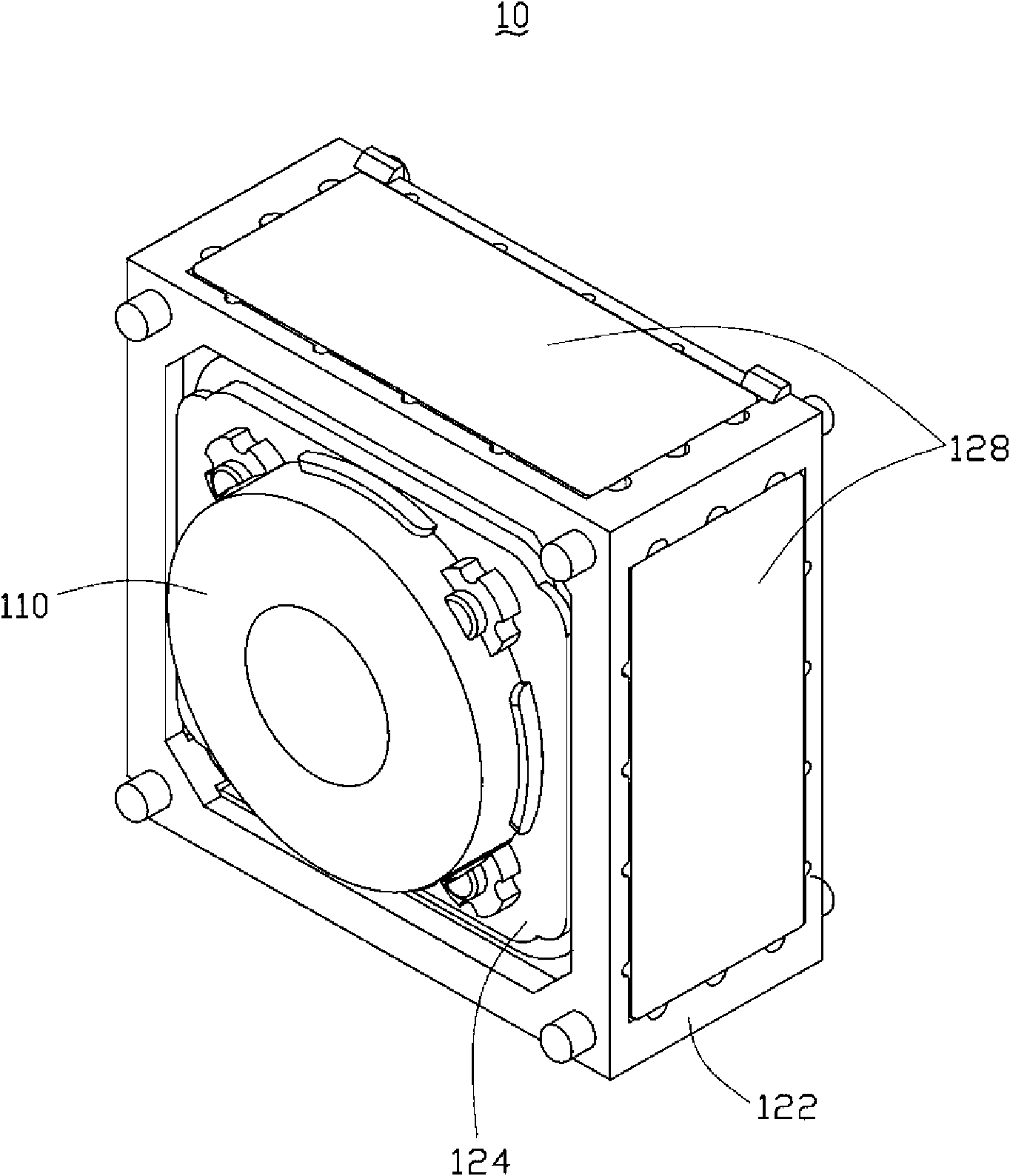

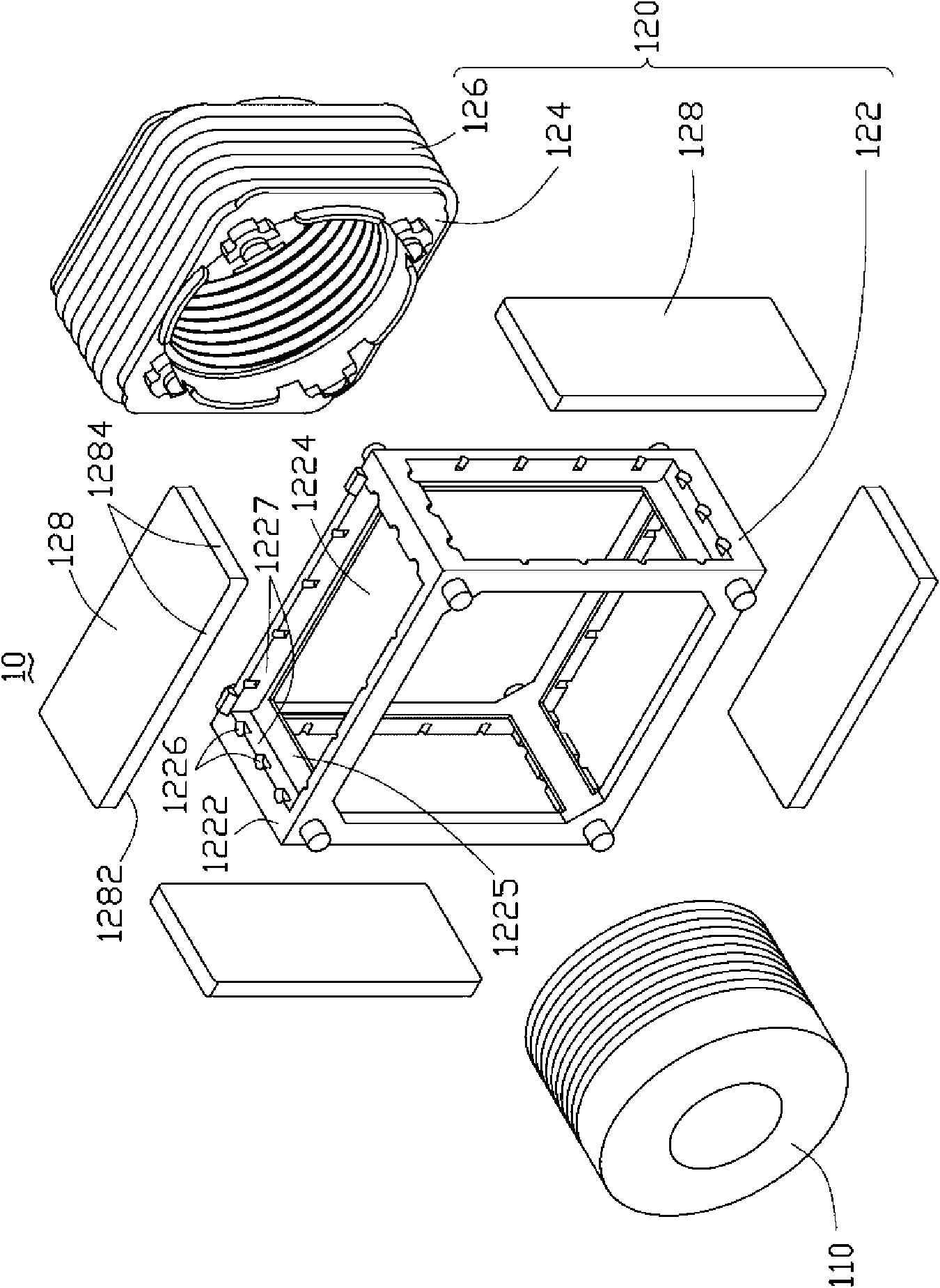

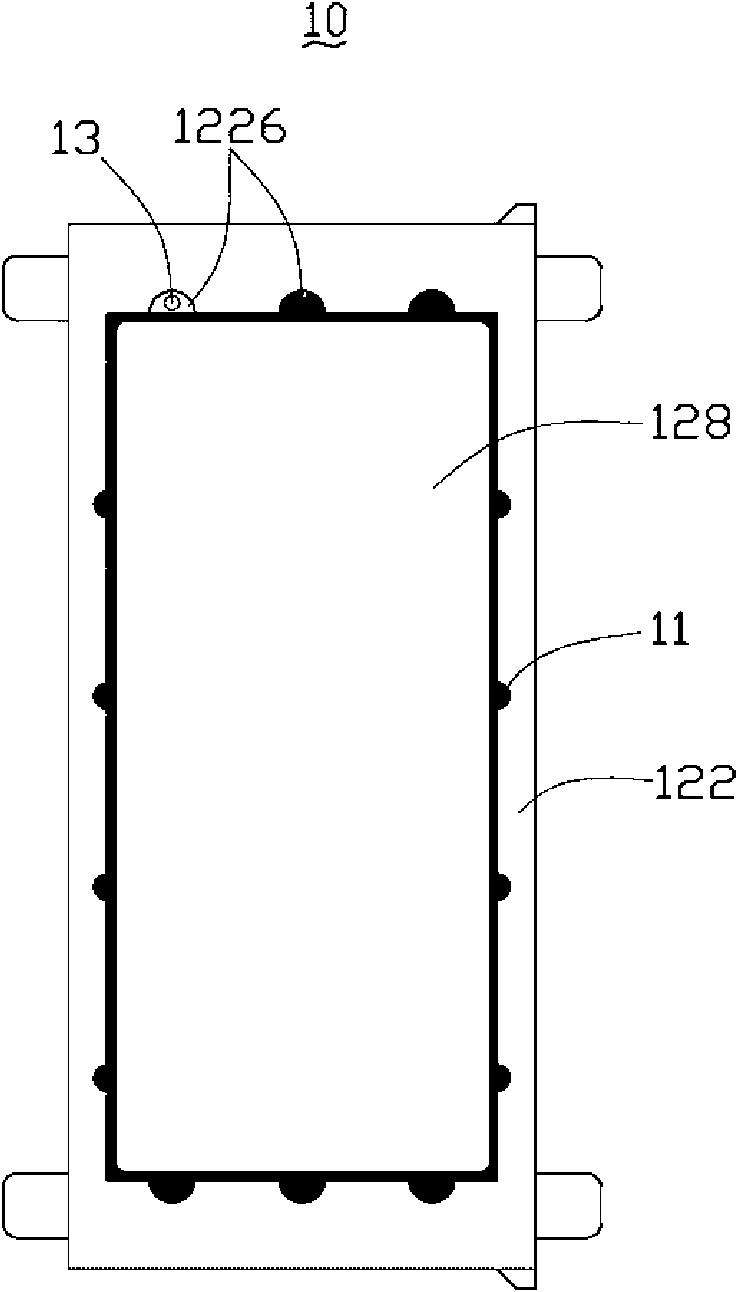

[0013] see figure 1 and figure 2 , is a lens module 10 provided by an embodiment of the present invention. The lens module 10 includes a lens 110 and a voice coil motor 120 connected to the lens 110 . The voice coil motor 120 includes an outer frame 122, a lens holder 124 arranged inside the outer frame 122, a set of coils 126 arranged on the lens holder 124, and four coils fixed on the outer frame 122. permanent magnet 128 .

[0014] The connection between the lens 110 and the lens holder 124 is screw connection.

[0015] The permanent magnet 128 has a bottom surface 1282 and four side surfaces 1284 adjacent to the bottom surface 1282 .

[0016] The four sides 1222 of the outer frame 122 are respectively provided with a receiving groove 1224, and the receiving groove 1224 has a bottom surface 1225 and four side surfaces 1227 adjacent to the bottom surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com